fuel type JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1429 of 3039

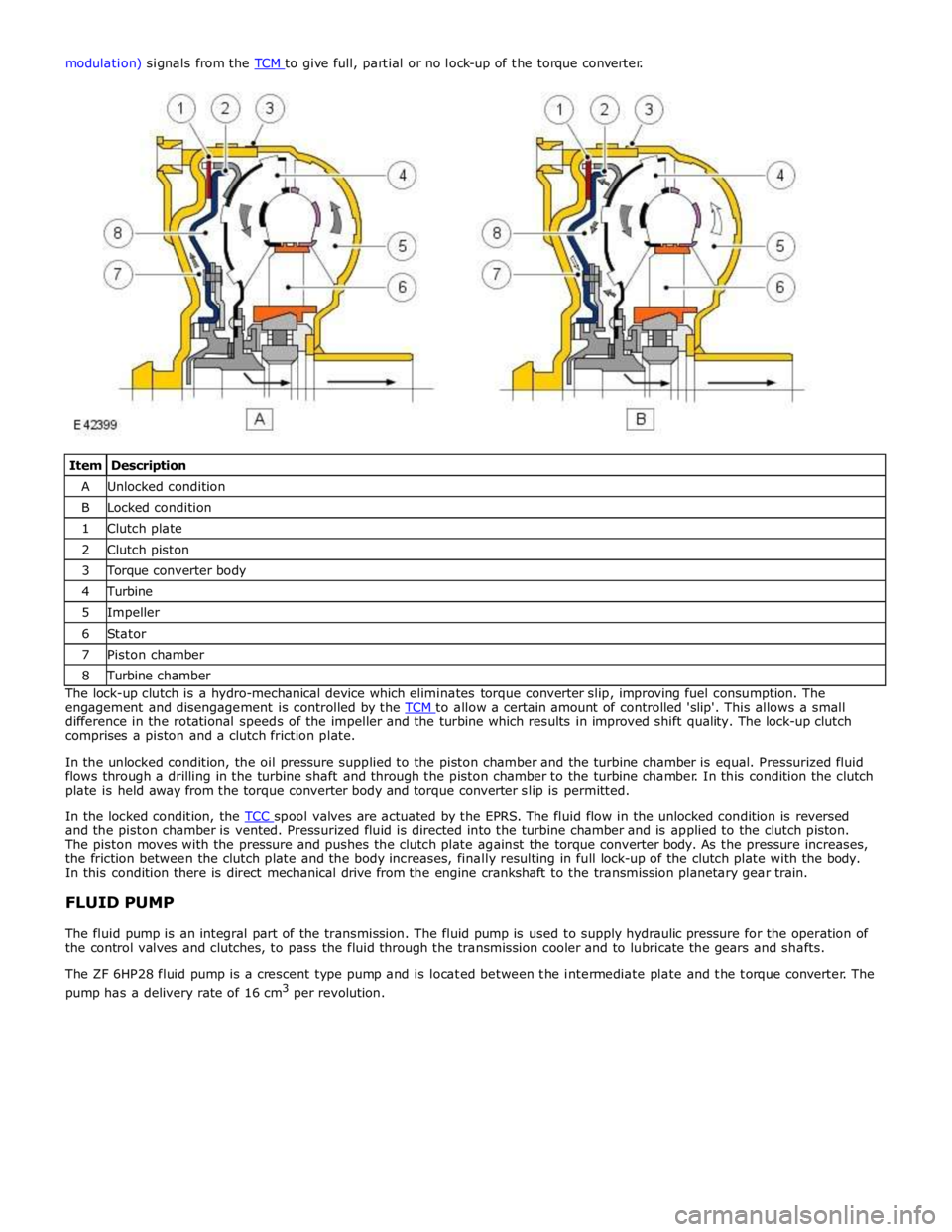

Item Description A Unlocked condition B Locked condition 1 Clutch plate 2 Clutch piston 3 Torque converter body 4 Turbine 5 Impeller 6 Stator 7 Piston chamber 8 Turbine chamber The lock-up clutch is a hydro-mechanical device which eliminates torque converter slip, improving fuel consumption. The

engagement and disengagement is controlled by the TCM to allow a certain amount of controlled 'slip'. This allows a small difference in the rotational speeds of the impeller and the turbine which results in improved shift quality. The lock-up clutch

comprises a piston and a clutch friction plate.

In the unlocked condition, the oil pressure supplied to the piston chamber and the turbine chamber is equal. Pressurized fluid

flows through a drilling in the turbine shaft and through the piston chamber to the turbine chamber. In this condition the clutch

plate is held away from the torque converter body and torque converter slip is permitted.

In the locked condition, the TCC spool valves are actuated by the EPRS. The fluid flow in the unlocked condition is reversed and the piston chamber is vented. Pressurized fluid is directed into the turbine chamber and is applied to the clutch piston.

The piston moves with the pressure and pushes the clutch plate against the torque converter body. As the pressure increases,

the friction between the clutch plate and the body increases, finally resulting in full lock-up of the clutch plate with the body.

In this condition there is direct mechanical drive from the engine crankshaft to the transmission planetary gear train.

FLUID PUMP

The fluid pump is an integral part of the transmission. The fluid pump is used to supply hydraulic pressure for the operation of

the control valves and clutches, to pass the fluid through the transmission cooler and to lubricate the gears and shafts.

The ZF 6HP28 fluid pump is a crescent type pump and is located between the intermediate plate and the torque converter. The

pump has a delivery rate of 16 cm3

per revolution.

Page 1573 of 3039

Fuel System - General Information - Spring Lock Couplings

General Procedures Published: 11-May-2011

Disconnect

1. WARNINGS:

Place the vehicle in a quarantined area and arrange "No

Smoking/Petrol Fumes" signs about the vehicle.

Before any work is carried out on the fuel system, ground the

vehicle to earth and maintain the ground connection until the work is

complete.

Do not smoke or carry lighted tobacco or open flame of any type

when working on or near any fuel related components. Highly flammable

vapors are always present and may ignite. Failure to follow these

instructions may result in personal injury.

