Rke module JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1788 of 3039

gage, odometer, trip distance and trip computer readouts. The trip distance and trip computer information is derived from

information supplied on the high speed CAN bus to the instrument cluster from the ABS module and the ECM.

The area above the message center displays the transmission gear position information and speed control related information.

The transmission information is supplied on the high speed CAN bus from the TCM (transmission control module).

NOTE: There is no engine coolant temperature gage displayed. If the engine coolant temperature increases to above a

predetermined threshold, a warning message is displayed in the message center. The message is sent from the ECM in a high speed CAN message to the instrument cluster.

TRANSMISSION GEAR SELECTION POSITION

The gear position display shows JaguarDrive selector position or selected gear when using the Jaguar Sequential Shift. The gear

selector module transmits a CAN message to the instrument cluster for gear selector lever position. The module also outputs a 'not in park' signal to the instrument cluster. The TCM transmits a high speed CAN message to the instrument cluster with data containing the selected gear when in Jaguar Sequential Shift mode.

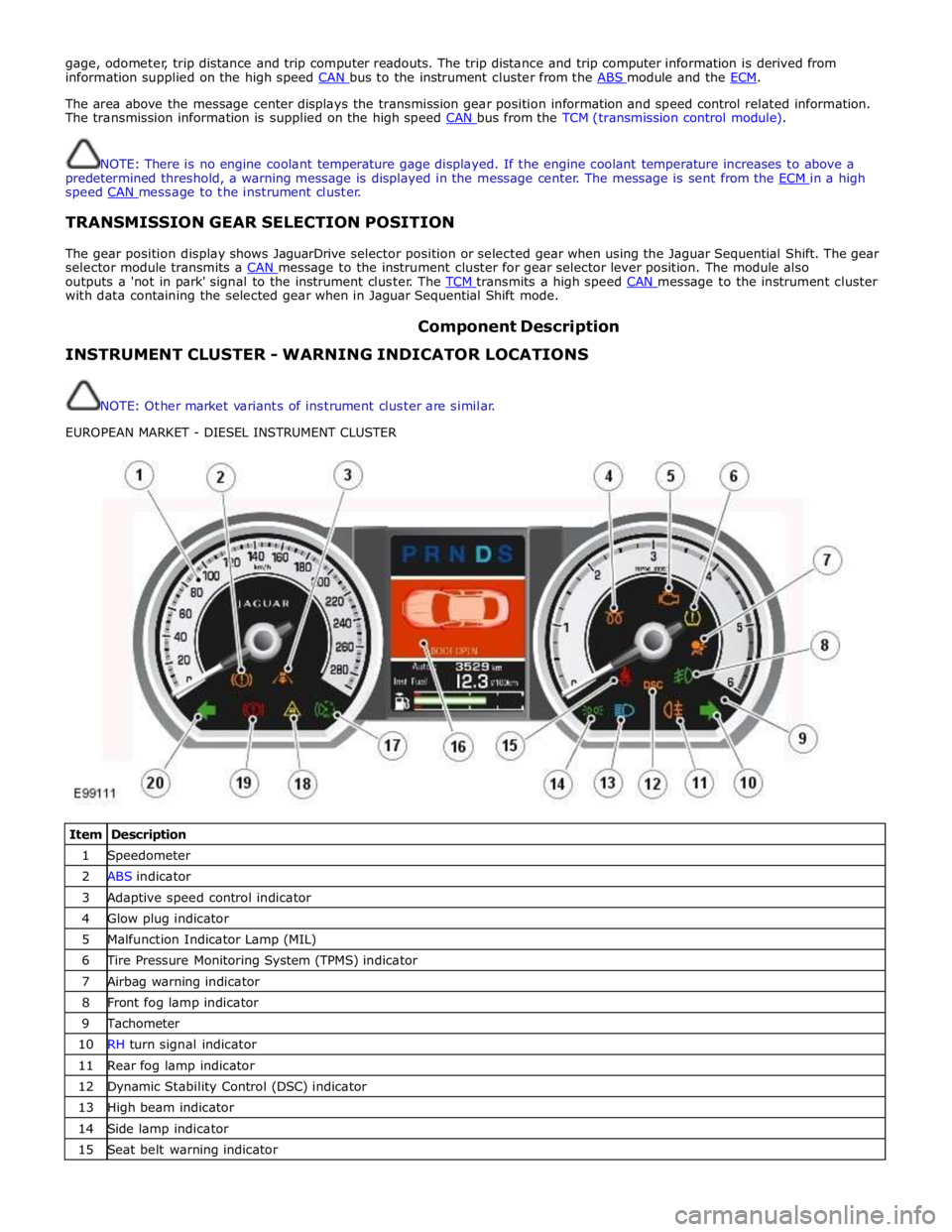

Component Description INSTRUMENT CLUSTER - WARNING INDICATOR LOCATIONS

NOTE: Other market variants of instrument cluster are similar.

