engine coolant JAGUAR S TYPE 2005 1.G Electrical Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 200, PDF Size: 5.93 MB

Page 9 of 200

DATE OF ISSUE: May 20045

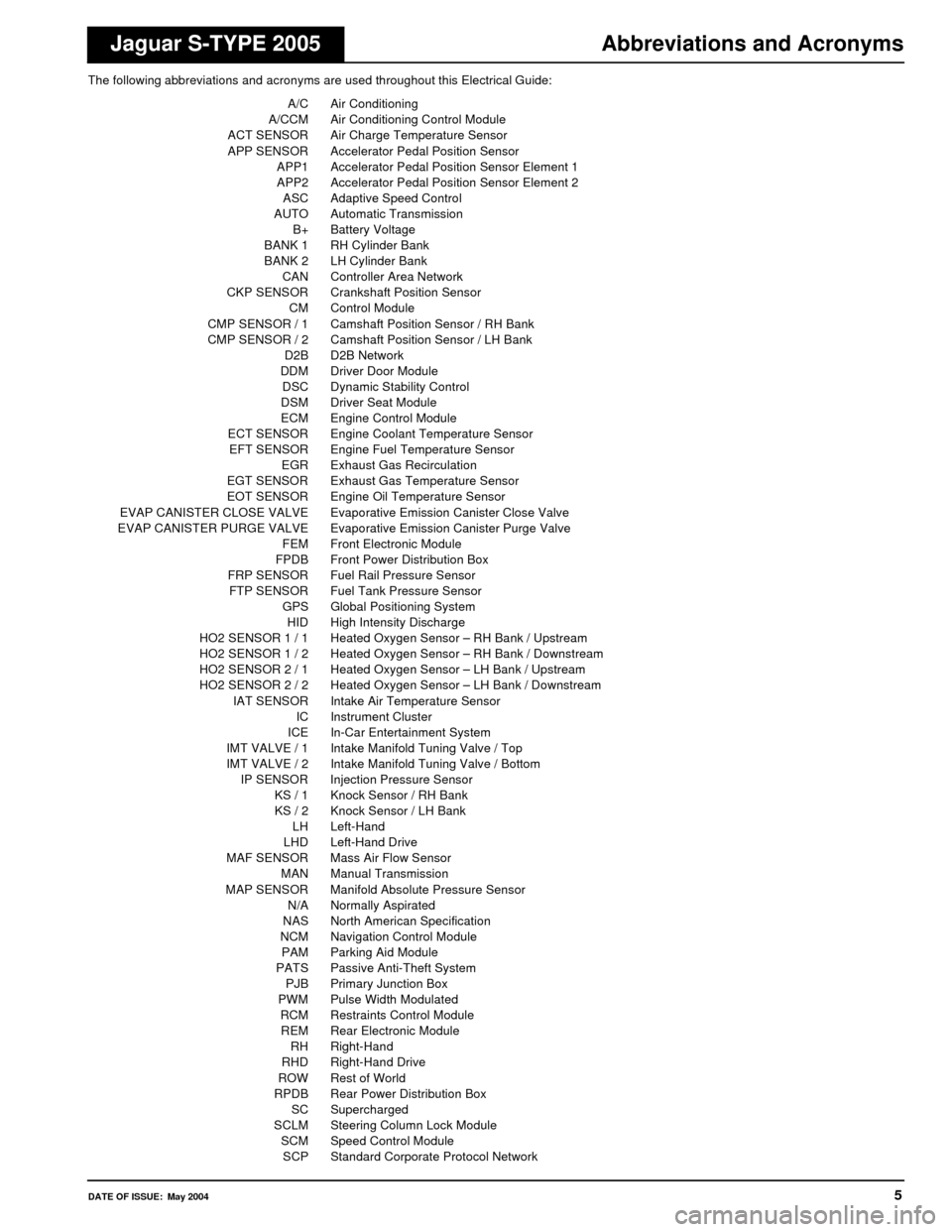

Abbreviations and AcronymsJaguar S-TYPE 2005

The following abbreviations and acronyms are used throughout this Electrical Guide:A/C Air Conditioning

A/CCM Air Conditioning Control Module

ACT SENSOR Air Charge Temperature Sensor

APP SENSOR Accelerator Pedal Position Sensor APP1 Accelerator Pedal Position Sensor Element 1

APP2 Accelerator Pedal Position Sensor Element 2ASC Adaptive Speed Control

AUTO Automatic Transmission B+ Battery Voltage

BANK 1 RH Cylinder Bank

BANK 2 LH Cylinder Bank CAN Controller Area Network

CKP SENSOR Crankshaft Position Sensor CM Control Module

CMP SENSOR / 1 Camshaft Position Sensor / RH Bank

CMP SENSOR / 2 Camshaft Position Sensor / LH Bank D2B D2B Network

DDM Driver Door Module DSC Dynamic Stability Control

DSM Driver Seat Module

ECM Engine Control Module

ECT SENSOR Engine Coolant Temperature Sensor EFT SENSOR Engine Fuel Temperature Sensor

EGR Exhaust Gas Recirculation

EGT SENSOR Exhaust Gas Temperature Sensor

EOT SENSOR Engine Oil Temperature Sensor

EVAP CANISTER CLOSE VALVE Evaporative Emission Canister Close Valve

EVAP CANISTER PURGE VALVE Evaporative Emission Canister Purge Valve FEM Front Electronic Module

FPDB Front Power Distribution Box

FRP SENSOR Fuel Rail Pressure Sensor FTP SENSOR Fuel Tank Pressure Sensor

GPS Global Positioning SystemHID High Intensity Discharge

HO2 SENSOR 1 / 1 Heated Oxygen Sensor – RH Bank / Upstream

HO2 SENSOR 1 / 2 Heated Oxygen Sensor – RH Bank / Downstream

HO2 SENSOR 2 / 1 Heated Oxygen Sensor – LH Bank / Upstream

HO2 SENSOR 2 / 2 Heated Oxygen Sensor – LH Bank / Downstream

IAT SENSOR Intake Air Temperature Sensor IC Instrument Cluster

ICE In-Car Entertainment System

IMT VALVE / 1 Intake Manifold Tuning Valve / Top

IMT VALVE / 2 Intake Manifold Tuning Valve / Bottom IP SENSOR Injection Pressure Sensor

KS / 1 Knock Sensor / RH Bank

KS / 2 Knock Sensor / LH BankLH Left-Hand

LHD Left-Hand Drive

MAF SENSOR Mass Air Flow Sensor MAN Manual Transmission

MAP SENSOR Manifold Absolute Pressure Sensor N/A Normally Aspirated

NAS North American Specification

NCM Navigation Control Module PAM Parking Aid Module

PATS Passive Anti-Theft System

PJB Primary Junction Box

PWM Pulse Width Modulated RCM Restraints Control ModuleREM Rear Electronic Module RH Right-Hand

RHD Right-Hand Drive

ROW Rest of World

RPDB Rear Power Distribution Box SC Supercharged

SCLM Steering Column Lock Module SCM Speed Control ModuleSCP Standard Corporate Protocol Network

Page 60 of 200

Refer to the front of this book for detailed information and illustrations regarding the location and identification of harnesses, relays, fuses, grounds,

control modules and control module pins.

NOTE: The values listed are approximately those that can be expected at the control module connector pins with all circuit conn

ections made and all

components connected and fitted. The following abbreviations are used to represent values for Control Module Pin-Out data

I Input

O Output

B+ Battery Voltage PG Power Ground

SS Sensor / Signal Supply V

SG Sensor / Signal GroundC CAN Network

S SCP Network

D2 D2B Network D Serial and Encoded Data

V Voltage (DC)

PWM Pulse Width Modulated

CAUTION: The information on this data page is furnished to ai d the user in understanding circuit operation. THIS INFORMATION SH OULD BE USED FOR

REFERENCE ONLY.DATE OF ISSUE: May 2004

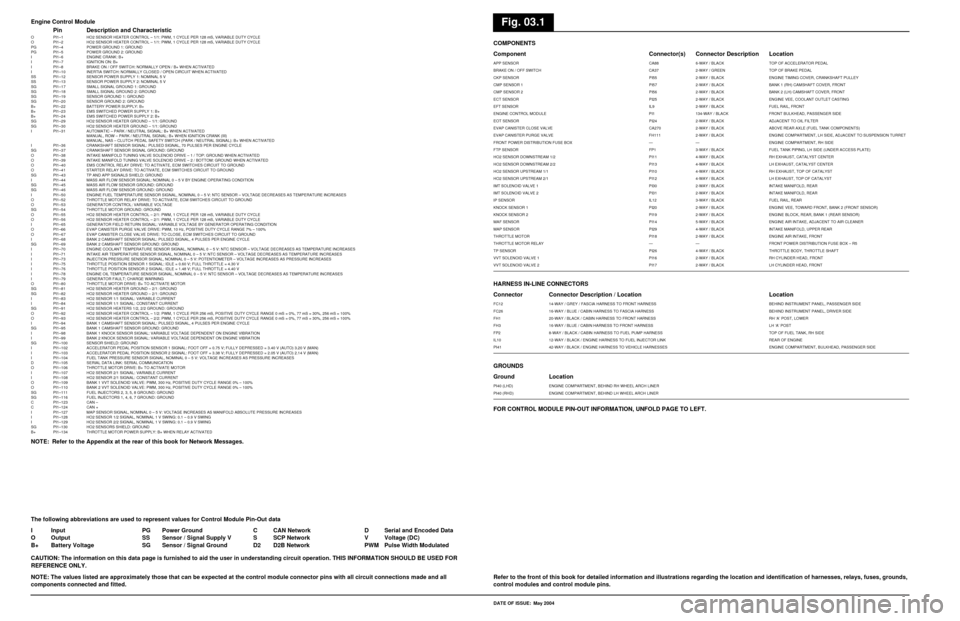

Fig. 03.1

FOR CONTROL MODULE PIN-OUT INFORMATION, UNFOLD PAGE TO LEFT. COMPONENTS

Component Connector(s) Connector Description LocationAPP SENSOR CA88 6-WAY / BLACK TOP OF ACCELERATOR PEDAL

BRAKE ON / OFF SWITCH CA37 2-WAY / GREEN TOP OF BRAKE PEDAL

CKP SENSOR PI55 2-WAY / BLACK ENGINE TIMING COVER, CRANKSHAFT PULLEY

CMP SENSOR 1 PI57 2-WAY / BLACK BANK 1 (RH) CAMSHAFT COVER, FRONT

CMP SENSOR 2 PI56 2-WAY / BLACK BANK 2 (LH) CAMSHAFT COVER, FRONT

ECT SENSOR PI25 2-WAY / BLACK ENGINE VEE, COOLANT OUTLET CASTING

EFT SENSOR IL9 2-WAY / BLACK FUEL RAIL, FRONT

ENGINE CONTROL MODULE PI1 134-WAY / BLACK FRONT BULKHEAD, P ASSENGER SIDE

EOT SENSOR PI24 2-WAY / BLACK ADJACENT TO OIL FILTER

EVAP CANISTER CLOSE VALVE CA270 2-WAY / BLACK ABOVE REAR AXLE (FUEL TANK COMPONENTS)

EVAP CANISTER PURGE VALVE FH111 2-WAY / BLACK ENGINE COMPARTMENT, LH SIDE, ADJACENT TO SUSPENSION TURRET

FRONT POWER DISTRIBUTION FUSE BOX — — ENGINE COMPARTMENT, RH SIDE

FTP SENSOR FP1 3-WAY / BLACK FUEL TANK PIPING, LH SIDE (UNDER ACCESS PLATE)

HO2 SENSOR DOWNSTREAM 1/2 PI11 4-WAY / BLACK RH EXHAUST, CATALYST CENTER

HO2 SENSOR DOWNSTREAM 2/2 PI13 4-WAY / BLACK LH EXHAUST, CATALYST CENTER

HO2 SENSOR UPSTREAM 1/1 PI10 4-WAY / BLACK RH EXHAUST, TOP OF CATALYST

HO2 SENSOR UPSTREAM 2/1 PI12 4-WAY / BLACK LH EXHAUST, TOP OF CATALYST

IMT SOLENOID VALVE 1 PI30 2-WAY / BLACK INTAKE MANIFOLD, REAR

IMT SOLENOID VALVE 2 PI31 2-WAY / BLACK INTAKE MANIFOLD, REAR

IP SENSOR IL12 3-WAY / BLACK FUEL RAIL, REAR

KNOCK SENSOR 1 PI20 2-WAY / BLACK ENGINE VEE, TOWARD FRONT, BANK 2 (FRONT SENSOR)

KNOCK SENSOR 2 PI19 2-WAY / BLACK ENGINE BLOCK, REAR, BANK 1 (REAR SENSOR)

