fuse box diagram JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1180 of 3039

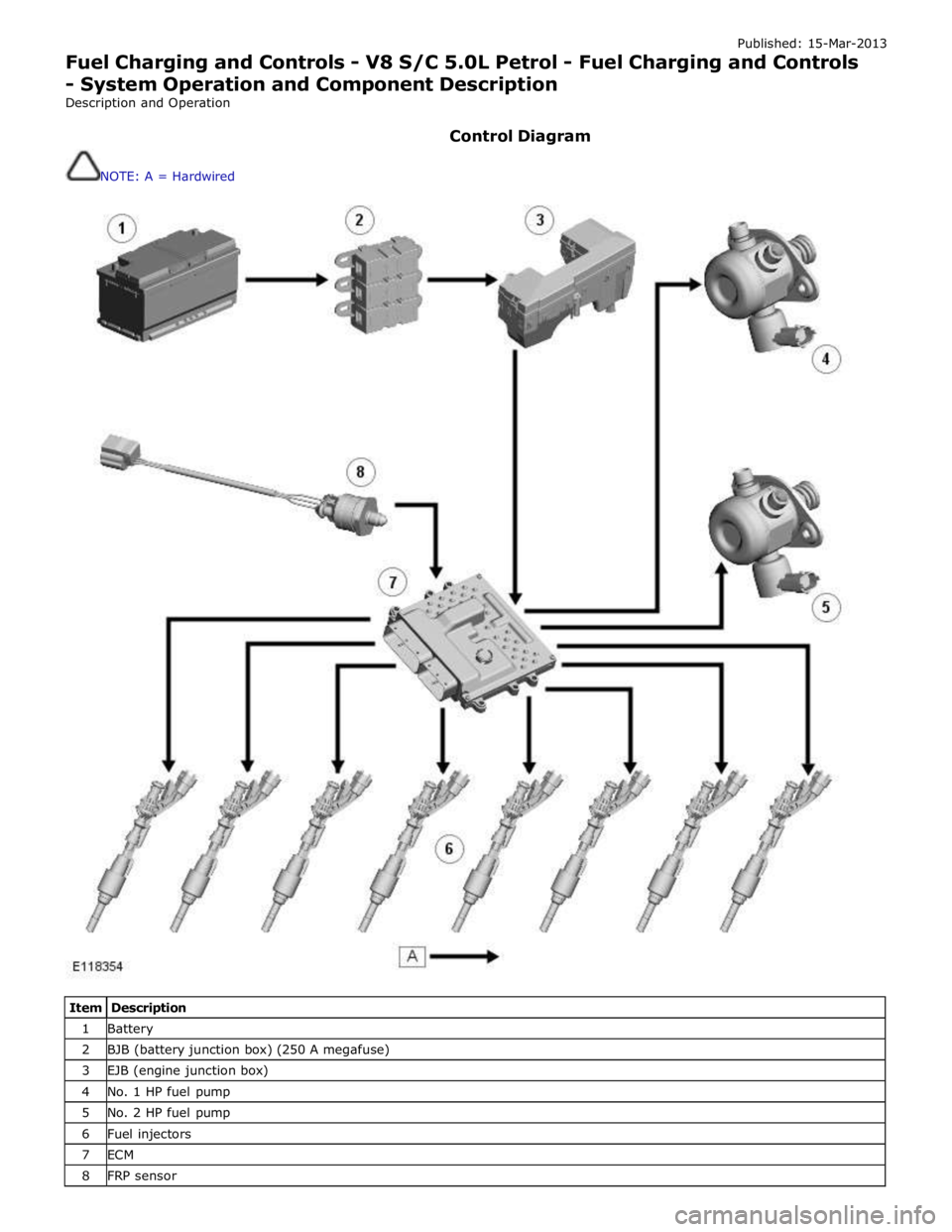

Published: 15-Mar-2013

Fuel Charging and Controls - V8 S/C 5.0L Petrol - Fuel Charging and Controls

- System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 No. 1 HP fuel pump 5 No. 2 HP fuel pump 6 Fuel injectors 7 ECM 8 FRP sensor