EUROPEAN MARKET - DIESEL INSTRUMENT CLUSTER

Item Description 1 Speedometer 2 ABS indicator 3 Adaptive speed control indicator 4 Glow plug indicator 5 Malfunction Indicator Lamp (MIL) 6 Tire Pressure Monitoring System (TPMS) indicator 7 Airbag warning indicator 8 Front fog lamp indicator 9 Tachometer 10 RH turn signal indicator 11 Rear fog lamp indicator 12 Dynamic Stability Control (DSC) indicator 13 High beam indicator 14 Side lamp indicator 15 Seat belt warning indicator

Page 1789 of 3039

17 Automatic Speed Limiter (ASL) indicator 18 Forward alert indicator 19 Brake warning indicator 20 LH turn signal indicator NAS MARKET - V8 NORMALLY ASPIRATED INSTRUMENT CLUSTER

Item Description 1 Speedometer 2 ABS indicator (NAS) 3 ABS indicator (ROW) 4 Adaptive speed control indicator 5 Tachometer 6 Malfunction Indicator Lamp (MIL) 7 Tire Pressure Monitoring System (TPMS) indicator 8 Airbag warning indicator 9 Front fog lamp indicator 10 RH turn signal indicator 11 Rear fog lamp indicator 12 Dynamic Stability Control (DSC) indicator 13 High beam indicator 14 Seat belt warning indicator 15 Side lamp indicator 16 Message center 17 Automatic Speed Limiter (ASL) indicator 18 Forward alert indicator 19 Brake warning indicator (NAS) 20 Brake warning indicator (ROW) 21 LH turn signal indicator The warning indicators are located in various positions in the instrument cluster. The indicators can be split into two groups;

instrument cluster controlled and externally controlled.

Instrument cluster controlled warning indicators are dependent on software logic within the instrument cluster for activation.

The cluster software controls the indicator illumination check at ignition on (power mode 6).

Externally controlled indicators are supplied with current from another vehicle system control module or illuminated by the

instrument cluster software on receipt of a bus message from another vehicle sub-system. The indicator illumination check at

ignition on (powermode 6) is also controlled by the sub-system module for these indicators.

Page 1799 of 3039

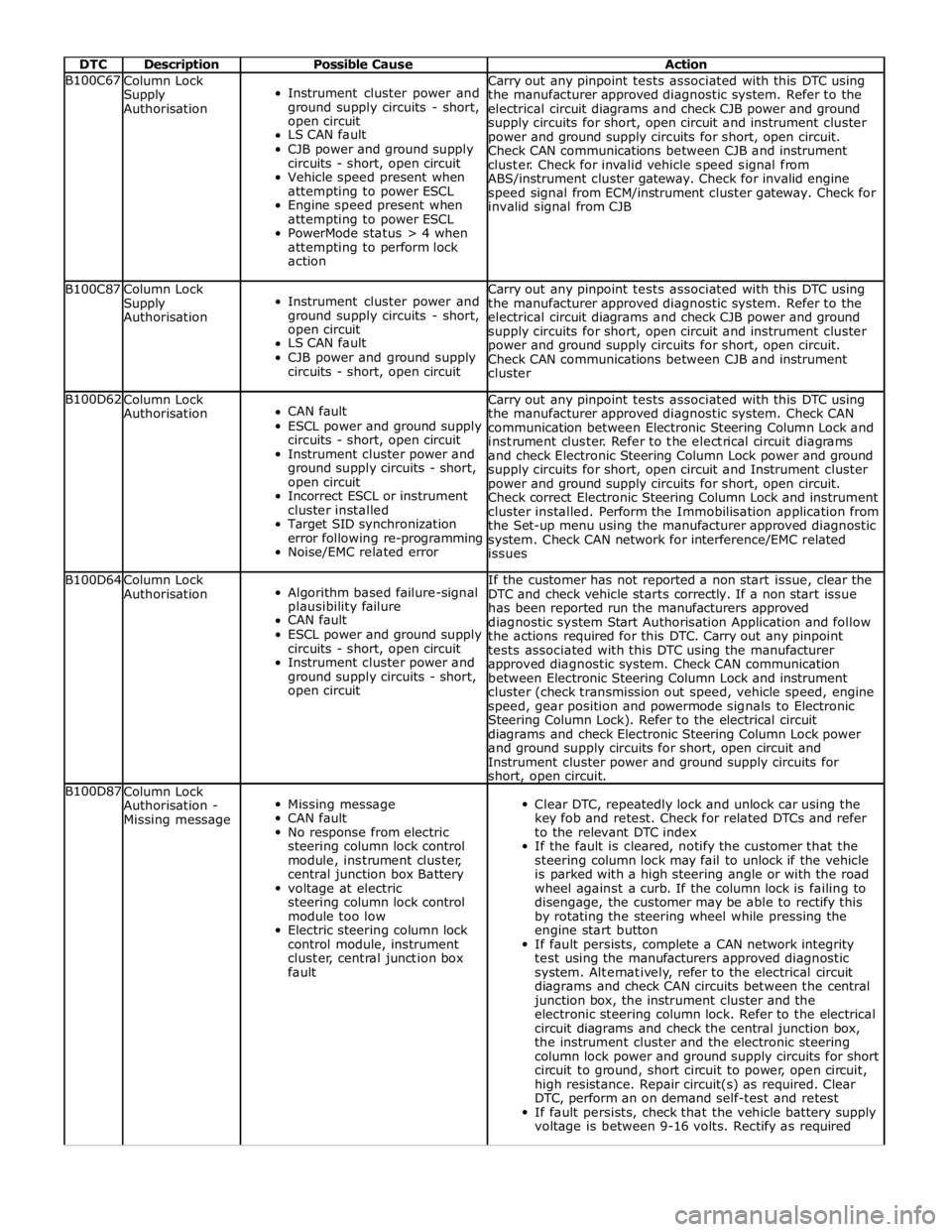

DTC Description Possible Cause Action B100C67

Column Lock

Supply

Authorisation

Instrument cluster power and

ground supply circuits - short,

open circuit

LS CAN fault

CJB power and ground supply

circuits - short, open circuit

Vehicle speed present when

attempting to power ESCL

Engine speed present when

attempting to power ESCL

PowerMode status > 4 when

attempting to perform lock

action Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check CJB power and ground

supply circuits for short, open circuit and instrument cluster

power and ground supply circuits for short, open circuit.

