drive transfer JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1412 of 3039

TCM (transmission control module) 6 Diagnostic socket 7 Instrument cluster 8 JaguarDrive selector 9 Clockspring 10 Steering wheel audio switches 11 Downshift paddle switch 12 Upshift paddle switch 13 ECM (engine control module)

POWER FLOWS System Operation

Operation of the transmission is controlled by the TCM (transmission control module), which electrically activates various

solenoids to control the transmission gear selection. The sequence of solenoid activation is based on programmed information

in the TCM memory and physical transmission operating conditions such as vehicle speed, throttle position, engine load and JaguarDrive selector position.

Item Description 1 Torque input from engine 2 Torque converter lock-up clutch 3 Single web planetary gear carrier 4 Single web planetary gears 5 Single web sunwheel 1 6 Double web sunwheel 2 7 Double web planetary gears - long 8 Double web planetary gear carrier 9 Double web planetary gears - short 10 Double web sunwheel 3 11 Torque output from transmission A Multiplate clutch B Multiplate clutch C Multiplate brake D Multiplate brake E Multiplate clutch Engine torque is transferred, via operation of single or combinations of clutches to the 2 planetary gear trains. Both gear trains

are controlled by reactionary inputs from brake clutches to produce the 6 forward gears and 1 reverse gear. The ratios are as

follows: www.JagDocs.com

Page 1427 of 3039

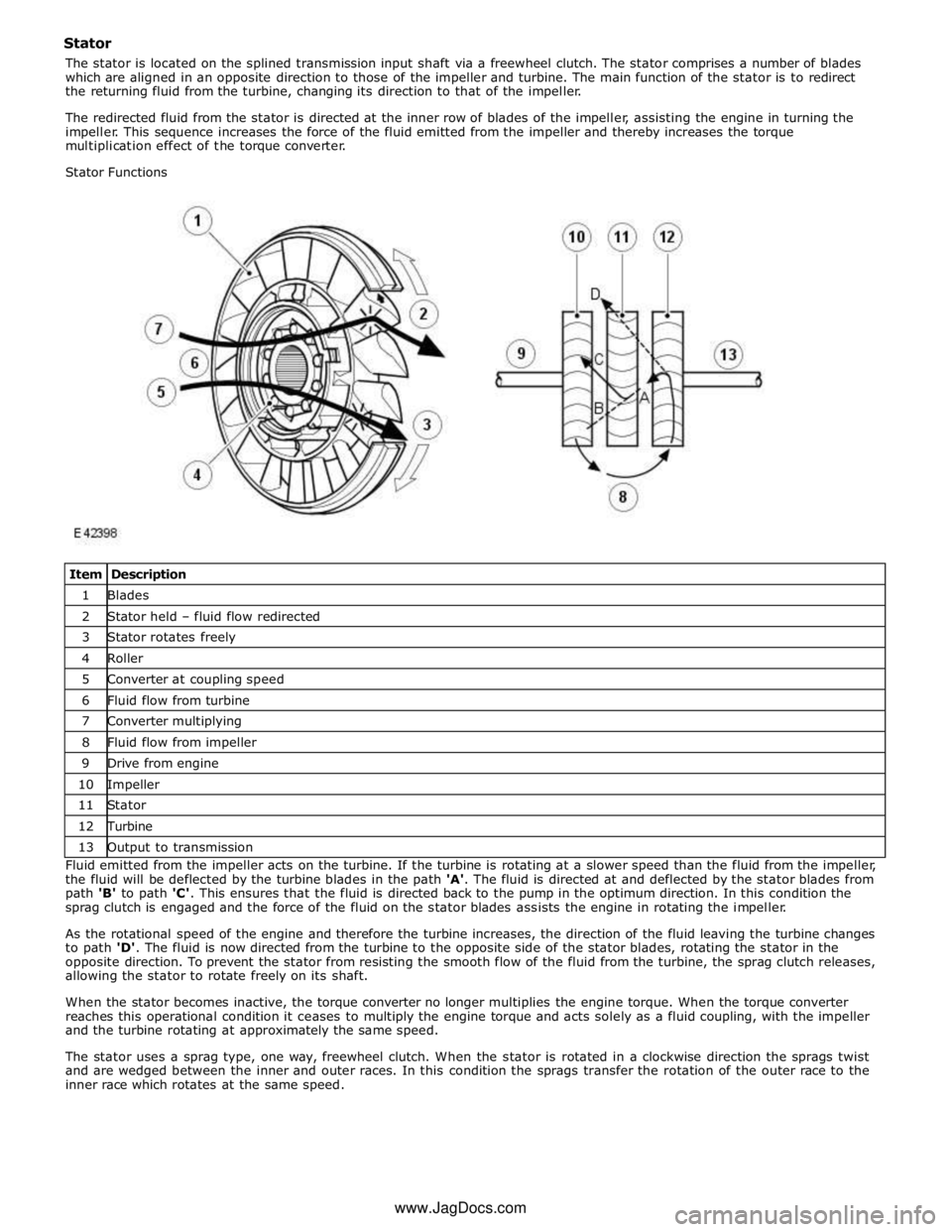

1 Blades 2 Stator held – fluid flow redirected 3 Stator rotates freely 4 Roller 5 Converter at coupling speed 6 Fluid flow from turbine 7 Converter multiplying 8 Fluid flow from impeller 9 Drive from engine 10 Impeller 11 Stator 12 Turbine 13 Output to transmission Fluid emitted from the impeller acts on the turbine. If the turbine is rotating at a slower speed than the fluid from the impeller,

the fluid will be deflected by the turbine blades in the path 'A'. The fluid is directed at and deflected by the stator blades from

path 'B' to path 'C'. This ensures that the fluid is directed back to the pump in the optimum direction. In this condition the

sprag clutch is engaged and the force of the fluid on the stator blades assists the engine in rotating the impeller.

