sport mode JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1868 of 3039

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure. The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

4.3 PDI / DELIVERY TO CUSTOMER

Before the vehicle is handed over to the customer and as part of the PDI, the condition of the battery needs to be confirmed.

The battery condition must be checked in accordance with the battery test process utilizing a JLR approved tester as outlined

in the Equipment section (Section 5) of this procedure.

NOTE: The Midtronics code from the tester must be recorded on the form.

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure. The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

4.4 REPLACEMENT BATTERIES FOR SERVICE

All service replacement batteries must have the battery condition checked within 24 hours of receipt and controlled on a ‘First

In First Out’ basis to ensure batteries are not allowed to age unnecessarily.

For batteries in storage and not yet fitted to a vehicle, they must be stored in a dry environment, not in direct sunlight or

under any direct heat source. Any batteries exhibiting any forms of damage or corrosion must not be fitted to any vehicle. Any

batteries which are dropped must be scrapped, this applies even if no external damage is apparent.

The battery condition must be checked every 30 days in accordance with the battery test process utilizing a JLR approved

tester as outlined in the Equipment section (Section 5) of this procedure.

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure.The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

4.5 BATTERY MAINTENANCE

Any battery whether it is in a vehicle or a replacement part must be tested and/or re-charged every 30 days and MUST be

re-charged after every 90 day period.

4.6 BATTERY TEST PROCESS

It is recommended that this test is conducted at least 24 hours after the vehicle engine has been run or the battery charged to

avoid the need of surface charge removal. If time constraints make this unacceptable then the surface charge must be

removed.

Surface Charge Removal

A vehicle which has had its battery charged or been driven in a 24 hour period before the test, must have its surface charge

removed.

Turn on the ignition (power mode 6) but do not start the vehicle

Switch on the headlamps on high beam for a minimum 3 minutes

Switch off the headlamps

Wait a minimum of 5 minutes before recording test results for any battery measurements

Battery Test

The battery may be tested either on a bench or on the vehicle.

The battery condition must be checked in accordance with the battery test process utilizing a JLR approved tester as outlined

in the Equipment section (Section 5) of this procedure.

NOTE: The Midtronics code from the tester must be recorded on the form.

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure. The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

CAUTION: DO NOT connect the tester to any other circuit or chassis point other than the battery negative terminal.

Page 1869 of 3039

5. EQUIPMENT

All equipment used must be functionally capable of meeting the compliance requirements. Please refer to the approved

equipment document (JLR 000015).

In the case of batteries fitted to a new vehicle at the dealership, battery condition should be measured using the appropriate

hand-held Midtronics tester as follows:

