steering wheel adjustment JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 583 of 3039

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is not

evident, attempt to duplicate the condition using the information from the description.

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From this

description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

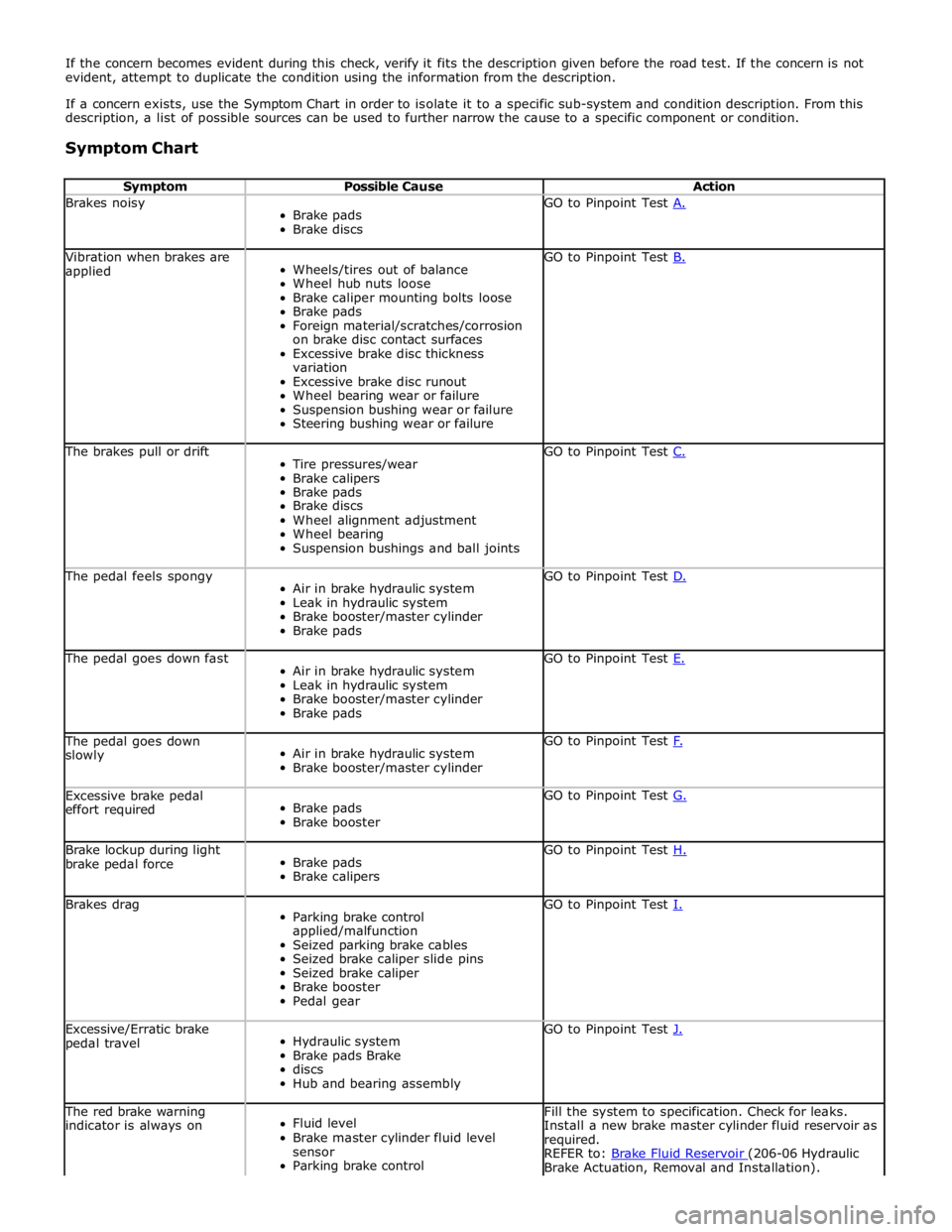

Symptom Chart

Symptom Possible Cause Action Brakes noisy

Brake pads

Brake discs GO to Pinpoint Test A. Vibration when brakes are

applied

Wheels/tires out of balance

Wheel hub nuts loose

Brake caliper mounting bolts loose

Brake pads

Foreign material/scratches/corrosion

on brake disc contact surfaces

Excessive brake disc thickness

variation

Excessive brake disc runout

Wheel bearing wear or failure

Suspension bushing wear or failure

Steering bushing wear or failure GO to Pinpoint Test B. The brakes pull or drift

Tire pressures/wear

Brake calipers

Brake pads

Brake discs

Wheel alignment adjustment

Wheel bearing

Suspension bushings and ball joints GO to Pinpoint Test C. The pedal feels spongy

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test D. The pedal goes down fast

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test E. The pedal goes down

slowly

Air in brake hydraulic system

Brake booster/master cylinder GO to Pinpoint Test F. Excessive brake pedal

effort required

Brake pads

Brake booster GO to Pinpoint Test G. Brake lockup during light

brake pedal force

Brake pads

Brake calipers GO to Pinpoint Test H. Brakes drag

Parking brake control

applied/malfunction

Seized parking brake cables

Seized brake caliper slide pins

Seized brake caliper

Brake booster

Pedal gear GO to Pinpoint Test I. Excessive/Erratic brake

pedal travel

Hydraulic system

Brake pads Brake

discs

Hub and bearing assembly GO to Pinpoint Test J. The red brake warning

indicator is always on

Fluid level

Brake master cylinder fluid level

sensor

Parking brake control Fill the system to specification. Check for leaks.

