change wheel JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 49 of 3039

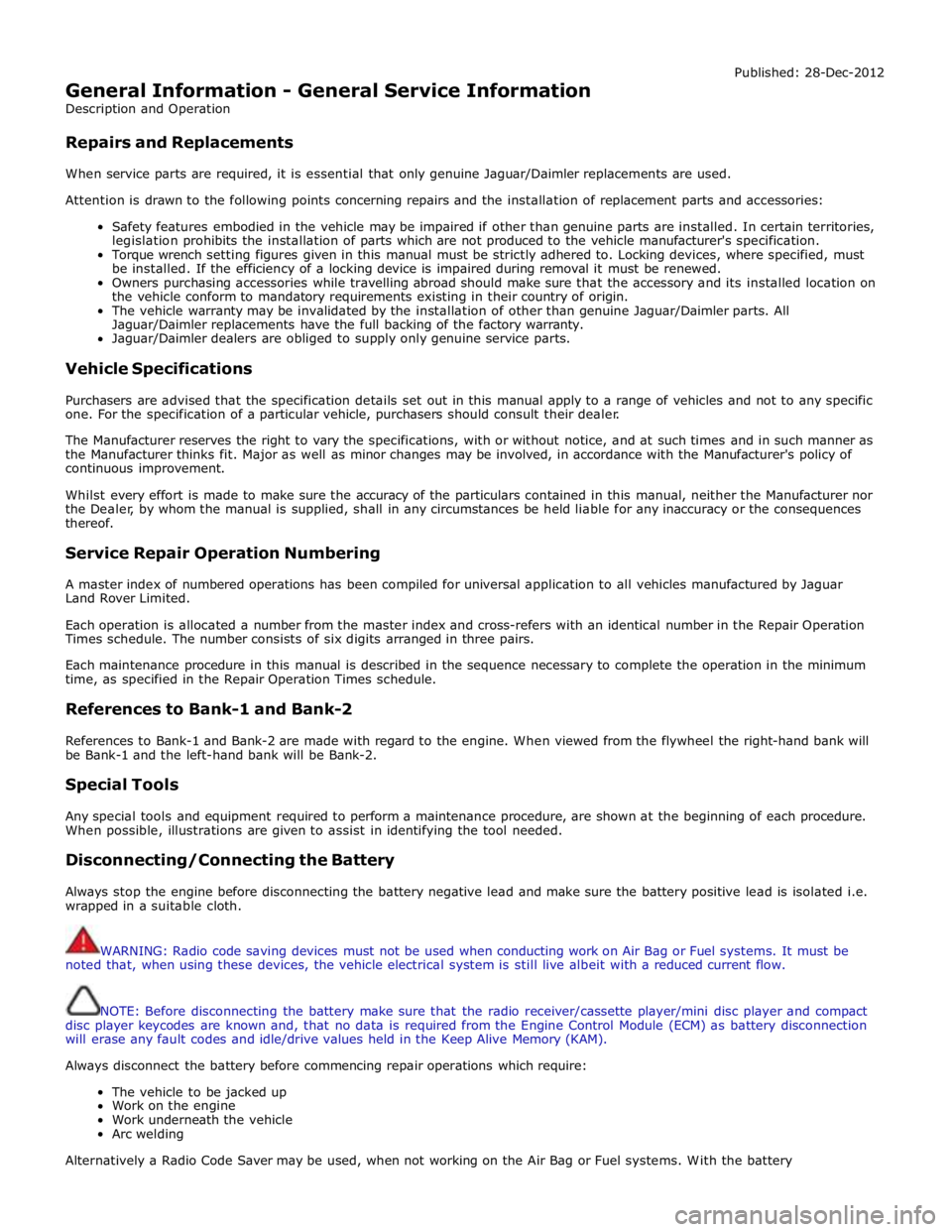

General Information - General Service Information

Description and Operation

Repairs and Replacements Published: 28-Dec-2012

When service parts are required, it is essential that only genuine Jaguar/Daimler replacements are used.

Attention is drawn to the following points concerning repairs and the installation of replacement parts and accessories:

Safety features embodied in the vehicle may be impaired if other than genuine parts are installed. In certain territories,

legislation prohibits the installation of parts which are not produced to the vehicle manufacturer's specification.

Torque wrench setting figures given in this manual must be strictly adhered to. Locking devices, where specified, must

be installed. If the efficiency of a locking device is impaired during removal it must be renewed.

Owners purchasing accessories while travelling abroad should make sure that the accessory and its installed location on

the vehicle conform to mandatory requirements existing in their country of origin.

The vehicle warranty may be invalidated by the installation of other than genuine Jaguar/Daimler parts. All

Jaguar/Daimler replacements have the full backing of the factory warranty.

Jaguar/Daimler dealers are obliged to supply only genuine service parts.

Vehicle Specifications

Purchasers are advised that the specification details set out in this manual apply to a range of vehicles and not to any specific

one. For the specification of a particular vehicle, purchasers should consult their dealer.

The Manufacturer reserves the right to vary the specifications, with or without notice, and at such times and in such manner as

the Manufacturer thinks fit. Major as well as minor changes may be involved, in accordance with the Manufacturer's policy of

continuous improvement.

Whilst every effort is made to make sure the accuracy of the particulars contained in this manual, neither the Manufacturer nor

the Dealer, by whom the manual is supplied, shall in any circumstances be held liable for any inaccuracy or the consequences

thereof.

Service Repair Operation Numbering

A master index of numbered operations has been compiled for universal application to all vehicles manufactured by Jaguar

Land Rover Limited.

Each operation is allocated a number from the master index and cross-refers with an identical number in the Repair Operation

Times schedule. The number consists of six digits arranged in three pairs.

Each maintenance procedure in this manual is described in the sequence necessary to complete the operation in the minimum

time, as specified in the Repair Operation Times schedule.

