battery JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1394 of 3039

Published: 11-May-2011

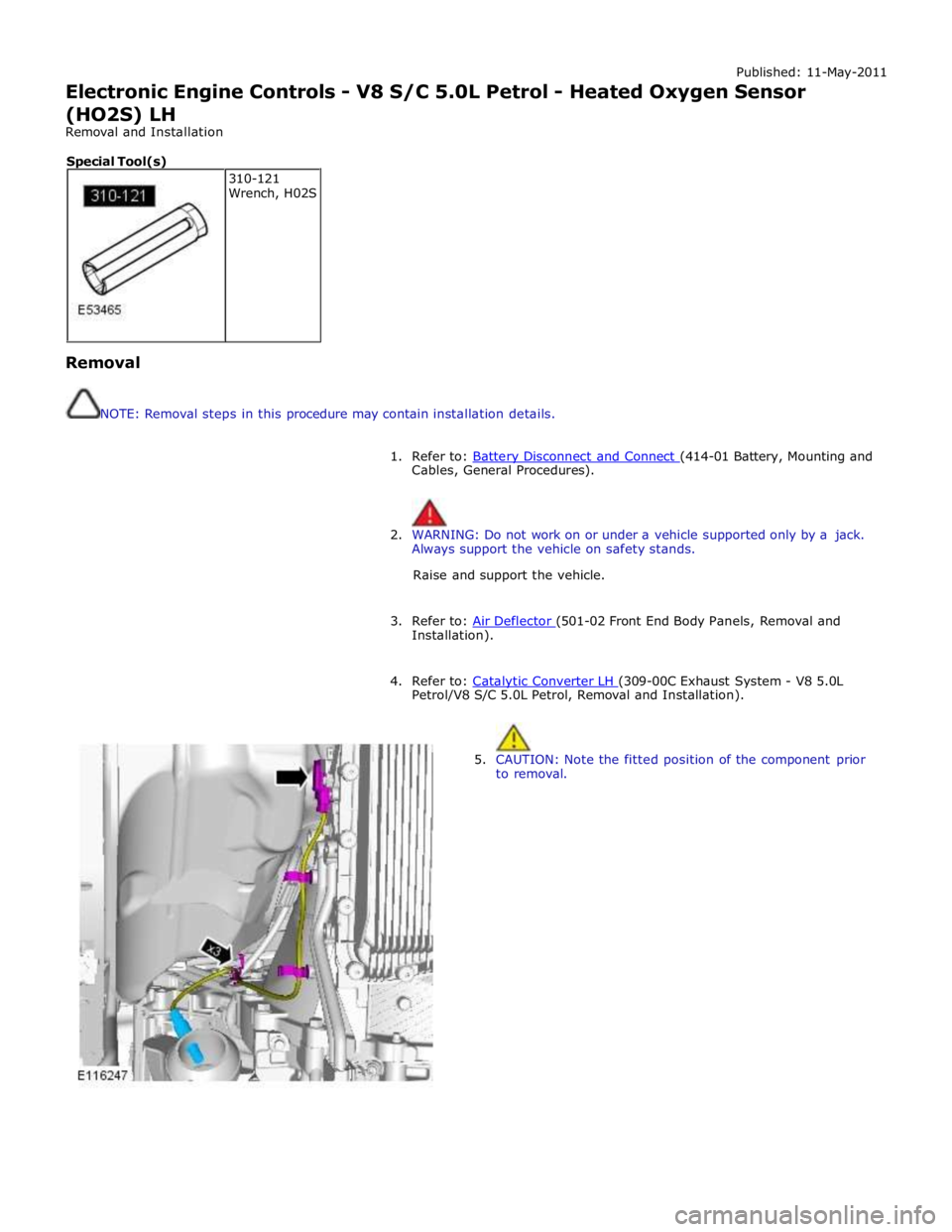

Electronic Engine Controls - V8 S/C 5.0L Petrol - Heated Oxygen Sensor

(HO2S) LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

4. Refer to: Catalytic Converter LH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

5. CAUTION: Note the fitted position of the component prior

to removal. 310-121

Wrench, H02S Special Tool(s)