Install a new brake master cylinder fluid reservoir as

required.

REFER to: Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

Page 694 of 3039

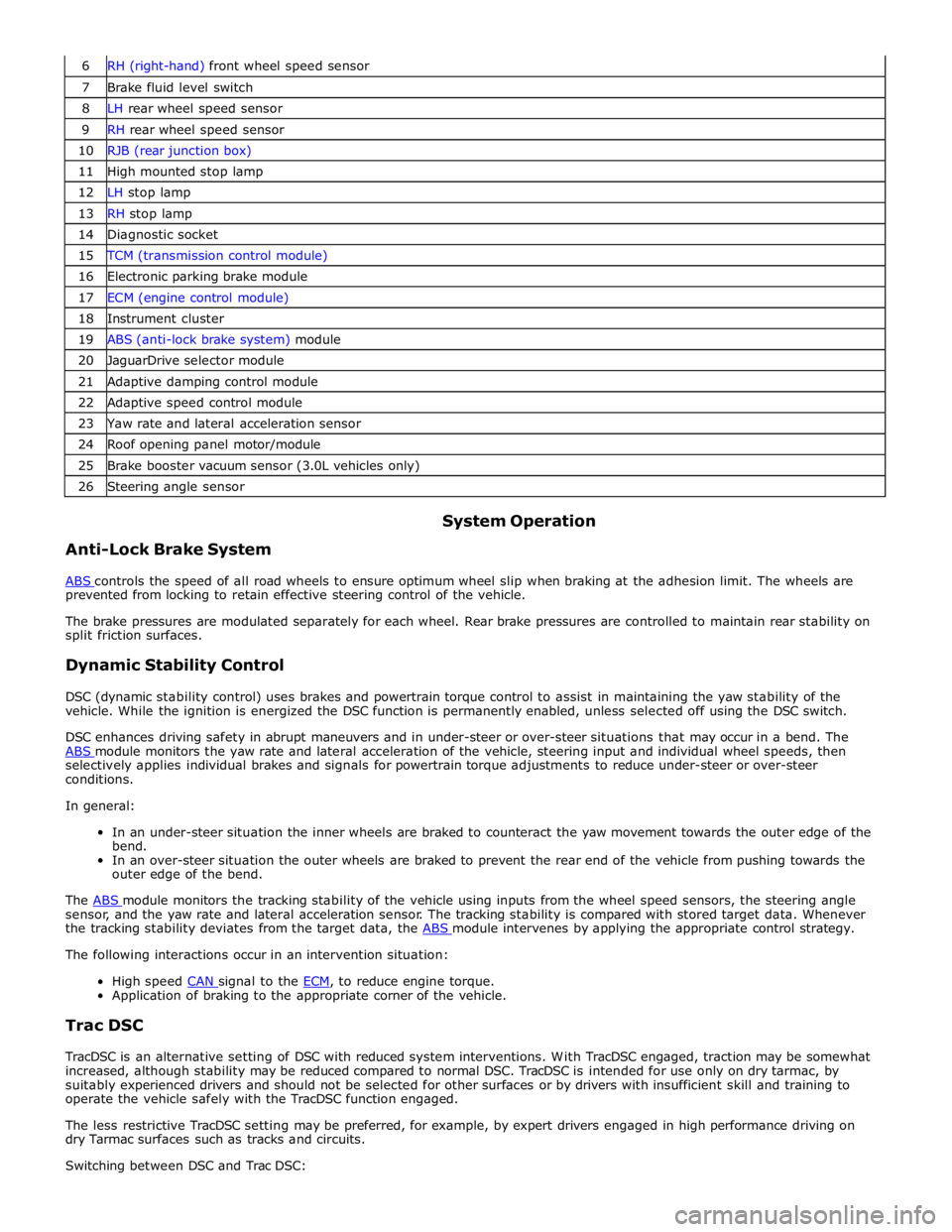

7 Brake fluid level switch 8 LH rear wheel speed sensor 9 RH rear wheel speed sensor 10 RJB (rear junction box) 11 High mounted stop lamp 12 LH stop lamp 13 RH stop lamp 14 Diagnostic socket 15 TCM (transmission control module) 16 Electronic parking brake module 17 ECM (engine control module) 18 Instrument cluster 19 ABS (anti-lock brake system) module 20 JaguarDrive selector module 21 Adaptive damping control module 22 Adaptive speed control module 23 Yaw rate and lateral acceleration sensor 24 Roof opening panel motor/module 25 Brake booster vacuum sensor (3.0L vehicles only) 26 Steering angle sensor

Anti-Lock Brake System System Operation

ABS controls the speed of all road wheels to ensure optimum wheel slip when braking at the adhesion limit. The wheels are prevented from locking to retain effective steering control of the vehicle.

The brake pressures are modulated separately for each wheel. Rear brake pressures are controlled to maintain rear stability on

split friction surfaces.

Dynamic Stability Control

DSC (dynamic stability control) uses brakes and powertrain torque control to assist in maintaining the yaw stability of the

vehicle. While the ignition is energized the DSC function is permanently enabled, unless selected off using the DSC switch.

DSC enhances driving safety in abrupt maneuvers and in under-steer or over-steer situations that may occur in a bend. The

ABS module monitors the yaw rate and lateral acceleration of the vehicle, steering input and individual wheel speeds, then selectively applies individual brakes and signals for powertrain torque adjustments to reduce under-steer or over-steer

conditions.