MAF SENSOR PI14 5-WAY / BLACK ENGINE AIR INTAKE, ADJACENT TO AIR CLEANER

MAP SENSOR PI29 4-WAY / BLACK INTAKE MANIFOLD, UPPER REAR

THROTTLE MOTOR PI18 2-WAY / BLACK ENGINE AIR INTAKE, FRONT

THROTTLE MOTOR RELAY — — FRONT POWER DISTRIBUTION FUSE BOX – R5

TP SENSOR PI26 4-WAY / BLACK THROTTLE BODY, THROTTLE SHAFT

VVT SOLENOID VALVE 1 PI16 2-WAY / BLACK RH CYLINDER HEAD, FRONT

VVT SOLENOID VALVE 2 PI17 2-WAY / BLACK LH CYLINDER HEAD, FRONTHARNESS IN-LINE CONNECTORS

Connector Connector Description / Location LocationFC12 14-WAY / GREY / FASCIA HARNESS TO FRONT HARNESS BEHIND INSTRUMENT PANEL, PASSENGER SIDE

FC26 16-WAY / BLUE / CABIN HARNESS TO FASCIA HARNESS BEHIND INSTRUMENT PANEL, DRIVER SIDE

FH1 20-WAY / BLACK / CABIN HARNESS TO FRONT HARNESS RH ‘A’ POST, LOWER

FH3 16-WAY / BLUE / CABIN HARNESS TO FRONT HARNESS LH ‘A’ POST

FP2 8-WAY / BLACK / CABIN HARNESS TO FUEL PUMP HARNESS TOP OF FUEL TANK, RH SIDE

IL10 12-WAY / BLACK / ENGINE HARNESS TO FUEL INJECTOR LINK REAR OF ENGINE

PI41 42-WAY / BLACK / ENGINE HARNESS TO VEHICLE HARNESSES ENGINE COMPARTMENT, BULKHEAD, PASSENGER SIDEGROUNDS

Ground LocationPI40 (LHD) ENGINE COMPARTMENT, BEHIND RH WHEEL ARCH LINER

PI40 (RHD) ENGINE COMPARTMENT, BEHIND LH WHEEL ARCH LINER

NOTE: Refer to the Appendix at the rear of this book for Network Messages. Engine Control Module Pin Description and CharacteristicO PI1–1 HO2 SENSOR HEATER CONTROL – 1/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

O PI1–2 HO2 SENSOR HEATER CONTROL – 1/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

PG PI1–4 POWER GROUND 1: GROUND

PG PI1–5 POWER GROUND 2: GROUND

I PI1–6 ENGINE CRANK: B+

I PI1–7 IGNITION ON: B+

I PI1–8 BRAKE ON / OFF SWITCH: NORMALLY OPEN / B+ WHEN ACTIVATED

I PI1–10 INERTIA SWITCH: NORMALLY CLOSED / OPEN CIRCUIT WHEN ACTIVATED

SS PI1–12 SENSOR POWER SUPPLY 1: NOMINAL 5 V

SS PI1–13 SENSOR POWER SUPPLY 2: NOMINAL 5 V

SG PI1–17 SMALL SIGNAL GROUND 1: GROUND

SG PI1–18 SMALL SIGNAL GROUND 2: GROUND

SG PI1–19 SENSOR GROUND 1: GROUND

SG PI1–20 SENSOR GROUND 2: GROUND

B+ PI1–22 BATTERY POWER SUPPLY: B+

B+ PI1–23 EMS SWITCHED POWER SUPPLY 1: B+

B+ PI1–24 EMS SWITCHED POWER SUPPLY 2: B+

SG PI1–29 HO2 SENSOR HEATER GROUND – 1/1: GROUND

SG PI1–30 HO2 SENSOR HEATER GROUND – 1/1: GROUND

I PI1–31 AUTOMATIC – PARK / NEUTRAL SIGNAL: B+ WHEN ACTIVATED MANUAL, ROW – PARK / NEUTRAL SIGNAL: B+ WHEN IGNITION CRANK (III)

MANUAL, NAS – CLUTCH PEDAL SAFETY SWITCH (PARK / NEUTRAL SIGNAL): B+ WHEN ACTIVATED

I PI1–36 CRANKSHAFT SENSOR SIGNAL: PULSED SIGNAL, 70 PULSES PER ENGINE CYCLE

SG PI1–37 CRANKSHAFT SENSOR SIGNAL GROUND: GROUND

O PI1–38 INTAKE MANIFOLD TUNING VALVE SOLENOID DRIVE – 1 / TOP: GROUND WHEN ACTIVATED

O PI1–39 INTAKE MANIFOLD TUNING VALVE SOLENOID DRIVE – 2 / BOTTOM: GROUND WHEN ACTIVATED

O PI1–40 EMS CONTROL RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

O PI1–41 STARTER RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

SG PI1–43 TP AND APP SIGNALS SHIELD: GROUND

I PI1–44 MASS AIR FLOW SENSOR SIGNAL: NOMINAL 0 – 5 V BY ENGINE OPERATING CONDITION

SG PI1–45 MASS AIR FLOW SENSOR GROUND: GROUND

SG PI1–46 MASS AIR FLOW SENSOR GROUND: GROUND

I PI1–50 ENGINE FUEL TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

O PI1–52 THROTTLE MOTOR RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

O PI1–53 GENERATOR CONTROL: VARIABLE VOLTAGE

SG PI1–54 THROTTLE MOTOR GROUND: GROUND

O PI1–55 HO2 SENSOR HEATER CONTROL – 2/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

O PI1–56 HO2 SENSOR HEATER CONTROL – 2/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

I PI1–65 GENERATOR FIELD RETURN SIGNAL: VARIABLE VOLTAGE BY GENERATOR OPERATING CONDITION

O PI1–66 EVAP CANISTER PURGE VALVE DRIVE: PWM, 10 Hz, POSITIVE DUTY CYCLE RANGE 7% – 100%

O PI1–67 EVAP CANISTER CLOSE VALVE DRIVE: TO CLOSE, ECM SWITCHES CIRCUIT TO GROUND

I PI1–68 BANK 2 CAMSHAFT SENSOR SIGNAL: PULSED SIGNAL, 4 PULSES PER ENGINE CYCLE

SG PI1–69 BANK 2 CAMSHAFT SENSOR GROUND: GROUND

I PI1–70 ENGINE COOLANT TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–71 INTAKE AIR TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–73 INJECTION PRESSURE SENSOR SIGNAL, NOMINAL 0 – 5 V: POTENTIOMETER – VOLTAGE INCREASES AS PRESSURE INCREASES

I PI1–75 THROTTLE POSITION SENSOR 1 SIGNAL: IDLE = 0.60 V; FULL THROTTLE = 4.30 V

I PI1–76 THROTTLE POSITION SENSOR 2 SIGNAL: IDLE = 1.48 V; FULL THROTTLE = 4.40 V

I PI1–78 ENGINE OIL TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–79 GENERATOR FAULT; CHARGE WARNING

O PI1–80 THROTTLE MOTOR DRIVE: B+ TO ACTIVATE MOTOR

SG PI1–81 HO2 SENSOR HEATER GROUND – 2/1: GROUND

SG PI1–82 HO2 SENSOR HEATER GROUND – 2/1: GROUND

I PI1–83 HO2 SENSOR 1/1 SIGNAL: VARIABLE CURRENT

I PI1–84 HO2 SENSOR 1/1 SIGNAL: CONSTANT CURRENT

SG PI1–91 HO2 SENSOR HEATERS 1/2, 2/2 GROUND: GROUND

O PI1–92 HO2 SENSOR HEATER CONTROL – 1/2: PWM, 1 CYCLE PER 256 mS, POSITIVE DUTY CYCLE RANGE 0 mS = 0%, 77 mS = 30%, 256 mS = 100%

O PI1–93 HO2 SENSOR HEATER CONTROL – 2/2: PWM, 1 CYCLE PER 256 mS, POSITIVE DUTY CYCLE RANGE 0 mS = 0%, 77 mS = 30%, 256 mS = 100%

I PI1–94 BANK 1 CAMSHAFT SENSOR SIGNAL: PULSED SIGNAL, 4 PULSES PER ENGINE CYCLE

SG PI1–95 BANK 1 CAMSHAFT SENSOR GROUND: GROUND

I PI1–98 BANK 1 KNOCK SENSOR SIGNAL: VARIABLE VOLTAGE DEPENDENT ON ENGINE VIBRATION

I PI1–99 BANK 2 KNOCK SENSOR SIGNAL: VARIABLE VOLTAGE DEPENDENT ON ENGINE VIBRATION

SG PI1–100 SENSOR SHIELD: GROUND

I PI1–102 ACCELERATOR PEDAL POSITION SENSOR 1 SIGNAL: FOOT OFF = 0.75 V; FULLY DEPRESSED = 3.40 V (AUTO) 3.20 V (MAN)

I PI1–103 ACCELERATOR PEDAL POSITION SENSOR 2 SIGNAL: FOOT OFF = 3.38 V; FULLY DEPRESSED = 2.05 V (AUTO) 2.14 V (MAN)

I PI1–104 FUEL TANK PRESSURE SENSOR SIGNAL, NOMINAL 0 – 5 V: VOLTAGE INCREASES AS PRESSURE INCREASES

D PI1–105 SERIAL DATA LINK: SERIAL COMMUNICATION

O PI1–106 THROTTLE MOTOR DRIVE: B+ TO ACTIVATE MOTOR

I PI1–107 HO2 SENSOR 2/1 SIGNAL: VARIABLE CURRENT

I PI1–108 HO2 SENSOR 2/1 SIGNAL: CONSTANT CURRENT

O PI1–109 BANK 1 VVT SOLENOID VALVE: PWM, 300 Hz, POSITIVE DUTY CYCLE RANGE 0% – 100%

O PI1–110 BANK 2 VVT SOLENOID VALVE: PWM, 300 Hz, POSITIVE DUTY CYCLE RANGE 0% – 100%

SG PI1–111 FUEL INJECTORS 2, 3, 5, 8 GROUND: GROUND

SG PI1–116 FUEL INJECTORS 1, 4, 6, 7 GROUND: GROUND

C PI1–123 CAN –

C PI1–124 CAN +

I PI1–127 MAP SENSOR SIGNAL, NOMINAL 0 – 5 V: VOLTAGE INCREASES AS MANIFOLD ABSOLUTE PRESSURE INCREASES

I PI1–128 HO2 SENSOR 1/2 SIGNAL, NOMINAL 1 V SWING: 0.1 – 0.9 V SWING

I PI1–129 HO2 SENSOR 2/2 SIGNAL, NOMINAL 1 V SWING: 0.1 – 0.9 V SWING

SG PI1–130 HO2 SENSORS SHIELD: GROUND

B+ PI1–134 THROTTLE MOTOR POWER SUPPLY: B+ WHEN RELAY ACTIVATED

Page 64 of 200

Refer to the front of this book for detailed information and illustrations regarding the location and identification of harnesses, relays, fuses, grounds,

control modules and control module pins.

NOTE: The values listed are approximately those that can be expected at the control module connector pins with all circuit conn

ections made and all

components connected and fitted. The following abbreviations are used to represent values for Control Module Pin-Out data

I Input

O Output

B+ Battery Voltage PG Power Ground

SS Sensor / Signal Supply V

SG Sensor / Signal GroundC CAN Network

S SCP Network

D2 D2B Network D Serial and Encoded Data

V Voltage (DC)

PWM Pulse Width Modulated

CAUTION: The information on this data page is furnished to ai d the user in understanding circuit operation. THIS INFORMATION SH OULD BE USED FOR

REFERENCE ONLY.DATE OF ISSUE: May 2004

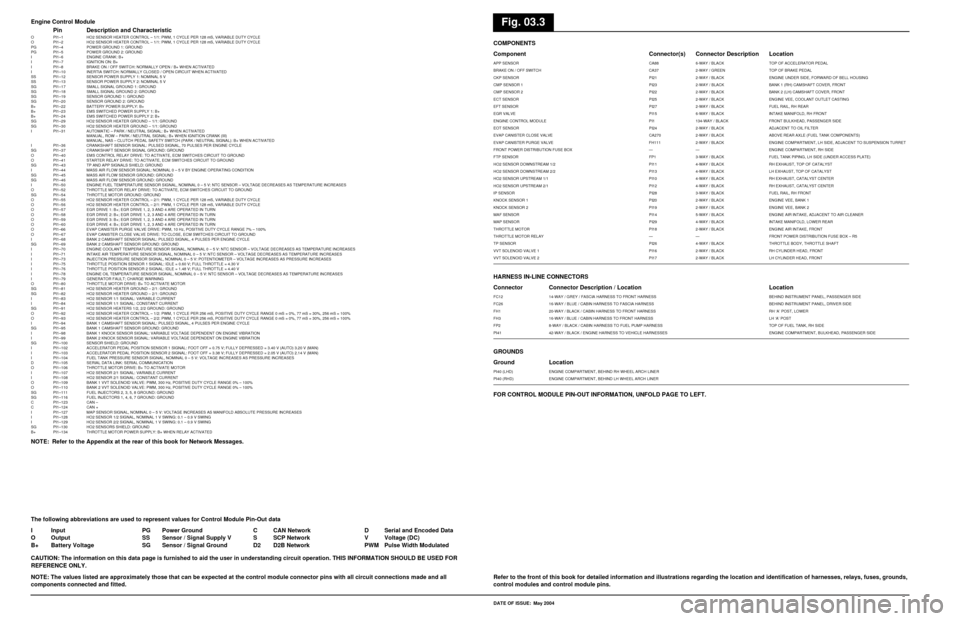

Fig. 03.3

FOR CONTROL MODULE PIN-OUT INFORMATION, UNFOLD PAGE TO LEFT. COMPONENTS

Component Connector(s) Connector Description LocationAPP SENSOR CA88 6-WAY / BLACK TOP OF ACCELERATOR PEDAL

