auxiliary battery JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2101 of 3039

Published: 11-May-2011

Module Communications Network - Auxiliary Junction Box (AJB)

Removal and Installation

Removal

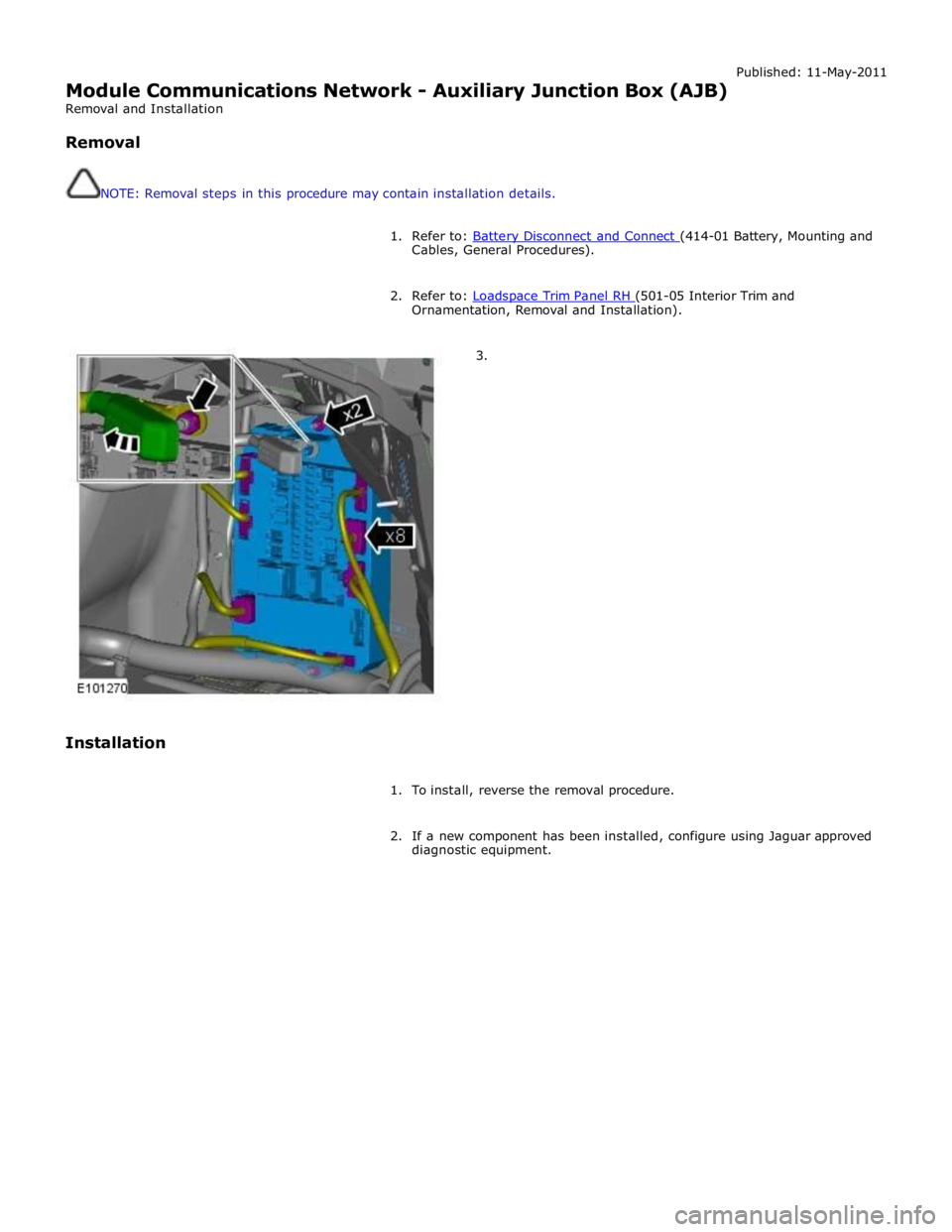

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Loadspace Trim Panel RH (501-05 Interior Trim and Ornamentation, Removal and Installation).

3.