In general:

In an under-steer situation the inner wheels are braked to counteract the yaw movement towards the outer edge of the

bend.

In an over-steer situation the outer wheels are braked to prevent the rear end of the vehicle from pushing towards the

outer edge of the bend.

The ABS module monitors the tracking stability of the vehicle using inputs from the wheel speed sensors, the steering angle sensor, and the yaw rate and lateral acceleration sensor. The tracking stability is compared with stored target data. Whenever

the tracking stability deviates from the target data, the ABS module intervenes by applying the appropriate control strategy. The following interactions occur in an intervention situation:

High speed CAN signal to the ECM, to reduce engine torque. Application of braking to the appropriate corner of the vehicle.

Trac DSC

TracDSC is an alternative setting of DSC with reduced system interventions. With TracDSC engaged, traction may be somewhat

increased, although stability may be reduced compared to normal DSC. TracDSC is intended for use only on dry tarmac, by

suitably experienced drivers and should not be selected for other surfaces or by drivers with insufficient skill and training to

operate the vehicle safely with the TracDSC function engaged.

The less restrictive TracDSC setting may be preferred, for example, by expert drivers engaged in high performance driving on

dry Tarmac surfaces such as tracks and circuits.

Switching between DSC and Trac DSC:

Page 721 of 3039

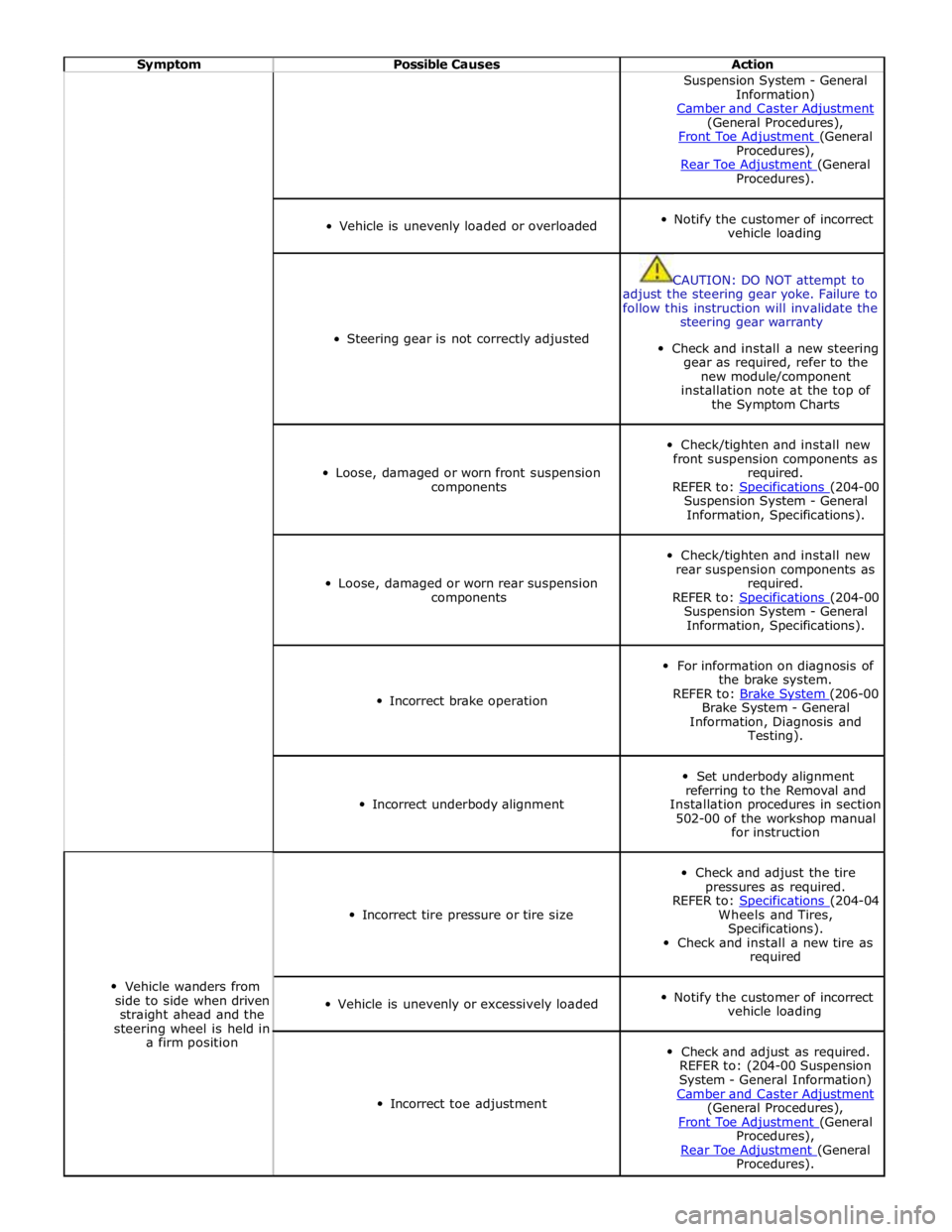

Symptom Possible Causes Action Suspension System - General

Information)

Camber and Caster Adjustment (General Procedures),

Front Toe Adjustment (General Procedures),

Rear Toe Adjustment (General Procedures).