BRAKE ON / OFF SWITCH CA37 2-WAY / GREEN TOP OF BRAKE PEDAL

CKP SENSOR PI21 2-WAY / BLACK ENGINE UNDER SIDE, FORWARD OF BELL HOUSING

CMP SENSOR 1 PI23 2-WAY / BLACK BANK 1 (RH) CAMSHAFT COVER, FRONT

CMP SENSOR 2 PI22 2-WAY / BLACK BANK 2 (LH) CAMSHAFT COVER, FRONT

ECT SENSOR PI25 2-WAY / BLACK ENGINE VEE, COOLANT OUTLET CASTING

EFT SENSOR PI27 2-WAY / BLACK FUEL RAIL, RH REAR

EGR VALVE PI15 6-WAY / BLACK INTAKE MANIFOLD, RH FRONT

ENGINE CONTROL MODULE PI1 134-WAY / BLACK FRONT BULKHEAD, P ASSENGER SIDE

EOT SENSOR PI24 2-WAY / BLACK ADJACENT TO OIL FILTER

EVAP CANISTER CLOSE VALVE CA270 2-WAY / BLACK ABOVE REAR AXLE (FUEL TANK COMPONENTS)

EVAP CANISTER PURGE VALVE FH111 2-WAY / BLACK ENGINE COMPARTMENT, LH SIDE, ADJACENT TO SUSPENSION TURRET

FRONT POWER DISTRIBUTION FUSE BOX — — ENGINE COMPARTMENT, RH SIDE

FTP SENSOR FP1 3-WAY / BLACK FUEL TANK PIPING, LH SIDE (UNDER ACCESS PLATE)

HO2 SENSOR DOWNSTREAM 1/2 PI11 4-WAY / BLACK RH EXHAUST, TOP OF CATALYST

HO2 SENSOR DOWNSTREAM 2/2 PI13 4-WAY / BLACK LH EXHAUST, TOP OF CATALYST

HO2 SENSOR UPSTREAM 1/1 PI10 4-WAY / BLACK RH EXHAUST, CATALYST CENTER

HO2 SENSOR UPSTREAM 2/1 PI12 4-WAY / BLACK RH EXHAUST, CATALYST CENTER

IP SENSOR PI28 3-WAY / BLACK FUEL RAIL, RH FRONT

KNOCK SENSOR 1 PI20 2-WAY / BLACK ENGINE VEE, BANK 1

KNOCK SENSOR 2 PI19 2-WAY / BLACK ENGINE VEE, BANK 2

MAF SENSOR PI14 5-WAY / BLACK ENGINE AIR INTAKE, ADJACENT TO AIR CLEANER

MAP SENSOR PI29 4-WAY / BLACK INTAKE MANIFOLD, LOWER REAR

THROTTLE MOTOR PI18 2-WAY / BLACK ENGINE AIR INTAKE, FRONT

THROTTLE MOTOR RELAY — — FRONT POWER DISTRIBUTION FUSE BOX – R5

TP SENSOR PI26 4-WAY / BLACK THROTTLE BODY, THROTTLE SHAFT

VVT SOLENOID VALVE 1 PI16 2-WAY / BLACK RH CYLINDER HEAD, FRONT

VVT SOLENOID VALVE 2 PI17 2-WAY / BLACK LH CYLINDER HEAD, FRONTHARNESS IN-LINE CONNECTORS

Connector Connector Description / Location LocationFC12 14-WAY / GREY / FASCIA HARNESS TO FRONT HARNESS BEHIND INSTRUMENT PANEL, PASSENGER SIDE

FC26 16-WAY / BLUE / CABIN HARNESS TO FASCIA HARNESS BEHIND INSTRUMENT PANEL, DRIVER SIDE

FH1 20-WAY / BLACK / CABIN HARNESS TO FRONT HARNESS RH ‘A’ POST, LOWER

FH3 16-WAY / BLUE / CABIN HARNESS TO FRONT HARNESS LH ‘A’ POST

FP2 8-WAY / BLACK / CABIN HARNESS TO FUEL PUMP HARNESS TOP OF FUEL TANK, RH SIDE

PI41 42-WAY / BLACK / ENGINE HARNESS TO VEHICLE HARNESSES ENGINE COMPARTMENT, BULKHEAD, PASSENGER SIDEGROUNDS

Ground LocationPI40 (LHD) ENGINE COMPARTMENT, BEHIND RH WHEEL ARCH LINER

PI40 (RHD) ENGINE COMPARTMENT, BEHIND LH WHEEL ARCH LINER

NOTE: Refer to the Appendix at the rear of this book for Network Messages. Engine Control Module Pin Description and CharacteristicO PI1–1 HO2 SENSOR HEATER CONTROL – 1/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

O PI1–2 HO2 SENSOR HEATER CONTROL – 1/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

PG PI1–4 POWER GROUND 1: GROUND

PG PI1–5 POWER GROUND 2: GROUND

I PI1–6 ENGINE CRANK: B+

I PI1–7 IGNITION ON: B+

I PI1–8 BRAKE ON / OFF SWITCH: NORMALLY OPEN / B+ WHEN ACTIVATED

I PI1–10 INERTIA SWITCH: NORMALLY CLOSED / OPEN CIRCUIT WHEN ACTIVATED

SS PI1–12 SENSOR POWER SUPPLY 1: NOMINAL 5 V

SS PI1–13 SENSOR POWER SUPPLY 2: NOMINAL 5 V

SG PI1–17 SMALL SIGNAL GROUND 1: GROUND

SG PI1–18 SMALL SIGNAL GROUND 2: GROUND

SG PI1–19 SENSOR GROUND 1: GROUND

SG PI1–20 SENSOR GROUND 2: GROUND

B+ PI1–22 BATTERY POWER SUPPLY: B+

B+ PI1–23 EMS SWITCHED POWER SUPPLY 1: B+

B+ PI1–24 EMS SWITCHED POWER SUPPLY 2: B+

SG PI1–29 HO2 SENSOR HEATER GROUND – 1/1: GROUND

SG PI1–30 HO2 SENSOR HEATER GROUND – 1/1: GROUND

I PI1–31 AUTOMATIC – PARK / NEUTRAL SIGNAL: B+ WHEN ACTIVATED MANUAL, ROW – PARK / NEUTRAL SIGNAL: B+ WHEN IGNITION CRANK (III)

MANUAL, NAS – CLUTCH PEDAL SAFETY SWITCH (PARK / NEUTRAL SIGNAL): B+ WHEN ACTIVATED

I PI1–36 CRANKSHAFT SENSOR SIGNAL: PULSED SIGNAL, 70 PULSES PER ENGINE CYCLE

SG PI1–37 CRANKSHAFT SENSOR SIGNAL GROUND: GROUND

O PI1–40 EMS CONTROL RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

O PI1–41 STARTER RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

SG PI1–43 TP AND APP SIGNALS SHIELD: GROUND

I PI1–44 MASS AIR FLOW SENSOR SIGNAL: NOMINAL 0 – 5 V BY ENGINE OPERATING CONDITION

SG PI1–45 MASS AIR FLOW SENSOR GROUND: GROUND

SG PI1–46 MASS AIR FLOW SENSOR GROUND: GROUND

I PI1–50 ENGINE FUEL TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

O PI1–52 THROTTLE MOTOR RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

SG PI1–54 THROTTLE MOTOR GROUND: GROUND

O PI1–55 HO2 SENSOR HEATER CONTROL – 2/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

O PI1–56 HO2 SENSOR HEATER CONTROL – 2/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

O PI1–57 EGR DRIVE 1: B+; EGR DRIVE 1, 2, 3 AND 4 ARE OPERATED IN TURN

O PI1–58 EGR DRIVE 2: B+; EGR DRIVE 1, 2, 3 AND 4 ARE OPERATED IN TURN

O PI1–59 EGR DRIVE 3: B+; EGR DRIVE 1, 2, 3 AND 4 ARE OPERATED IN TURN

O PI1–60 EGR DRIVE 4: B+; EGR DRIVE 1, 2, 3 AND 4 ARE OPERATED IN TURN

O PI1–66 EVAP CANISTER PURGE VALVE DRIVE: PWM, 10 Hz, POSITIVE DUTY CYCLE RANGE 7% – 100%

O PI1–67 EVAP CANISTER CLOSE VALVE DRIVE: TO CLOSE, ECM SWITCHES CIRCUIT TO GROUND

I PI1–68 BANK 2 CAMSHAFT SENSOR SIGNAL: PULSED SIGNAL, 4 PULSES PER ENGINE CYCLE

SG PI1–69 BANK 2 CAMSHAFT SENSOR GROUND: GROUND

I PI1–70 ENGINE COOLANT TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–71 INTAKE AIR TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–73 INJECTION PRESSURE SENSOR SIGNAL, NOMINAL 0 – 5 V: POTENTIOMETER – VOLTAGE INCREASES AS PRESSURE INCREASES

I PI1–75 THROTTLE POSITION SENSOR 1 SIGNAL: IDLE = 0.60 V; FULL THROTTLE = 4.30 V

I PI1–76 THROTTLE POSITION SENSOR 2 SIGNAL: IDLE = 1.48 V; FULL THROTTLE = 4.40 V

I PI1–78 ENGINE OIL TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–79 GENERATOR FAULT; CHARGE WARNING

O PI1–80 THROTTLE MOTOR DRIVE: B+ TO ACTIVATE MOTOR

SG PI1–81 HO2 SENSOR HEATER GROUND – 2/1: GROUND

SG PI1–82 HO2 SENSOR HEATER GROUND – 2/1: GROUND

I PI1–83 HO2 SENSOR 1/1 SIGNAL: VARIABLE CURRENT

I PI1–84 HO2 SENSOR 1/1 SIGNAL: CONSTANT CURRENT

SG PI1–91 HO2 SENSOR HEATERS 1/2, 2/2 GROUND: GROUND

O PI1–92 HO2 SENSOR HEATER CONTROL – 1/2: PWM, 1 CYCLE PER 256 mS, POSITIVE DUTY CYCLE RANGE 0 mS = 0%, 77 mS = 30%, 256 mS = 100%

O PI1–93 HO2 SENSOR HEATER CONTROL – 2/2: PWM, 1 CYCLE PER 256 mS, POSITIVE DUTY CYCLE RANGE 0 mS = 0%, 77 mS = 30%, 256 mS = 100%

I PI1–94 BANK 1 CAMSHAFT SENSOR SIGNAL: PULSED SIGNAL, 4 PULSES PER ENGINE CYCLE

SG PI1–95 BANK 1 CAMSHAFT SENSOR GROUND: GROUND

I PI1–98 BANK 1 KNOCK SENSOR SIGNAL: VARIABLE VOLTAGE DEPENDENT ON ENGINE VIBRATION

I PI1–99 BANK 2 KNOCK SENSOR SIGNAL: VARIABLE VOLTAGE DEPENDENT ON ENGINE VIBRATION

SG PI1–100 SENSOR SHIELD: GROUND

I PI1–102 ACCELERATOR PEDAL POSITION SENSOR 1 SIGNAL: FOOT OFF = 0.75 V; FULLY DEPRESSED = 3.40 V (AUTO) 3.20 V (MAN)

I PI1–103 ACCELERATOR PEDAL POSITION SENSOR 2 SIGNAL: FOOT OFF = 3.38 V; FULLY DEPRESSED = 2.05 V (AUTO) 2.14 V (MAN)

I PI1–104 FUEL TANK PRESSURE SENSOR SIGNAL, NOMINAL 0 – 5 V: VOLTAGE INCREASES AS PRESSURE INCREASES

D PI1–105 SERIAL DATA LINK: SERIAL COMMUNICATION

O PI1–106 THROTTLE MOTOR DRIVE: B+ TO ACTIVATE MOTOR

I PI1–107 HO2 SENSOR 2/1 SIGNAL: VARIABLE CURRENT

I PI1–108 HO2 SENSOR 2/1 SIGNAL: CONSTANT CURRENT

O PI1–109 BANK 1 VVT SOLENOID VALVE: PWM, 300 Hz, POSITIVE DUTY CYCLE RANGE 0% – 100%

O PI1–110 BANK 2 VVT SOLENOID VALVE: PWM, 300 Hz, POSITIVE DUTY CYCLE RANGE 0% – 100%

SG PI1–111 FUEL INJECTORS 2, 3, 5, 8 GROUND: GROUND

SG PI1–116 FUEL INJECTORS 1, 4, 6, 7 GROUND: GROUND

C PI1–123 CAN –

C PI1–124 CAN +

I PI1–127 MAP SENSOR SIGNAL, NOMINAL 0 – 5 V: VOLTAGE INCREASES AS MANIFOLD ABSOLUTE PRESSURE INCREASES

I PI1–128 HO2 SENSOR 1/2 SIGNAL, NOMINAL 1 V SWING: 0.1 – 0.9 V SWING

I PI1–129 HO2 SENSOR 2/2 SIGNAL, NOMINAL 1 V SWING: 0.1 – 0.9 V SWING

SG PI1–130 HO2 SENSORS SHIELD: GROUND

B+ PI1–134 THROTTLE MOTOR POWER SUPPLY: B+ WHEN RELAY ACTIVATED

Page 68 of 200

Refer to the front of this book for detailed information and illustrations regarding the location and identification of harnesses, relays, fuses, grounds,

control modules and control module pins.