Installation

1. To install, reverse the removal procedure.

2. If a new component has been installed, configure using Jaguar approved

diagnostic equipment.

Page 2172 of 3039

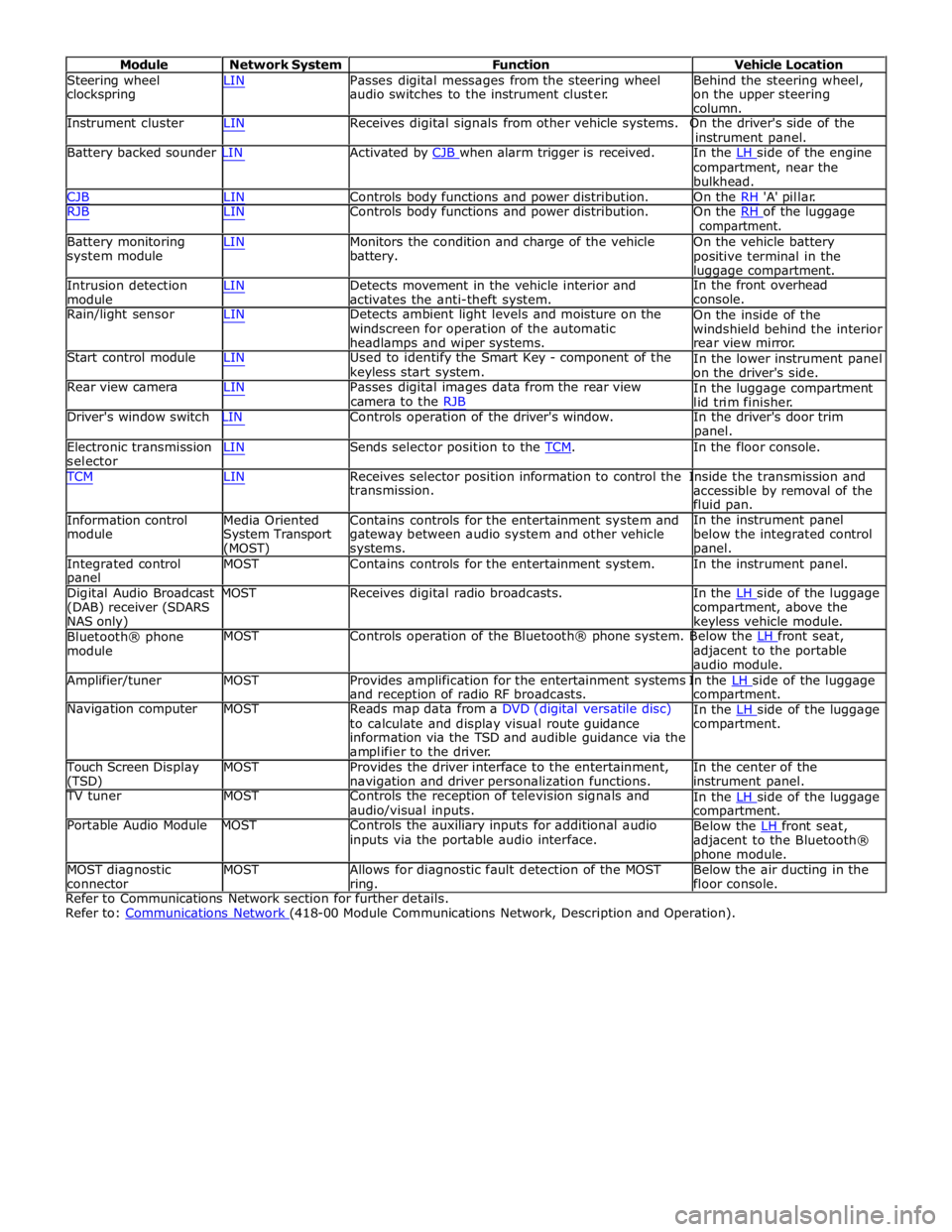

Module Network System Function Vehicle Location

Steering wheel

clockspring LIN Passes digital messages from the steering wheel

audio switches to the instrument cluster. Behind the steering wheel,

on the upper steering

column.

