park brake JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 161 of 3039

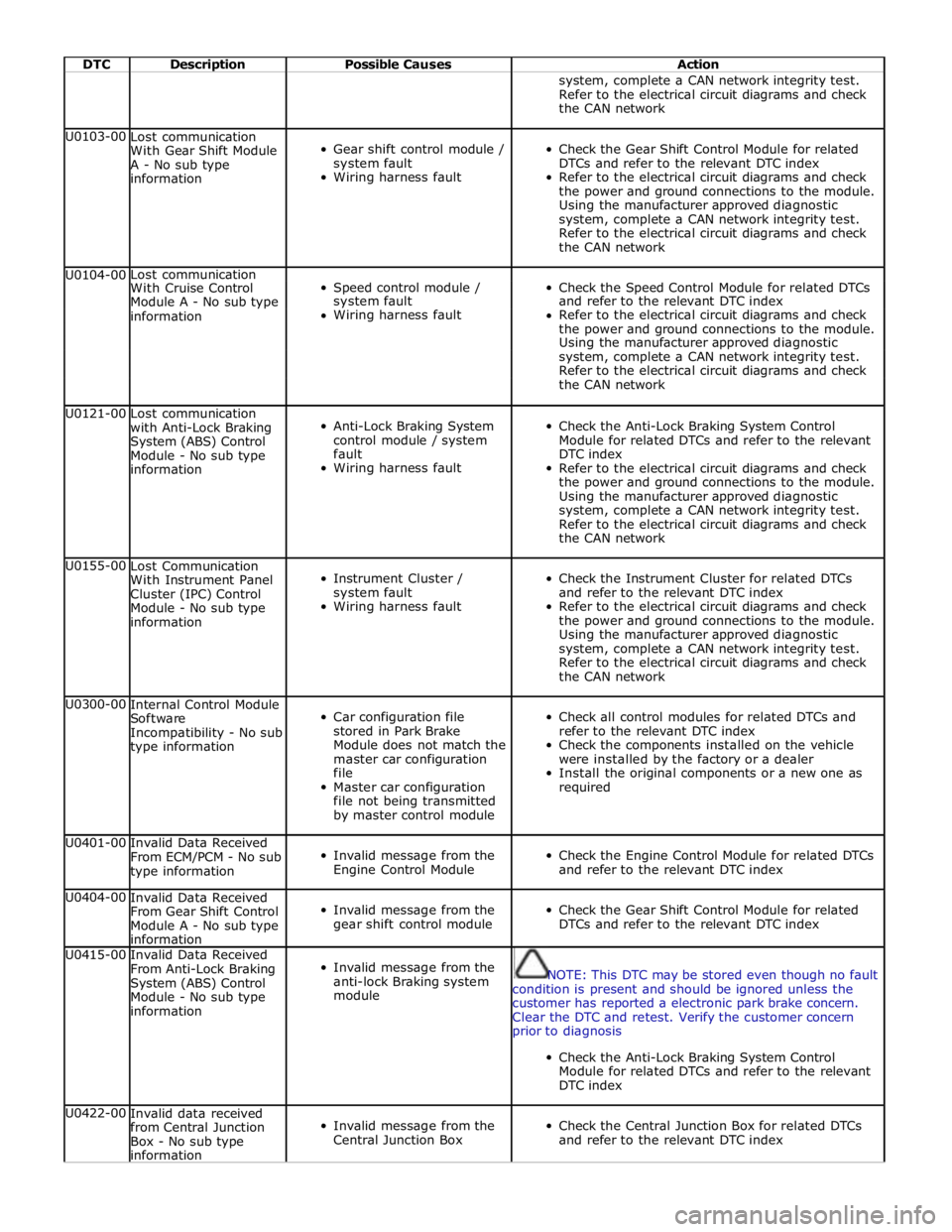

DTC Description Possible Causes Action system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network U0103-00

Lost communication

With Gear Shift Module

A - No sub type

information

Gear shift control module /

system fault

Wiring harness fault

Check the Gear Shift Control Module for related

DTCs and refer to the relevant DTC index

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network U0104-00 Lost communication

Speed control module /

Check the Speed Control Module for related DTCs With Cruise Control Module A - No sub type system fault and refer to the relevant DTC index information Wiring harness fault Refer to the electrical circuit diagrams and check the power and ground connections to the module. Using the manufacturer approved diagnostic system, complete a CAN network integrity test. Refer to the electrical circuit diagrams and check the CAN network U0121-00

Lost communication

with Anti-Lock Braking

System (ABS) Control

Module - No sub type

information

Anti-Lock Braking System

control module / system

fault

Wiring harness fault

Check the Anti-Lock Braking System Control

Module for related DTCs and refer to the relevant

DTC index

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Instrument Cluster /

system fault

Wiring harness fault

Check the Instrument Cluster for related DTCs

and refer to the relevant DTC index

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network U0300-00

Internal Control Module

Software

Incompatibility - No sub

type information

Car configuration file

stored in Park Brake

Module does not match the

master car configuration

file

Master car configuration

file not being transmitted

by master control module

Check all control modules for related DTCs and

refer to the relevant DTC index

Check the components installed on the vehicle

were installed by the factory or a dealer

Install the original components or a new one as

required U0401-00

Invalid Data Received

From ECM/PCM - No sub

type information

Invalid message from the

Engine Control Module

Check the Engine Control Module for related DTCs

and refer to the relevant DTC index U0404-00

Invalid Data Received

From Gear Shift Control

Module A - No sub type

information

Invalid message from the

gear shift control module

Check the Gear Shift Control Module for related

DTCs and refer to the relevant DTC index U0415-00

Invalid Data Received

From Anti-Lock Braking

System (ABS) Control

Module - No sub type

information

Invalid message from the

anti-lock Braking system

module

NOTE: This DTC may be stored even though no fault

condition is present and should be ignored unless the

customer has reported a electronic park brake concern.

