belt JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 204 of 3039

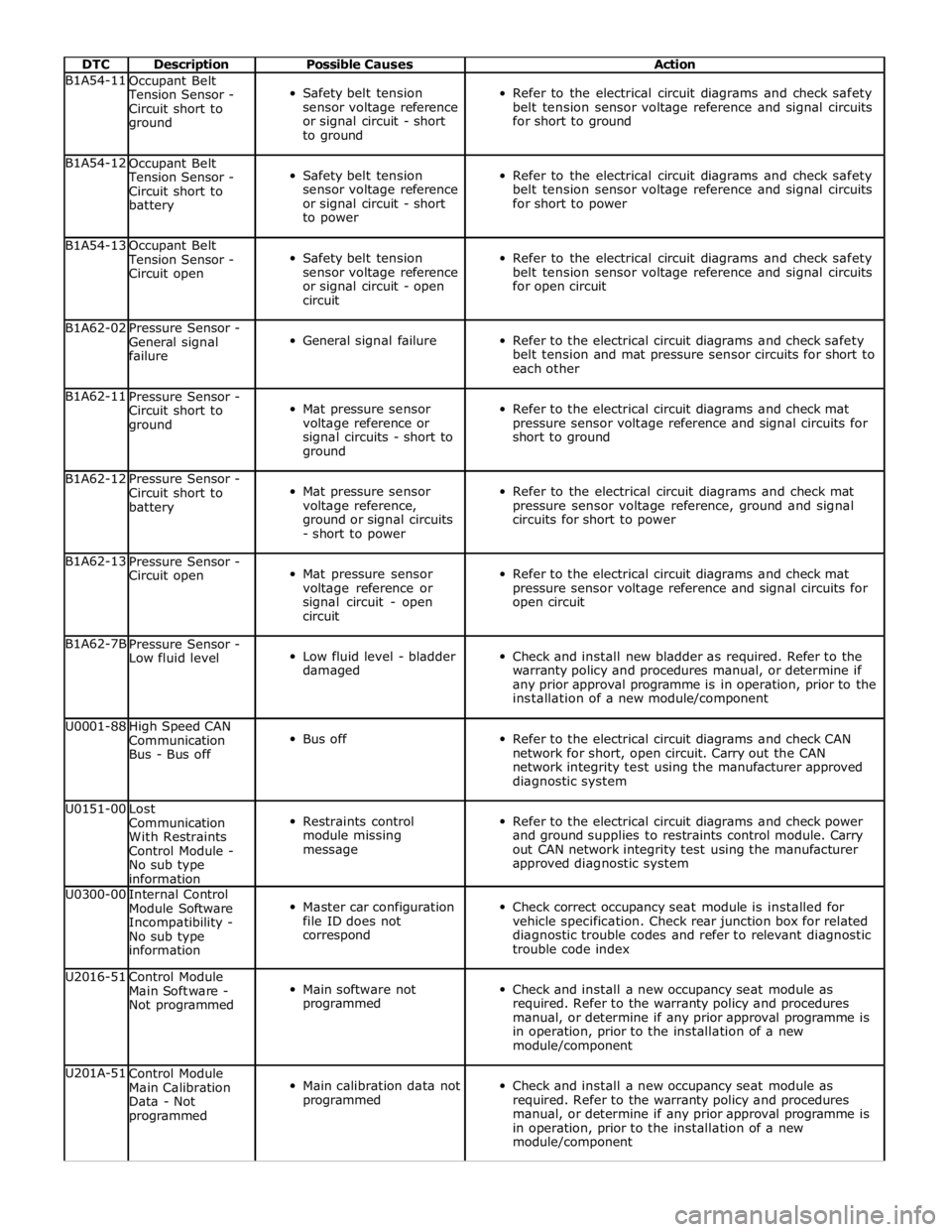

DTC Description Possible Causes Action B1A54-11

Occupant Belt Tension Sensor -

Circuit short to

ground

Safety belt tension

sensor voltage reference

or signal circuit - short

to ground

Refer to the electrical circuit diagrams and check safety

belt tension sensor voltage reference and signal circuits

for short to ground B1A54-12

Occupant Belt Tension Sensor -

Circuit short to

battery

Safety belt tension

sensor voltage reference

or signal circuit - short

to power

Refer to the electrical circuit diagrams and check safety

belt tension sensor voltage reference and signal circuits

for short to power B1A54-13

Occupant Belt Tension Sensor -

Circuit open

Safety belt tension

sensor voltage reference

or signal circuit - open

circuit

Refer to the electrical circuit diagrams and check safety

belt tension sensor voltage reference and signal circuits

for open circuit B1A62-02

Pressure Sensor -

General signal

failure

General signal failure

Refer to the electrical circuit diagrams and check safety

belt tension and mat pressure sensor circuits for short to

each other B1A62-11

Pressure Sensor -

Circuit short to

ground

Mat pressure sensor

voltage reference or

signal circuits - short to

ground

Refer to the electrical circuit diagrams and check mat

pressure sensor voltage reference and signal circuits for

short to ground B1A62-12

Pressure Sensor -

Circuit short to

battery

Mat pressure sensor

voltage reference,

ground or signal circuits

- short to power

Refer to the electrical circuit diagrams and check mat

pressure sensor voltage reference, ground and signal

circuits for short to power B1A62-13

Pressure Sensor -

Circuit open

Mat pressure sensor

voltage reference or

signal circuit - open

circuit

Refer to the electrical circuit diagrams and check mat

pressure sensor voltage reference and signal circuits for

open circuit B1A62-7B

Pressure Sensor -

Low fluid level

Low fluid level - bladder

damaged

Check and install new bladder as required. Refer to the

warranty policy and procedures manual, or determine if

any prior approval programme is in operation, prior to the

installation of a new module/component U0001-88

High Speed CAN

Communication

Bus - Bus off

Bus off

Refer to the electrical circuit diagrams and check CAN

network for short, open circuit. Carry out the CAN

network integrity test using the manufacturer approved

diagnostic system U0151-00

Lost

Communication

With Restraints

Control Module -

No sub type

