wiring JAGUAR XFR 2010 1.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1397 of 3039

Installation 6. CAUTION: Make sure that the mating faces are clean

and free of foreign material.

Special Tool(s): 310-121 Torque: 48 Nm

1. CAUTIONS:

Make sure the anti-seize compound does not contact the HO2S tip.

If accidentally dropped or knocked install a new sensor.

Make sure the HO2S wiring harness is not twisted more than 180

degrees and is not in contact with either the exhaust or driveshaft.

NOTE: If the original sensor is to be installed, apply lubricant

meeting specification ESE-M12A4-A to the thread of the sensor.

To install, reverse the removal procedure.

2. NOTE: For NAS vehicles only.

If required, carry out a long drive cycle.

Refer to: Powertrain Control Module (PCM) Long Drive Cycle Self-Test (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, General

Procedures).

Page 1436 of 3039

Visual Inspection

Mechanical Electrical Hydraulic

Damaged/stuck shift mechanism

Damaged automatic transmission casing

Blown fuse(s)

Damaged, loose or corroded connectors

Wiring harness

Fluid level too high/low

Poor condition of fluid

Fluid leak

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for diagnostic trouble codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module/transmission is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to the

installation of a new module/transmission.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action P0121-86 Throttle/Pedal Position

Sensor A Circuit

Range/Performance - signal

invalid

Throttle/Pedal Position

Sensor Fault (Data

received over CAN Bus) Check Engine Control Module for stored DTCs P0219-86 Engine Overspeed Condition

- signal invalid

Engine speed too low or

too high (Data received

over CAN Bus) Check Engine Control Module for stored DTCs P0500-81

Vehicle Speed Sensor A -

invalid serial data received

Vehicle Speed Sensor

fault (Data received over

CAN Bus) Check DSC module for stored DTCs P0501-81 Vehicle Speed Sensor A

Vehicle Speed receive Check Anti-lock braking system module for stored Range/Performance invalid DTCs. Check correct Differential is installed to the serial data received over CAN Bus does not

vehicle match Transmission Output-Shaft speed P0561-1C

System Voltage Unstable -

Circuit voltage out of range

Power supply voltage out

of range when engine

running Check Engine control module for stored DTCs. Check

Charging System and Battery condition P0562-21

System Voltage Low - signal

amplitude < minimum

Circuit low voltage.

