keyless JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1805 of 3039

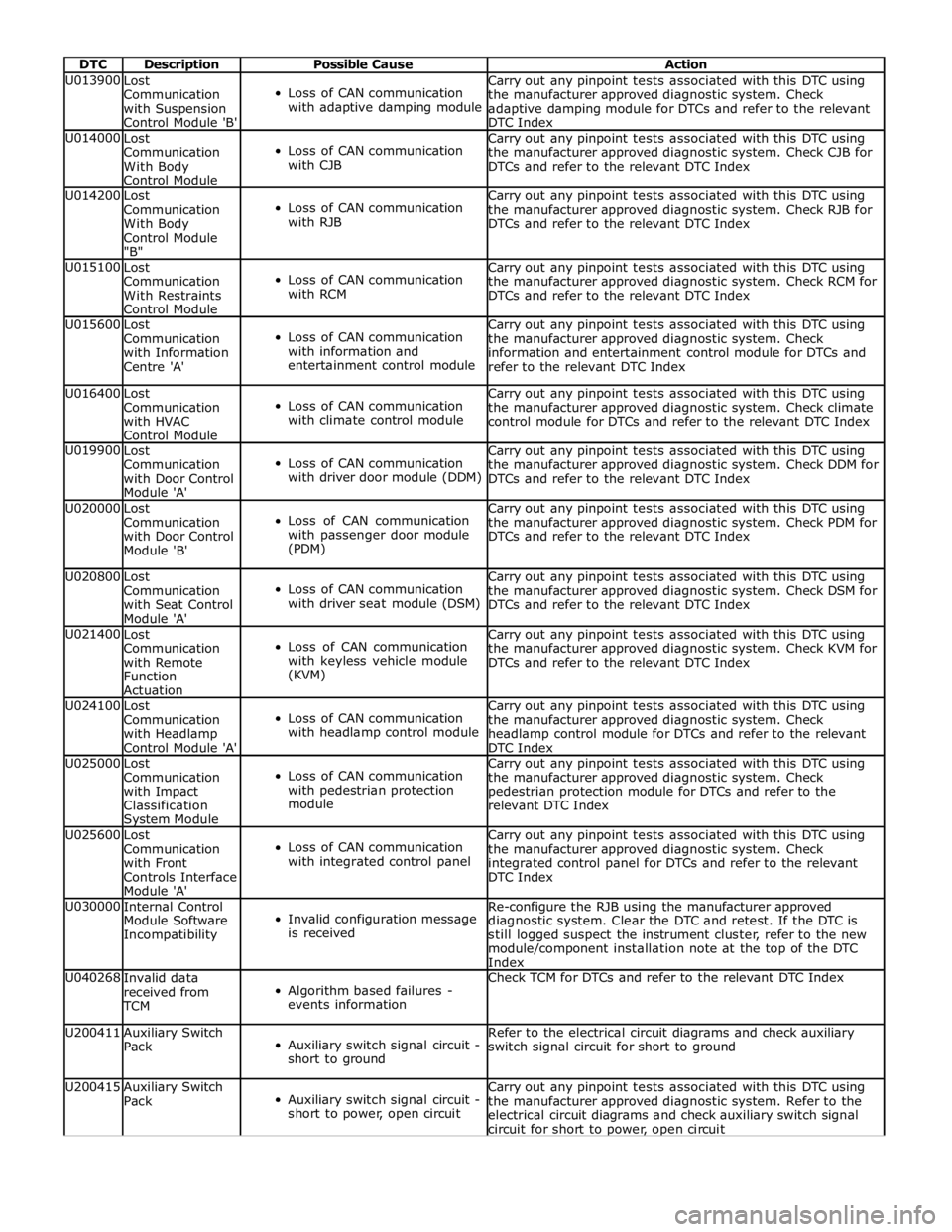

DTC Description Possible Cause Action U013900

Lost

Communication

with Suspension

Control Module 'B'

Loss of CAN communication

with adaptive damping module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

adaptive damping module for DTCs and refer to the relevant

DTC Index U014000

Lost

Communication

With Body

Control Module

Loss of CAN communication

with CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

DTCs and refer to the relevant DTC Index U014200

Lost

Communication

With Body

Control Module

"B"

Loss of CAN communication

with RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

DTCs and refer to the relevant DTC Index U015100

Lost

Communication

With Restraints

Control Module

Loss of CAN communication

with RCM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RCM for

DTCs and refer to the relevant DTC Index U015600

Lost

Communication

with Information

Centre 'A'

Loss of CAN communication

with information and

entertainment control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment control module for DTCs and

refer to the relevant DTC Index U016400

Lost

Communication

with HVAC

Control Module

Loss of CAN communication

with climate control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check climate

control module for DTCs and refer to the relevant DTC Index U019900

Lost

Communication

with Door Control

Module 'A'

Loss of CAN communication

with driver door module (DDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DDM for

DTCs and refer to the relevant DTC Index U020000

Lost

Communication

with Door Control

Module 'B'

Loss of CAN communication

with passenger door module

(PDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check PDM for

DTCs and refer to the relevant DTC Index U020800

Lost

Communication

with Seat Control

Module 'A'

Loss of CAN communication

with driver seat module (DSM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DSM for

DTCs and refer to the relevant DTC Index U021400

Lost

Communication

with Remote

Function

Actuation

Loss of CAN communication

with keyless vehicle module

(KVM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check KVM for

DTCs and refer to the relevant DTC Index U024100

Lost

Communication

with Headlamp

Control Module 'A'

Loss of CAN communication

with headlamp control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

headlamp control module for DTCs and refer to the relevant

DTC Index U025000

Lost

Communication

with Impact

Classification System Module

Loss of CAN communication

with pedestrian protection

module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

pedestrian protection module for DTCs and refer to the

relevant DTC Index U025600

Lost

Communication

with Front

Controls Interface

Module 'A'

Loss of CAN communication

with integrated control panel Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

integrated control panel for DTCs and refer to the relevant

DTC Index U030000

Internal Control

Module Software

Incompatibility

Invalid configuration message

is received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC is

still logged suspect the instrument cluster, refer to the new

module/component installation note at the top of the DTC

Index U040268

Invalid data

received from

TCM

Algorithm based failures -

events information Check TCM for DTCs and refer to the relevant DTC Index U200411

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to ground Refer to the electrical circuit diagrams and check auxiliary

switch signal circuit for short to ground U200415

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check auxiliary switch signal

circuit for short to power, open circuit

Page 1866 of 3039

Published: 07-Aug-2014

Battery and Charging System - General Information - Battery Care

Requirements

Description and Operation

1. INTRODUCTION

This document defines the requirements for care and maintenance of batteries, and the standard of battery care at dealers and

retailers for new vehicles.