NOTE: The values listed are approximately those that can be expected at the control module connector pins with all circuit conn

ections made and all

components connected and fitted. The following abbreviations are used to represent values for Control Module Pin-Out data

I Input

O Output

B+ Battery Voltage PG Power Ground

SS Sensor / Signal Supply V

SG Sensor / Signal GroundC CAN Network

S SCP Network

D2 D2B Network D Serial and Encoded Data

V Voltage (DC)

PWM Pulse Width Modulated

CAUTION: The information on this data page is furnished to ai d the user in understanding circuit operation. THIS INFORMATION SH OULD BE USED FOR

REFERENCE ONLY.DATE OF ISSUE: May 2004

Fig. 03.5

FOR CONTROL MODULE PIN-OUT INFORMATION, UNFOLD PAGE TO LEFT. COMPONENTS

Component Connector(s) Connector Description LocationAPP SENSOR CA88 6-WAY / BLACK TOP OF ACCELERATOR PEDAL

BRAKE ON / OFF SWITCH CA37 2-WAY / GREEN TOP OF BRAKE PEDAL

CKP SENSOR PI21 2-WAY / BLACK ENGINE UNDER SIDE, FORWARD OF BELL HOUSING

CMP SENSOR 1 PI23 2-WAY / BLACK BANK 1 (RH) CAMSHAFT COVER, FRONT

CMP SENSOR 2 PI22 2-WAY / BLACK BANK 2 (LH) CAMSHAFT COVER, FRONT

ECT SENSOR PI25 2-WAY / BLACK ENGINE VEE, COOLANT OUTLET CASTING

EFT SENSOR PI27 2-WAY / BLACK FUEL RAIL, RH REAR

EGR VALVE PI15 6-WAY / BLACK INTAKE MANIFOLD, REAR

ENGINE CONTROL MODULE PI1 134-WAY / BLACK FRONT BULKHEAD, P ASSENGER SIDE

EOT SENSOR PI24 2-WAY / BLACK ADJACENT TO OIL FILTER

EVAP CANISTER CLOSE VALVE CA270 2-WAY / BLACK ABOVE REAR AXLE (FUEL TANK COMPONENTS)

EVAP CANISTER PURGE VALVE FH111 2-WAY / BLACK ENGINE COMPARTMENT, LH SIDE, ADJACENT TO SUSPENSION TURRET

FRONT POWER DISTRIBUTION FUSE BOX — — ENGINE COMPARTMENT, RH SIDE

FTP SENSOR FP1 3-WAY / BLACK FUEL TANK PIPING, LH SIDE (UNDER ACCESS PLATE)

HO2 SENSOR DOWNSTREAM 1/2 PI11 4-WAY / BLACK RH EXHAUST, TOP OF CATALYST

HO2 SENSOR DOWNSTREAM 2/2 PI13 4-WAY / BLACK LH EXHAUST, TOP OF CATALYST

HO2 SENSOR UPSTREAM 1/1 PI10 4-WAY / BLACK RH EXHAUST, CATALYST CENTER

HO2 SENSOR UPSTREAM 2/1 PI12 4-WAY / BLACK RH EXHAUST, CATALYST CENTER

IAT SENSOR 2 PI43 2-WAY / BLACK INTAKE MANIFOLD, RH SIDE, REAR

IP SENSOR PI28 3-WAY / BLACK FUEL RAIL, LH REAR

KNOCK SENSOR 1 PI20 2-WAY / BLACK ENGINE VEE, BANK 1

KNOCK SENSOR 2 PI19 2-WAY / BLACK ENGINE VEE, BANK 2

MAF SENSOR PI14 5-WAY / BLACK ENGINE AIR INTAKE, ADJACENT TO AIR CLEANER

MAP SENSOR PI29 4-WAY / BLACK INTAKE MANIFOLD, REAR, BELOW THROTTLE ASSEMBLY

THROTTLE MOTOR PI18 2-WAY / BLACK ENGINE AIR INTAKE, REAR

THROTTLE MOTOR RELAY — — FRONT POWER DISTRIBUTION FUSE BOX – R5

TP SENSOR PI26 4-WAY / BLACK THROTTLE BODY, THROTTLE SHAFTHARNESS IN-LINE CONNECTORS

Connector Connector Description / Location LocationFC12 14-WAY / GREY / FASCIA HARNESS TO FRONT HARNESS BEHIND INSTRUMENT PANEL, PASSENGER SIDE

FC26 16-WAY / BLUE / CABIN HARNESS TO FASCIA HARNESS BEHIND INSTRUMENT PANEL, DRIVER SIDE

FH1 20-WAY / BLACK / CABIN HARNESS TO FRONT HARNESS RH ‘A’ POST, LOWER

FH3 16-WAY / BLUE / CABIN HARNESS TO FRONT HARNESS LH ‘A’ POST

FP2 8-WAY / BLACK / CABIN HARNESS TO FUEL PUMP HARNESS TOP OF FUEL TANK, RH SIDE

PI41 42-WAY / BLACK / ENGINE HARNESS TO VEHICLE HARNESSES ENGINE COMPARTMENT, BULKHEAD, PASSENGER SIDEGROUNDS

Ground LocationPI40 (LHD) ENGINE COMPARTMENT, BEHIND RH WHEEL ARCH LINER

PI40 (RHD) ENGINE COMPARTMENT, BEHIND LH WHEEL ARCH LINER

NOTE: Refer to the Appendix at the rear of this book for Network Messages. Engine Control Module

Pin Description and CharacteristicO PI1–1 HO2 SENSOR HEATER CONTROL – 1/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

O PI1–2 HO2 SENSOR HEATER CONTROL – 1/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

PG PI1–4 POWER GROUND 1: GROUND

PG PI1–5 POWER GROUND 2: GROUND

I PI1–6 ENGINE CRANK: B+

I PI1–7 IGNITION ON: B+

I PI1–8 BRAKE ON / OFF SWITCH: NORMALLY OPEN / B+ WHEN ACTIVATED

I PI1–10 INERTIA SWITCH: NORMALLY CLOSED / OPEN CIRCUIT WHEN ACTIVATED

SS PI1–12 SENSOR POWER SUPPLY 1: NOMINAL 5 V

SS PI1–13 SENSOR POWER SUPPLY 2: NOMINAL 5 V

SG PI1–17 SMALL SIGNAL GROUND 1: GROUND

SG PI1–18 SMALL SIGNAL GROUND 2: GROUND

SG PI1–19 SENSOR GROUND 1: GROUND

SG PI1–20 SENSOR GROUND 2: GROUND

B+ PI1–22 BATTERY POWER SUPPLY: B+

B+ PI1–23 EMS SWITCHED POWER SUPPLY 1: B+

B+ PI1–24 EMS SWITCHED POWER SUPPLY 2: B+

SG PI1–29 HO2 SENSOR HEATER GROUND – 1/1: GROUND

SG PI1–30 HO2 SENSOR HEATER GROUND – 1/1: GROUND

I PI1–31 AUTOMATIC – PARK / NEUTRAL SIGNAL: B+ WHEN ACTIVATED MANUAL, ROW – PARK / NEUTRAL SIGNAL: B+ WHEN IGNITION CRANK (III)

MANUAL, NAS – CLUTCH PEDAL SAFETY SWITCH (PARK / NEUTRAL SIGNAL): B+ WHEN ACTIVATED

I PI1–36 CRANKSHAFT SENSOR SIGNAL: PULSED SIGNAL, 70 PULSES PER ENGINE CYCLE

SG PI1–37 CRANKSHAFT SENSOR SIGNAL GROUND: GROUND

O PI1–40 EMS CONTROL RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

O PI1–41 STARTER RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

SG PI1–43 TP AND APP SIGNALS SHIELD: GROUND

I PI1–44 MASS AIR FLOW SENSOR SIGNAL: NOMINAL 0 – 5 V BY ENGINE OPERATING CONDITION

SG PI1–45 MASS AIR FLOW SENSOR GROUND: GROUND

SG PI1–46 MASS AIR FLOW SENSOR GROUND: GROUND

I PI1–50 ENGINE FUEL TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

O PI1–52 THROTTLE MOTOR RELAY DRIVE: TO ACTIVATE, ECM SWITCHES CIRCUIT TO GROUND

SG PI1–54 THROTTLE MOTOR GROUND: GROUND

O PI1–55 HO2 SENSOR HEATER CONTROL – 2/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

O PI1–56 HO2 SENSOR HEATER CONTROL – 2/1: PWM, 1 CYCLE PER 128 mS, VARIABLE DUTY CYCLE

O PI1–57 EGR DRIVE 1: B+; EGR DRIVE 1, 2, 3 AND 4 ARE OPERATED IN TURN

O PI1–58 EGR DRIVE 2: B+; EGR DRIVE 1, 2, 3 AND 4 ARE OPERATED IN TURN

O PI1–59 EGR DRIVE 3: B+; EGR DRIVE 1, 2, 3 AND 4 ARE OPERATED IN TURN

O PI1–60 EGR DRIVE 4: B+; EGR DRIVE 1, 2, 3 AND 4 ARE OPERATED IN TURN

O PI1–66 EVAP CANISTER PURGE VALVE DRIVE: PWM, 10 Hz, POSITIVE DUTY CYCLE RANGE 7% – 100%

O PI1–67 EVAP CANISTER CLOSE VALVE DRIVE: TO CLOSE, ECM SWITCHES CIRCUIT TO GROUND

I PI1–68 BANK 2 CAMSHAFT SENSOR SIGNAL: PULSED SIGNAL, 4 PULSES PER ENGINE CYCLE

SG PI1–69 BANK 2 CAMSHAFT SENSOR GROUND: GROUND

I PI1–70 ENGINE COOLANT TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–71 INTAKE AIR TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–72 INTAKE AIR TEMPERATURE SENSOR 2 SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–73 INJECTION PRESSURE SENSOR SIGNAL, NOMINAL 0 – 5 V: POTENTIOMETER – VOLTAGE INCREASES AS PRESSURE INCREASES

I PI1–75 THROTTLE POSITION SENSOR 1 SIGNAL: IDLE = 0.60 V; FULL THROTTLE = 4.30 V

I PI1–76 THROTTLE POSITION SENSOR 2 SIGNAL: IDLE = 1.48 V; FULL THROTTLE = 4.40 V

I PI1–78 ENGINE OIL TEMPERATURE SENSOR SIGNAL, NOMINAL 0 – 5 V: NTC SENSOR – VOLTAGE DECREASES AS TEMPERATURE INCREASES

I PI1–79 GENERATOR FAULT; CHARGE WARNING

O PI1–80 THROTTLE MOTOR DRIVE: B+ TO ACTIVATE MOTOR

SG PI1–81 HO2 SENSOR HEATER GROUND – 2/1: GROUND

SG PI1–82 HO2 SENSOR HEATER GROUND – 2/1: GROUND

I PI1–83 HO2 SENSOR 1/1 SIGNAL: VARIABLE CURRENT

I PI1–84 HO2 SENSOR 1/1 SIGNAL: CONSTANT CURRENT

SG PI1–91 HO2 SENSOR HEATERS 1/2, 2/2 GROUND: GROUND

O PI1–92 HO2 SENSOR HEATER CONTROL – 1/2: PWM, 1 CYCLE PER 256 mS, POSITIVE DUTY CYCLE RANGE 0 mS = 0%, 77 mS = 30%, 256 mS = 100%

O PI1–93 HO2 SENSOR HEATER CONTROL – 2/2: PWM, 1 CYCLE PER 256 mS, POSITIVE DUTY CYCLE RANGE 0 mS = 0%, 77 mS = 30%, 256 mS = 100%

I PI1–94 BANK 1 CAMSHAFT SENSOR SIGNAL: PULSED SIGNAL, 4 PULSES PER ENGINE CYCLE

SG PI1–95 BANK 1 CAMSHAFT SENSOR GROUND: GROUND

I PI1–98 BANK 1 KNOCK SENSOR SIGNAL: VARIABLE VOLTAGE DEPENDENT ON ENGINE VIBRATION

I PI1–99 BANK 2 KNOCK SENSOR SIGNAL: VARIABLE VOLTAGE DEPENDENT ON ENGINE VIBRATION

SG PI1–100 SENSOR SHIELD: GROUND

I PI1–102 ACCELERATOR PEDAL POSITION SENSOR 1 SIGNAL: FOOT OFF = 0.75 V; FULLY DEPRESSED = 3.40 V (AUTO) 3.20 V (MAN)