information

Restraints control

module missing

message

Refer to the electrical circuit diagrams and check power

and ground supplies to restraints control module. Carry

out CAN network integrity test using the manufacturer

approved diagnostic system U0300-00

Internal Control

Module Software

Incompatibility -

No sub type

information

Master car configuration

file ID does not

correspond

Check correct occupancy seat module is installed for

vehicle specification. Check rear junction box for related

diagnostic trouble codes and refer to relevant diagnostic

trouble code index U2016-51

Control Module

Main Software -

Not programmed

Main software not

programmed

Check and install a new occupancy seat module as

required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is

in operation, prior to the installation of a new

module/component U201A-51

Control Module

Main Calibration

Data - Not

programmed

Main calibration data not

programmed

Check and install a new occupancy seat module as

required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is

in operation, prior to the installation of a new

module/component

Page 231 of 3039

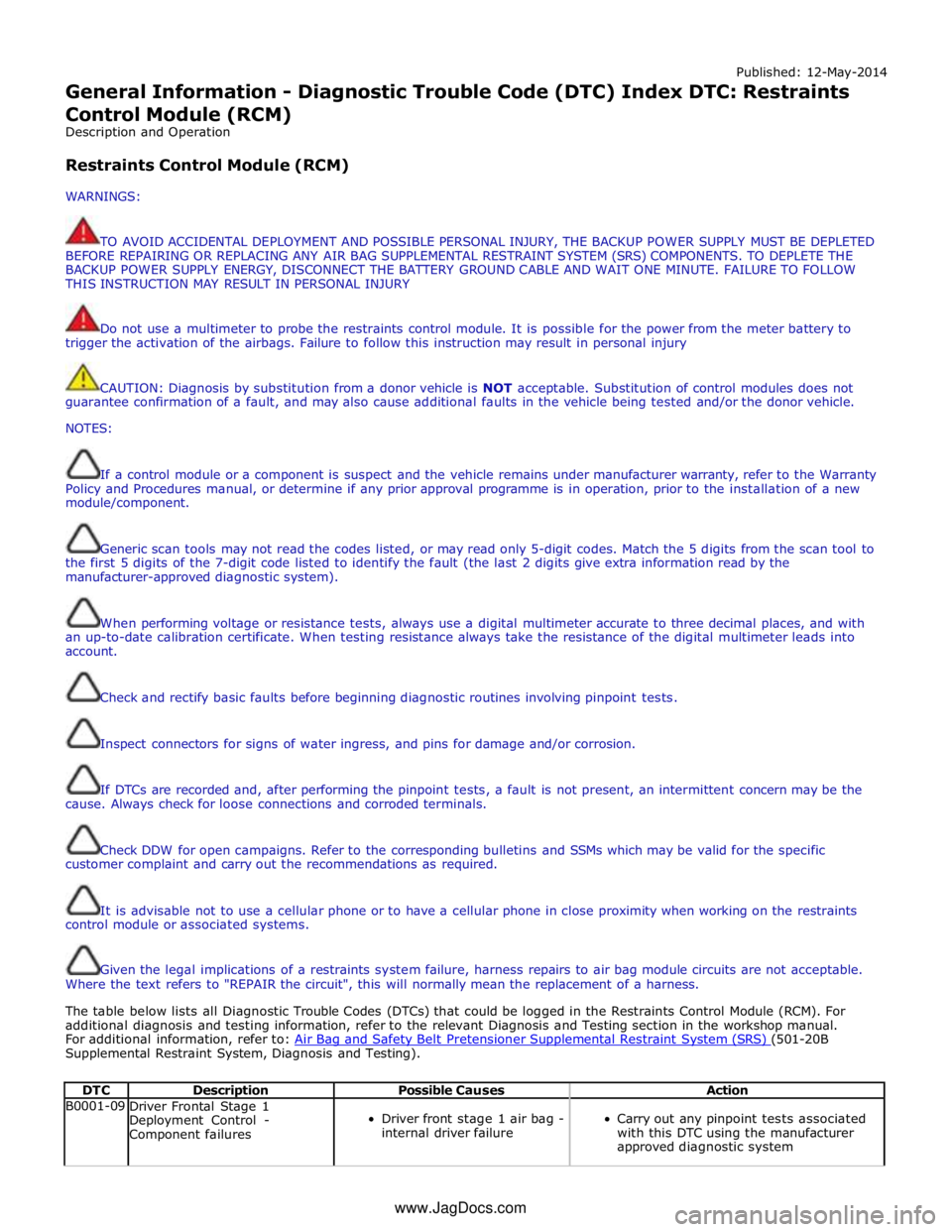

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Restraints

Control Module (RCM)

Description and Operation

Restraints Control Module (RCM)

WARNINGS:

TO AVOID ACCIDENTAL DEPLOYMENT AND POSSIBLE PERSONAL INJURY, THE BACKUP POWER SUPPLY MUST BE DEPLETED

BEFORE REPAIRING OR REPLACING ANY AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS) COMPONENTS. TO DEPLETE THE

BACKUP POWER SUPPLY ENERGY, DISCONNECT THE BATTERY GROUND CABLE AND WAIT ONE MINUTE. FAILURE TO FOLLOW

THIS INSTRUCTION MAY RESULT IN PERSONAL INJURY

Do not use a multimeter to probe the restraints control module. It is possible for the power from the meter battery to

trigger the activation of the airbags. Failure to follow this instruction may result in personal injury

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

It is advisable not to use a cellular phone or to have a cellular phone in close proximity when working on the restraints

control module or associated systems.

Given the legal implications of a restraints system failure, harness repairs to air bag module circuits are not acceptable.

Where the text refers to "REPAIR the circuit", this will normally mean the replacement of a harness.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Restraints Control Module (RCM). For

additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (501-20B Supplemental Restraint System, Diagnosis and Testing).

