brake fluid JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 709 of 3039

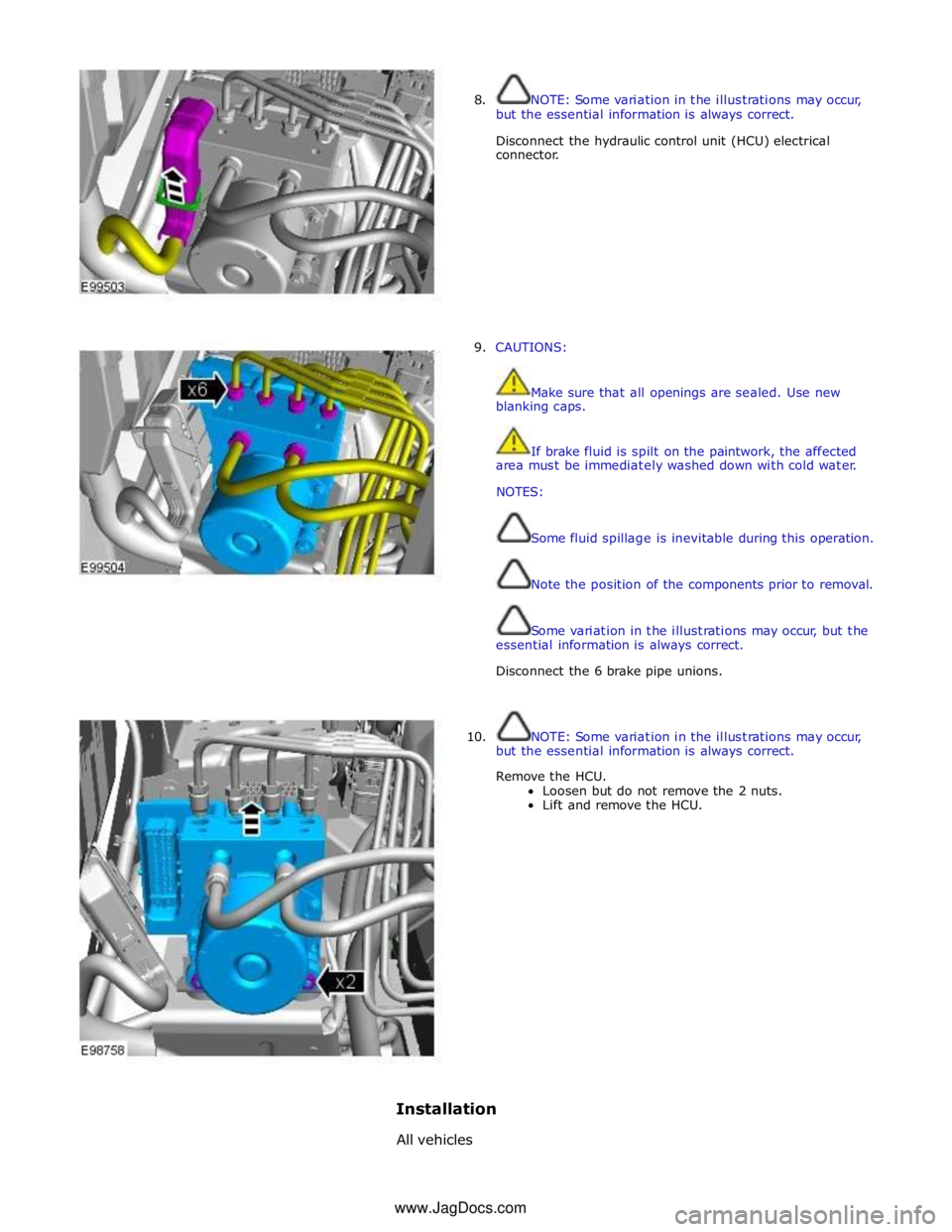

8. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Disconnect the hydraulic control unit (HCU) electrical

connector.