Page 1273 of 3039

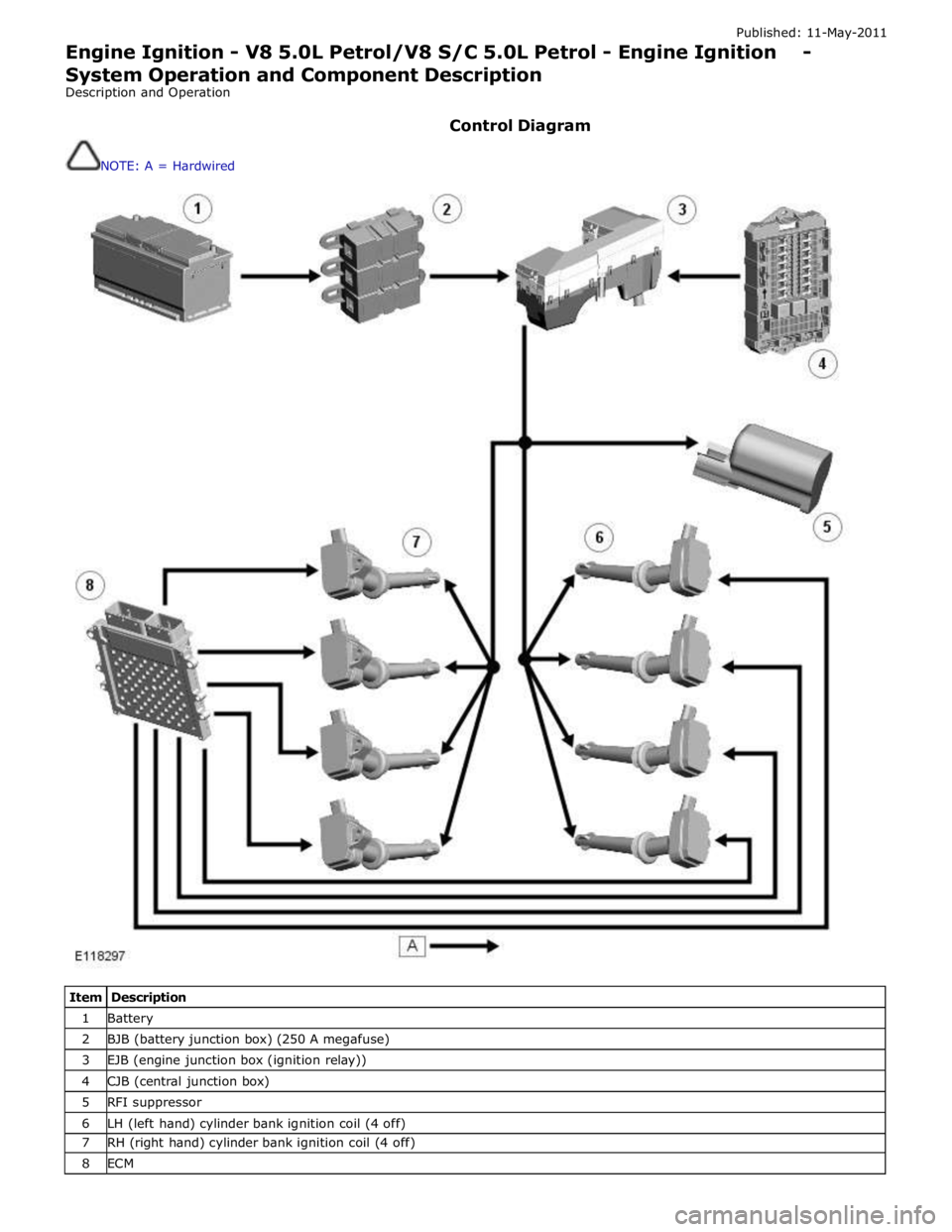

Published: 11-May-2011

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Ignition - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box (ignition relay)) 4 CJB (central junction box) 5 RFI suppressor 6 LH (left hand) cylinder bank ignition coil (4 off) 7 RH (right hand) cylinder bank ignition coil (4 off) 8 ECM