References to Bank-1 and Bank-2

References to Bank-1 and Bank-2 are made with regard to the engine. When viewed from the flywheel the right-hand bank will

be Bank-1 and the left-hand bank will be Bank-2.

Special Tools

Any special tools and equipment required to perform a maintenance procedure, are shown at the beginning of each procedure.

When possible, illustrations are given to assist in identifying the tool needed.

Disconnecting/Connecting the Battery

Always stop the engine before disconnecting the battery negative lead and make sure the battery positive lead is isolated i.e.

wrapped in a suitable cloth.

WARNING: Radio code saving devices must not be used when conducting work on Air Bag or Fuel systems. It must be

noted that, when using these devices, the vehicle electrical system is still live albeit with a reduced current flow.

NOTE: Before disconnecting the battery make sure that the radio receiver/cassette player/mini disc player and compact

disc player keycodes are known and, that no data is required from the Engine Control Module (ECM) as battery disconnection

will erase any fault codes and idle/drive values held in the Keep Alive Memory (KAM).

Always disconnect the battery before commencing repair operations which require:

The vehicle to be jacked up

Work on the engine

Work underneath the vehicle

Arc welding

Alternatively a Radio Code Saver may be used, when not working on the Air Bag or Fuel systems. With the battery

Page 109 of 3039

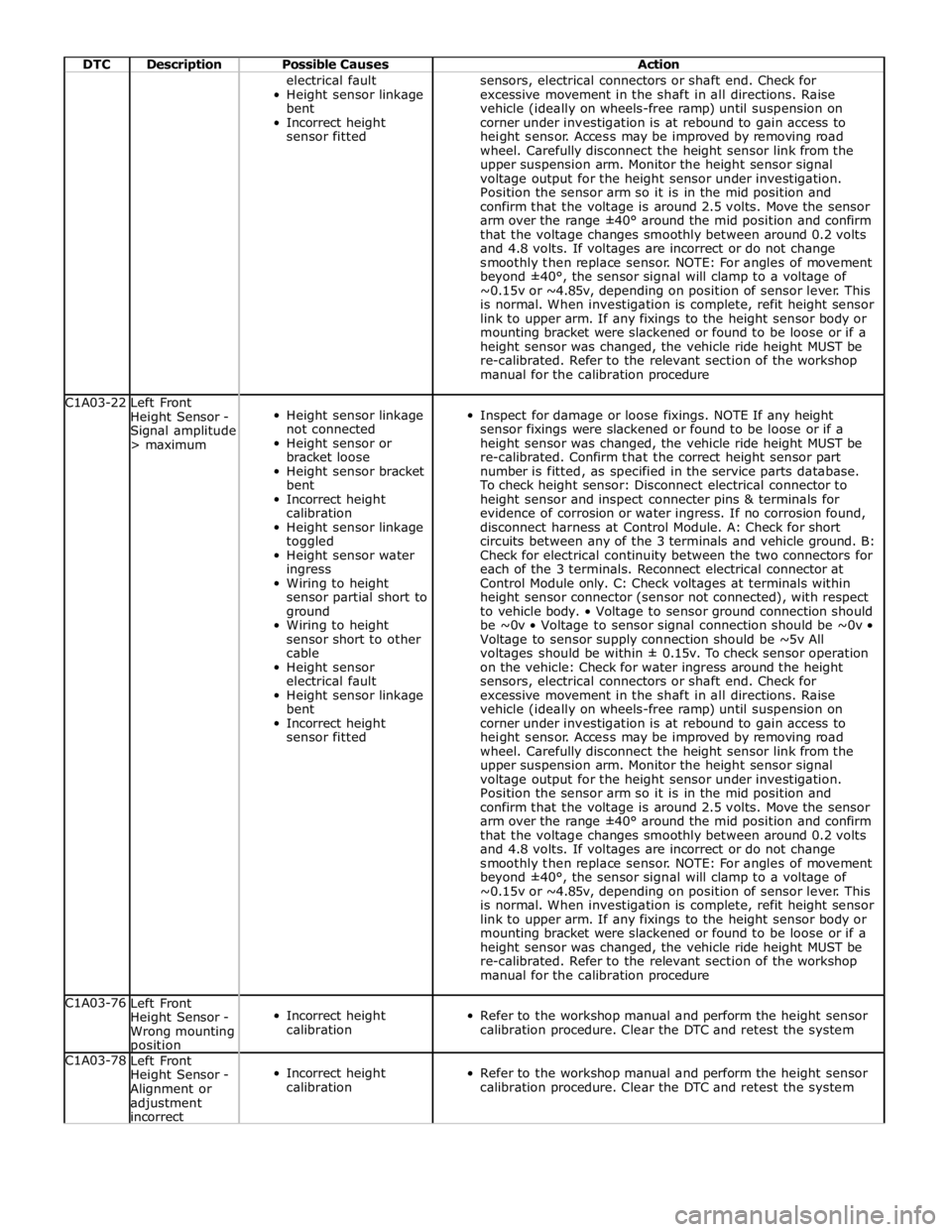

DTC Description Possible Causes Action electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A03-22