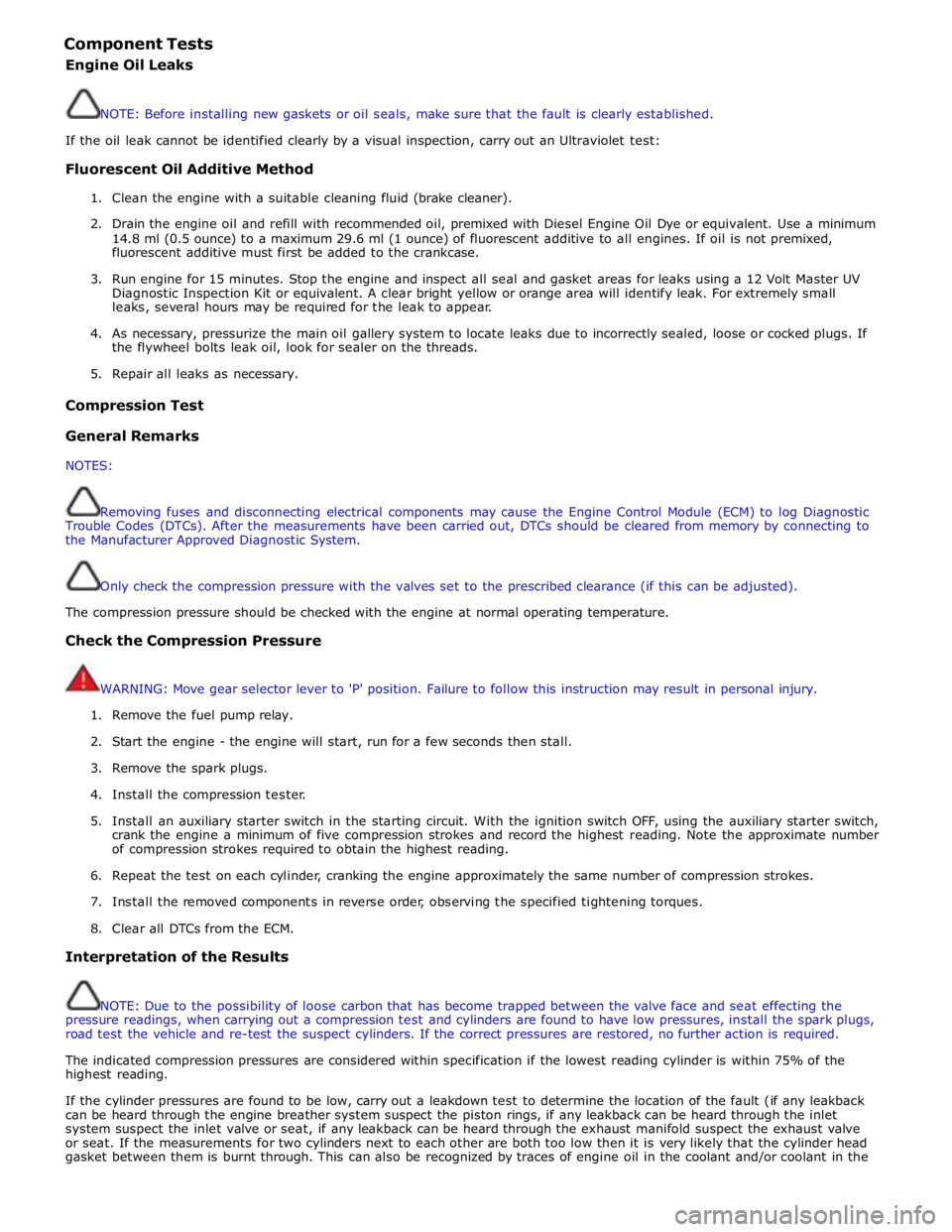

9. CAUTIONS:

Make sure that all openings are sealed. Use new

blanking caps.

If brake fluid is spilt on the paintwork, the affected

area must be immediately washed down with cold water.

NOTES:

Some fluid spillage is inevitable during this operation.

Note the position of the components prior to removal.

Some variation in the illustrations may occur, but the

essential information is always correct.

Disconnect the 6 brake pipe unions.