Clear the DTC and retest. Verify the customer concern

prior to diagnosis

Check the Anti-Lock Braking System Control

Module for related DTCs and refer to the relevant

DTC index U0422-00

Invalid data received

from Central Junction

Box - No sub type

information

Invalid message from the

Central Junction Box

Check the Central Junction Box for related DTCs

and refer to the relevant DTC index

Page 162 of 3039

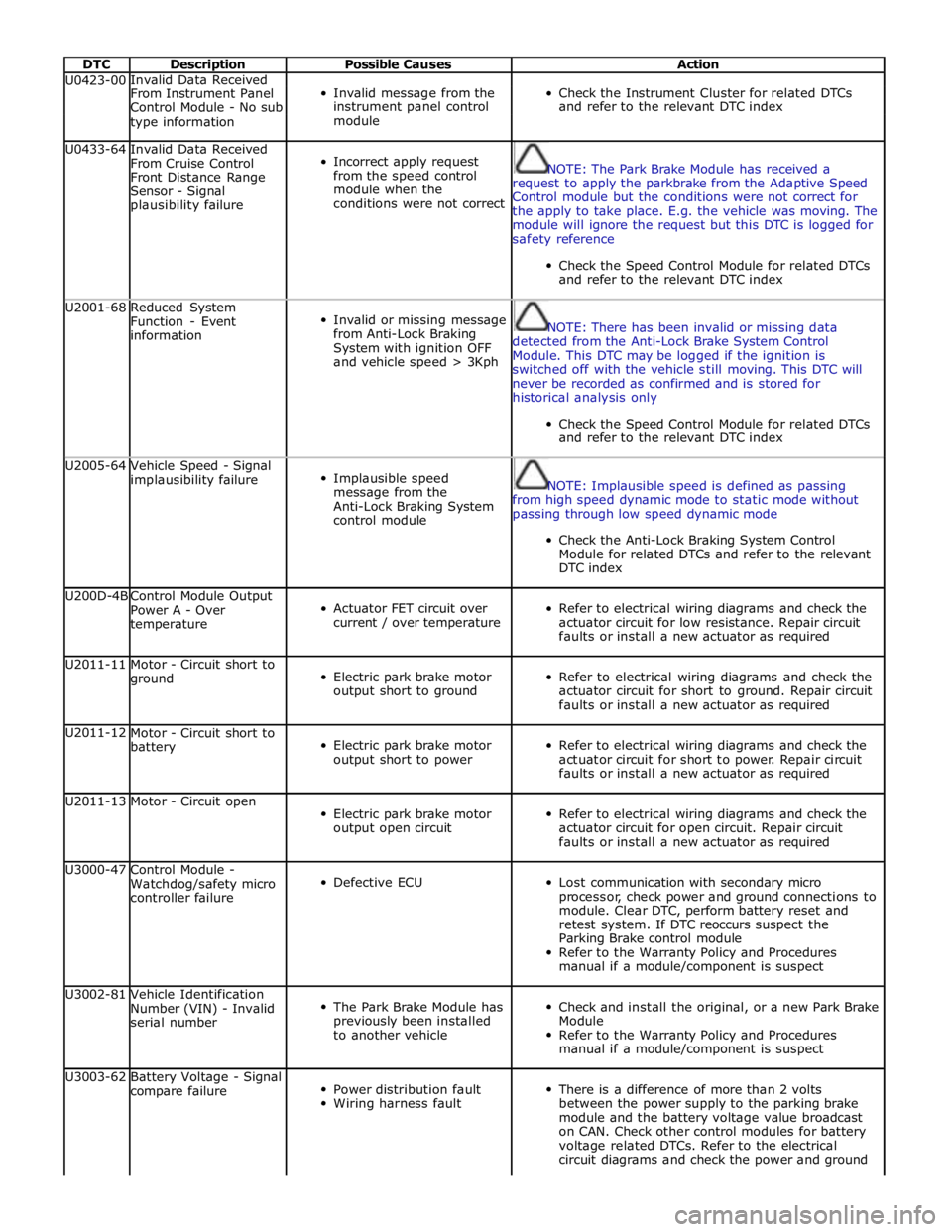

DTC Description Possible Causes Action U0423-00 Invalid Data Received

Invalid message from the

Check the Instrument Cluster for related DTCs From Instrument Panel Control Module - No sub instrument panel control and refer to the relevant DTC index type information module U0433-64

