wheel JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 536 of 3039

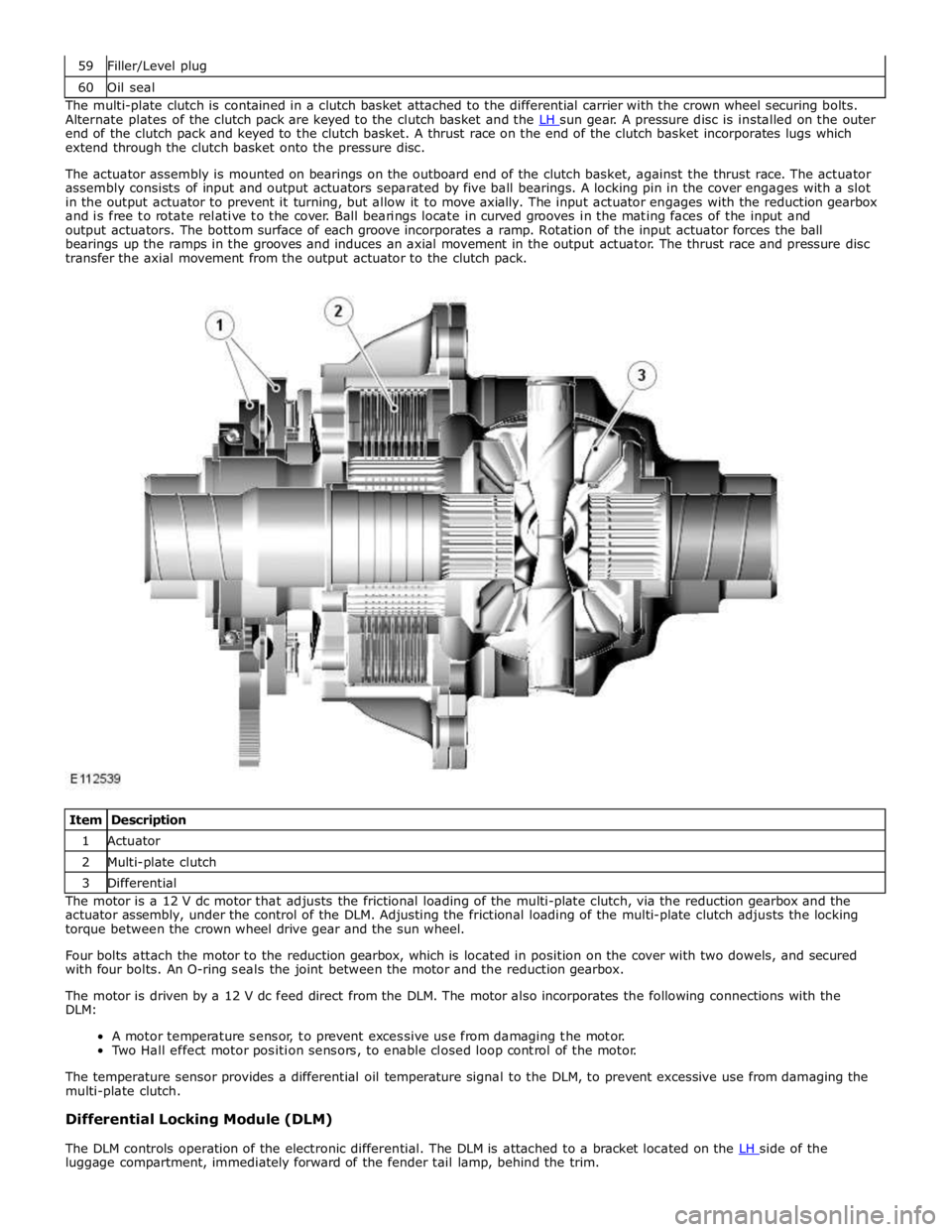

60 Oil seal The multi-plate clutch is contained in a clutch basket attached to the differential carrier with the crown wheel securing bolts.

Alternate plates of the clutch pack are keyed to the clutch basket and the LH sun gear. A pressure disc is installed on the outer end of the clutch pack and keyed to the clutch basket. A thrust race on the end of the clutch basket incorporates lugs which

extend through the clutch basket onto the pressure disc.

The actuator assembly is mounted on bearings on the outboard end of the clutch basket, against the thrust race. The actuator

assembly consists of input and output actuators separated by five ball bearings. A locking pin in the cover engages with a slot

in the output actuator to prevent it turning, but allow it to move axially. The input actuator engages with the reduction gearbox

and is free to rotate relative to the cover. Ball bearings locate in curved grooves in the mating faces of the input and

output actuators. The bottom surface of each groove incorporates a ramp. Rotation of the input actuator forces the ball

bearings up the ramps in the grooves and induces an axial movement in the output actuator. The thrust race and pressure disc

transfer the axial movement from the output actuator to the clutch pack.

Item Description 1 Actuator 2 Multi-plate clutch 3 Differential The motor is a 12 V dc motor that adjusts the frictional loading of the multi-plate clutch, via the reduction gearbox and the

actuator assembly, under the control of the DLM. Adjusting the frictional loading of the multi-plate clutch adjusts the locking

torque between the crown wheel drive gear and the sun wheel.

Four bolts attach the motor to the reduction gearbox, which is located in position on the cover with two dowels, and secured

with four bolts. An O-ring seals the joint between the motor and the reduction gearbox.

The motor is driven by a 12 V dc feed direct from the DLM. The motor also incorporates the following connections with the

DLM:

A motor temperature sensor, to prevent excessive use from damaging the motor.