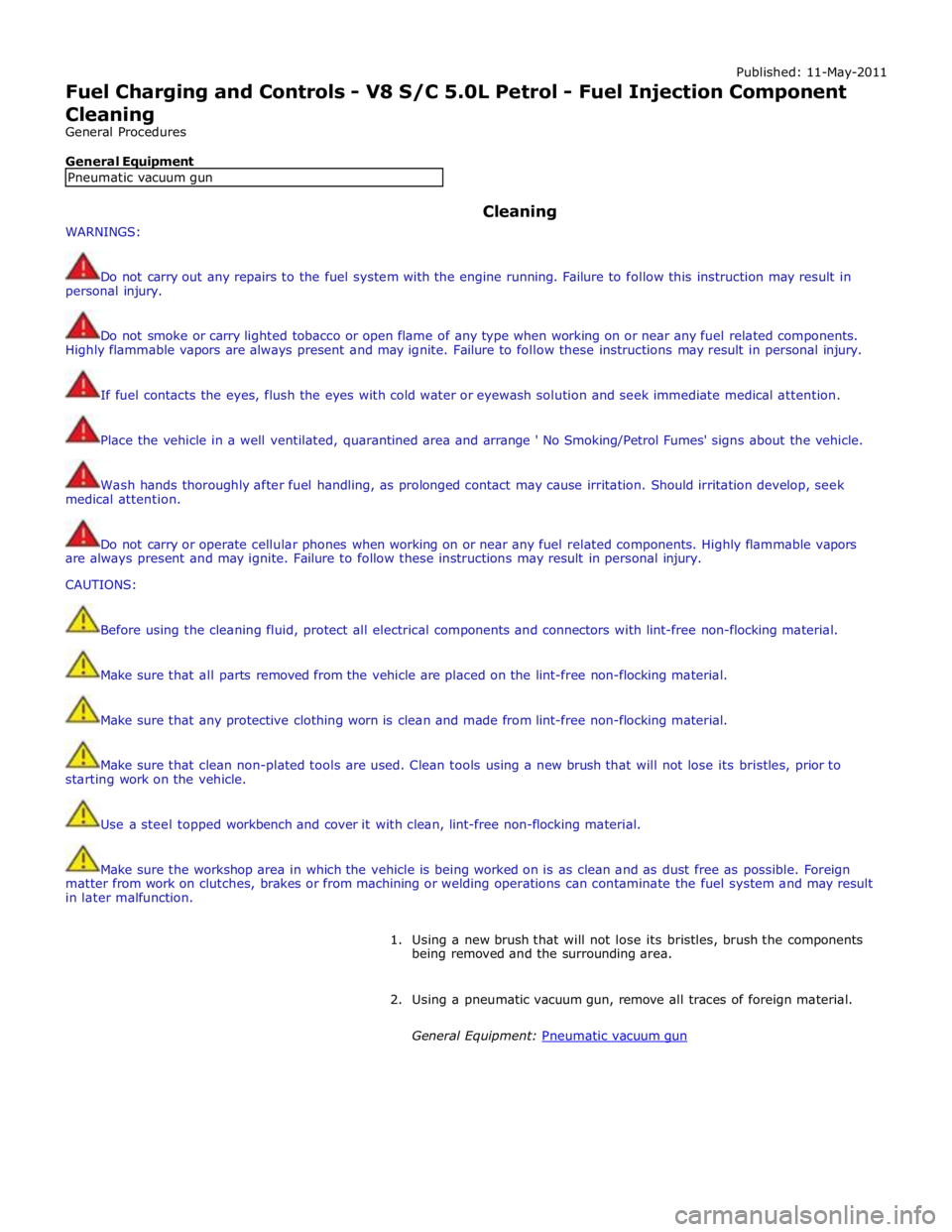

10. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Remove the HCU.

Loosen but do not remove the 2 nuts.

Lift and remove the HCU.

Installation

All vehicles www.JagDocs.com

Page 813 of 3039

Component Tests

Engine Oil Leaks

NOTE: Before installing new gaskets or oil seals, make sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual inspection, carry out an Ultraviolet test:

Fluorescent Oil Additive Method

1. Clean the engine with a suitable cleaning fluid (brake cleaner).

2. Drain the engine oil and refill with recommended oil, premixed with Diesel Engine Oil Dye or equivalent. Use a minimum

14.8 ml (0.5 ounce) to a maximum 29.6 ml (1 ounce) of fluorescent additive to all engines. If oil is not premixed,

fluorescent additive must first be added to the crankcase.

3. Run engine for 15 minutes. Stop the engine and inspect all seal and gasket areas for leaks using a 12 Volt Master UV

Diagnostic Inspection Kit or equivalent. A clear bright yellow or orange area will identify leak. For extremely small

leaks, several hours may be required for the leak to appear.

4. As necessary, pressurize the main oil gallery system to locate leaks due to incorrectly sealed, loose or cocked plugs. If

the flywheel bolts leak oil, look for sealer on the threads.

5. Repair all leaks as necessary.

Compression Test General Remarks

NOTES:

Removing fuses and disconnecting electrical components may cause the Engine Control Module (ECM) to log Diagnostic

Trouble Codes (DTCs). After the measurements have been carried out, DTCs should be cleared from memory by connecting to

the Manufacturer Approved Diagnostic System.

Only check the compression pressure with the valves set to the prescribed clearance (if this can be adjusted).

The compression pressure should be checked with the engine at normal operating temperature.

Check the Compression Pressure

WARNING: Move gear selector lever to 'P' position. Failure to follow this instruction may result in personal injury.

1. Remove the fuel pump relay.

2. Start the engine - the engine will start, run for a few seconds then stall.

3. Remove the spark plugs.

4. Install the compression tester.

5. Install an auxiliary starter switch in the starting circuit. With the ignition switch OFF, using the auxiliary starter switch,

crank the engine a minimum of five compression strokes and record the highest reading. Note the approximate number

of compression strokes required to obtain the highest reading.

6. Repeat the test on each cylinder, cranking the engine approximately the same number of compression strokes.

7. Install the removed components in reverse order, observing the specified tightening torques.

8. Clear all DTCs from the ECM.

Interpretation of the Results

NOTE: Due to the possibility of loose carbon that has become trapped between the valve face and seat effecting the

pressure readings, when carrying out a compression test and cylinders are found to have low pressures, install the spark plugs,

road test the vehicle and re-test the suspect cylinders. If the correct pressures are restored, no further action is required.

The indicated compression pressures are considered within specification if the lowest reading cylinder is within 75% of the

highest reading.

If the cylinder pressures are found to be low, carry out a leakdown test to determine the location of the fault (if any leakback

can be heard through the engine breather system suspect the piston rings, if any leakback can be heard through the inlet

system suspect the inlet valve or seat, if any leakback can be heard through the exhaust manifold suspect the exhaust valve

or seat. If the measurements for two cylinders next to each other are both too low then it is very likely that the cylinder head

gasket between them is burnt through. This can also be recognized by traces of engine oil in the coolant and/or coolant in the

Page 1189 of 3039

Published: 11-May-2011

Fuel Charging and Controls - V8 S/C 5.0L Petrol - Fuel Injection Component Cleaning

General Procedures

General Equipment

WARNINGS: Cleaning

Do not carry out any repairs to the fuel system with the engine running. Failure to follow this instruction may result in

personal injury.

Do not smoke or carry lighted tobacco or open flame of any type when working on or near any fuel related components.

Highly flammable vapors are always present and may ignite. Failure to follow these instructions may result in personal injury.

If fuel contacts the eyes, flush the eyes with cold water or eyewash solution and seek immediate medical attention.

Place the vehicle in a well ventilated, quarantined area and arrange ' No Smoking/Petrol Fumes' signs about the vehicle.