Page 1396 of 3039

Published: 11-May-2011

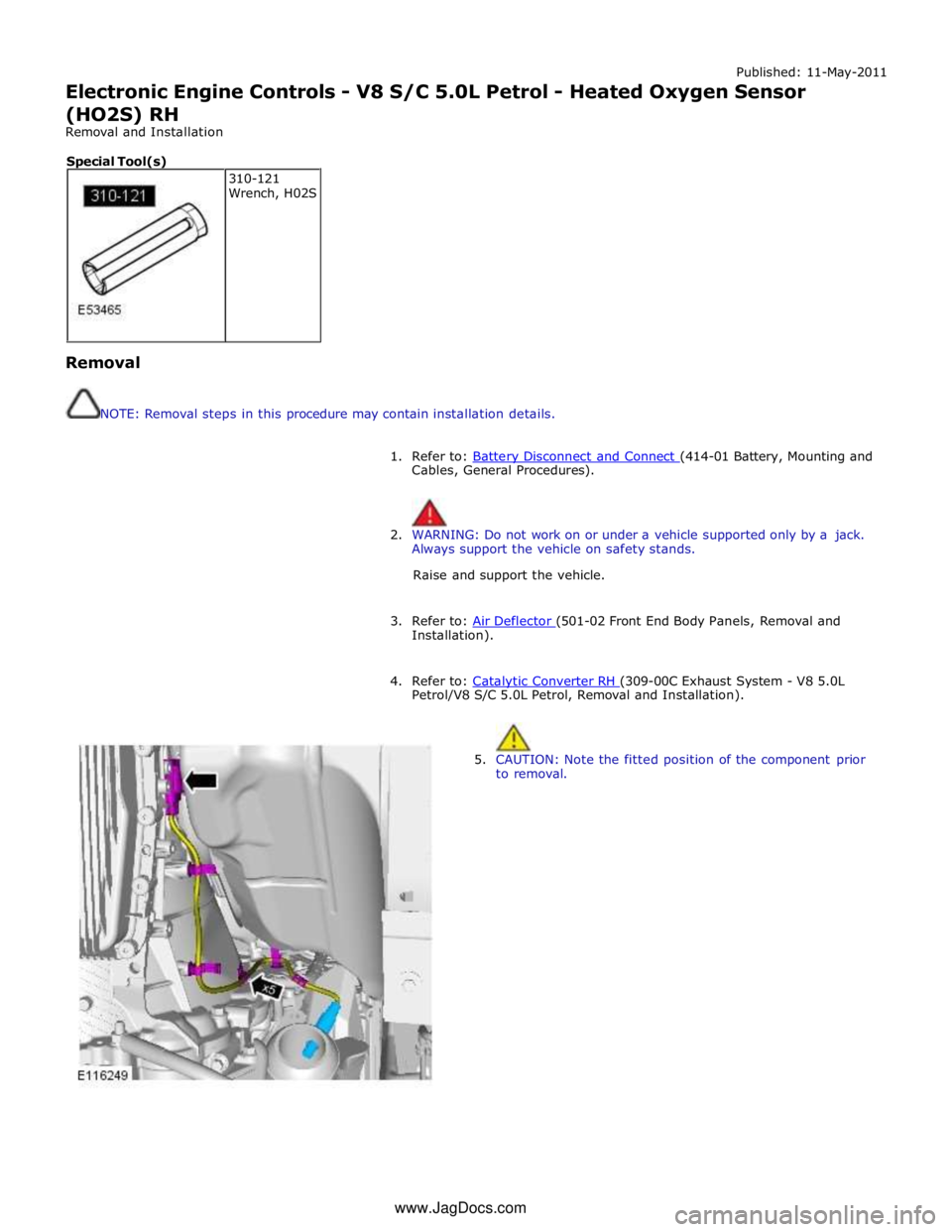

Electronic Engine Controls - V8 S/C 5.0L Petrol - Heated Oxygen Sensor

(HO2S) RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

4. Refer to: Catalytic Converter RH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

5. CAUTION: Note the fitted position of the component prior

to removal. 310-121