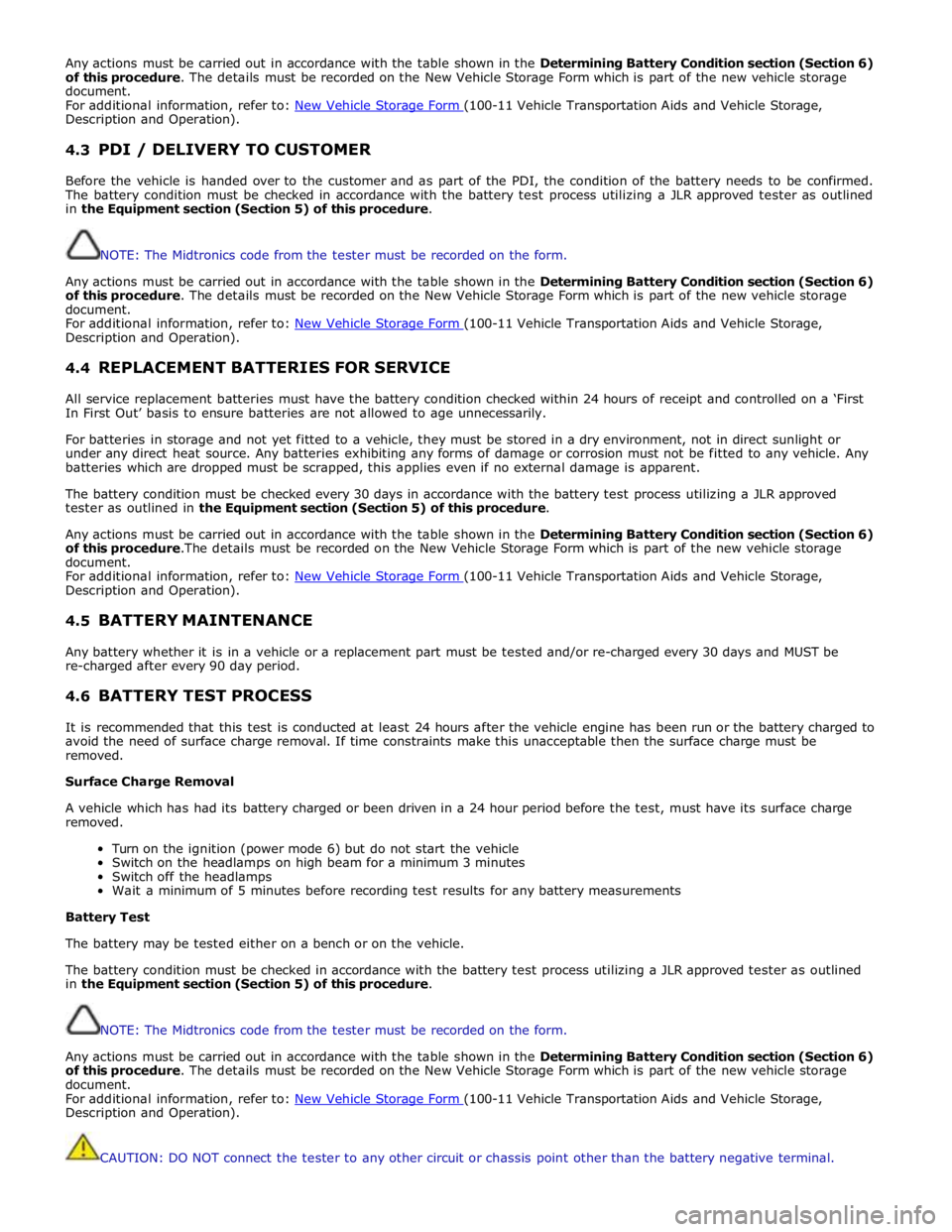

Battery Type Battery Tester Battery Tester Jaguar Land Rover AGM & Flooded Midtronics EXP1080, GRX 3080 Midtronics EXP1080, GRX 3080 The test results must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