Invalid Data Received

From Cruise Control

Front Distance Range

Sensor - Signal

plausibility failure

Incorrect apply request

from the speed control

module when the

conditions were not correct

NOTE: The Park Brake Module has received a

request to apply the parkbrake from the Adaptive Speed

Control module but the conditions were not correct for

the apply to take place. E.g. the vehicle was moving. The

module will ignore the request but this DTC is logged for

safety reference

Check the Speed Control Module for related DTCs

and refer to the relevant DTC index U2001-68

Reduced System

Function - Event

information

Invalid or missing message

from Anti-Lock Braking

System with ignition OFF

and vehicle speed > 3Kph

NOTE: There has been invalid or missing data

detected from the Anti-Lock Brake System Control

Module. This DTC may be logged if the ignition is

switched off with the vehicle still moving. This DTC will

never be recorded as confirmed and is stored for

historical analysis only

Check the Speed Control Module for related DTCs

and refer to the relevant DTC index U2005-64

Vehicle Speed - Signal

implausibility failure

Implausible speed

message from the

Anti-Lock Braking System

control module

NOTE: Implausible speed is defined as passing

from high speed dynamic mode to static mode without

passing through low speed dynamic mode

Check the Anti-Lock Braking System Control

Module for related DTCs and refer to the relevant

DTC index U200D-4B

Control Module Output

Power A - Over

temperature

Actuator FET circuit over

current / over temperature

Refer to electrical wiring diagrams and check the

actuator circuit for low resistance. Repair circuit

faults or install a new actuator as required U2011-11

Motor - Circuit short to

ground

Electric park brake motor

output short to ground

Refer to electrical wiring diagrams and check the

actuator circuit for short to ground. Repair circuit

faults or install a new actuator as required U2011-12

Motor - Circuit short to

battery

Electric park brake motor

output short to power

Refer to electrical wiring diagrams and check the

actuator circuit for short to power. Repair circuit

faults or install a new actuator as required U2011-13 Motor - Circuit open

Electric park brake motor

output open circuit

Refer to electrical wiring diagrams and check the

actuator circuit for open circuit. Repair circuit

faults or install a new actuator as required U3000-47

Control Module -

Watchdog/safety micro

controller failure

Defective ECU

Lost communication with secondary micro

processor, check power and ground connections to

module. Clear DTC, perform battery reset and

retest system. If DTC reoccurs suspect the

Parking Brake control module

Refer to the Warranty Policy and Procedures

manual if a module/component is suspect U3002-81

Vehicle Identification

Number (VIN) - Invalid

serial number

The Park Brake Module has

previously been installed

to another vehicle

Check and install the original, or a new Park Brake

Module

Refer to the Warranty Policy and Procedures

manual if a module/component is suspect U3003-62

Battery Voltage - Signal

compare failure

Power distribution fault

Wiring harness fault

There is a difference of more than 2 volts

between the power supply to the parking brake

module and the battery voltage value broadcast

on CAN. Check other control modules for battery

voltage related DTCs. Refer to the electrical

circuit diagrams and check the power and ground

Page 163 of 3039

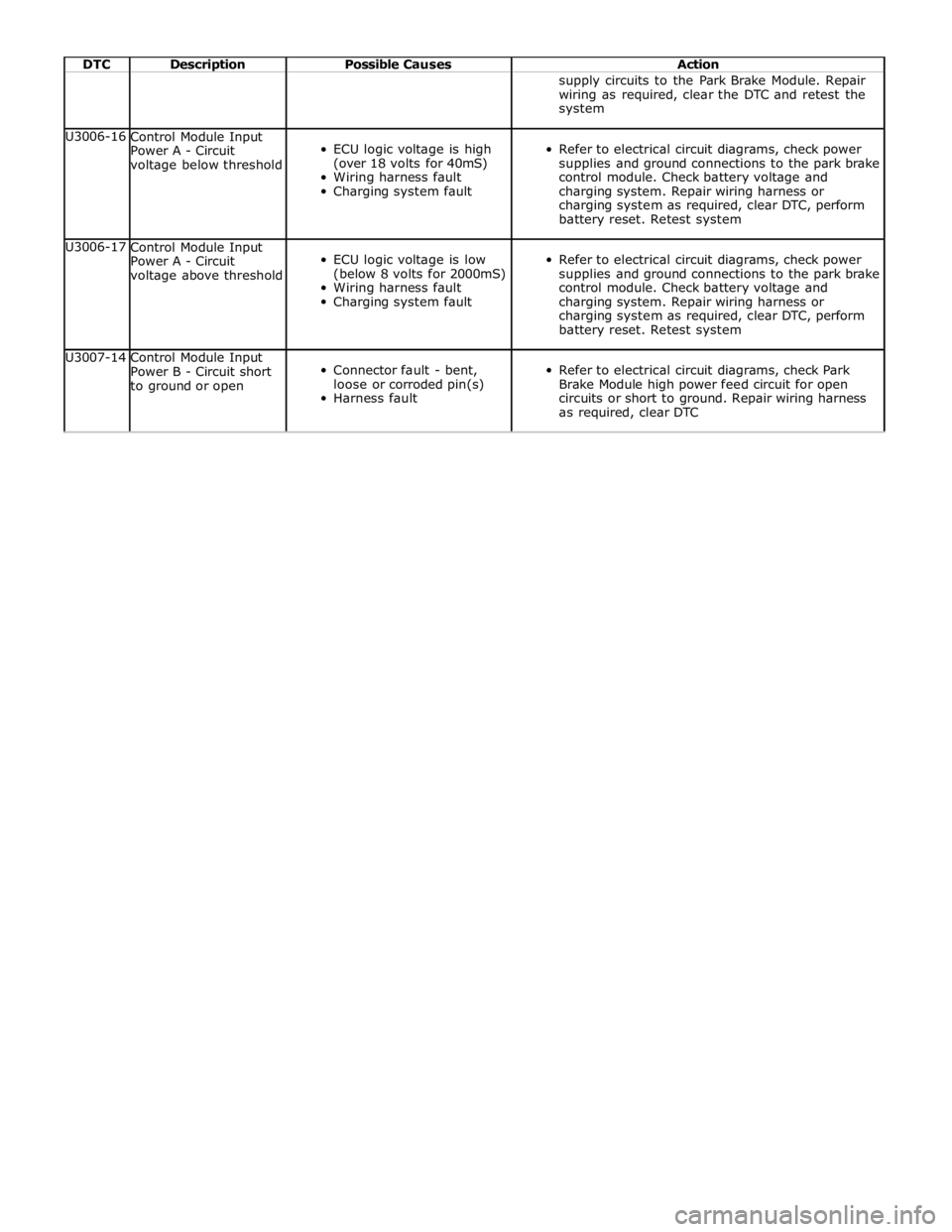

DTC Description Possible Causes Action supply circuits to the Park Brake Module. Repair

wiring as required, clear the DTC and retest the

system U3006-16

Control Module Input

Power A - Circuit

voltage below threshold

ECU logic voltage is high

(over 18 volts for 40mS)

Wiring harness fault

Charging system fault

Refer to electrical circuit diagrams, check power

supplies and ground connections to the park brake

control module. Check battery voltage and

charging system. Repair wiring harness or

charging system as required, clear DTC, perform

battery reset. Retest system U3006-17

Control Module Input

Power A - Circuit

voltage above threshold

ECU logic voltage is low

(below 8 volts for 2000mS)

Wiring harness fault

Charging system fault

Refer to electrical circuit diagrams, check power

supplies and ground connections to the park brake

control module. Check battery voltage and

charging system. Repair wiring harness or

charging system as required, clear DTC, perform

battery reset. Retest system U3007-14

Control Module Input

Power B - Circuit short

to ground or open

Connector fault - bent,

loose or corroded pin(s)