Wrench, H02S Special Tool(s) www.JagDocs.com

Page 1401 of 3039

Published: 11-May-2011

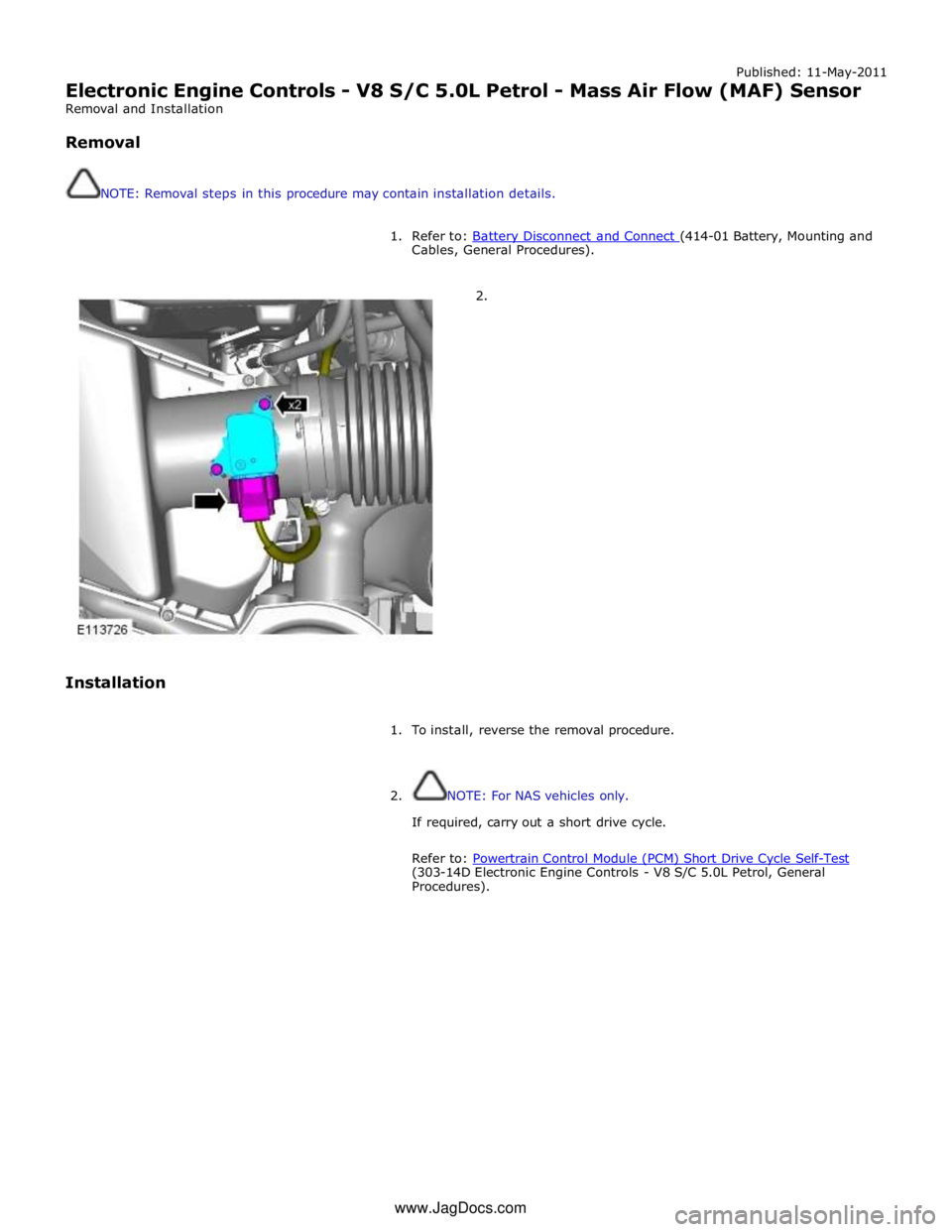

Electronic Engine Controls - V8 S/C 5.0L Petrol - Mass Air Flow (MAF) Sensor

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2.

Installation

1. To install, reverse the removal procedure.

2. NOTE: For NAS vehicles only.

If required, carry out a short drive cycle.