Check CAN communications between CJB and instrument

cluster. Check for invalid vehicle speed signal from

ABS/instrument cluster gateway. Check for invalid engine

speed signal from ECM/instrument cluster gateway. Check for

invalid signal from CJB B100C87

Column Lock

Supply

Authorisation

Instrument cluster power and

ground supply circuits - short,

open circuit

LS CAN fault

CJB power and ground supply

circuits - short, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check CJB power and ground

supply circuits for short, open circuit and instrument cluster

power and ground supply circuits for short, open circuit.

Check CAN communications between CJB and instrument

cluster B100D62

Column Lock

Authorisation

CAN fault

ESCL power and ground supply

circuits - short, open circuit

Instrument cluster power and

ground supply circuits - short,

open circuit

Incorrect ESCL or instrument

cluster installed

Target SID synchronization

error following re-programming

Noise/EMC related error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CAN

communication between Electronic Steering Column Lock and

instrument cluster. Refer to the electrical circuit diagrams

and check Electronic Steering Column Lock power and ground

supply circuits for short, open circuit and Instrument cluster

power and ground supply circuits for short, open circuit.

Check correct Electronic Steering Column Lock and instrument

cluster installed. Perform the Immobilisation application from

the Set-up menu using the manufacturer approved diagnostic

system. Check CAN network for interference/EMC related

issues B100D64

Column Lock

Authorisation

Algorithm based failure-signal

plausibility failure

CAN fault

ESCL power and ground supply

circuits - short, open circuit

Instrument cluster power and

ground supply circuits - short,

open circuit If the customer has not reported a non start issue, clear the

DTC and check vehicle starts correctly. If a non start issue

has been reported run the manufacturers approved

diagnostic system Start Authorisation Application and follow

the actions required for this DTC. Carry out any pinpoint

tests associated with this DTC using the manufacturer

approved diagnostic system. Check CAN communication

between Electronic Steering Column Lock and instrument

cluster (check transmission out speed, vehicle speed, engine

speed, gear position and powermode signals to Electronic

Steering Column Lock). Refer to the electrical circuit

diagrams and check Electronic Steering Column Lock power

and ground supply circuits for short, open circuit and

Instrument cluster power and ground supply circuits for

short, open circuit. B100D87

Column Lock

Authorisation -

Missing message

Missing message

CAN fault

No response from electric

steering column lock control

module, instrument cluster,

central junction box Battery

voltage at electric

steering column lock control

module too low

Electric steering column lock

control module, instrument

cluster, central junction box

fault

Clear DTC, repeatedly lock and unlock car using the

key fob and retest. Check for related DTCs and refer

to the relevant DTC index

If the fault is cleared, notify the customer that the

steering column lock may fail to unlock if the vehicle

is parked with a high steering angle or with the road

wheel against a curb. If the column lock is failing to

disengage, the customer may be able to rectify this

by rotating the steering wheel while pressing the

engine start button

If fault persists, complete a CAN network integrity

test using the manufacturers approved diagnostic

system. Alternatively, refer to the electrical circuit

diagrams and check CAN circuits between the central

junction box, the instrument cluster and the

electronic steering column lock. Refer to the electrical

circuit diagrams and check the central junction box,

the instrument cluster and the electronic steering