NOTE: All equipment must be calibrated

6 DETERMINING BATTERY CONDITION

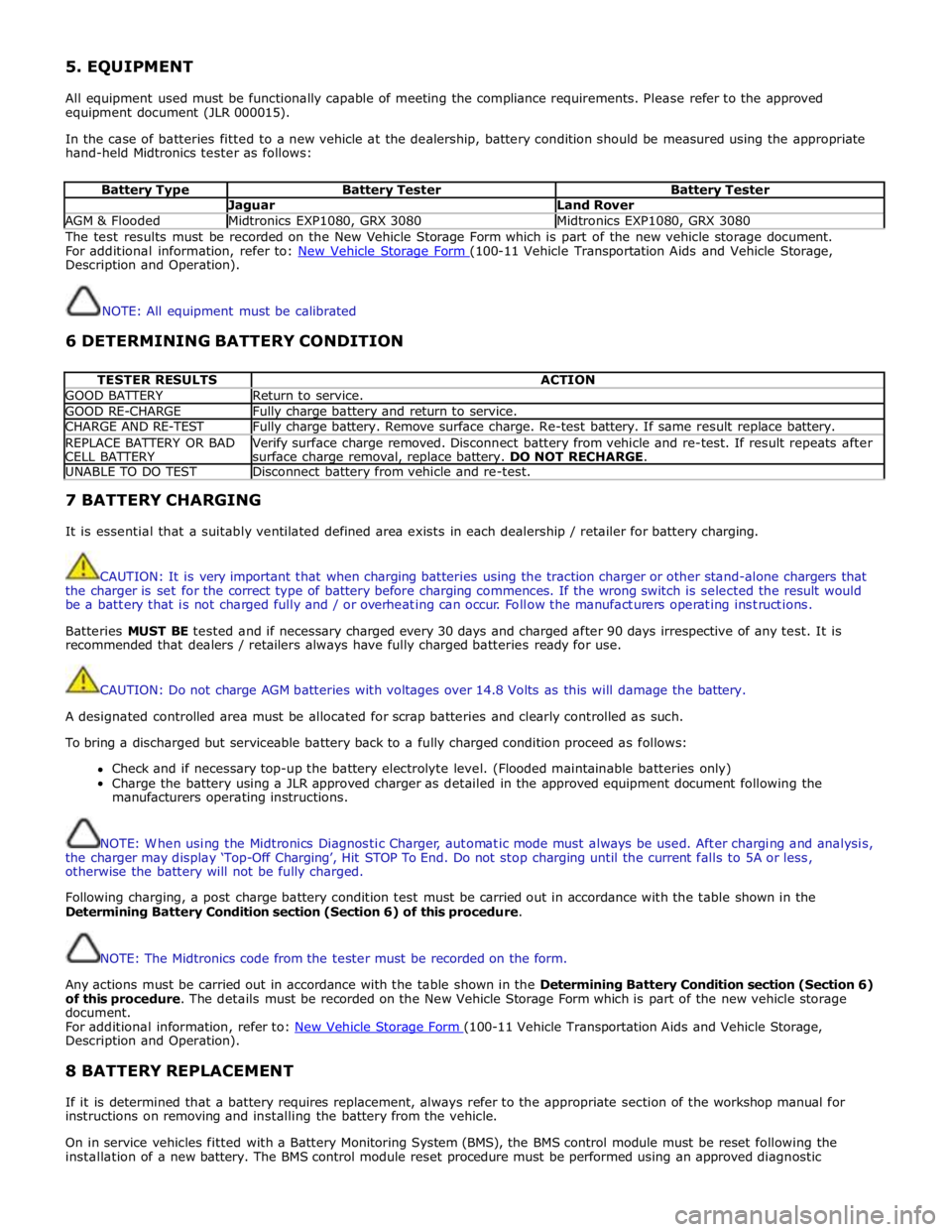

TESTER RESULTS ACTION GOOD BATTERY Return to service. GOOD RE-CHARGE Fully charge battery and return to service. CHARGE AND RE-TEST Fully charge battery. Remove surface charge. Re-test battery. If same result replace battery. REPLACE BATTERY OR BAD

CELL BATTERY Verify surface charge removed. Disconnect battery from vehicle and re-test. If result repeats after

surface charge removal, replace battery. DO NOT RECHARGE. UNABLE TO DO TEST Disconnect battery from vehicle and re-test. 7 BATTERY CHARGING

It is essential that a suitably ventilated defined area exists in each dealership / retailer for battery charging.

CAUTION: It is very important that when charging batteries using the traction charger or other stand-alone chargers that

the charger is set for the correct type of battery before charging commences. If the wrong switch is selected the result would

be a battery that is not charged fully and / or overheating can occur. Follow the manufacturers operating instructions.

Batteries MUST BE tested and if necessary charged every 30 days and charged after 90 days irrespective of any test. It is

recommended that dealers / retailers always have fully charged batteries ready for use.

CAUTION: Do not charge AGM batteries with voltages over 14.8 Volts as this will damage the battery.

A designated controlled area must be allocated for scrap batteries and clearly controlled as such.

To bring a discharged but serviceable battery back to a fully charged condition proceed as follows:

Check and if necessary top-up the battery electrolyte level. (Flooded maintainable batteries only)

Charge the battery using a JLR approved charger as detailed in the approved equipment document following the

manufacturers operating instructions.

NOTE: When using the Midtronics Diagnostic Charger, automatic mode must always be used. After charging and analysis,

the charger may display ‘Top-Off Charging’, Hit STOP To End. Do not stop charging until the current falls to 5A or less,

otherwise the battery will not be fully charged.

Following charging, a post charge battery condition test must be carried out in accordance with the table shown in the

Determining Battery Condition section (Section 6) of this procedure.

NOTE: The Midtronics code from the tester must be recorded on the form.

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure. The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

8 BATTERY REPLACEMENT

If it is determined that a battery requires replacement, always refer to the appropriate section of the workshop manual for

instructions on removing and installing the battery from the vehicle.

On in service vehicles fitted with a Battery Monitoring System (BMS), the BMS control module must be reset following the

installation of a new battery. The BMS control module reset procedure must be performed using an approved diagnostic