This applies to all types of 12 Volt Lead Acid Batteries used in Jaguar and Land Rover vehicles whether they are conventional

flooded technology or Absorbed Glass Mat (AGM – also known as Valve Regulated Lead Acid (VRLA)) technology and also

applies to both Primary, Secondary and Auxiliary Batteries. AGM batteries offer improved resistance to cycling as seen in stop

start applications.

In order to prevent damage to the battery and ensure a satisfactory service life, all processes detailed within this document

must be rigorously adhered to.

It is equally important therefore to note the following key points:

All new vehicles leave the factory with either a transit relay installed and/or have a transit mode programmed into the

vehicle control modules. The transit relay must be removed and the transit mode disabled (where applicable) using an

approved diagnostic system, NOT MORE THAN 72 HOURS before the customer takes delivery.

The battery can be discharged by the following mechanisms:

- Self Discharge: - A lead acid battery will very slowly discharge itself due to its own internal chemical processes

whether it is connected to a vehicle or not.

- Quiescent Discharge: - The vehicle electrical systems when connected to the battery will draw charge from the

battery.

12 Volt Lead Acid Batteries rely on internal chemical processes to create a voltage and deliver current. These processes and

the internal chemical structure of the battery can be damaged if the battery is allowed to discharge over a number of weeks /

months, or is left in a discharged state for a lengthy time period.

On vehicles with conventional ignition keys, these must not be left in the ignition lock barrel when the transit relay

has been removed, otherwise quiescent current will increase and the battery will discharge more rapidly.

For keyless vehicles, the Smart Key must be stored at least 5m (16 ft) away from the vehicle when the vehicle is

parked or stored.

AGM Batteries are fully sealed and cannot have the electrolyte level topped up.

NOTE: Dealers and retailers involved in the storage / handling of vehicles and replacement batteries have a responsibility

to ensure that only a fully charged battery may be processed through the distribution selling chain.

2. GENERAL RULES FOR BATTERY CARE

2.1 Dealer Demonstration Vehicles

Vehicles used as dealer demonstrator(s), in a showroom, must be connected to a JLR approved showroom conditioner capable

of delivering 50 Amps. This will prevent the battery from being damaged.

2.2 Software Reflash, SDD work or Ignition On related workshop activities

Due to the high electrical current demand and high depth of discharge that can occur during vehicle software re-flash activities,

SDD work or ignition on (power mode 6) related work in the workshop, vehicles that are undergoing such activities MUST have a

JLR approved power supply capable of delivering 50 Amps or more.

2.3 Extended Vehicle Rework

For any extended vehicle rework that results in consuming vehicle power, either the battery should be disconnected or a JLR

approved power supply connected.

2.4 Jump Starting New vehicles before they have been delivered to the customer

It is the dealer / retailers responsibility to make sure the battery is not allowed to discharge by following the

instructions and processes defined in this manual.

However, if circumstances dictate that a new vehicle must be jump started due to a discharged battery whilst the

vehicle is in the dealer / retailers care, the battery on this vehicle must be replaced with a new one prior to delivery

to the customer at the dealer / retailers liability.

The vehicle should also undergo investigation as to why the battery became discharged.

Do not connect the jump starting cable to the negative (-) terminal of the battery. Always connect to the recommended

earth point. As defined in the owners handbook or service documentation for that vehicle. 2.5 AGM Batteries

AGM batteries must not be charged above 14.8 Volts. Doing so will damage them.

AGM Batteries must be tested with a capable battery tester as detailed in the Equipment section (Section 5) of this

Page 1871 of 3039

Published: 21-Dec-2012

Battery and Charging System - General Information - Quiescent Drain

Description and Operation

VEHICLE QUIESCENT CURRENT TESTING

On vehicles fitted with a Battery Monitoring System (BMS), the diagnostic routine for quiescent drain testing in the approved

Jaguar or Land Rover diagnostic system should be utilized.

If a customer complains of a vehicle battery that discharges continuously or when left for a prolonged period of time, it is

recommended that a quiescent drain test is performed as described below.

The battery drain should be measured using the approved Jaguar or Land Rover diagnostic system or a Digital Multi-Meter

(DVOM). A procedure for quiescent drain measurement using the diagnostic system is available in the Diagnosis and Testing

section of the Workshop Manual. The vehicle should be in the locked/armed state (for example vehicle alarm fully armed), all

doors, engine and luggage compartment lids are open and latched (so as to appear closed from an electrical point of view).

The test should take place after the vehicle has entered shutdown mode. The time taken for this to occur after the ignition is

switched off varies according to model (Refer to the Topix On line resource for details).

When the vehicle is armed, the effect of the security system Light Emitting Diode (LED) flashing is to cause a pulsation in the

measured current drain. In this case, either the average current should be taken (using a Digital Multi- Meter (DVOM) with an

averaging system) or the current reading taken, ignoring the brief high current peaks.

EQUIPMENT

Approved Jaguar or Land Rover diagnostic system with current probeOR Digital Multi-Meter (DVOM) with current probe.

