automatic transmission fluid JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1388 of 2490

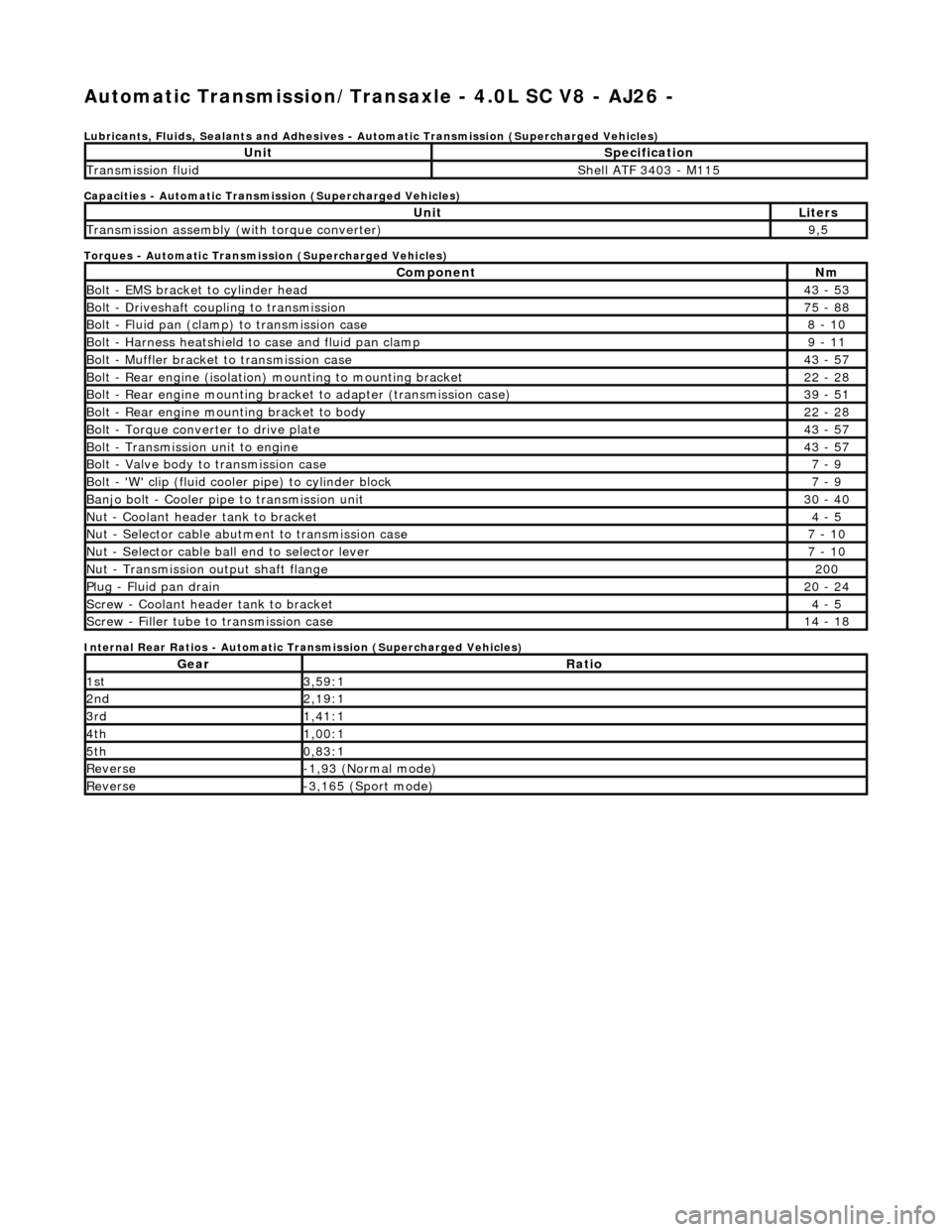

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 -

Lubricants, Fluids, Sealants and Adhesives - Automatic Transmission (Supercharged Vehicles)

Capacities - Automatic Transmission (Supercharged Vehicles)

Torques - Automatic Transmission (Supercharged Vehicles)

Internal Rear Ratios - Automatic Transmission (Supercharged Vehicles)