Page 1872 of 3039

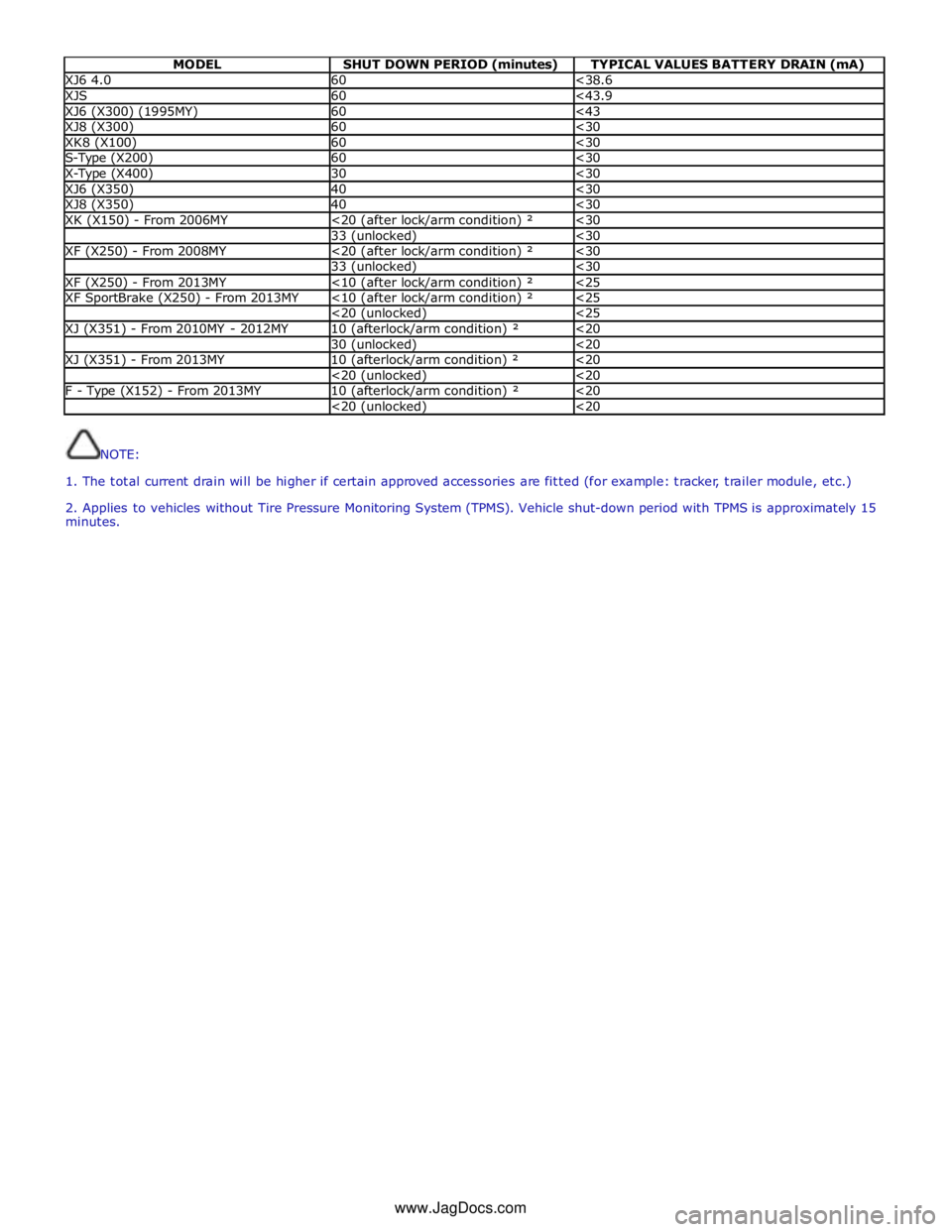

MODEL SHUT DOWN PERIOD (minutes) TYPICAL VALUES BATTERY DRAIN (mA) XJ6 4.0 60 <38.6 XJS 60 <43.9 XJ6 (X300) (1995MY) 60 <43 XJ8 (X300) 60 <30 XK8 (X100) 60 <30 S-Type (X200) 60 <30 X-Type (X400) 30 <30 XJ6 (X350) 40 <30 XJ8 (X350) 40 <30 XK (X150) - From 2006MY <20 (after lock/arm condition) ² <30 33 (unlocked) <30 XF (X250) - From 2008MY <20 (after lock/arm condition) ² <30 33 (unlocked) <30 XF (X250) - From 2013MY <10 (after lock/arm condition) ² <25 XF SportBrake (X250) - From 2013MY <10 (after lock/arm condition) ² <25 <20 (unlocked) <25 XJ (X351) - From 2010MY - 2012MY 10 (afterlock/arm condition) ² <20 30 (unlocked) <20 XJ (X351) - From 2013MY 10 (afterlock/arm condition) ² <20 <20 (unlocked) <20 F - Type (X152) - From 2013MY 10 (afterlock/arm condition) ² <20 <20 (unlocked) <20

NOTE:

1. The total current drain will be higher if certain approved accessories are fitted (for example: tracker, trailer module, etc.)

2. Applies to vehicles without Tire Pressure Monitoring System (TPMS). Vehicle shut-down period with TPMS is approximately 15

minutes.

www.JagDocs.com

Page 1968 of 3039

System Operation

PRINCIPLES OF OPERATION

Pri mary us er cont rol of t he phone s ys tem is vi a t he Touch-s creen and JaguarVoi ce cont rol s wit ch. Selecti on of

'phone/comms ' on the Touch-s creen home menu sends a control si gnal t o t he tel ephone cont rol unit on the MO ST (medi a

ori ent ated sys tems trans port ) ring, opening the phone s ubmenu opt ions .