The fuel system remains pressurized for a long time after the

ignition is switched off. The fuel pressure must be relieved before

attempting any repairs. Failure to follow these instructions may result in

personal injury.

After carrying out repairs, the fuel system must be checked visually

for leaks. Failure to follow these instructions may result in personal

injury.

This procedure involves fuel handling. Be prepared for fuel spillage

at all times and always observe fuel handling precautions. Failure to

follow these instructions may result in personal injury.

If taken internally do not induce vomiting, seek immediate medical

attention. Failure to follow these instructions may result in personal

injury.

If fuel contacts the eyes, flush the eyes with cold water or

eyewash solution and seek medical attention.

Wash hands thoroughly after handling, as prolonged contact may

cause irritation. Should irritation develop, seek medical attention.

Relieve the fuel system pressure. For additional information, refer to the

procedure in this section: Pressure Relief. Spring Lock Coupling Tool or Equivalent

310-D005 (23-040) Special Tool(s)

Page 1577 of 3039

Fuel System - General Information - Quick Release Coupling

General Procedures

Disconnect Published: 11-May-2011

1. WARNINGS:

Place the vehicle in a quarantined area and arrange "No

Smoking/Petrol Fumes" signs about the vehicle.

Before any work is carried out on the fuel system, ground the

vehicle to earth and maintain the ground connection until the work is

complete.

Do not smoke or carry lighted tobacco or open flame of any type

when working on or near any fuel related components. Highly flammable

vapors are always present and may ignite. Failure to follow these

instructions may result in personal injury.

The fuel system remains pressurized for a long time after the

ignition is switched off. The fuel pressure must be relieved before

attempting any repairs. Failure to follow these instructions may result in

personal injury.

After carrying out repairs, the fuel system must be checked visually

for leaks. Failure to follow these instructions may result in personal

injury.

This procedure involves fuel handling. Be prepared for fuel spillage

at all times and always observe fuel handling precautions. Failure to

follow these instructions may result in personal injury.

If taken internally do not induce vomiting, seek immediate medical

attention. Failure to follow these instructions may result in personal

injury.

If fuel contacts the eyes, flush the eyes with cold water or

eyewash solution and seek medical attention.

Wash hands thoroughly after handling, as prolonged contact may

cause irritation. Should irritation develop, seek medical attention.

Relieve the fuel system pressure. For additional information, refer to the

procedure in this section: Pressure Relief.

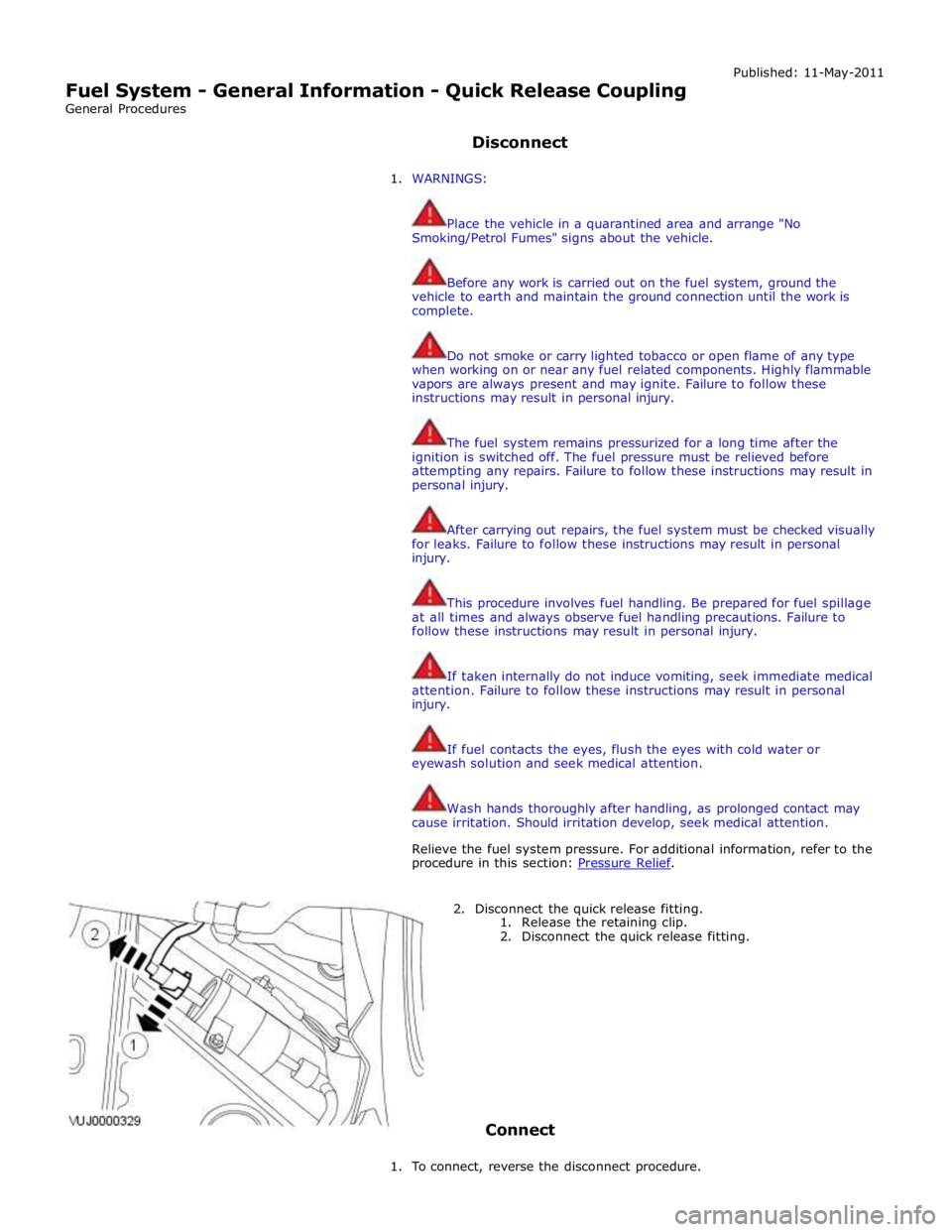

2. Disconnect the quick release fitting.

1. Release the retaining clip.

2. Disconnect the quick release fitting.

Connect

1. To connect, reverse the disconnect procedure.

Page 1578 of 3039

Published: 11-May-2011

Fuel System - General Information - Quick Release Coupling - Push Connect

General Procedures

Disconnect

1. WARNINGS:

Place the vehicle in a quarantined area and arrange "No

Smoking/Petrol Fumes" signs about the vehicle.