Wash hands thoroughly after fuel handling, as prolonged contact may cause irritation. Should irritation develop, seek

medical attention.

Do not carry or operate cellular phones when working on or near any fuel related components. Highly flammable vapors

are always present and may ignite. Failure to follow these instructions may result in personal injury.

CAUTIONS:

Before using the cleaning fluid, protect all electrical components and connectors with lint-free non-flocking material.

Make sure that all parts removed from the vehicle are placed on the lint-free non-flocking material.

Make sure that any protective clothing worn is clean and made from lint-free non-flocking material.

Make sure that clean non-plated tools are used. Clean tools using a new brush that will not lose its bristles, prior to

starting work on the vehicle.

Use a steel topped workbench and cover it with clean, lint-free non-flocking material.

Make sure the workshop area in which the vehicle is being worked on is as clean and as dust free as possible. Foreign

matter from work on clutches, brakes or from machining or welding operations can contaminate the fuel system and may result

in later malfunction.

1. Using a new brush that will not lose its bristles, brush the components

being removed and the surrounding area.

2. Using a pneumatic vacuum gun, remove all traces of foreign material.

General Equipment: Pneumatic vacuum gun Pneumatic vacuum gun

Page 1413 of 3039

Ration 4.171 2.340 1.521 1.143 0.867 0.691 3.403 Shift Elements

Item Description 1 Turbine shaft 2 Stator shaft 3 Single web planetary gear train 4 Ring gear 1 5 Clutch A 6 Clutch B 7 Clutch E 8 Brake clutch C 9 Fixed connection to transmission housing 10 Shaft key 11 Brake clutch D 12 Double web planetary gear train 13 Planetary gears - long 14 Ring gear 2 15 Sunwheel 2 16 Sunwheel 3 17 Double web planetary gear carrier 18 Planetary gears - short 19 Single web planetary gear carrier 20 Sunwheel 1 The shift elements are three rotating multiplate clutches (A, B and E) and two fixed multiplate brakes (C and D). All shifts

from 1st to 6th gears are power-on overlapping shifts. Overlapping shifts can be described as one of the clutches continuing to

transmit drive at a lower main pressure until the next required clutch is able to accept the input torque.

The shift elements, clutches and brakes are actuated hydraulically. Fluid pressure is applied to the required clutch and/or brake,

pressing the plates together and allowing drive to be transmitted through the plates. The purpose of the shift elements

is to perform power-on shifts with no interruption to traction and smooth transition between gear ratios.

Page 1423 of 3039

The TCM can be reprogrammed using a Jaguar approved diagnostic system using a flash code. The TCM processor has a 440 kb internal flash memory. Of this capacity, approximately 370 kb are used by the basic transmission program. The remainder,

approximately 70 kb is used to store vehicle-specific application data.

Engine Stall

If the vehicle stalls it will coast down in gear, with the transmission providing drive to the engine. A restart can be attempted

at this point and the engine may start and the driver can continue.

If the coast down speed reduces such that the speed of the engine is less than 600 rev/min, the transmission will go to

neutral, D illumination will flash in the instrument cluster. The driver needs to select neutral or park and then press the brake

pedal to restart the engine.

If the start/stop button is pressed when driving, the message ENGINE STOP BUTTON PRESSED is displayed in the message

center but there will be no change to the ignition state. If the driver requires to switch off the engine, the start/stop button

must be pressed for a second time. The engine will be stopped and will be back driven by the transmission as the vehicle

coasts down. When the engine speed is less than 600 rev/min the transmission engages neutral (flashing D illumination in the

instrument cluster). When vehicle speed is less than 2 km/h (1.2 mph) Park is engaged. The JaguarDrive selector automatically

rotates back to its lowered P position and the vehicle ignition is switched off.

The park engagement is prevented in a stall case as the ignition power is on and D was the last selected gear. The park

engagement speed at ignition off is from the least value of the wheel speeds (CAN signal) and transmission output speed (internal signal).

TRANSMISSION Component Description

The transmission comprises the main casing which houses all of the transmission components. The main casing also

incorporates an integral bell housing.

A fluid pan is attached to the lower face of the main casing and is secured with bolts. The fluid pan is sealed to the main

casing with a gasket. Removal of the fluid pan allows access to the Mechatronic valve block. The fluid pan has a magnet

located around the drain plug which collects any metallic particles present in the transmission fluid.

A fluid filter is located inside the fluid pan. If the transmission fluid becomes contaminated or after any service work, the fluid

pan with integral filter must be replaced.

The integral bell housing provides protection for the torque converter assembly and also provides the attachment for the

gearbox to the engine cylinder block. The torque converter is a non-serviceable assembly which also contains the lock-up clutch

mechanism. The torque converter drives a crescent type pump via drive tangs. The fluid pump is located in the main casing,

behind the torque converter.

The main casing contains the following major components:

Input shaft

Output shaft

Mechatronic valve block which contains the solenoids, speed sensors and the TCM Three rotating multiplate drive clutches

Two fixed multiplate brake clutches

A single planetary gear train and a double planetary gear train.