Instrument cluster LIN Receives digital signals from other vehicle systems. On the driver's side of the

instrument panel.

Battery backed sounder LIN Activated by CJB when alarm trigger is received. In the LH side of the engine compartment, near the

bulkhead.

CJB LIN Controls body functions and power distribution. On the RH 'A' pillar.

RJB LIN Controls body functions and power distribution. On the RH of the luggage compartment.

Battery monitoring

system module

Intrusion detection

module LIN Monitors the condition and charge of the vehicle

battery.

LIN Detects movement in the vehicle interior and

activates the anti-theft system. On the vehicle battery

positive terminal in the

luggage compartment.

In the front overhead

console.

Rain/light sensor LIN Detects ambient light levels and moisture on the

windscreen for operation of the automatic

headlamps and wiper systems.

Start control module LIN Used to identify the Smart Key - component of the

keyless start system.

Rear view camera LIN Passes digital images data from the rear view

camera to the RJB On the inside of the

windshield behind the interior

rear view mirror.

In the lower instrument panel

on the driver's side.

In the luggage compartment

lid trim finisher.

Driver's window switch LIN Controls operation of the driver's window. In the driver's door trim

panel.

Electronic transmission

selector LIN Sends selector position to the TCM. In the floor console. TCM LIN Receives selector position information to control the Inside the transmission and

Information control

module

Media Oriented

System Transport

(MOST) transmission.

Contains controls for the entertainment system and

gateway between audio system and other vehicle

systems. accessible by removal of the

fluid pan.

In the instrument panel

below the integrated control

panel.

Integrated control

panel MOST Contains controls for the entertainment system. In the instrument panel.

Digital Audio Broadcast MOST Receives digital radio broadcasts. In the LH side of the luggage (DAB) receiver (SDARS

NAS only)

Bluetooth® phone

module compartment, above the

keyless vehicle module.

MOST Controls operation of the Bluetooth® phone system. Below the LH front seat, adjacent to the portable

audio module.

Amplifier/tuner MOST Provides amplification for the entertainment systems In the LH side of the luggage and reception of radio RF broadcasts.

Navigation computer MOST Reads map data from a DVD (digital versatile disc)

to calculate and display visual route guidance

information via the TSD and audible guidance via the

amplifier to the driver. compartment.

In the LH side of the luggage compartment.

Touch Screen Display

(TSD) MOST Provides the driver interface to the entertainment,

navigation and driver personalization functions. In the center of the

instrument panel.

TV tuner MOST Controls the reception of television signals and

audio/visual inputs.

Portable Audio Module MOST Controls the auxiliary inputs for additional audio

inputs via the portable audio interface. In the LH side of the luggage compartment.

Below the LH front seat, adjacent to the Bluetooth®

phone module.

MOST diagnostic

connector MOST Allows for diagnostic fault detection of the MOST

ring. Below the air ducting in the

floor console.

Refer to Communications Network section for further details.

Refer to: Communications Network (418-00 Module Communications Network, Description and Operation).

Page 2177 of 3039

DTC Description Possible Cause Action C1B1415 Sensor Supply #1

Window position hall sensors

supply circuit - short to power,

open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and test window

position hall sensors supply circuit for short to power, open circuit C1B1511 Sensor Supply #2

Hall sensor supply circuit - short

to ground Refer to the electrical circuit diagrams and test window

position hall sensors supply circuit for short to ground C1B1515 Sensor Supply #2

Hall sensor supply circuit - short

to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and test window

position hall sensors supply circuit for short to power, open circuit U001000

Medium Speed CAN

Communication Bus

Bus off Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U014000

Lost Communication

With Body Control

Module

Missing message from CJB Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U020800

Lost Communication

With Seat Control

Module "A"

Missing message from driver

seat module Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U030000

Internal Control

Module Software

Incompatibility

Invalid configuration message is

received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC

remains suspect the DDM. Check and install a new

module as required, refer to the new module/component

installation note at the top of the DTC Index U200224 Switch

Signal stuck high Clear DTC and re-test. If DTC remains, suspect the

passenger side window switch. Check and install a new passenger side window switch U200424