As the rotational speed of the engine and therefore the turbine increases, the direction of the fluid leaving the turbine changes

to path 'D'. The fluid is now directed from the turbine to the opposite side of the stator blades, rotating the stator in the

opposite direction. To prevent the stator from resisting the smooth flow of the fluid from the turbine, the sprag clutch releases,

allowing the stator to rotate freely on its shaft.

When the stator becomes inactive, the torque converter no longer multiplies the engine torque. When the torque converter

reaches this operational condition it ceases to multiply the engine torque and acts solely as a fluid coupling, with the impeller

and the turbine rotating at approximately the same speed.

The stator uses a sprag type, one way, freewheel clutch. When the stator is rotated in a clockwise direction the sprags twist

and are wedged between the inner and outer races. In this condition the sprags transfer the rotation of the outer race to the

inner race which rotates at the same speed. www.JagDocs.com

Page 1428 of 3039

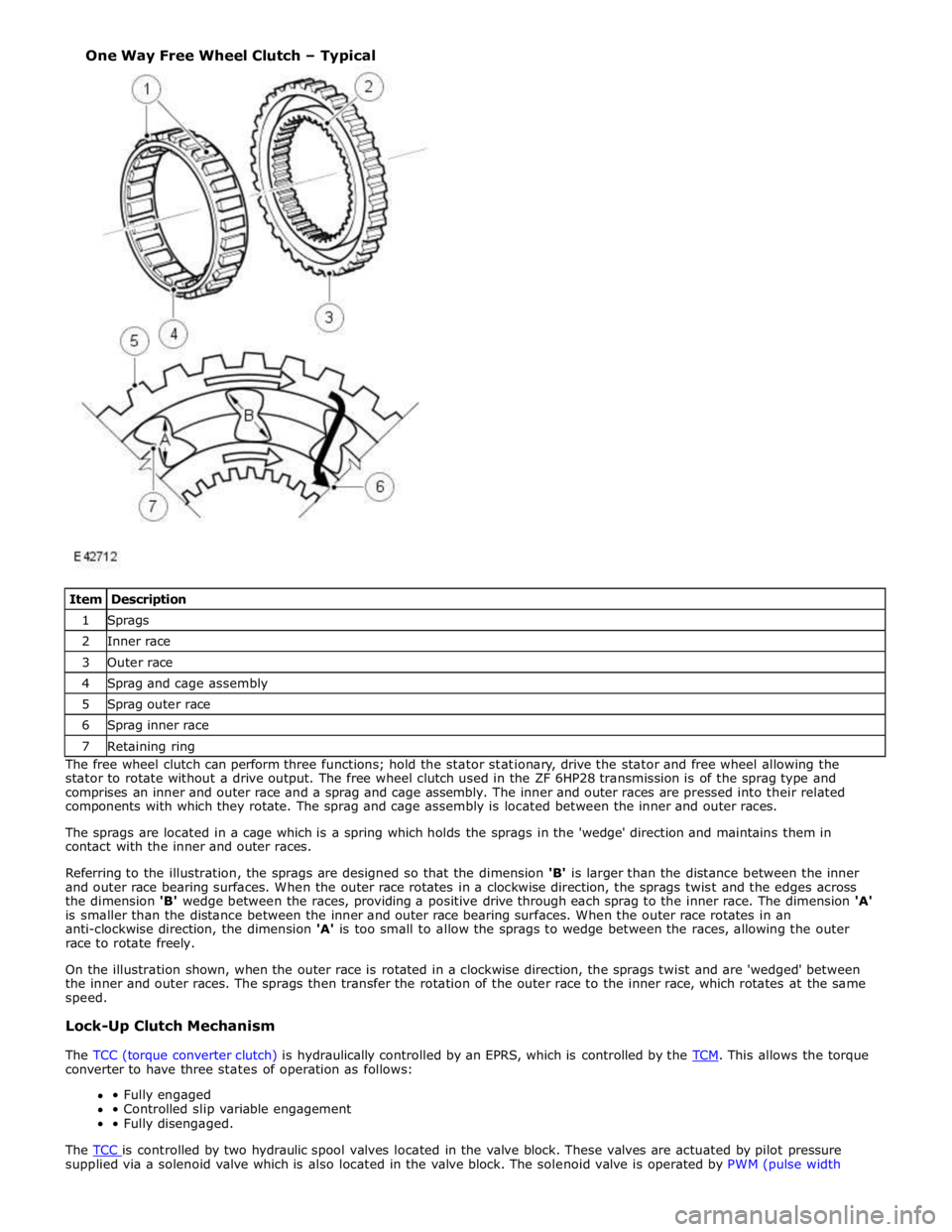

1 Sprags 2 Inner race 3 Outer race 4 Sprag and cage assembly 5 Sprag outer race 6 Sprag inner race 7 Retaining ring The free wheel clutch can perform three functions; hold the stator stationary, drive the stator and free wheel allowing the

stator to rotate without a drive output. The free wheel clutch used in the ZF 6HP28 transmission is of the sprag type and

comprises an inner and outer race and a sprag and cage assembly. The inner and outer races are pressed into their related

components with which they rotate. The sprag and cage assembly is located between the inner and outer races.