METHOD OF MEASUREMENT

Using an Approved Jaguar or Land Rover Diagnostic System.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the approved Jaguar or Land Rover diagnostic system

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

Using a digital multimeter

Do not use an in-line DVOM to measure the quiescent drain on vehicles fitted with an electronic throttle (for example XK 2006

onwards). The current exceeds the maximum amount the fuse in the DVOM is capable of handling.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the digital multmeter

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

QUIESCENT CURRENT TESTING

1. Switch ignition to ‘on’ or select ignition mode in keyless vehicles and switch to ‘off’ (do not crank)

2. Remove key from ignition switch (if equipped)

3. Open and latch all doors, hood and luggage compartment lid

4. Lock the vehicle using the remote function on the remote handset. (Single lock only to avoid volumetric alarm arming)

5. Remove any other potential electrical drains such as accessories plugged into accessory sockets

6. Record the amperage readings after the shutdown period referenced in the Topix on line resource for details. Note all

cars from 10MY onwards and XK from 07MY and XF from 08MY should be less than 30mA after 30 minutes

7. Record the final reading on the battery report form

The preferred method of testing following an excessive current consumption figure is to use a current probe around individual

junction box leads to the various suspected circuits to identify a potential cause. This is in preference to the old method of

removing fuses for the following reasons:

The drain may be caused by a module remaining active and preventing the quiescent drain from reducing to normal

levels

The drain may be caused by a relay winding that is activated. Pulling the fuse can allow this to ‘reset’ and the drain will

be lost and go un-diagnosed

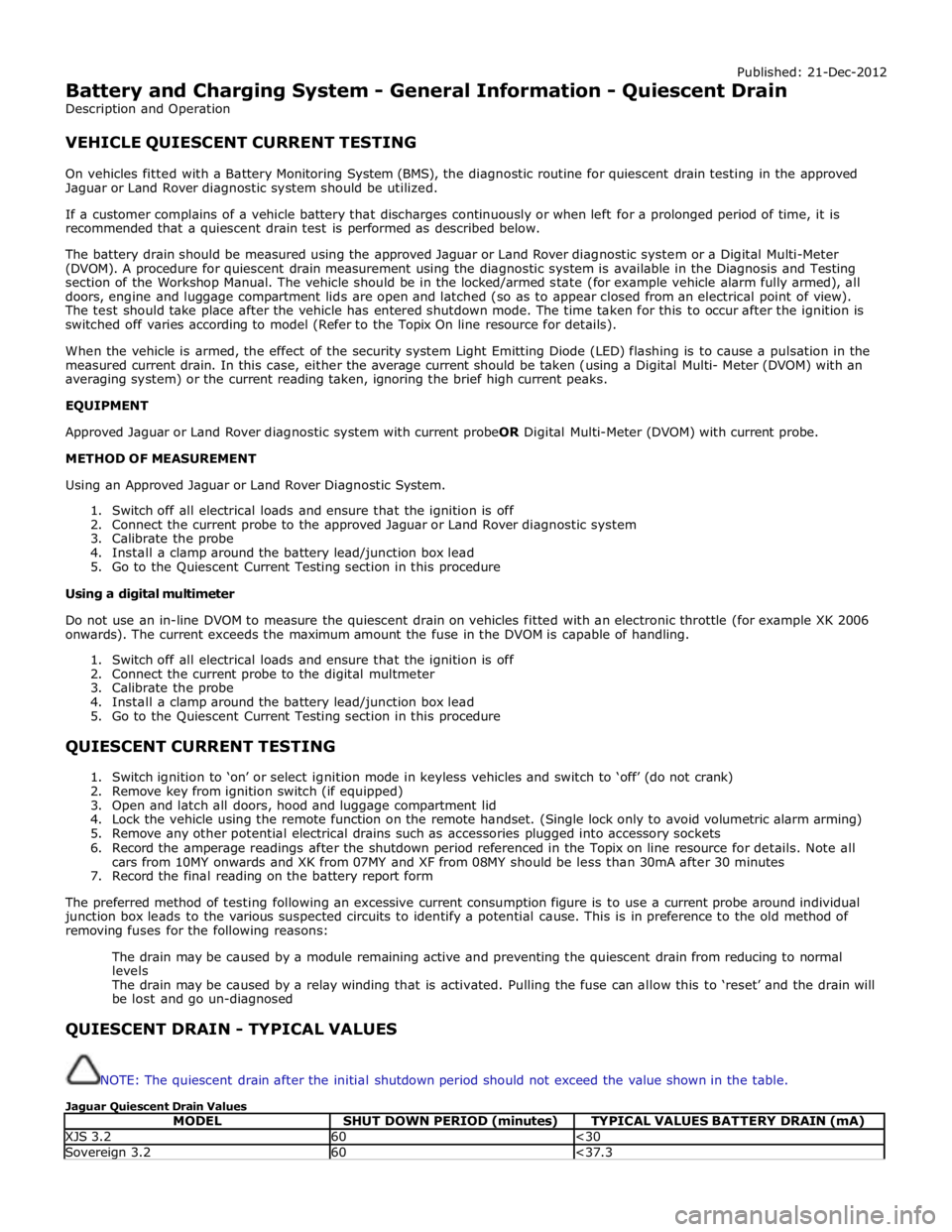

QUIESCENT DRAIN - TYPICAL VALUES

NOTE: The quiescent drain after the initial shutdown period should not exceed the value shown in the table.

Jaguar Quiescent Drain Values

MODEL SHUT DOWN PERIOD (minutes) TYPICAL VALUES BATTERY DRAIN (mA) XJS 3.2 60 <30 Sovereign 3.2 60 <37.3