W hen maki ng an outgoing phone call us ing t he JaguarVoice funct ion t he ICM (informat i on control modul e) proces s es the

anal ogue si gnal from the swi tch i nto a digit al s ignal . The digit al si gnal i s pass ed from the ICM (i nformat ion cont rol

module) onto the MO ST (medi a ori ent ated sys tems trans port ) s yst em t o t he JaguarVoi ce cont rol unit which i s int egral wit h

t he navi gat ion computer.

The navi gat ion comput er s ends an i ns t ructi on via MO ST (medi a ori ent ated sys tems trans port ) t o t he IAM (i ntegrat ed audi o

module) t o t urn on t he mi crophone faci li ty.

The voice command s ignals are rel ayed from t he IAM (i ntegrat ed audio module) vi a the MOST (medi a orientat ed s ys t ems

t ransport) ring t o t he navi gati on comput er for process ing.

The process ed voice command i s rel ayed on the MO ST (medi a ori ent ated sys tems trans port ) ring from the navigat ion

comput er to the phone cont rol module.

Speech out put i nformat ion is t rans ferred from the phone control modul e via t he Bl uet oot h® connect ion to t he cell phone.

Incomi ng cal ls are received from the Bl uet ooth® phone by the phone cont rol module. The i nformat ion is proces sed by the

phone cont rol module and t rans ferred on t he MOST (media ori ent ated s ys tems trans port ) ri ng t o the power ampl ifi er or IAM

(integrat ed audio modul e) for audi o output t hrough the vehicle’s audi o s peaker s ys t e m.

A number of res pons es by t he t el ephone and voice s ys tems are reinforced by mess ages appearing i n the ins trument cl us t er

mes s age center di spl ay. Informat ion is relayed to the mess age cent er from t he phone cont rol module and navigat ion

comput er on t he MOST (media orientat ed s ys t ems t rans port) ring t o t he ICM (informat ion cont rol module).

The ICM (informati on cont rol module) i s the gat eway from t he MOST (media ori ent ated s ys tems trans port ) ri ng t o the

medium s peed CAN. The ICM (informat ion control modul e) trans fers t he mes sage center i nformat ion ont o t he medium

s peed CAN which i s received and process ed for dis play on t he ins t rument clus ter mes s age cente r.

Us ers can pair & dock t heir hands et us ing t hei r phone or t he t ouch s creen. If t here i s no phone already docked wit h t he

s ys t em, a us er can us e t heir phone to search for Bluetoot h Devices. If the vehicl es Bluetooth s ys t em has been s uccess fully

dis covered, t he phone wil l di spl ay "Jaguar" as a device t o pair & connect t o. Us ing t his met hod requires the us er t o enter

t he Jaguar PIN of 1313. Alt ernati vel y, after acces s ing t he phone menu from t he Touch-s creen home menu, sel ect ing

‘Search New’ s earches for the Bluetooth® enabl ed hands et s wit hin range, di spl ays t he ir ident it ies on s creen, and al lows

t he user t o pair and dock the phone ready for use, us ing a random four-di git s ecurit y code di s pl ayed on screen. The s yst em

wil l normall y t ry t o dock (aut omati cal ly) to the las t phone docked, but if a di ffere nt Bluetoot h® enabled phone enters the

car i t wil l become avail abl e on t he s creen’s l is t of hands ets once t he s earch has be en complet ed.

Once a phone is pai red and docked a digit di al s creen i s dis played, incl uding phonebook opti ons . W it h a Bl uet oot h®

compat ibl e hands et and s oft ware vers i on there is the opt ion, through t he s ett ings me nu, t o automat ically downl oad the

cont ents of t he hands et’s phonebook t o the vehicl e s ys t em. Becaus e t here is no indus try s tandard for arranging the

phonebook, t he downloaded li st s from individual hands ets may vary.

Cell phone hands et manufact urers cont inuall y updat e hardware and s oft ware t o s t andard specificati ons laid down by the

Bluet oot h® Special Int eres t Group (SIG), which defi ned how Bluet oot h® woul d work in an aut omoti ve envi ronment.

However, becaus e different makes and models may use different s oft ware, not all hands ets are full y compat ible wit h

Jaguar, but t hrough tes t ing i ndi vi dual handset models Jaguar has produced a lis t of compat ibl e hands et s and the

appropri at e s oft ware vers ion for Jaguar Bl uet ooth® connecti vi ty. Referral to the lis t als o des cri bes how to check the

s oft ware vers i on of each i ndi vidual cell phone manufacturer. This l is t mus t be cons ult ed by us ers , s al es & s ervi ce teams t o

confirm whet her cus tomer's handset s are compat ible or not .

Jaguar is conti nual ly vali dati ng compat ible hands et and software combinati ons . The mos t up-t o-dat e compat ibi lit y l is t wil l

always be avail abl e on-l ine from Jaguar.