Page 1288 of 3039

Published: 11-May-2011

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Intake Air

Distribution and Filtering - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) (EMS high current relay) 4 Tuning valve 5 ECM (engine control module)

Page 1358 of 3039

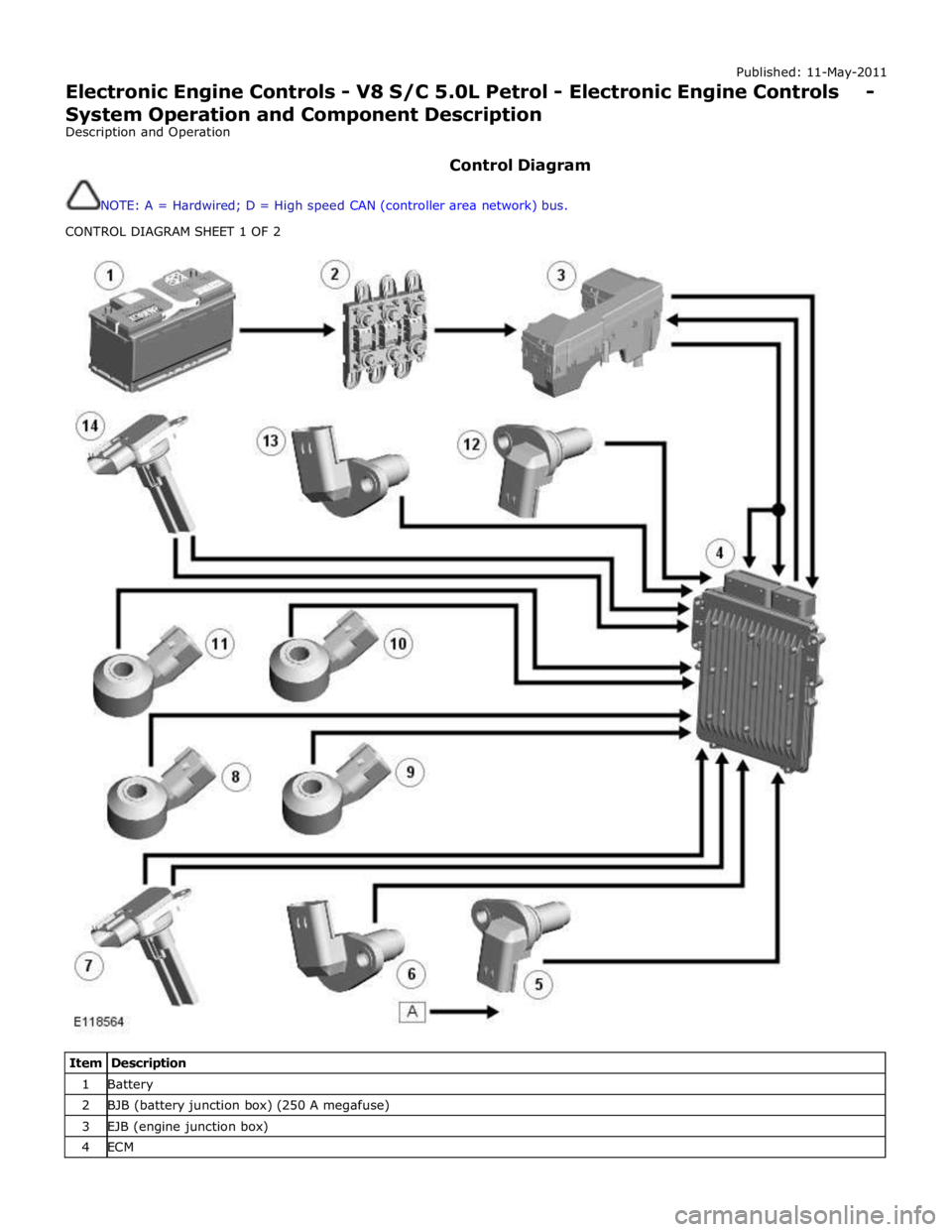

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Electronic Engine Controls - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus.

