catalytic converter JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 905 of 2490

пЃ¬Remove the bolts which secure the downpipe to the lower

mounting bracket.

пЃ¬Remove the downpipe assembly.

пЃ¬Repeat the above operations for the other downpipe

catalytic converter.

47. Remove the two bolts which secure each mounting bracket to

the bell housing and remove the brackets.

48. Disconnect the driveshaft (propshaft) flange from the

transmission output flange.

пЃ¬Remove the three bolts which secure the flange. Rotate

the shaft for access to each bolt.

пЃ¬Disconnect the shaft and reposition it to the side.

49. Remove the securing bolt and disconnect the ground lead

from the transmission casing.

50. Disconnect the oil cooler pi pes (where fitted) from the

engine.

1. Remove the bolt which secures the pipe clamping

plate. Remove the clamping plate.

2. Place a drain tray beneat h the pipes and disconnect

Page 913 of 2490

пЃ¬R

emove the engine re

ar lifting eyes.

10. Move the crane away from the vehicle.

11. Raise the vehicle on the ramp.

12

.

Connect the transmission selector cable.

1. Fit the selector lever to the cross shaft.

2. Fit the nut which secures the selector lever to the transmission cross shaft.

3. Reposition the selector cable abutment bracket to the transmission and fit the securing bolts.

13

.

Connect the transmission harness connector.

1. Connect the transmission harness connector.

2. Secure the leve r lock mechanism.

14

.

Reposition the ground lead to the transmission casing and fit

the securing bolt.

15. Fit the brackets which suppo rt the downpipe catalytic

converters to the bell housing.

пЃ¬Po

sition the mounting bracket and fit the two bolts which

secure it to the bell housing.

Page 914 of 2490

пЃ¬Repeat

the above procedure for the other side.

16 . Connect

the driveshaft (propshaft

) flange to the transmission

output flange.

пЃ¬F i

t the three bolts which secure the flange.

17 . F

it the downpipe catalytic converters.

1. Fit a new gasket to the downpipe flange and fit the

downpipe assembly. to the manifold.

пЃ¬F i

t the bolts which secure

the downpipe to the lower

mounting bracket.

пЃ¬Repeat the above operation

s

for the other downpipe

catalytic converter.

18 . F

rom above the vehicle, tighte

n the manifold flange nuts, A-

Bank and B-Bank flanges, to the correct torque.

19. Fit the front muffler assembly.

пЃ¬Locate the front muf fler into the

downpipe catalytic

converters.

20. Move the front muffler forwar d to allow the intermediate

mufflers to be connected.

Page 915 of 2490

пЃ¬Connect

the front muffler to

the intermediate muffler,

noting the alignment of the indicator rings.

пЃ¬W

ith the front muffler positioned correctly, tighten the

clamps (left-hand and right-hand sides) to the catalytic

converter.

21

.

Tighten the clamps (left-hand and right-hand sides),

intermediate mufflers to front muffler.

22

.

Tighten the downpipe bracket se curing bolts to the correct

torque

23

.

Connect the oil cooler pipes (w here fitted) to the engine.

1. Remove the blanking plugs from the pipes and from the mating unions on the engine.

2. Fit new O-ring seals to the pipes and lubricate with new engine oil.

3. Connect the pipes to the engine and fit the clamping

plate and bolt.

24. Lower the vehicle on the ramp.

25. Connect the heater and brake servo hoses.

1. Connect the heat er return hose.

2. Connect the heater feed hose and secure the locking

lever.