Page 2058 of 3039

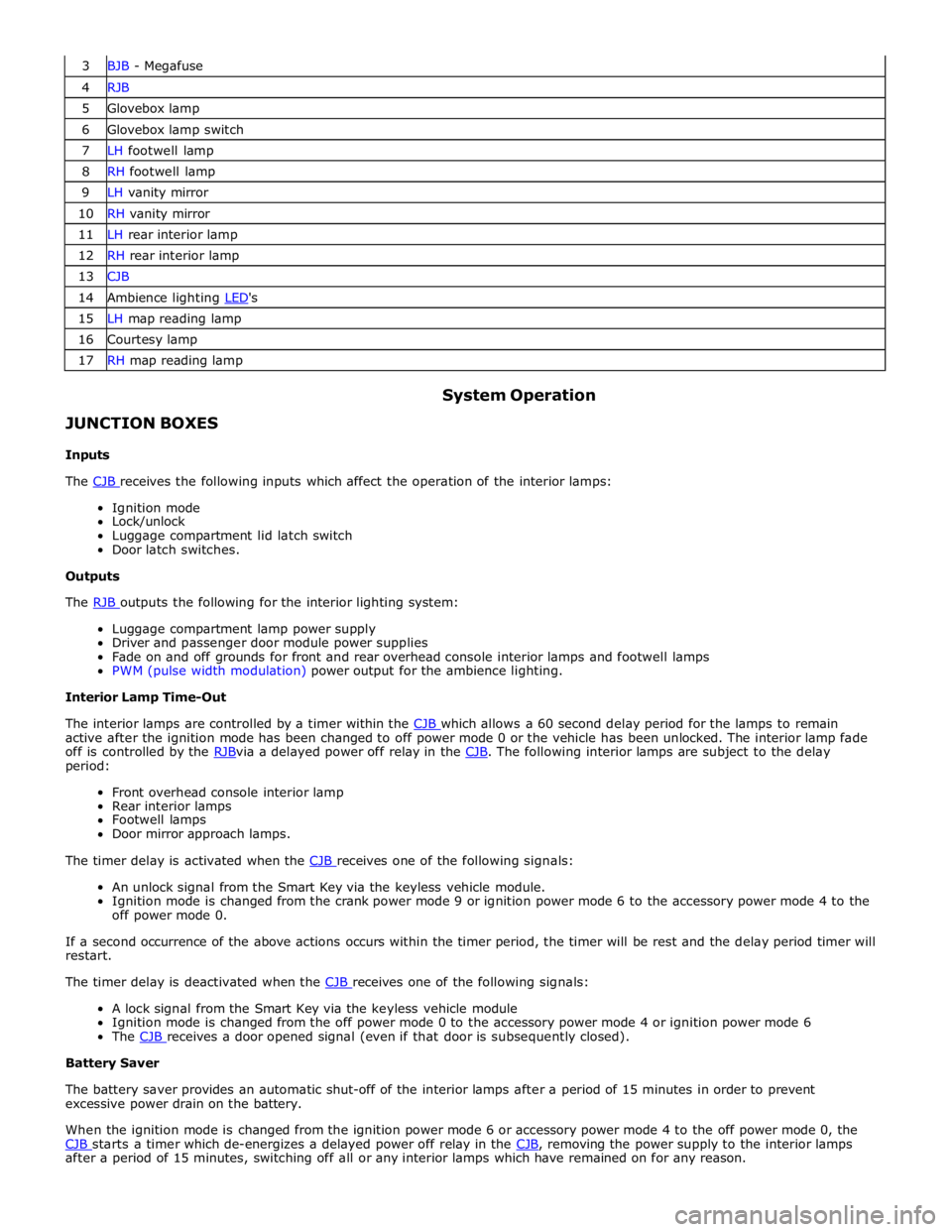

3 BJB - Megafuse 4 RJB 5 Glovebox lamp 6 Glovebox lamp switch 7 LH footwell lamp 8 RH footwell lamp 9 LH vanity mirror 10 RH vanity mirror 11 LH rear interior lamp 12 RH rear interior lamp 13 CJB 14 Ambience lighting LED's 15 LH map reading lamp 16 Courtesy lamp 17 RH map reading lamp

JUNCTION BOXES

Inputs System Operation

The CJB receives the following inputs which affect the operation of the interior lamps: Ignition mode

Lock/unlock

Luggage compartment lid latch switch

Door latch switches.

Outputs

The RJB outputs the following for the interior lighting system: Luggage compartment lamp power supply

Driver and passenger door module power supplies

Fade on and off grounds for front and rear overhead console interior lamps and footwell lamps

PWM (pulse width modulation) power output for the ambience lighting.

Interior Lamp Time-Out

The interior lamps are controlled by a timer within the CJB which allows a 60 second delay period for the lamps to remain active after the ignition mode has been changed to off power mode 0 or the vehicle has been unlocked. The interior lamp fade

off is controlled by the RJBvia a delayed power off relay in the CJB. The following interior lamps are subject to the delay period:

Front overhead console interior lamp

Rear interior lamps

Footwell lamps

Door mirror approach lamps.

The timer delay is activated when the CJB receives one of the following signals: An unlock signal from the Smart Key via the keyless vehicle module.

Ignition mode is changed from the crank power mode 9 or ignition power mode 6 to the accessory power mode 4 to the

off power mode 0.

If a second occurrence of the above actions occurs within the timer period, the timer will be rest and the delay period timer will

restart.

The timer delay is deactivated when the CJB receives one of the following signals: A lock signal from the Smart Key via the keyless vehicle module

Ignition mode is changed from the off power mode 0 to the accessory power mode 4 or ignition power mode 6

The CJB receives a door opened signal (even if that door is subsequently closed). Battery Saver

The battery saver provides an automatic shut-off of the interior lamps after a period of 15 minutes in order to prevent

excessive power drain on the battery.

When the ignition mode is changed from the ignition power mode 6 or accessory power mode 4 to the off power mode 0, the

CJB starts a timer which de-energizes a delayed power off relay in the CJB, removing the power supply to the interior lamps after a period of 15 minutes, switching off all or any interior lamps which have remained on for any reason.

Page 2059 of 3039

Once the timer has expired and the lamps are off, any one of the following will 'wake up' the battery saver and the interior

lamps will function again. The timer will be restarted as soon as an input is received by the CJB from one of the following:

Ignition mode changed from off power mode 0 to accessory power mode 4, ignition power mode 6 or crank power mode

9.

Any door, including the luggage compartment lid is opened

An unlock request is received from the Smart Key via the keyless vehicle module

Overhead console interior lamp is switched on via the JaguarSense function.

INTERIOR LAMPS

When the interior lighting system switches the interior lamps on, the CJB ramps the lamps up to full power over a period of 1.3 seconds. When the system switches the lamps off, after the time-out period has expired, the CJB fades the lamps off over a period of 2.6 seconds.

The interior lighting system will illuminate the interior lamps when one of the following events occurs:

The CJB receives an unlock signal from the Smart Key via the keyless vehicle module Any door is opened including the luggage compartment lid

The ignition mode is changed from ignition power mode 6 or accessory power mode 4 to off power mode 0.