The sprags are located in a cage which is a spring which holds the sprags in the 'wedge' direction and maintains them in

contact with the inner and outer races.

Referring to the illustration, the sprags are designed so that the dimension 'B' is larger than the distance between the inner

and outer race bearing surfaces. When the outer race rotates in a clockwise direction, the sprags twist and the edges across

the dimension 'B' wedge between the races, providing a positive drive through each sprag to the inner race. The dimension 'A'

is smaller than the distance between the inner and outer race bearing surfaces. When the outer race rotates in an

anti-clockwise direction, the dimension 'A' is too small to allow the sprags to wedge between the races, allowing the outer

race to rotate freely.

On the illustration shown, when the outer race is rotated in a clockwise direction, the sprags twist and are 'wedged' between

the inner and outer races. The sprags then transfer the rotation of the outer race to the inner race, which rotates at the same

speed.

Lock-Up Clutch Mechanism

The TCC (torque converter clutch) is hydraulically controlled by an EPRS, which is controlled by the TCM. This allows the torque converter to have three states of operation as follows:

• Fully engaged

• Controlled slip variable engagement

• Fully disengaged.

The TCC is controlled by two hydraulic spool valves located in the valve block. These valves are actuated by pilot pressure supplied via a solenoid valve which is also located in the valve block. The solenoid valve is operated by PWM (pulse width One Way Free Wheel Clutch – Typical

Page 1430 of 3039

1 Securing ring 2 Shaft oil seal 3 O-ring seal 4 Pump housing 5 Ring gear 6 Crescent spacer 7 Roller bearing 8 Impeller 9 Centering pin 10 Spring washer 11 Outlet port (high pressure) 12 Inlet port (low pressure) The pump comprises a housing, a crescent spacer, an impeller and a ring gear. The housing has inlet and outlet ports to direct

flow and is located in the intermediate plate by a centering pin. The pump action is achieved by the impeller, ring gear and

crescent spacer.

The crescent spacer is fixed in its position by a pin and is located between the ring gear and the impeller. The impeller is

driven by drive from the torque converter hub which is located on a needle roller bearing in the pump housing. The impeller

teeth mesh with those of the ring gear. When the impeller is rotated, the motion is transferred to the ring gear which rotates

in the same direction.

The rotational motion of the ring gear and the impeller collects fluid from the intake port in the spaces between the teeth.

When the teeth reach the crescent spacer, the oil is trapped in the spaces between the teeth and is carried with the rotation

of the gears. The spacer tapers near the outlet port. This reduces the space between the gear teeth causing a build up of fluid

pressure as the oil reaches the outlet port. When the teeth pass the end of the spacer the pressurized fluid is released into

the outlet port.

The fluid emerging from the outlet port is passed through the fluid pressure control valve. At high operating speeds the

pressure control valve maintains the output pressure to the gearbox at a predetermined maximum level. Excess fluid is

relieved from the pressure control valve and is directed, via the main pressure valve in the valve block, back to the pump inlet

port. This provides a pressurized feed to the pump inlet which prevents cavitation and reduces pump noise.

Page 1443 of 3039

DTC Description Possible Cause Action P0967-12

Pressure Control Solenoid B

Control Circuit High - Circuit

Short to Battery

Pressure control solenoid

2 Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0968-14

Pressure Control Solenoid C

Control Circuit / Open -

Circuit Short to Ground or

Open

Pressure control solenoid

3 Circuit Short to Ground

or Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0970-11

Pressure Control Solenoid C

Control Circuit Low - Circuit

Short to Ground

Pressure control solenoid

3 Circuit Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0971-12

Pressure Control Solenoid C

Control Circuit High - Circuit

Short to Battery

Pressure control solenoid

3 Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0972-22

Shift Solenoid A Control

Circuit Range/Performance -

signal amplitude >

maximum

Pressure control solenoid

1 current too large Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0973-11

Shift Solenoid A Control

Circuit Low - Circuit Short to

Ground

Shift solenoid A control

Circuit Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0973-14

Shift Solenoid A Control

Circuit Low - Circuit Short to

Ground or Open

Pressure control solenoid

1 Circuit Short to Ground

or Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0973-1A

Shift Solenoid A Control

Circuit Low - Circuit

Resistance Below Threshold

Shift Solenoid A control

circuit resistance below

threshold Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0973-1E

Shift Solenoid A Control

Circuit Low - Circuit

Resistance Out Of Range

Shift Solenoid A control

circuit resistance out of

range Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0976-11

Shift Solenoid B Control

Circuit Low - Circuit Short to

Ground

Solenoid valve 2 Circuit

Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0976-14

Shift Solenoid B Control

Circuit Low - Circuit Short to

Ground or Open

Solenoid valve 2 Circuit

Short to Ground or Open

Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P1674-04

Control Module Software

Corrupted - System Internal

Failures

System internal failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P1674-48

Control Module Software

Corrupted - Supervision

Software Failure

Supervision software

failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P1707-07 Transfer Case Neutral or

Park/Neutral Indication

Circuit - commanded

position not reachable

Transfer case neutral or

park/neutral indication

circuit - mechanical

failures Clear the DTC. Test drive the Vehicle, engaging and

disengaging the parking lock several times. If the DTC

recurs, check parking lock components and replace as

required. If no faulty park lock component is found

Clear DTC and the DTC returns suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P1707-72 Transfer Case Neutral or

Park/Neutral Indication

Circuit - Actuator Stuck Open

Transfer case neutral or

park/neutral indication

circuit - Actuator stuck

open Clear the DTC. Test drive the Vehicle, engaging and

disengaging the parking lock several times. If the DTC

recurs, check parking lock components and replace as

required. If no faulty park lock component is found

Clear DTC and the DTC returns suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index