Auxiliary Switch

Pack

Left or right rear door local

switch - signal stuck high Check for stuck rear window switch. Refer to the

electrical circuit diagrams and check left or right rear

door local switch circuit for short circuit U201011 Switch illumination

Rear window switch illumination

circuit - short to ground Refer to the electrical circuit diagrams and check rear

window switch illumination circuit for short to ground U201208

Car Configuration

Parameter(s)

Bus signal/message failures Cycle the ignition status and re-test. If DTC remains,

re-configure the RJB using the manufacturer approved diagnostic system U201324 Switch Pack

Signal stuck high Clear DTC and re-test. If DTC remains, install a new

driver door switch pack U201444

Control Module

Hardware

Data memory failure Suspect the DDM. Check and install a new DDM as

required, refer to the new module/component

installation note at the top of the DTC Index U210000

Initial Configuration

Not Complete

No sub type information Re-configure the DDM using the manufacturer approved

diagnostic system U300049 Control Module

Internal electronic failure Suspect the DDM. Check and install a new DDM as

required, refer to the new module/component

installation note at the top of the DTC Index U300255

Vehicle

Identification

Number

Not configured Re-configure the DDM as new using the manufacturer

approved diagnostic system and re-test. If DTC remains

install a new module, refer to the new

module/component installation note at the top of the

DTC Index U300281

Vehicle

Identification

Number (VIN)

Vehicle/component mis-match.

Corrupt VIN data being

transmitted, module previously

installed to other vehicle Check and install correct/new module as required, refer

to the new module/component installation note at the

top of the DTC Index U300362 Battery voltage

Mis-match in battery voltage, of

2 volts or more, between DDM

and RJB Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system

Page 2186 of 3039

DTC Description Possible Cause Action C1B1415 Sensor Supply #1

Front window position hall

sensor supply circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and test front

window position hall sensor supply circuit for short to power, open circuit C1B1511 Sensor Supply #2

Hall sensor supply circuit - short

to ground Refer to the electrical circuit diagrams and test window

position hall sensors supply circuit for short to ground C1B1515 Sensor Supply #2

Hall sensor supply circuit - short

to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and test window

position hall sensors supply circuit for short to power, open circuit U001000

Medium Speed CAN

Communication Bus

Bus off Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U014000

Lost Communication

With Body Control

Module

Missing message from CJB Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U020800

Lost Communication

With Seat Control

Module "A"

Missing message from driver

seat module Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U030000

Internal Control

Module Software

Incompatibility

Invalid configuration message is

received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC

remains suspect the PDM. Check and install a new

module as required, refer to the new module/component

installation note at the top of the DTC Index U200224 Switch

Signal stuck high Clear DTC and re-test. If DTC remains, suspect the

passenger side window switch. Check and install a new passenger side window switch U200424

Auxiliary Switch

Pack

Left or right rear door local

switch - signal stuck high Check for stuck rear window switch. Refer to the

electrical circuit diagrams and check left or right rear

door local switch circuit for short circuit U201011 Switch illumination

Rear window switch illumination

circuit - short to ground Refer to the electrical circuit diagrams and check rear

window switch illumination circuit for short to ground U201208

Car Configuration

Parameter(s)

Bus signal/message failures Cycle the ignition status and re-test. If DTC remains,

re-configure the RJB using the manufacturer approved diagnostic system U201324 Switch Pack

Signal stuck high Clear DTC and re-test. If DTC remains, install a new

driver door switch pack U201444

Control Module

Hardware

Data memory failure Suspect the PDM. Check and install a new PDM as

required, refer to the new module/component

installation note at the top of the DTC Index U210000

Initial Configuration

Not Complete

No sub type information Re-configure the PDM using the manufacturer approved

diagnostic system U300049 Control Module

Internal electronic failure Suspect the PDM. Check and install a new PDM as

required, refer to the new module/component

installation note at the top of the DTC Index U300255

Vehicle

Identification

Number

Not configured Re-configure the PDM as new using the manufacturer

approved diagnostic system and re-test. If DTC remains

install a new module, refer to the new

module/component installation note at the top of the

DTC Index U300281

Vehicle

Identification

Number (VIN)

Vehicle/component mis-match.