The interior lighting system will turn off the interior lamps when one of the following events occurs:

Once the time-out timer delay has expired since the lamps were either activated or the last door is closed and the

vehicle is not locked

The ignition is in off power mode 0 and an external lock is requested (using either the door lock buttons or the Smart

Key) with all doors closed

The ignition mode is changed from the off power mode 0 or the accessory power mode 4 to the ignition power mode 6

The last door is closed and the vehicle is externally locked, on receipt of an unlock request from the Smart Key or door

handle operation detected when the time-out timer is still active.

DELIVERY MODE

Delivery mode is set at the factory on vehicles to minimize battery drain. The mode enables the switching off of non-critical

electrical components, including the interior lighting system. The delivery mode feature is cancelled by the dealer during the

Pre-Delivery Inspection using an approved Jaguar diagnostic system.

CRASH ILLUMINATION

When a crash signal is received from the RCM (restraints control module), the CJB activates the interior lamps once the vehicle speed has reduced to 5 km/h (3.1 mph). The hazard flashers are also activated and the doors are prevented from being locked.

The lamps remain on until the crash signal is removed, they cannot be switched off using the JaguarSense feature. The crash

signal is removed by completing one ignition on and off cycle.

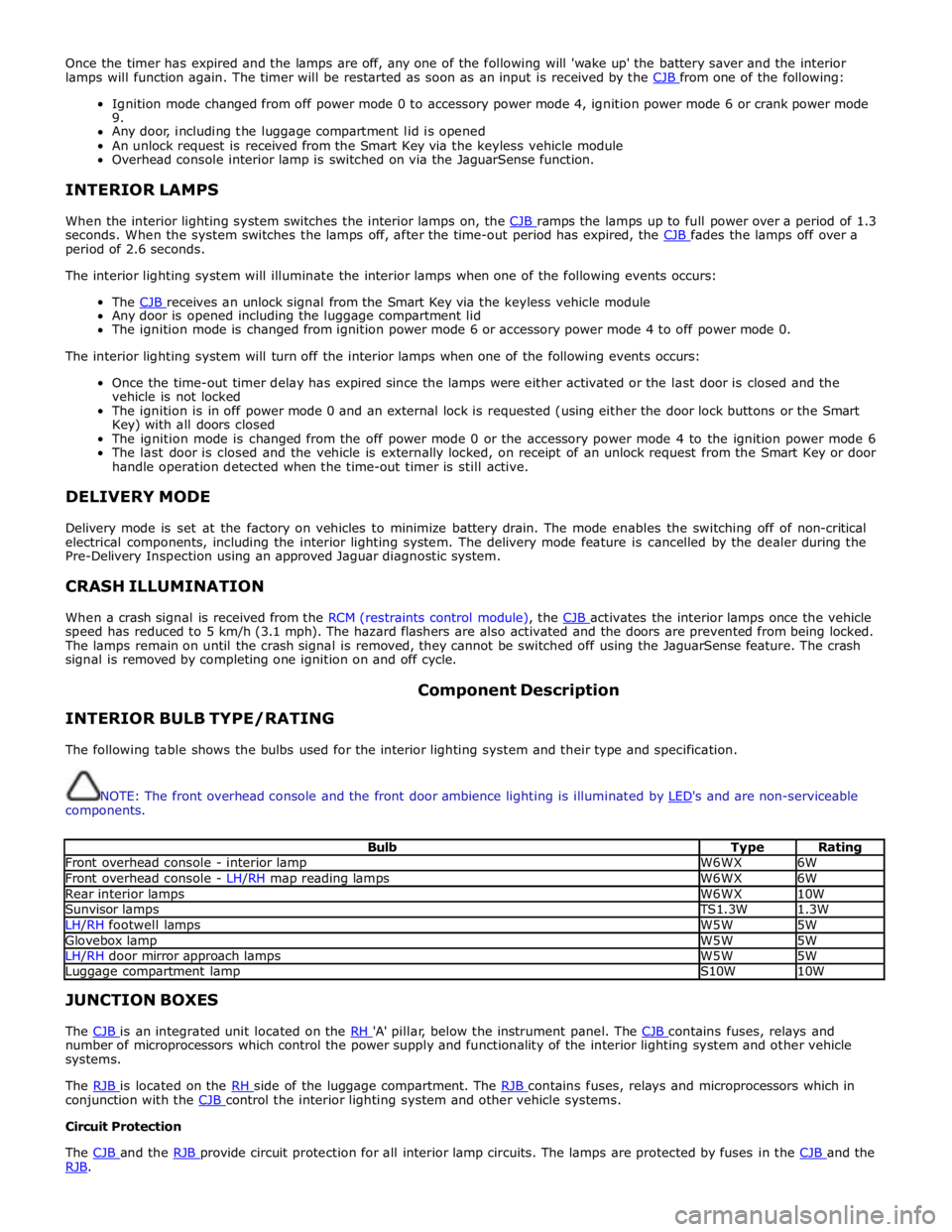

INTERIOR BULB TYPE/RATING Component Description

The following table shows the bulbs used for the interior lighting system and their type and specification.

NOTE: The front overhead console and the front door ambience lighting is illuminated by LED's and are non-serviceable components.

Bulb Type Rating Front overhead console - interior lamp W6WX 6W Front overhead console - LH/RH map reading lamps W6WX 6W Rear interior lamps W6WX 10W Sunvisor lamps TS1.3W 1.3W LH/RH footwell lamps W5W 5W Glovebox lamp W5W 5W LH/RH door mirror approach lamps W5W 5W Luggage compartment lamp S10W 10W JUNCTION BOXES

The CJB is an integrated unit located on the RH 'A' pillar, below the instrument panel. The CJB contains fuses, relays and number of microprocessors which control the power supply and functionality of the interior lighting system and other vehicle

systems.

The RJB is located on the RH side of the luggage compartment. The RJB contains fuses, relays and microprocessors which in conjunction with the CJB control the interior lighting system and other vehicle systems. Circuit Protection

The CJB and the RJB provide circuit protection for all interior lamp circuits. The lamps are protected by fuses in the CJB and the RJB.