I PI1–103 ACCELERATOR PEDAL POSITION SENSOR 2 SIGNAL: FOOT OFF = 3.38 V; FULLY DEPRESSED = 2.05 V (AUTO) 2.14 V (MAN)

I PI1–104 FUEL TANK PRESSURE SENSOR SIGNAL, NOMINAL 0 – 5 V: VOLTAGE INCREASES AS PRESSURE INCREASES

D PI1–105 SERIAL DATA LINK: SERIAL COMMUNICATION

O PI1–106 THROTTLE MOTOR DRIVE: B+ TO ACTIVATE MOTOR

I PI1–107 HO2 SENSOR 2/1 SIGNAL: VARIABLE CURRENT

I PI1–108 HO2 SENSOR 2/1 SIGNAL: CONSTANT CURRENT

SG PI1–111 FUEL INJECTORS 2, 3, 5, 8 GROUND: GROUND

SG PI1–116 FUEL INJECTORS 1, 4, 6, 7 GROUND: GROUND

C PI1–123 CAN –

C PI1–124 CAN +

I PI1–127 MAP SENSOR SIGNAL, NOMINAL 0 – 5 V: VOLTAGE INCREASES AS MANIFOLD ABSOLUTE PRESSURE INCREASES

I PI1–128 HO2 SENSOR 1/2 SIGNAL, NOMINAL 1 V SWING: 0.1 – 0.9 V SWING

I PI1–129 HO2 SENSOR 2/2 SIGNAL, NOMINAL 1 V SWING: 0.1 – 0.9 V SWING

SG PI1–130 HO2 SENSORS SHIELD: GROUND

B+ PI1–134 THROTTLE MOTOR POWER SUPPLY: B+ WHEN RELAY ACTIVATED

Page 90 of 200

Refer to the front of this book for detailed information and illustrations regarding the location and identification of harnesses, relays, fuses, grounds,

control modules and control module pins.

NOTE: The values listed are approximately those that can be expected at the control module connector pins with all circuit conn

ections made and all

components connected and fitted. The following abbreviations are used to represent values for Control Module Pin-Out data

I Input

O Output

B+ Battery Voltage PG Power Ground

SS Sensor / Signal Supply V

SG Sensor / Signal GroundC CAN Network

S SCP Network

D2 D2B Network D Serial and Encoded Data

V Voltage (DC)

PWM Pulse Width Modulated

CAUTION: The information on this data page is furnished to ai d the user in understanding circuit operation. THIS INFORMATION SH OULD BE USED FOR

REFERENCE ONLY.DATE OF ISSUE: May 2004

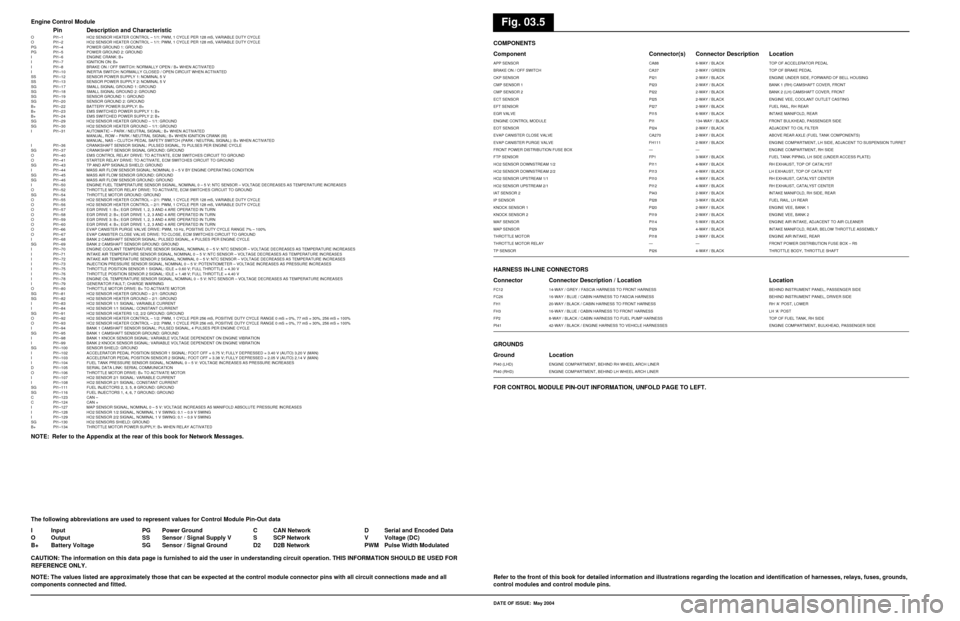

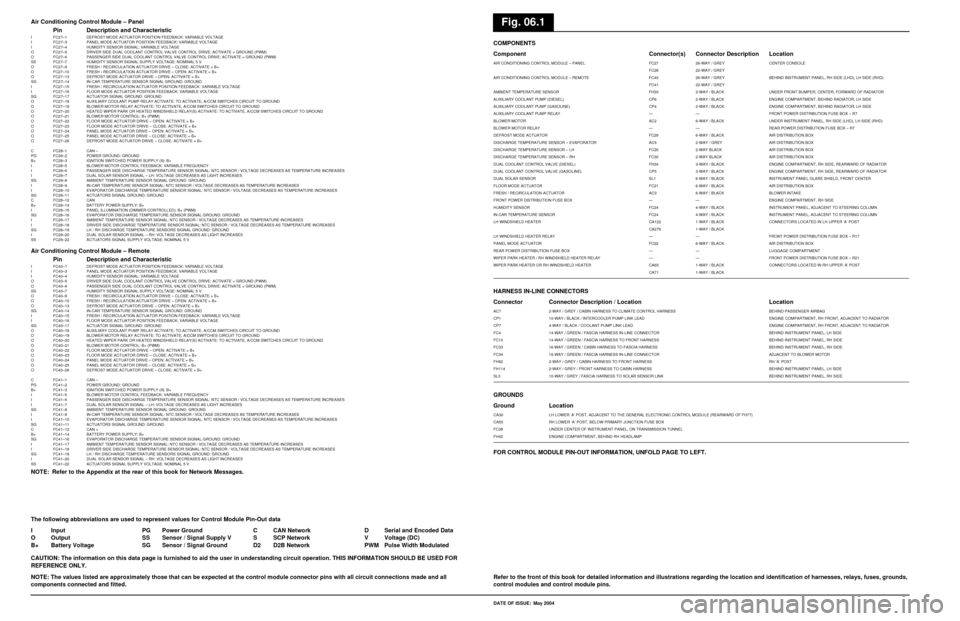

Fig. 06.1

FOR CONTROL MODULE PIN-OUT INFORMATION, UNFOLD PAGE TO LEFT. COMPONENTS

Component Connector(s) Connector Description LocationAIR CONDITIONING CONTROL MODULE – PANEL FC27 26-WAY / GREY CENTER CONSOLE

FC28 22-WAY / GREY

AIR CONDITIONING CONTROL MODULE – REMOTE FC40 26-WAY / GREY BEHIND INSTRUMENT PANEL, RH SIDE (LHD), LH SIDE (RHD) FC41 22-WAY / GREY

AMBIENT TEMPERATURE SENSOR FH30 2-WAY / BLACK UNDER FRONT BUMPER, CENTER, FORWARD OF RADIATOR

AUXILIARY COOLANT PUMP (DIESEL) CP6 2-WAY / BLACK ENGINE COMPARTMENT, BEHIND RADIATOR, LH SIDE

AUXILIARY COOLANT PUMP (GASOLINE) CP4 2-WAY / BLACK ENGINE COMPARTMENT, BEHIND RADIATOR, LH SIDE

AUXILIARY COOLANT PUMP RELAY — — FRONT POWER DISTRIBUTION FUSE BOX – R7

BLOWER MOTOR AC2 6-WAY / BLACK UNDER INSTRUMENT PANEL, RH SIDE (LHD), LH SIDE (RHD)

BLOWER MOTOR RELAY — — REAR POWER DISTRIBUTION FUSE BOX – R7

DEFROST MODE ACTUATOR FC29 6-WAY / BLACK AIR DISTRIBUTION BOX

DISCHARGE TEMPERATURE SENSOR – EVAPORATOR AC5 2-WAY / GREY AIR DISTRIBUTION BOX

DISCHARGE TEMPERATURE SENSOR – LH FC20 2-WAY BLACK AIR DISTRIBUTION BOX

DISCHARGE TEMPERATURE SENSOR – RH FC30 2-WAY BLACK AIR DISTRIBUTION BOX

DUAL COOLANT CONTROL VALVE (DIESEL) FH34 3-WAY / BLACK ENGINE COMPARTMENT, RH SIDE, REARWARD OF RADIATOR

DUAL COOLANT CONTROL VALVE (GASOLINE) CP5 3-WAY / BLACK ENGINE COMPARTMENT, RH SIDE, REARWARD OF RADIATOR

DUAL SOLAR SENSOR SL1 6-WAY / BLACK INSTRUMENT PANEL GLARE SHIELD, FRONT CENTER

FLOOR MODE ACTUATOR FC21 6-WAY / BLACK AIR DISTRIBUTION BOX

FRESH / RECIRCULATION ACTUATOR AC3 6-WAY / BLACK BLOWER INTAKE

FRONT POWER DISTRIBUTION FUSE BOX — — ENGINE COMPARTMENT, RH SIDE

HUMIDITY SENSOR FC24 4-WAY / BLACK INSTRUMENT PANEL, ADJACENT TO STEERING COLUMN

IN-CAR TEMPERATURE SENSOR FC24 4-WAY / BLACK INSTRUMENT PANEL, ADJACENT TO STEERING COLUMN

LH WINDSHIELD HEATER CA122 1-WAY / BLACK CONNECTORS LOCATED IN LH UPPER ‘A’ POST

CA279 1-WAY / BLACK

LH WINDSHIELD HEATER RELAY — — FRONT POWER DISTRIBUTION FUSE BOX – R17

PANEL MODE ACTUATOR FC22 6-WAY / BLACK AIR DISTRIBUTION BOX

REAR POWER DISTRIBUTION FUSE BOX — — LUGGAGE COMPARTMENT

WIPER PARK HEATER / RH WINDSHIELD HEATER RELAY — — FRONT POWER DISTRIBUTION FUSE BOX – R21

WIPER PARK HEATER OR RH WINDSHIELD HEATER CA65 1-WAY / BLACK CONNECTORS LOCATED IN RH UPPER ‘A’ POST CA71 1-WAY / BLACKHARNESS IN-LINE CONNECTORS

Connector Connector Description / Location LocationAC7 2-WAY / GREY / CABIN HARNESS TO CLIMATE CONTROL HARNESS BEHIND PASSENGER AIRBAG

CP1 10-WAY / BLACK / INTERCOOLER PUMP LINK LEAD ENGINE COMPARTMENT, RH FRONT, ADJACENT TO RADIATOR

CP7 4-WAY / BLACK / COOLANT PUMP LINK LEAD ENGINE COMPARTMENT, RH FRONT, ADJACENT TO RADIATOR

FC4 14-WAY / GREEN / FASCIA HARNESS IN-LINE CONNECTOR BEHIND INSTRUMENT PANEL, LH SIDE

FC10 14-WAY / GREEN / FASCIA HARNESS TO FRONT HARNESS BEHIND INSTRUMENT PANEL, RH SIDE

FC33 16-WAY / GREEN / CABIN HARNESS TO FASCIA HARNESS BEHIND INSTRUMENT PANEL, RH SIDE

FC34 16-WAY / GREEN / FASCIA HARNESS IN-LINE CONNECTOR ADJACENT TO BLOWER MOTOR

FH82 2-WAY / GREY / CABIN HARNESS TO FRONT HARNESS RH ‘A’ POST

FH114 2-WAY / GREY / FRONT HARNESS TO CABIN HARNESS BEHIND INSTRUMENT PANEL, LH SIDE

SL3 10-WAY / GREY / FASCIA HARNESS TO SOLAR SENSOR LINK BEHIND INSTRUMENT PANEL, RH SIDEGROUNDS

Ground LocationCA30 LH LOWER ‘A’ POST, ADJACENT TO THE GENERAL ELECTRONIC CONTROL MODULE (REARWARD OF FH77)

CA50 RH LOWER ‘A’ POST, BELOW PRIMARY JUNCTION FUSE BOX

FC38 UNDER CENTER OF INSTRUMENT PANEL, ON TRANSMISSION TUNNEL

FH42 ENGINE COMPARTMENT, BEHIND RH HEADLAMP

NOTE: Refer to the Appendix at the rear of this book for Network Messages. Air Conditioning Control Module – Panel Pin Description and CharacteristicI FC27–1 DEFROST MODE ACTUATOR POSITION FEEDBACK: VARIABLE VOLTAGE