Battery supply voltage to

Transmission Control

Module (Transmission Refer to Circuit diagrams and check Power and Ground

Circuit for fault. Check Engine control module for

stored DTCs. Check Charging System and Battery

condition

Page 1542 of 3039

Published: 11-May-2011

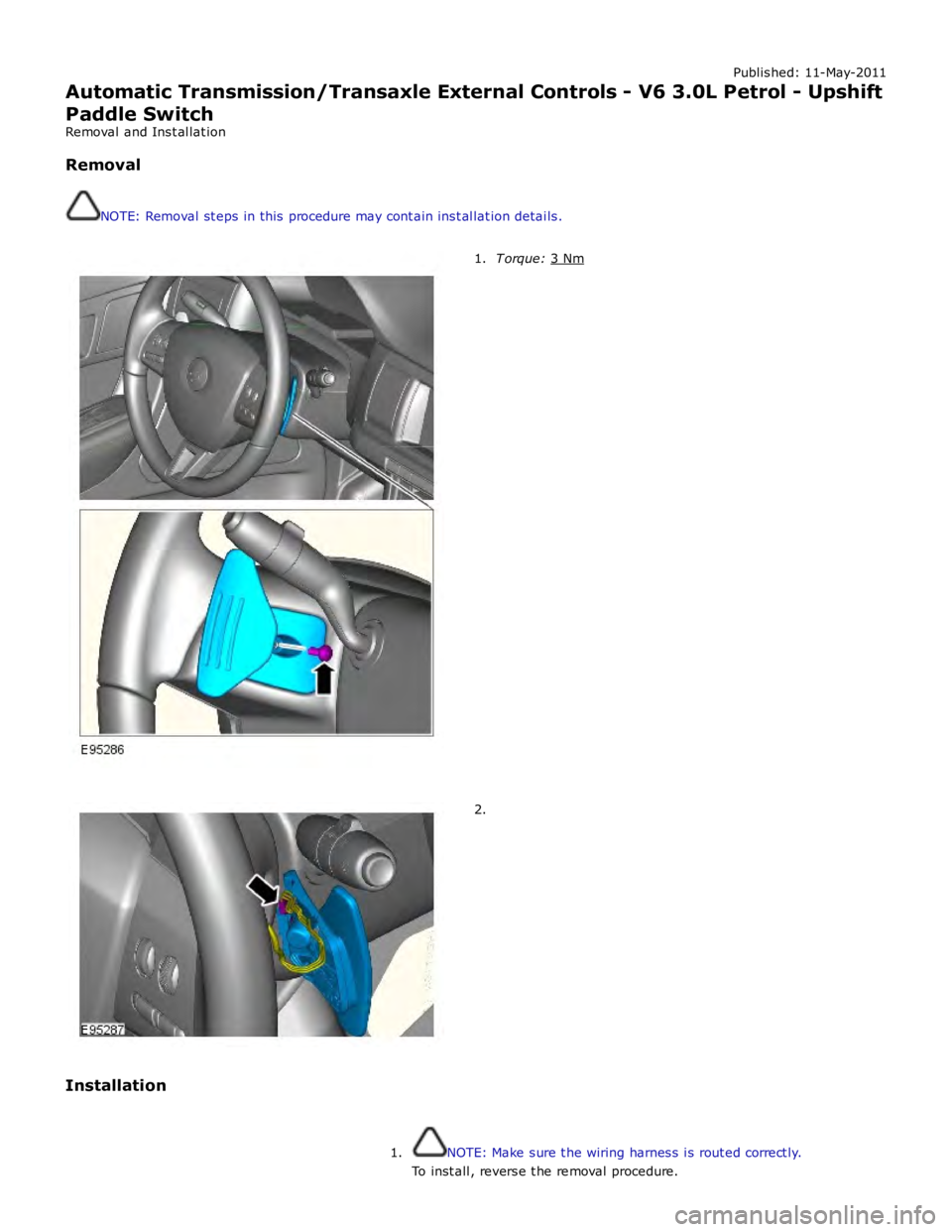

Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol - Upshift

Paddle Switch

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain inst allation details.T orque: 3 Nm 1.2.

Installation

NOTE: Make sure the wiring harness is routed correct ly. 1.To inst all, reverse t he removal procedure.