Before any work is carried out on the fuel system, ground the

vehicle to earth and maintain the ground connection until the work is

complete.

Do not smoke or carry lighted tobacco or open flame of any type

when working on or near any fuel related components. Highly flammable

vapors are always present and may ignite. Failure to follow these

instructions may result in personal injury.

The fuel system remains pressurized for a long time after the

ignition is switched off. The fuel pressure must be relieved before

attempting any repairs. Failure to follow these instructions may result in

personal injury.

After carrying out repairs, the fuel system must be checked visually

for leaks. Failure to follow these instructions may result in personal

injury.

This procedure involves fuel handling. Be prepared for fuel spillage

at all times and always observe fuel handling precautions. Failure to

follow these instructions may result in personal injury.

If taken internally do not induce vomiting, seek immediate medical

attention. Failure to follow these instructions may result in personal

injury.

If fuel contacts the eyes, flush the eyes with cold water or

eyewash solution and seek medical attention.

Wash hands thoroughly after handling, as prolonged contact may

cause irritation. Should irritation develop, seek medical attention.

Relieve the fuel system pressure. For additional information, refer to the

procedure in this section:

For additional information, refer to: Fuel System Pressure Release

(310-00 Fuel System - General Information, General Procedures).

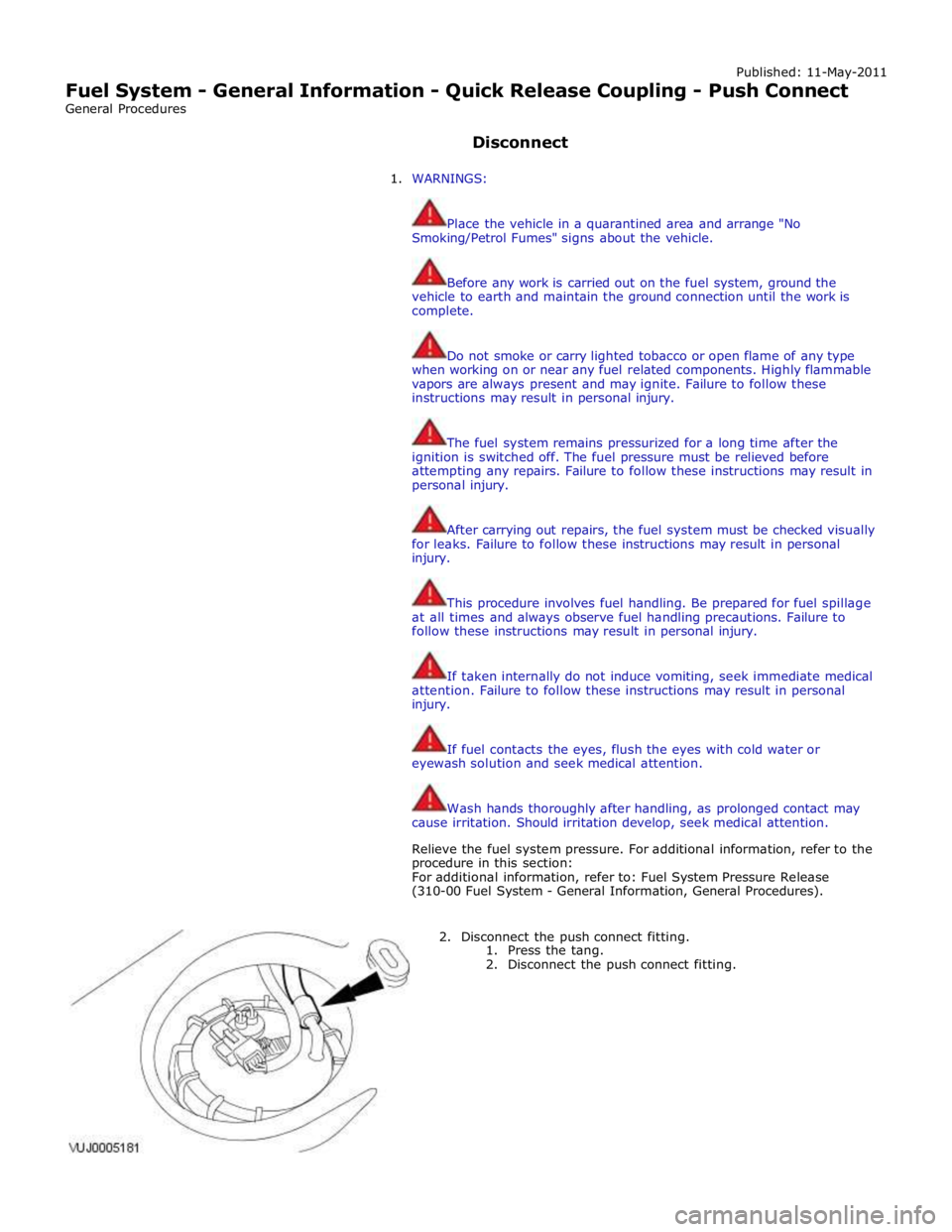

2. Disconnect the push connect fitting.

1. Press the tang.

2. Disconnect the push connect fitting.

Page 1586 of 3039

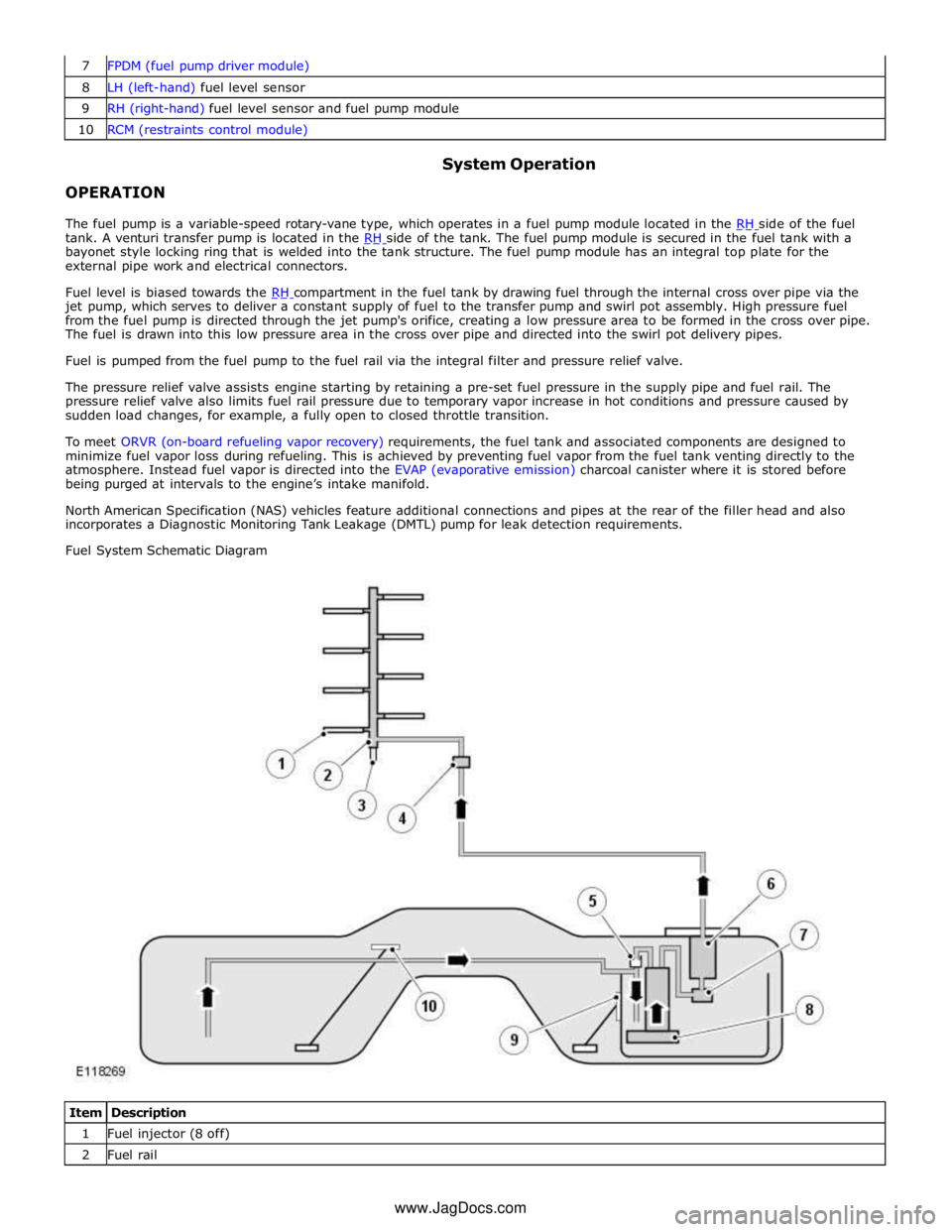

8 LH (left-hand) fuel level sensor 9 RH (right-hand) fuel level sensor and fuel pump module 10 RCM (restraints control module)

OPERATION System Operation