DTC Description Possible Causes Action B0001-09

Driver Frontal Stage 1

Deployment Control -

Component failures

Driver front stage 1 air bag -

internal driver failure

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system www.JagDocs.com

Page 235 of 3039

DTC Description Possible Causes Action B0029-09

Right Curtain Deployment

Control 1 - Component failures

Right curtain deployment

control 1 circuit - internal

driver failure

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system B0029-11

Right Curtain Deployment

Control 1 - Circuit short to

ground

Right curtain deployment

control 1 circuit - short to

ground

Refer to electrical circuit diagrams and

check right curtain deployment control 1

circuit for short to ground B0029-12

Right Curtain Deployment

Control 1 - Circuit short to

battery

Right curtain deployment

control 1 circuit - short to

power

Refer to electrical circuit diagrams and

check right curtain deployment control 1

circuit for short to power B0029-1A

Right Curtain Deployment

Control 1 - Circuit resistance

below threshold

Circuit resistance below

threshold

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system B0029-1B

Right Curtain Deployment

Control 1 - Circuit resistance

above threshold

Circuit resistance above

threshold

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system B0029-1C

Right Curtain Deployment

Control 1 - Circuit voltage out

of range

Right curtain deployment

control 1 circuit - high

resistance

Refer to electrical circuit diagrams and

test right curtain deployment control 1

circuit for high resistance B0029-56

Right Curtain Deployment

Control 1 - Invalid/incomplete

configuration

Incompatible configuration

Re-configure the RCM using the

manufacturer approved diagnostic

system B0029-95

Right Curtain Deployment

Control 1 - Incorrect assembly

Crosscoupling with other

firing loop

Refer to electrical circuit diagrams and

test right curtain deployment control 1

circuit for crosscoupling with other firing

loop B0050-11

Driver Safety Belt Sensor -

Circuit short to ground

Driver safety belt sensor

circuit - short to ground

Refer to the electrical circuit diagrams

and test driver safety belt sensor circuit

for short to ground B0050-12

Driver Safety Belt Sensor -

Circuit short to battery

Driver safety belt sensor

circuit - short to power

Refer to the electrical circuit diagrams

and test driver safety belt sensor circuit

for short to power B0050-13

Driver Safety Belt Sensor -

Circuit open

Driver safety belt sensor

circuit - open circuit

Refer to the electrical circuit diagrams

and test driver safety belt sensor circuit

for open circuit B0050-1E

Driver Safety Belt Sensor -

Circuit resistance out of range

Driver safety belt sensor

circuit - resistance out of

range

Carry out any pinpoint tests associated

with this DTC using the manufacturer

approved diagnostic system B0050-56

Driver Safety Belt Sensor -

Invalid/incomplete

configuration

Incompatible configuration

Re-configure the RCM using the

manufacturer approved diagnostic

system B0052-11

Passenger Safety Belt Sensor -

Circuit short to ground

Passenger safety belt sensor

circuit - short to ground

Refer to the electrical circuit diagrams

and test passenger safety belt sensor

circuit for short to ground B0052-12

Passenger Safety Belt Sensor -

Circuit short to battery

Passenger safety belt sensor

circuit - short to power

Refer to the electrical circuit diagrams

and test passenger safety belt sensor

circuit for short to power B0052-13

Passenger Safety Belt Sensor -

Circuit open

Passenger safety belt sensor

circuit - open circuit

Refer to the electrical circuit diagrams

and test passenger safety belt sensor

circuit for open circuit

Page 301 of 3039

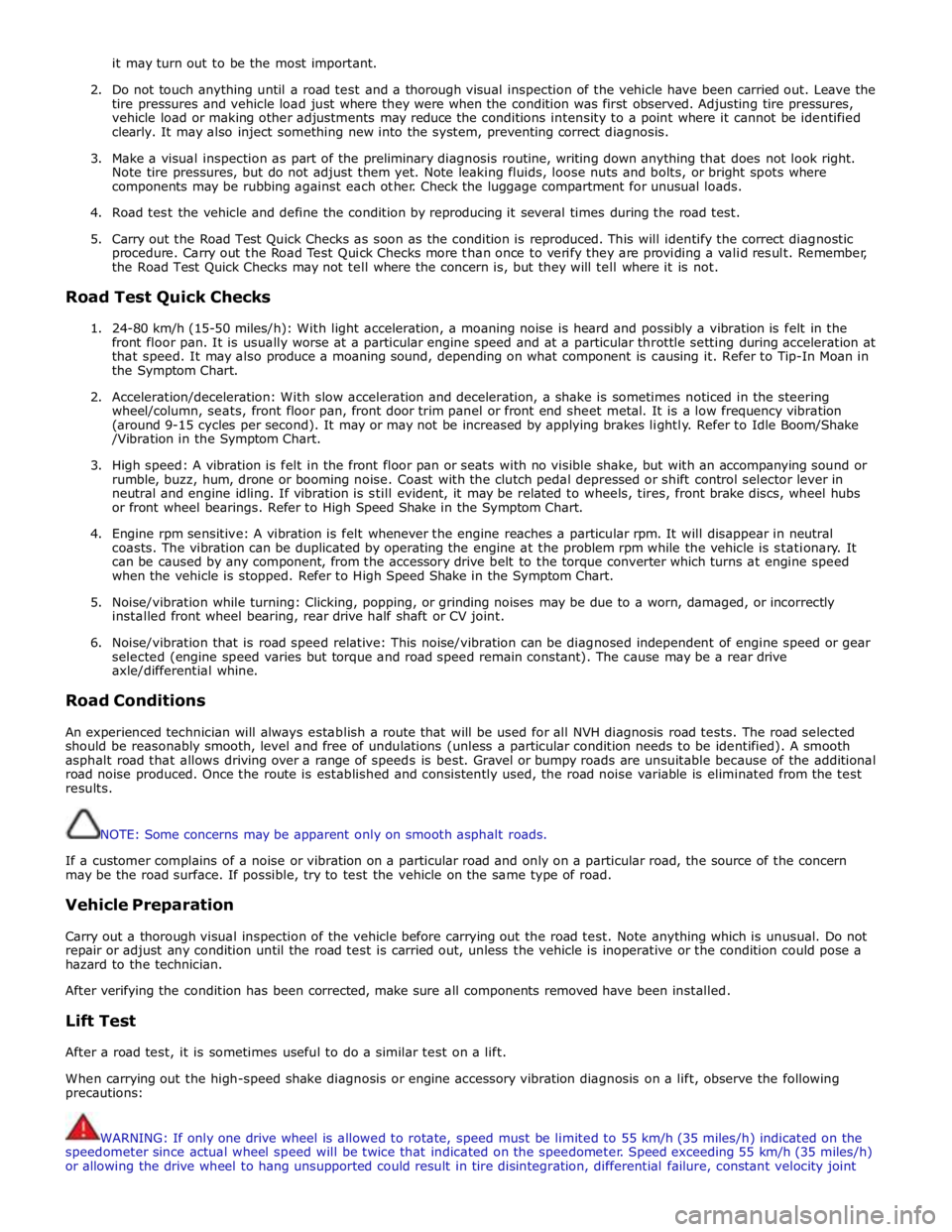

it may turn out to be the most important.

2. Do not touch anything until a road test and a thorough visual inspection of the vehicle have been carried out. Leave the

tire pressures and vehicle load just where they were when the condition was first observed. Adjusting tire pressures,

vehicle load or making other adjustments may reduce the conditions intensity to a point where it cannot be identified

clearly. It may also inject something new into the system, preventing correct diagnosis.

3. Make a visual inspection as part of the preliminary diagnosis routine, writing down anything that does not look right.

Note tire pressures, but do not adjust them yet. Note leaking fluids, loose nuts and bolts, or bright spots where

components may be rubbing against each other. Check the luggage compartment for unusual loads.

4. Road test the vehicle and define the condition by reproducing it several times during the road test.

5. Carry out the Road Test Quick Checks as soon as the condition is reproduced. This will identify the correct diagnostic

procedure. Carry out the Road Test Quick Checks more than once to verify they are providing a valid result. Remember,

the Road Test Quick Checks may not tell where the concern is, but they will tell where it is not.

Road Test Quick Checks

1. 24-80 km/h (15-50 miles/h): With light acceleration, a moaning noise is heard and possibly a vibration is felt in the

front floor pan. It is usually worse at a particular engine speed and at a particular throttle setting during acceleration at

that speed. It may also produce a moaning sound, depending on what component is causing it. Refer to Tip-In Moan in

the Symptom Chart.

2. Acceleration/deceleration: With slow acceleration and deceleration, a shake is sometimes noticed in the steering

wheel/column, seats, front floor pan, front door trim panel or front end sheet metal. It is a low frequency vibration

(around 9-15 cycles per second). It may or may not be increased by applying brakes lightly. Refer to Idle Boom/Shake

/Vibration in the Symptom Chart.