column lock power and ground supply circuits for short

circuit to ground, short circuit to power, open circuit,

high resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required

Page 1800 of 3039

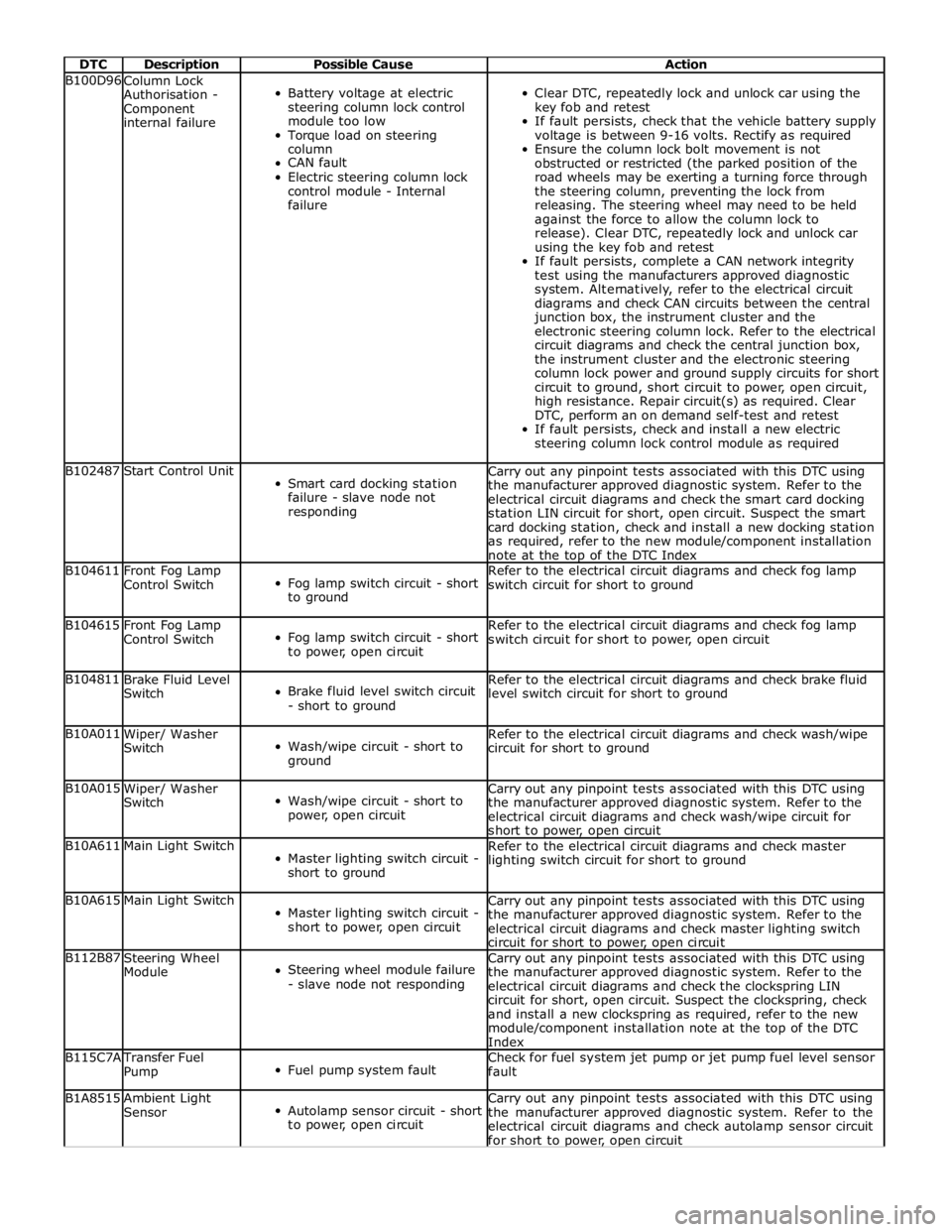

DTC Description Possible Cause Action B100D96

Column Lock

Authorisation -

Component

internal failure

Battery voltage at electric

steering column lock control

module too low

Torque load on steering

column

CAN fault

Electric steering column lock

control module - Internal

failure

Clear DTC, repeatedly lock and unlock car using the

key fob and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required

Ensure the column lock bolt movement is not

obstructed or restricted (the parked position of the

road wheels may be exerting a turning force through

the steering column, preventing the lock from

releasing. The steering wheel may need to be held

against the force to allow the column lock to

release). Clear DTC, repeatedly lock and unlock car

using the key fob and retest

If fault persists, complete a CAN network integrity

test using the manufacturers approved diagnostic

system. Alternatively, refer to the electrical circuit

diagrams and check CAN circuits between the central

junction box, the instrument cluster and the

electronic steering column lock. Refer to the electrical

circuit diagrams and check the central junction box,

the instrument cluster and the electronic steering

column lock power and ground supply circuits for short

circuit to ground, short circuit to power, open circuit,

high resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check and install a new electric

steering column lock control module as required B102487 Start Control Unit

Smart card docking station

failure - slave node not

responding Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check the smart card docking

station LIN circuit for short, open circuit. Suspect the smart

card docking station, check and install a new docking station

as required, refer to the new module/component installation

note at the top of the DTC Index B104611

Front Fog Lamp

Control Switch

Fog lamp switch circuit - short

to ground Refer to the electrical circuit diagrams and check fog lamp

switch circuit for short to ground B104615

Front Fog Lamp

Control Switch

Fog lamp switch circuit - short

to power, open circuit Refer to the electrical circuit diagrams and check fog lamp

switch circuit for short to power, open circuit B104811

Brake Fluid Level

Switch

Brake fluid level switch circuit

- short to ground Refer to the electrical circuit diagrams and check brake fluid

level switch circuit for short to ground B10A011

Wiper/ Washer

Switch

Wash/wipe circuit - short to

ground Refer to the electrical circuit diagrams and check wash/wipe

circuit for short to ground B10A015

Wiper/ Washer

Switch

Wash/wipe circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check wash/wipe circuit for

short to power, open circuit B10A611 Main Light Switch

Master lighting switch circuit -

short to ground Refer to the electrical circuit diagrams and check master

lighting switch circuit for short to ground B10A615 Main Light Switch

Master lighting switch circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check master lighting switch

circuit for short to power, open circuit B112B87

Steering Wheel

Module

Steering wheel module failure

- slave node not responding Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check the clockspring LIN

circuit for short, open circuit. Suspect the clockspring, check

and install a new clockspring as required, refer to the new

module/component installation note at the top of the DTC

Index B115C7A

Transfer Fuel

Pump

Fuel pump system fault Check for fuel system jet pump or jet pump fuel level sensor

fault B1A8515

Ambient Light

Sensor

Autolamp sensor circuit - short

to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check autolamp sensor circuit