Page 1543 of 3039

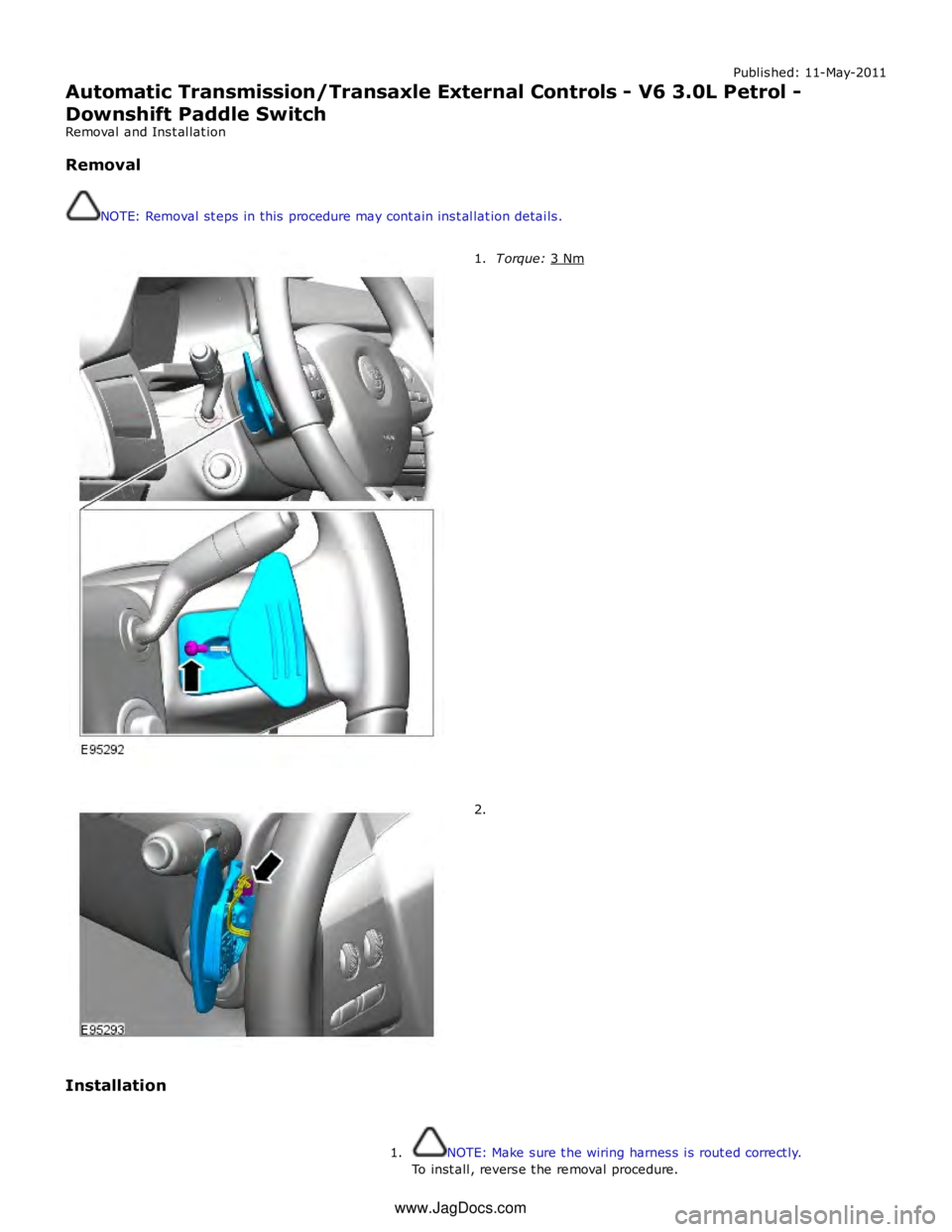

Published: 11-May-2011

Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol -

Downshift Paddle Switch

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain inst allation details.T orque: 3 Nm 1.2.

Installation

NOTE: Make sure the wiring harness is routed correct ly. 1.To inst all, reverse t he removal procedure.