3. High speed: A vibration is felt in the front floor pan or seats with no visible shake, but with an accompanying sound or

rumble, buzz, hum, drone or booming noise. Coast with the clutch pedal depressed or shift control selector lever in

neutral and engine idling. If vibration is still evident, it may be related to wheels, tires, front brake discs, wheel hubs

or front wheel bearings. Refer to High Speed Shake in the Symptom Chart.

4. Engine rpm sensitive: A vibration is felt whenever the engine reaches a particular rpm. It will disappear in neutral

coasts. The vibration can be duplicated by operating the engine at the problem rpm while the vehicle is stationary. It

can be caused by any component, from the accessory drive belt to the torque converter which turns at engine speed

when the vehicle is stopped. Refer to High Speed Shake in the Symptom Chart.

5. Noise/vibration while turning: Clicking, popping, or grinding noises may be due to a worn, damaged, or incorrectly

installed front wheel bearing, rear drive half shaft or CV joint.

6. Noise/vibration that is road speed relative: This noise/vibration can be diagnosed independent of engine speed or gear

selected (engine speed varies but torque and road speed remain constant). The cause may be a rear drive

axle/differential whine.

Road Conditions

An experienced technician will always establish a route that will be used for all NVH diagnosis road tests. The road selected

should be reasonably smooth, level and free of undulations (unless a particular condition needs to be identified). A smooth

asphalt road that allows driving over a range of speeds is best. Gravel or bumpy roads are unsuitable because of the additional

road noise produced. Once the route is established and consistently used, the road noise variable is eliminated from the test

results.

NOTE: Some concerns may be apparent only on smooth asphalt roads.

If a customer complains of a noise or vibration on a particular road and only on a particular road, the source of the concern

may be the road surface. If possible, try to test the vehicle on the same type of road.

Vehicle Preparation

Carry out a thorough visual inspection of the vehicle before carrying out the road test. Note anything which is unusual. Do not

repair or adjust any condition until the road test is carried out, unless the vehicle is inoperative or the condition could pose a

hazard to the technician.

After verifying the condition has been corrected, make sure all components removed have been installed.

Lift Test

After a road test, it is sometimes useful to do a similar test on a lift.

When carrying out the high-speed shake diagnosis or engine accessory vibration diagnosis on a lift, observe the following

precautions:

WARNING: If only one drive wheel is allowed to rotate, speed must be limited to 55 km/h (35 miles/h) indicated on the

speedometer since actual wheel speed will be twice that indicated on the speedometer. Speed exceeding 55 km/h (35 miles/h)

or allowing the drive wheel to hang unsupported could result in tire disintegration, differential failure, constant velocity joint

Page 302 of 3039

and drive half shaft failure, which could cause serious personal injury and extensive vehicle damage. Failure to follow these

instructions may result in personal injury.

CAUTION: The suspension should not be allowed to hang free. When the CV joint is run at a very high angle, extra

vibration as well as damage to the seals and joints can occur.

The rear suspension lower arm should be supported as far outboard as possible. To bring the vehicle to its correct ride height,

the full weight of the vehicle should be supported in the rear by floor jacks. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

1. Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

2. Explore the speed range of interest using the Road Test Quick Checks as previously described.

3. Carry out a coast down in neutral. If the vehicle is free of vibration when operating at a steady indicated speed and

behaves very differently in drive and coast, a transmission concern is likely.

Note, however, that a test on the lift may produce different vibrations and noises than a road test because of the effect of the

lift. It is not unusual to find vibrations on the lift that were not found in the road test. If the condition found on the road can

be duplicated on the lift, carrying out experiments on the lift may save a great deal of time.

Exhaust Neutralization Procedure

1. Raise vehicle on lift and slacken all exhaust fixings.

2. With all fixings loose, neutralize the exhaust system.

3. Tighten all fixings to correct torque, starting at the rear-most point working towards the front of the vehicle.

Symptom Chart

Symptom Possible Cause Action High-speed shake

Wheel end vibration

Engine/transmission

Driveline GO to Pinpoint Test A. Tip-in moan

Air cleaner

Power steering

Powertrain

Engine mounts

Exhaust system GO to Pinpoint Test B. Idle boom/shake/vibration, or shudder

Cable(s)/hoses(s)

Intake air distribution and filtering system

Engine mounts

Exhaust system

Belt/pulleys GO to Pinpoint Test C. Wheel end vibration analysis

Suspension/rear drive halfshaft and CV joints

Tires/wheels

Wheel bearings

CV joint boots GO to Pinpoint Test D. Non-axle noise

Trim/mouldings

A/C system

Accessories GO to Pinpoint Test E. Pinpoint Tests

NOTE: These Pinpoint Tests are designed to take the technician through a step-by-step diagnosis procedure to determine

the cause of a condition. It may not always be necessary to follow the chart to its conclusion. Carry out only the Pinpoint Test

steps necessary to correct the condition. Then check operation of the system to make sure the condition is corrected.

After verifying that the condition has been corrected, make sure all components removed have been installed.