The fuel pump is a variable-speed rotary-vane type, which operates in a fuel pump module located in the RH side of the fuel tank. A venturi transfer pump is located in the RH side of the tank. The fuel pump module is secured in the fuel tank with a bayonet style locking ring that is welded into the tank structure. The fuel pump module has an integral top plate for the

external pipe work and electrical connectors.

Fuel level is biased towards the RH compartment in the fuel tank by drawing fuel through the internal cross over pipe via the jet pump, which serves to deliver a constant supply of fuel to the transfer pump and swirl pot assembly. High pressure fuel

from the fuel pump is directed through the jet pump's orifice, creating a low pressure area to be formed in the cross over pipe.

The fuel is drawn into this low pressure area in the cross over pipe and directed into the swirl pot delivery pipes.

Fuel is pumped from the fuel pump to the fuel rail via the integral filter and pressure relief valve.

The pressure relief valve assists engine starting by retaining a pre-set fuel pressure in the supply pipe and fuel rail. The

pressure relief valve also limits fuel rail pressure due to temporary vapor increase in hot conditions and pressure caused by

sudden load changes, for example, a fully open to closed throttle transition.

To meet ORVR (on-board refueling vapor recovery) requirements, the fuel tank and associated components are designed to

minimize fuel vapor loss during refueling. This is achieved by preventing fuel vapor from the fuel tank venting directly to the

atmosphere. Instead fuel vapor is directed into the EVAP (evaporative emission) charcoal canister where it is stored before

being purged at intervals to the engine’s intake manifold.

North American Specification (NAS) vehicles feature additional connections and pipes at the rear of the filler head and also

incorporates a Diagnostic Monitoring Tank Leakage (DMTL) pump for leak detection requirements.