Harness fault

Refer to electrical circuit diagrams, check Park

Brake Module high power feed circuit for open

circuits or short to ground. Repair wiring harness

as required, clear DTC

Page 190 of 3039

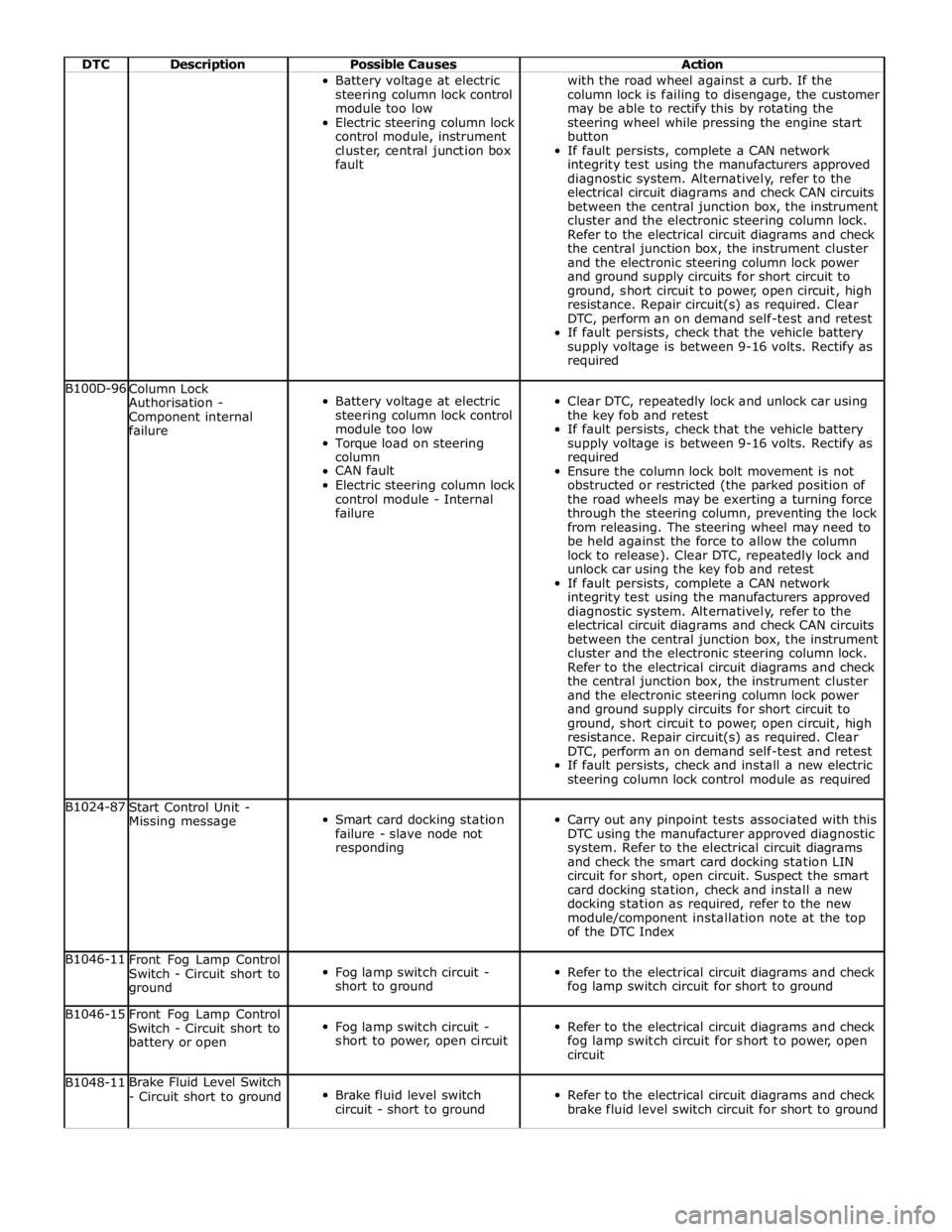

DTC Description Possible Causes Action Battery voltage at electric

steering column lock control

module too low

Electric steering column lock

control module, instrument

cluster, central junction box

fault with the road wheel against a curb. If the

column lock is failing to disengage, the customer

may be able to rectify this by rotating the

steering wheel while pressing the engine start

button

If fault persists, complete a CAN network

integrity test using the manufacturers approved

diagnostic system. Alternatively, refer to the

electrical circuit diagrams and check CAN circuits

between the central junction box, the instrument

cluster and the electronic steering column lock.

Refer to the electrical circuit diagrams and check

the central junction box, the instrument cluster

and the electronic steering column lock power

and ground supply circuits for short circuit to

ground, short circuit to power, open circuit, high

resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery

supply voltage is between 9-16 volts. Rectify as

required B100D-96

Column Lock

Authorisation -

Component internal

failure

Battery voltage at electric

steering column lock control

module too low

Torque load on steering

column

CAN fault

Electric steering column lock

control module - Internal

failure

Clear DTC, repeatedly lock and unlock car using

the key fob and retest

If fault persists, check that the vehicle battery

supply voltage is between 9-16 volts. Rectify as

required

Ensure the column lock bolt movement is not

obstructed or restricted (the parked position of

the road wheels may be exerting a turning force

through the steering column, preventing the lock

from releasing. The steering wheel may need to

be held against the force to allow the column

lock to release). Clear DTC, repeatedly lock and

unlock car using the key fob and retest

If fault persists, complete a CAN network

integrity test using the manufacturers approved

diagnostic system. Alternatively, refer to the

electrical circuit diagrams and check CAN circuits

between the central junction box, the instrument

cluster and the electronic steering column lock.

Refer to the electrical circuit diagrams and check

the central junction box, the instrument cluster

and the electronic steering column lock power

and ground supply circuits for short circuit to

ground, short circuit to power, open circuit, high

resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check and install a new electric

steering column lock control module as required B1024-87

Start Control Unit -

Missing message

Smart card docking station

failure - slave node not

responding

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check the smart card docking station LIN