PINPOINT TEST A : HIGH-SPEED SHAKE TEST DETAILS/RESULTS/ACTIONS www.JagDocs.com

Page 303 of 3039

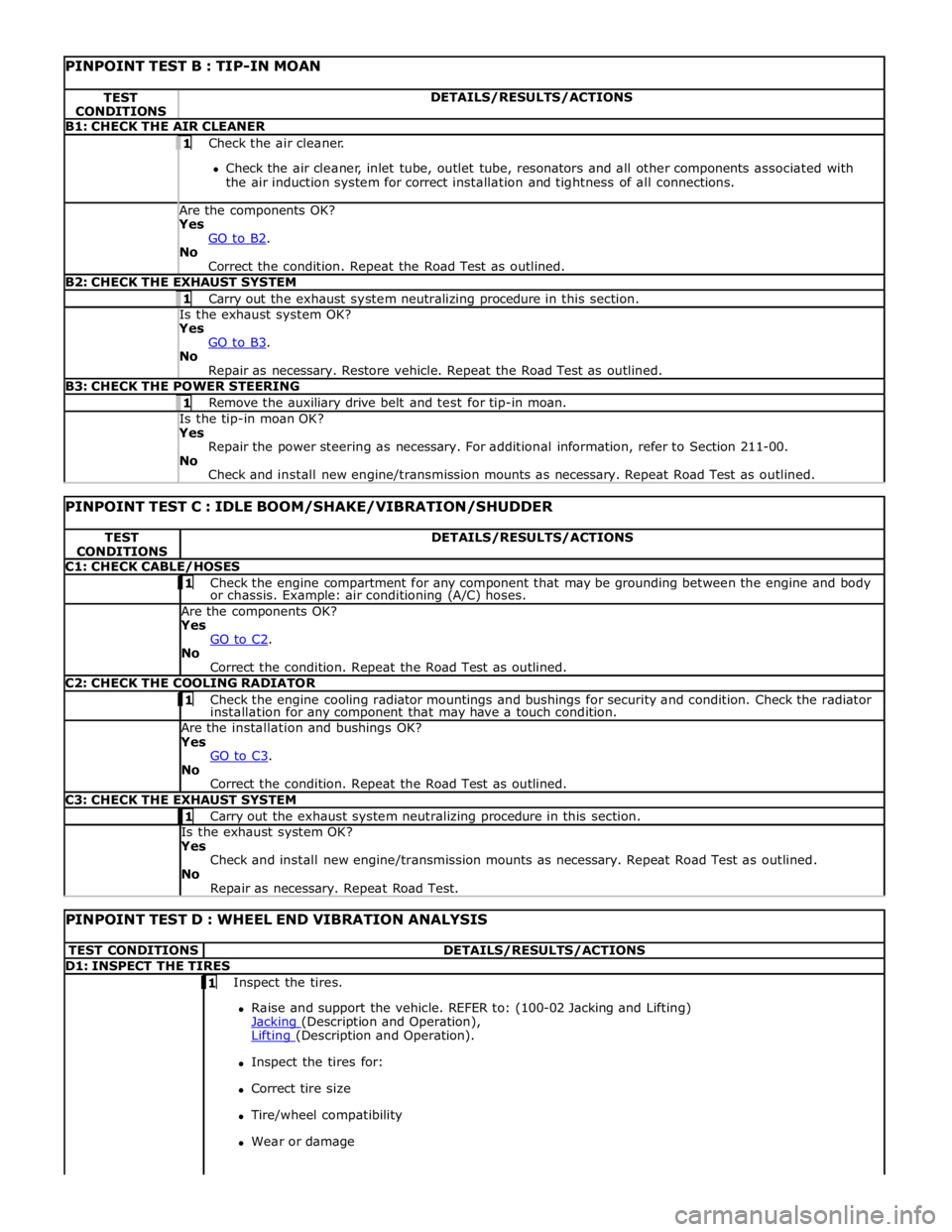

PINPOINT TEST B : TIP-IN MOAN TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: CHECK THE AIR CLEANER 1 Check the air cleaner.

Check the air cleaner, inlet tube, outlet tube, resonators and all other components associated with

the air induction system for correct installation and tightness of all connections. Are the components OK? Yes

GO to B2. No

Correct the condition. Repeat the Road Test as outlined. B2: CHECK THE EXHAUST SYSTEM 1 Carry out the exhaust system neutralizing procedure in this section. Is the exhaust system OK? Yes

GO to B3. No

Repair as necessary. Restore vehicle. Repeat the Road Test as outlined. B3: CHECK THE POWER STEERING 1 Remove the auxiliary drive belt and test for tip-in moan. Is the tip-in moan OK? Yes

Repair the power steering as necessary. For additional information, refer to Section 211-00.

No

Check and install new engine/transmission mounts as necessary. Repeat Road Test as outlined.

PINPOINT TEST C : IDLE BOOM/SHAKE/VIBRATION/SHUDDER TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CHECK CABLE/HOSES 1 Check the engine compartment for any component that may be grounding between the engine and body or chassis. Example: air conditioning (A/C) hoses. Are the components OK? Yes

GO to C2. No

Correct the condition. Repeat the Road Test as outlined. C2: CHECK THE COOLING RADIATOR 1 Check the engine cooling radiator mountings and bushings for security and condition. Check the radiator installation for any component that may have a touch condition. Are the installation and bushings OK? Yes

GO to C3. No

Correct the condition. Repeat the Road Test as outlined. C3: CHECK THE EXHAUST SYSTEM 1 Carry out the exhaust system neutralizing procedure in this section. Is the exhaust system OK? Yes

Check and install new engine/transmission mounts as necessary. Repeat Road Test as outlined.

No

Repair as necessary. Repeat Road Test.

PINPOINT TEST D : WHEEL END VIBRATION ANALYSIS TEST CONDITIONS DETAILS/RESULTS/ACTIONS D1: INSPECT THE TIRES 1 Inspect the tires.

Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

Inspect the tires for:

Correct tire size

Tire/wheel compatibility

Wear or damage

Page 722 of 3039

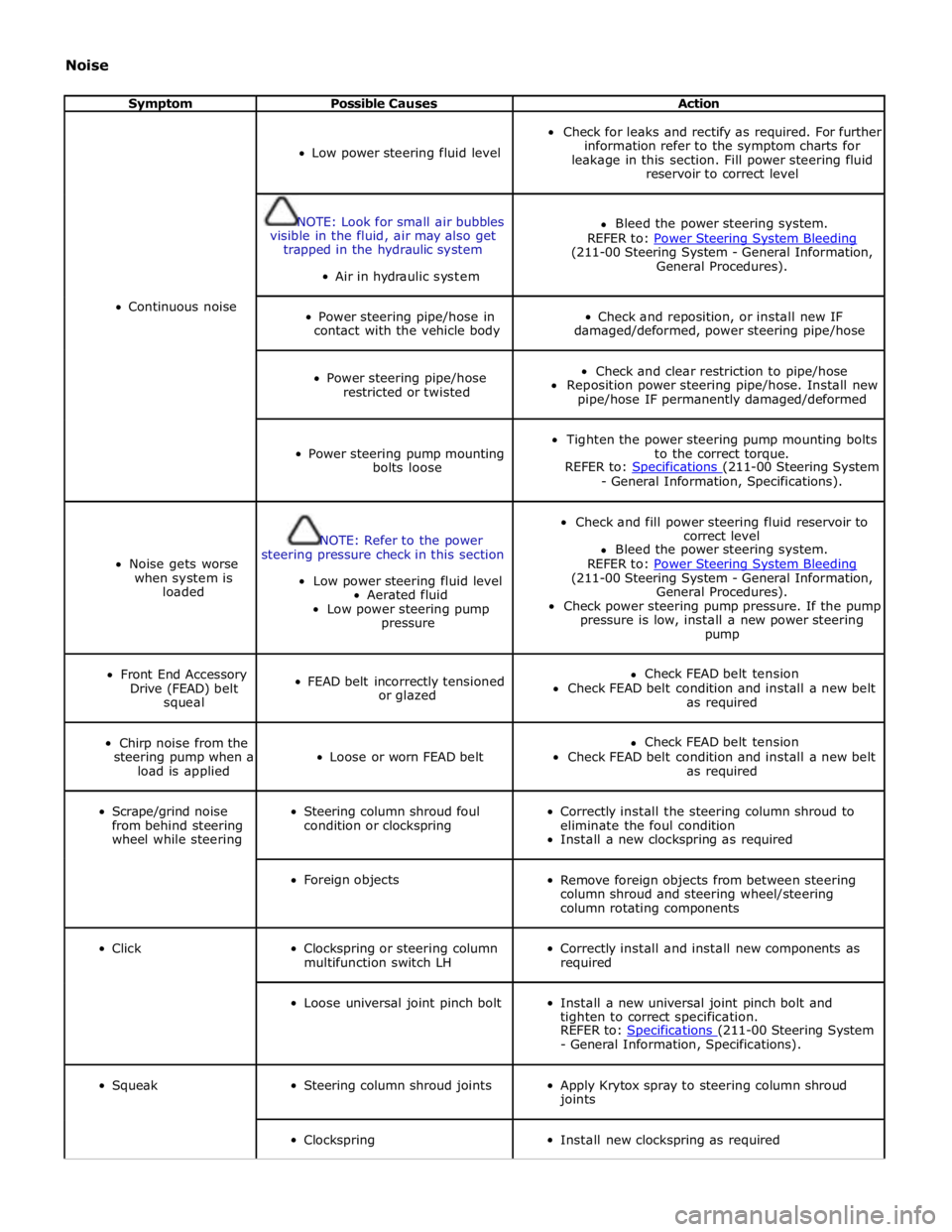

Noise

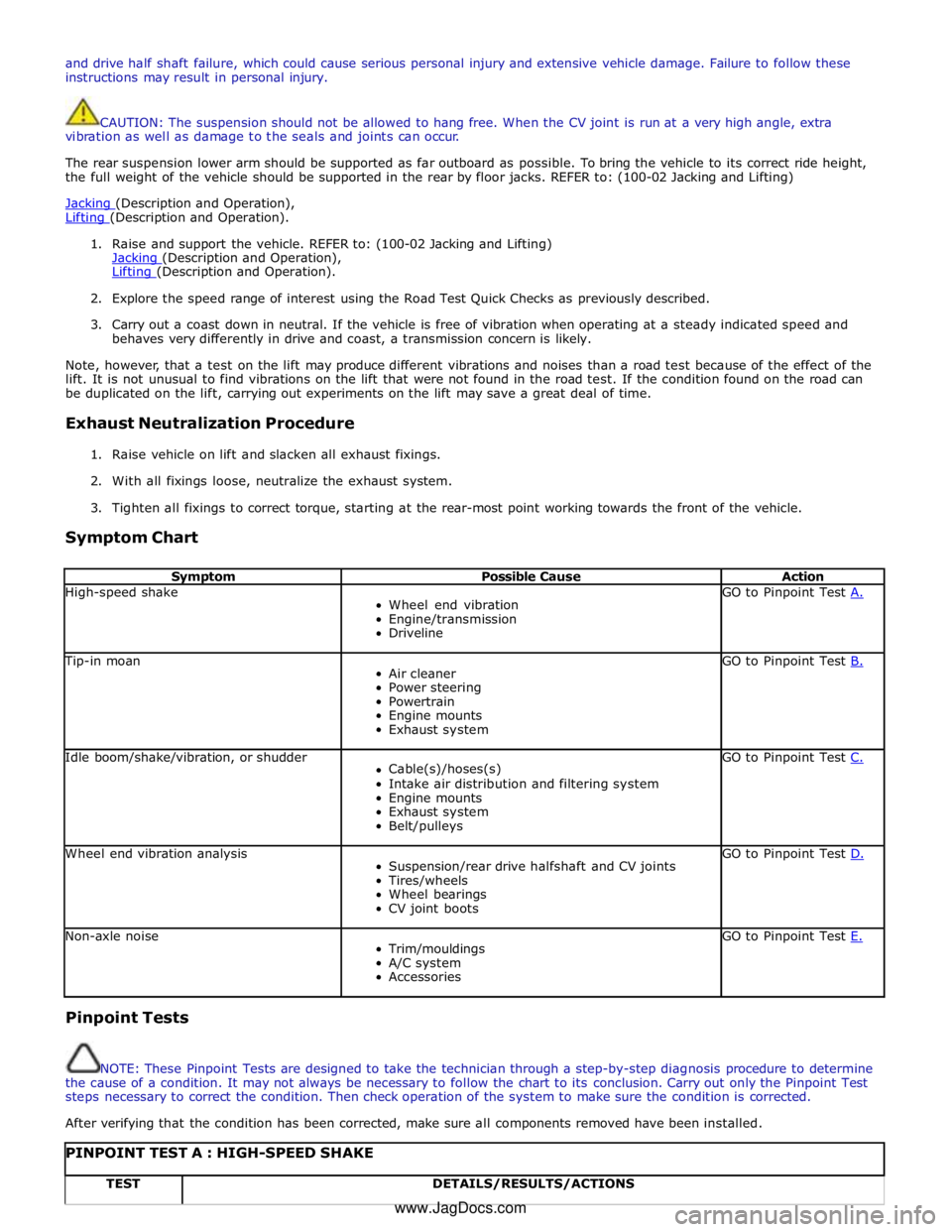

Symptom Possible Causes Action

Continuous noise

Low power steering fluid level

Check for leaks and rectify as required. For further

information refer to the symptom charts for

leakage in this section. Fill power steering fluid

reservoir to correct level

NOTE: Look for small air bubbles

visible in the fluid, air may also get

trapped in the hydraulic system

Air in hydraulic system

Bleed the power steering system.

REFER to: Power Steering System Bleeding (211-00 Steering System - General Information,

General Procedures).

Power steering pipe/hose in

contact with the vehicle body

Check and reposition, or install new IF

damaged/deformed, power steering pipe/hose

Power steering pipe/hose

restricted or twisted

Check and clear restriction to pipe/hose

Reposition power steering pipe/hose. Install new

pipe/hose IF permanently damaged/deformed

Power steering pump mounting

bolts loose

Tighten the power steering pump mounting bolts

to the correct torque.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Noise gets worse

when system is

loaded

NOTE: Refer to the power

steering pressure check in this section

Low power steering fluid level

Aerated fluid

Low power steering pump

pressure

Check and fill power steering fluid reservoir to

correct level

Bleed the power steering system.

REFER to: Power Steering System Bleeding (211-00 Steering System - General Information,

General Procedures).

Check power steering pump pressure. If the pump

pressure is low, install a new power steering

pump

Front End Accessory

Drive (FEAD) belt

squeal

FEAD belt incorrectly tensioned

or glazed

Check FEAD belt tension

Check FEAD belt condition and install a new belt

as required

Chirp noise from the

steering pump when a

load is applied

Loose or worn FEAD belt

Check FEAD belt tension

Check FEAD belt condition and install a new belt

as required

Scrape/grind noise

from behind steering

wheel while steering

Steering column shroud foul

condition or clockspring

Correctly install the steering column shroud to

eliminate the foul condition

Install a new clockspring as required

Foreign objects

Remove foreign objects from between steering

column shroud and steering wheel/steering

column rotating components

Click

Clockspring or steering column

multifunction switch LH

Correctly install and install new components as

required

Loose universal joint pinch bolt

Install a new universal joint pinch bolt and

tighten to correct specification.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Squeak