Fuel System Schematic Diagram

Item Description 1 Fuel injector (8 off) 2 Fuel rail www.JagDocs.com

Page 1588 of 3039

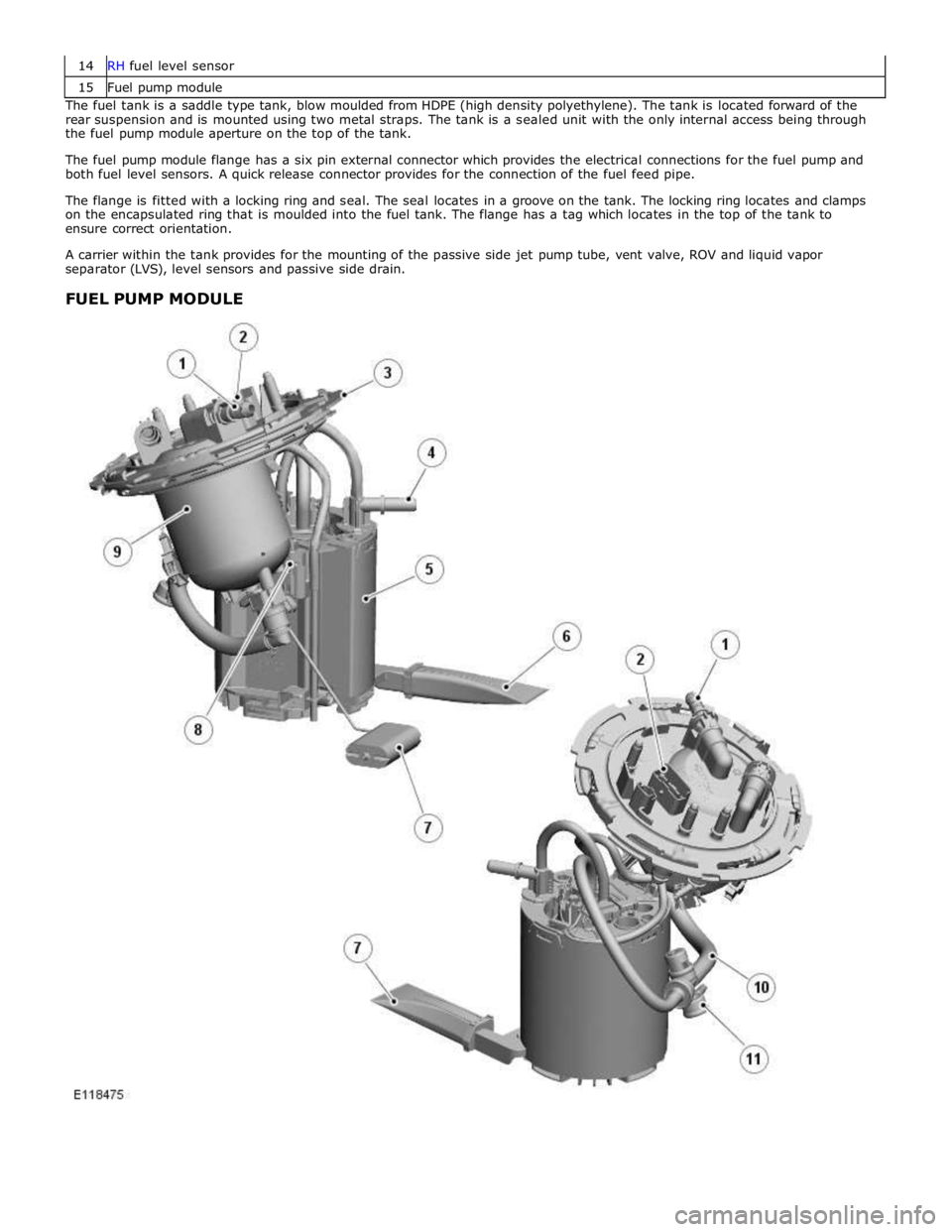

15 Fuel pump module The fuel tank is a saddle type tank, blow moulded from HDPE (high density polyethylene). The tank is located forward of the

rear suspension and is mounted using two metal straps. The tank is a sealed unit with the only internal access being through

the fuel pump module aperture on the top of the tank.

The fuel pump module flange has a six pin external connector which provides the electrical connections for the fuel pump and

both fuel level sensors. A quick release connector provides for the connection of the fuel feed pipe.

The flange is fitted with a locking ring and seal. The seal locates in a groove on the tank. The locking ring locates and clamps

on the encapsulated ring that is moulded into the fuel tank. The flange has a tag which locates in the top of the tank to

ensure correct orientation.

A carrier within the tank provides for the mounting of the passive side jet pump tube, vent valve, ROV and liquid vapor

separator (LVS), level sensors and passive side drain.

FUEL PUMP MODULE

Page 1589 of 3039

1 Fuel supply connection 2 Electrical connector 3 Flange locking ring and seal 4 Sucking jet connector 5 Fuel pump module 6 Fuel pick up filter 7 Level sensor float 8 RH level sensor 9 Fuel filter 10 Pressure relief valve 11 Pump supply to flange connection 12 The fuel pump is a variable speed rotary vane type. The pump is energized by the fuel pump relay which is located in the RJB and the FPDM which is located under the RH floor pan above the rear suspension stabilizer bar. The relay and FPDM are controlled by the ECM.

A fine mesh filter is located in the lower section of the pump module. This provides filtration to the fuel as it is drawn into the

module. There is a winged filter on the fuel pump that gives additional protection and a life time fuel filter integrated into the

flange which eliminates the need for an additional filter further downstream in the fuel system.

The RH fuel level sensor is mounted into the pump module housing.