Page 1425 of 3039

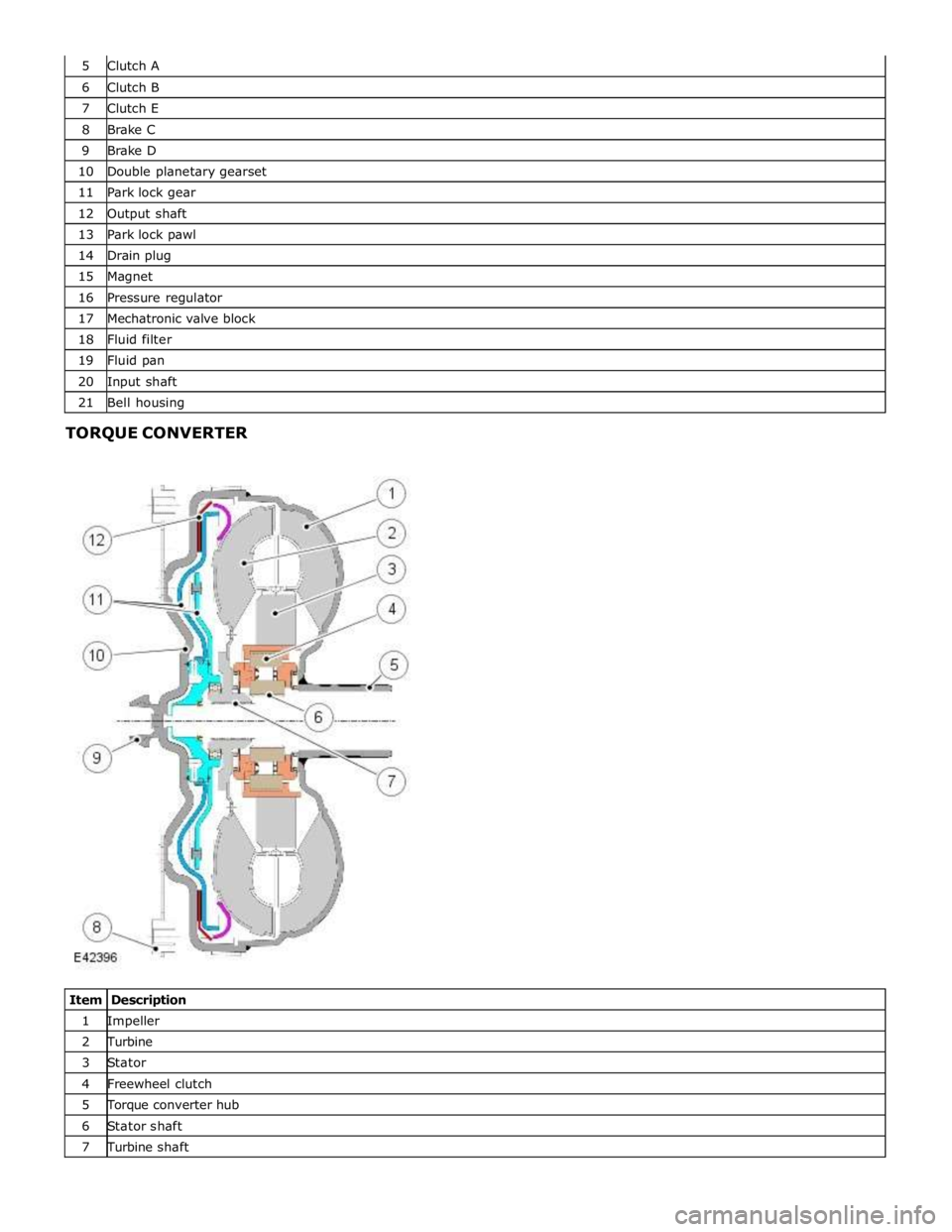

6 Clutch B 7 Clutch E 8 Brake C 9 Brake D 10 Double planetary gearset 11 Park lock gear 12 Output shaft 13 Park lock pawl 14 Drain plug 15 Magnet 16 Pressure regulator 17 Mechatronic valve block 18 Fluid filter 19 Fluid pan 20 Input shaft 21 Bell housing TORQUE CONVERTER

Item Description 1 Impeller 2 Turbine 3 Stator 4 Freewheel clutch 5 Torque converter hub 6 Stator shaft 7 Turbine shaft

Page 1426 of 3039

9 Journal - Drive plate/crankshaft location 10 Torque converter cover 11 Lock-up clutch piston 12 Lock-up clutch plate The torque converter is the coupling element between the engine and the transmission and is located in the bell housing, on

the engine side of the transmission. The driven power from the engine crankshaft is transmitted hydraulically and mechanically

through the torque converter to the transmission. The torque converter is connected to the engine by a drive plate attached to

the rear of the crankshaft.

The torque converter comprises an impeller, a stator and a turbine. The torque converter is a sealed unit with all components

located between the converter housing cover and the impeller. The two components are welded together to form a sealed, fluid

filled housing. With the impeller welded to the converter housing cover, the impeller is therefore driven at engine crankshaft

speed.

The converter housing cover has four threaded bosses, which provide for attachment of the engine drive plate. The threaded

bosses also provide for location of special tools which are required to remove the torque converter from the bell housing.