Left Front

Height Sensor -

Signal amplitude

> maximum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A03-76

Left Front

Height Sensor -

Wrong mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A03-78

Left Front

Height Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system

Page 110 of 3039

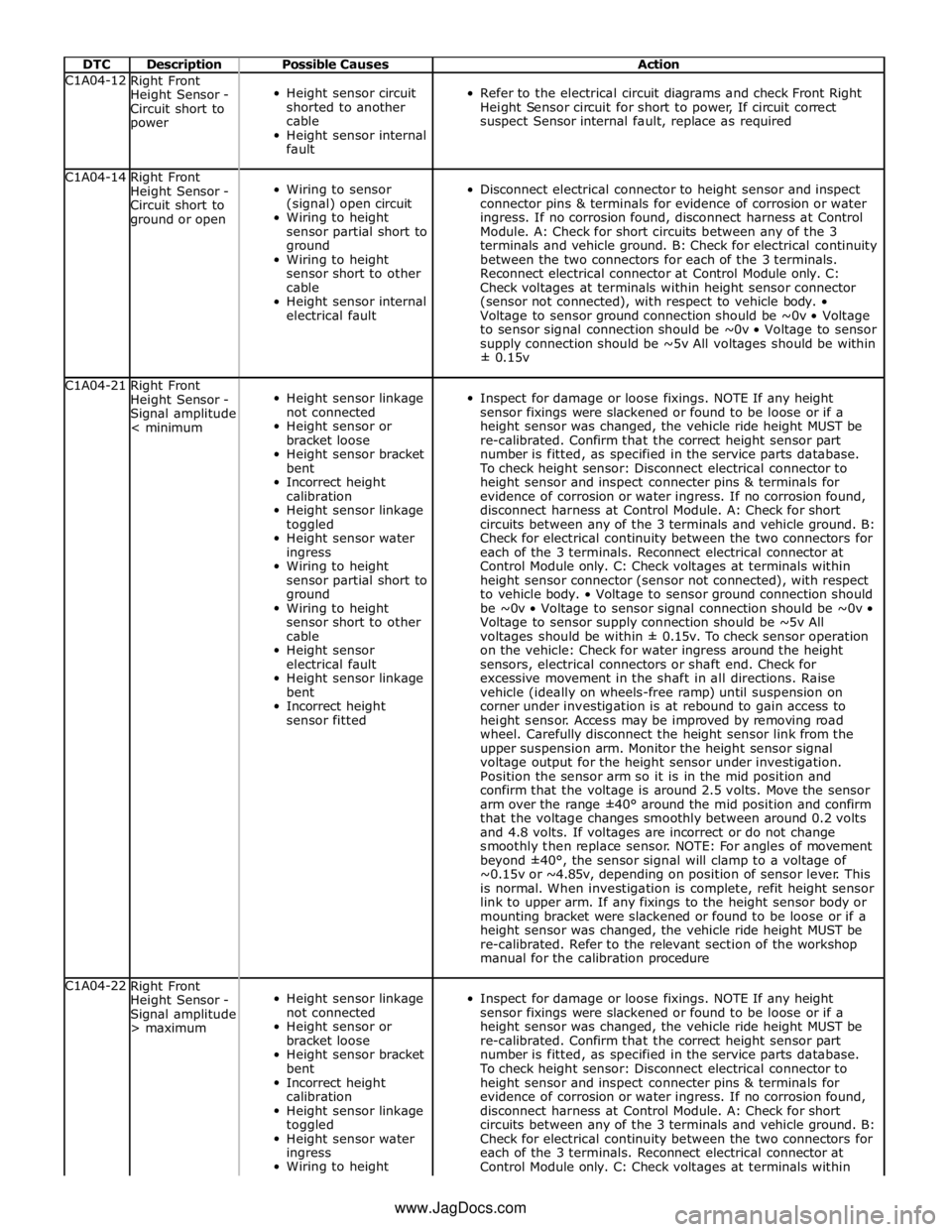

DTC Description Possible Causes Action C1A04-12

Right Front

Height Sensor -

Circuit short to

power

Height sensor circuit

shorted to another

cable

Height sensor internal

fault

Refer to the electrical circuit diagrams and check Front Right

Height Sensor circuit for short to power, If circuit correct

suspect Sensor internal fault, replace as required C1A04-14

Right Front

Height Sensor -

Circuit short to

ground or open

Wiring to sensor

(signal) open circuit

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor internal

electrical fault

Disconnect electrical connector to height sensor and inspect

connector pins & terminals for evidence of corrosion or water

ingress. If no corrosion found, disconnect harness at Control

Module. A: Check for short circuits between any of the 3

terminals and vehicle ground. B: Check for electrical continuity

between the two connectors for each of the 3 terminals.

Reconnect electrical connector at Control Module only. C:

Check voltages at terminals within height sensor connector

(sensor not connected), with respect to vehicle body. •

Voltage to sensor ground connection should be ~0v • Voltage

to sensor signal connection should be ~0v • Voltage to sensor

supply connection should be ~5v All voltages should be within

± 0.15v C1A04-21

Right Front

Height Sensor -

Signal amplitude

< minimum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A04-22

Right Front

Height Sensor -

Signal amplitude

> maximum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within www.JagDocs.com