Vehicle is unevenly loaded or overloaded

Notify the customer of incorrect

vehicle loading

Steering gear is not correctly adjusted

CAUTION: DO NOT attempt to

adjust the steering gear yoke. Failure to

follow this instruction will invalidate the

steering gear warranty

Check and install a new steering

gear as required, refer to the

new module/component

installation note at the top of

the Symptom Charts

Loose, damaged or worn front suspension

components

Check/tighten and install new

front suspension components as

required.

REFER to: Specifications (204-00 Suspension System - General

Information, Specifications).

Loose, damaged or worn rear suspension

components

Check/tighten and install new

rear suspension components as

required.

REFER to: Specifications (204-00 Suspension System - General

Information, Specifications).

Incorrect brake operation

For information on diagnosis of

the brake system.

REFER to: Brake System (206-00 Brake System - General

Information, Diagnosis and

Testing).

Incorrect underbody alignment

Set underbody alignment

referring to the Removal and

Installation procedures in section

502-00 of the workshop manual

for instruction

Vehicle wanders from

side to side when driven

straight ahead and the

steering wheel is held in

a firm position

Incorrect tire pressure or tire size

Check and adjust the tire

pressures as required.

REFER to: Specifications (204-04 Wheels and Tires,

Specifications).

Check and install a new tire as

required

Vehicle is unevenly or excessively loaded

Notify the customer of incorrect

vehicle loading

Incorrect toe adjustment

Check and adjust as required.

REFER to: (204-00 Suspension

System - General Information)

Camber and Caster Adjustment (General Procedures),

Front Toe Adjustment (General Procedures),

Rear Toe Adjustment (General Procedures).

Page 723 of 3039

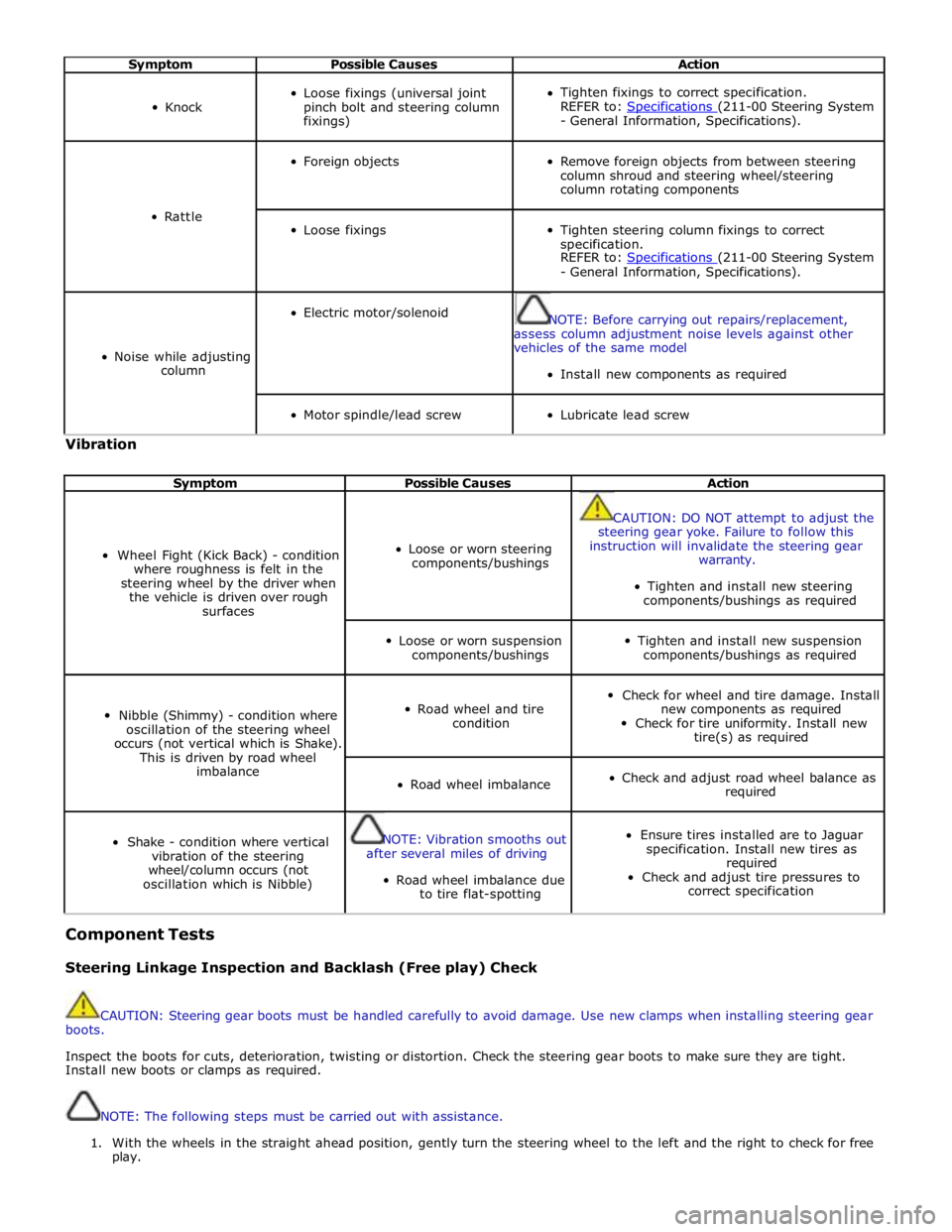

Symptom Possible Causes Action

Knock

Loose fixings (universal joint

pinch bolt and steering column

fixings)