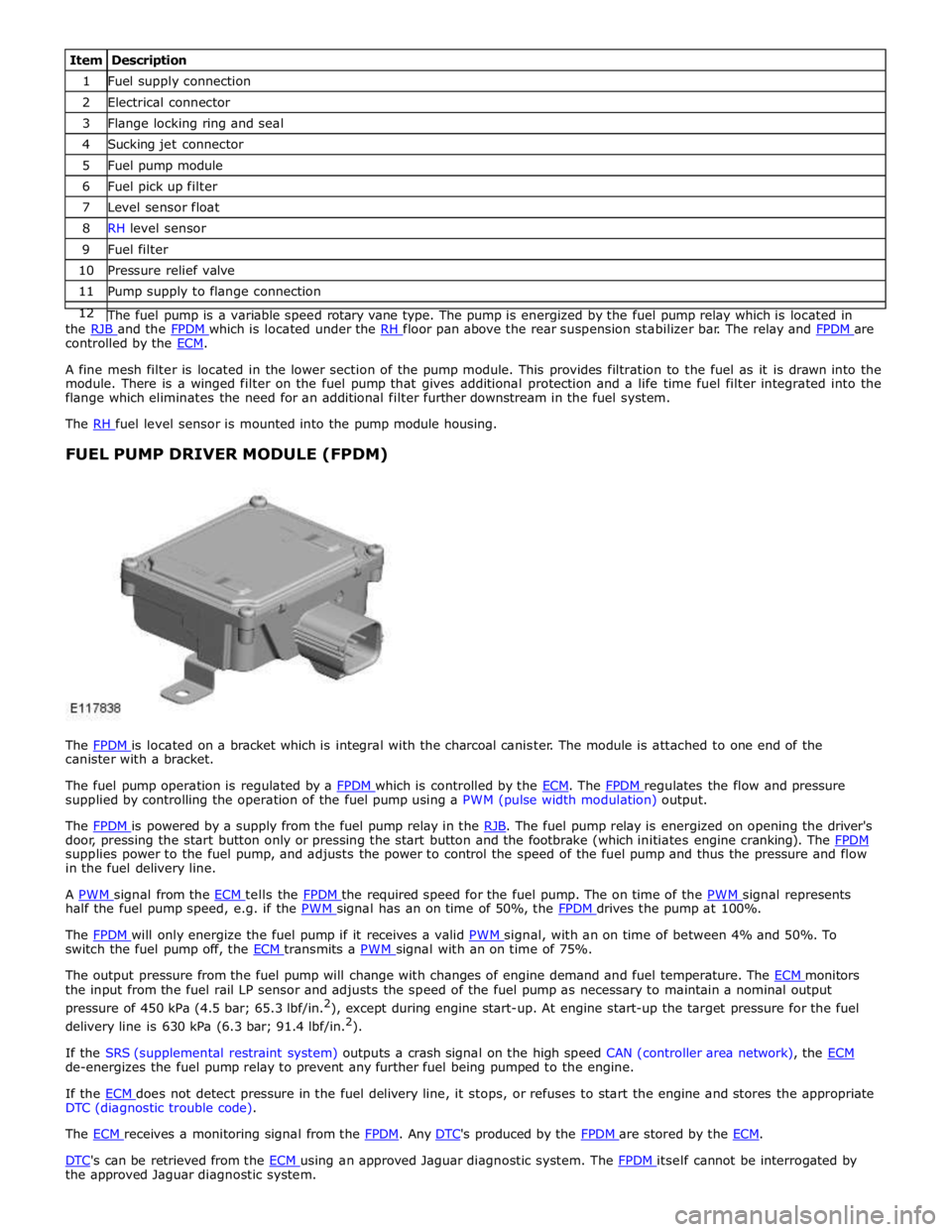

FUEL PUMP DRIVER MODULE (FPDM)

The FPDM is located on a bracket which is integral with the charcoal canister. The module is attached to one end of the canister with a bracket.

The fuel pump operation is regulated by a FPDM which is controlled by the ECM. The FPDM regulates the flow and pressure supplied by controlling the operation of the fuel pump using a PWM (pulse width modulation) output.

The FPDM is powered by a supply from the fuel pump relay in the RJB. The fuel pump relay is energized on opening the driver's door, pressing the start button only or pressing the start button and the footbrake (which initiates engine cranking). The FPDM supplies power to the fuel pump, and adjusts the power to control the speed of the fuel pump and thus the pressure and flow

in the fuel delivery line.

A PWM signal from the ECM tells the FPDM the required speed for the fuel pump. The on time of the PWM signal represents half the fuel pump speed, e.g. if the PWM signal has an on time of 50%, the FPDM drives the pump at 100%.

The FPDM will only energize the fuel pump if it receives a valid PWM signal, with an on time of between 4% and 50%. To switch the fuel pump off, the ECM transmits a PWM signal with an on time of 75%.

The output pressure from the fuel pump will change with changes of engine demand and fuel temperature. The ECM monitors the input from the fuel rail LP sensor and adjusts the speed of the fuel pump as necessary to maintain a nominal output

pressure of 450 kPa (4.5 bar; 65.3 lbf/in.2

), except during engine start-up. At engine start-up the target pressure for the fuel

delivery line is 630 kPa (6.3 bar; 91.4 lbf/in.2

).

If the SRS (supplemental restraint system) outputs a crash signal on the high speed CAN (controller area network), the ECM de-energizes the fuel pump relay to prevent any further fuel being pumped to the engine.

If the ECM does not detect pressure in the fuel delivery line, it stops, or refuses to start the engine and stores the appropriate DTC (diagnostic trouble code).

The ECM receives a monitoring signal from the FPDM. Any DTC's produced by the FPDM are stored by the ECM.

DTC's can be retrieved from the ECM using an approved Jaguar diagnostic system. The FPDM itself cannot be interrogated by the approved Jaguar diagnostic system.