Page 111 of 3039

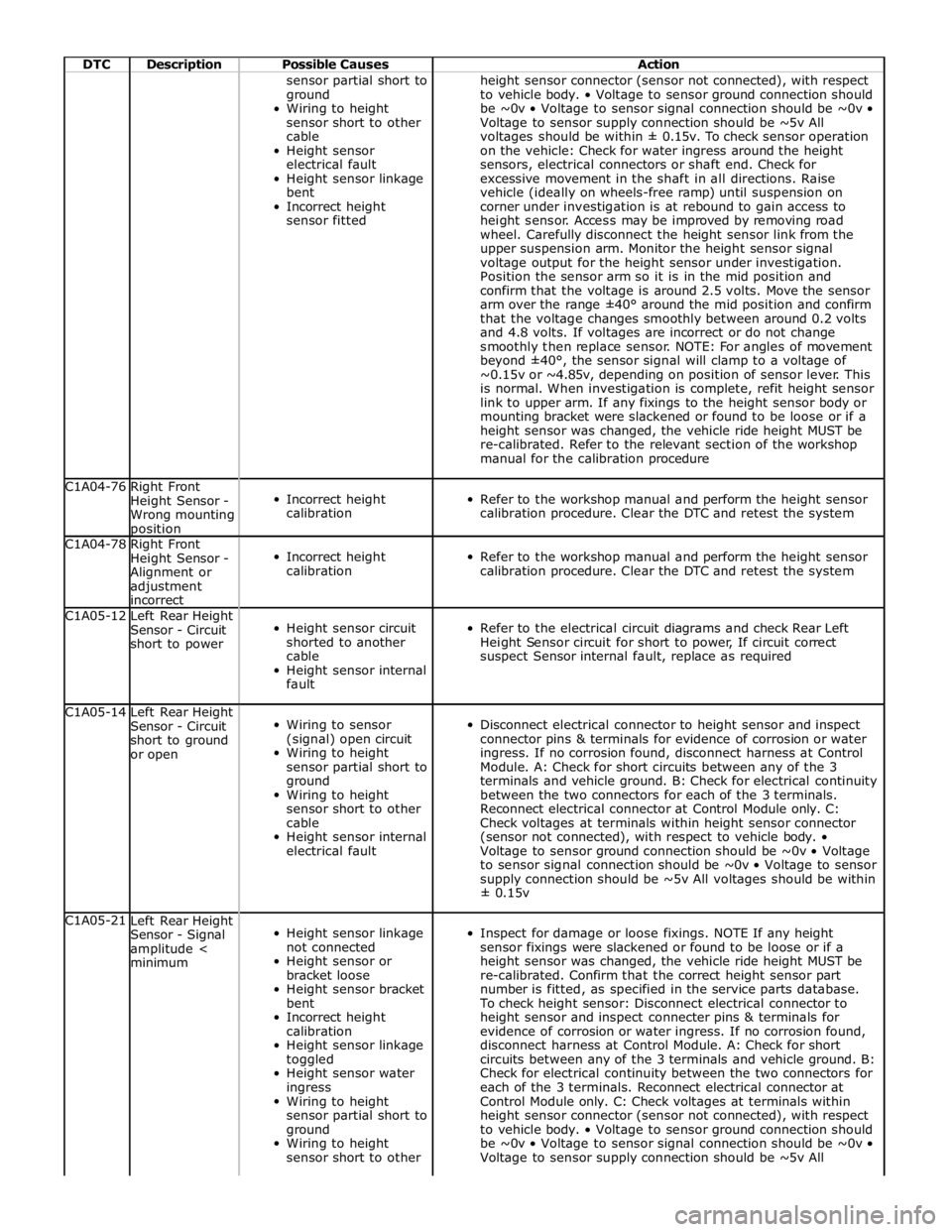

DTC Description Possible Causes Action sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A04-76

Right Front

Height Sensor -

Wrong mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A04-78

Right Front

Height Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A05-12

Left Rear Height

Sensor - Circuit

short to power

Height sensor circuit

shorted to another

cable

Height sensor internal

fault

Refer to the electrical circuit diagrams and check Rear Left

Height Sensor circuit for short to power, If circuit correct

suspect Sensor internal fault, replace as required C1A05-14

Left Rear Height

Sensor - Circuit

short to ground

or open

Wiring to sensor

(signal) open circuit

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor internal

electrical fault

Disconnect electrical connector to height sensor and inspect

connector pins & terminals for evidence of corrosion or water

ingress. If no corrosion found, disconnect harness at Control

Module. A: Check for short circuits between any of the 3

terminals and vehicle ground. B: Check for electrical continuity

between the two connectors for each of the 3 terminals.

Reconnect electrical connector at Control Module only. C:

Check voltages at terminals within height sensor connector

(sensor not connected), with respect to vehicle body. •

Voltage to sensor ground connection should be ~0v • Voltage

to sensor signal connection should be ~0v • Voltage to sensor

supply connection should be ~5v All voltages should be within

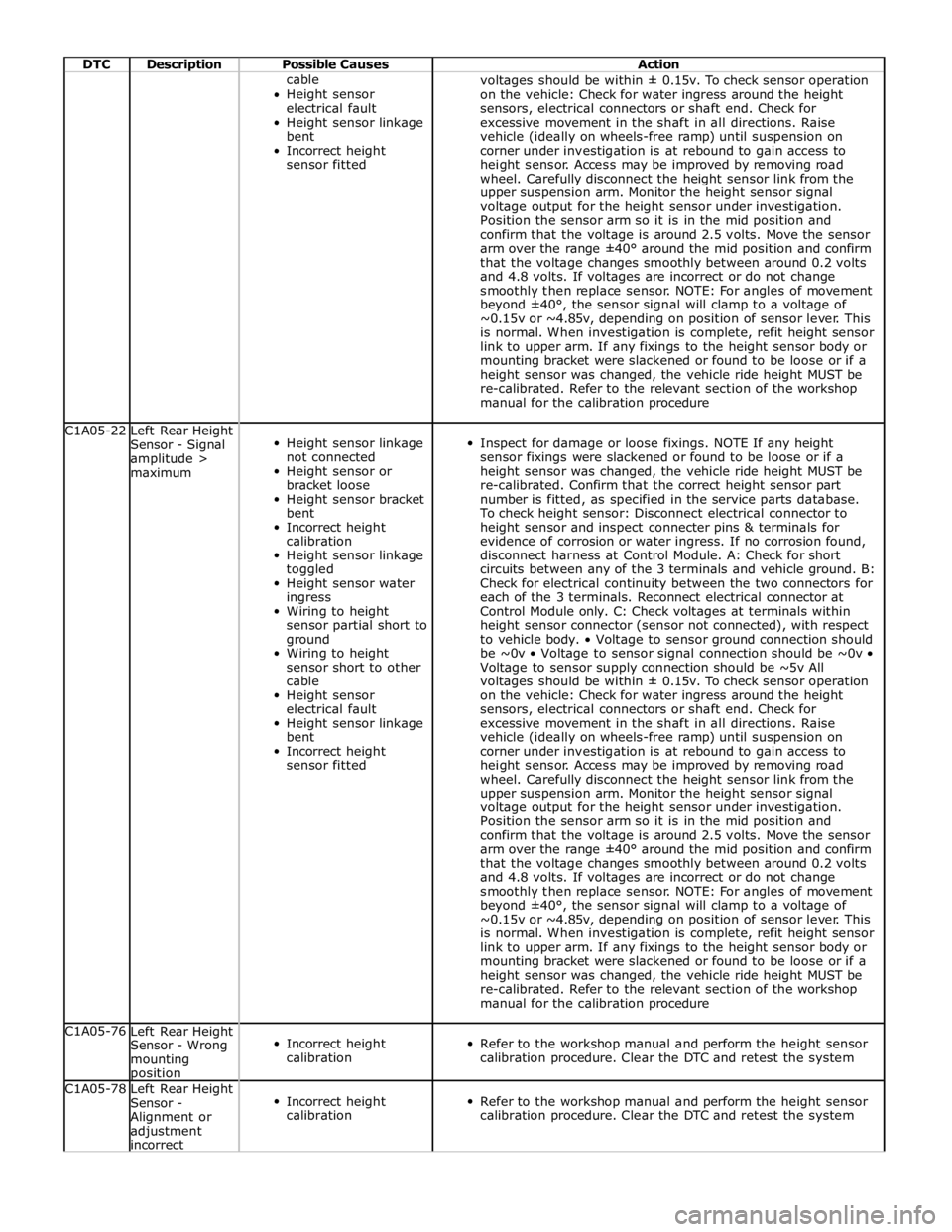

± 0.15v C1A05-21

Left Rear Height

Sensor - Signal

amplitude <

minimum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

Page 112 of 3039

DTC Description Possible Causes Action cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A05-22

Left Rear Height

Sensor - Signal

amplitude >

maximum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A05-76

Left Rear Height

Sensor - Wrong

mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A05-78

Left Rear Height

Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system

Page 113 of 3039

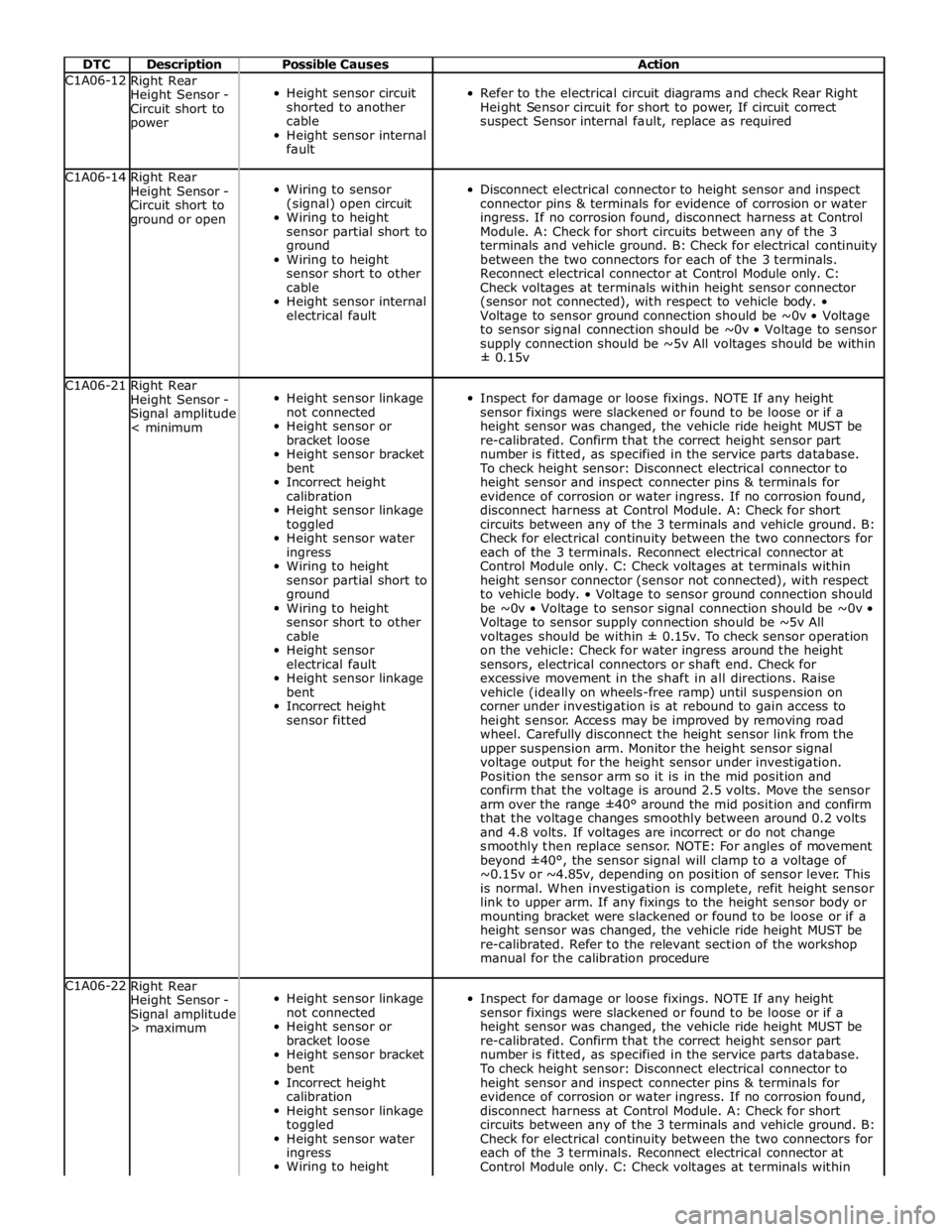

DTC Description Possible Causes Action C1A06-12

Right Rear

Height Sensor -

Circuit short to

power

Height sensor circuit

shorted to another

cable

Height sensor internal

fault

Refer to the electrical circuit diagrams and check Rear Right

Height Sensor circuit for short to power, If circuit correct

suspect Sensor internal fault, replace as required C1A06-14

Right Rear

Height Sensor -

Circuit short to

ground or open

Wiring to sensor

(signal) open circuit

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor internal

electrical fault

Disconnect electrical connector to height sensor and inspect

connector pins & terminals for evidence of corrosion or water

ingress. If no corrosion found, disconnect harness at Control

Module. A: Check for short circuits between any of the 3

terminals and vehicle ground. B: Check for electrical continuity

between the two connectors for each of the 3 terminals.