circuit for short, open circuit. Suspect the smart

card docking station, check and install a new

docking station as required, refer to the new

module/component installation note at the top

of the DTC Index B1046-11

Front Fog Lamp Control

Switch - Circuit short to

ground

Fog lamp switch circuit -

short to ground

Refer to the electrical circuit diagrams and check

fog lamp switch circuit for short to ground B1046-15

Front Fog Lamp Control

Switch - Circuit short to

battery or open

Fog lamp switch circuit -

short to power, open circuit

Refer to the electrical circuit diagrams and check

fog lamp switch circuit for short to power, open

circuit B1048-11 Brake Fluid Level Switch

- Circuit short to ground

Brake fluid level switch

circuit - short to ground

Refer to the electrical circuit diagrams and check

brake fluid level switch circuit for short to ground

Page 239 of 3039

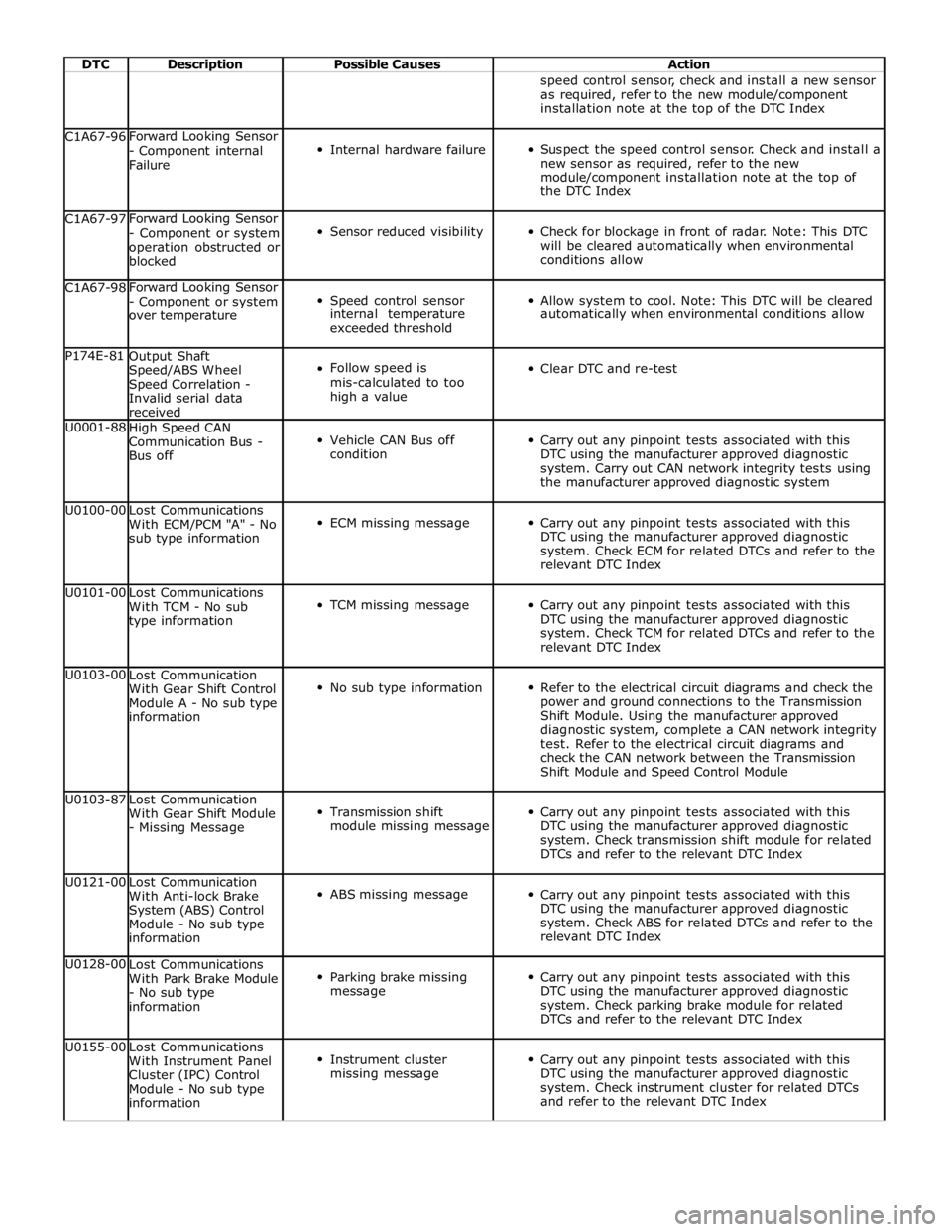

DTC Description Possible Causes Action speed control sensor, check and install a new sensor

as required, refer to the new module/component

installation note at the top of the DTC Index C1A67-96 Forward Looking Sensor

- Component internal

Failure

Internal hardware failure

Suspect the speed control sensor. Check and install a

new sensor as required, refer to the new

module/component installation note at the top of

the DTC Index C1A67-97 Forward Looking Sensor

- Component or system

operation obstructed or

blocked

Sensor reduced visibility

Check for blockage in front of radar. Note: This DTC

will be cleared automatically when environmental

conditions allow C1A67-98 Forward Looking Sensor

- Component or system

over temperature

Speed control sensor

internal temperature

exceeded threshold

Allow system to cool. Note: This DTC will be cleared

automatically when environmental conditions allow P174E-81

Output Shaft

Speed/ABS Wheel

Speed Correlation -

Invalid serial data

received

Follow speed is

mis-calculated to too

high a value

Clear DTC and re-test U0001-88

High Speed CAN

Communication Bus -

Bus off

Vehicle CAN Bus off

condition

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity tests using

the manufacturer approved diagnostic system U0100-00

Lost Communications

With ECM/PCM "A" - No

sub type information

ECM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ECM for related DTCs and refer to the

relevant DTC Index U0101-00

Lost Communications

With TCM - No sub

type information

TCM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check TCM for related DTCs and refer to the

relevant DTC Index U0103-00

Lost Communication

With Gear Shift Control

Module A - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check the

power and ground connections to the Transmission

Shift Module. Using the manufacturer approved

diagnostic system, complete a CAN network integrity

test. Refer to the electrical circuit diagrams and

check the CAN network between the Transmission

Shift Module and Speed Control Module U0103-87

Lost Communication

With Gear Shift Module

- Missing Message

Transmission shift

module missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check transmission shift module for related

DTCs and refer to the relevant DTC Index U0121-00

Lost Communication

With Anti-lock Brake

System (ABS) Control

Module - No sub type

information

ABS missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ABS for related DTCs and refer to the

relevant DTC Index U0128-00

Lost Communications

With Park Brake Module

- No sub type

information

Parking brake missing

message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check parking brake module for related

DTCs and refer to the relevant DTC Index U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Instrument cluster

missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check instrument cluster for related DTCs