Page 2071 of 3039

N = Medium speed CAN (controller area network) bus 1 Parking aid module 2 RJB 3 Keyless vehicle module 4 RH blind spot monitoring module 5 Driver's seat module 6 Front seat climate control module 7 Information control module 8 ATC module 9 CJB 10 Diagnostic socket 11 Instrument cluster 12 Integrated control panel 13 Front passenger door control module

Page 2085 of 3039

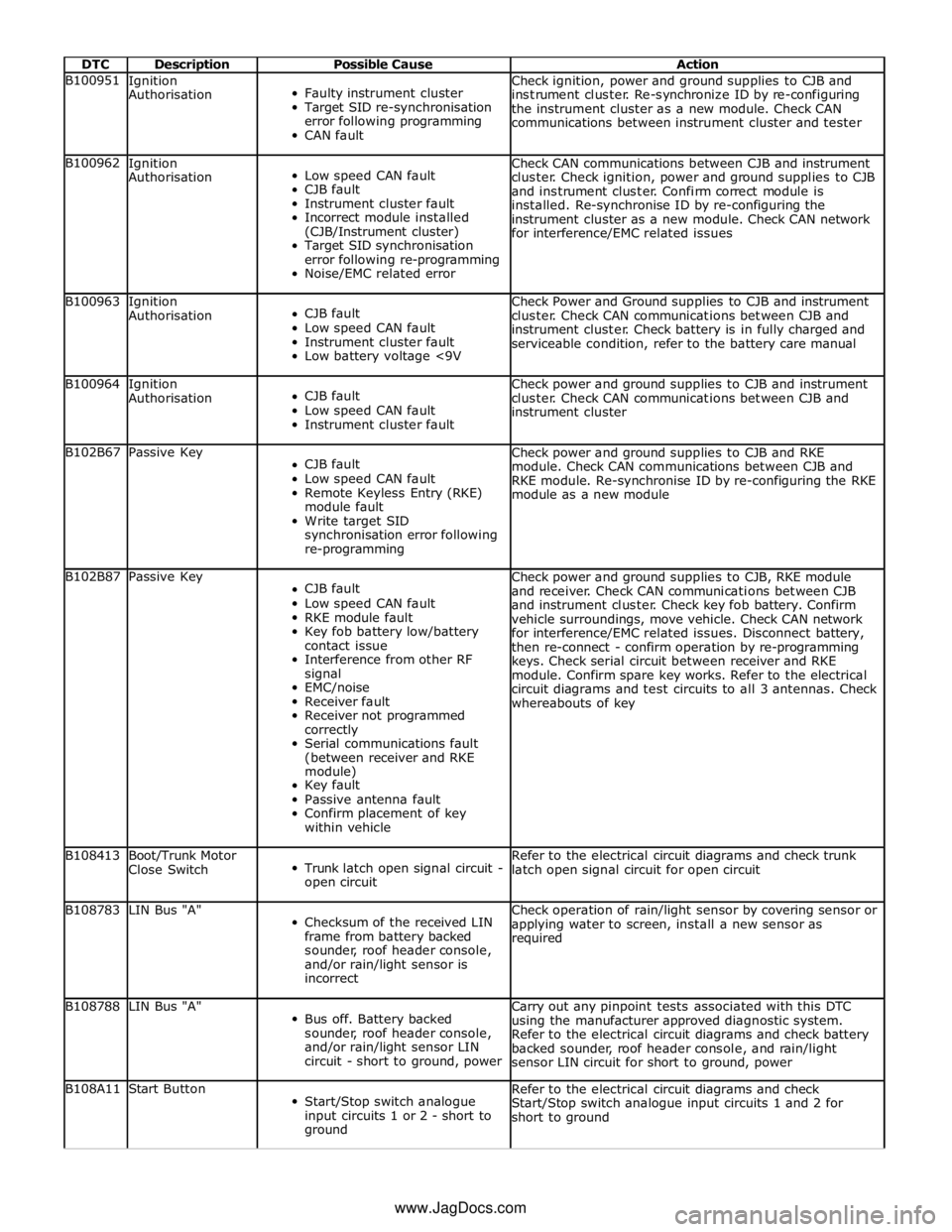

DTC Description Possible Cause Action B100951

Ignition

Authorisation

Faulty instrument cluster

Target SID re-synchronisation

error following programming

CAN fault Check ignition, power and ground supplies to CJB and

instrument cluster. Re-synchronize ID by re-configuring

the instrument cluster as a new module. Check CAN

communications between instrument cluster and tester B100962

Ignition

Authorisation

Low speed CAN fault

CJB fault

Instrument cluster fault

Incorrect module installed

(CJB/Instrument cluster)

Target SID synchronisation

error following re-programming

Noise/EMC related error Check CAN communications between CJB and instrument

cluster. Check ignition, power and ground supplies to CJB

and instrument cluster. Confirm correct module is

installed. Re-synchronise ID by re-configuring the

instrument cluster as a new module. Check CAN network

for interference/EMC related issues B100963

Ignition

Authorisation

CJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V Check Power and Ground supplies to CJB and instrument

cluster. Check CAN communications between CJB and

instrument cluster. Check battery is in fully charged and

serviceable condition, refer to the battery care manual B100964

Ignition

Authorisation

CJB fault

Low speed CAN fault

Instrument cluster fault Check power and ground supplies to CJB and instrument

cluster. Check CAN communications between CJB and

instrument cluster B102B67 Passive Key

CJB fault

Low speed CAN fault

Remote Keyless Entry (RKE)

module fault

Write target SID

synchronisation error following

re-programming Check power and ground supplies to CJB and RKE

module. Check CAN communications between CJB and

RKE module. Re-synchronise ID by re-configuring the RKE

module as a new module B102B87 Passive Key

CJB fault

Low speed CAN fault

RKE module fault

Key fob battery low/battery

contact issue

Interference from other RF

signal

EMC/noise

Receiver fault

Receiver not programmed

correctly

Serial communications fault

(between receiver and RKE

module)

Key fault

Passive antenna fault

Confirm placement of key

within vehicle Check power and ground supplies to CJB, RKE module

and receiver. Check CAN communications between CJB

and instrument cluster. Check key fob battery. Confirm

vehicle surroundings, move vehicle. Check CAN network

for interference/EMC related issues. Disconnect battery,

then re-connect - confirm operation by re-programming

keys. Check serial circuit between receiver and RKE

module. Confirm spare key works. Refer to the electrical

circuit diagrams and test circuits to all 3 antennas. Check

whereabouts of key B108413

Boot/Trunk Motor

Close Switch

Trunk latch open signal circuit -

open circuit Refer to the electrical circuit diagrams and check trunk

latch open signal circuit for open circuit B108783 LIN Bus "A"