for short to power, open circuit

Page 1824 of 3039

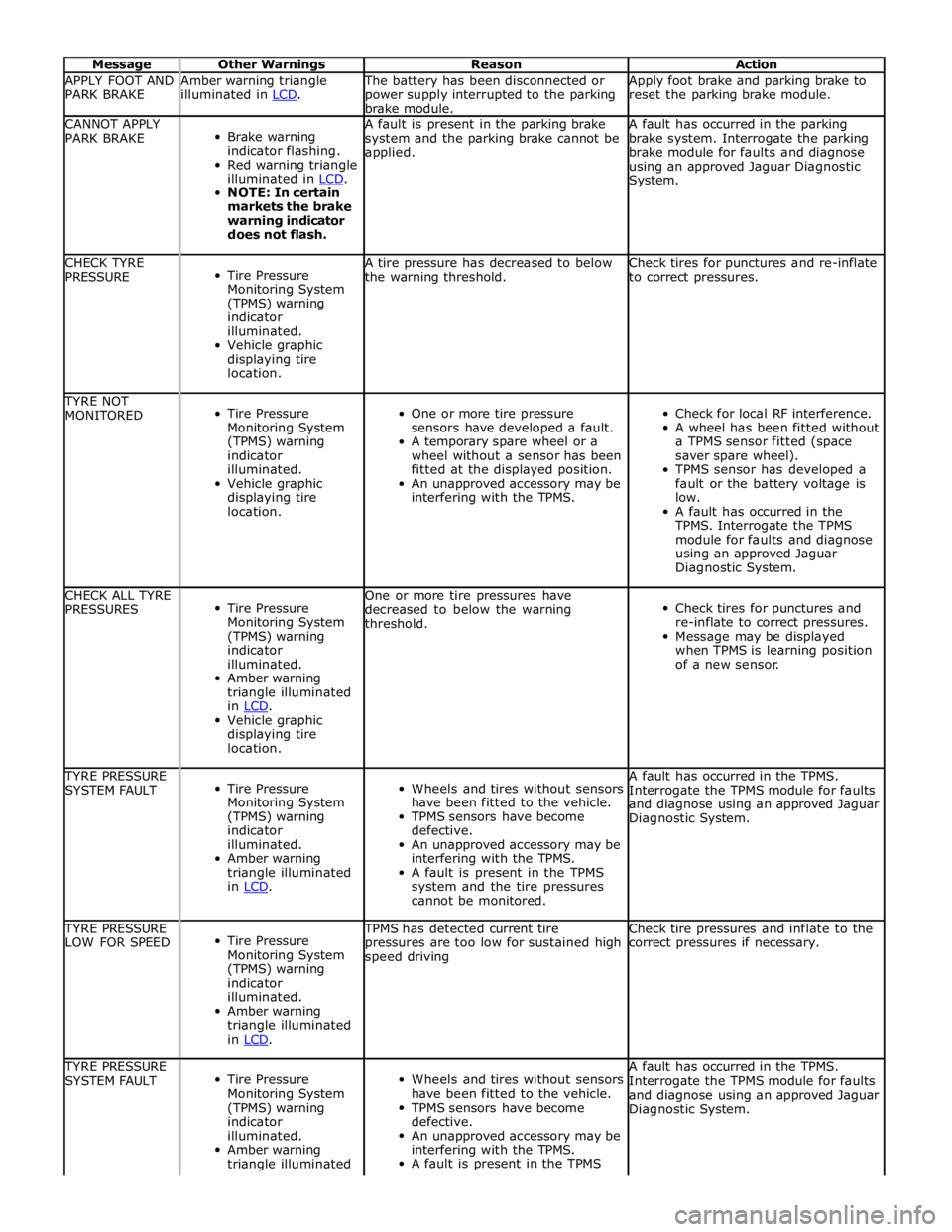

Message Other Warnings Reason Action APPLY FOOT AND

PARK BRAKE Amber warning triangle

illuminated in LCD. The battery has been disconnected or

power supply interrupted to the parking

brake module. Apply foot brake and parking brake to

reset the parking brake module. CANNOT APPLY

PARK BRAKE

Brake warning

indicator flashing.

Red warning triangle

illuminated in LCD. NOTE: In certain

markets the brake

warning indicator

does not flash. A fault is present in the parking brake

system and the parking brake cannot be

applied. A fault has occurred in the parking

brake system. Interrogate the parking

brake module for faults and diagnose

using an approved Jaguar Diagnostic

System. CHECK TYRE

PRESSURE

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Vehicle graphic

displaying tire

location. A tire pressure has decreased to below

the warning threshold. Check tires for punctures and re-inflate

to correct pressures. TYRE NOT

MONITORED

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Vehicle graphic

displaying tire

location.

One or more tire pressure

sensors have developed a fault.

A temporary spare wheel or a

wheel without a sensor has been

fitted at the displayed position.

An unapproved accessory may be

interfering with the TPMS.

Check for local RF interference.

A wheel has been fitted without

a TPMS sensor fitted (space

saver spare wheel).

TPMS sensor has developed a

fault or the battery voltage is

low.

A fault has occurred in the

TPMS. Interrogate the TPMS

module for faults and diagnose

using an approved Jaguar

Diagnostic System. CHECK ALL TYRE

PRESSURES

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD. Vehicle graphic

displaying tire

location. One or more tire pressures have

decreased to below the warning

threshold.

Check tires for punctures and

re-inflate to correct pressures.

Message may be displayed

when TPMS is learning position

of a new sensor. TYRE PRESSURE

SYSTEM FAULT

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD.

Wheels and tires without sensors

have been fitted to the vehicle.

TPMS sensors have become

defective.

An unapproved accessory may be

interfering with the TPMS.

A fault is present in the TPMS

system and the tire pressures

cannot be monitored. A fault has occurred in the TPMS.

Interrogate the TPMS module for faults

and diagnose using an approved Jaguar

Diagnostic System. TYRE PRESSURE

LOW FOR SPEED

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD. TPMS has detected current tire

pressures are too low for sustained high

speed driving Check tire pressures and inflate to the

correct pressures if necessary. TYRE PRESSURE

SYSTEM FAULT

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

Wheels and tires without sensors

have been fitted to the vehicle.

TPMS sensors have become

defective.

An unapproved accessory may be

interfering with the TPMS.

A fault is present in the TPMS A fault has occurred in the TPMS.

Interrogate the TPMS module for faults

and diagnose using an approved Jaguar

Diagnostic System.

Page 1866 of 3039

Published: 07-Aug-2014

Battery and Charging System - General Information - Battery Care

Requirements

Description and Operation

1. INTRODUCTION

This document defines the requirements for care and maintenance of batteries, and the standard of battery care at dealers and

retailers for new vehicles.

This applies to all types of 12 Volt Lead Acid Batteries used in Jaguar and Land Rover vehicles whether they are conventional

flooded technology or Absorbed Glass Mat (AGM – also known as Valve Regulated Lead Acid (VRLA)) technology and also

applies to both Primary, Secondary and Auxiliary Batteries. AGM batteries offer improved resistance to cycling as seen in stop

start applications.