www.JagDocs.com

Page 1550 of 3039

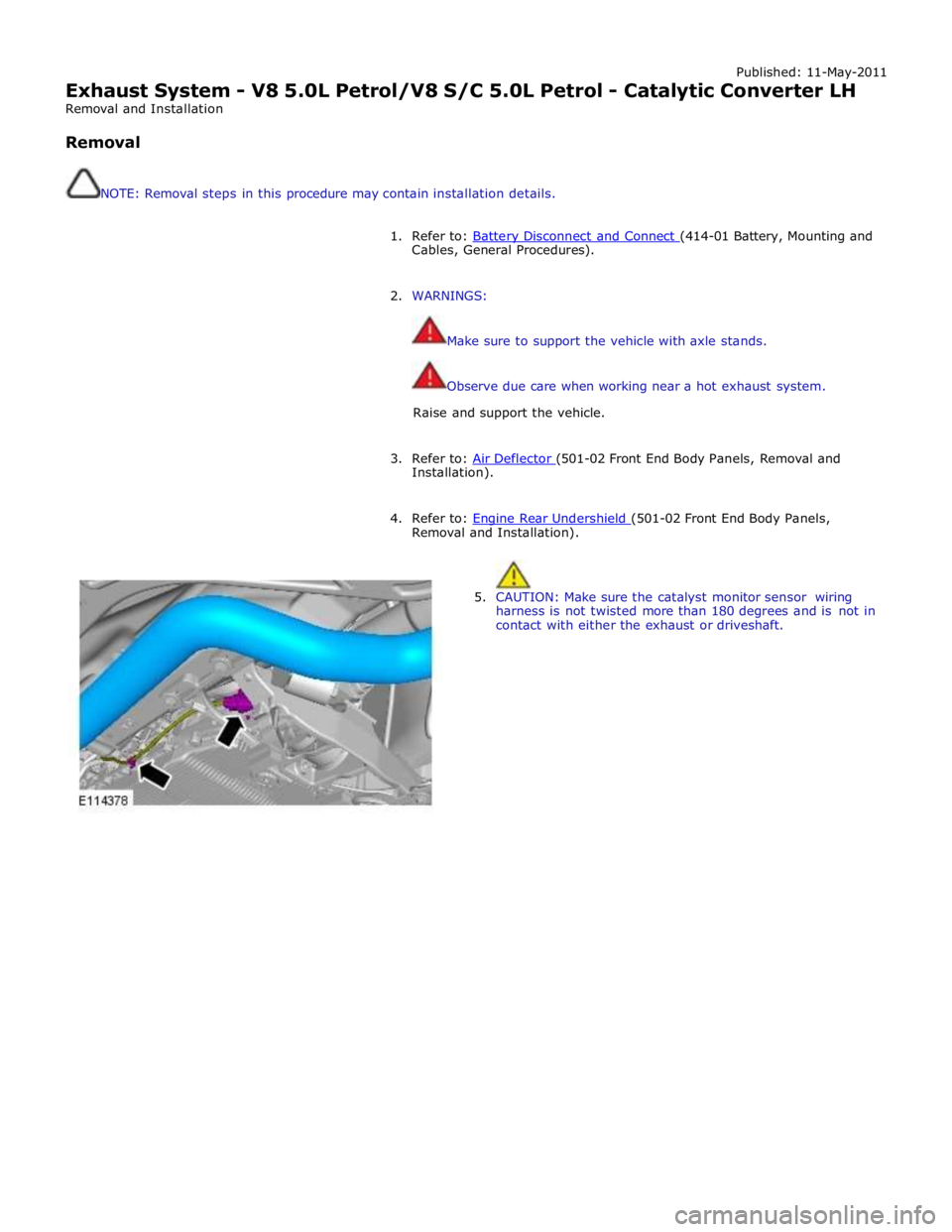

Published: 11-May-2011

Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Catalytic Converter LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNINGS:

Make sure to support the vehicle with axle stands.

Observe due care when working near a hot exhaust system.

Raise and support the vehicle.

3. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

4. Refer to: Engine Rear Undershield (501-02 Front End Body Panels, Removal and Installation).

5. CAUTION: Make sure the catalyst monitor sensor wiring

harness is not twisted more than 180 degrees and is not in

contact with either the exhaust or driveshaft.