and refer to the relevant DTC Index

Page 240 of 3039

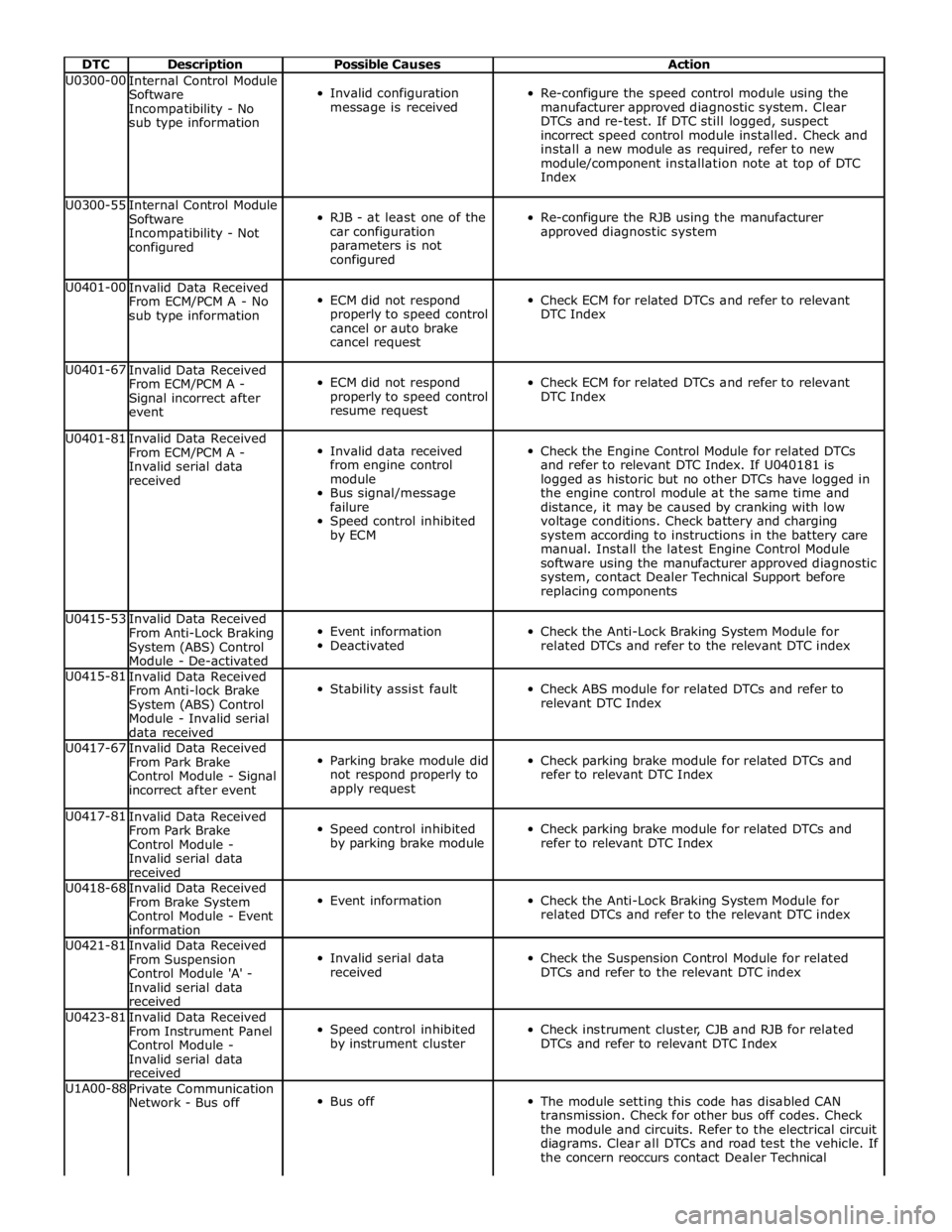

DTC Description Possible Causes Action U0300-00

Internal Control Module

Software

Incompatibility - No

sub type information

Invalid configuration

message is received

Re-configure the speed control module using the

manufacturer approved diagnostic system. Clear

DTCs and re-test. If DTC still logged, suspect

incorrect speed control module installed. Check and

install a new module as required, refer to new

module/component installation note at top of DTC

Index U0300-55

Internal Control Module

Software

Incompatibility - Not

configured

RJB - at least one of the

car configuration

parameters is not

configured

Re-configure the RJB using the manufacturer

approved diagnostic system U0401-00

Invalid Data Received

From ECM/PCM A - No

sub type information

ECM did not respond

properly to speed control

cancel or auto brake

cancel request

Check ECM for related DTCs and refer to relevant

DTC Index U0401-67

Invalid Data Received

From ECM/PCM A -

Signal incorrect after

event

ECM did not respond

properly to speed control

resume request

Check ECM for related DTCs and refer to relevant

DTC Index U0401-81

Invalid Data Received

From ECM/PCM A -

Invalid serial data

received

Invalid data received

from engine control

module

Bus signal/message

failure

Speed control inhibited

by ECM

Check the Engine Control Module for related DTCs

and refer to relevant DTC Index. If U040181 is

logged as historic but no other DTCs have logged in

the engine control module at the same time and

distance, it may be caused by cranking with low

voltage conditions. Check battery and charging

system according to instructions in the battery care

manual. Install the latest Engine Control Module

software using the manufacturer approved diagnostic

system, contact Dealer Technical Support before

replacing components U0415-53

Invalid Data Received

From Anti-Lock Braking

System (ABS) Control

Module - De-activated

Event information

Deactivated

Check the Anti-Lock Braking System Module for

related DTCs and refer to the relevant DTC index U0415-81

Invalid Data Received

From Anti-lock Brake

System (ABS) Control

Module - Invalid serial

data received

Stability assist fault

Check ABS module for related DTCs and refer to

relevant DTC Index U0417-67

Invalid Data Received

From Park Brake

Control Module - Signal

incorrect after event

Parking brake module did

not respond properly to

apply request

Check parking brake module for related DTCs and

refer to relevant DTC Index U0417-81

Invalid Data Received

From Park Brake

Control Module -

Invalid serial data

received

Speed control inhibited

by parking brake module

Check parking brake module for related DTCs and

refer to relevant DTC Index U0418-68

Invalid Data Received

From Brake System

Control Module - Event

information

Event information

Check the Anti-Lock Braking System Module for

related DTCs and refer to the relevant DTC index U0421-81

Invalid Data Received

From Suspension

Control Module 'A' -

Invalid serial data

received

Invalid serial data

received

Check the Suspension Control Module for related

DTCs and refer to the relevant DTC index U0423-81

Invalid Data Received

From Instrument Panel

Control Module -

Invalid serial data

received

Speed control inhibited

by instrument cluster

Check instrument cluster, CJB and RJB for related

DTCs and refer to relevant DTC Index U1A00-88

Private Communication

Network - Bus off

Bus off

The module setting this code has disabled CAN

transmission. Check for other bus off codes. Check

the module and circuits. Refer to the electrical circuit

diagrams. Clear all DTCs and road test the vehicle. If

the concern reoccurs contact Dealer Technical

Page 267 of 3039

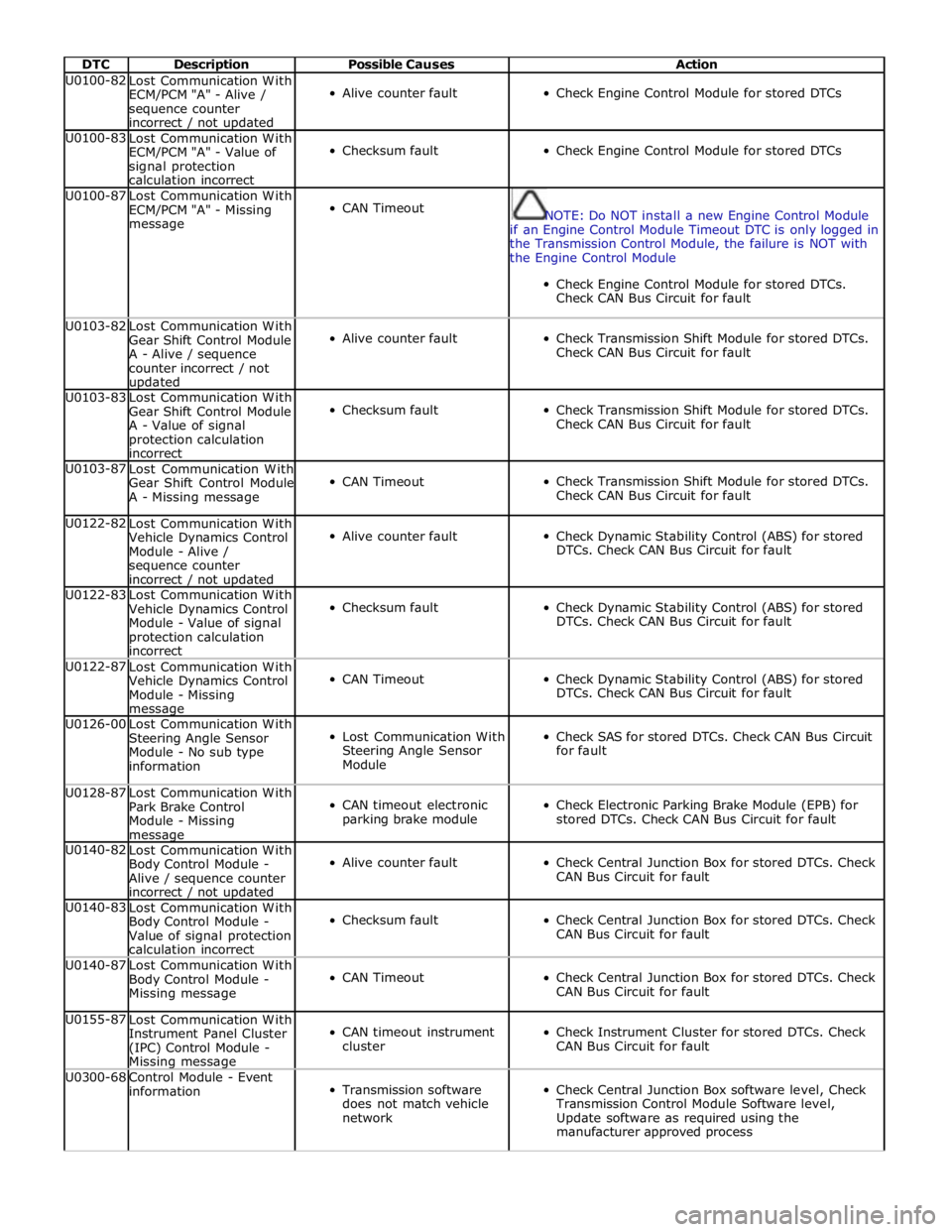

DTC Description Possible Causes Action U0100-82

Lost Communication With

ECM/PCM "A" - Alive /

sequence counter

incorrect / not updated

Alive counter fault

Check Engine Control Module for stored DTCs U0100-83