In order to prevent damage to the battery and ensure a satisfactory service life, all processes detailed within this document

must be rigorously adhered to.

It is equally important therefore to note the following key points:

All new vehicles leave the factory with either a transit relay installed and/or have a transit mode programmed into the

vehicle control modules. The transit relay must be removed and the transit mode disabled (where applicable) using an

approved diagnostic system, NOT MORE THAN 72 HOURS before the customer takes delivery.

The battery can be discharged by the following mechanisms:

- Self Discharge: - A lead acid battery will very slowly discharge itself due to its own internal chemical processes

whether it is connected to a vehicle or not.

- Quiescent Discharge: - The vehicle electrical systems when connected to the battery will draw charge from the

battery.

12 Volt Lead Acid Batteries rely on internal chemical processes to create a voltage and deliver current. These processes and

the internal chemical structure of the battery can be damaged if the battery is allowed to discharge over a number of weeks /

months, or is left in a discharged state for a lengthy time period.

On vehicles with conventional ignition keys, these must not be left in the ignition lock barrel when the transit relay

has been removed, otherwise quiescent current will increase and the battery will discharge more rapidly.

For keyless vehicles, the Smart Key must be stored at least 5m (16 ft) away from the vehicle when the vehicle is

parked or stored.

AGM Batteries are fully sealed and cannot have the electrolyte level topped up.

NOTE: Dealers and retailers involved in the storage / handling of vehicles and replacement batteries have a responsibility

to ensure that only a fully charged battery may be processed through the distribution selling chain.

2. GENERAL RULES FOR BATTERY CARE

2.1 Dealer Demonstration Vehicles

Vehicles used as dealer demonstrator(s), in a showroom, must be connected to a JLR approved showroom conditioner capable

of delivering 50 Amps. This will prevent the battery from being damaged.

2.2 Software Reflash, SDD work or Ignition On related workshop activities

Due to the high electrical current demand and high depth of discharge that can occur during vehicle software re-flash activities,

SDD work or ignition on (power mode 6) related work in the workshop, vehicles that are undergoing such activities MUST have a

JLR approved power supply capable of delivering 50 Amps or more.

2.3 Extended Vehicle Rework

For any extended vehicle rework that results in consuming vehicle power, either the battery should be disconnected or a JLR

approved power supply connected.

2.4 Jump Starting New vehicles before they have been delivered to the customer

It is the dealer / retailers responsibility to make sure the battery is not allowed to discharge by following the

instructions and processes defined in this manual.

However, if circumstances dictate that a new vehicle must be jump started due to a discharged battery whilst the

vehicle is in the dealer / retailers care, the battery on this vehicle must be replaced with a new one prior to delivery

to the customer at the dealer / retailers liability.

The vehicle should also undergo investigation as to why the battery became discharged.

Do not connect the jump starting cable to the negative (-) terminal of the battery. Always connect to the recommended

earth point. As defined in the owners handbook or service documentation for that vehicle. 2.5 AGM Batteries

AGM batteries must not be charged above 14.8 Volts. Doing so will damage them.

AGM Batteries must be tested with a capable battery tester as detailed in the Equipment section (Section 5) of this

Page 1930 of 3039

The navigation will restart upon completion of the map update.

NOTE: Remove USB stick immediately

Turn off the engine.

Exit, lock the vehicle and leave for at 15 minutes before using the navigation system.

Japanese Navigation

The Japanese satellite navigation system uses a separate navigation computer module.

The HDD in the ACM/IAM is not used for navigation downloads in this market.

Map updates are supplied in DVD format. The DVD is loaded into the navigation module. Map data is read directly from the

DVD.

SD Card Navigation Updates (Asia Navigation)

The Asia market navigation system is an aftermarket unit.

Map updates are supplied in an SD card format. The SD card is loaded into the navigation module. Map data is read directly

from the SD card.

NOTE: The following countries use SD card navigation updates.

Country ANGOLA ARGENTINA AZERBAIJAN BAHAMAS BARBADOS BENIN BOTSWANA BRAZIL BRUNEI BURUNDI CAYMAN ISLANDS CHILE CHINA COLOMBIA EGYPT FIJI GHANA HONG KONG INDIA INDONESIA ISRAEL JAMAICA KENYA LEBANON LESOTHO MALAWI MALI MAURITIUS MONGOLIA MOROCCO MOZAMBIQUE NAMIBIA NIGER www.JagDocs.com

Page 1936 of 3039

Is 'Jaguar' identified in Bluetooth device list? Yes

Select device from list, then continue with diagnosis.GO to A3. No

Carry out further Bluetooth device search, to a maximum of 4 times, waiting approximately 20 seconds

between searches. If 'Jaguar' still not identified in Bluetooth device list, set ignition status to OFF, wait

approximately 30 seconds and set ignition status to ON. Carry out further Bluetooth device search, to a

maximum of 4 times, waiting approximately 20 seconds between searches. If 'Jaguar' still not identified in

Bluetooth device list, contact your local in market support for further assistance. A3: TELEPHONE HANDSET ERROR 1 Check for any error shown on the telephone handset when 'Jaguar' is selected from the Bluetooth device list. Was an error immediately shown on the telephone handset? Yes

Wait approximately 10 seconds then re-attempt selection, to a maximum of 4 times, waiting

approximately 10 seconds between each attempt. If error still being displayed, contact your local in

market support for assistance.