• NOTE: To achieve ful l Bl uetooth® hands et functi onal it y it is crucial t hat t he phone s oftware l evel mat ches t he vers ion

detail ed in the lis t of compat ibl e hands et s.

The upgraded hands free profi le of t his s ys tem allows the di spl ay of t he network s ignal st rengt h, net work operat or and

phone bat tery level indicati on on t he vehi cl e dis play. Als o, if appli cable, t he phone hands et wil l s how a "car" or "heads et"

s ymbol t o i ndi cat e i t is i n hands free profil e.

BLUETOOTH®

Bluet oot h® i s a s hort -range RF (radio frequency) t echnology t hat operat es at 2.4 GHz and is capabl e of t rans mit ti ng voice

and data wirel ess l y. The effecti ve range of Bluetoot h® devices is 32 feet (10 meters ) wit h a dat a t ransfer rat e of 1 Mbps .

Bluet oot h® i s es sent iall y a wi rel es s connect ion whi ch operat es wi th the us er's own mobil e hands et , does not have to be

fi xed int o t he car and i s desi gned to funct ion wit hout an external aerial. The hands et can be l ocat ed anywhere wit hin t he

cabi n, even i n a bag, or jacket pocket . It could work from the luggage compart ment , al though t he s ignal could be

compromi sed. The hands et can be charged from t he 12 volt power s ocket or USB (if s upported) whil e in use.

Component Description

Touch-Screen

The Touch-screen communi cat es wit h t he tel ephone control modul e on t he MOST (media orientat ed s ys t ems t rans port) ring

and provides t he pri mary us er int erface and di spl ay of the phone s yst em.

Page 2033 of 3039

Halogen Low/high Beam Headlamp

The halogen low/high beam headlamp uses a projector lens, similar to the xenon headlamp. The projector module comprises

an ellipsoidal lens and a reflector. The projector reflector collects the light produced by the halogen bulb and projects the light

into a focal plane containing a shield. The contour of the shield is projected onto the road by the lens. The low/high beam

bulbs are quartz halogen and are retained in the headlamp unit with conventional wire retaining clips.

A tourist lever mechanism is located on the right hand side of the projector module. This mechanism moves a flap to blank off

a portion of the beam spread to enable the vehicle to be driven in opposite drive hand markets without applying blanking

decals to the headlamp lens. The beam is changed by removing the access cover at the rear of the lamp assembly and moving

a small lever located near the bulb holder, at the side of the projector.

Halogen High Beam Headlamp - Xenon and Halogen

The xenon and halogen headlamps use a complex surface reflector for the halogen fill in high beam lamp only lighting unit,

which is of the same design on both headlamp types. This type of reflector has the reflector divided into separate parabolic

segments, with each segment having a different focal length.

The high beam headlamp bulbs are quartz halogen and are retained in the headlamp unit with conventional wire retaining

clips.

Cornering Lamps

NOTE: The cornering lamps are not fitted to NAS vehicles.

The cornering lamps are an optional feature designed to illuminate the direction of travel when cornering at low speeds. The

design of the lens projects a spread of light from the vehicle at approximately 45 degrees to the vehicle axis. The cornering

lamp is incorporated into the headlamp assembly and shares the same housing as the low beam headlamp. The cornering lamp

uses a 35W Halogen H8 bulb which is permanently located in an integral holder which is connected on the headlamp housing.

The holder is located in an aperture in the headlamp housing and rotated to lock. The bulb is accessible via a removable cover

on the base of the headlamp housing.

The cornering lamps are controlled by the LH steering column multifunction switch with the lighting control switch in the headlamp position and the ignition in power mode 6. The cornering lamps are supplied power via the ignition circuit to ensure

that they do not function with the headlamp delay feature. The cornering lamps are deactivated if the vehicle speed exceeds

25 mph (40 km/h). Only one cornering lamp will illuminate at any one time. If the left hand turn signal indicators are selected

on, the left hand cornering lamp will be illuminated and vice versa, providing the vehicle speed and lighting control switch

positions are correct.

Static Bending Lamps

NOTE: The static bending lamps are not fitted to NAS vehicles.

The static bending lamps are designed to illuminate the direction of travel when cornering at low speeds. The static bending

lamp functionality, which is controlled by the CJB and the headlamp leveling module, operates using inputs from the steering angle sensor and vehicle speed information from the ABS (anti-lock brake system) module. The static bending lamp is

incorporated into the headlamp assembly and shares the same housing as the low beam headlamp. The design of the lens

projects a spread of light from the vehicle at approximately 45 degrees to the vehicle axis. The static bending lamp uses a

35W Halogen H8 bulb which locates in a holder which is connected via wires to the main connector on the headlamp housing.