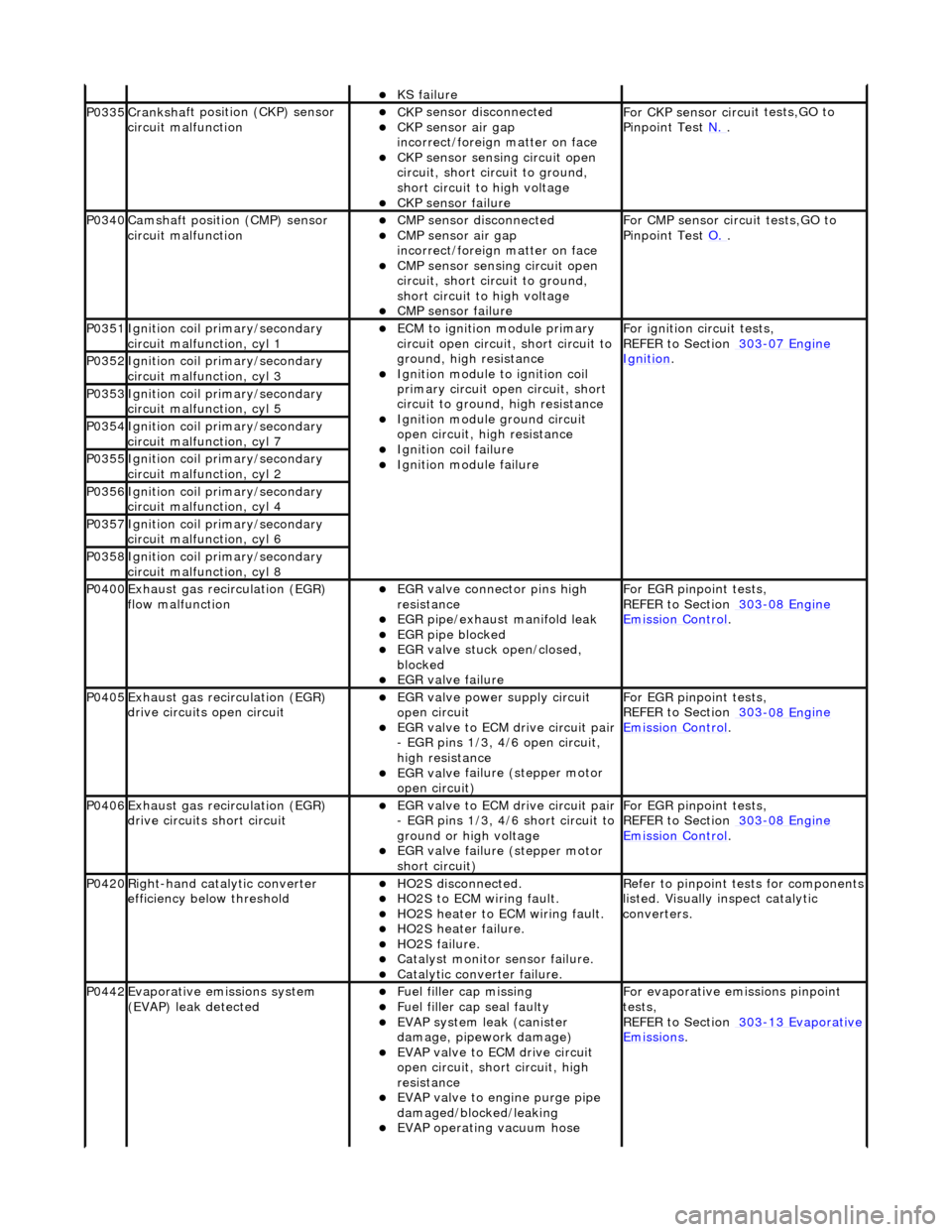

Page 1200 of 2490

пЃ¬KS fail

ure

P0335Cranksh

a

ft positi

on (CKP) sensor

circuit malfunction

пЃ¬CK P

sensor disconnected

пЃ¬CKP sensor air gap

i

n

correct/foreign matter on face

пЃ¬CKP sensor sen

s

ing circuit open

circuit, short circuit to ground,

short circuit to high voltage

пЃ¬CKP s e

nsor failure

F

or CKP sensor circ ui

t tests,GO to

Pinpoint Test N.

.

P0340Camshaft position

(CMP) sensor

circuit malfunction

пЃ¬CM P

sensor disconnected

пЃ¬CMP sensor air gap

i

n

correct/foreign matter on face

пЃ¬CMP sensor sen

s

ing circuit open

circuit, short circuit to ground,

short circuit to high voltage

пЃ¬CMP s e

nsor failure

F

or CMP sensor circ ui

t tests,GO to

Pinpoint Test O.