Page 1593 of 3039

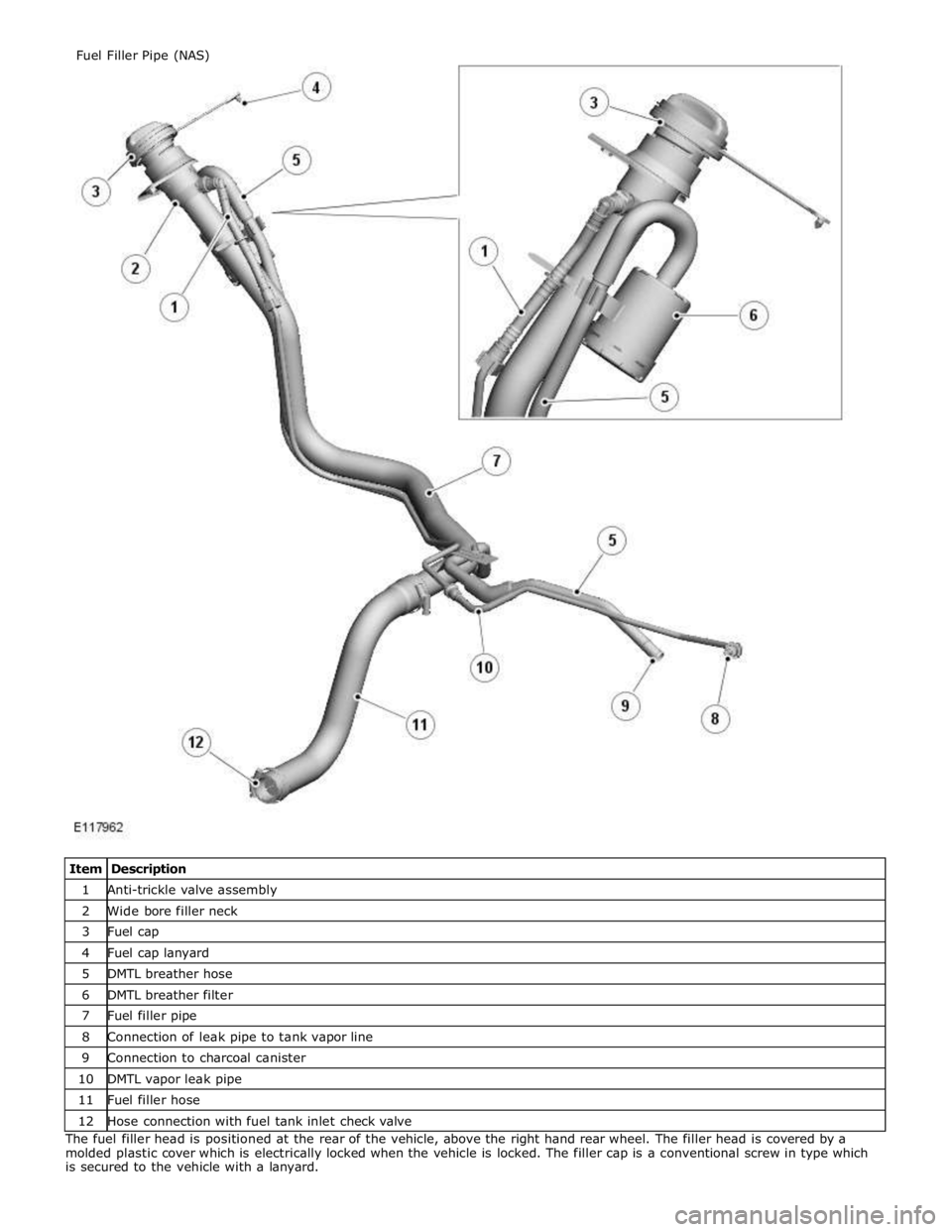

1 Anti-trickle valve assembly 2 Wide bore filler neck 3 Fuel cap 4 Fuel cap lanyard 5 DMTL breather hose 6 DMTL breather filter 7 Fuel filler pipe 8 Connection of leak pipe to tank vapor line 9 Connection to charcoal canister 10 DMTL vapor leak pipe 11 Fuel filler hose 12 Hose connection with fuel tank inlet check valve The fuel filler head is positioned at the rear of the vehicle, above the right hand rear wheel. The filler head is covered by a

molded plastic cover which is electrically locked when the vehicle is locked. The filler cap is a conventional screw in type which

is secured to the vehicle with a lanyard. Fuel Filler Pipe (NAS)