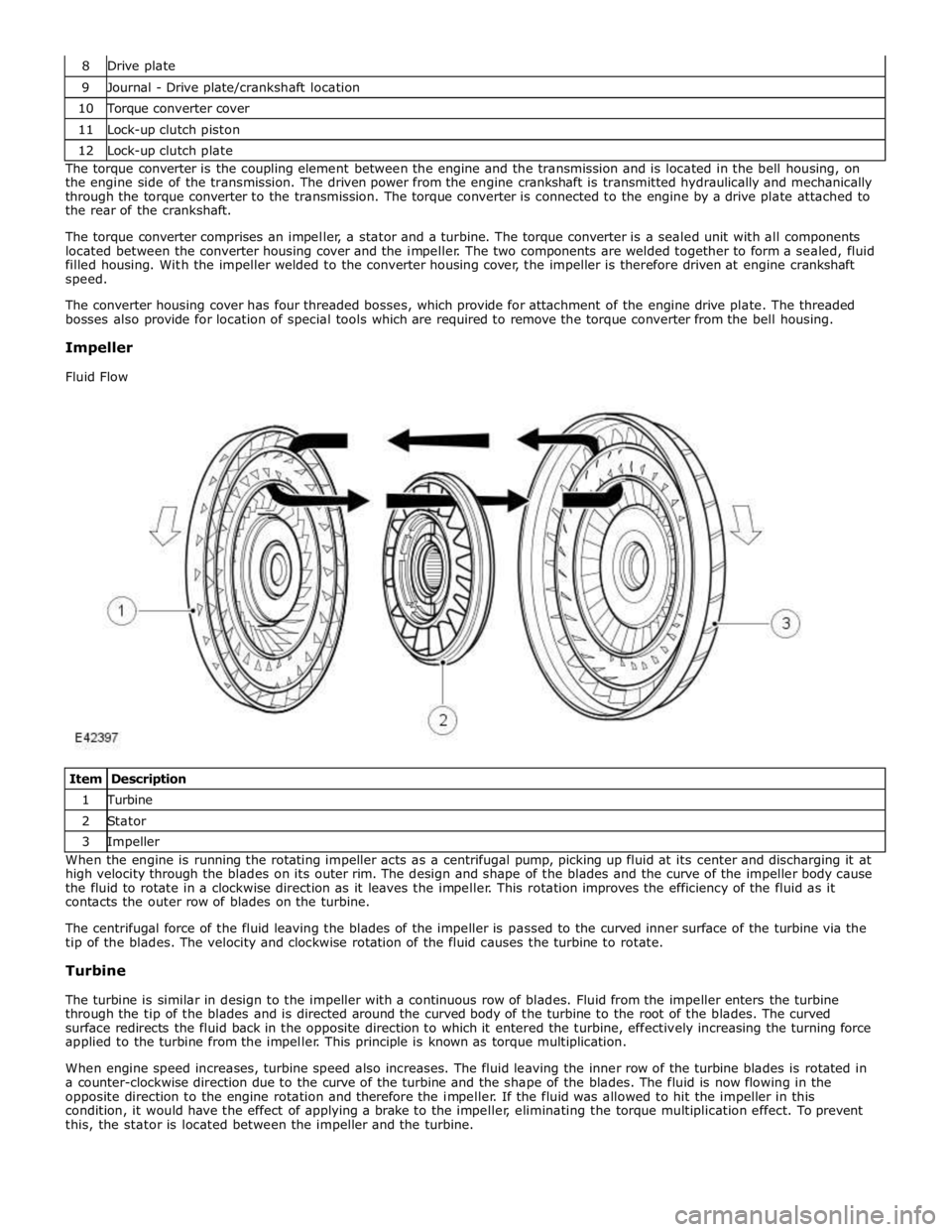

Impeller

Fluid Flow

Item Description 1 Turbine 2 Stator 3 Impeller When the engine is running the rotating impeller acts as a centrifugal pump, picking up fluid at its center and discharging it at

high velocity through the blades on its outer rim. The design and shape of the blades and the curve of the impeller body cause

the fluid to rotate in a clockwise direction as it leaves the impeller. This rotation improves the efficiency of the fluid as it

contacts the outer row of blades on the turbine.

The centrifugal force of the fluid leaving the blades of the impeller is passed to the curved inner surface of the turbine via the

tip of the blades. The velocity and clockwise rotation of the fluid causes the turbine to rotate.

Turbine

The turbine is similar in design to the impeller with a continuous row of blades. Fluid from the impeller enters the turbine

through the tip of the blades and is directed around the curved body of the turbine to the root of the blades. The curved

surface redirects the fluid back in the opposite direction to which it entered the turbine, effectively increasing the turning force

applied to the turbine from the impeller. This principle is known as torque multiplication.

When engine speed increases, turbine speed also increases. The fluid leaving the inner row of the turbine blades is rotated in

a counter-clockwise direction due to the curve of the turbine and the shape of the blades. The fluid is now flowing in the

opposite direction to the engine rotation and therefore the impeller. If the fluid was allowed to hit the impeller in this

condition, it would have the effect of applying a brake to the impeller, eliminating the torque multiplication effect. To prevent

this, the stator is located between the impeller and the turbine.