CONTROL DIAGRAM SHEET 1 OF 2

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 ECM

Page 1411 of 3039

Published: 11-May-2011

Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Transmission Description - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; B = K bus; D = High speed CAN (controller area network) bus; O = LIN (local interconnect

network) bus

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 CJB (central junction box)

Page 1529 of 3039

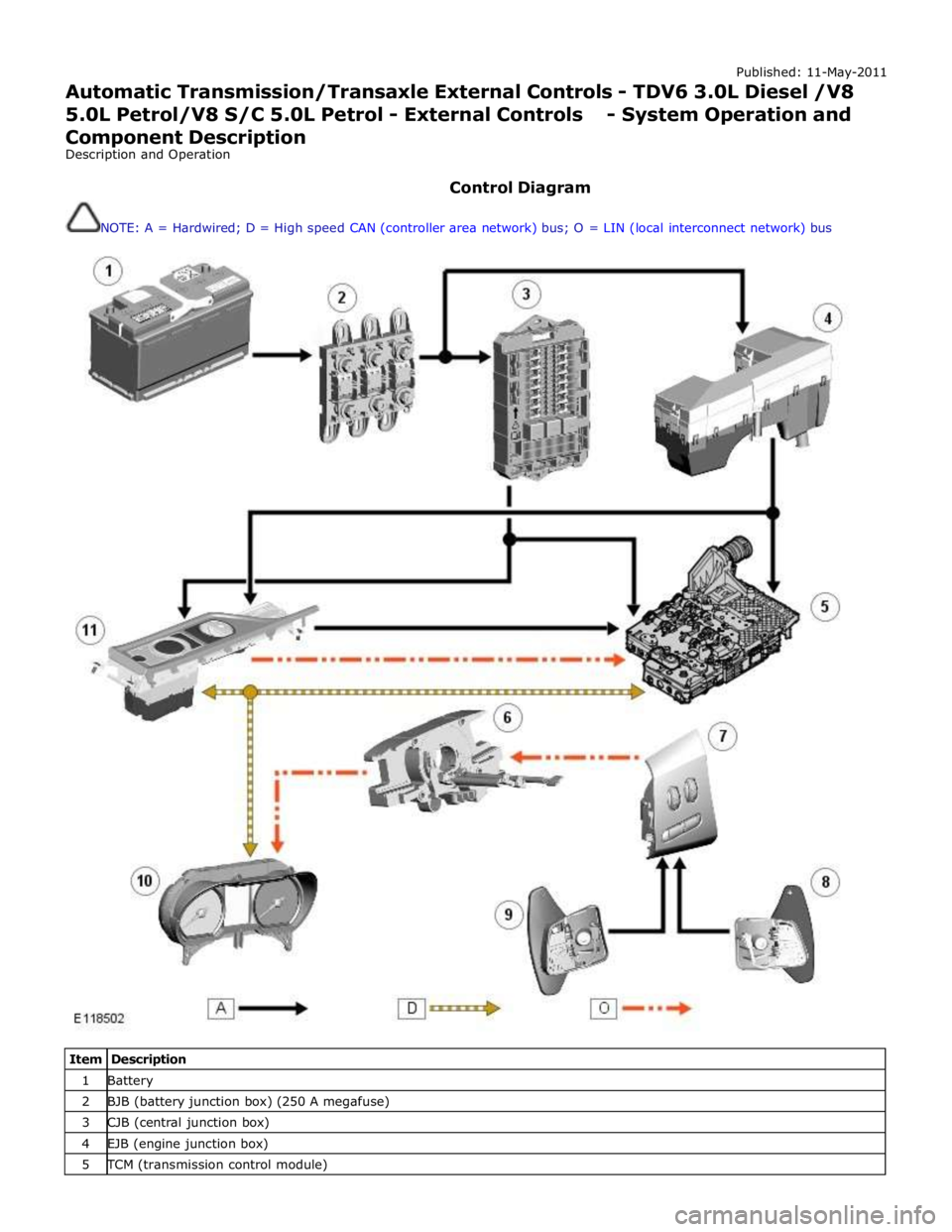

Published: 11-May-2011

Automatic Transmission/Transaxle External Controls - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - External Controls - System Operation and

Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus; O = LIN (local interconnect network) bus

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 CJB (central junction box) 4 EJB (engine junction box) 5 TCM (transmission control module)