Tighten fixings to correct specification.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Rattle

Foreign objects

Remove foreign objects from between steering

column shroud and steering wheel/steering

column rotating components

Loose fixings

Tighten steering column fixings to correct

specification.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Noise while adjusting

column

Electric motor/solenoid

NOTE: Before carrying out repairs/replacement,

assess column adjustment noise levels against other

vehicles of the same model

Install new components as required

Motor spindle/lead screw

Lubricate lead screw Vibration

Symptom Possible Causes Action

Wheel Fight (Kick Back) - condition

where roughness is felt in the

steering wheel by the driver when

the vehicle is driven over rough

surfaces

Loose or worn steering

components/bushings

CAUTION: DO NOT attempt to adjust the

steering gear yoke. Failure to follow this

instruction will invalidate the steering gear

warranty.

Tighten and install new steering

components/bushings as required

Loose or worn suspension

components/bushings

Tighten and install new suspension

components/bushings as required

Nibble (Shimmy) - condition where

oscillation of the steering wheel

occurs (not vertical which is Shake).

This is driven by road wheel

imbalance

Road wheel and tire

condition

Check for wheel and tire damage. Install

new components as required

Check for tire uniformity. Install new

tire(s) as required

Road wheel imbalance

Check and adjust road wheel balance as

required

Shake - condition where vertical

vibration of the steering

wheel/column occurs (not

oscillation which is Nibble)

NOTE: Vibration smooths out

after several miles of driving

Road wheel imbalance due

to tire flat-spotting

Ensure tires installed are to Jaguar

specification. Install new tires as

required

Check and adjust tire pressures to

correct specification Component Tests

Steering Linkage Inspection and Backlash (Free play) Check

CAUTION: Steering gear boots must be handled carefully to avoid damage. Use new clamps when installing steering gear

boots.

Inspect the boots for cuts, deterioration, twisting or distortion. Check the steering gear boots to make sure they are tight.

Install new boots or clamps as required.

NOTE: The following steps must be carried out with assistance.

1. With the wheels in the straight ahead position, gently turn the steering wheel to the left and the right to check for free

play.