The holder is located in an aperture in the headlamp housing and rotated to lock. The bulb is accessible via a removable cover

at the rear of the headlamp housing.

The static bending lamps operate with a steering angle sensor CAN bus signal which is received by the CJB. The CJB monitors this signal and vehicle speed and activates the static bending lamp bulb. When the operation parameters of the lamp are

reached, the CJB fades the static bending lamp bulb on using a PWM (pulse width modulation) voltage over a period of approximately 2 seconds. When the lamp is switched off, the CJB fades the bulb off by decreasing the PWM voltage in a linear manner depending on steering angle and vehicle speed. The cornering lamps can only be active for a maximum of 3 minutes.

NOTE: Static bending lamps only operate when the transmission is in DRIVE or in SPORT.

Turn Signal Indicators

The turn signal indicator lamp is incorporated into the outer part of the headlamp assembly. The turn signal indicator lamp

uses a PY21W bayonet orange colored bulb in ROW markets, a S8W 27/7W wedge bulb is used in NAS markets. The bulb is

fitted into a holder which connects with contacts in the headlamp housing. The holder is fitted into an aperture in the

headlamp housing and rotated to lock into position.

When active, the turn signal indicator lamps will flash at a frequency cycle of 380ms on and 380ms off. If a bulb fails, the

remaining turn signal lamps bulbs continue to flash at normal speed. The turn signal indicators in the instrument cluster will

flash at double speed to indicate the bulb failure to the driver.

Side Lamps

The side lamp is located between the headlamp projector module and the high bean headlamp. The side lamp uses a W5W

wedge fitting bulb which locates in a holder which connected via wires to the main connector on the headlamp housing. The

holder is a push fit into a receptacle in the headlamp housing. The bulb is accessible by removal of the inner cover on the rear

of the headlamp housing. Access to the bulb requires removal of the headlamp from the vehicle. The side lamps are operated

by selecting side lamps or headlamps on the lighting control switch. The side lamps are functional at all times and are

Page 2067 of 3039

Published: 11-May-2011

Module Communications Network - Communications Network - Overview

Description and Operation

OVERVIEW

A number of different types of communication network are incorporated into the vehicle wiring harnesses for the transmission

of commands and information between control modules. The configuration installed on a particular vehicle depends on the

model and equipment level.

NOTE: The control diagrams shown later in this section are schematics reflecting communications networks fitted to LH

(left-hand) vehicles only. For detailed layouts of the various communications networks fitted to LHD (left-hand drive) and RHD

(right-hand drive) vehicles, refer to the Electrical Guide.

The communications networks available on the vehicle are shown in the table below.

Network Baud Rate LIN (local interconnect network) bus 9.6 kbits/s Medium speed CAN (controller area network) bus 125 kbits/s High speed CAN bus 500 kbits/s Media Orientated System Transport (MOST) ring 24 mbits/s

Page 2684 of 3039

7 RH accelerometer 8 LH accelerometer 9 RJB (rear junction box) 10 BJB (battery junction box)

System Operation

The pedestrian protection system is operational when the vehicle is traveling at speeds between approximately 20 km/h (12.4

mph) and 45 km/h (28 mph). A vehicle speed signal is received by the pedestrian protection system control module over the

high speed CAN bus.

The system is able to determine if contact is made with a pedestrian or another object, such as a traffic cone, using signals

from accelerometers mounted behind the front bumper. When the system determines contact is made with a pedestrian it fires

the actuators to lift the rear of the hood approximately 130 mm within 35 ms of the 'fire' signal.

When an impact condition is registered, the pedestrian protection system control module outputs an impact signal on the high

speed CAN bus. This signal is used by the RJB to initiate the hazard warning lamps. If this occurs, the hazard warning lamp switch is disabled for the remainder of the current ignition cycle.

If the pedestrian protection system control module detects a fault with the system, it outputs a message on the high speed

CAN bus to the instrument cluster message center. On receipt of this, the message center will display the message 'CHECK PEDESTRIAN SYSTEM'.

The pedestrian protection system control module also stores the VIN (vehicle identification number). If a new control module

is fitted to the vehicle the Jaguar approved diagnostic tool must be used to program the unit with the vehicles VIN.

When the vehicle is delivered from the factory the pedestrian protection system is in a 'safe' plant mode. Normal operating

mode should be activated using the Jaguar approved diagnostic tool during the Pre-Delivery Inspection (PDI) prior to delivery

to the customer. For additional information, refer to the PDI manual.