Two Hall effect motor position sensors, to enable closed loop control of the motor.

The temperature sensor provides a differential oil temperature signal to the DLM, to prevent excessive use from damaging the

multi-plate clutch.

Differential Locking Module (DLM)

The DLM controls operation of the electronic differential. The DLM is attached to a bracket located on the LH side of the luggage compartment, immediately forward of the fender tail lamp, behind the trim.

Page 537 of 3039

bus allows the DLM to communicate with other systems on the vehicle.

A certain amount of differential slip is required to allow the vehicle to turn corners and to remain stable under control of the

ABS. The ADM monitors the driver's demands through primary vehicle controls and automatically sets the slip torque in the differential. The system is completely automatic and does not require any special driver input.

The differential strategy in the ADM includes:

A pre-loading function, increasing locking torque with increased driving torque.

A slip controller to decrease locking torque for optimum comfort, e.g. parking.

The ADM memorizes the position of the motor when the ignition is switched off.

CAN bus messages used by the ADM include wheel speed, steering angle, automatic transmission speed, temperature information, car configuration, axle ratios and mode inputs.

The ADM also sends messages via the CAN bus to tell other control modules on the network the status of the electronic differential. The clutch torque and default mode status are some of the main signals sent out by the ADM.

If the DLM or ADM are replaced, a Jaguar approved diagnostic system must be connected to the vehicle and the differential

self-calibration procedure must be performed. This procedure must also be performed if the motor or electronic differential is

replaced.

If a fault occurs with the electronic differential, the ADM, the DLM, or one of the required input signals, the ADM records an

error code and displays a warning in the message center.

The following messages can be displayed:

Message Description Chime E-DIFF NOT

AVAILABLE Differential temperature has reached the overheat threshold. System deactivated until temperature

returns within limits. Single E-DIFF FAULT Fault has occurred with electronic differential. System deactivated until fault rectified. Single

Page 563 of 3039

Published: 11-May-2011

Rear Drive Halfshafts - Rear Drive Halfshafts - System Operation and

Component Description

Description and Operation

System Operation

Rear Drive Halfshafts Component Description

The solid-steel halfshafts are of unequal length, with each halfshaft comprising inner and outer CV (constant velocity) joints.

The CV joints are the 'ball and socket' type packed with grease and protected by gaiters.

The outer CV joint is an interference fit into the wheel hub and secured by a locking nut. The inner CV joint is a slide fit and is

retained in the differential with a spring clip.

www.JagDocs.com

Page 566 of 3039

Removal

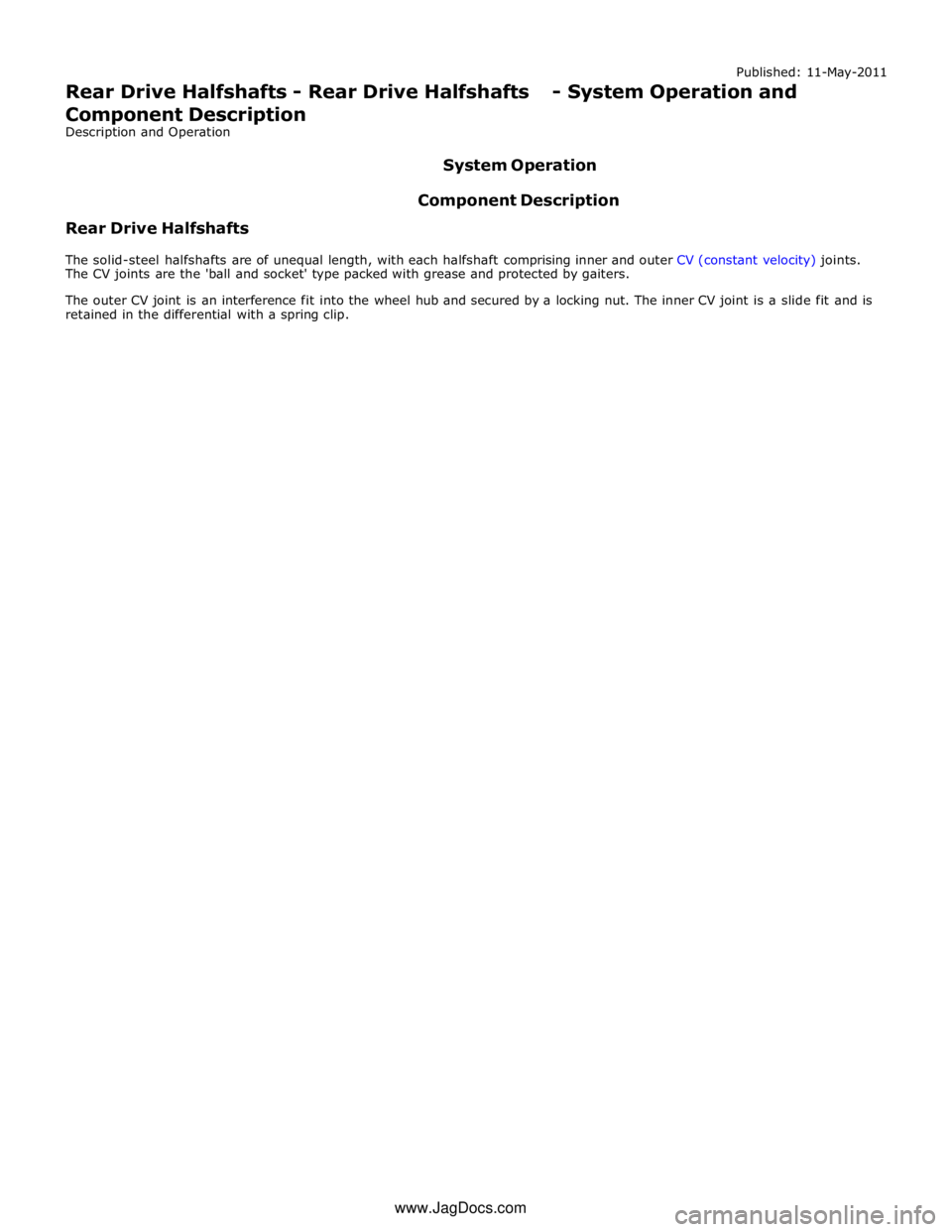

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the LH rear wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

3. With assistance, remove the halfshaft retaining nut, and

retain it for the install procedure.