Reconnect electrical connector at Control Module only. C:

Check voltages at terminals within height sensor connector

(sensor not connected), with respect to vehicle body. •

Voltage to sensor ground connection should be ~0v • Voltage

to sensor signal connection should be ~0v • Voltage to sensor

supply connection should be ~5v All voltages should be within

± 0.15v C1A06-21

Right Rear

Height Sensor -

Signal amplitude

< minimum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A06-22

Right Rear

Height Sensor -

Signal amplitude

> maximum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

Page 114 of 3039

DTC Description Possible Causes Action sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A06-76

Right Rear

Height Sensor -

Wrong mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A06-78

Right Rear

Height Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

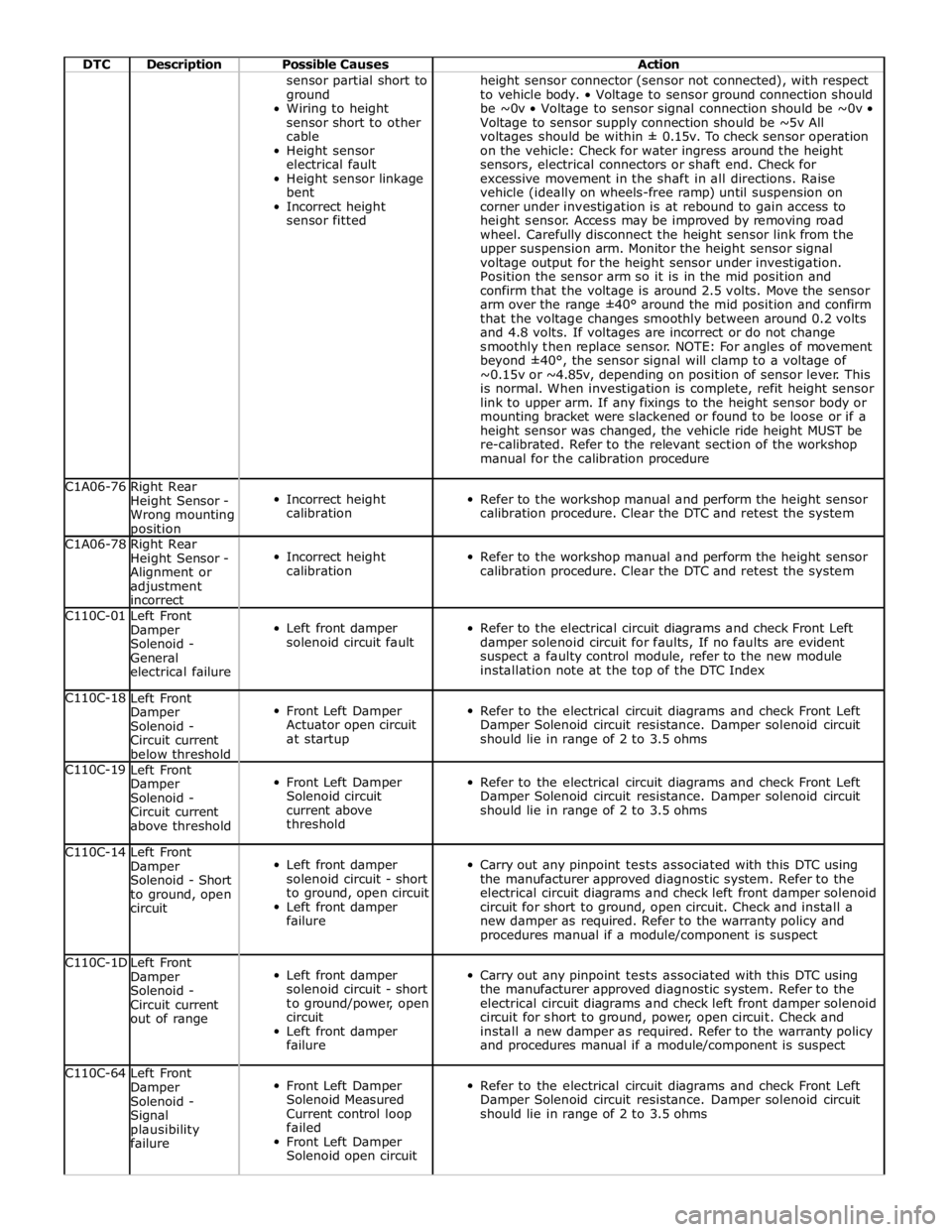

calibration procedure. Clear the DTC and retest the system C110C-01

Left Front

Damper

Solenoid -

General

electrical failure

Left front damper

solenoid circuit fault

Refer to the electrical circuit diagrams and check Front Left

damper solenoid circuit for faults, If no faults are evident

suspect a faulty control module, refer to the new module

installation note at the top of the DTC Index C110C-18

Left Front

Damper

Solenoid -

Circuit current

below threshold

Front Left Damper

Actuator open circuit

at startup

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms C110C-19

Left Front

Damper

Solenoid -

Circuit current

above threshold

Front Left Damper

Solenoid circuit

current above

threshold

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms C110C-14

Left Front

Damper

Solenoid - Short

to ground, open

circuit

Left front damper

solenoid circuit - short

to ground, open circuit

Left front damper

failure

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check left front damper solenoid

circuit for short to ground, open circuit. Check and install a

new damper as required. Refer to the warranty policy and

procedures manual if a module/component is suspect C110C-1D

Left Front

Damper

Solenoid -

Circuit current

out of range

Left front damper

solenoid circuit - short

to ground/power, open

circuit

Left front damper

failure

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check left front damper solenoid