Lost Communication With

ECM/PCM "A" - Value of

signal protection

calculation incorrect

Checksum fault

Check Engine Control Module for stored DTCs U0100-87

Lost Communication With

ECM/PCM "A" - Missing

message

CAN Timeout

NOTE: Do NOT install a new Engine Control Module

if an Engine Control Module Timeout DTC is only logged in

the Transmission Control Module, the failure is NOT with

the Engine Control Module

Check Engine Control Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-82

Lost Communication With

Gear Shift Control Module

A - Alive / sequence

counter incorrect / not updated

Alive counter fault

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-83

Lost Communication With

Gear Shift Control Module

A - Value of signal

protection calculation

incorrect

Checksum fault

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-87

Lost Communication With

Gear Shift Control Module

A - Missing message

CAN Timeout

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0122-82

Lost Communication With

Vehicle Dynamics Control

Module - Alive /

sequence counter

incorrect / not updated

Alive counter fault

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0122-83

Lost Communication With

Vehicle Dynamics Control

Module - Value of signal

protection calculation

incorrect

Checksum fault

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0122-87

Lost Communication With

Vehicle Dynamics Control

Module - Missing message

CAN Timeout

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0126-00

Lost Communication With

Steering Angle Sensor

Module - No sub type

information

Lost Communication With

Steering Angle Sensor

Module

Check SAS for stored DTCs. Check CAN Bus Circuit

for fault U0128-87

Lost Communication With

Park Brake Control

Module - Missing message

CAN timeout electronic

parking brake module

Check Electronic Parking Brake Module (EPB) for

stored DTCs. Check CAN Bus Circuit for fault U0140-82

Lost Communication With

Body Control Module -

Alive / sequence counter

incorrect / not updated

Alive counter fault

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0140-83

Lost Communication With

Body Control Module -

Value of signal protection

calculation incorrect

Checksum fault

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0140-87

Lost Communication With

Body Control Module -

Missing message

CAN Timeout

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0155-87

Lost Communication With

Instrument Panel Cluster

(IPC) Control Module - Missing message

CAN timeout instrument

cluster

Check Instrument Cluster for stored DTCs. Check

CAN Bus Circuit for fault U0300-68

Control Module - Event

information

Transmission software

does not match vehicle

network

Check Central Junction Box software level, Check

Transmission Control Module Software level,

Update software as required using the

manufacturer approved process

Page 294 of 3039

Jacking and Lifting - Jacking

Description and Operation

Safety Precautions Published: 11-May-2011

WARNING: The jack provided with the vehicle is intended to be used in an emergency for changing a deflated tire. To

avoid damage to the vehicle, never use the jack to raise the vehicle for any other purpose. Refer to the Driver Handbook when

using the jack supplied with the vehicle. Failure to follow these instructions may result in personal injury.

The following safety precautions must be observed when raising the vehicle to carry out service operations:

Never rely on a jack alone to support a vehicle. Always use suitable vehicle stands to provide rigid support.

When working beneath a vehicle, whenever possible use a vehicle hoist instead of a jack and vehicle stands.

Make sure that the vehicle is standing on firm, level ground before using a jack.

Do not rely on the parking brake alone; chock the wheels and put the automatic transmission into Park if possible.

Check that any lifting equipment used has adequate capacity for the load being lifted and is in correct working order.