Refer to: Powertrain Control Module (PCM) Short Drive Cycle Self-Test (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, General

Procedures). www.JagDocs.com

Page 1402 of 3039

Published: 11-May-2011

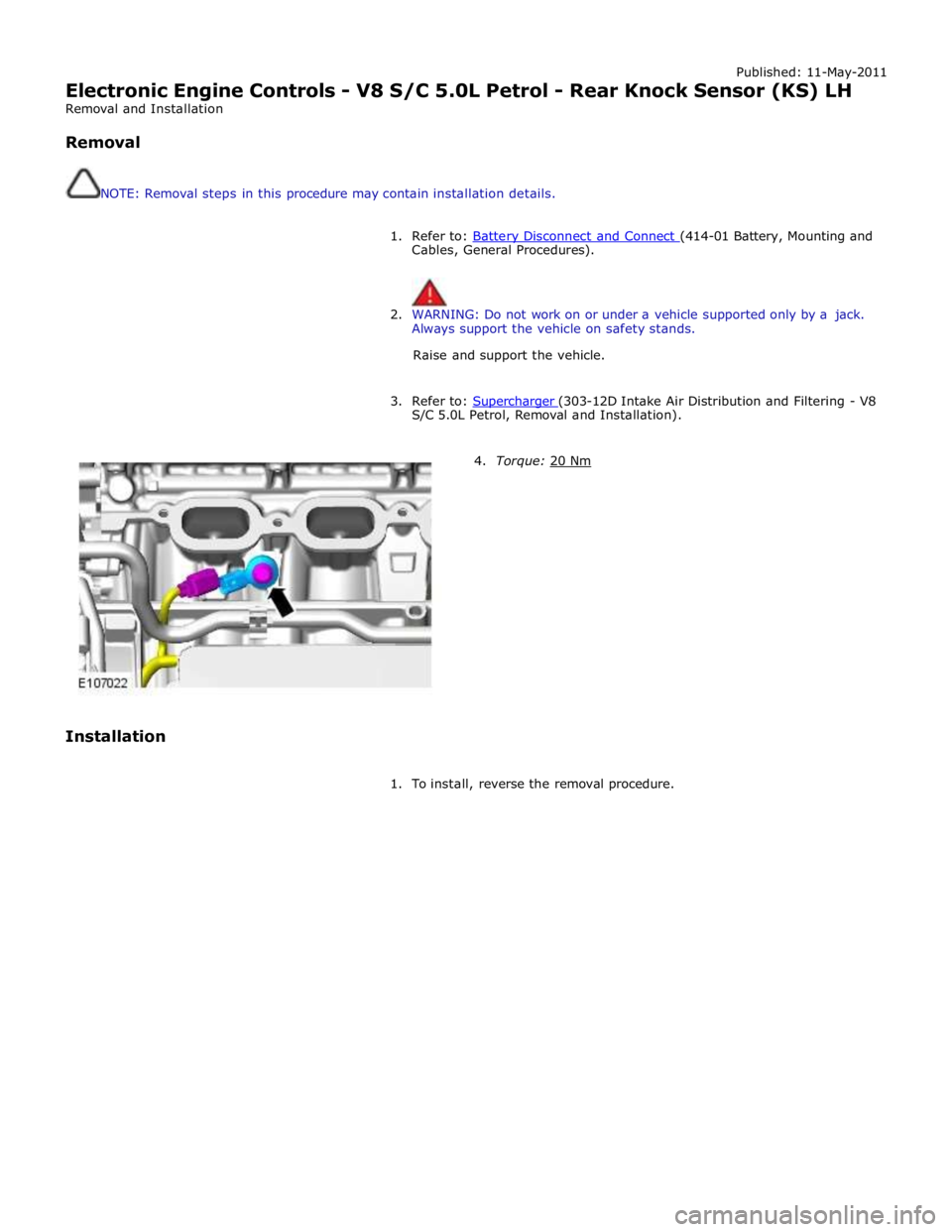

Electronic Engine Controls - V8 S/C 5.0L Petrol - Rear Knock Sensor (KS) LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Supercharger (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