No

Enter PIN '1313' then continue with diagnosis.GO to A4. A4: PIN ENTRY STATUS 1 Check for successful PIN entry. Was PIN entry successful? Yes

GO to A5. No

Wait approximately 10 seconds then re-attempt PIN entry, to a maximum of 4 times, waiting

approximately 10 seconds between each attempt. If PIN entry is still un-successful, contact your local in

market support for assistance. A5: 'NO PHONE FITTED' DISPLAY 1 Carry out checks to determine if 'No Phone Fitted' is still shown on vehicle display. Is 'No Phone Fitted' still displayed? Yes

From the telephone handset, select the connect option for the 'Land Rover' device identified in the

Bluetooth device list. If 'No Phone Fitted' is still displayed, suspect a telephone handset fault. Carry out

Pinpoint test again using known good telephone handset.

No

The telephone is paired and connected to the system. No further action is required for this symptom.

PINPOINT TEST B : NOT AUTOMATICALLY CONNECTING TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: BLUETOOTH MODULE PAIRED DEVICE LIST

NOTE: Prior to continuing with any diagnosis, ensure that the Customer telephone and level of software is included on

the JLR approved list, the telephone battery is fully charged and in a serviceable condition, the bluetooth and auto connect

functions are activated and the telephone handset is placed within the vehicle cabin area. 1 Carry out checks to determine if the Customer telephone is shown in the Bluetooth Module paired device list. Is the Customer telephone in the Bluetooth Module paired device list?

Yes

GO to B2. No

Carry out Unable to Pair Pinpoint Test.GO to A. B2: CUSTOMER HANDSET PAIRED DEVICE LIST 1 Carry out checks to determine if the Bluetooth Module is shown in the Customer telephone paired device list. Is the Bluetooth Module in the Customer telephone paired device list?

Yes

GO to B3. No

Carry out Unable to Pair Pinpoint Test.GO to A. B3: CUSTOMER TELEPHONE IN POSITION 1 1 Carry out checks to determine if the Customer telephone is in position 1 in the Bluetooth Module paired device list. Is the Customer telephone in position 1?

Yes

GO to B4. No

Advise Customer that auto connection will only be attempted with the device that is shown in position 1

in Bluetooth Module paired device list. B4: CHECK FOR DTC B1A56-13 1 Using Manufacturer approved diagnostic system, check for DTC B1A56-13.

Page 1937 of 3039

Is DTC B1A56-13 logged?

Yes

Carry out remedial actions as outlined in DTC Index. If symptom remains, contact your local in market

support for assistance.

No

GO to B5. B5: BLUETOOTH CONNECTION 1 Carry out checks to determine if Bluetooth connection icon is shown on Customer Bluetooth telephone screen but shows 'No Phone Fitted' on vehicle screen. Is Bluetooth connection icon shown on the Customer handset but 'No Phone Fitted' displayed on vehicle

screen?

Yes

GO to B9. No

GO to B6. B6: 'LAND ROVER' AUTHORISATION

NOTE: Some handsets may require operator intervention to manually authorise connection. 1 Carry out checks to determine if 'Land Rover' is authorised in the Customer Bluetooth telephone device list menu. Is 'Land Rover' authorised in the Customer Bluetooth telephone device list menu?

Yes

GO to B7. No

Advise customer that 'Land Rover' needs to be authorised in the Customer Bluetooth telephone device

list menu, or operator intervention may be required to manually authorise connection. B7: SEARCH FOR DEVICES SCREEN 1 Select the search for devices button on the vehicle display. Does pressing the search for devices button bring up the searching screen on the vehicle display?

Yes

Contact your local in market support for assistance.

No

GO to B8. B8: CYCLE IGNITION AND CHECK SEARCH FOR DEVICES SCREEN 1 Lock vehicle (wait 60s) before unlocking and turning Ignition status back to ON. Does pressing the search for devices button bring up the searching screen on the vehicle display?

Yes

No further action required for this Symptom. Possible intermitent fault.

No

Contact your local in market support for assistance. B9: PAIRED DEVICE 1 Check Customer telephone paired device list to establish which device the Customer telephone is connected to. Is the Customer telephone connected to the vehicle?

Yes

Lock vehicle (wait 60s) before unlocking and turning Ignition status back to ON. If Not Automatically

Connecting, contact you local in market support for assistance.

No

Using the Customer telephone controls, disconnect from the currently connected device and delete from

paired device list. Lock vehicle (wait for 60s) before unlocking and turning Igition status to ON. If Not Automatically Connecting, contact your local in market support for assistance.

PINPOINT TEST C : NO AUDIO TO THIRD PARTY TEST CONDITIONS DETAILS/RESULTS/ACTIONS C1: MICROPHONE DIAGNOSTIC TROUBLE CODES (DTCS)

NOTE: Prior to continuing with any diagnosis, ensure that the Customer telephone and level of software is included on

the JLR approved list, the telephone battery is fully charged and in a serviceable condition, the telephone is placed within the

vehicle cabin area and is connected to the vehicle via bluetooth. 1 Using the Manufacturer approved diagnostic system, check for any logged microphone DTCs in Audio Front Control module. Is DTC B1D79-01 logged? Yes

Carry out diagnosis of electrical failure as advised in Action column of DTC Index.

No

Contact your local in market support for assistance.