I FC27–3 PANEL MODE ACTUATOR POSITION FEEDBACK: VARIABLE VOLTAGE

I FC27–4 HUMIDITY SENSOR SIGNAL: VARIABLE VOLTAGE

O FC27–5 DRIVER SIDE DUAL COOLANT CONTROL VALVE CONTROL DRIVE: ACTIVATE = GROUND (PWM)

O FC27–6 PASSENGER SIDE DUAL COOLANT CONTROL VALVE CONTROL DRIVE: ACTIVATE = GROUND (PWM)

SS FC27–7 HUMIDITY SENSOR SIGNAL SUPPLY VOLTAGE: NOMINAL 5 V

O FC27–9 FRESH / RECIRCULATION ACTUATOR DRIVE – CLOSE: ACTIVATE = B+

O FC27–10 FRESH / RECIRCULATION ACTUATOR DRIVE – OPEN: ACTIVATE = B+

O FC27–13 DEFROST MODE ACTUATOR DRIVE – OPEN: ACTIVATE = B+

SG FC27–14 IN-CAR TEMPERATURE SENSOR SIGNAL GROUND: GROUND

I FC27–15 FRESH / RECIRCULATION ACTUATOR POSITION FEEDBACK: VARIABLE VOLTAGE

I FC27–16 FLOOR MODE ACTUATOR POSITION FEEDBACK: VARIABLE VOLTAGE

SG FC27–17 ACTUATOR SIGNAL GROUND: GROUND

O FC27–18 AUXILIARY COOLANT PUMP RELAY ACTIVATE: TO ACTIVATE, A/CCM SWITCHES CIRCUIT TO GROUND

O FC27–19 BLOWER MOTOR RELAY ACTIVATE: TO ACTIVATE, A/CCM SWITCHES CIRCUIT TO GROUND

O FC27–20 HEATED WIPER PARK OR HEATED WINDSHIELD RELAY(S) ACTIVATE: TO ACTIVATE, A/CCM SWITCHES CIRCUIT TO GROUND

O FC27–21 BLOWER MOTOR CONTROL: B+ (PWM)

O FC27–22 FLOOR MODE ACTUATOR DRIVE – OPEN: ACTIVATE = B+

O FC27–23 FLOOR MODE ACTUATOR DRIVE – CLOSE: ACTIVATE = B+

O FC27–24 PANEL MODE ACTUATOR DRIVE – OPEN: ACTIVATE = B+

O FC27–25 PANEL MODE ACTUATOR DRIVE – CLOSE: ACTIVATE = B+

O FC27–26 DEFROST MODE ACTUATOR DRIVE – CLOSE: ACTIVATE = B+

C FC28–1 CAN –

PG FC28–2 POWER GROUND: GROUND

B+ FC28–3 IGNITION SWITCHED POWER SUPPLY (II): B+

I FC28–5 BLOWER MOTOR CONTROL FEEDBACK: VARIABLE FREQUENCY

I FC28–6 PASSENGER SIDE DISCHARGE TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECREASES AS TEMPERATURE INCREASES

I FC28–7 DUAL SOLAR SENSOR SIGNAL – LH: VOLTAGE DECREASES AS LIGHT INCREASES

SG FC28–8 AMBIENT TEMPERATURE SENSOR SIGNAL GROUND: GROUND

I FC28–9 IN-CAR TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECREASES AS TEMPERATURE INCREASES

I FC28–10 EVAPORATOR DISCHARGE TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECREASES AS TEMPERATURE INCREASES

SG FC28–11 ACTUATORS SIGNAL GROUND: GROUND

C FC28–12 CAN

B+ FC28–14 BATTERY POWER SUPPLY: B+

I FC28–15 PANEL ILLUMINATION (DIMMER-CONTROLLED): B+ (PWM)

SG FC28–16 EVAPORATOR DISCHARGE TEMPERATURE SENSOR SIGNAL GROUND: GROUND

I FC28–17 AMBIENT TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECR EASES AS TEMPERATURE INCREASES

I FC28–18 DRIVER SIDE DISCHARGE TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECREA SES AS TEMPERATURE INCREASES

SG FC28–19 LH / RH DISCHARGE TEMPERATURE SENSORS SIGNAL GROUND: GROUND

I FC28–20 DUAL SOLAR SENSOR SIGNAL – RH: VOLTAGE DECREASES AS LIGHT INCREASES

SS FC28–22 ACTUATORS SIGNAL SUPPLY VOLTAGE: NOMINAL 5 VAir Conditioning Control Module – Remote

Pin Description and CharacteristicI FC40–1 DEFROST MODE ACTUATOR POSITION FEEDBACK: VARIABLE VOLTAGE

I FC40–3 PANEL MODE ACTUATOR POSITION FEEDBACK: VARIABLE VOLTAGE

I FC40–4 HUMIDITY SENSOR SIGNAL: VARIABLE VOLTAGE

O FC40–5 DRIVER SIDE DUAL COOLANT CONTROL VALVE CONTROL DRIVE: ACTIVATE = GROUND (PWM)

O FC40–6 PASSENGER SIDE DUAL COOLANT CONTROL VALVE CONTROL DRIVE: ACTIVATE = GROUND (PWM)

SS FC40–7 HUMIDITY SENSOR SIGNAL SUPPLY VOLTAGE: NOMINAL 5 V

O FC40–9 FRESH / RECIRCULATION ACTUATOR DRIVE – CLOSE: ACTIVATE = B+

O FC40–10 FRESH / RECIRCULATION ACTUATOR DRIVE – OPEN: ACTIVATE = B+

O FC40–13 DEFROST MODE ACTUATOR DRIVE – OPEN: ACTIVATE = B+

SG FC40–14 IN-CAR TEMPERATURE SENSOR SIGNAL GROUND: GROUND

I FC40–15 FRESH / RECIRCULATION ACTUATOR POSITION FEEDBACK: VARIABLE VOLTAGE

I FC40–16 FLOOR MODE ACTUATOR POSITION FEEDBACK: VARIABLE VOLTAGE

SG FC40–17 ACTUATOR SIGNAL GROUND: GROUND

O FC40–18 AUXILIARY COOLANT PUMP RELAY ACTIVATE: TO ACTIVATE, A/CCM SWITCHES CIRCUIT TO GROUND

O FC40–19 BLOWER MOTOR RELAY ACTIVATE: TO ACTIVATE, A/CCM SWITCHES CIRCUIT TO GROUND

O FC40–20 HEATED WIPER PARK OR HEATED WINDSHIELD RELAY(S) ACTIVATE: TO ACTIVATE, A/CCM SWITCHES CIRCUIT TO GROUND

O FC40–21 BLOWER MOTOR CONTROL: B+ (PWM)

O FC40–22 FLOOR MODE ACTUATOR DRIVE – OPEN: ACTIVATE = B+

O FC40–23 FLOOR MODE ACTUATOR DRIVE – CLOSE: ACTIVATE = B+

O FC40–24 PANEL MODE ACTUATOR DRIVE – OPEN: ACTIVATE = B+

O FC40–25 PANEL MODE ACTUATOR DRIVE – CLOSE: ACTIVATE = B+

O FC40–26 DEFROST MODE ACTUATOR DRIVE – CLOSE: ACTIVATE = B+

C FC41–1 CAN –

PG FC41–2 POWER GROUND: GROUND

B+ FC41–3 IGNITION SWITCHED POWER SUPPLY (II): B+

I FC41–5 BLOWER MOTOR CONTROL FEEDBACK: VARIABLE FREQUENCY

I FC41–6 PASSENGER SIDE DISCHARGE TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECREASES AS TEMPERATURE INCREASES

I FC41–7 DUAL SOLAR SENSOR SIGNAL – LH: VOLTAGE DECREASES AS LIGHT INCREASES

SG FC41–8 AMBIENT TEMPERATURE SENSOR SIGNAL GROUND: GROUND

I FC41–9 IN-CAR TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECREASES AS TEMPERATURE INCREASES

I FC41–10 EVAPORATOR DISCHARGE TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECREASES AS TEMPERATURE INCREASES

SG FC41–11 ACTUATORS SIGNAL GROUND: GROUND

C FC41–12 CAN +

B+ FC41–14 BATTERY POWER SUPPLY: B+

SG FC41–16 EVAPORATOR DISCHARGE TEMPERATURE SENSOR SIGNAL GROUND: GROUND

I FC41–17 AMBIENT TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECR EASES AS TEMPERATURE INCREASES

I FC41–18 DRIVER SIDE DISCHARGE TEMPERATURE SENSOR SIGNAL: NTC SENSOR / VOLTAGE DECREA SES AS TEMPERATURE INCREASES

SG FC41–19 LH / RH DISCHARGE TEMPERATURE SENSORS SIGNAL GROUND: GROUND

I FC41–20 DUAL SOLAR SENSOR SIGNAL – RH: VOLTAGE DECREASES AS LIGHT INCREASES

SS FC41–22 ACTUATORS SIGNAL SUPPLY VOLTAGE: NOMINAL 5 V

Page 92 of 200

Refer to the front of this book for detailed information and illustrations regarding the location and identification of harnesses, relays, fuses, grounds,

control modules and control module pins.

NOTE: The values listed are approximately those that can be expected at the control module connector pins with all circuit conn

ections made and all

components connected and fitted. The following abbreviations are used to represent values for Control Module Pin-Out data

I Input

O Output

B+ Battery Voltage PG Power Ground

SS Sensor / Signal Supply V

SG Sensor / Signal GroundC CAN Network

S SCP Network

D2 D2B Network D Serial and Encoded Data

V Voltage (DC)

PWM Pulse Width Modulated

CAUTION: The information on this data page is furnished to ai d the user in understanding circuit operation. THIS INFORMATION SH OULD BE USED FOR

REFERENCE ONLY.DATE OF ISSUE: May 2004

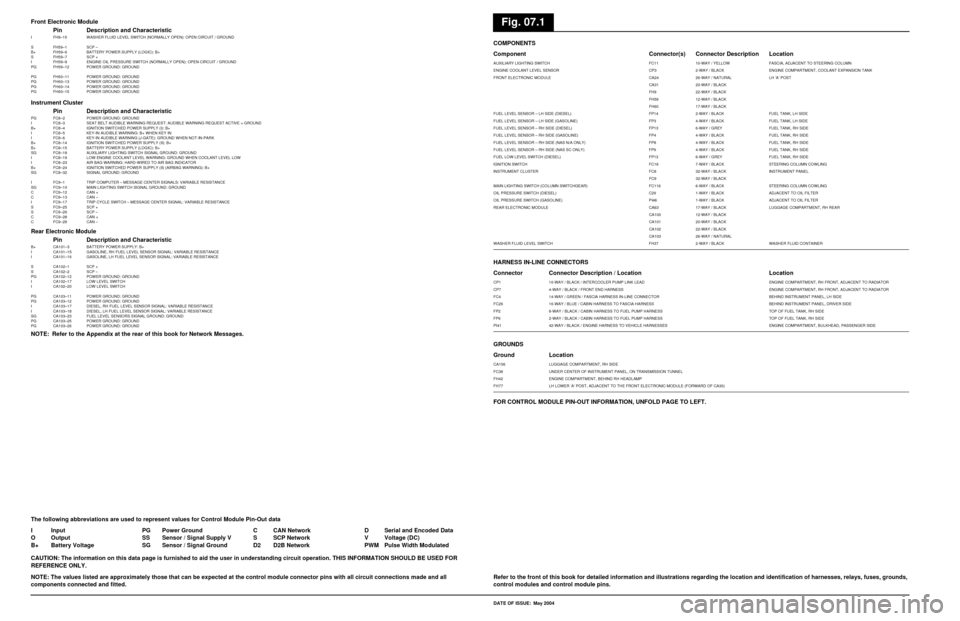

Fig. 07.1

FOR CONTROL MODULE PIN-OUT INFORMATION, UNFOLD PAGE TO LEFT. COMPONENTS

Component Connector(s) Connector Description LocationAUXILIARY LIGHTING SWITCH FC11 10-WAY / YELLOW FASCIA, ADJACENT TO STEERING COLUMN