Installation

4. Torque: 20 Nm

1. To install, reverse the removal procedure.

Page 1403 of 3039

Published: 11-May-2011

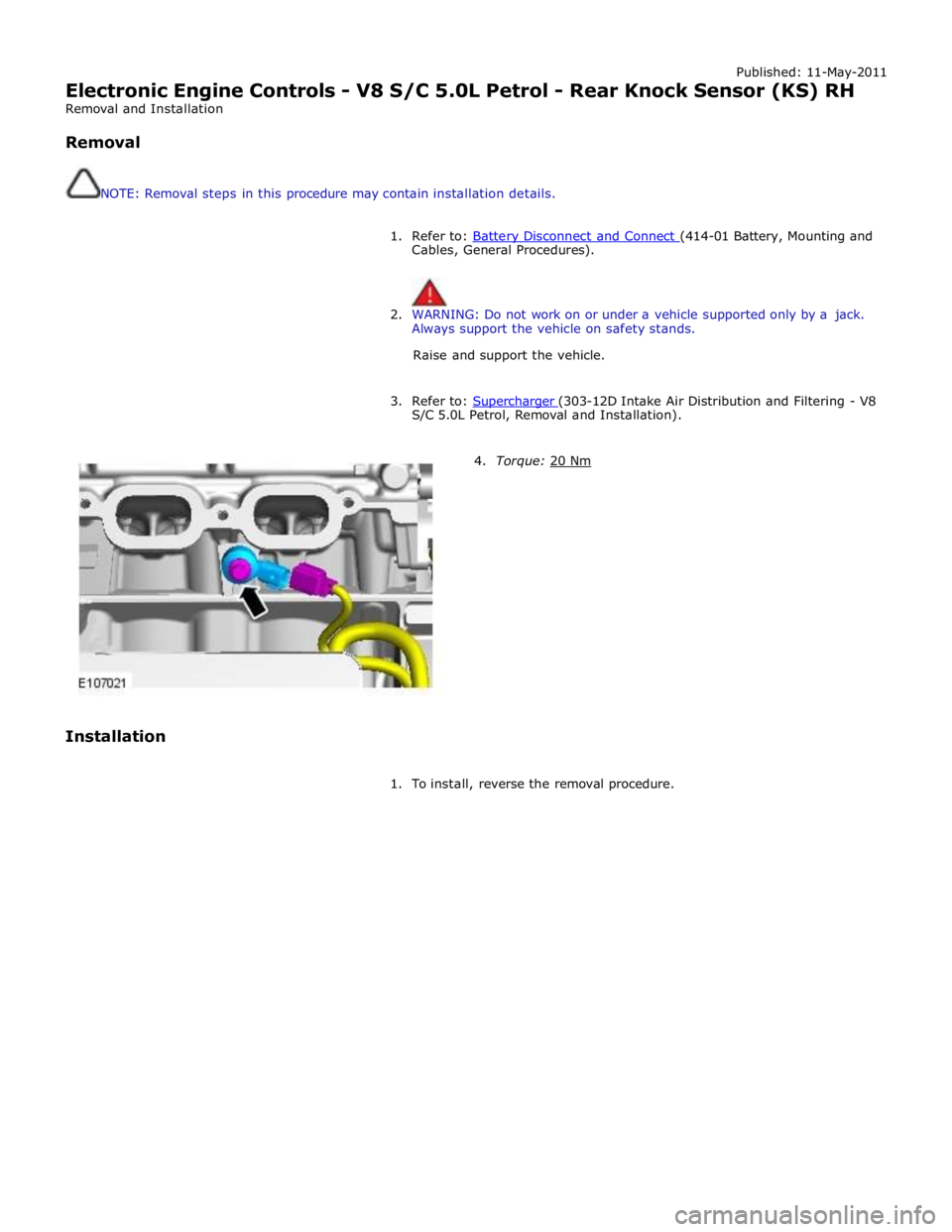

Electronic Engine Controls - V8 S/C 5.0L Petrol - Rear Knock Sensor (KS) RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Supercharger (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

Installation

4. Torque: 20 Nm

1. To install, reverse the removal procedure.

Page 1404 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Variable Valve Timing (VVT)

Oil Control Solenoid LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Disconnect the battery ground cable.