Page 776 of 3039

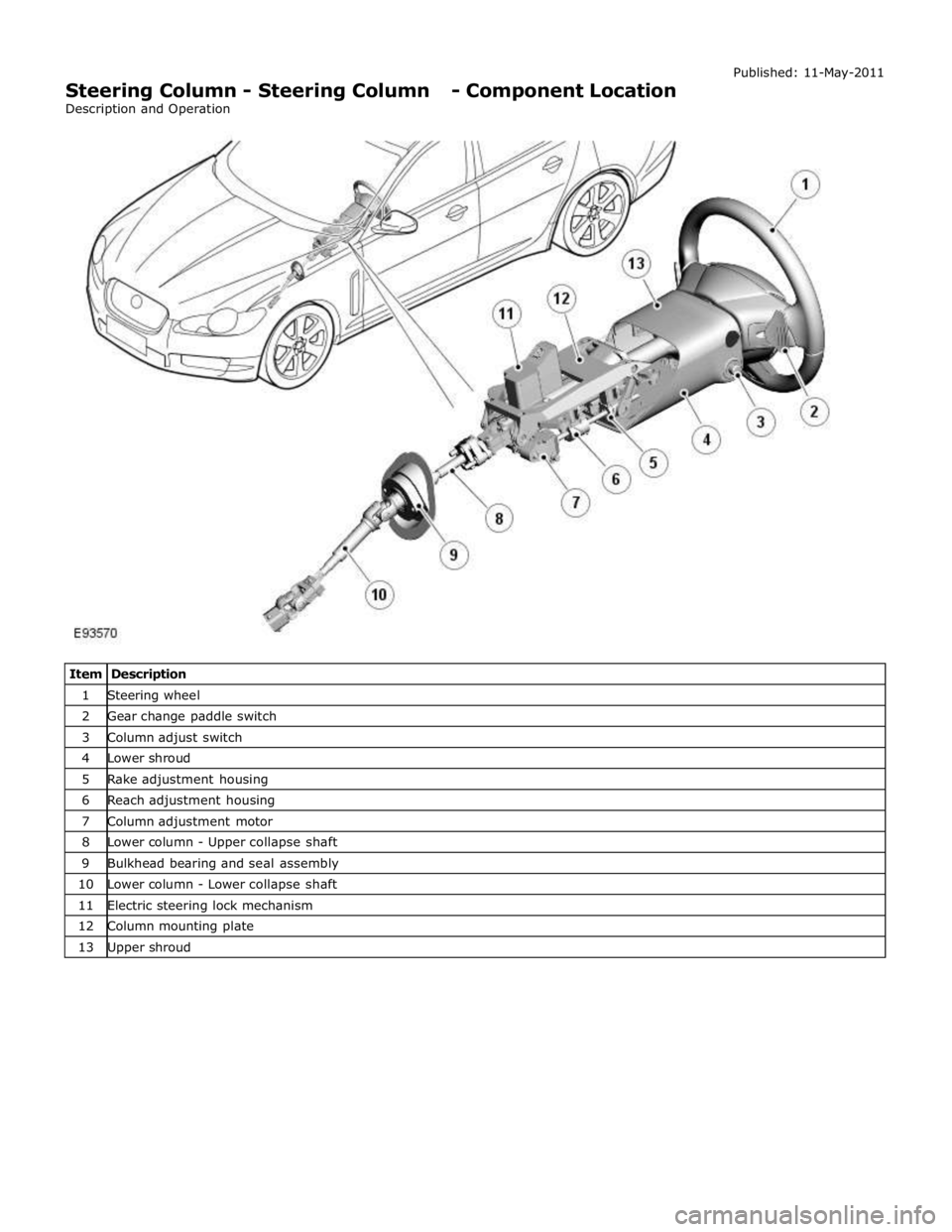

1 Steering wheel 2 Gear change paddle switch 3 Column adjust switch 4 Lower shroud 5 Rake adjustment housing 6 Reach adjustment housing 7 Column adjustment motor 8 Lower column - Upper collapse shaft 9 Bulkhead bearing and seal assembly 10 Lower column - Lower collapse shaft 11 Electric steering lock mechanism 12 Column mounting plate 13 Upper shroud

Page 777 of 3039

Steering Column - Steering Column - Overview

Description and Operation

OVERVIEW Published: 11-May-2011

The steering column comprises the upper column assembly, the lower column assembly and the steering wheel. The 3

components are positively connected together to pass driver rotary input from the steering wheel to a linear output of the

steering rack.

The upper column assembly contains electrical adjustment for steering wheel reach and rake, the electric steering lock

mechanism and the steering angle sensor. Steering adjustment memory positions are stored in the driver's seat module.

The electric steering column is a standard fitment on all models. The upper column assembly contains electrical adjustment for

steering wheel reach and rake, the electric column lock mechanism and the steering angle sensor. Steering adjustment memory

positions are stored in the driver's seat module. The column also features a 'tilt away' function which moves the steering

column away from the driver allowing easier exit and entry to the vehicle.

Column adjustment is provided by a single motor for both reach and rake adjustment. Operation of the column adjustment is

controlled by a four way joystick type switch located in the column lower shroud. Column adjustment is an integral part of the

driver position memory system.

www.JagDocs.com

Page 779 of 3039

8 Reach adjustment solenoid and potentiometer 9 Column adjustment motor 10 Instrument cluster 11 Steering column adjust switch 12 Driver's seat module (position memory)

STEERING COLUMN ADJUSTMENT System Operation

Power for the column adjustment motor is supplied via a megafuse in the BJB to the CJB. A fused supply from the CJB is passed to the instrument cluster which controls the power application to the motor.

The column adjust switch is hardwired to the instrument cluster. Up/down and in/out selections on the switch are each passed

through a resistor of differing values to the instrument cluster. The cluster monitors the output value from the switch and

operates the motor in the required direction and simultaneously energizes the required solenoid for rake or reach adjustment.

When the applicable solenoid is energized, a clutch is engaged and locates on a lead screw. The motor rotates the lead screw

and the rotational drive of the screw is transferred into linear movement of the applicable clutch to move either the rake or

reach adjustment. For reach adjustment, the lead screw drives the outer housing in or out as required. For rake adjustment the

lead screw drives a rake lever which moves the column up or down as required.

The position of the column is monitored by potentiometers which are connected to the instrument cluster. The cluster monitors

the output signal from the potentiometers to precisely control the positioning of the column in each plane.

The instrument cluster controls the memory positioning of the column via a medium speed CAN bus connection to the driver's seat module. The driver's seat module receives information regarding the particular remote handset used to enter the vehicle

and outputs positional information relative to that stored for the handset. This information is passed to the instrument cluster

via the medium speed CAN bus which moves the column to the memorized positions.

The column logic in the instrument cluster also incorporates an entry/exit mode. When the vehicle is unlocked or the ignition is

switched off, the instrument cluster lifts the column upwards to its maximum rake position to allow the driver more room below

the steering wheel and improve access/egress of the vehicle. When the ignition is next switched on the column will adjust to

its previous position.

The electric steering column lock is controlled by the CJB.