Checksum of the received LIN

frame from battery backed

sounder, roof header console,

and/or rain/light sensor is

incorrect Check operation of rain/light sensor by covering sensor or

applying water to screen, install a new sensor as

required B108788 LIN Bus "A"

Bus off. Battery backed

sounder, roof header console,

and/or rain/light sensor LIN

circuit - short to ground, power Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check battery

backed sounder, roof header console, and rain/light

sensor LIN circuit for short to ground, power B108A11 Start Button

Start/Stop switch analogue

input circuits 1 or 2 - short to

ground Refer to the electrical circuit diagrams and check

Start/Stop switch analogue input circuits 1 and 2 for

short to ground www.JagDocs.com

Page 2086 of 3039

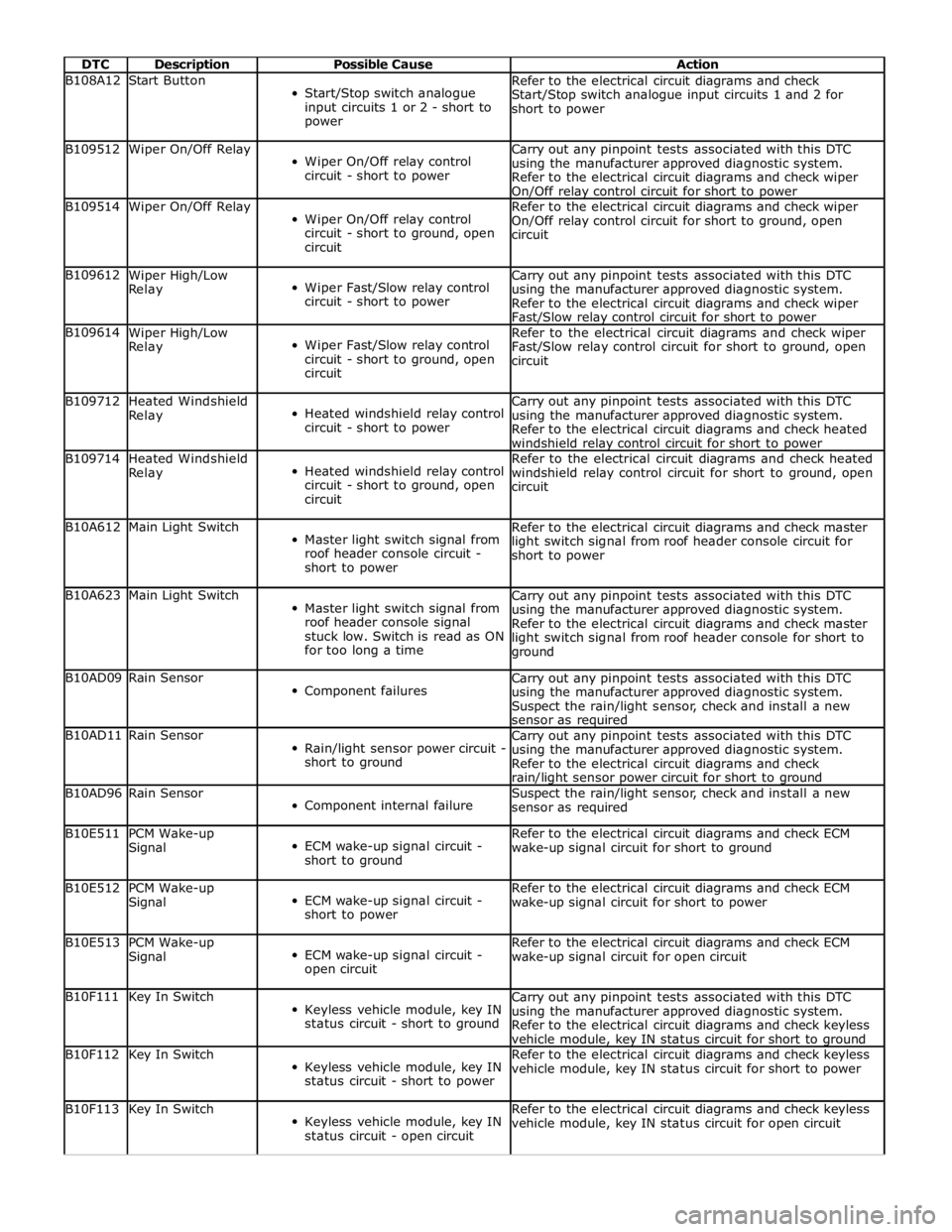

DTC Description Possible Cause Action B108A12 Start Button

Start/Stop switch analogue

input circuits 1 or 2 - short to

power Refer to the electrical circuit diagrams and check

Start/Stop switch analogue input circuits 1 and 2 for

short to power B109512 Wiper On/Off Relay

Wiper On/Off relay control

circuit - short to power Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check wiper

On/Off relay control circuit for short to power B109514 Wiper On/Off Relay

Wiper On/Off relay control

circuit - short to ground, open

circuit Refer to the electrical circuit diagrams and check wiper

On/Off relay control circuit for short to ground, open

circuit B109612

Wiper High/Low

Relay

Wiper Fast/Slow relay control

circuit - short to power Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check wiper

Fast/Slow relay control circuit for short to power B109614

Wiper High/Low

Relay

Wiper Fast/Slow relay control

circuit - short to ground, open

circuit Refer to the electrical circuit diagrams and check wiper

Fast/Slow relay control circuit for short to ground, open

circuit B109712

Heated Windshield

Relay

Heated windshield relay control

circuit - short to power Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check heated

windshield relay control circuit for short to power B109714

Heated Windshield

Relay

Heated windshield relay control

circuit - short to ground, open

circuit Refer to the electrical circuit diagrams and check heated

windshield relay control circuit for short to ground, open

circuit B10A612 Main Light Switch

Master light switch signal from

roof header console circuit -

short to power Refer to the electrical circuit diagrams and check master

light switch signal from roof header console circuit for

short to power B10A623 Main Light Switch

Master light switch signal from

roof header console signal

stuck low. Switch is read as ON

for too long a time Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check master

light switch signal from roof header console for short to

ground B10AD09 Rain Sensor

Component failures Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Suspect the rain/light sensor, check and install a new

sensor as required B10AD11 Rain Sensor

Rain/light sensor power circuit -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check rain/light sensor power circuit for short to ground B10AD96 Rain Sensor