UnitSpecification

Transmission fluidShell ATF 3403 - M115

UnitLiters

Transmission assembly (with torque converter)9,5

ComponentNm

Bolt - EMS bracket to cylinder head43 - 53

Bolt - Driveshaft coupling to transmission75 - 88

Bolt - Fluid pan (clamp) to transmission case8 - 10

Bolt - Harness heatshield to case and fluid pan clamp9 - 11

Bolt - Muffler bracket to transmission case43 - 57

Bolt - Rear engine (isolation) mounting to mounting bracket22 - 28

Bolt - Rear engine mounting brac ket to adapter (transmission case)39 - 51

Bolt - Rear engine mounting bracket to body22 - 28

Bolt - Torque converter to drive plate43 - 57

Bolt - Transmission unit to engine43 - 57

Bolt - Valve body to transmission case7 - 9

Bolt - 'W' clip (fluid cooler pipe) to cylinder block7 - 9

Banjo bolt - Cooler pipe to transmission unit30 - 40

Nut - Coolant header tank to bracket4 - 5

Nut - Selector cable abutment to transmission case7 - 10

Nut - Selector cable ball end to selector lever7 - 10

Nut - Transmission output shaft flange200

Plug - Fluid pan drain20 - 24

Screw - Coolant header tank to bracket4 - 5

Screw - Filler tube to transmission case14 - 18

GearRatio

1st3,59:1

2nd2,19:1

3rd1,41:1

4th1,00:1

5th0,83:1

Reverse-1,93 (Normal mode)

Reverse-3,165 (Sport mode)