Page 1614 of 3039

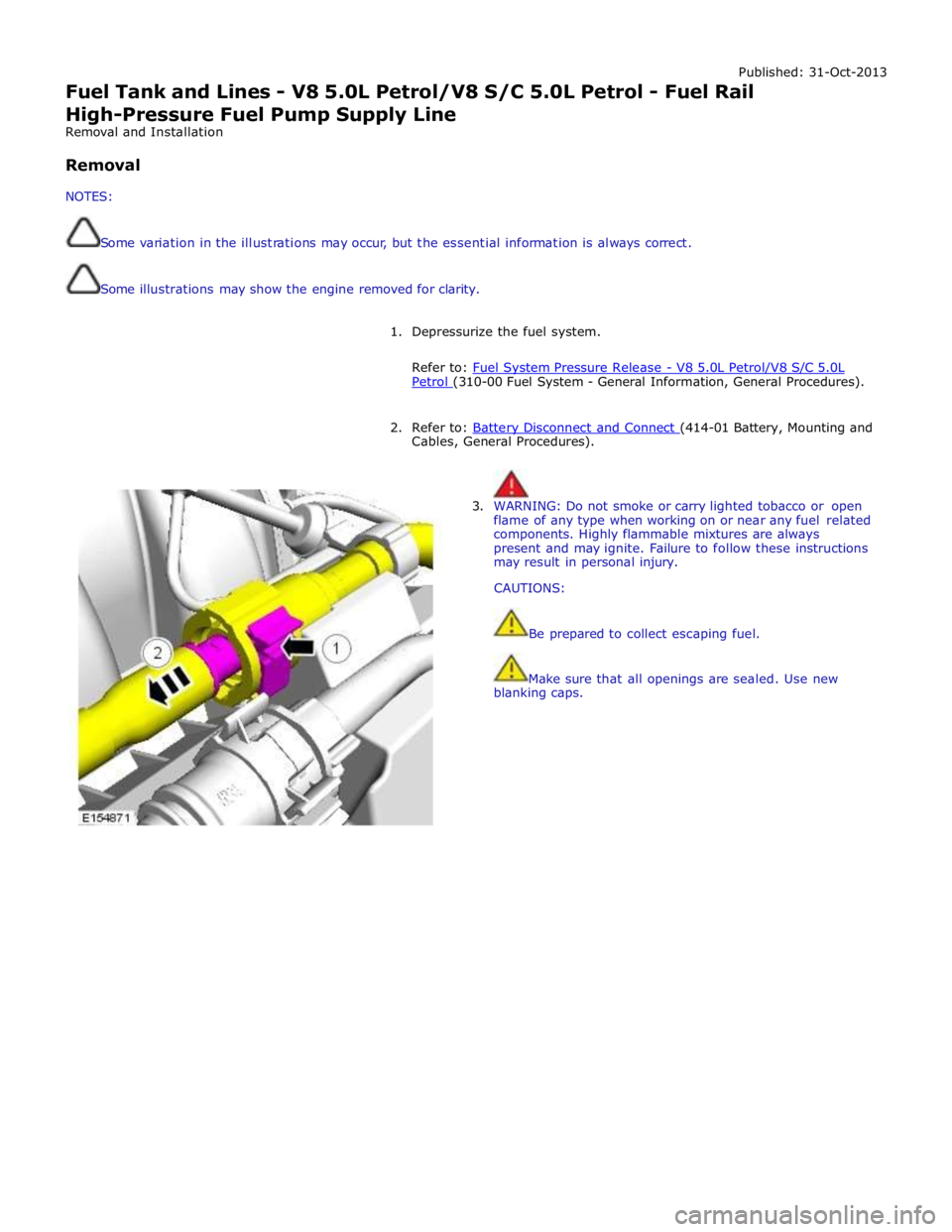

Published: 31-Oct-2013

Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Fuel Rail High-Pressure Fuel Pump Supply Line

Removal and Installation

Removal

NOTES:

Some variation in the illustrations may occur, but the essential information is always correct.

Some illustrations may show the engine removed for clarity.

1. Depressurize the fuel system.

Refer to: Fuel System Pressure Release - V8 5.0L Petrol/V8 S/C 5.0L Petrol (310-00 Fuel System - General Information, General Procedures).

2. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. WARNING: Do not smoke or carry lighted tobacco or open

flame of any type when working on or near any fuel related

components. Highly flammable mixtures are always

present and may ignite. Failure to follow these instructions

may result in personal injury.

CAUTIONS:

Be prepared to collect escaping fuel.

Make sure that all openings are sealed. Use new

blanking caps.

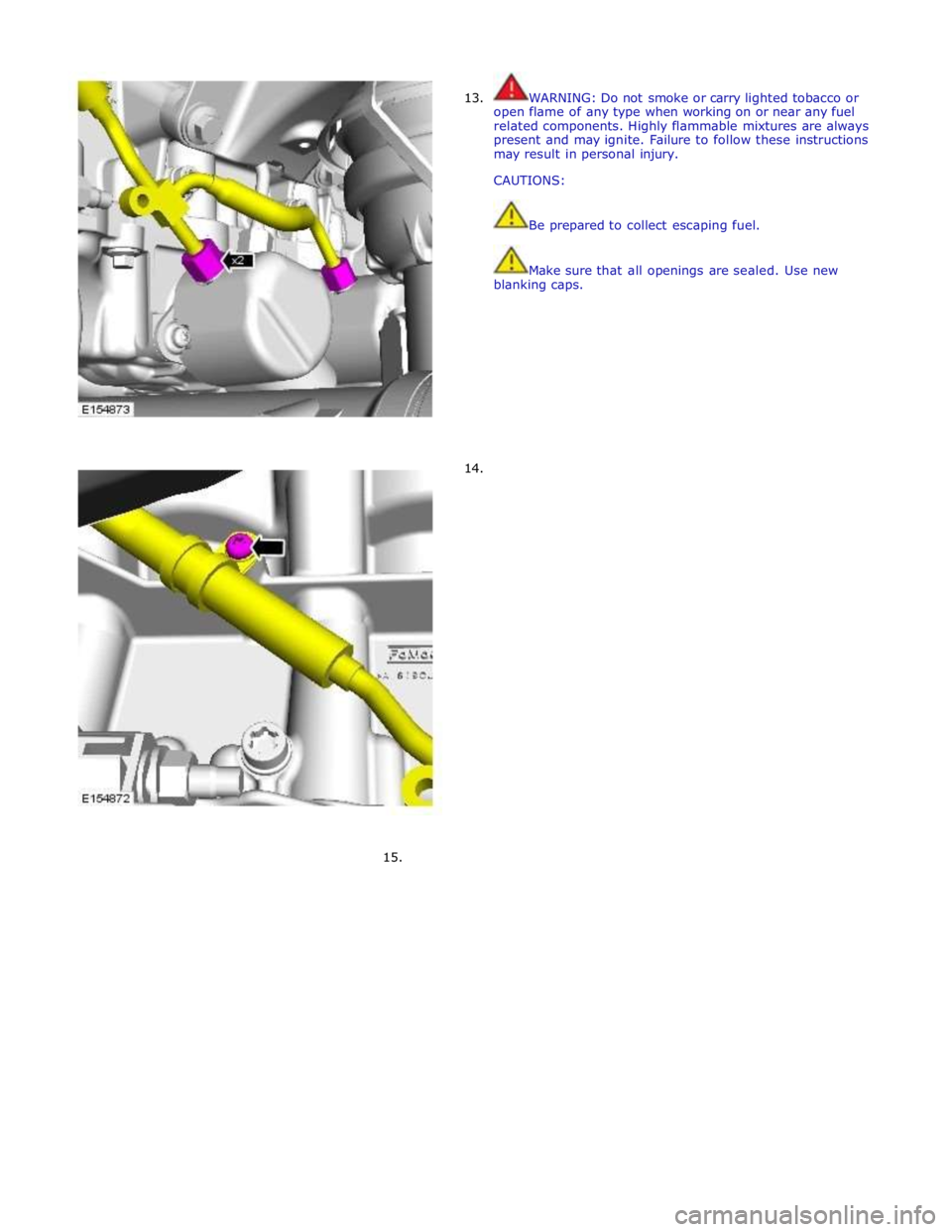

Page 1618 of 3039

15.

13.

14.

WARNING: Do not smoke or carry lighted tobacco or

open flame of any type when working on or near any fuel

related components. Highly flammable mixtures are always

present and may ignite. Failure to follow these instructions

may result in personal injury.

CAUTIONS:

Be prepared to collect escaping fuel.

Make sure that all openings are sealed. Use new

blanking caps.