.

P0351Igniti

on coil primary/secondary

circuit malfunction, cyl 1

пЃ¬ECM to ignit

ion module primary

circuit open circuit, short circuit to

ground, high resistance

пЃ¬Igniti

on module to ignition coil

primary circuit open circuit, short

circuit to ground, high resistance

пЃ¬Ignition modu le

ground circuit

open circuit, hi gh resistance

пЃ¬Ignition coil fail

ure

пЃ¬Ignition modul

e

failure

F

o

r ignition circuit tests,

REFER to Section 303

-07 En

gine

Ignition. P0352Ignit

i

on coil primary/secondary

circuit malfunction, cyl 3

P0353Ignit i

on coil primary/secondary

circuit malfunction, cyl 5

P0354Ignit i

on coil primary/secondary

circuit malfunction, cyl 7

P0355Ignit i

on coil primary/secondary

circuit malfunction, cyl 2

P0356Ignit i

on coil primary/secondary

circuit malfunction, cyl 4

P0357Ignit i

on coil primary/secondary

circuit malfunction, cyl 6

P0358Ignit i

on coil primary/secondary

circuit malfunction, cyl 8

P0400Exhaus t gas

recirculation (EGR)

flow malfunction

пЃ¬EGR valve c

onnector pins high

resistance

пЃ¬EGR pipe/exhaust manifol

d leak

пЃ¬EGR pipe blocke

d

пЃ¬EGR valve st

uck open/closed,

blocked

пЃ¬EGR valve fai

lure

For EGR

pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emission Control.

P0405Exhaus

t gas

recirculation (EGR)

drive circuits open circuit

пЃ¬EGR valve power supply circuit

o p

en circuit

пЃ¬EGR valve t

o

ECM drive circuit pair

- EGR pins 1/3, 4/6 open circuit,

high resistance

пЃ¬EGR val v

e failure (stepper motor

open circuit)

For EGR pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emissi

on Control.

P0406Exhaus t gas

recirculation (EGR)

drive circuits short circuit

пЃ¬EGR valve t o

ECM drive circuit pair

- EGR pins 1/3, 4/6 short circuit to

ground or high voltage

пЃ¬EGR val v

e failure (stepper motor

short circuit)

For EGR pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emissi

on Control.

P0420Right-

hand catalytic converter

efficiency below threshold

пЃ¬HO2S di

sconnected.

пЃ¬HO2

S

to ECM wiring fault.

пЃ¬HO2

S

heater to ECM wiring fault.

пЃ¬HO2

S

heater failure.

пЃ¬HO2

S

failure.

пЃ¬Cat

a

lyst monitor sensor failure.

пЃ¬Catal

y

tic converter failure.

R

e

fer to pinpoint tests for components

listed. Visually inspect catalytic

converters.

P0442Evaporati v

e emissions system

(EVAP) leak detected

пЃ¬Fue l

filler cap missing

пЃ¬Fu

el filler cap seal faulty

пЃ¬EVAP system

leak (can

ister

damage, pipework damage)

пЃ¬EVAP v a

lve to ECM drive circuit

open circuit, short circuit, high

resistance

пЃ¬EVAP valve to engine pu rge pipe

damaged/blocked/leaking

пЃ¬EVAP ope r

ating vacuum hose

F

or evaporati

ve emissions pinpoint

tests,

REFER to Section 303

-1 3

Evaporative

Emissi

ons

.

Page 1376 of 2490

2. Reposition the tank.

8. Install engine lifting bracket 303 - 536 at the rear LH.

9. Support the engine using 303 - 021.

1. Adjust and locate the stan ds in the LH and RH fender

channels and tighten the beam fixings.