ENGINE COOLANT LEVEL SENSOR CP3 2-WAY / BLACK ENGINE COMPARTMENT, COOLANT EXPANSION TANK

FRONT ELECTRONIC MODULE CA24 26-WAY / NATURAL LH ‘A’ POST

CA31 20-WAY / BLACK

FH9 22-WAY / BLACK

FH59 12-WAY / BLACK

FH60 17-WAY / BLACK

FUEL LEVEL SENSOR – LH SIDE (DIESEL) FP14 2-WAY / BLACK FUEL TANK, LH SIDE

FUEL LEVEL SENSOR – LH SIDE (GASOLINE) FP3 4-WAY / BLACK FUEL TANK, LH SIDE

FUEL LEVEL SENSOR – RH SIDE (DIESEL) FP13 6-WAY / GREY FUEL TANK, RH SIDE

FUEL LEVEL SENSOR – RH SIDE (GASOLINE) FP4 4-WAY / BLACK FUEL TANK, RH SIDE

FUEL LEVEL SENSOR – RH SIDE (NAS N/A ONLY) FP8 4-WAY / BLACK FUEL TANK, RH SIDE

FUEL LEVEL SENSOR – RH SIDE (NAS SC ONLY) FP9 4-WAY / BLACK FUEL TANK, RH SIDE

FUEL LOW LEVEL SWITCH (DIESEL) FP13 6-WAY / GREY FUEL TANK, RH SIDE

IGNITION SWITCH FC18 7-WAY / BLACK STEERING COLUMN COWLING

INSTRUMENT CLUSTER FC8 32-WAY / BLACK INSTRUMENT PANEL FC9 32-WAY / BLACK

MAIN LIGHTING SWITCH (COLUMN SWITCHGEAR) FC116 6-WAY / BLACK STEERING COLUMN COWLING

OIL PRESSURE SWITCH (DIESEL) C29 1-WAY / BLACK ADJACENT TO OIL FILTER

OIL PRESSURE SWITCH (GASOLINE) PI46 1-WAY / BLACK ADJACENT TO OIL FILTER

REAR ELECTRONIC MODULE CA63 17-WAY / BLACK LUGGAGE COMPARTMENT, RH REAR CA100 12-WAY / BLACK

CA101 20-WAY / BLACK

CA102 22-WAY / BLACK

CA103 26-WAY / NATURAL

WASHER FLUID LEVEL SWITCH FH37 2-WAY / BLACK WASHER FLUID CONTAINERHARNESS IN-LINE CONNECTORS

Connector Connector Description / Location LocationCP1 10-WAY / BLACK / INTERCOOLER PUMP LINK LEAD ENGINE COMPARTMENT, RH FRONT, ADJACENT TO RADIATOR

CP7 4-WAY / BLACK / FRONT END HARNESS ENGINE COMPARTMENT, RH FRONT, ADJACENT TO RADIATOR

FC4 14-WAY / GREEN / FASCIA HARNESS IN-LINE CONNECTOR BEHIND INSTRUMENT PANEL, LH SIDE

FC26 16-WAY / BLUE / CABIN HARNESS TO FASCIA HARNESS BEHIND INSTRUMENT PANEL, DRIVER SIDE

FP2 8-WAY / BLACK / CABIN HARNESS TO FUEL PUMP HARNESS TOP OF FUEL TANK, RH SIDE

FP6 2-WAY / BLACK / CABIN HARNESS TO FUEL PUMP HARNESS TOP OF FUEL TANK, RH SIDE

PI41 42-WAY / BLACK / ENGINE HARNESS TO VEHICLE HARNESSES ENGINE COMPARTMENT, BULKHEAD, PASSENGER SIDEGROUNDS

Ground LocationCA156 LUGGAGE COMPARTMENT, RH SIDE

FC38 UNDER CENTER OF INSTRUMENT PANEL, ON TRANSMISSION TUNNEL

FH42 ENGINE COMPARTMENT, BEHIND RH HEADLAMP

FH77 LH LOWER ‘A’ POST, ADJACENT TO THE FRONT ELECTRONIC MODULE (FORWARD OF CA30)

NOTE: Refer to the Appendix at the rear of this book for Network Messages. Front Electronic Module Pin Description and CharacteristicI FH9–15 WASHER FLUID LEVEL SWITCH (NORMALLY OPEN): OPEN CIRCUIT / GROUND

S FH59–1 SCP –

B+ FH59–6 BATTERY POWER SUPPLY (LOGIC): B+

S FH59–7 SCP +

I FH59–9 ENGINE OIL PRESSURE SWITCH (NORMALLY OPEN): OPEN CIRCUIT / GROUND

PG FH59–12 POWER GROUND: GROUND

PG FH60–11 POWER GROUND: GROUND

PG FH60–13 POWER GROUND: GROUND

PG FH60–14 POWER GROUND: GROUND

PG FH60–15 POWER GROUND: GROUNDInstrument ClusterPin Description and CharacteristicPG FC8–2 POWER GROUND: GROUND

I FC8–3 SEAT BELT AUDIBLE WARNING REQUEST: AUDIBLE WARNING REQUEST ACTIVE = GROUND

B+ FC8–4 IGNITION SWITCHED POWER SUPPLY (I): B+

I FC8–5 KEY-IN AUDIBLE WARNING: B+ WHEN KEY IN

I FC8–6 KEY-IN AUDIBLE WARNING (J-GATE): GROUND WHEN NOT-IN-PARK

B+ FC8–14 IGNITION SWITCHED POWER SUPPLY (II): B+

B+ FC8–15 BATTERY POWER SUPPLY (LOGIC): B+

SG FC8–18 AUXILIARY LIGHTING SWITCH SIGNAL GROUND: GROUND

I FC8–19 LOW ENGINE COOLANT LEVEL WARNING: GROUND WHEN COOLANT LEVEL LOW

I FC8–23 AIR BAG WARNING: HARD-WIRED TO AIR BAG INDICATOR

B+ FC8–24 IGNITION SWITCHED POWER SUPPLY (II) (AIRBAG WARNING): B+

SG FC8–32 SIGNAL GROUND: GROUND

I FC9–1 TRIP COMPUTER – MESSAGE CENTER SIGNALS: VARIABLE RESISTANCE

SG FC9–10 MAIN LIGHTING SWITCH SIGNAL GROUND: GROUND

C FC9–12 CAN +

C FC9–13 CAN –

I FC9–17 TRIP CYCLE SWITCH – MESSAGE CENTER SIGNAL: VARIABLE RESISTANCE

S FC9–25 SCP +

S FC9–26 SCP –

C FC9–28 CAN +

C FC9–29 CAN –Rear Electronic ModulePin Description and CharacteristicB+ CA101–3 BATTERY POWER SUPPLY: B+

I CA101–15 GASOLINE, RH FUEL LEVEL SENSOR SIGNAL: VARIABLE RESISTANCE

I CA101–16 GASOLINE, LH FUEL LEVEL SENSOR SIGNAL: VARIABLE RESISTANCE

S CA102–1 SCP +

S CA102–2 SCP –

PG CA102–12 POWER GROUND: GROUND

I CA102–17 LOW LEVEL SWITCH

I CA102–20 LOW LEVEL SWITCH

PG CA103–11 POWER GROUND: GROUND

PG CA103–12 POWER GROUND: GROUND

I CA103–17 DIESEL, RH FUEL LEVEL SENSOR SIGNAL: VARIABLE RESISTANCE

I CA103–18 DIESEL, LH FUEL LEVEL SENSOR SIGNAL: VARIABLE RESISTANCE

SG CA103–23 FUEL LEVEL SENSORS SIGNAL GROUND: GROUND

PG CA103–25 POWER GROUND: GROUND

PG CA103–26 POWER GROUND: GROUND

Page 93 of 200

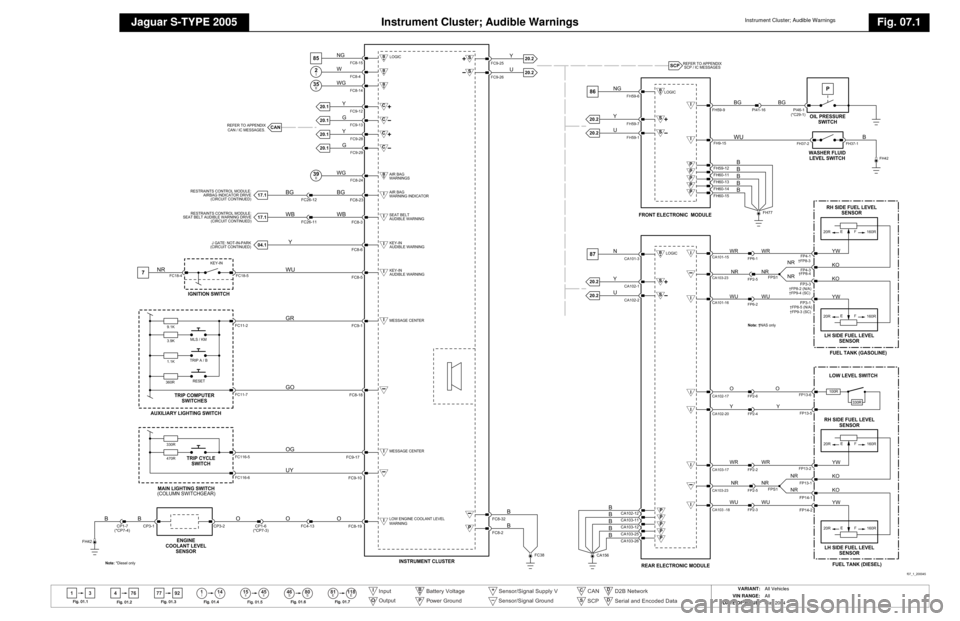

Instrument Cluster; Audible Warnings

Jaguar S-TYPE 2005

Instrument Cluster; Audible Warnings

Fig. 07.1

13 4114

46 80

76 77 92

ll

15 45ll ll SS

81 118EE

Fig .01.1

Fig .01 .2 F

ig .01.3

Fig .01 .4

Fig . 01.5 F

ig . 01.6 F

ig .01 .7

Input

OutputI

O

B

P+Battery VoltagePower Ground Sensor/Signal Supply V

Sensor/Signal Ground Serial and Encoded Data

CAN

+

SCPC

S DD

–

D2B Network2

f07_1_200045

SS

FC9-26 FC9-25

U Y

20.220.2

G Y

20.120.1

FC9-12

FC9-13G Y

20.120.1

FC9-28

FC9-29

FC26-12

O

CP1-7

(*CP7-4) (*CP7-3)

FH42

B

CP1-6 FC4-13

CP3-1 CP3-2

NGWG

FC8-15

FC8-14

FC8-2

B

FC38

FC8-3

WB

I

8535II

P

B

FC18-5

FC18-4

NR

W

FC8-4

WG

FC8-24

BB

2I39II

FC8-23

BG

I

FC8-32

B

CCCC

CAN

7

FC8-5

WU

IB

FC9-1

GR

I

FC26-11

WB BG

17.117.1

FC8-18

GO

FC11-7FC11-2

9.1K

3.9K

1.1K

360R

SCP

U Y

FH59-7

FH59-1

NG

FH59-6

FH60-15

B

86

P

B

20.220.2

SS

U Y

CA102-1

CA102-2

N

CA101-3

87

B

20.220.2

SS

FH60-14

B

P

FH60-13

B

P

FH59-12

B

P

FH60-11

B

P

FH77

CA103-26

B

P

CA103-25

B

P

CA103-12

B

P

CA103-11

B

P

CA102-12

B

P

CA156

FC8-19

O

I

FC8-6

Y

I

04.1

O

B

FH59-9

BG

I

P

PI41-16

BG

WU

FH9-15

B

I

FH42

CA101-15

WR

I

CA103-23

NR

CA101-16

WU

I

FP6-1

FP2-5

FP6-2

F

E

160R

20R

NRFPS1

NR

F

E

160R

20R

NR

WU WR

470R330R

I

FC9-17

OG

FC116-5

FC9-10

UY

FC116-6

CA103-17

WR

III

CA103-23

NR

CA103 -18

WU

I

FP2-2

FP2-5

FP2-3

NRFPS1

NRNR

WU WR

CA102-17

O

FP2-6

O

CA102-20

Y

FP2-4

Y

YW

KO

KO

YW

FP3-3

FP3-1

MAIN LIGHTING SWITCH

(COLUMN SWITCHGEAR)

REFER TO APPENDIX

CAN / IC MESSAGES.