Page 1432 of 3039

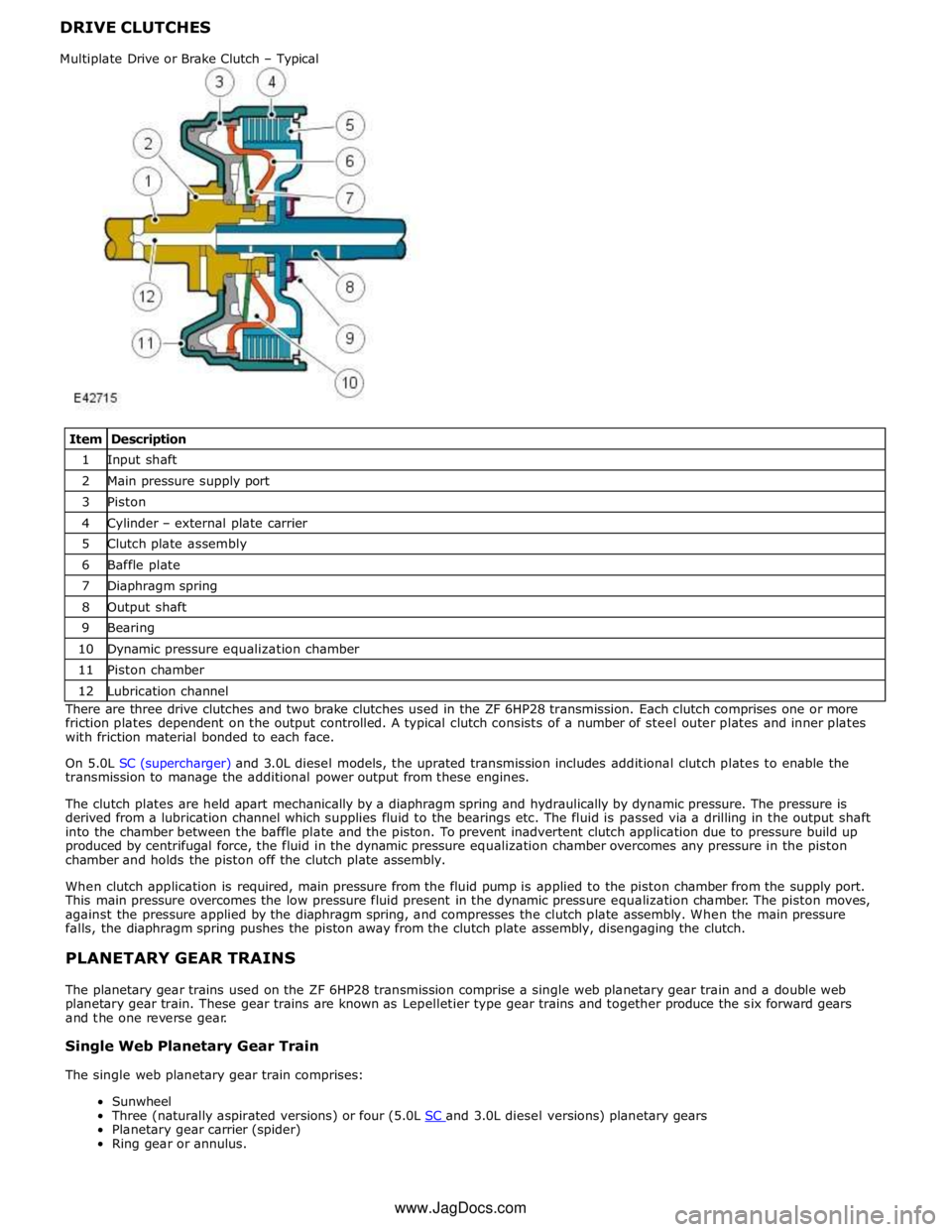

DRIVE CLUTCHES

Item Description 1 Input shaft 2 Main pressure supply port 3 Piston 4 Cylinder – external plate carrier 5 Clutch plate assembly 6 Baffle plate 7 Diaphragm spring 8 Output shaft 9 Bearing 10 Dynamic pressure equalization chamber 11 Piston chamber 12 Lubrication channel There are three drive clutches and two brake clutches used in the ZF 6HP28 transmission. Each clutch comprises one or more

friction plates dependent on the output controlled. A typical clutch consists of a number of steel outer plates and inner plates

with friction material bonded to each face.

On 5.0L SC (supercharger) and 3.0L diesel models, the uprated transmission includes additional clutch plates to enable the

transmission to manage the additional power output from these engines.

The clutch plates are held apart mechanically by a diaphragm spring and hydraulically by dynamic pressure. The pressure is

derived from a lubrication channel which supplies fluid to the bearings etc. The fluid is passed via a drilling in the output shaft

into the chamber between the baffle plate and the piston. To prevent inadvertent clutch application due to pressure build up

produced by centrifugal force, the fluid in the dynamic pressure equalization chamber overcomes any pressure in the piston

chamber and holds the piston off the clutch plate assembly.

When clutch application is required, main pressure from the fluid pump is applied to the piston chamber from the supply port.

This main pressure overcomes the low pressure fluid present in the dynamic pressure equalization chamber. The piston moves,

against the pressure applied by the diaphragm spring, and compresses the clutch plate assembly. When the main pressure

falls, the diaphragm spring pushes the piston away from the clutch plate assembly, disengaging the clutch.

PLANETARY GEAR TRAINS

The planetary gear trains used on the ZF 6HP28 transmission comprise a single web planetary gear train and a double web

planetary gear train. These gear trains are known as Lepelletier type gear trains and together produce the six forward gears

and the one reverse gear.