Page 1444 of 3039

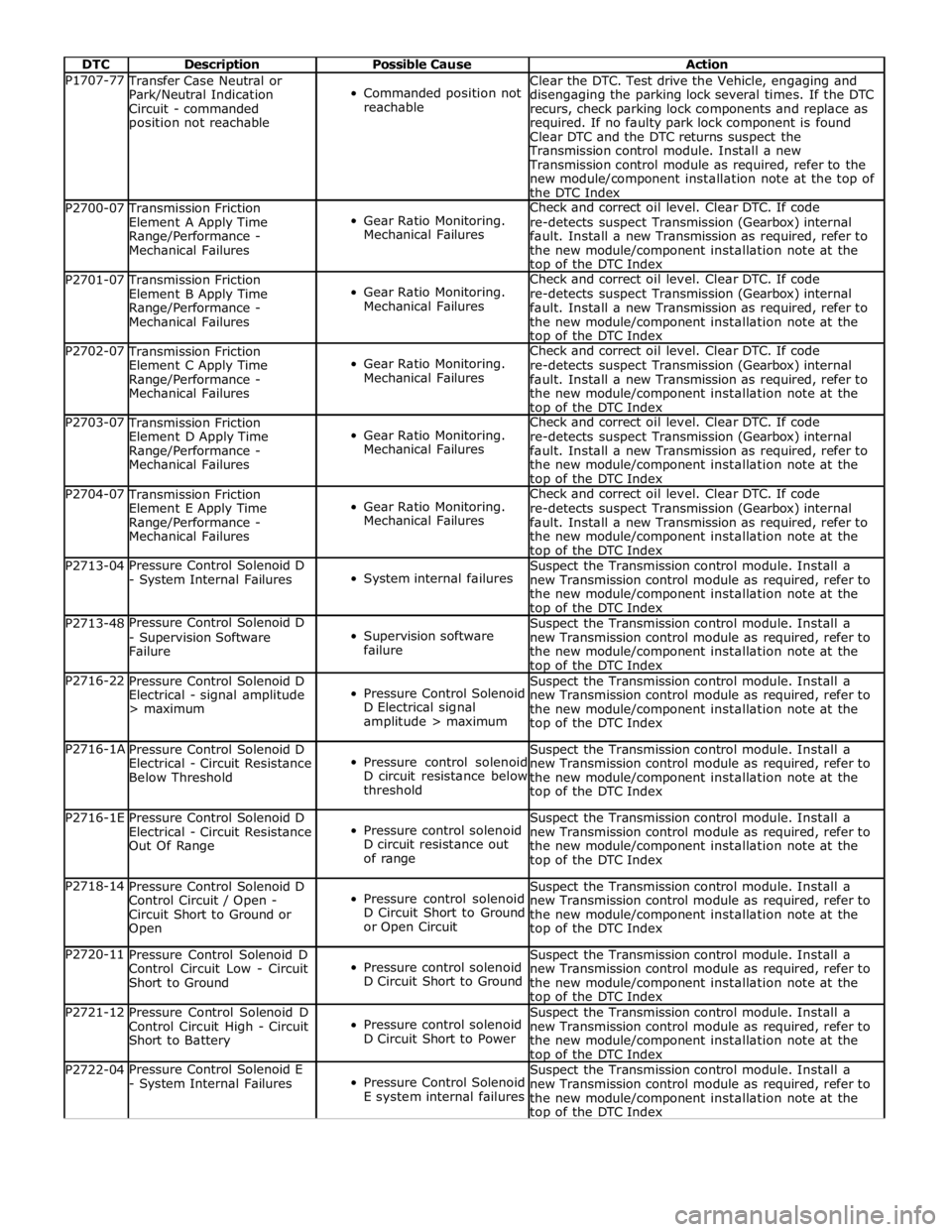

DTC Description Possible Cause Action P1707-77 Transfer Case Neutral or

Park/Neutral Indication

Circuit - commanded

position not reachable

Commanded position not

reachable Clear the DTC. Test drive the Vehicle, engaging and

disengaging the parking lock several times. If the DTC

recurs, check parking lock components and replace as

required. If no faulty park lock component is found

Clear DTC and the DTC returns suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P2700-07 Transmission Friction

Element A Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2701-07 Transmission Friction

Element B Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2702-07 Transmission Friction

Element C Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2703-07 Transmission Friction

Element D Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2704-07 Transmission Friction

Element E Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2713-04 Pressure Control Solenoid D

- System Internal Failures

System internal failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2713-48 Pressure Control Solenoid D

- Supervision Software

Failure

Supervision software

failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2716-22

Pressure Control Solenoid D

Electrical - signal amplitude

> maximum

Pressure Control Solenoid

D Electrical signal

amplitude > maximum Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2716-1A

Pressure Control Solenoid D

Electrical - Circuit Resistance

Below Threshold

Pressure control solenoid

D circuit resistance below

threshold Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2716-1E

Pressure Control Solenoid D

Electrical - Circuit Resistance

Out Of Range

Pressure control solenoid

D circuit resistance out

of range Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2718-14

Pressure Control Solenoid D

Control Circuit / Open -

Circuit Short to Ground or

Open

Pressure control solenoid

D Circuit Short to Ground

or Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2720-11

Pressure Control Solenoid D

Control Circuit Low - Circuit

Short to Ground

Pressure control solenoid

D Circuit Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2721-12

Pressure Control Solenoid D

Control Circuit High - Circuit

Short to Battery

Pressure control solenoid

D Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2722-04 Pressure Control Solenoid E