circuit for short to ground, power, open circuit. Check and

install a new damper as required. Refer to the warranty policy

and procedures manual if a module/component is suspect C110C-64

Left Front

Damper

Solenoid -

Signal

plausibility

failure

Front Left Damper

Solenoid Measured

Current control loop

failed

Front Left Damper

Solenoid open circuit

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms

Page 260 of 3039

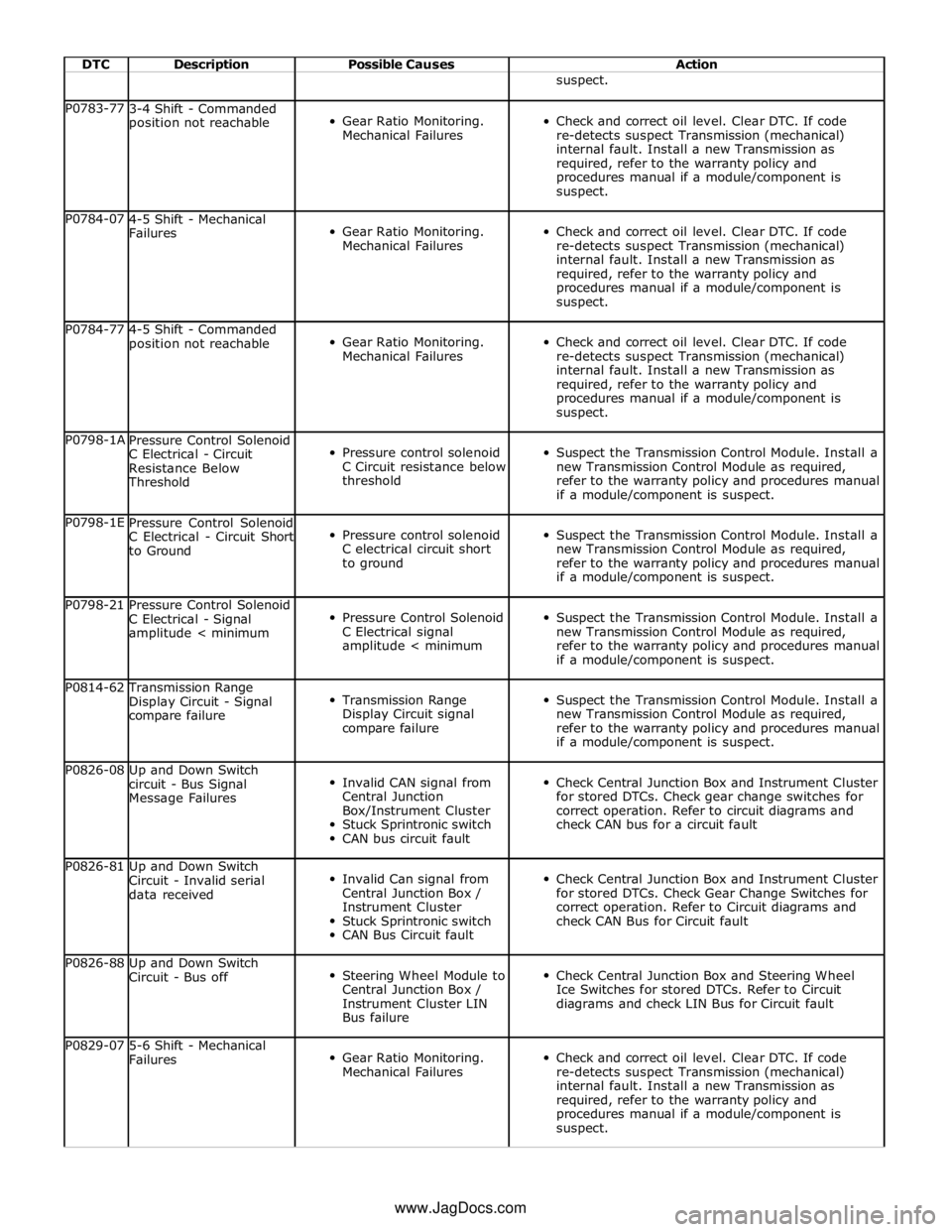

DTC Description Possible Causes Action suspect. P0783-77

3-4 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0784-07

4-5 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0784-77

4-5 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0798-1A

Pressure Control Solenoid

C Electrical - Circuit

Resistance Below Threshold

Pressure control solenoid

C Circuit resistance below

threshold

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0798-1E

Pressure Control Solenoid

C Electrical - Circuit Short

to Ground

Pressure control solenoid

C electrical circuit short

to ground

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0798-21

Pressure Control Solenoid

C Electrical - Signal

amplitude < minimum

Pressure Control Solenoid

C Electrical signal

amplitude < minimum

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0814-62 Transmission Range

Display Circuit - Signal

compare failure

Transmission Range

Display Circuit signal

compare failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0826-08

Up and Down Switch

circuit - Bus Signal

Message Failures

Invalid CAN signal from

Central Junction

Box/Instrument Cluster

Stuck Sprintronic switch

CAN bus circuit fault

Check Central Junction Box and Instrument Cluster

for stored DTCs. Check gear change switches for

correct operation. Refer to circuit diagrams and

check CAN bus for a circuit fault P0826-81

Up and Down Switch

Circuit - Invalid serial

data received

Invalid Can signal from

Central Junction Box /

Instrument Cluster

Stuck Sprintronic switch

CAN Bus Circuit fault

Check Central Junction Box and Instrument Cluster

for stored DTCs. Check Gear Change Switches for

correct operation. Refer to Circuit diagrams and

check CAN Bus for Circuit fault P0826-88

Up and Down Switch

Circuit - Bus off

Steering Wheel Module to

Central Junction Box /

Instrument Cluster LIN

Bus failure

Check Central Junction Box and Steering Wheel

Ice Switches for stored DTCs. Refer to Circuit

diagrams and check LIN Bus for Circuit fault P0829-07

5-6 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. www.JagDocs.com

Page 439 of 3039

Wheels and Tires - Wheels and Tires - Overview

Description and Operation

OVERVIEW Published: 25-May-2012

A number of alloy wheel designs are available ranging from 17 to 20 inch in diameter. A Tire Pressure Monitoring System

(TPMS) is used to monitor the air pressure in each tire and inform the driver if the pressure falls below predetermined

thresholds.