Refer to: Specifications (414-00, Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Thermostat Housing - Vehicles With: Supercharger (303-03,

Removal and Installation).

4. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

Torque: 10 Nm

5. CAUTION: Evenly and progressively, remove the VVT

units from each side.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Page 1406 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Variable Valve Timing (VVT)

Oil Control Solenoid RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Disconnect the battery ground cable.

Refer to: Specifications (414-00, Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Thermostat Housing - Vehicles With: Supercharger (303-03,

Removal and Installation).

4. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

5. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Torque: 10 Nm www.JagDocs.com

Page 1411 of 3039

Published: 11-May-2011

Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Transmission Description - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; B = K bus; D = High speed CAN (controller area network) bus; O = LIN (local interconnect

network) bus

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 CJB (central junction box)

Page 1436 of 3039

Visual Inspection

Mechanical Electrical Hydraulic

Damaged/stuck shift mechanism

Damaged automatic transmission casing

Blown fuse(s)

Damaged, loose or corroded connectors

Wiring harness

Fluid level too high/low

Poor condition of fluid

Fluid leak

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for diagnostic trouble codes (DTCs) and refer to the DTC Index.

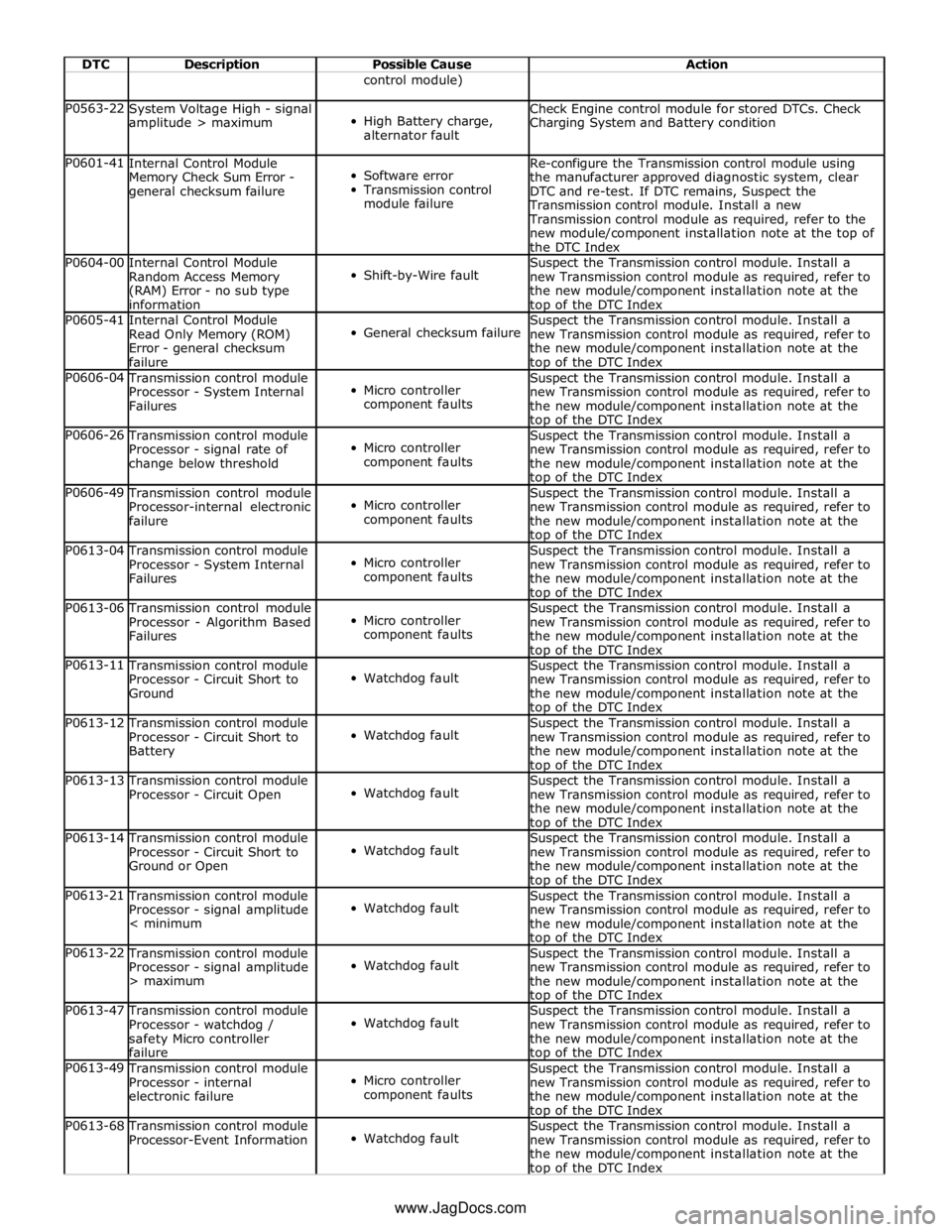

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module/transmission is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to the

installation of a new module/transmission.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action P0121-86 Throttle/Pedal Position

Sensor A Circuit

Range/Performance - signal

invalid

Throttle/Pedal Position

Sensor Fault (Data

received over CAN Bus) Check Engine Control Module for stored DTCs P0219-86 Engine Overspeed Condition

- signal invalid

Engine speed too low or

too high (Data received

over CAN Bus) Check Engine Control Module for stored DTCs P0500-81

Vehicle Speed Sensor A -

invalid serial data received

Vehicle Speed Sensor

fault (Data received over

CAN Bus) Check DSC module for stored DTCs P0501-81 Vehicle Speed Sensor A

Vehicle Speed receive Check Anti-lock braking system module for stored Range/Performance invalid DTCs. Check correct Differential is installed to the serial data received over CAN Bus does not

vehicle match Transmission Output-Shaft speed P0561-1C

System Voltage Unstable -

Circuit voltage out of range

Power supply voltage out

of range when engine

running Check Engine control module for stored DTCs. Check

Charging System and Battery condition P0562-21

System Voltage Low - signal

amplitude < minimum

Circuit low voltage.

Battery supply voltage to

Transmission Control

Module (Transmission Refer to Circuit diagrams and check Power and Ground