- System Internal Failures

Pressure Control Solenoid

E system internal failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index

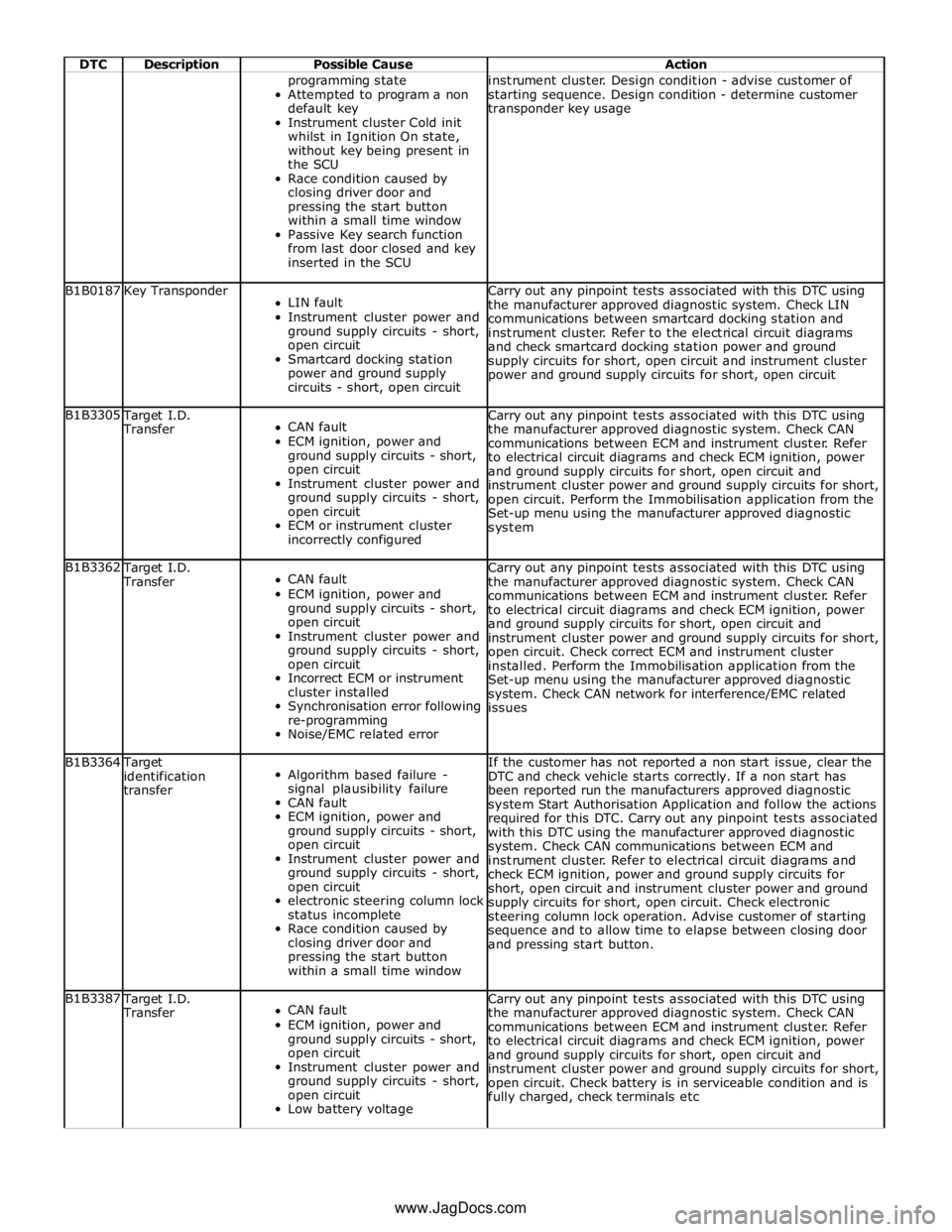

Page 1802 of 3039

DTC Description Possible Cause Action programming state

Attempted to program a non

default key

Instrument cluster Cold init

whilst in Ignition On state,

without key being present in

the SCU

Race condition caused by

closing driver door and

pressing the start button

within a small time window

Passive Key search function

from last door closed and key

inserted in the SCU instrument cluster. Design condition - advise customer of

starting sequence. Design condition - determine customer

transponder key usage B1B0187 Key Transponder

LIN fault

Instrument cluster power and

ground supply circuits - short,

open circuit

Smartcard docking station

power and ground supply

circuits - short, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check LIN

communications between smartcard docking station and

instrument cluster. Refer to the electrical circuit diagrams

and check smartcard docking station power and ground

supply circuits for short, open circuit and instrument cluster

power and ground supply circuits for short, open circuit B1B3305

Target I.D.

Transfer

CAN fault

ECM ignition, power and

ground supply circuits - short,

open circuit

Instrument cluster power and

ground supply circuits - short,

open circuit

ECM or instrument cluster

incorrectly configured Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CAN

communications between ECM and instrument cluster. Refer

to electrical circuit diagrams and check ECM ignition, power

and ground supply circuits for short, open circuit and

instrument cluster power and ground supply circuits for short,

open circuit. Perform the Immobilisation application from the

Set-up menu using the manufacturer approved diagnostic

system B1B3362

Target I.D.