If any damage is caused to the front of the vehicle, be it cosmetic or structural, repairs must be carried out in line with the

processes contained in the workshop manual. Failure to carry out the correct repair process could compromise operation of the

pedestrian protection system. Refer to GTR for the latest information.

The vehicle must be left for 1 minute after disconnecting the battery before any work can be carried out on the pedestrian

protection system.

Failure Mode Detection

In service, if any fault is detected, or any part of the system is recognized as not being present, the message center displays

the warning 'Check Pedestrian System'.

The bonnet deployment actuators are non-serviceable components, and if they must be replaced due to a fault, or due to

having been deployed, or following any other accident, their barcode labels must be read and recorded in the service database

against the vehicle VIN for security purposes.

After deployment of the pedestrian protection system, the vehicle must be stopped as soon as it is safe to do so. The hazard

warning lamps will be activated and can only be switched off by pressing the engine START/STOP button to turn the engine off

and on again. A warning message 'CHECK PEDESTRIAN SYSTEM' will appear on the message center and the vehicle should be

transported to the nearest dealer/authorised repairer. The vehicle must not be driven when the bonnet has been deployed.

NOTE: If the warning message 'CHECK PEDESTRIAN SYSTEM' appears in the message center when the bonnet has not

been deployed, the vehicle should be taken to the nearest dealer/authorised repairer immediately. It can be driven.

If any significant damage occurs to the front bumper it should be inspected by a dealer/authorised repairer as soon as

possible.

CONTROL MODULE Component Description

The control module is mounted below the hood release lever behind the side trim in the left hand front footwell.

The deployment signal is received from the pedestrian protection system control module. The second-generation system

adopted for XF is all-new to Jaguar and, although similar, differs from that introduced on XK by having an accelerometer-based

sensing system rather than a contact-sensing system. The accelerometer-based system is supplied by Bosch. Mounted very

close to the skin of the bumper, it examines the characteristics of vibration waves caused by impact. Its response time is

quicker, because it does not rely on the front of the bumper being loaded. It uses the 'saved' time to make more complex

decisions, and so has fewer error states. The speed of vehicle and the length of the bonnet define the time available to get

the bonnet into its deployed and stabilized position. It is possible, therefore, to create a time-line counting back from the

predicted moment of head impact to the time when the deployment signals need to be sent. That in turn defines a time from

first contact to decision time.

www.JagDocs.com

Page 2718 of 3039

Part N-umber

Body Repairs - Corrosion Protection - Corrosion Protection

Description and Operation

General Published: 11-May-2011

The corrosion protection provided in production must be carefully maintained and/or reproduced during and after body repair

work. It is only then that the long-term warranty against penetrative corrosion damage can be assured.

Only Jaguar original bodywork components and Jaguar approved repair materials, (sealer, paint etc.), are to be used for

bodywork repairs.

Jaguar Original Parts

All Jaguar bodywork components have a cathodic base coating. Individual bodywork components are zinc plated on one or both

sides, (in different areas depending on vehicle model).

Together with elastic paint coating, this guarantees an optimum, highly resistant protection against corrosion caused by the

impact of small objects such as gravel.

NOTE: If possible, the individual protective layers, (zinc, cathodic base coat), on Jaguar bodywork components must not

be damaged or destroyed by sanding or other mechanical operations.

If hairline cracks at "bodywork connection areas" appear after reshaping work, (e.g. at door hinges), it must be ensured that

the corrosion protection provided in production is recreated. The complete paint covering must be re-created if necessary. The

same applies to reshaping work on heavily profiled bodywork components, (e.g. floor pan). Renew or touch-up the paint

coating, sealing beads and underbody protection as necessary.

After repair, any interior surfaces which are no longer visible or accessible must be primed before cavity wax is applied. To be

certain of an even coating on inner surfaces, careful application of spray, (twice, with drying time in-between), must be carried

out throughout the whole cavity.

If bodywork panels are strongly heated during repair work, this will invariably result in damage to or even destruction of the

applied corrosion protection material. The effectiveness of the cavity protection material is reduced if heating occurs.

Reworking of the affected areas is therefore vital.

Welded areas should be made good before corrosion protection is applied.

The corrosion protection measures to be taken when bodywork components are renewed are described on the following pages.

Corrosion Protection of New Components

All new components must be inspected for transport or storage damage such as scratches or dents. The following operations

may be necessary, depending on the extent of damage:

Undamaged New Component

Do not grind the cathodic primer.

Thoroughly clean with silicone remover and rub dry.

Slightly Damaged New Component

Sand out scratches.

Finely sand the surrounding surface.

Thoroughly clean with silicone remover and rub dry.

Apply corrosion protection primer to bare areas.

Damaged New Components (bumps and dents)

Beat out the dented area and sand down to bare metal.