Circuit for fault. Check Engine control module for

stored DTCs. Check Charging System and Battery

condition

Page 1437 of 3039

DTC Description Possible Cause Action control module)

P0563-22

System Voltage High - signal

amplitude > maximum

High Battery charge,

alternator fault Check Engine control module for stored DTCs. Check

Charging System and Battery condition P0601-41

Internal Control Module

Memory Check Sum Error -

general checksum failure

Software error

Transmission control

module failure Re-configure the Transmission control module using

the manufacturer approved diagnostic system, clear

DTC and re-test. If DTC remains, Suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P0604-00

Internal Control Module

Random Access Memory

(RAM) Error - no sub type

information

Shift-by-Wire fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0605-41

Internal Control Module

Read Only Memory (ROM)

Error - general checksum

failure

General checksum failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0606-04 Transmission control module

Processor - System Internal

Failures

Micro controller

component faults Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0606-26 Transmission control module

Processor - signal rate of

change below threshold

Micro controller

component faults Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0606-49 Transmission control module

Processor-internal electronic

failure

Micro controller

component faults Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-04 Transmission control module

Processor - System Internal

Failures

Micro controller

component faults Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-06 Transmission control module

Processor - Algorithm Based

Failures

Micro controller

component faults Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-11 Transmission control module

Processor - Circuit Short to

Ground

Watchdog fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-12 Transmission control module

Processor - Circuit Short to

Battery

Watchdog fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-13 Transmission control module

Processor - Circuit Open

Watchdog fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-14 Transmission control module

Processor - Circuit Short to

Ground or Open

Watchdog fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-21 Transmission control module

Processor - signal amplitude

< minimum

Watchdog fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-22 Transmission control module

Processor - signal amplitude

> maximum

Watchdog fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-47 Transmission control module

Processor - watchdog /

safety Micro controller

failure

Watchdog fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-49 Transmission control module

Processor - internal

electronic failure

Micro controller

component faults Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0613-68 Transmission control module

Processor-Event Information

Watchdog fault Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index www.JagDocs.com