Transfer

CAN fault

ECM ignition, power and

ground supply circuits - short,

open circuit

Instrument cluster power and

ground supply circuits - short,

open circuit

Incorrect ECM or instrument

cluster installed

Synchronisation error following

re-programming

Noise/EMC related error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CAN

communications between ECM and instrument cluster. Refer

to electrical circuit diagrams and check ECM ignition, power

and ground supply circuits for short, open circuit and

instrument cluster power and ground supply circuits for short,

open circuit. Check correct ECM and instrument cluster

installed. Perform the Immobilisation application from the

Set-up menu using the manufacturer approved diagnostic

system. Check CAN network for interference/EMC related

issues B1B3364

Target

identification

transfer

Algorithm based failure -

signal plausibility failure

CAN fault

ECM ignition, power and

ground supply circuits - short,

open circuit

Instrument cluster power and

ground supply circuits - short,

open circuit

electronic steering column lock

status incomplete

Race condition caused by

closing driver door and

pressing the start button

within a small time window If the customer has not reported a non start issue, clear the

DTC and check vehicle starts correctly. If a non start has

been reported run the manufacturers approved diagnostic

system Start Authorisation Application and follow the actions

required for this DTC. Carry out any pinpoint tests associated

with this DTC using the manufacturer approved diagnostic

system. Check CAN communications between ECM and

instrument cluster. Refer to electrical circuit diagrams and

check ECM ignition, power and ground supply circuits for

short, open circuit and instrument cluster power and ground

supply circuits for short, open circuit. Check electronic

steering column lock operation. Advise customer of starting

sequence and to allow time to elapse between closing door

and pressing start button. B1B3387

Target I.D.

Transfer

CAN fault

ECM ignition, power and

ground supply circuits - short,

open circuit

Instrument cluster power and

ground supply circuits - short,

open circuit

Low battery voltage Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CAN

communications between ECM and instrument cluster. Refer

to electrical circuit diagrams and check ECM ignition, power

and ground supply circuits for short, open circuit and

instrument cluster power and ground supply circuits for short,

open circuit. Check battery is in serviceable condition and is

fully charged, check terminals etc www.JagDocs.com

Page 1847 of 3039

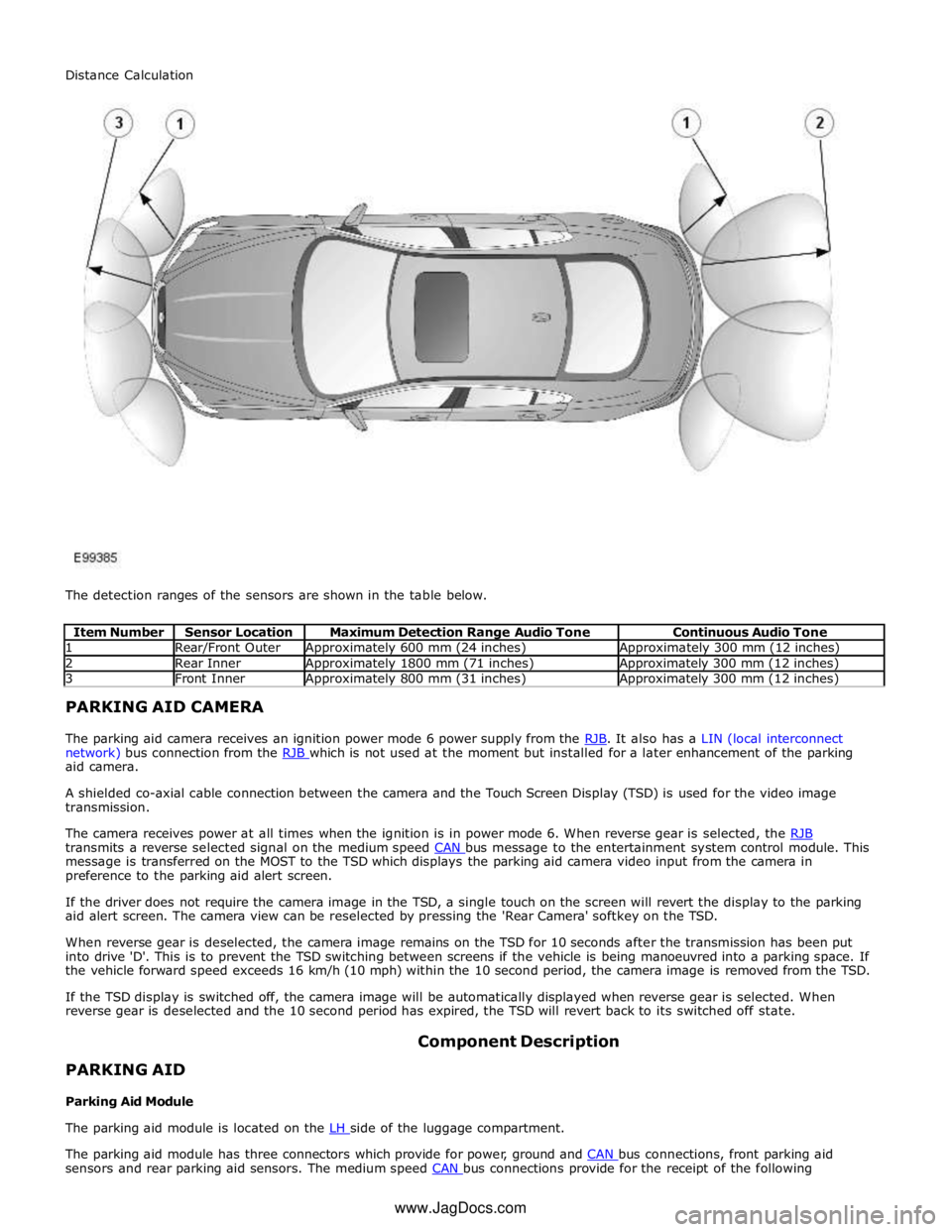

1 Rear/Front Outer Approximately 600 mm (24 inches) Approximately 300 mm (12 inches) 2 Rear Inner Approximately 1800 mm (71 inches) Approximately 300 mm (12 inches) 3 Front Inner Approximately 800 mm (31 inches) Approximately 300 mm (12 inches) PARKING AID CAMERA

The parking aid camera receives an ignition power mode 6 power supply from the RJB. It also has a LIN (local interconnect network) bus connection from the RJB which is not used at the moment but installed for a later enhancement of the parking aid camera.