RESTRAINTS CONTROL MODULE: AIRBAG INDICATOR DRIVE(CIRCUIT CONTINUED)

RESTRAINTS CONTROL MODULE:

SEAT BELT AUDIBLE WARNING DRIVE (CIRCUIT CONTINUED)

J GATE: NOT-IN-PARK

(CIRCUIT CONTINUED)

KEY-IN

IGNITION SWITCH

TRIP COMPUTER SWITCHES

AUXILIARY LIGHTING SWITCH

TRIP CYCLESWITCH

INSTRUMENT CLUSTER

LOW ENGINE COOLANT LEVEL

WARNINGMESSAGE CENTER MESSAGE CENTER

KEY-IN

AUDIBLE WARNING KEY-IN

AUDIBLE WARNING

SEAT BELT

AUDIBLE WARNING AIR BAG

WARNING INDICATOR AIR BAG

WARNINGS LOGIC

LOGIC

LOGIC REFER TO APPENDIX

SCP/ICMESSAGES

FRONT ELECTRONIC MODULE

REAR ELECTRONIC MODULE

PI46-1

(*C29-1)

OIL PRESSURE SWITCH

FH37-2 FH37-1

WASHER FLUIDLEVEL SWITCH

RH SIDE FUEL LEVELSENSOR

LH SIDE FUEL LEVEL SENSOR

FUEL TANK (GASOLINE)

FP4-3 FP4-1

†FP8-3

†FP8-4

†FP8-2 (N/A)

†FP9-4 (SC)

†FP9-3 (SC)†FP8-5 (N/A)

RESET

TRIP A / B MLS / KM

Note:

*Diesel only

ENGINE

COOLANT LEVEL SENSOR

F

E

160R

20R

F

E

160R

20R

YW

KO

KO

YW

FP14-1

FP14-2

RH SIDE FUEL LEVEL

SENSOR

LH SIDE FUEL LEVEL SENSOR

FUEL TANK (DIESEL)

FP13-1

FP13-2FP13-5

FP13-6

100RLOW LEVEL SWITCH

330R

Note: †

NAS only

VARIANT: All Vehicles

VIN RANGE: All

DATE OF ISSUE: May 2004

Page 187 of 200

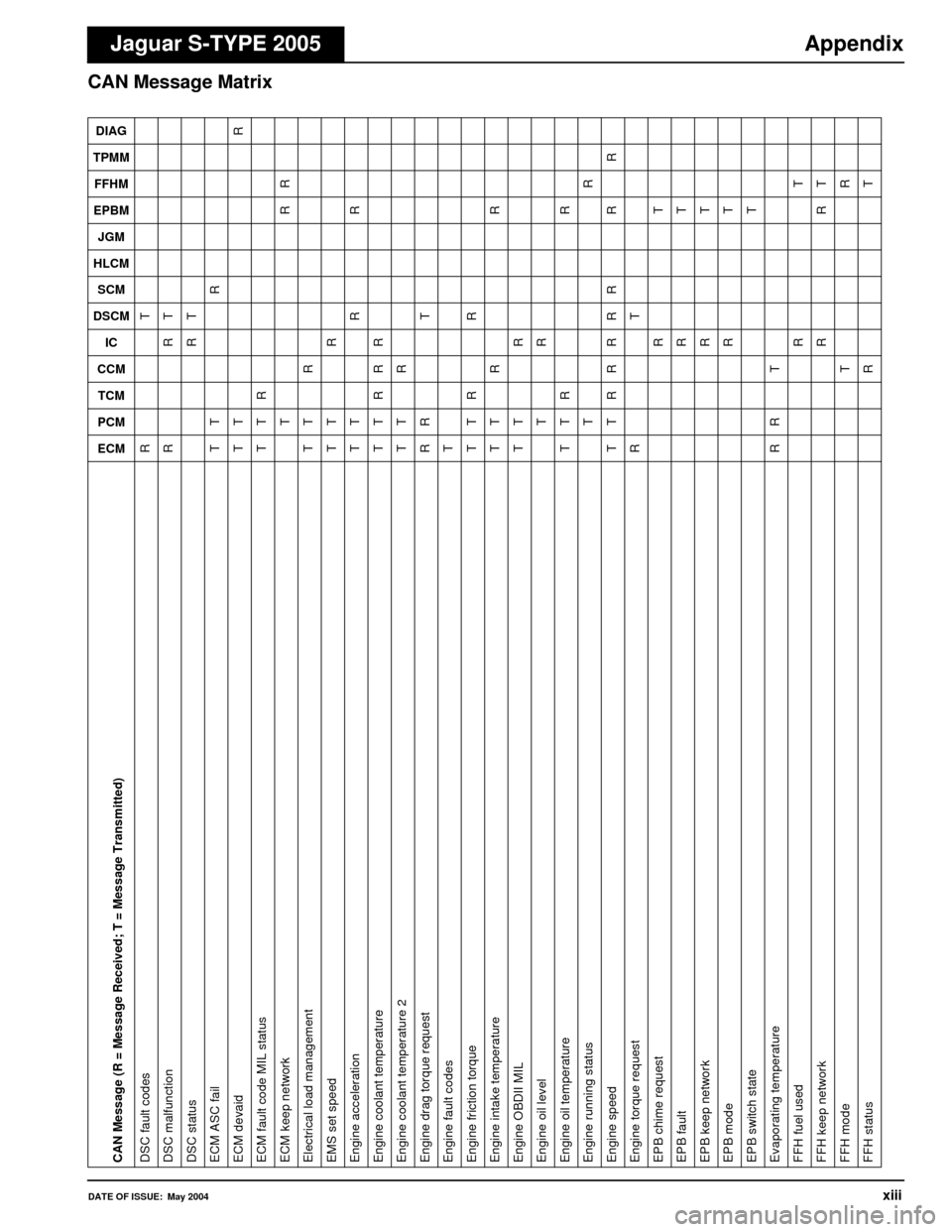

DATE OF ISSUE: May 2004xiii

AppendixJaguar S-TYPE 2005

CAN Message Matrix

DSC fault codesRT

DSC malfunction RRT

DSC status RT

ECM ASC fail TT R

ECM devaid TT R

ECM fault code MIL status TTR

ECM keep network TRR

Electrical load management TT R

EMS set speed TT R

Engine acceleration TT R R

Engine coolant temperature T TRRR

Engine coolant temperature 2 TT R

Engine drag torque request RR T

Engine fault codes T

Engine friction torque TTR R

Engine intake temperature TT R R

Engine OBDII MIL TT R

Engine oil level TR

Engine oil temperature TTR R

Engine running status TR

Engine speed T TRRRRR R R

Engine torque request RT

EPB chime request RT

EPB fault RT

EPB keep network RT

EPB mode RT

EPB switch state T

Evaporating temperature RR T

FFH fuel used RT

FFH keep network RRT

FFH mode TR

FFH status RT

CAN Message (R = Message Received; T = Message Transmitted)

ECM PCM

TCM

CCM IC

DSCM SCM

HLCM JGM

EPBM

FFHM

TPMM DIAG

Page 194 of 200

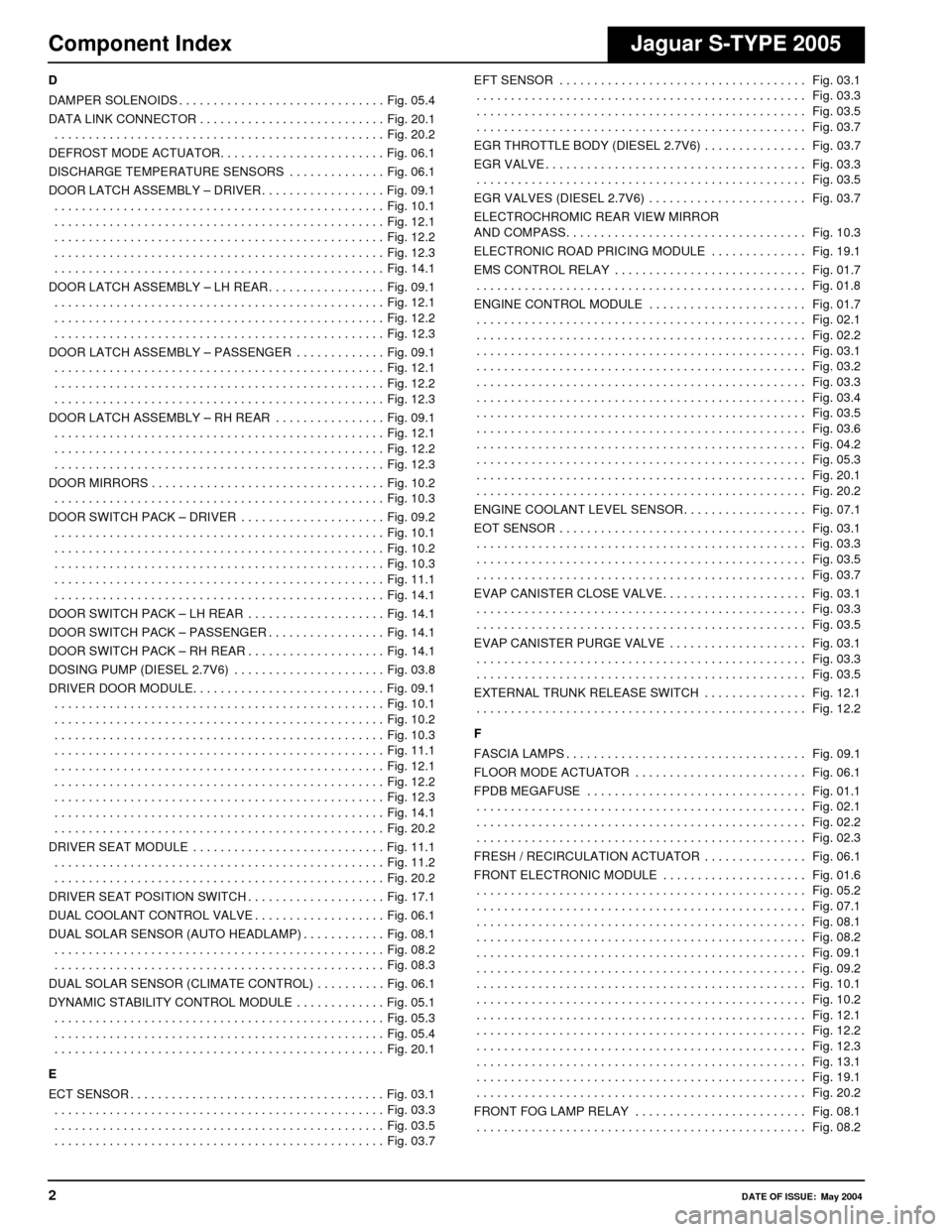

2DATE OF ISSUE: May 2004

Component IndexJaguar S-TYPE 2005

D

DAMPER SOLENOIDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 05.4

DATA LINK CONNECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 20.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 20.2

DEFROST MODE ACTUATOR. . . . . . . . . . . . . . . . . . . . . . . . Fig. 06.1

DISCHARGE TEMPERATURE SENSORS . . . . . . . . . . . . . . Fig. 06.1

DOOR LATCH ASSEMBLY – DRIVER . . . . . . . . . . . . . . . . . . Fig. 09.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 14.1

DOOR LATCH ASSEMBLY – LH REAR . . . . . . . . . . . . . . . . . Fig. 09.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.3

DOOR LATCH ASSEMBLY – PASSENGER . . . . . . . . . . . . . Fig. 09.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.3

DOOR LATCH ASSEMBLY – RH REAR . . . . . . . . . . . . . . . . Fig. 09.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.3

DOOR MIRRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.3

DOOR SWITCH PACK – DRIVER . . . . . . . . . . . . . . . . . . . . . Fig. 09.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 11.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 14.1

DOOR SWITCH PACK – LH REAR . . . . . . . . . . . . . . . . . . . . Fig. 14.1

DOOR SWITCH PACK – PASSENGER . . . . . . . . . . . . . . . . . Fig. 14.1

DOOR SWITCH PACK – RH REAR . . . . . . . . . . . . . . . . . . . . Fig. 14.1

DOSING PUMP (DIESEL 2.7V6) . . . . . . . . . . . . . . . . . . . . . . Fig. 03.8

DRIVER DOOR MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 09.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 11.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 14.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 20.2

DRIVER SEAT MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 11.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 11.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 20.2

DRIVER SEAT POSITION SWITCH . . . . . . . . . . . . . . . . . . . . Fig. 17.1

DUAL COOLANT CONTROL VALVE . . . . . . . . . . . . . . . . . . . Fig. 06.1

DUAL SOLAR SENSOR (AUTO HEADLAMP) . . . . . . . . . . . . Fig. 08.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 08.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 08.3

DUAL SOLAR SENSOR (CLIMATE CONTROL) . . . . . . . . . . Fig. 06.1

DYNAMIC STABILITY CONTROL MODULE . . . . . . . . . . . . . Fig. 05.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 05.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 05.4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 20.1

E

ECT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.7 EFT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.7

EGR THROTTLE BODY (DIESEL 2.7V6) . . . . . . . . . . . . . . . Fig. 03.7

EGR VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.5

EGR VALVES (DIESEL 2.7V6) . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.7

ELECTROCHROMIC REAR VIEW MIRROR

AND COMPASS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.3

ELECTRONIC ROAD PRICING MODULE . . . . . . . . . . . . . . Fig. 19.1

EMS CONTROL RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 01.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 01.8

ENGINE CONTROL MODULE . . . . . . . . . . . . . . . . . . . . . . . Fig. 01.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 02.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 02.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 04.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 05.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 20.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 20.2

ENGINE COOLANT LEVEL SENSOR. . . . . . . . . . . . . . . . . . Fig. 07.1

EOT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.7

EVAP CANISTER CLOSE VALVE. . . . . . . . . . . . . . . . . . . . . Fig. 03.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.5

EVAP CANISTER PURGE VALVE . . . . . . . . . . . . . . . . . . . . Fig. 03.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 03.5

EXTERNAL TRUNK RELEASE SWITCH . . . . . . . . . . . . . . . Fig. 12.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.2

F

FASCIA LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 09.1

FLOOR MODE ACTUATOR . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 06.1

FPDB MEGAFUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 01.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 02.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 02.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 02.3

FRESH / RECIRCULATION ACTUATOR . . . . . . . . . . . . . . . Fig. 06.1

FRONT ELECTRONIC MODULE . . . . . . . . . . . . . . . . . . . . . Fig. 01.6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 05.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 07.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 08.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 08.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 09.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 09.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 10.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 12.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 13.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 19.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 20.2

FRONT FOG LAMP RELAY . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 08.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fig. 08.2