Page 1389 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Description

Description and Operation

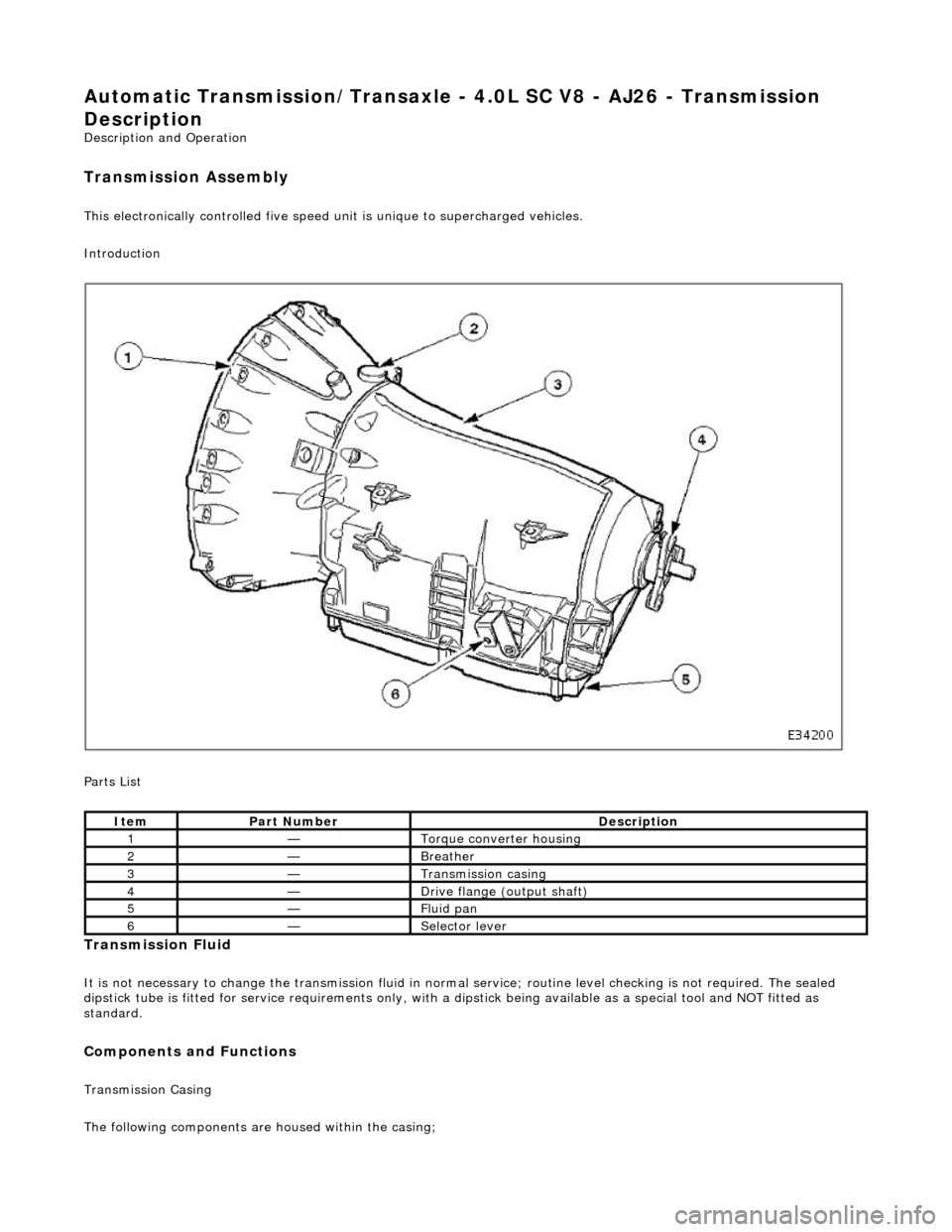

Transmission Assembly

This electronically controlled five speed unit is unique to supercharged vehicles.

Introduction

Parts List

Transmission Fluid

It is not necessary to change the transmis sion fluid in normal service; routine level checking is not required. The sealed

dipstick tube is fitted for service requir ements only, with a dipstick being availa ble as a special tool and NOT fitted as

standard.

Components and Functions

Transmission Casing

The following components are housed within the casing;

ItemPart NumberDescription

1—Torque converter housing

2—Breather

3—Transmission casing

4—Drive flange (output shaft)