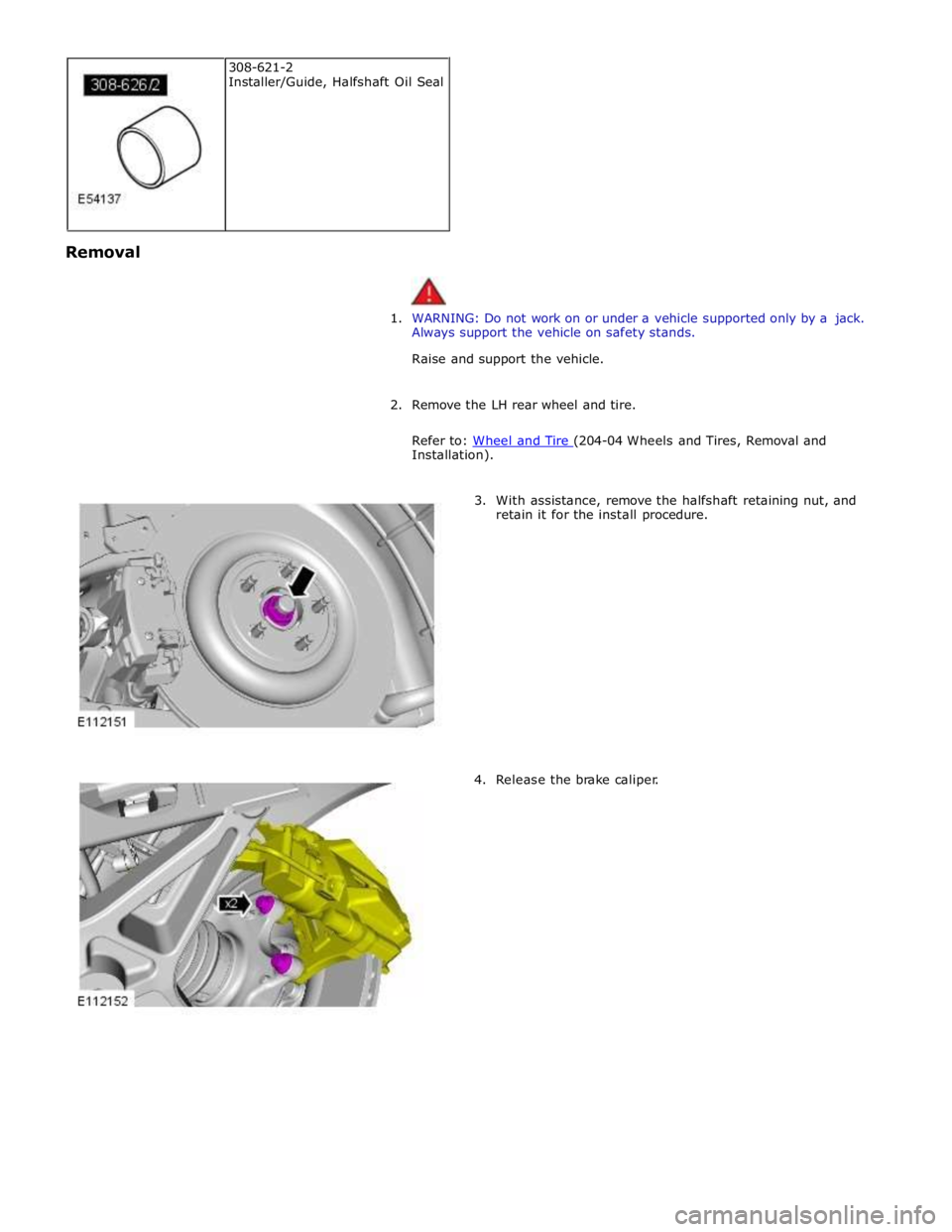

4. Release the brake caliper. 308-621-2

Installer/Guide, Halfshaft Oil Seal

Page 568 of 3039

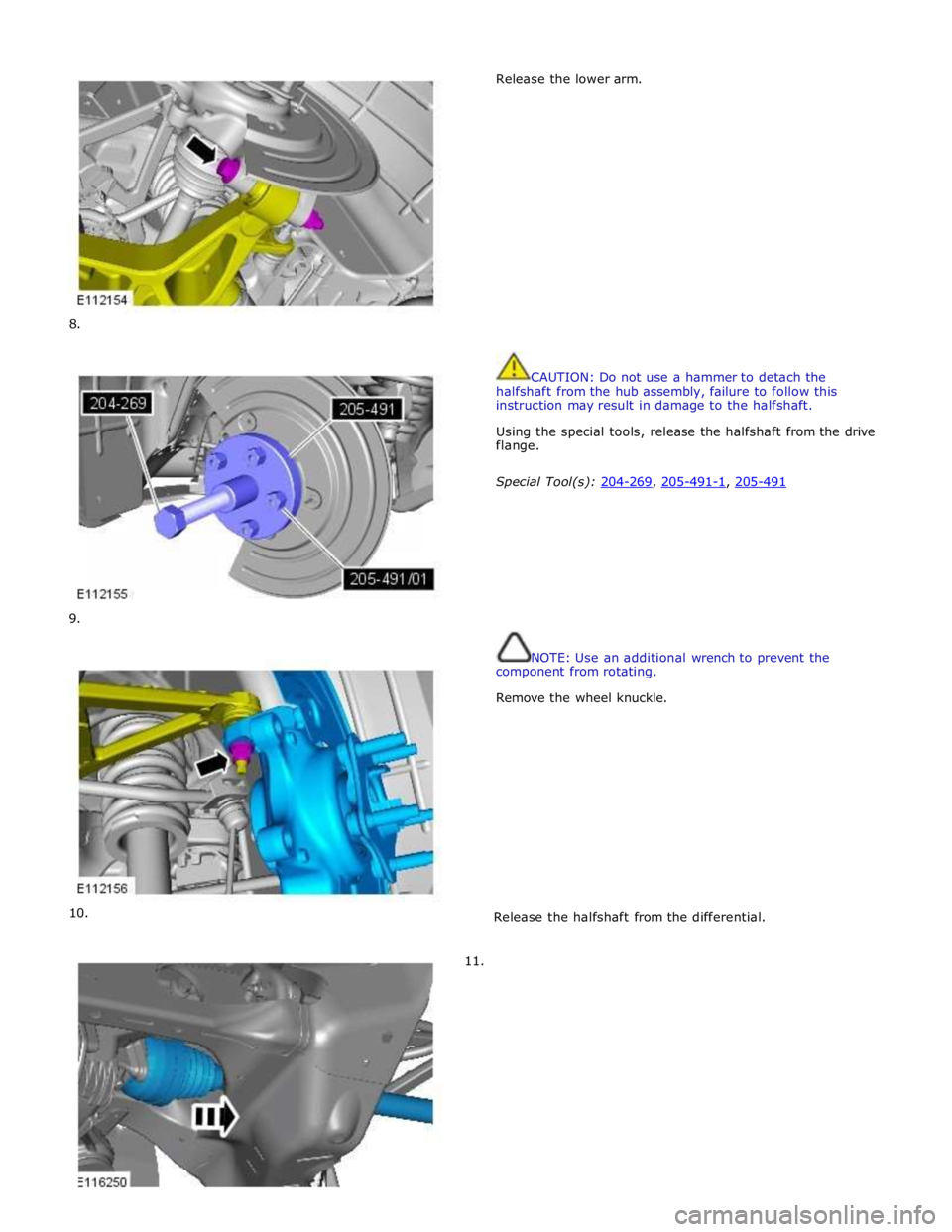

8.