Page 1585 of 3039

Published: 11-May-2011

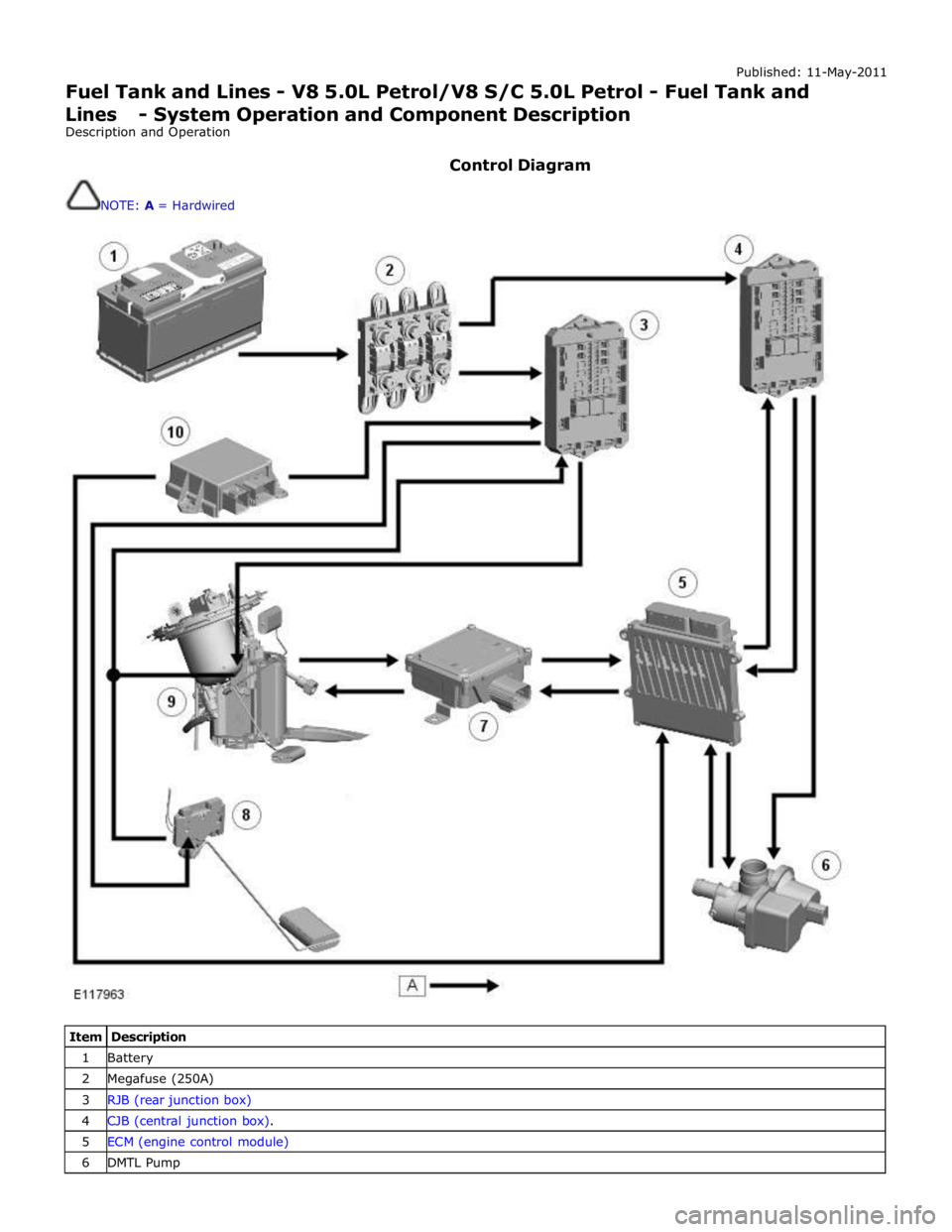

Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Fuel Tank and Lines - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 Megafuse (250A) 3 RJB (rear junction box) 4 CJB (central junction box). 5 ECM (engine control module) 6 DMTL Pump