Single Web Planetary Gear Train

The single web planetary gear train comprises:

Sunwheel

Three (naturally aspirated versions) or four (5.0L SC and 3.0L diesel versions) planetary gears Planetary gear carrier (spider)

Ring gear or annulus. Multiplate Drive or Brake Clutch – Typical www.JagDocs.com

Page 1449 of 3039

Published: 11-May-2011

Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Transmission Fluid Level Check

General Procedures

WARNINGS: Activation

Observe due care when draining, as the fluid can be very hot.

Observe due care when working near a hot exhaust system.

1.

The following steps must be observed before starting the

transmission fluid level check.

The vehicle must be on a horizontal ramp.

The parking brake must be applied.

The engine must be running for 2 minutes with the transmission

control switch (TCS) in the "P" position.

2. CAUTION: Make sure that the transmission fluid temperature is

below 30 degrees before starting the fluid level check.

Connect Jaguar approved diagnostic equipment to the vehicle.

3.

Apply, and hold, the footbrake.

Move the selector lever from 'P' through all the gear positions,

pausing in each gear position for 2-3 seconds and return to the

'P' position.

4. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

5. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

6. Place a suitable container under the transmission fluid fill plug. 307-452

Wrench, Transmission Filler Plug Special Tool(s)

Page 1464 of 3039

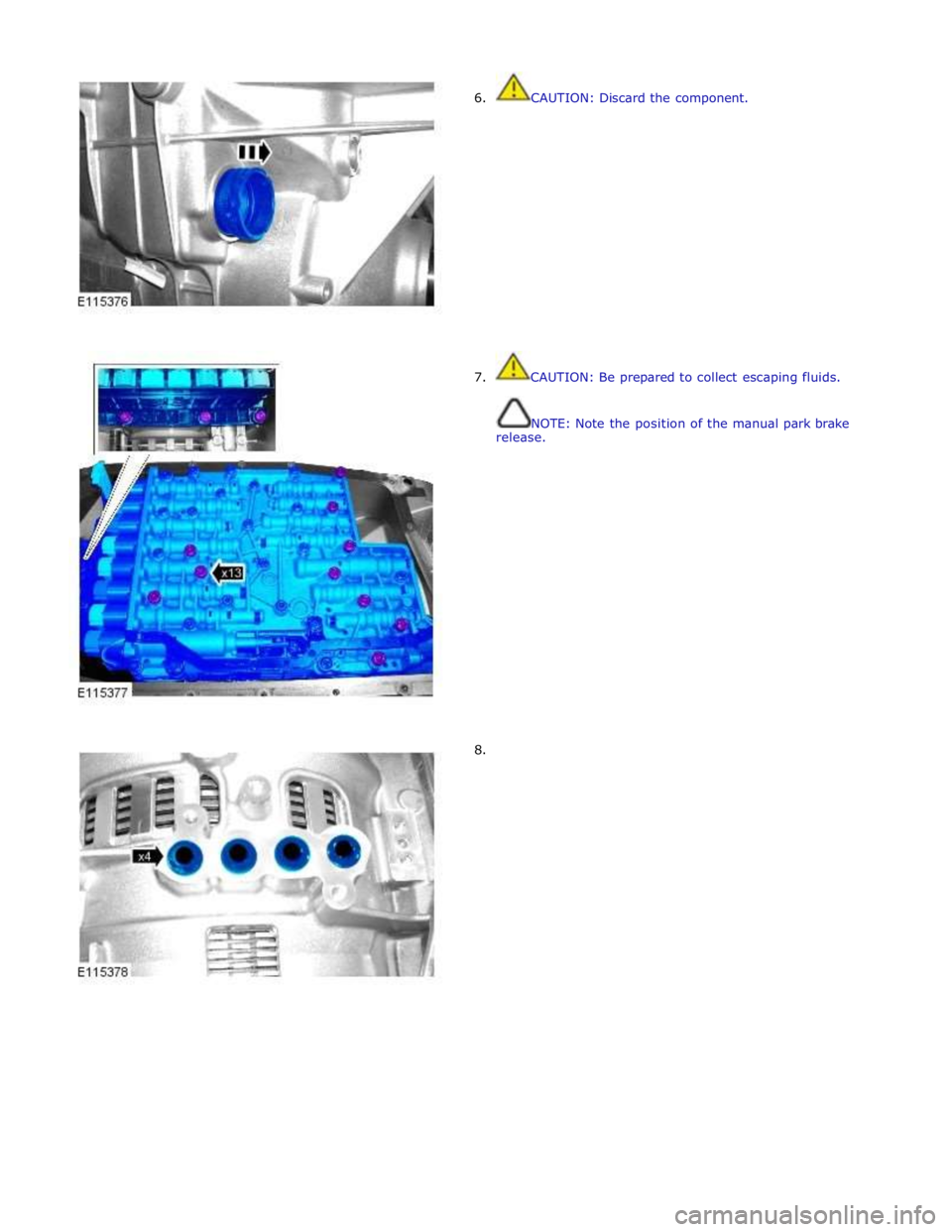

6. CAUTION: Discard the component.

7. CAUTION: Be prepared to collect escaping fluids.

NOTE: Note the position of the manual park brake

release.

8.