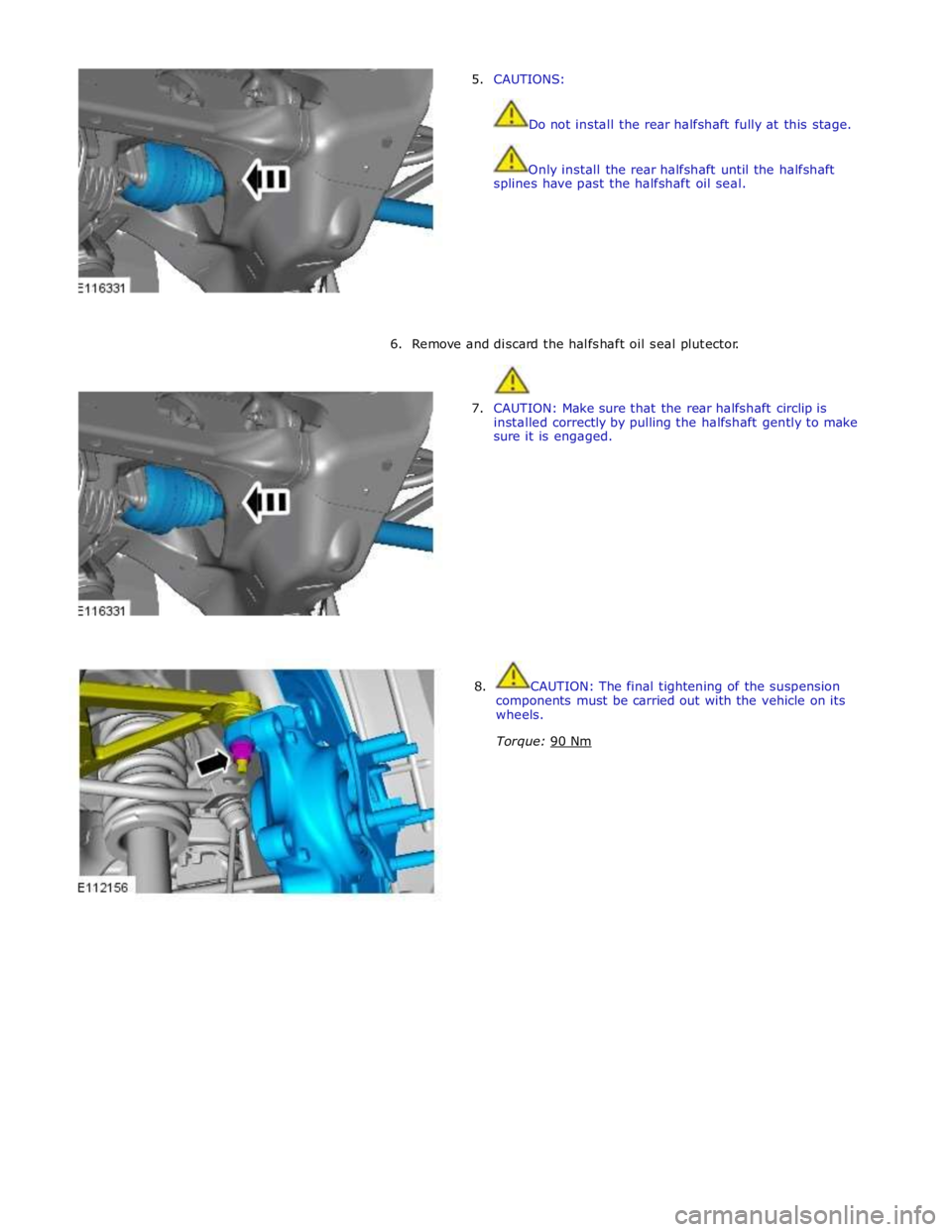

9.

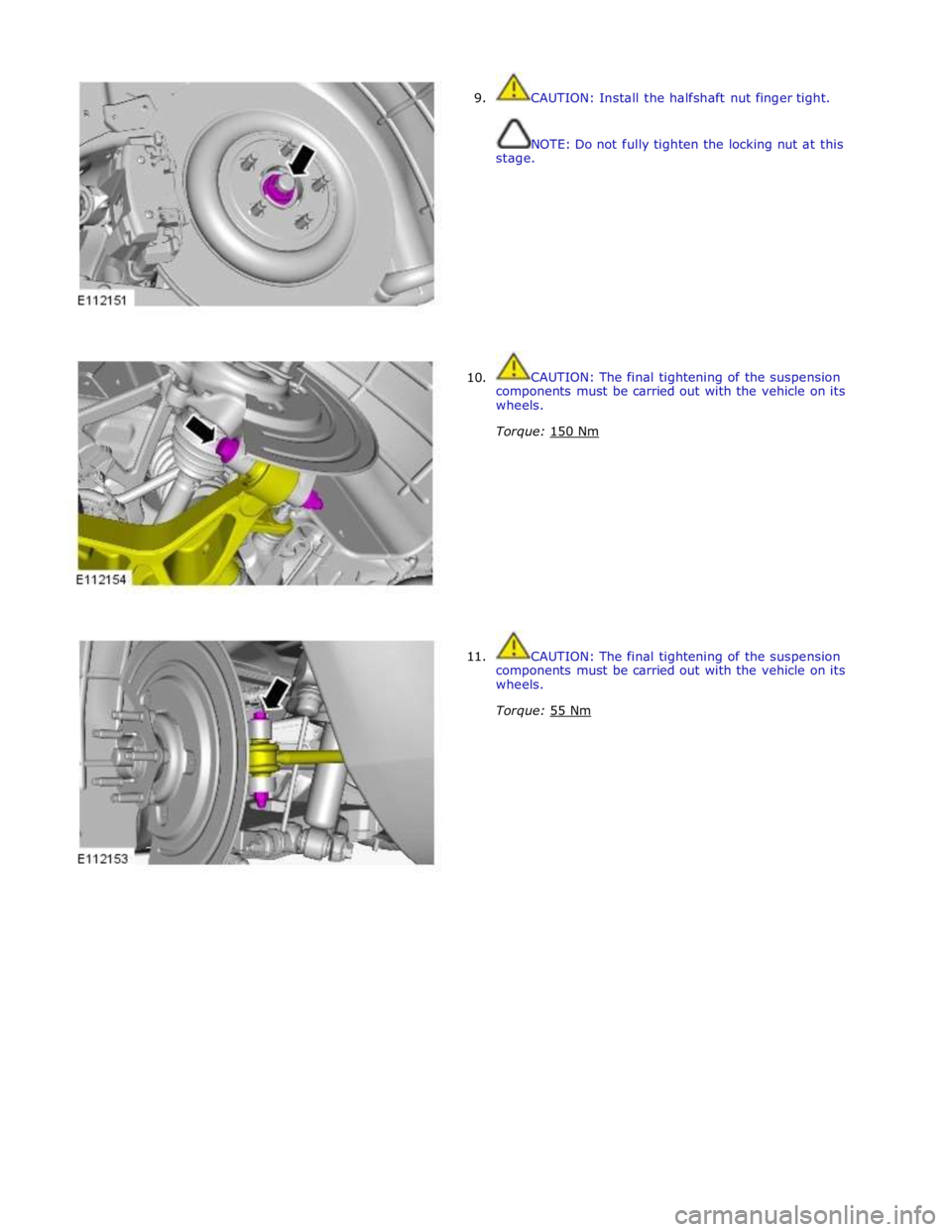

10.

11. Release the lower arm.

CAUTION: Do not use a hammer to detach the

halfshaft from the hub assembly, failure to follow this

instruction may result in damage to the halfshaft.

Using the special tools, release the halfshaft from the drive

flange.

Special Tool(s): 204-269, 205-491-1, 205-491

NOTE: Use an additional wrench to prevent the

component from rotating.

Remove the wheel knuckle.