Page 1791 of 3039

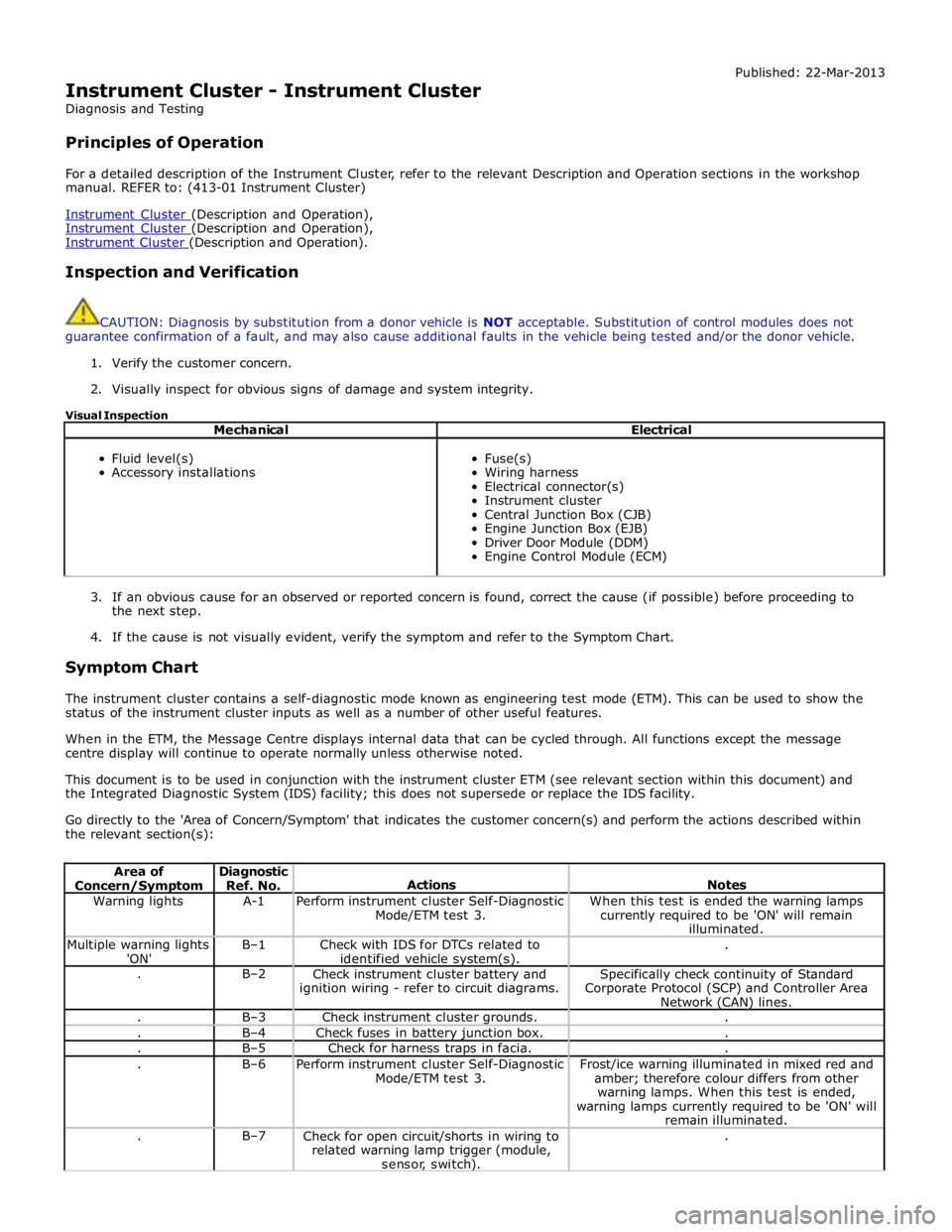

Instrument Cluster - Instrument Cluster

Diagnosis and Testing

Principles of Operation Published: 22-Mar-2013

For a detailed description of the Instrument Cluster, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: (413-01 Instrument Cluster)

Instrument Cluster (Description and Operation), Instrument Cluster (Description and Operation), Instrument Cluster (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Fluid level(s)

Accessory installations

Fuse(s)

Wiring harness

Electrical connector(s)

Instrument cluster

Central Junction Box (CJB)

Engine Junction Box (EJB)

Driver Door Module (DDM)

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

The instrument cluster contains a self-diagnostic mode known as engineering test mode (ETM). This can be used to show the

status of the instrument cluster inputs as well as a number of other useful features.

When in the ETM, the Message Centre displays internal data that can be cycled through. All functions except the message

centre display will continue to operate normally unless otherwise noted.

This document is to be used in conjunction with the instrument cluster ETM (see relevant section within this document) and