Steering column shroud joints

Apply Krytox spray to steering column shroud

joints

Clockspring

Install new clockspring as required

Page 726 of 3039

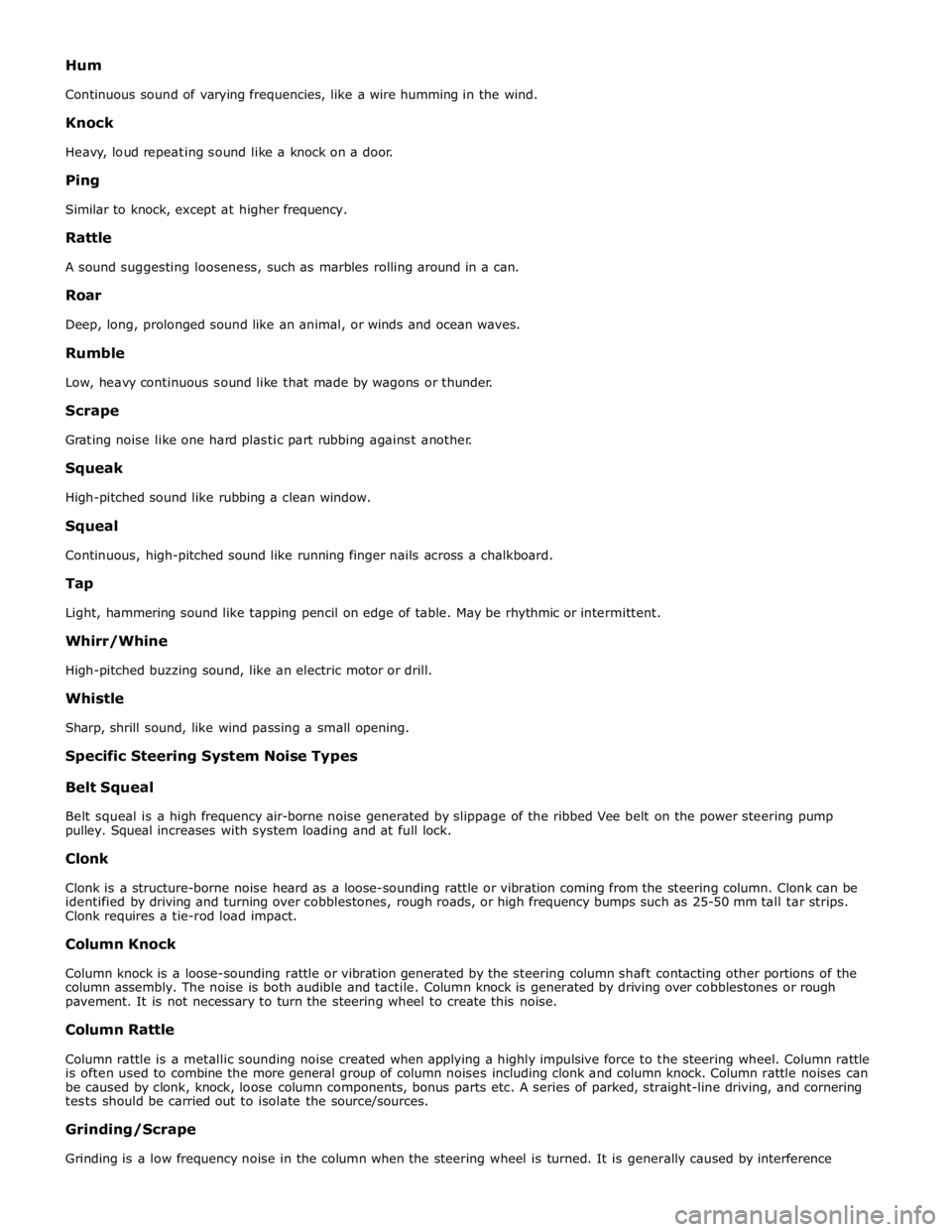

Hum

Continuous sound of varying frequencies, like a wire humming in the wind.

Knock

Heavy, loud repeating sound like a knock on a door.

Ping

Similar to knock, except at higher frequency.

Rattle

A sound suggesting looseness, such as marbles rolling around in a can.

Roar

Deep, long, prolonged sound like an animal, or winds and ocean waves.

Rumble

Low, heavy continuous sound like that made by wagons or thunder.

Scrape

Grating noise like one hard plastic part rubbing against another.

Squeak

High-pitched sound like rubbing a clean window.

Squeal

Continuous, high-pitched sound like running finger nails across a chalkboard.

Tap

Light, hammering sound like tapping pencil on edge of table. May be rhythmic or intermittent.

Whirr/Whine

High-pitched buzzing sound, like an electric motor or drill.

Whistle

Sharp, shrill sound, like wind passing a small opening.

Specific Steering System Noise Types

Belt Squeal

Belt squeal is a high frequency air-borne noise generated by slippage of the ribbed Vee belt on the power steering pump

pulley. Squeal increases with system loading and at full lock.

Clonk

Clonk is a structure-borne noise heard as a loose-sounding rattle or vibration coming from the steering column. Clonk can be

identified by driving and turning over cobblestones, rough roads, or high frequency bumps such as 25-50 mm tall tar strips.

Clonk requires a tie-rod load impact.

Column Knock

Column knock is a loose-sounding rattle or vibration generated by the steering column shaft contacting other portions of the

column assembly. The noise is both audible and tactile. Column knock is generated by driving over cobblestones or rough

pavement. It is not necessary to turn the steering wheel to create this noise.

Column Rattle

Column rattle is a metallic sounding noise created when applying a highly impulsive force to the steering wheel. Column rattle

is often used to combine the more general group of column noises including clonk and column knock. Column rattle noises can

be caused by clonk, knock, loose column components, bonus parts etc. A series of parked, straight-line driving, and cornering

tests should be carried out to isolate the source/sources.

Grinding/Scrape

Grinding is a low frequency noise in the column when the steering wheel is turned. It is generally caused by interference