5—Fluid pan

6—Selector lever

Page 1429 of 2490

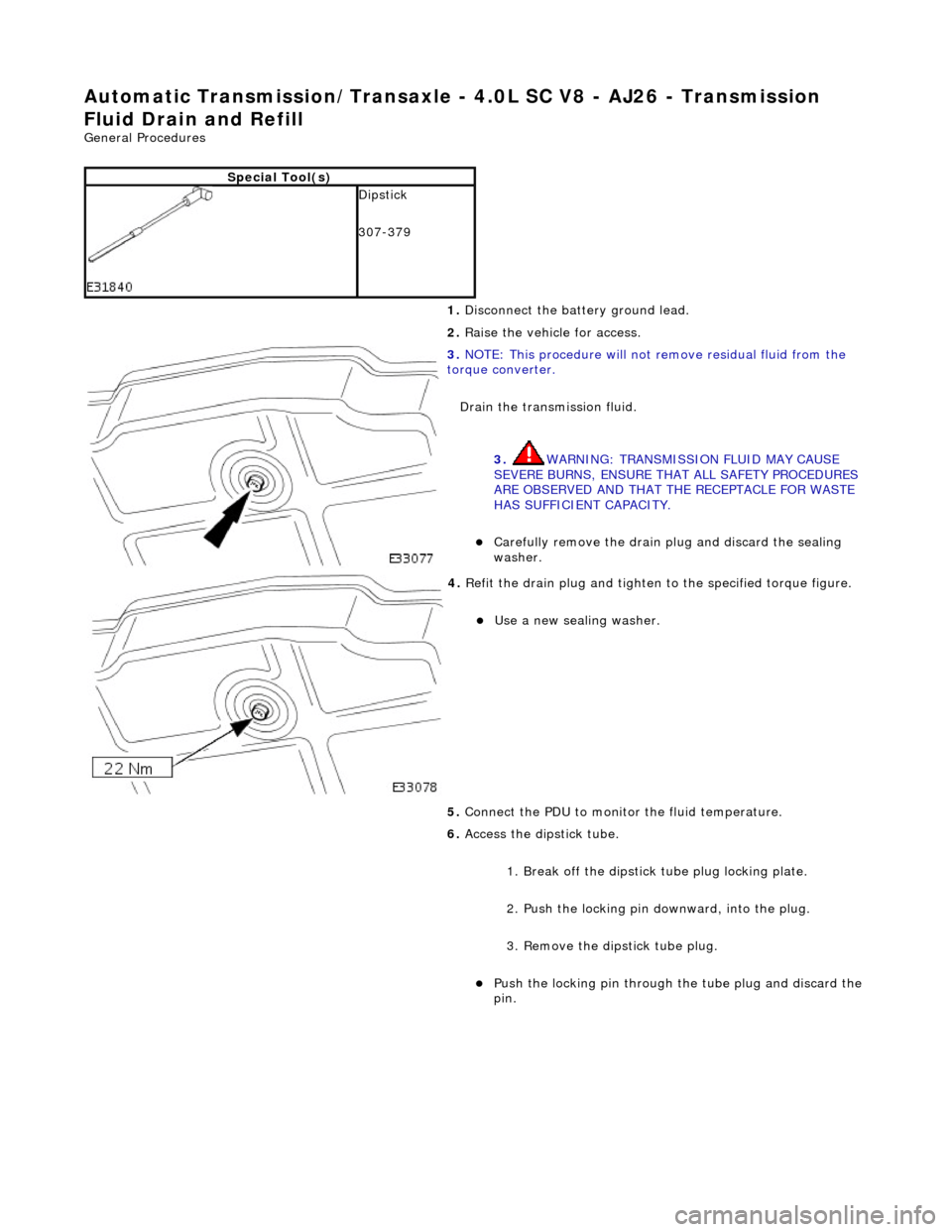

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Fluid Drain and Refill

General Procedures

Special Tool(s)

Dipstick

307-379

1. Disconnect the battery ground lead.

2. Raise the vehicle for access.

3. NOTE: This procedure will not re move residual fluid from the

torque converter.

Drain the transmission fluid.

3. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED AND THAT THE RECEPTACLE FOR WASTE

HAS SUFFICIENT CAPACITY.

пЃ¬Carefully remove the drain pl ug and discard the sealing

washer.

4. Refit the drain plug and tighten to the specified torque figure.

пЃ¬Use a new sealing washer.

5. Connect the PDU to monitor the fluid temperature.

6. Access the dipstick tube.

1. Break off the dipstick tube plug locking plate.

2. Push the locking pin downward, into the plug.

3. Remove the dipstick tube plug.

пЃ¬Push the locking pin through the tube plug and discard the

pin.

Page 1436 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Main Control

Valve Body

In-vehicle Repair

Removal

• NOTE: This procedure will not remove re sidual fluid from the torque converter.

1. Disconnect the battery ground lead.

2. Raise the vehicle for access.

3. Remove the RH catalytic converter; refer to Operation

17.50.10.

4. Remove the harness heatshield lower fixing.

пЃ¬Remove the screw heatshield / fluid pan clamp.

5. Remove the harness heatshield.

пЃ¬Pull the heatshield from under the clip.

6. Disconnect the transmission link harness connector.

1. Release the locking lever.

7. Release the (transmission case mounted) female connector.

пЃ¬Remove the (center) retaining bolt.

Page 1440 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Fluid Filter

In-vehicle Repair

Installation

1.

Disconnect the battery ground lead.

2. Raise the vehicle for access.

3. Remove the fluid pan, refer to Operation 44.24.04.

4. Remove the fluid filter.

пЃ¬Pull the filter squarely to disengage the pick-up 'O' ring

and location tang - there is NO mechanical retention.

1. Installation is the reverse of the removal procedure noting

that:

2. Renew the 'O' ring.

3. Refer to Operation 44.24.02 for fluid fill procedure.

4. Check for leaks and remove spilt fluid.

Page 1441 of 2490

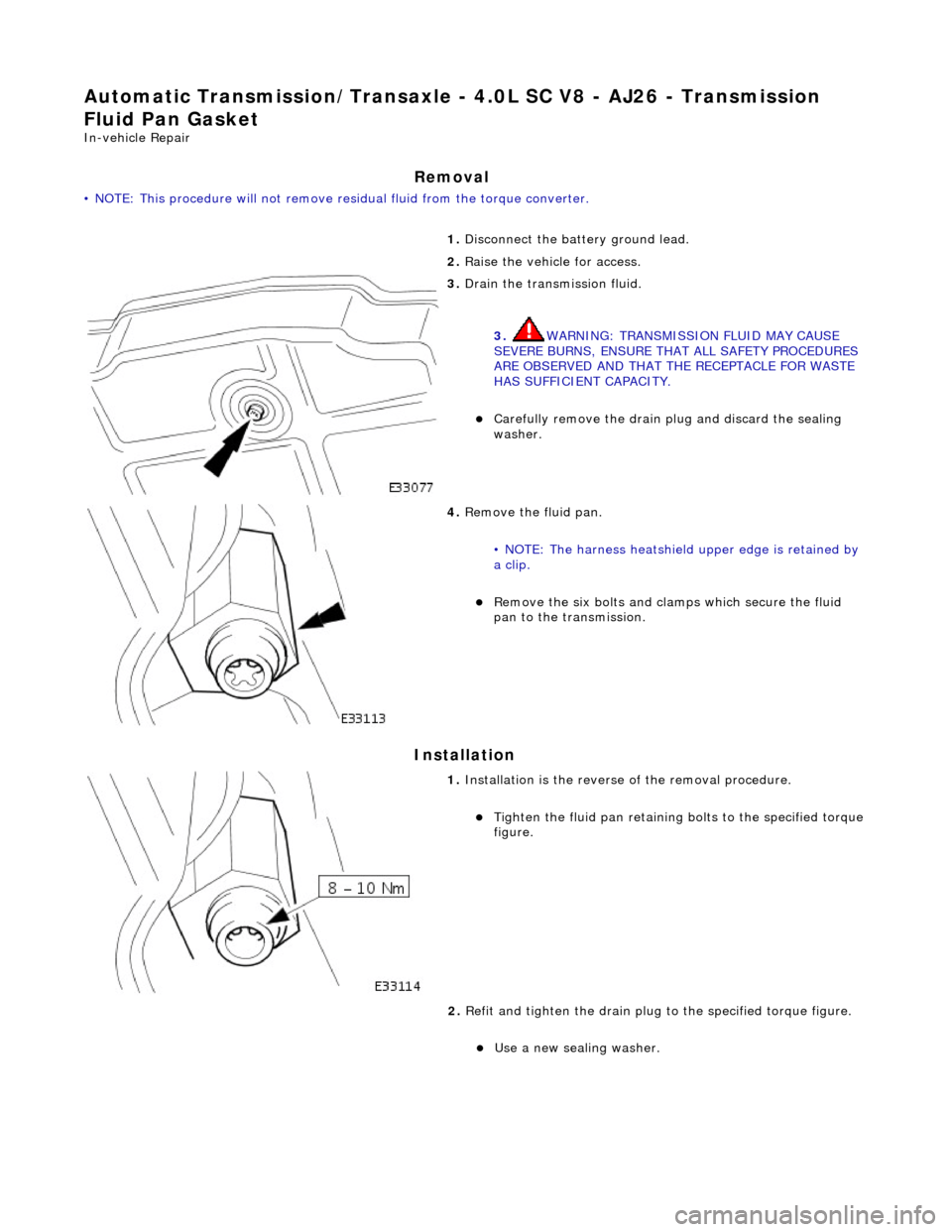

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Fluid Pan Gasket

In-vehicle Repair

Removal

• NOTE: This procedure will not remove re sidual fluid from the torque converter.

Installation

1. Disconnect the battery ground lead.

2. Raise the vehicle for access.

3. Drain the transmission fluid.

3. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED AND THAT THE RECEPTACLE FOR WASTE

HAS SUFFICIENT CAPACITY.

пЃ¬Carefully remove the drain pl ug and discard the sealing

washer.

4. Remove the fluid pan.

• NOTE: The harness heatshield upper edge is retained by

a clip.

пЃ¬Remove the six bolts and clam ps which secure the fluid

pan to the transmission.

1. Installation is th e reverse of the re moval procedure.

пЃ¬Tighten the fluid pan retaining bolts to the specified torque figure.

2. Refit and tighten the drain plug to the specified torque figure.

пЃ¬Use a new sealing washer.

Page 1443 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Internal Wiring Harness Electr ical Connector O-Ring Seals

In-vehicle Repair

Removal

1. Disconnect the batt ery ground cable.

2. Open the engine compartment and fit paint protection sheets.

3. Raise the vehicle for access.

4. WARNING: TRANSMISSION FLUID MAY CAUSE SEVERE

BURNS, ENSURE THAT ALL SAFET Y PROCEDURES ARE OBSERVED

AND THAT THE RECEPTACLE FOR WASTE HAS SUFFICIENT

CAPACITY.

Drain the transmission fluid.

пЃ¬Carefully remove the drain pl ug and discard the sealing

washer.

5. Remove the harness heatshield lower fixing.

пЃ¬Remove the screw heatshield / fluid pan clamp.

6. Remove the harness heatshield.

пЃ¬Pull the heatshield from under the clip.