Page 296 of 3039

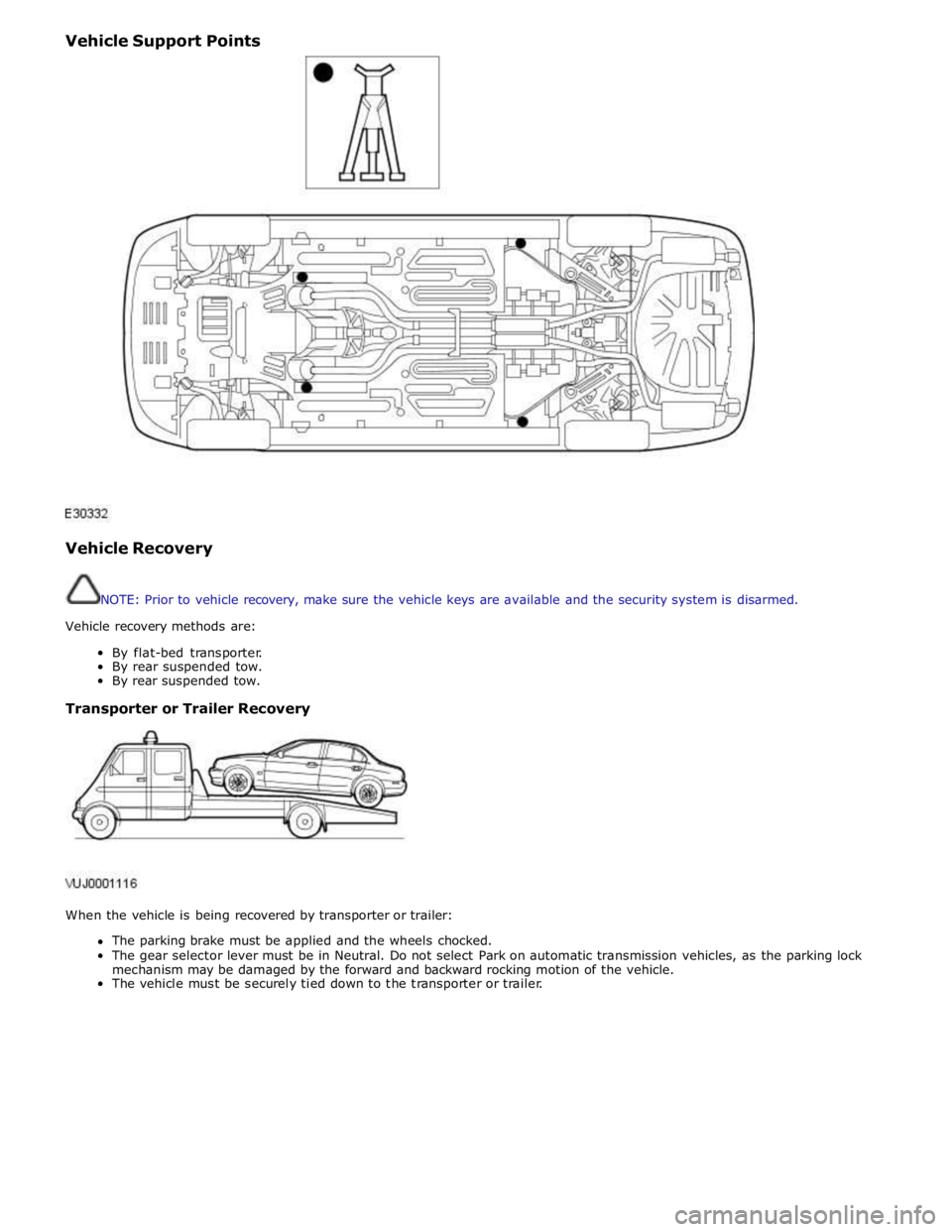

Vehicle Support Points

Vehicle Recovery

NOTE: Prior to vehicle recovery, make sure the vehicle keys are available and the security system is disarmed.

Vehicle recovery methods are:

By flat-bed transporter.

By rear suspended tow.

By rear suspended tow.

Transporter or Trailer Recovery

When the vehicle is being recovered by transporter or trailer:

The parking brake must be applied and the wheels chocked.

The gear selector lever must be in Neutral. Do not select Park on automatic transmission vehicles, as the parking lock

mechanism may be damaged by the forward and backward rocking motion of the vehicle.

The vehicle must be securely tied down to the transporter or trailer.

Page 317 of 3039

Published: 16-Oct-2013

Suspension System - General Information - Four-Wheel Alignment

General Procedures

CAUTIONS:

Make sure the vehicle is on a flat level surface.

Make sure the tire pressures are within specification.

Make sure that only the manufacturers' recommended four wheel alignment equipment is used.

Make sure the steering is in the straight ahead position.

1. For wheel alignment information, refer to the suspension specification

section.

For additional information, refer to: Specifications (204-00 Suspension System - General Information, Specifications).

2. Check the tie rod ends, suspension joints, wheel bearings and wheels

and tires for damage, wear and free play.

Adjust or repair any worn, damaged or incorrectly adjusted

components.

3. Check and adjust tire pressures.

4. Position the vehicle on a calibrated, level, vehicle lift.

5. Vehicles with air suspension.

For additional information, refer to: Air Suspension Manual Tight

Tolerance Setting Mode (204-05, General Procedures).

6. Release the vehicle parking brake.

7. Using only four-wheel alignment equipment approved by Jaguar, check

the wheel alignment.

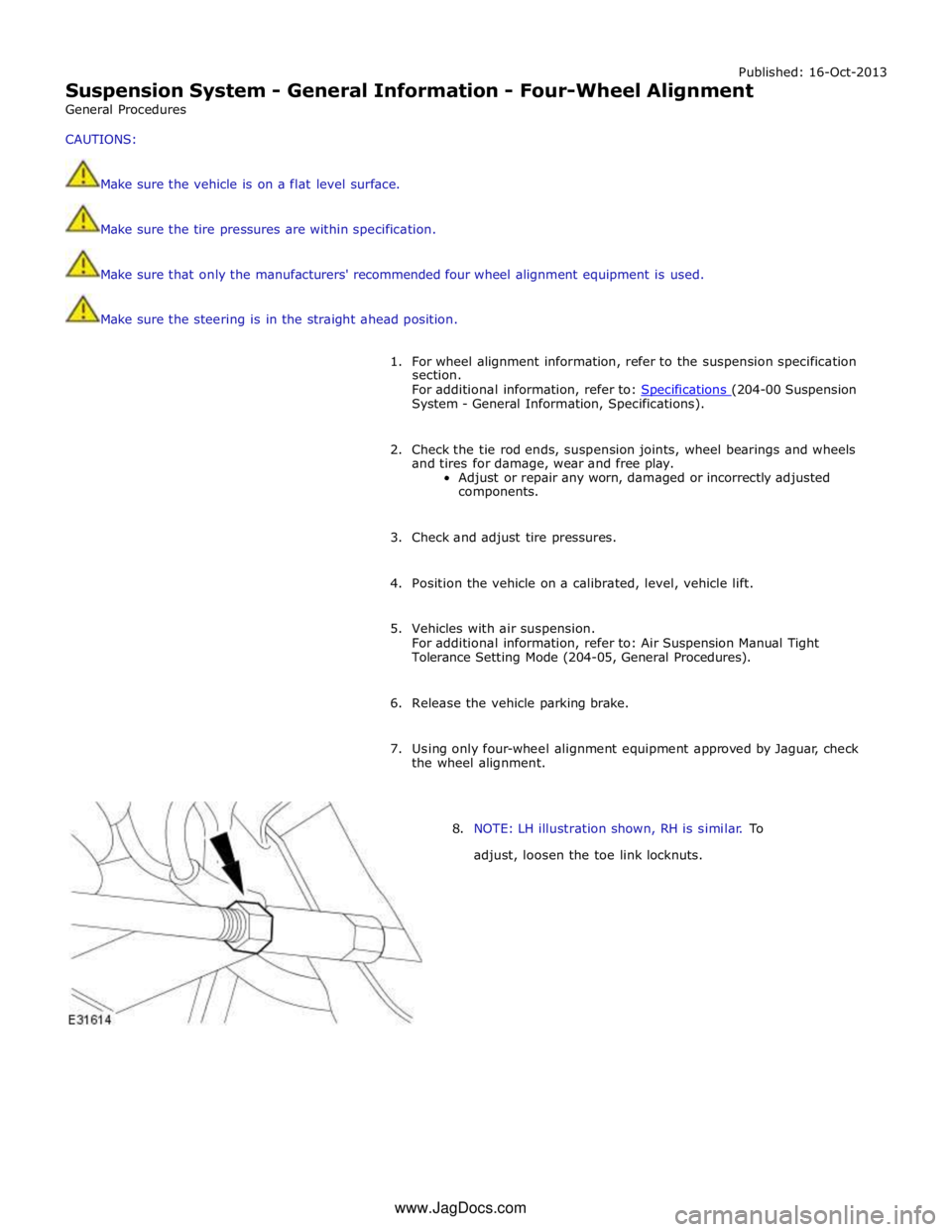

8. NOTE: LH illustration shown, RH is similar. To

adjust, loosen the toe link locknuts. www.JagDocs.com