2. Engage the support hook s in the lifting brackets.

3. Tighten the support hook adjusters and take the weight of the engine.

10. Raise the vehicle for access.

11. Remove the LH downpipe cata lytic converter (17.50.09).

12. Remove the front muffler (30.10.18).

13. Remove the RH downpipe catalytic converter (17.50.09 and

17.50.10).

14. Drain the transmission fluid, (44.24.02).

15. Locate a transmission jack, Epco V-100 or similar, under the

transmission unit.

пЃ¬Adjust the angle of the jack to suit the transmission.

пЃ¬Secure the side clamps.

пЃ¬Pass the safety chain over the transmission unit and

secure.

Page 1386 of 2490

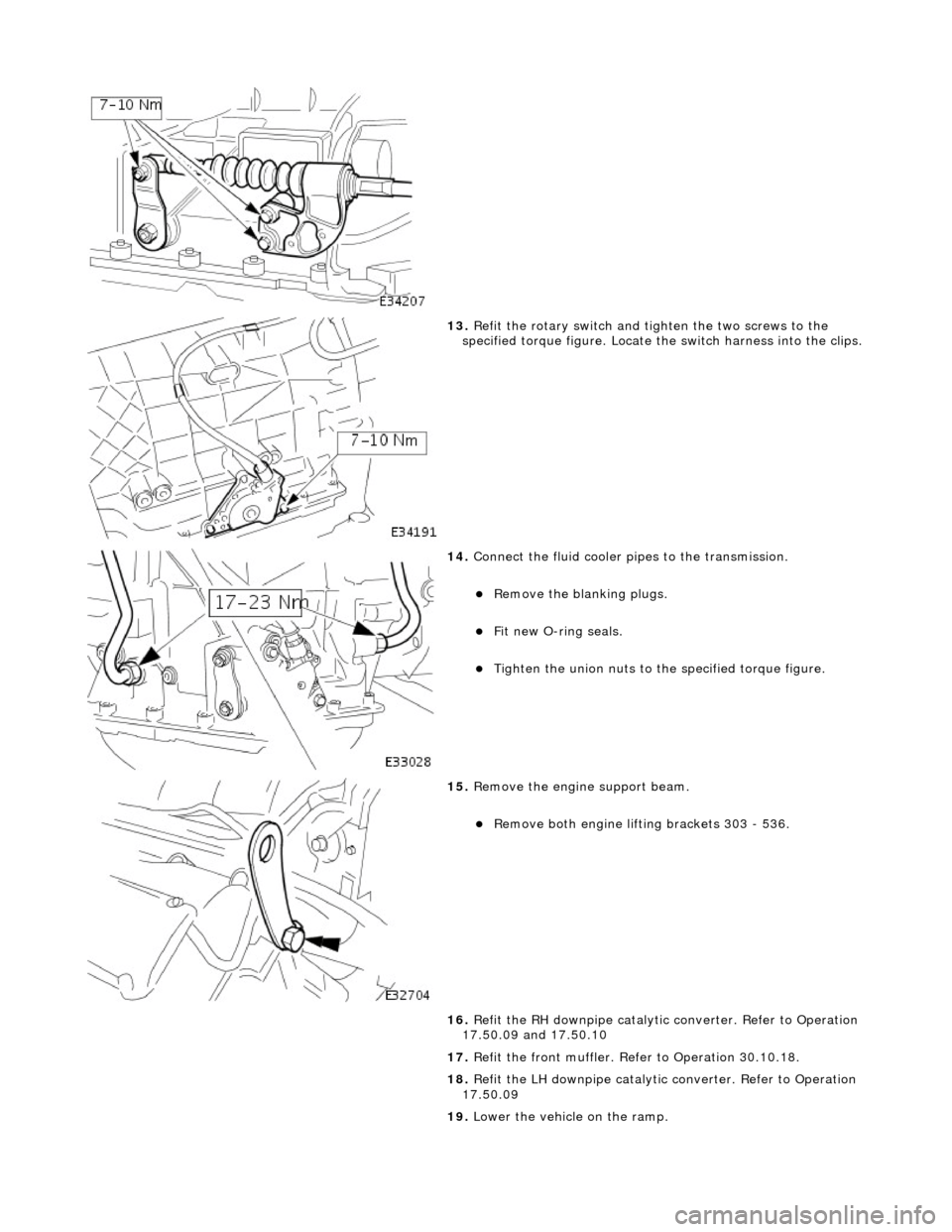

13. Refit the rotary switch and tighten the two screws to the

specified torque figure. Locate the switch harness into the clips.