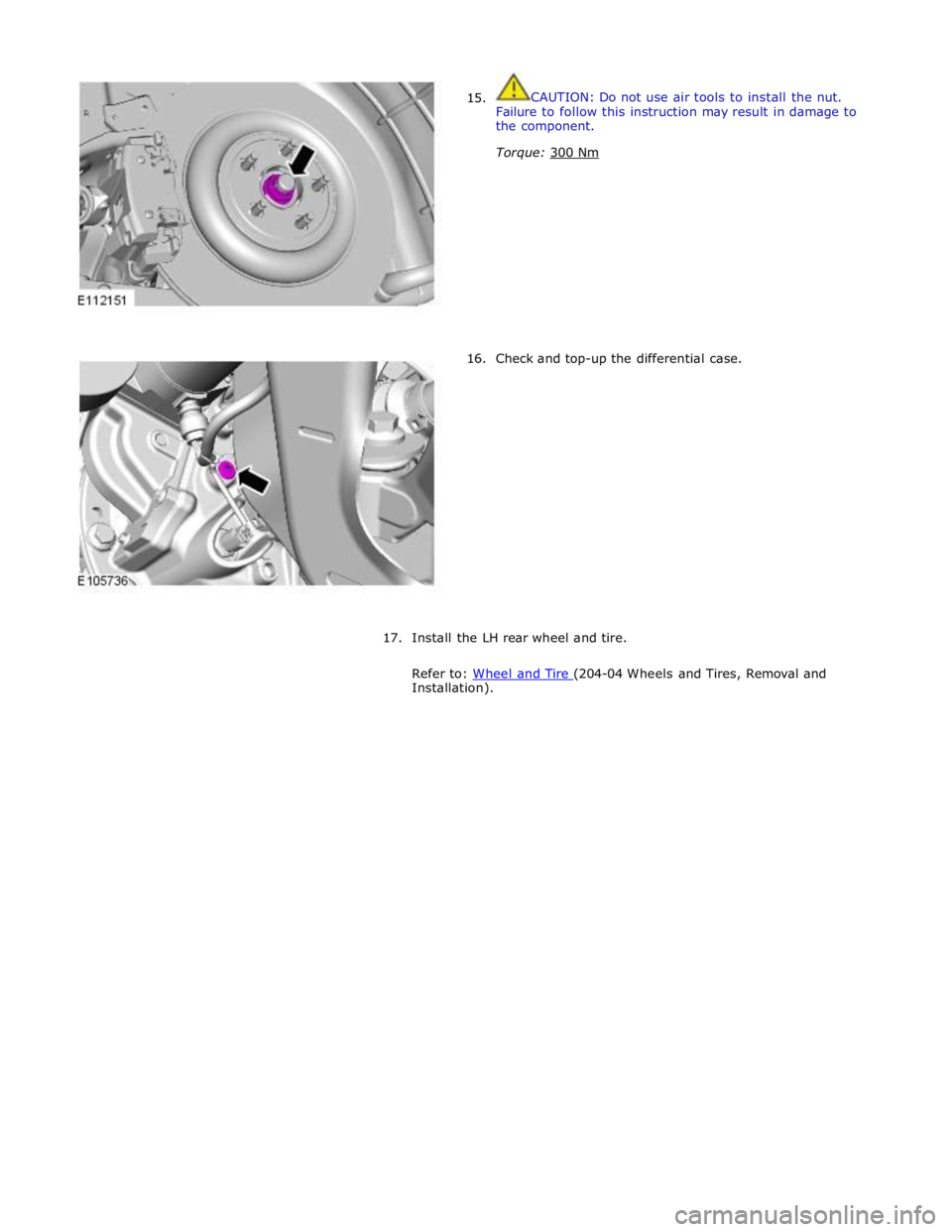

Release the halfshaft from the differential.

Page 571 of 3039

5. CAUTIONS:

Do not install the rear halfshaft fully at this stage.

Only install the rear halfshaft until the halfshaft

splines have past the halfshaft oil seal.

6. Remove and discard the halfshaft oil seal plutector.

7. CAUTION: Make sure that the rear halfshaft circlip is

installed correctly by pulling the halfshaft gently to make

sure it is engaged.

8. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 90 Nm

Page 572 of 3039

9.

10.

11. CAUTION: Install the halfshaft nut finger tight.

NOTE: Do not fully tighten the locking nut at this

stage.

CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 150 Nm

CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 55 Nm

Page 574 of 3039

15.

16. CAUTION: Do not use air tools to install the nut.

Failure to follow this instruction may result in damage to

the component.

Torque: 300 Nm

Check and top-up the differential case.

17.

Install the LH rear wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

Page 582 of 3039

Brake System - General Information - Brake System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the brake system, refer to the relevant Description and Operation sections in the workshop

manual. REFER to:

Front Disc Brake (206-03, Description and Operation),

Front Disc Brake (206-03, Description and Operation),

Front Disc Brake (206-03, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Brake Booster (206-07 Power Brake Actuation, Description and Operation), Brake Booster (206-07 Power Brake Actuation, Description and Operation), Brake Booster (206-07, Description and Operation).

Inspection and Verification

Visually examine the front and rear wheel and tire assemblies for damage such as uneven wear patterns, tread worn out or

sidewall damage. Verify the tires are the same size, type and, where possible, same manufacturer. Replace the damaged

wheel or excessively worn tire.

Wheels and tires must be cleared of any foreign matter and tire pressures adjusted to the correct specification.

If the tires exhibit uneven wear or feathering, the cause must be corrected. Check the steering and suspension components for

damage or wear and, if necessary, check and adjust front wheel alignment. REFER to: (204-00 Suspension System - General

Information)

Specifications (Specifications), Front Toe Adjustment (General Procedures).