the Integrated Diagnostic System (IDS) facility; this does not supersede or replace the IDS facility.

Go directly to the 'Area of Concern/Symptom' that indicates the customer concern(s) and perform the actions described within

the relevant section(s):

Area of Concern/Symptom Diagnostic

Ref. No.

Actions

Notes Warning lights A-1

Perform instrument cluster Self-Diagnostic

Mode/ETM test 3. When this test is ended the warning lamps

currently required to be 'ON' will remain

illuminated. Multiple warning lights

'ON' B–1

Check with IDS for DTCs related to

identified vehicle system(s). . . B–2

Check instrument cluster battery and

ignition wiring - refer to circuit diagrams. Specifically check continuity of Standard

Corporate Protocol (SCP) and Controller Area

Network (CAN) lines. . B–3 Check instrument cluster grounds. . . B–4 Check fuses in battery junction box. . . B–5 Check for harness traps in facia. . . B–6

Perform instrument cluster Self-Diagnostic

Mode/ETM test 3. Frost/ice warning illuminated in mixed red and

amber; therefore colour differs from other

warning lamps. When this test is ended,

warning lamps currently required to be 'ON' will

remain illuminated. . B–7

Check for open circuit/shorts in wiring to

related warning lamp trigger (module,

sensor, switch). .