14. Connect the fluid cooler pipes to the transmission.

пЃ¬Remove the blanking plugs.

пЃ¬Fit new O-ring seals.

пЃ¬Tighten the union nuts to the specified torque figure.

15. Remove the engine support beam.

пЃ¬Remove both engine lifting brackets 303 - 536.

16. Refit the RH downpipe catalytic converter. Refer to Operation

17.50.09 and 17.50.10

17. Refit the front muffler. Refer to Operation 30.10.18.

18. Refit the LH downpipe catalytic converter. Refer to Operation

17.50.09

19. Lower the vehicle on the ramp.

Page 1436 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Main Control

Valve Body

In-vehicle Repair

Removal

• NOTE: This procedure will not remove re sidual fluid from the torque converter.

1. Disconnect the battery ground lead.

2. Raise the vehicle for access.

3. Remove the RH catalytic converter; refer to Operation

17.50.10.

4. Remove the harness heatshield lower fixing.

пЃ¬Remove the screw heatshield / fluid pan clamp.

5. Remove the harness heatshield.

пЃ¬Pull the heatshield from under the clip.

6. Disconnect the transmission link harness connector.

1. Release the locking lever.

7. Release the (transmission case mounted) female connector.

пЃ¬Remove the (center) retaining bolt.

Page 1450 of 2490

brackets.

3. Tighten the support hook adjusters to take the weight of the engine.

12. Raise the vehicle for access.

13. Remove the LH downpipe catalytic converter. Refer to

Operation 17.50.09.

14. Remove the front muffler. Re fer to Operation 30.10.18.

15. Remove the RH downpipe catalytic converter. Refer to

Operation 17.50.09 and 17.50.10.

16. Drain the transmission fluid. Refer to Operation 44.24.02.

17. Locate an Epco V-100, or sim ilar lift, under the transmission

unit.

пЃ¬Adjust the angle of the lift to suit the transmission.

пЃ¬Secure the side clamps.

пЃ¬Pass the safety chain over the transmission unit and

tighten the clamp to secure the assembly.

18. Remove the rear engine mounting bracket.

1. Remove the centre bolt from the engine/transmission

mounting.

2. Remove the four bolts which secure the mounting

bracket to the body.

19. Detach the driveshaft (prop- shaft) from the transmission

drive flange.

пЃ¬If the transmission is to be refitted, mark the position of

the coupling relative to the drive flange.

19. CAUTION: Under no circ umstances remove the

driveshaft to flexible coupling fixings.

1. Remove the transmission drive flange to flexible

coupling fixings.

Page 1456 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Input Shaft Seal

Disassembly and Assembly of Subassemblies

Special Tool(s)

Oil seal replacer

307-378

1. Disconnect the battery ground lead.

2. Remove the air intake / MAFM assembly, refer to Operation

19.10.30.

3. Raise the vehicle for access.

4. Remove the front muffler, 30.10.18

5. Remove the RH and LH catalytic converters, refer to Operation

17.50.09 and 17.50.10.

6. Drain the transmission fluid, refer to Operation 44.24.02.

7. Remove the transmission unit, refer to Operation 44.20.01.

8. Remove the torque converter fro m the transmission unit, refer

to Operation 44.17.07.

9. Remove the front oil seal.

пЃ¬Using a proprietary tool remove the seal, taking care not

to damage the shaft or bore diameters.

10. Installation is the reverse of the removal procedure noting

that:

11. Fit the oil seal.

1. Lubricate the housing seal bore.

2. Lubricate the outside diameter of the seal.

3. Using seal replacer 307 - 379, drive the seal squarely into place.