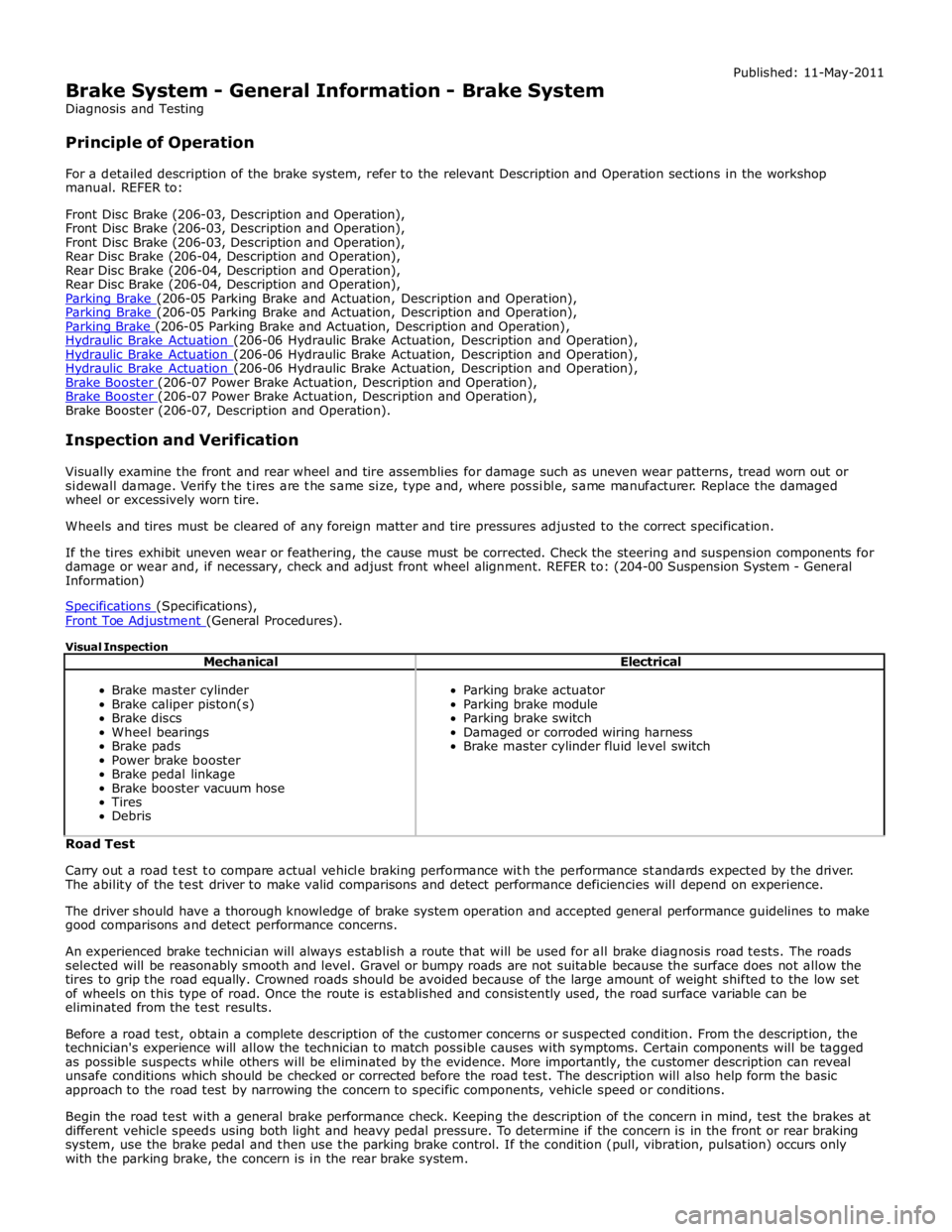

Visual Inspection

Mechanical Electrical

Brake master cylinder

Brake caliper piston(s)

Brake discs

Wheel bearings

Brake pads

Power brake booster

Brake pedal linkage

Brake booster vacuum hose

Tires

Debris

Parking brake actuator

Parking brake module

Parking brake switch

Damaged or corroded wiring harness

Brake master cylinder fluid level switch Road Test

Carry out a road test to compare actual vehicle braking performance with the performance standards expected by the driver.

The ability of the test driver to make valid comparisons and detect performance deficiencies will depend on experience.

The driver should have a thorough knowledge of brake system operation and accepted general performance guidelines to make

good comparisons and detect performance concerns.

An experienced brake technician will always establish a route that will be used for all brake diagnosis road tests. The roads

selected will be reasonably smooth and level. Gravel or bumpy roads are not suitable because the surface does not allow the

tires to grip the road equally. Crowned roads should be avoided because of the large amount of weight shifted to the low set

of wheels on this type of road. Once the route is established and consistently used, the road surface variable can be

eliminated from the test results.

Before a road test, obtain a complete description of the customer concerns or suspected condition. From the description, the

technician's experience will allow the technician to match possible causes with symptoms. Certain components will be tagged

as possible suspects while others will be eliminated by the evidence. More importantly, the customer description can reveal

unsafe conditions which should be checked or corrected before the road test. The description will also help form the basic

approach to the road test by narrowing the concern to specific components, vehicle speed or conditions.

Begin the road test with a general brake performance check. Keeping the description of the concern in mind, test the brakes at

different vehicle speeds using both light and heavy pedal pressure. To determine if the concern is in the front or rear braking

system, use the brake pedal and then use the parking brake control. If the condition (pull, vibration, pulsation) occurs only

with the parking brake, the concern is in the rear brake system.