7. Disconnect the transmission link harness connector.

1. Release the locking lever on the guide bush and disconnect the harness connector.

Page 1456 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Input Shaft Seal

Disassembly and Assembly of Subassemblies

Special Tool(s)

Oil seal replacer

307-378

1. Disconnect the battery ground lead.

2. Remove the air intake / MAFM assembly, refer to Operation

19.10.30.

3. Raise the vehicle for access.

4. Remove the front muffler, 30.10.18

5. Remove the RH and LH catalytic converters, refer to Operation

17.50.09 and 17.50.10.

6. Drain the transmission fluid, refer to Operation 44.24.02.

7. Remove the transmission unit, refer to Operation 44.20.01.

8. Remove the torque converter fro m the transmission unit, refer

to Operation 44.17.07.

9. Remove the front oil seal.

пЃ¬Using a proprietary tool remove the seal, taking care not

to damage the shaft or bore diameters.

10. Installation is the reverse of the removal procedure noting

that:

11. Fit the oil seal.

1. Lubricate the housing seal bore.

2. Lubricate the outside diameter of the seal.

3. Using seal replacer 307 - 379, drive the seal squarely into place.

Page 1504 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L SC V8 - AJ26 -

External Controls

Diagnosis and Testing

Problem Solving - Transmission Shift

Quick Reference Fault Chart

Special Tool(s)

Digital multimeter

Generic scan tool

SymptomPossible SourcesAction

Shift stuck in P Selector cable seized

*GO to 44.15.08

*

Interlock solenoid not operating

*GO to PDU

*

Interlock latch seized

Transmission faulty

*

*Mechanical check

*

Operator sequence error

*Correct the sequence

*

Vehicle rolls on P Incorrect cable adjustment

*GO 44.15.07

*

Faulty parking pawl (transmission internal)

*Mechanical check

*

R does not engageIncorrect cable adjustment

*GO to 44.15.07

*

Transmission fluid level incorrect

*GO to 44.24.02

*

N not achievedIncorrect cable adjustment

Transmission faulty

*

*GO to 44.15.07

*

D does not engageIncorrect cable adjustment *GO to 44.15.07

*

Transmission fluid level incorrect

*GO to 44.24.02

*

Transmission faulty

*Mechanical check

*

Lower ratios will not holdExcessive engine temperature

DLS fault

*

*GO to PDU

*

Shift lever position not visually correctIncorrect DLS adjustment

*GO to 44.15.07

*

Shift lever has no effect upon the

transmission and resistance cannot be

feltCable disconnected or broken

Transmission selector problem

Shift lever drive pin adrift

*

*

*Mechanical check

*

Shift lever position not align correctly

following manual selection of lower

ratiosSliding block drive pin displaced - following road debris contact

*Mechanical check. Renew the selector if

damaged, or re-align the drive pin and

sliding block

*

Shift lever detent indistinct in 3

causing poor locationDLS detent fault

*GO to Renew the DLS

*

Shift may be moved from P without

brake pedal operationInterlock latch fault

*Mechanical check

*

Solenoid permanently activated

*GO to PDU

*

Engine may be started in positions

other than P or N Incorrect cable adjustment

DLS fault

*

*GO to 44.15.07

*

Shift lever vibrationLoose selector assembly

Cable isolation fault

*

*Mechanical check

*

Noise / rattle from 'J' gateDebris in the mechanism

*Clean

*

Worn 'J' gate track gasket

allowing lever and moulding to

contact

*GO to 44.15.05

*

Page 1813 of 2490

пЃ¬Connect hose.

пЃ¬Install bolt (8-10 Nm).

6. Connect compressor to condenser discharge line at condenser.

пЃ¬Remove blanking plugs.

пЃ¬Install new O-ring seal an d lubricate with clean A/C

compressor oil.

пЃ¬Connect hose.

пЃ¬Install bolt (8-10 Nm).

7. Connect transmission o il cooler upper pipe.

пЃ¬Remove blanking plugs.

пЃ¬Install new O-ring seal and lu bricate with clean automatic

transmission fluid.

пЃ¬Connect union nut to radiator and tighten.

8. Connect transmission oil cooler lower pipe.

пЃ¬Remove blanking plugs.

пЃ¬Install new O-ring seal and lu bricate with clean automatic

transmission fluid.

9. Connect radiator blee d hose to radiator.