Page 1553 of 3039

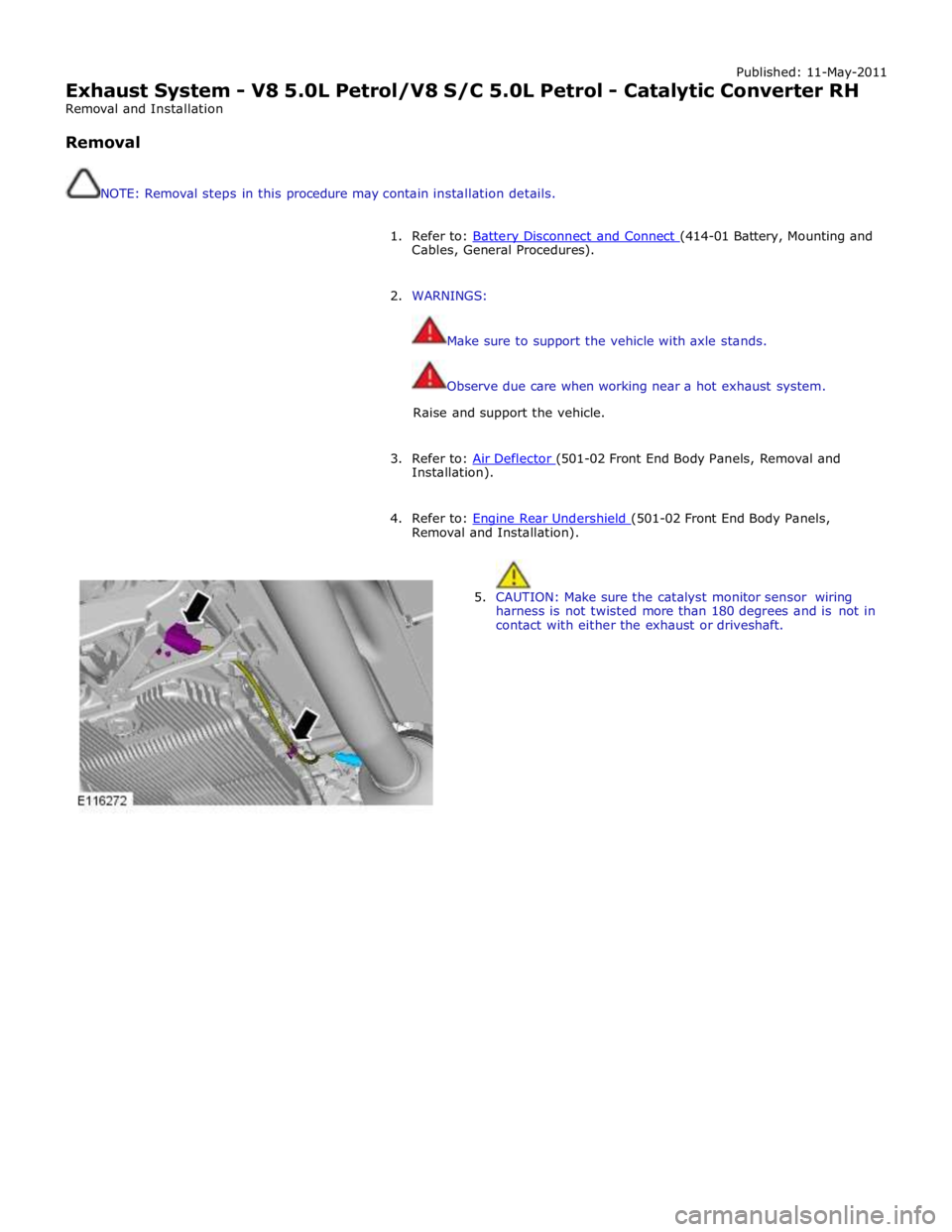

Published: 11-May-2011

Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Catalytic Converter RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNINGS:

Make sure to support the vehicle with axle stands.

Observe due care when working near a hot exhaust system.

Raise and support the vehicle.

3. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

4. Refer to: Engine Rear Undershield (501-02 Front End Body Panels, Removal and Installation).

5. CAUTION: Make sure the catalyst monitor sensor wiring

harness is not twisted more than 180 degrees and is not in

contact with either the exhaust or driveshaft.

Page 1631 of 3039

Acceleration Control - Acceleration Control

Diagnosis and Testing

Principles of Operation Published: 11-May-2011

For a detailed description of the acceleration controls, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: Acceleration Control (310-02, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Accelerator pedal

Throttle body

Fuses

Wiring harness

Electrical connector(s)

Sensor(s)

Engine control module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the module or a component is suspect and the vehicle remains under the Manufacturers warranty, refer to the Warranty

Policy and Procedure manual (section B1.2), or determine if any prior approval programme is in operation, prior to the

installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action P012100 Throttle/Pedal

Position Sensor A

Circuit

Range/Performance

TP sensor sensing

circuits TP 1 and TP

2 - short to power,

high resistance

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuits TP 1 and TP 2

for short to power, high resistance. Check and install a new throttle

body as required www.JagDocs.com

Page 1646 of 3039

Published: 08-Nov-2013

Speed Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Speed Control

Diagnosis and Testing

Principles of Operation

For a detailed description of the speed control system, refer to the relevant Description and Operation sections in the

workshop manual.

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Speed control sensor

Ensure the speed control sensor is free from obstructions

Speed control module

Brake switch

Fuses

Wiring harness

Electrical connector(s)

Steering wheel switches

Brake switch

Speed control sensor

Speed control module

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively, check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Speed Control Sensor Adjustment (vehicles with adaptive system installed)

An incorrectly aligned speed control sensor can cause incorrect system operation. Before starting any repair work on the speed

control system, on vehicles with the adaptive system installed, check speed control sensor for correct vertical alignment, and

carry out speed control sensor alignment procedure using manufacturer approved diagnostic system.