A shielded co-axial cable connection between the camera and the Touch Screen Display (TSD) is used for the video image

transmission.

The camera receives power at all times when the ignition is in power mode 6. When reverse gear is selected, the RJB transmits a reverse selected signal on the medium speed CAN bus message to the entertainment system control module. This message is transferred on the MOST to the TSD which displays the parking aid camera video input from the camera in

preference to the parking aid alert screen.

If the driver does not require the camera image in the TSD, a single touch on the screen will revert the display to the parking

aid alert screen. The camera view can be reselected by pressing the 'Rear Camera' softkey on the TSD.

When reverse gear is deselected, the camera image remains on the TSD for 10 seconds after the transmission has been put

into drive 'D'. This is to prevent the TSD switching between screens if the vehicle is being manoeuvred into a parking space. If

the vehicle forward speed exceeds 16 km/h (10 mph) within the 10 second period, the camera image is removed from the TSD.

If the TSD display is switched off, the camera image will be automatically displayed when reverse gear is selected. When

reverse gear is deselected and the 10 second period has expired, the TSD will revert back to its switched off state.

PARKING AID

Parking Aid Module Component Description

The parking aid module is located on the LH side of the luggage compartment.

The parking aid module has three connectors which provide for power, ground and CAN bus connections, front parking aid sensors and rear parking aid sensors. The medium speed CAN bus connections provide for the receipt of the following Distance Calculation

www.JagDocs.com

Page 1849 of 3039

PARKING AID CAMERA

The parking aid camera receives an ignition power mode 6 power supply from the RJB. It also has a LIN bus connection with the RJB, which is used as a gateway. A shielded co-axial cable connection between the camera and the TSD is used for the video image transmission.

The camera receives power at all times when the ignition is in power mode 6. When reverse gear is selected, the RJB transmits a reverse selected message on the medium speed CAN bus. The information and entertainment module transfers the message on the MOST ring to the TSD, which displays the video input from the parking aid camera in preference to the parking

aid alert screen.