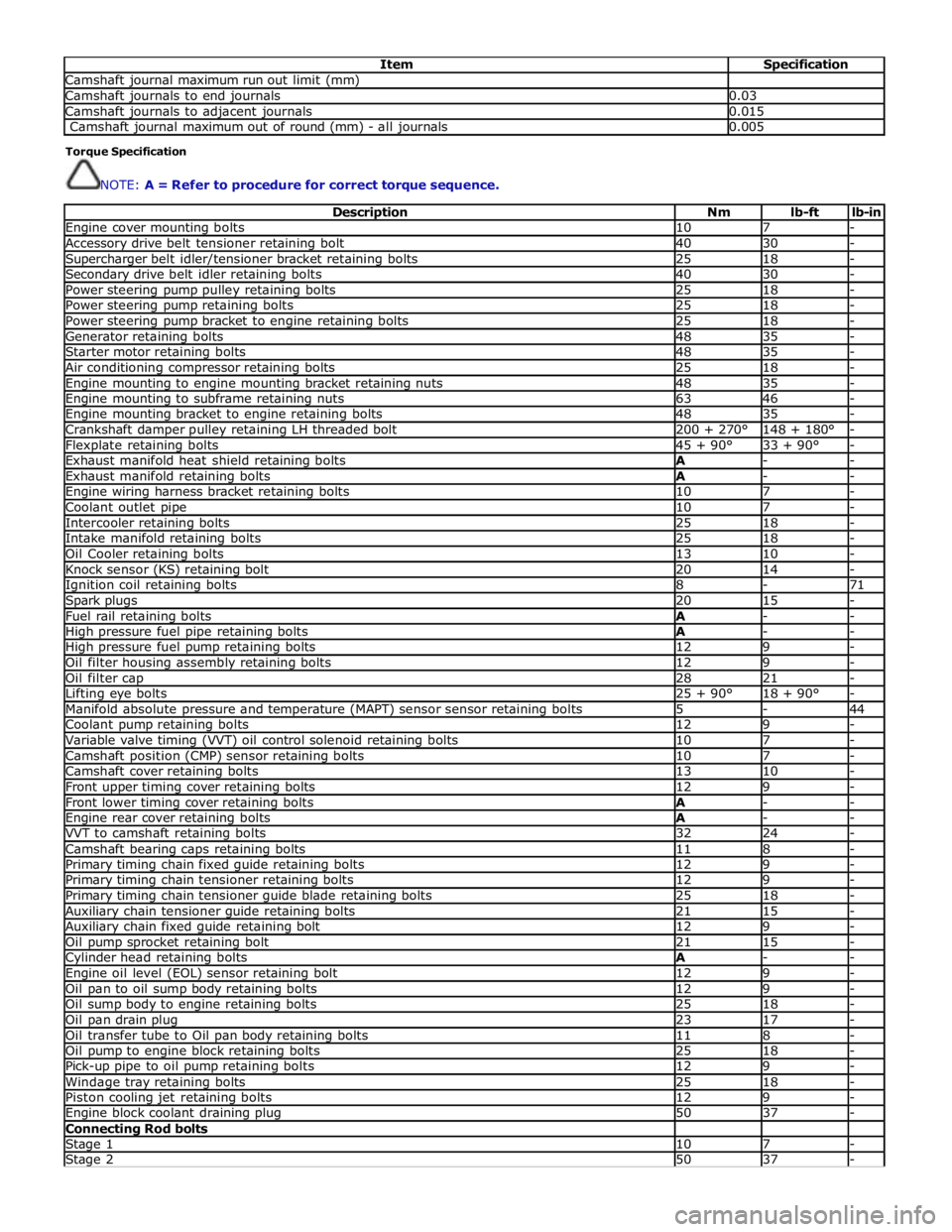

Page 845 of 3039

Item Specification Camshaft journal maximum run out limit (mm) Camshaft journals to end journals 0.03 Camshaft journals to adjacent journals 0.015 Camshaft journal maximum out of round (mm) - all journals 0.005 Torque Specification

NOTE: A = Refer to procedure for correct torque sequence.

Description Nm lb-ft lb-in Engine cover mounting bolts 10 7 - Accessory drive belt tensioner retaining bolt 40 30 - Supercharger belt idler/tensioner bracket retaining bolts 25 18 - Secondary drive belt idler retaining bolts 40 30 - Power steering pump pulley retaining bolts 25 18 - Power steering pump retaining bolts 25 18 - Power steering pump bracket to engine retaining bolts 25 18 - Generator retaining bolts 48 35 - Starter motor retaining bolts 48 35 - Air conditioning compressor retaining bolts 25 18 - Engine mounting to engine mounting bracket retaining nuts 48 35 - Engine mounting to subframe retaining nuts 63 46 - Engine mounting bracket to engine retaining bolts 48 35 - Crankshaft damper pulley retaining LH threaded bolt 200 + 270° 148 + 180° - Flexplate retaining bolts 45 + 90° 33 + 90° - Exhaust manifold heat shield retaining bolts A - - Exhaust manifold retaining bolts A - - Engine wiring harness bracket retaining bolts 10 7 - Coolant outlet pipe 10 7 - Intercooler retaining bolts 25 18 - Intake manifold retaining bolts 25 18 - Oil Cooler retaining bolts 13 10 - Knock sensor (KS) retaining bolt 20 14 - Ignition coil retaining bolts 8 - 71 Spark plugs 20 15 - Fuel rail retaining bolts A - - High pressure fuel pipe retaining bolts A - - High pressure fuel pump retaining bolts 12 9 - Oil filter housing assembly retaining bolts 12 9 - Oil filter cap 28 21 - Lifting eye bolts 25 + 90° 18 + 90° - Manifold absolute pressure and temperature (MAPT) sensor sensor retaining bolts 5 - 44 Coolant pump retaining bolts 12 9 - Variable valve timing (VVT) oil control solenoid retaining bolts 10 7 - Camshaft position (CMP) sensor retaining bolts 10 7 - Camshaft cover retaining bolts 13 10 - Front upper timing cover retaining bolts 12 9 - Front lower timing cover retaining bolts A - - Engine rear cover retaining bolts A - - VVT to camshaft retaining bolts 32 24 - Camshaft bearing caps retaining bolts 11 8 - Primary timing chain fixed guide retaining bolts 12 9 - Primary timing chain tensioner retaining bolts 12 9 - Primary timing chain tensioner guide blade retaining bolts 25 18 - Auxiliary chain tensioner guide retaining bolts 21 15 - Auxiliary chain fixed guide retaining bolt 12 9 - Oil pump sprocket retaining bolt 21 15 - Cylinder head retaining bolts A - - Engine oil level (EOL) sensor retaining bolt 12 9 - Oil pan to oil sump body retaining bolts 12 9 - Oil sump body to engine retaining bolts 25 18 - Oil pan drain plug 23 17 - Oil transfer tube to Oil pan body retaining bolts 11 8 - Oil pump to engine block retaining bolts 25 18 - Pick-up pipe to oil pump retaining bolts 12 9 - Windage tray retaining bolts 25 18 - Piston cooling jet retaining bolts 12 9 - Engine block coolant draining plug 50 37 - Connecting Rod bolts Stage 1 10 7 - Stage 2 50 37 -

Page 1025 of 3039

Engine - V8 S/C 5.0L Petrol - Timing Cover

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 12-Sep-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Accessory Drive Belt (303-05D Accessory Drive - V8 S/C 5.0L Petrol, Removal and Installation).

4. Refer to: Accessory Drive Belt Tensioner (303-05D Accessory Drive - V8 S/C 5.0L Petrol, Removal and Installation).

5. Refer to: Thermostat Housing - Vehicles With: Supercharger (303-03C Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and

Installation).

6. Refer to: Valve Cover LH (303-01D Engine - V8 S/C 5.0L Petrol, Removal and Installation).

7. Refer to: Valve Cover RH (303-01D Engine - V8 S/C 5.0L Petrol, Removal and Installation).

8. Refer to: Crankshaft Pulley (303-01D Engine - V8 S/C 5.0L Petrol, Removal and Installation).

9. NOTE: Engine shown removed for clarity.