Component internal failure Suspect the rain/light sensor, check and install a new

sensor as required B10E511

PCM Wake-up

Signal

ECM wake-up signal circuit -

short to ground Refer to the electrical circuit diagrams and check ECM

wake-up signal circuit for short to ground B10E512

PCM Wake-up

Signal

ECM wake-up signal circuit -

short to power Refer to the electrical circuit diagrams and check ECM

wake-up signal circuit for short to power B10E513

PCM Wake-up

Signal

ECM wake-up signal circuit -

open circuit Refer to the electrical circuit diagrams and check ECM

wake-up signal circuit for open circuit B10F111 Key In Switch

Keyless vehicle module, key IN

status circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check keyless

vehicle module, key IN status circuit for short to ground B10F112 Key In Switch

Keyless vehicle module, key IN

status circuit - short to power Refer to the electrical circuit diagrams and check keyless

vehicle module, key IN status circuit for short to power B10F113 Key In Switch

Keyless vehicle module, key IN

status circuit - open circuit Refer to the electrical circuit diagrams and check keyless

vehicle module, key IN status circuit for open circuit

Page 2119 of 3039

Anti-Theft - Active - Anti-Theft - Active - Component Location

Description and Operation

Component Location Published: 11-May-2011

Item Description 1 Alarm indicator 2 Latch mechanism - front door 3 Intrusion detection module 4 Latch mechanism - rear door 5 Central locking Radio Frequency (RF) receiver 6 Luggage compartment lid latch mechanism 7 Keyless vehicle module 8 Latch mechanism - rear door 9 Latch mechanism - front door

Page 2122 of 3039

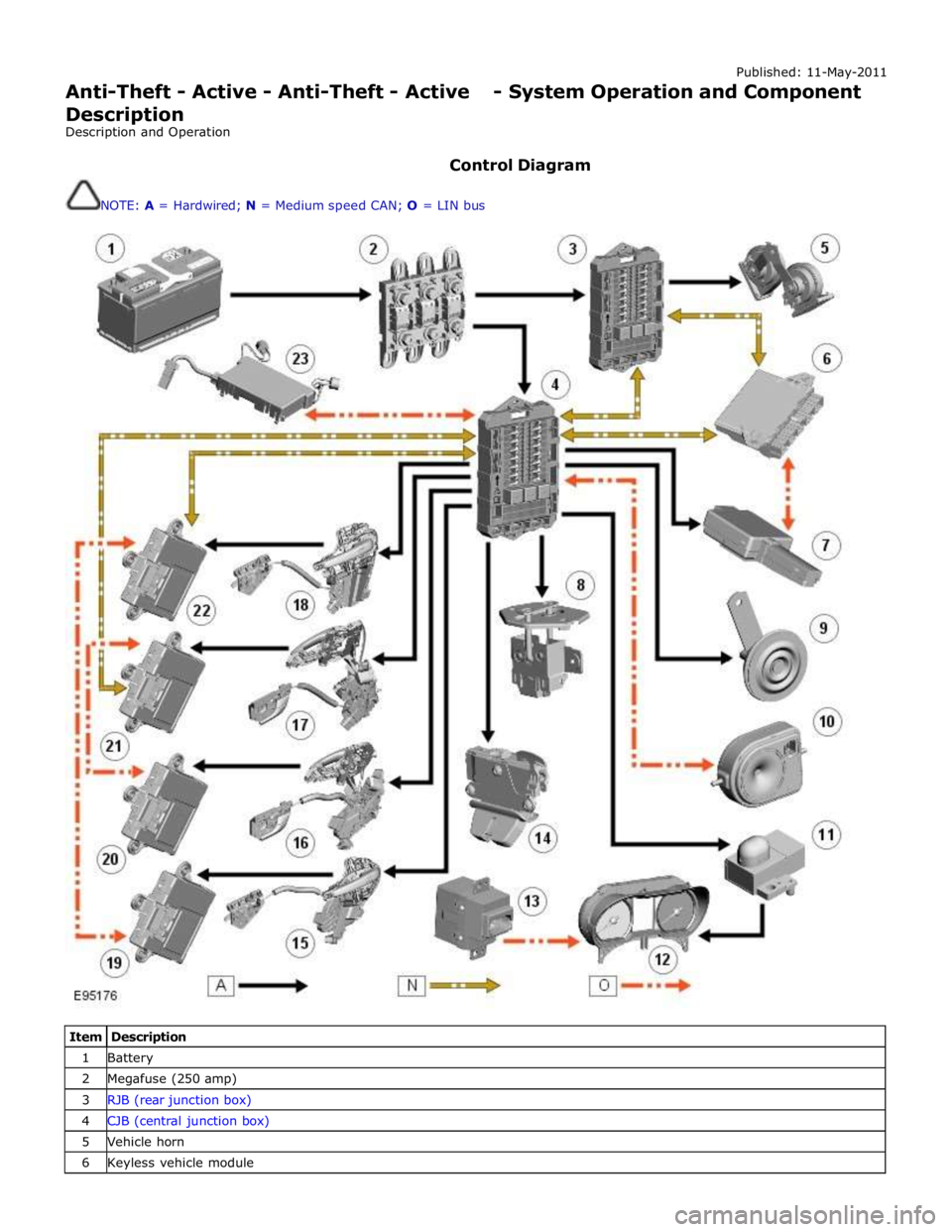

Published: 11-May-2011

Anti-Theft - Active - Anti-Theft - Active - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; N = Medium speed CAN; O = LIN bus

Item Description 1 Battery 2 Megafuse (250 amp) 3 RJB (rear junction box) 4 CJB (central junction box) 5 Vehicle horn 6 Keyless vehicle module