Page 780 of 3039

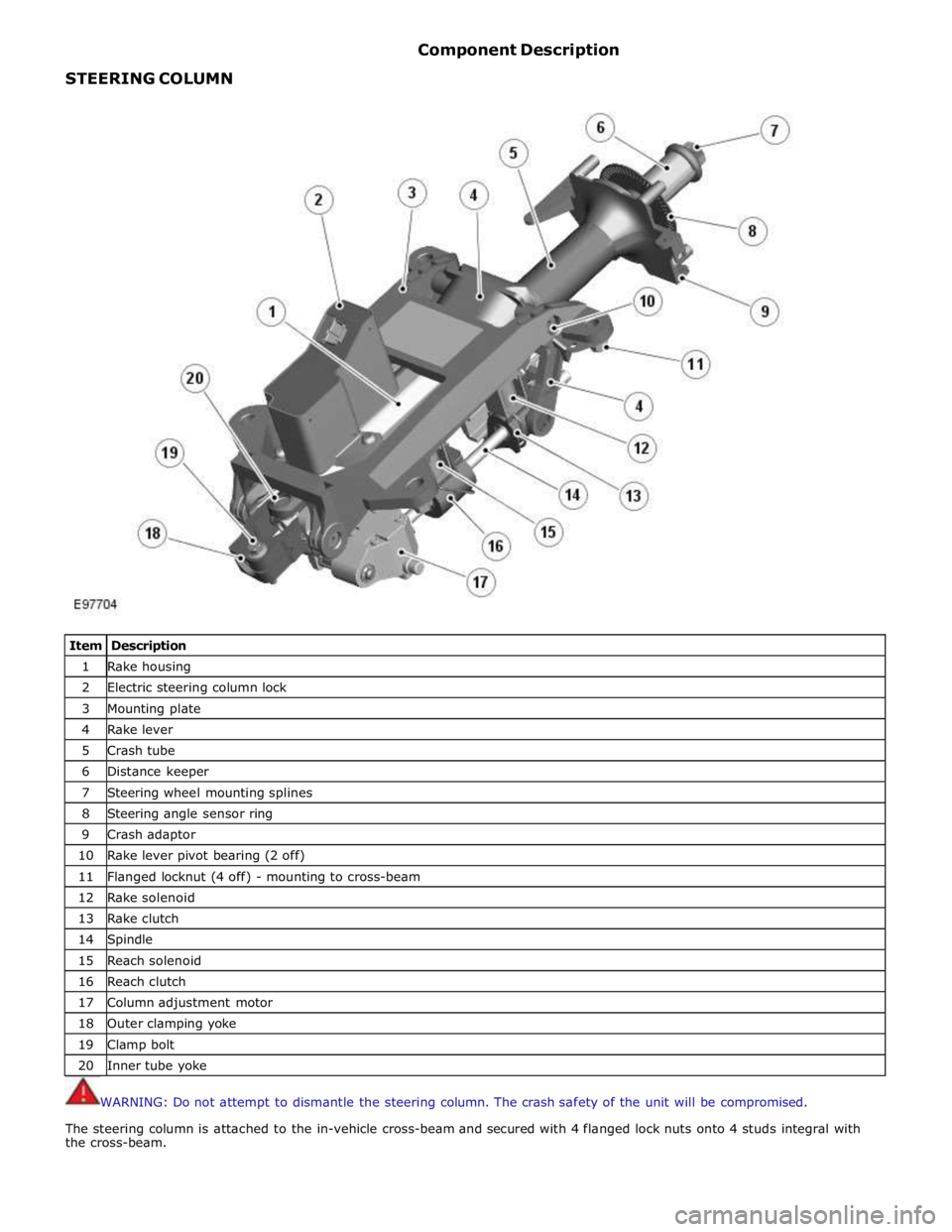

STEERING COLUMN Component Description

Item Description 1 Rake housing 2 Electric steering column lock 3 Mounting plate 4 Rake lever 5 Crash tube 6 Distance keeper 7 Steering wheel mounting splines 8 Steering angle sensor ring 9 Crash adaptor 10 Rake lever pivot bearing (2 off) 11 Flanged locknut (4 off) - mounting to cross-beam 12 Rake solenoid 13 Rake clutch 14 Spindle 15 Reach solenoid 16 Reach clutch 17 Column adjustment motor 18 Outer clamping yoke 19 Clamp bolt 20 Inner tube yoke

WARNING: Do not attempt to dismantle the steering column. The crash safety of the unit will be compromised.

The steering column is attached to the in-vehicle cross-beam and secured with 4 flanged lock nuts onto 4 studs integral with

the cross-beam.