Symptom Chart

Symptom Possible Causes Action Speed control inhibited or

disabled

Power or ground supply to

speed control module or speed

control sensor

Steering wheel speed control

switch/circuits

Throttle sensors

Brake switch

Anti-Lock Brake System fault

Check for DTCs that could be caused by power or

ground failure to the module or sensor and refer to

DTC Index

Check for sticking, jammed and broken speed control

switches. Refer to the electrical circuit diagrams and

check speed control switch circuits for short, open

circuit

For throttle position sensor tests. REFER to:

Electronic Engine Controls - 3.0L Diesel (303-14

Electronic Engine Controls - 3.0L Diesel, Diagnosis and

Testing),

Electronic Engine Controls - 3.0L (303-14B Electronic Engine Controls - V6 3.0L Petrol, Diagnosis and

Testing),

Electronic Engine Controls (303-14 Electronic Engine

Controls - V8 4.2L Petrol/V8 S/C 4.2L Petrol, Diagnosis

and Testing).

Check for correct installation and adjustment of brake

switch. Refer to the electrical circuit diagrams and

check brake switch circuits for short, open circuit

Check ABS system for related DTCs and refer to the

relevant DTC Index Unable to regulate/adjust

vehicle speed

Steering wheel switch

malfunction

Check for sticking, jammed and broken speed control

switches. Refer to the electrical circuit diagrams and

check speed control switch circuits for short, open

circuit

Page 1664 of 3039

Published: 11-Jul-2014

Climate Control System - General Information - Climate Control System

Diagnosis and Testing

Principles of Operation

For a detailed description of the Climate Control System, refer to the relevant Description and Operation sections in the

Workshop Manual. REFER to:

Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation).

Inspection and Verification

WARNING: Servicing must be carried out by personnel familiar with both vehicle system and the charging and testing

equipment. All operations must be carried out in a well ventilated area away from open flame and heat sources.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Coolant level

Hose(s)

Coolant pump

Control flap(s)

Duct(s)

Vent(s)

Cabin air filter

Drive belt

Air conditioning compressor

Thermostatic expansion valve

Evaporator

Receiver drier

Air conditioning condenser

Refrigerant pipes Auxiliary

drive belt

Fuel fired booster heater

Fuel fired booster heater fuel pump

Fuel fired booster heater fuel pipes

Fuse(s)

Wiring harness

Electrical connectors

Blower

Air conditioning compressor

Electric cooling fan

Automatic Temperature Control Module (ATCM)

Refrigerant pressure sensor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Page 1712 of 3039

bus. Temperature control for the heater element is provided by the steering wheel heater control module which receives a

temperature feedback signal from a NTC (negative temperature coefficient) thermistor located within the steering wheel.