Corrupt VIN data being

transmitted, module previously

installed to other vehicle Check and install correct/new module as required, refer

to the new module/component installation note at the

top of the DTC Index U300362 Battery voltage

Mis-match in battery voltage, of

2 volts or more, between PDM

and RJB Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system

Page 2943 of 3039

Rear End Sheet Metal Repairs - Back Panel

Removal and Installation

Removal Published: 11-May-2011

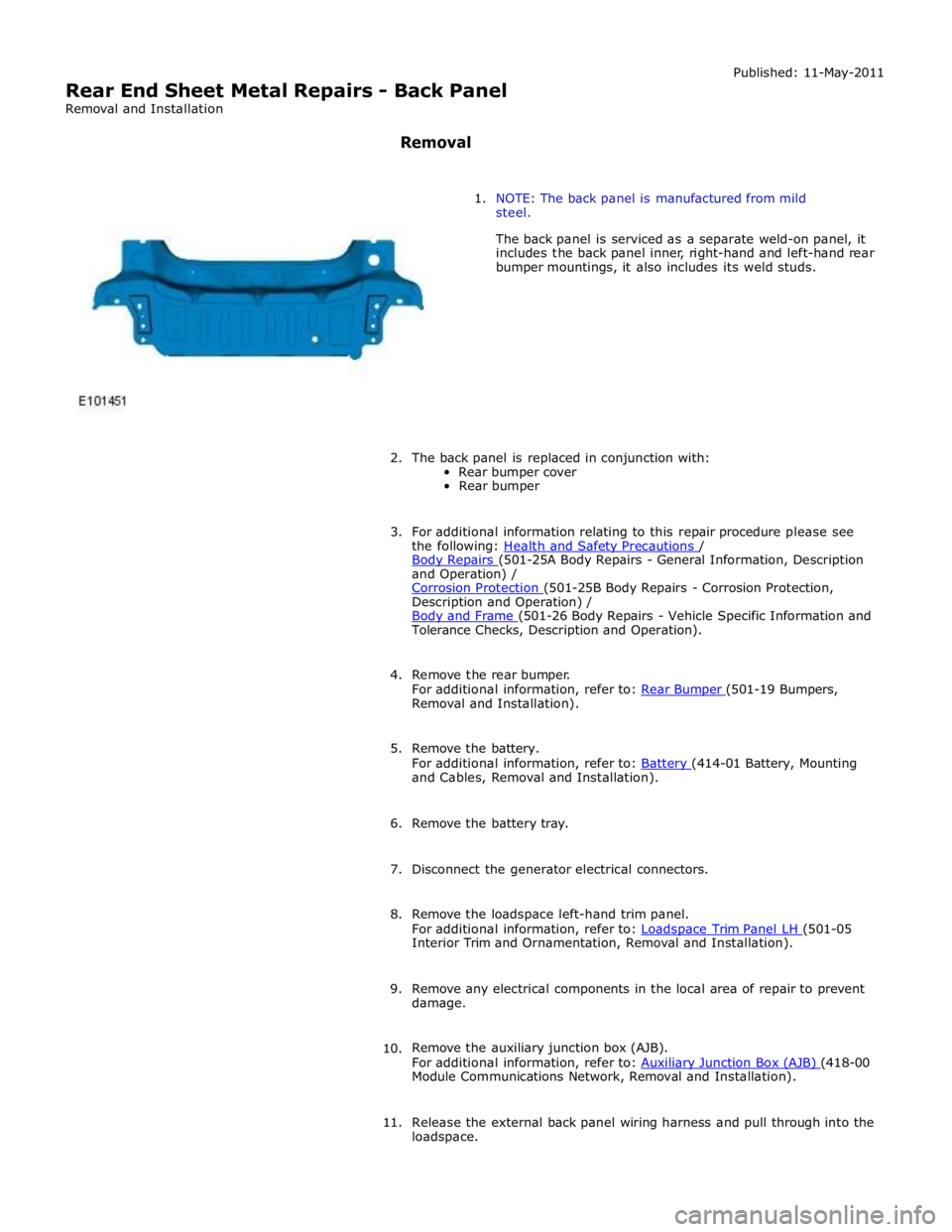

1. NOTE: The back panel is manufactured from mild

steel.