PINPOINT TEST D : NO AUDIO FROM THIRD PARTY TEST CONDITIONS DETAILS/RESULTS/ACTIONS D1: 'IN CALL' DISPLAY

Page 1940 of 3039

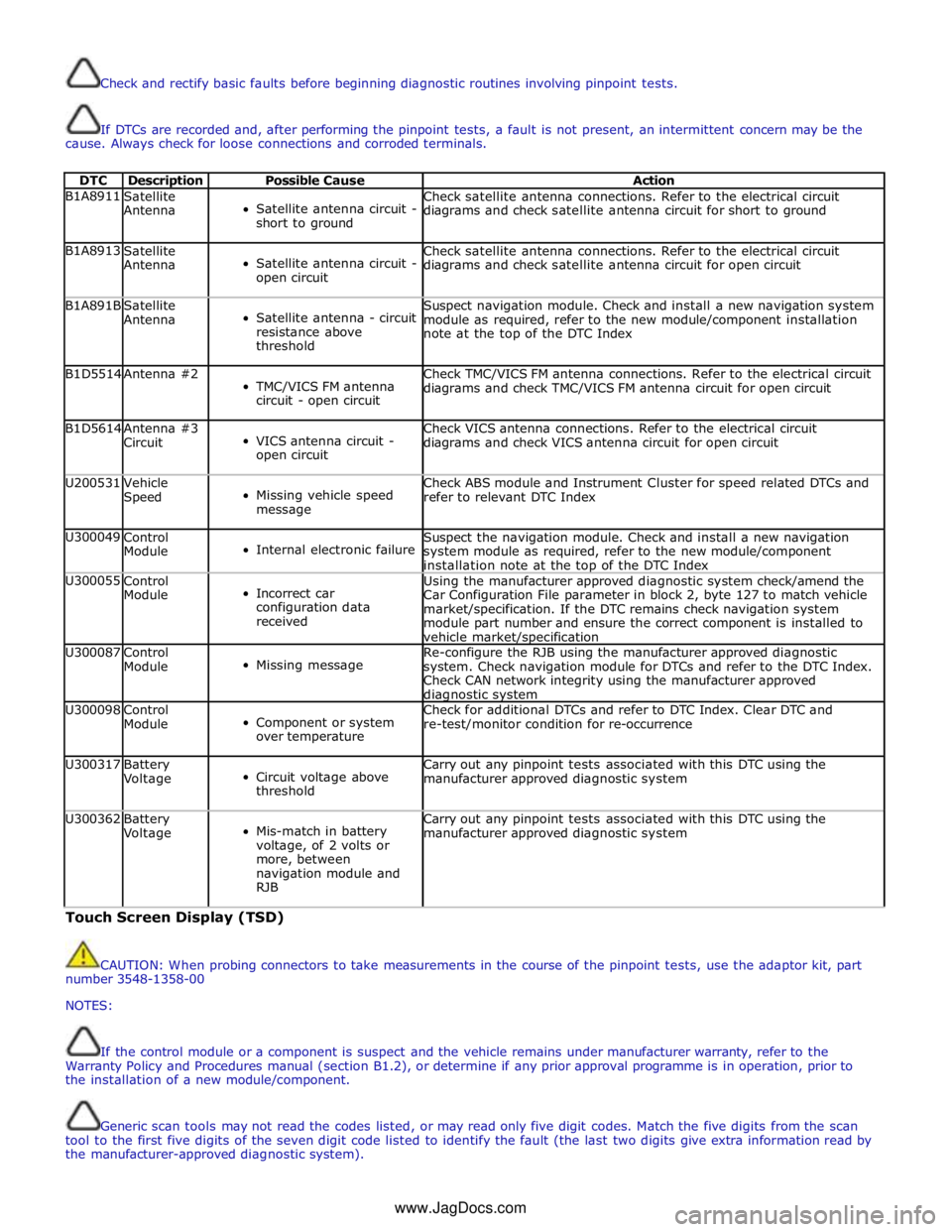

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B1A8911

Satellite

Antenna

Satellite antenna circuit -

short to ground Check satellite antenna connections. Refer to the electrical circuit

diagrams and check satellite antenna circuit for short to ground B1A8913

Satellite

Antenna

Satellite antenna circuit -

open circuit Check satellite antenna connections. Refer to the electrical circuit

diagrams and check satellite antenna circuit for open circuit B1A891B

Satellite

Antenna

Satellite antenna - circuit

resistance above

threshold Suspect navigation module. Check and install a new navigation system

module as required, refer to the new module/component installation

note at the top of the DTC Index B1D5514 Antenna #2

TMC/VICS FM antenna

circuit - open circuit Check TMC/VICS FM antenna connections. Refer to the electrical circuit

diagrams and check TMC/VICS FM antenna circuit for open circuit B1D5614

Antenna #3

Circuit

VICS antenna circuit -

open circuit Check VICS antenna connections. Refer to the electrical circuit

diagrams and check VICS antenna circuit for open circuit U200531

Vehicle

Speed

Missing vehicle speed

message Check ABS module and Instrument Cluster for speed related DTCs and

refer to relevant DTC Index U300049

Control

Module

Internal electronic failure Suspect the navigation module. Check and install a new navigation

system module as required, refer to the new module/component

installation note at the top of the DTC Index U300055

Control

Module

Incorrect car

configuration data

received Using the manufacturer approved diagnostic system check/amend the

Car Configuration File parameter in block 2, byte 127 to match vehicle

market/specification. If the DTC remains check navigation system

module part number and ensure the correct component is installed to

vehicle market/specification U300087

Control

Module

Missing message Re-configure the RJB using the manufacturer approved diagnostic

system. Check navigation module for DTCs and refer to the DTC Index.

Check CAN network integrity using the manufacturer approved diagnostic system U300098

Control

Module

Component or system

over temperature Check for additional DTCs and refer to DTC Index. Clear DTC and

re-test/monitor condition for re-occurrence U300317

Battery

Voltage

Circuit voltage above

threshold Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system U300362

Battery

Voltage

Mis-match in battery

voltage, of 2 volts or

more, between

navigation module and

RJB Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system Touch Screen Display (TSD)

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give extra information read by

the manufacturer-approved diagnostic system).

www.JagDocs.com