Page 2025 of 3039

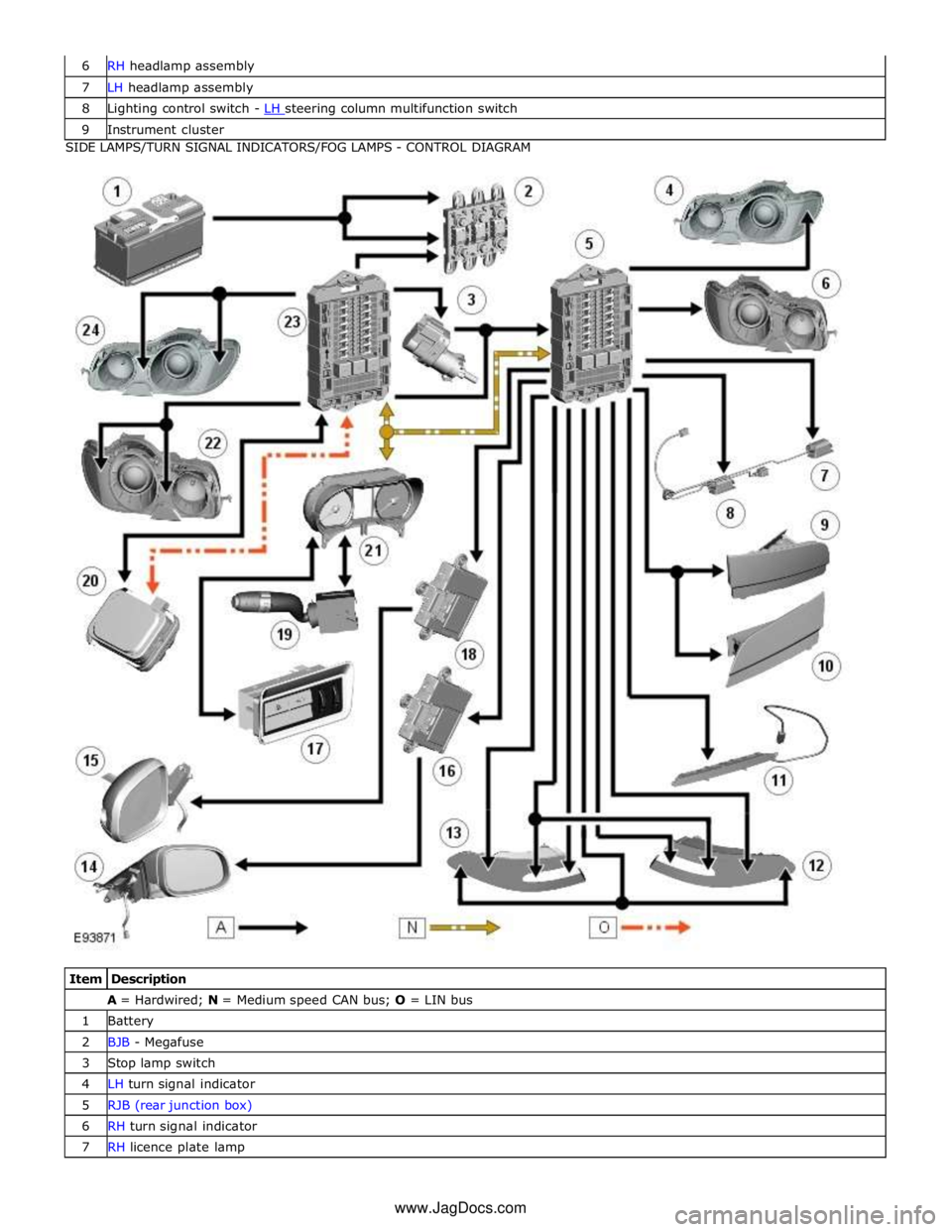

7 LH headlamp assembly 8 Lighting control switch - LH steering column multifunction switch 9 Instrument cluster SIDE LAMPS/TURN SIGNAL INDICATORS/FOG LAMPS - CONTROL DIAGRAM

Item Description A = Hardwired; N = Medium speed CAN bus; O = LIN bus 1 Battery 2 BJB - Megafuse 3 Stop lamp switch 4 LH turn signal indicator 5 RJB (rear junction box) 6 RH turn signal indicator 7 RH licence plate lamp www.JagDocs.com

Page 2057 of 3039

8 Passenger door module 9 LH (left-hand) rear door latch 10 RH (right-hand) rear door latch 11 LH front door latch 12 RH front door latch 13 CJB (central junction box) 14 LH front door handle LED (light emitting diode) illumination 15 RH front door handle LED illumination CONTROL DIAGRAM (SHEET 2 OF 2)

Item Description A = Hardwired 1 Battery 2 BJB - Megafuse