Page 781 of 3039

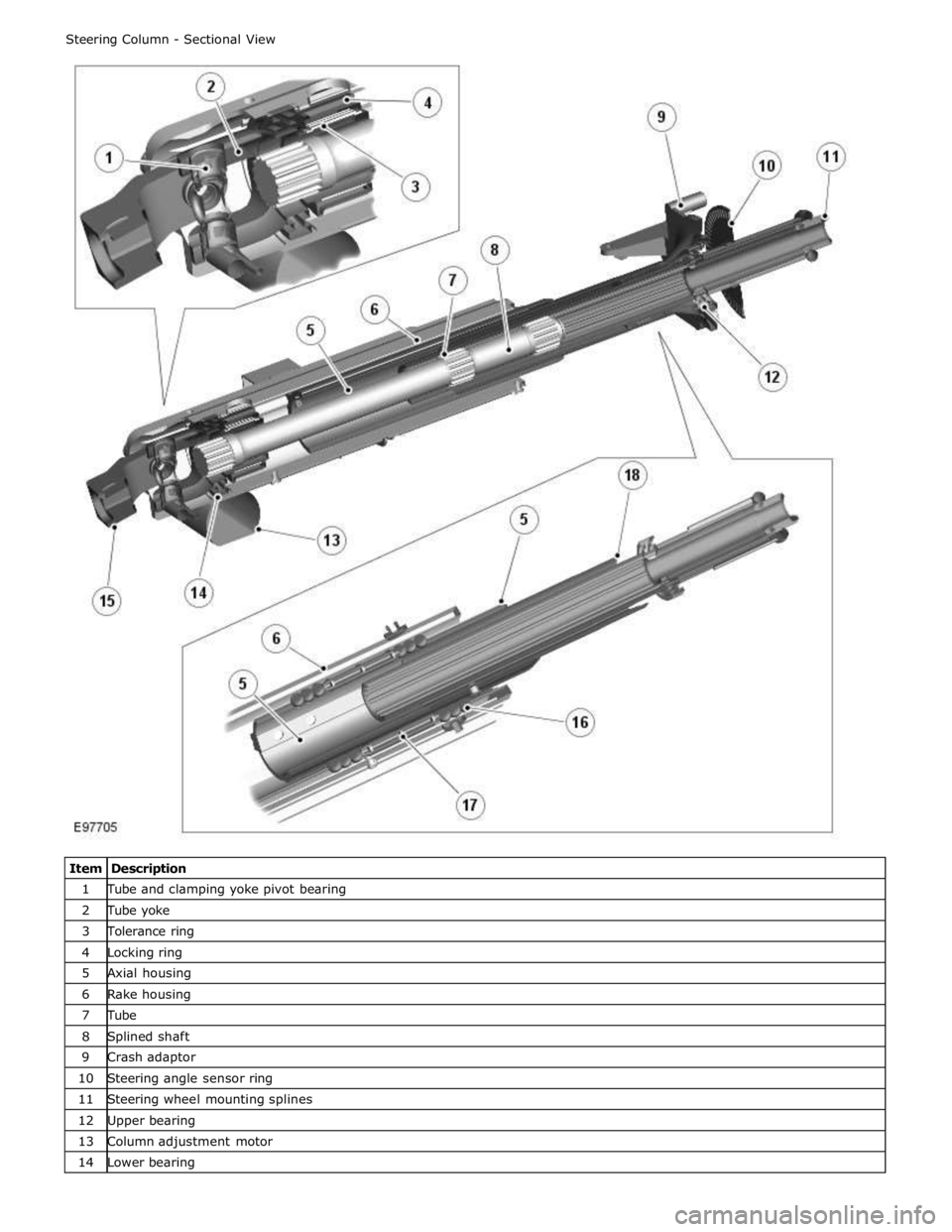

1 Tube and clamping yoke pivot bearing 2 Tube yoke 3 Tolerance ring 4 Locking ring 5 Axial housing 6 Rake housing 7 Tube 8 Splined shaft 9 Crash adaptor 10 Steering angle sensor ring 11 Steering wheel mounting splines 12 Upper bearing 13 Column adjustment motor 14 Lower bearing

Page 782 of 3039

16 Ball (12 off) 17 Distance keeper 18 Crash tube The column comprises a cast magnesium mounting bracket which provides the attachment to the cross-beam. Attached to the

mounting bracket is a rake lever which is attached to the mounting bracket at the lower end with two pivot bearings. The

bearings allow the rake lever to rotate upwards or downward to adjust the column rake.

The rake lever also provides for the attachment of the rake housing which can slide within the lever to provide the reach

adjustment. Within the rake housing is the axial housing which is supported on each side with 6 ball bearings which allow the

rake housing to move forward or backwards. The bearings on each side are arranged in groups of 3 bearings and are separated

by a distance keeper which allows the housing to supported on bearings along its length. Within the axial housing is a tube

which is supported at the upper end of the column on the upper bearing. The tube has a central splined hole which provides for

the fitment of the splined shaft. The splined shaft can slide within the tube on the splines when the column reach is adjusted

or the column collapses in a crash condition. The splined shaft also passes rotary motion from the steering wheel through the

length of the column to the outer clamping yoke which is supported on the lower bearing.

The electric steering column lock is attached to the top of the rake lever. A lock bolt within the steering column lock engages in

one of 8 slots in the locking sleeve located at the lower end of the column preventing rotation of the steering wheel. The

locking sleeve is retained by a tolerance ring which in turn is located on the outer diameter of the tube yoke. The tolerance

ring allows a specified amount of torque to be applied to the splined shaft before it slips, preventing damage to the column

lock due to excessive force being applied to the steering wheel when the lock is engaged. The tolerance ring is designed to

slip on the splined shaft when the applied torque exceeds the fitted slip load of 200 Nm minimum. Repeated rotation of the

lock collar will reduce its slipping torque to 100 Nm minimum. The lock is controlled by the CJB.

A steering angle sensor is located at the upper end of the steering column and is attached to the crash adaptor. The sensor

measures steering rotation via a toothed wheel located on the splined tube at the upper end of the column. The sensor

receives a power supply from the CJB and supplies 2 signals (A and B) relating to the steering rotation to the ABS (anti-lock brake system) module. The module transmits this data on the high speed CAN bus for use by other vehicle systems. Refer to: Anti-Lock Control - Stability Assist (206-09 Anti-Lock Control - Stability Assist, Description and Operation).

The steering column is adjustable electrically, for reach and rake. The adjustment mechanism comprises an electric adjustment

motor, a lead screw, a rake solenoid, a reach solenoid, a reach clutch and a rake clutch. The column adjustment is controlled

manually using a joystick switch located on the LH (left-hand) side of the column lower cowl. The joystick can be moved

forward and backward to adjust the column reach in and out and moved up and down to adjust the rake. The switch selection

energizes the adjustment motor in the applicable direction and also engages the applicable solenoid and clutch.

When the joystick switch is rotated to the 'auto' position, the steering column will adjust to the uppermost rake position when

the ignition is switched off. It will re-adjust to the position corresponding to the memory position for the remote handset when

the ignition is switched on.

The memory function of the electric column is linked to and controlled by the driver's seat module. The module provides for the

storage of three separate memory positions which are stored against 3 individual remote handsets.

Refer to: Seats (501-10 Seating, Description and Operation).

The steering wheel locates on a splined shaft in the upper column assembly and is secured with a bolt. The steering wheel

houses the driver's airbag and switches for the audio system, gear change and speed control. A clockspring is used to connect

the steering wheel electrical components to the vehicle harness.

Two plastic shrouds are fitted to the upper column assembly. The lower shroud is fitted with an energy absorbing foam pad to

minimize leg injury in the event of an accident.

www.JagDocs.com