The back panel is serviced as a separate weld-on panel, it

includes the back panel inner, right-hand and left-hand rear

bumper mountings, it also includes its weld studs.

2. The back panel is replaced in conjunction with:

Rear bumper cover

Rear bumper

3. For additional information relating to this repair procedure please see

the following: Health and Safety Precautions / Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the rear bumper.

For additional information, refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

5. Remove the battery.

For additional information, refer to: Battery (414-01 Battery, Mounting and Cables, Removal and Installation).

6. Remove the battery tray.

7. Disconnect the generator electrical connectors.

8. Remove the loadspace left-hand trim panel.

For additional information, refer to: Loadspace Trim Panel LH (501-05 Interior Trim and Ornamentation, Removal and Installation).

9. Remove any electrical components in the local area of repair to prevent

damage.

10. Remove the auxiliary junction box (AJB).

For additional information, refer to: Auxiliary Junction Box (AJB) (418-00 Module Communications Network, Removal and Installation).

11. Release the external back panel wiring harness and pull through into the

loadspace.

Page 2949 of 3039

Removal and Installation).

7. Remove the battery.

For additional information, refer to: Battery (414-01 Battery, Mounting and Cables, Removal and Installation).

8. Disconnect the generator electrical connectors.

9. If the left-hand rear quarter panel is to be repaired, remove the

loadspace left-hand trim panel.

For additional information, refer to: Loadspace Trim Panel LH (501-05 Interior Trim and Ornamentation, Removal and Installation).

10. If the right-hand rear quarter panel is to be repaired, remove the

auxiliary junction box (AJB).

For additional information, refer to: Auxiliary Junction Box (AJB) (418-00 Module Communications Network, Removal and Installation).

11. Remove any electrical components in the local area of repair to prevent

damage.

12. Remove the rear muffler.

For additional information, refer to: Rear Muffler (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation) /

Rear Muffler (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation) /

Rear Muffler (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

13. Remove the exhaust muffler and tailpipe heatshield.

14. Remove the rear scuff plate trim panel.

For additional information, refer to: Rear Scuff Plate Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

15. Remove the loadspace trim panel.

For additional information, refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

16. Remove the forced air extraction grille.

17. Release and lay aside the back panel and loadspace wiring harness.

18. Remove the luggage compartment lid weatherstrip.

19. Remove the rear bumper cover side retainer.

20. Remove the roof moulding.

21. Remove the headliner.

For additional information, refer to: Headliner (501-05 Interior Trim and Ornamentation, Removal and Installation).

22. Remove the side air curtain module.

www.JagDocs.com

Page 2964 of 3039

Rear End Sheet Metal Repairs - Rear Bumper Mounting

Removal and Installation

Removal Published: 11-May-2011

1. NOTE: The rear bumper mounting is manufactured from

mild steel.

The rear bumper mounting is serviced on the back panel

and must be removed from this to carry out this procedure.

2. The rear bumper mounting is replaced in conjunction with:

Rear bumper cover

Rear bumper

3. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

5. If the right-hand rear bumper mounting is to be repaired, remove the

battery.

For additional information, refer to: Battery (414-01 Battery, Mounting and Cables, Removal and Installation).

6. If the right-hand rear bumper mounting is to be repaired, remove the

battery tray.

7. Disconnect the generator electrical connectors.

8. Remove the rear bumper.

For additional information, refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

9. Remove any electrical components in the local area of repair to prevent

damage.

10. If the right-hand rear bumper mounting is to be repaired, remove the

auxiliary junction box (AJB).

For additional information, refer to: Auxiliary Junction Box (AJB) (418-00 Module Communications Network, Removal and Installation). www.JagDocs.com