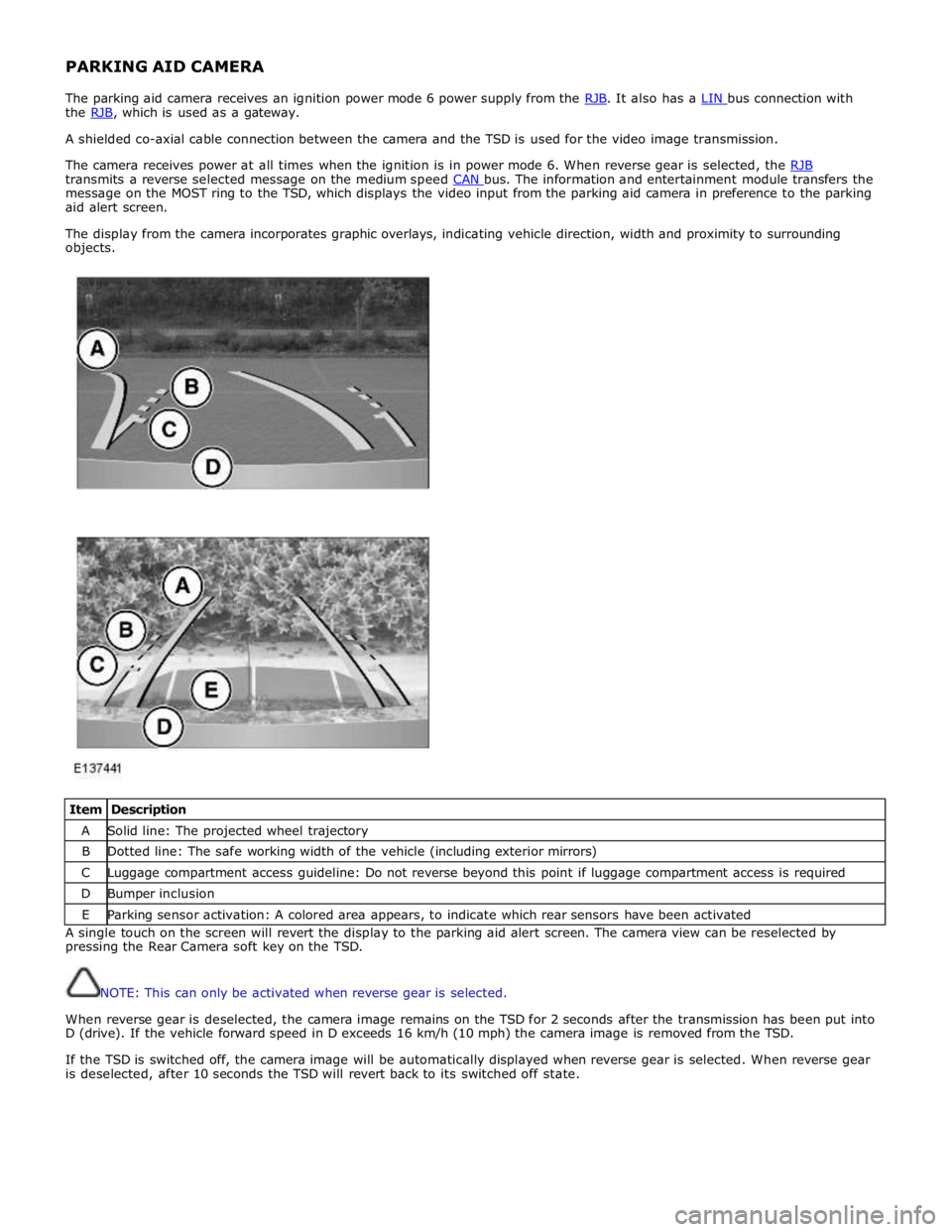

The display from the camera incorporates graphic overlays, indicating vehicle direction, width and proximity to surrounding

objects.

Item Description A Solid line: The projected wheel trajectory B Dotted line: The safe working width of the vehicle (including exterior mirrors) C Luggage compartment access guideline: Do not reverse beyond this point if luggage compartment access is required D Bumper inclusion E Parking sensor activation: A colored area appears, to indicate which rear sensors have been activated A single touch on the screen will revert the display to the parking aid alert screen. The camera view can be reselected by

pressing the Rear Camera soft key on the TSD.

NOTE: This can only be activated when reverse gear is selected.

When reverse gear is deselected, the camera image remains on the TSD for 2 seconds after the transmission has been put into

D (drive). If the vehicle forward speed in D exceeds 16 km/h (10 mph) the camera image is removed from the TSD.

If the TSD is switched off, the camera image will be automatically displayed when reverse gear is selected. When reverse gear

is deselected, after 10 seconds the TSD will revert back to its switched off state.

Page 1948 of 3039

3 Satellite Radio digital receiver (Optional - NAS only) 4 Telephone control module (Optional) 5 Touch-screen 6 TV tuner (Optional) 7 Power amplifier (Not fitted to the Jaguar Sound System) 8 IAM (integrated audio module) 9 Portable audio module (Optional) 10 ICM (information control module)

AUDIO SYSTEM OPERATION System Operation

The components of the audio/infotainment system are all connected on the MOST (media orientated systems transport) ring.

The MOST (media orientated systems transport) ring is a fibre optic communications bus for multimedia applications. Audio

and control information is passed around the MOST (media orientated systems transport) ring and can be picked up by any of

the systems units. For example, radio station tuning/selection input by the vehicle user into the Touch-screen is sent along the

MOST (media orientated systems transport) ring and collected by the IAM (integrated audio module) which then selects the

requested radio station.

MOST (media orientated systems transport) technology uses a plastic optical fibre which forms a network connecting the audio

and multimedia system components. Each component in the ring is connected to the plastic optical fibre through a device

known as a FOT (fibre optical transceiver). Each FOT (fibre optical transceiver) has two optical connections; one connection is

sensitive to light and is the input, the second connection forms the light source and is the output. The system operates by

connecting the output from one FOT (fibre optical transceiver) to the input of another FOT (fibre optical transceiver).

The light signals are sent in one direction only and are formed in the following way:

Electrical signals are converted into an electrical current

The current then drives an LED (light emitting diode) in the FOT (fibre optical transceiver) to produce a high intensity

red light

The LED transmits the light through a fibre optic cable A photo diode in the FOT (fibre optical transceiver) at the opposite end of the fibre optic cable detects the light.

The following components may be connected to the MOST ring dependant on the vehicle equipment level:

IAM (integrated audio module)

Touch-screen

ICM (information control module)

DAB (digital audio broadcasting) radio receiver (Optional - Europe only)

Satellite radio digital receiver (Optional - NAS only)

Power amplifier (Not fitted to the Jaguar Sound System)

Portable audio module (Optional)

Telephone control module (Optional)

Navigation computer (Optional)

TV tuner (Optional)

NOTE: Do not view the red light directly

MOST is a synchronous network. A timing master supplies the clock information and all other devices on the network

synchronize their operation to this clock. The timing master for the MOST (media orientated systems transport) network on this

vehicle is the ICM (information control module). This unit also controls and manages the MOST (media orientated systems

transport) ring and the system components.

An Optical Bus tester is used in conjunction with the Jaguar diagnostic system to diagnose the MOST (media orientated

systems transport) system. The Optical Bus tester emits a visible, high intensity red light which can be connected into the ring

at any point to test the ring integrity. Disconnecting a MOST (media orientated systems transport) connector will reveal if the

high intensity red light is visible.

If a break occurs in the MOST (media orientated systems transport) ring fault codes are stored in the ICM (information control

module) which can be retrieved using the Jaguar diagnostic system equipment.

With reference to the audio system information and signal transfer the instrument cluster is the gateway between the high

and medium speed CAN bus communication protocols. The ICM (information control module) is the gateway between medium speed CAN and the MOST (media orientated systems transport) systems.

A typical example of information transfer is vehicle speed information from the ABS (anti-lock brake system) module used to

control the automatic volume control function. The vehicle speed information from the ABS module is sent on the high speed CAN network and collected by the instrument panel gateway. The signal is passed to the medium speed CAN network and onto the ICM (information control module) gateway. The ICM (information control module) calculates the volume adjustment

required. The corrected audio volume level signal is sent on the MOST (media orientated systems transport) network to the

IAM (integrated audio module) or Power amplifier (dependant on vehicle equipment level) for output to the speaker system.