ATC Module Component Description

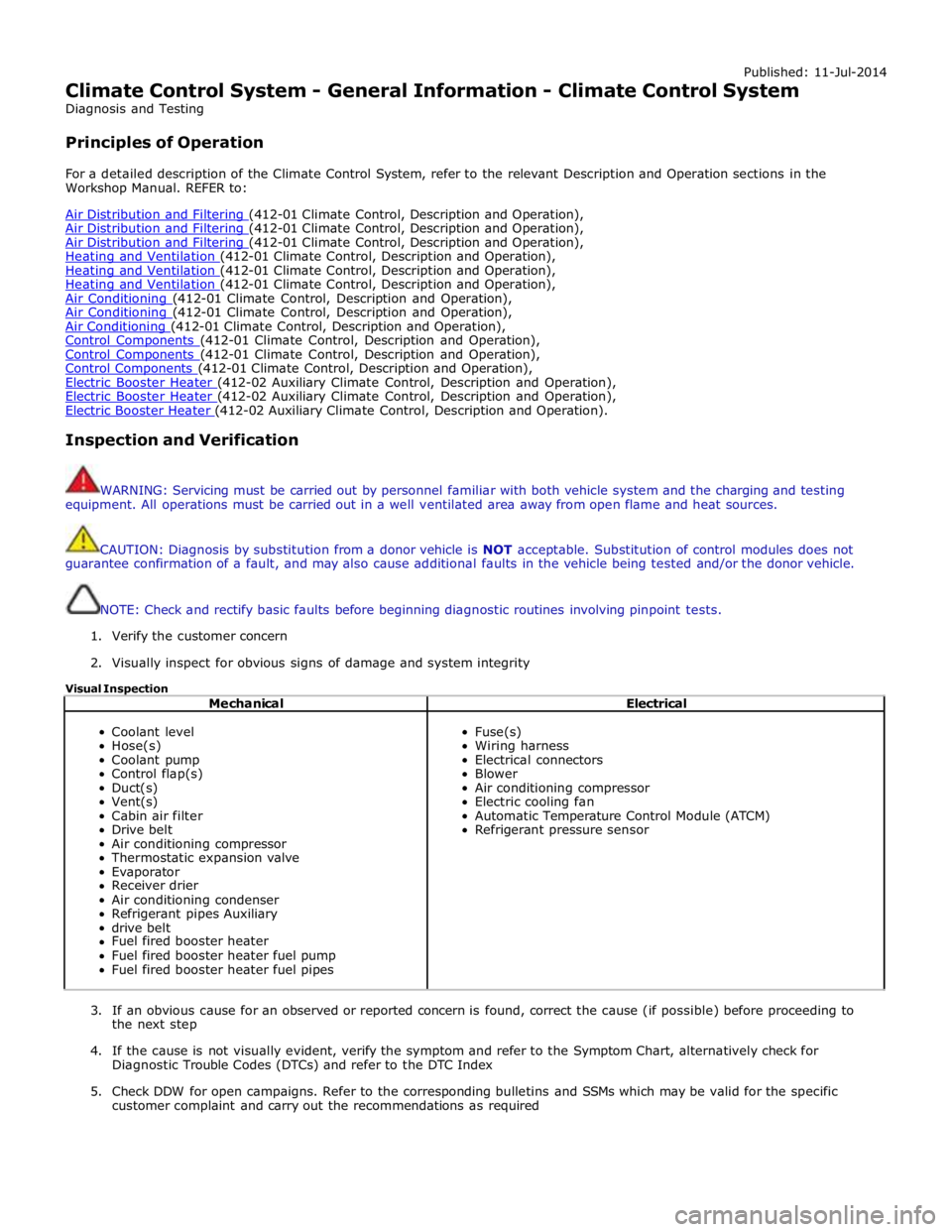

The ATC module is mounted on the outboard end of the air inlet duct, behind the front passenger side of the instrument panel. The ATC module processes inputs from the TSD, the switches on the integrated control panel and the system sensors. In response to these inputs, the ATC module outputs control signals to the A/C system and the heating and ventilation system.

Two electrical connectors provide the interface between the ATC module and the vehicle wiring. The ATC module uses hardwired inputs from the system sensors, the LIN bus to communicate with the stepper motors and the medium speed CAN bus to communicate with other control modules on the vehicle.

A/C Compressor Solenoid Valve

The A/C compressor solenoid valve is integral with the A/C compressor. Operation of the solenoid valve is controlled by the ATC module using a hardwired drive current of differing values. By controlling the flow of refrigerant through the compressor, the

solenoid valve can control the A/C system pressure and the evaporator operating temperature.

Refrigerant Pressure Sensor

The refrigerant pressure sensor provides the ATC module with a pressure input from the high pressure side of the refrigerant system. The refrigerant pressure sensor is located in the refrigerant line between the condenser and the thermostatic

expansion valve.

The ATC module supplies a 5 V reference voltage to the refrigerant pressure sensor and receives a return signal voltage, between 0 V and 5 V, related to system pressure.

The ATC module uses the signal from the pressure sensor to protect the refrigerant system from extremes of pressure. The ATC module transmits the A/C pressure, along with the compressor drive current value, to the instrument cluster on the medium speed CAN bus. These signals are broadcast to the ECM on the high speed CAN bus to allow it to calculate the torque being applied to the engine by the compressor. www.JagDocs.com