Page 583 of 3039

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is not

evident, attempt to duplicate the condition using the information from the description.

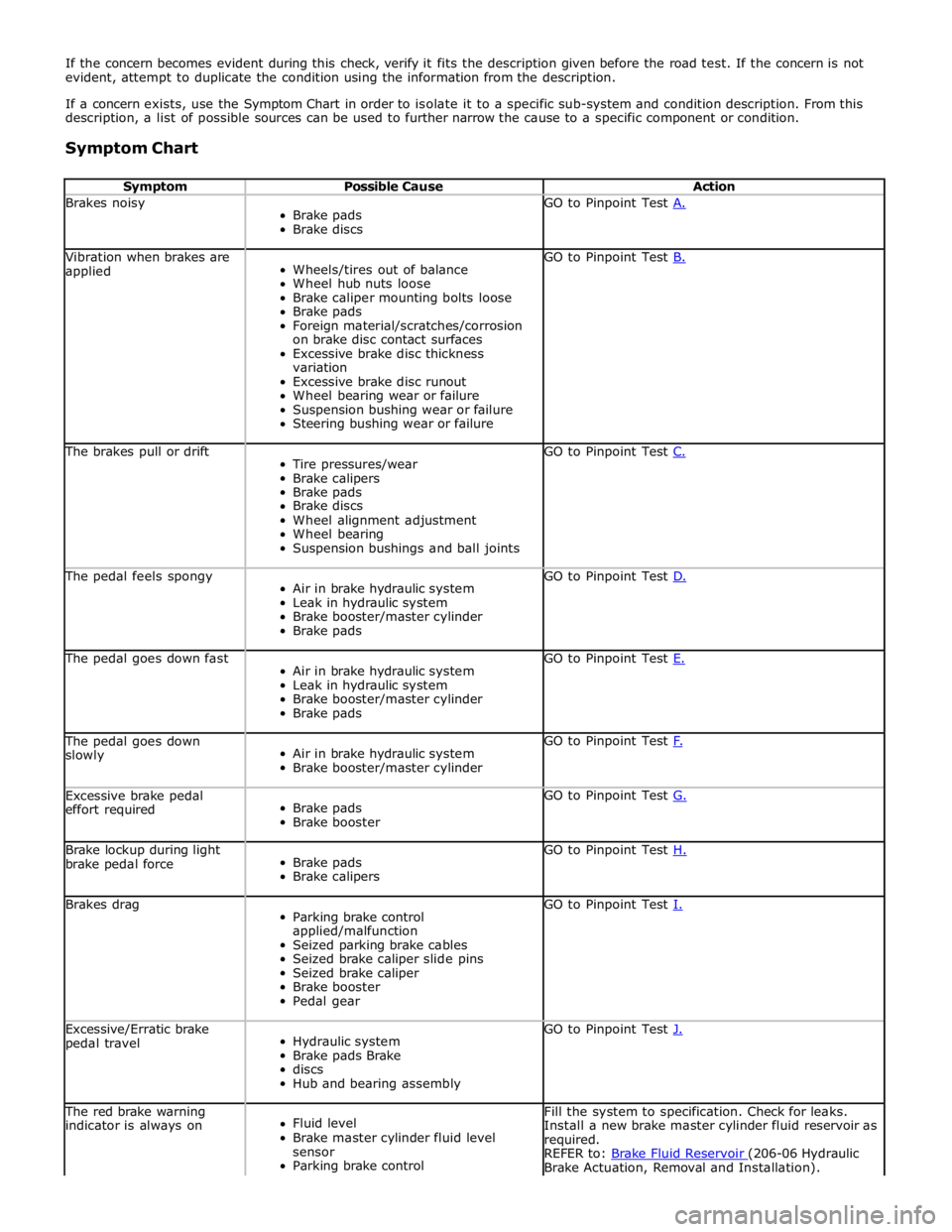

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From this

description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

Symptom Chart

Symptom Possible Cause Action Brakes noisy

Brake pads

Brake discs GO to Pinpoint Test A. Vibration when brakes are

applied

Wheels/tires out of balance

Wheel hub nuts loose

Brake caliper mounting bolts loose

Brake pads

Foreign material/scratches/corrosion

on brake disc contact surfaces

Excessive brake disc thickness

variation

Excessive brake disc runout

Wheel bearing wear or failure

Suspension bushing wear or failure

Steering bushing wear or failure GO to Pinpoint Test B. The brakes pull or drift

Tire pressures/wear

Brake calipers

Brake pads

Brake discs

Wheel alignment adjustment

Wheel bearing

Suspension bushings and ball joints GO to Pinpoint Test C. The pedal feels spongy

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test D. The pedal goes down fast

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test E. The pedal goes down

slowly

Air in brake hydraulic system

Brake booster/master cylinder GO to Pinpoint Test F. Excessive brake pedal

effort required

Brake pads

Brake booster GO to Pinpoint Test G. Brake lockup during light

brake pedal force

Brake pads

Brake calipers GO to Pinpoint Test H. Brakes drag

Parking brake control

applied/malfunction

Seized parking brake cables

Seized brake caliper slide pins

Seized brake caliper

Brake booster

Pedal gear GO to Pinpoint Test I. Excessive/Erratic brake

pedal travel

Hydraulic system

Brake pads Brake

discs

Hub and bearing assembly GO to Pinpoint Test J. The red brake warning

indicator is always on

Fluid level

Brake master cylinder fluid level

sensor

Parking brake control Fill the system to specification. Check for leaks.

Install a new brake master cylinder fluid reservoir as

required.

REFER to: Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).