All wheels are of cast construction in aluminum alloy with the choice of wheel design dependant on the vehicle trim level and

engine derivative.

On normally aspirated petrol models and all diesel models a 4J X 18 inch temporary spare wheel is supplied as standard,

supercharged petrol models are supplied with a 4Jx19 inch temporary spare wheel. In some major European markets an Instant

Mobility System is offered as an alternative to the spare wheel. The Instant Mobility System is capable of providing a

temporary repair and tire inflation to a puncture of up to 6mm in diameter in the tread area of the tire. A puncture in the tire

wall cannot be repaired using the system.

The vehicle jack and accessories are stored in the spare wheel-well in the luggage compartment.

Tire Changing

WARNINGS:

Tires must be inflated to the recommended pressures when the tires are cold (ambient temperature) only. Refer to label

on the 'B' pillar for recommended tire pressures. If the tires have been subjected to use or exposed to direct sunlight, move

the vehicle into a shaded position and allow the tires to cool before checking or adjusting the pressures.

Valve stem seal, washer nut, valve core and cap should be replaced at every tire change. Valve stem seal, washer and

nut must be replaced if the valve retention nut is loosened. Sensor units and nuts must be fitted using correct torque figures

and associated profile. Damage to the vehicle and consequently injury to the vehicle's occupants may result if these

instructions are not adhered to.

NOTE: The TPMS valve should be serviced using the suitable service kit, each time the tyre is dismounted, to ensure an

air tight seal. Attention should be made to the detail of fitting this kit.

Vehicles fitted with TPMS can be visually identified by an external metal locknut and valve of the tire pressure sensor on the

road wheels. Vehicles without TPMS will have rubber tire valve.

www.JagDocs.com

Page 443 of 3039

7 Initiators 8 TPMS module 9 Instrument cluster

Tire Pressure Monitoring System (TPMS) System Operation

The controlling software for the Tire Pressure Monitoring System (TPMS) is located within a Tire Pressure Monitoring System

Module. The software detects the following:

When the tire pressure is below the recommended low pressure value - under inflated tire.

The location of the tire on the vehicle that is below the recommended pressure.

Malfunction warning.

The TPMS system comprises:

Tire pressure monitoring system module located below the right-hand front seat.

Tire pressure receiver located near the gear shifter within the floor console.

Two front initiators positioned forward of the wheels and behind the fender splash shields.

Two rear initiators positioned rearward of the wheels and assembled on dedicated brackets located behind the fender

splash shields.

Four sensors, each sensor is integral with a tire valve and located within the tire; the space saver spare wheel is not

fitted with a sensor.

The four initiators are hard wired to the TPMS module. The initiators transmit 125 KHz Low Frequency (LF) signals to the tire

pressure sensors which respond by modifying the mode status within the Radio Frequency (RF) transmission. The 315 or 433

MHz RF signals are detected by the tire pressure receiver which is connected directly to the TPMS module. The received RF

signals from the tire pressure sensors are passed to the TPMS module and contain identification, pressure, temperature and

acceleration information for each wheel and tire.

The TPMS module communicates with the instrument cluster via the medium speed CAN bus to provide the driver with

appropriate warnings. The TPMS module also indicates status or failure of the TPMS or components.

Tire Location and Identification

The TPMS can identify the position of the wheels on the vehicle and assign a received tire pressure sensor identification to a

specific position on the vehicle, for example front left, front right, rear left and rear right. This feature is required because of

the different pressure targets and threshold that could exist between the front and rear tires.

The wheel location is performed automatically by the TPMS module using an 'auto-location' function. This function is fully

automatic and requires no input from the driver. The TPMS module automatically re-learns the position of the wheels on the

vehicle if the tire pressure sensors are replaced or the wheel positions on the vehicle are changed.

The TPMS software can automatically detect, under all operating conditions, the following:

one or more new tire pressure sensors have been fitted

one or more tire pressure sensors have stopped transmitting

TPMS module can reject identifications from tire pressure sensors which do not belong to the vehicle

two 'running' wheels on the vehicle have changed positions.

If a new tire pressure sensor is fitted on any 'running' wheel, the module can learn the new sensor identification automatically

through the tire learn and location process.

The tire-learn and location process is ready to commence when the vehicle has been stationary or traveling at less than 12

mph (20 km/h) for 15 minutes. This is known as 'parking mode'. The learn/locate process requires the vehicle to be driven at

speeds of more than 12 mph (20 km/h) for 15 minutes. If the vehicle speed reduces to below 12 mph (20 km/h), the learn

process timer is suspended until the vehicle speed increases to more than 12 mph (20 km/h), after which time the timer is

resumed. If the vehicle speed remains below 12 mph (20 km/h) for more than 15 minutes, the timer is set to zero and process

starts again.

Low Pressure Monitoring

The tire low pressure sensor transmits by RF (315 MHz or 433 MHz depending on market) signal. These signals contain data

which corresponds to tire low pressure sensor identification, tire pressure, tire temperature, acceleration and tire low pressure

sensor mode.

Each time the vehicle is driven, the tire pressure monitoring system module activates each LF antenna in turn. The

corresponding tire low pressure sensor detects the LF signal and responds by modifying the mode status within the RF

transmission.

The system enters 'parking mode' after the vehicle speed has been less than 20 km/h (12.5 miles/h) for 12 minutes. In parking

mode the tire low pressure sensors transmit a coded signal to the tire pressure monitoring system module once every 13

hours. If the tire pressure decreases by more than 0.06 bar (1 lbf/in²) the tire low pressure sensor will transmit more often as

pressure is lost.

As each wheel responds to the LF signal from the tire pressure monitoring system module, it is assigned a position on the

vehicle and is monitored for the remainder of that drive cycle in that position.