battery JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2251 of 3039

Published: 11-May-2011

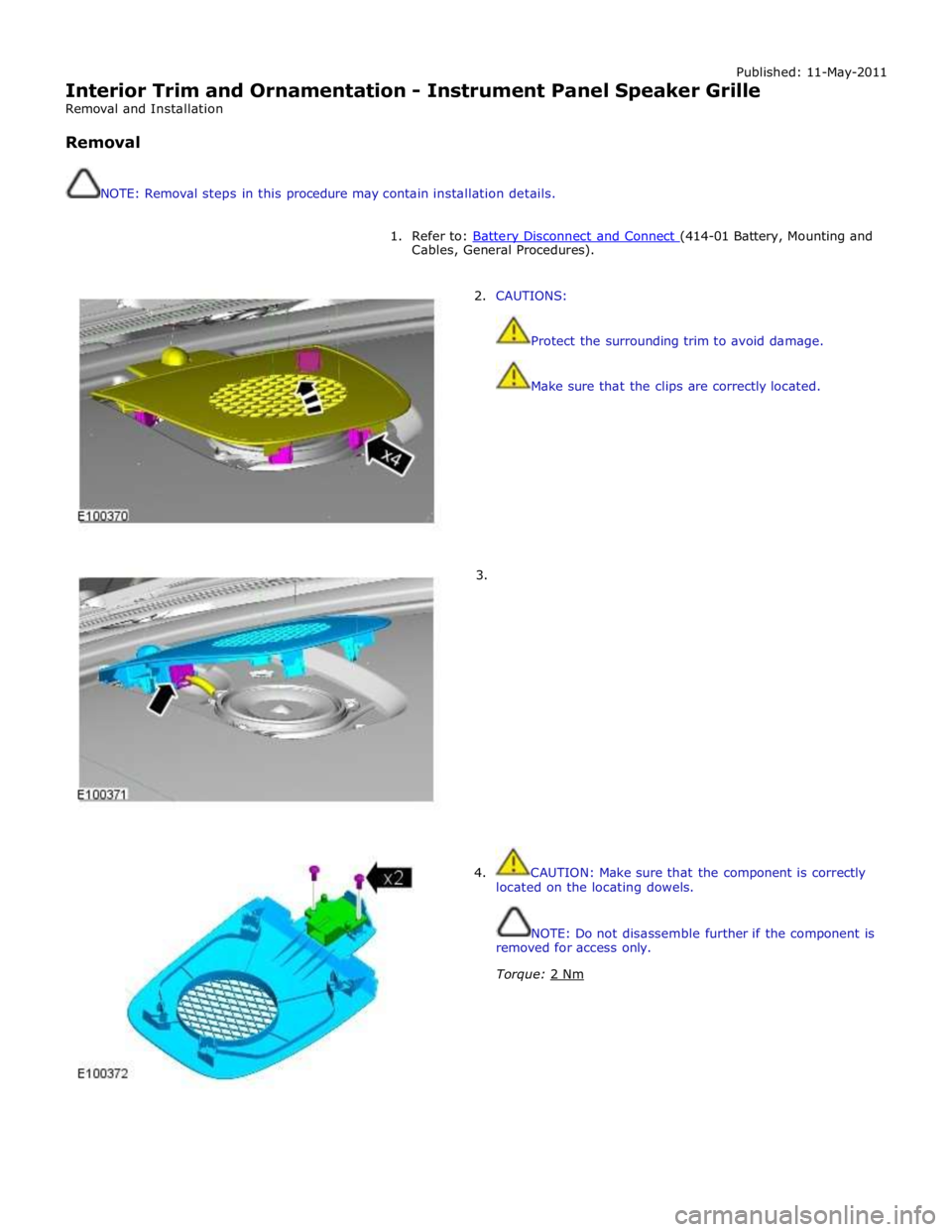

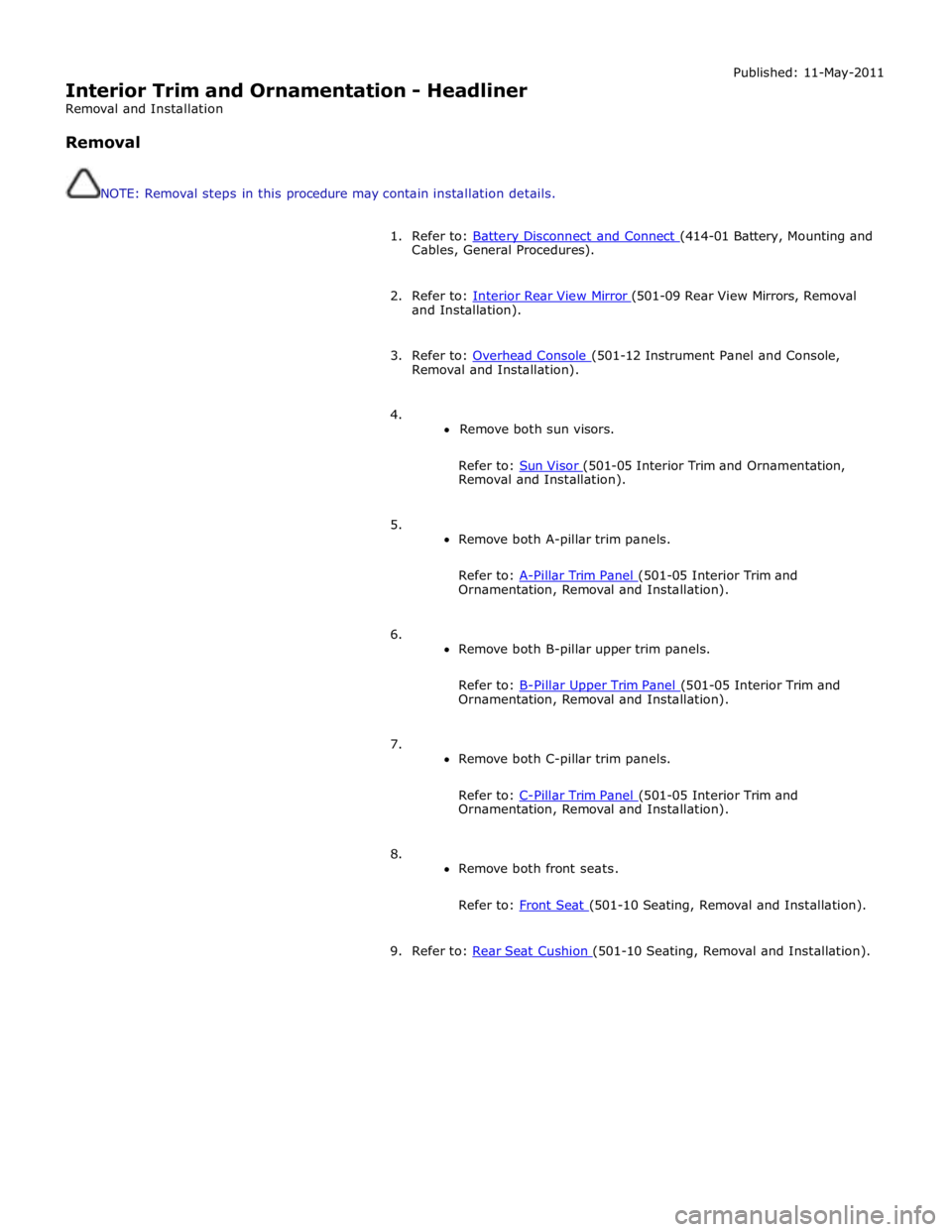

Interior Trim and Ornamentation - Instrument Panel Speaker Grille

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. CAUTIONS:

Protect the surrounding trim to avoid damage.

Make sure that the clips are correctly located.

3.

4. CAUTION: Make sure that the component is correctly

located on the locating dowels.

NOTE: Do not disassemble further if the component is

removed for access only.

Torque: 2 Nm

Page 2253 of 3039

Interior Trim and Ornamentation - Headliner

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Interior Rear View Mirror (501-09 Rear View Mirrors, Removal and Installation).

3. Refer to: Overhead Console (501-12 Instrument Panel and Console, Removal and Installation).

4.

Remove both sun visors.

Refer to: Sun Visor (501-05 Interior Trim and Ornamentation, Removal and Installation).

5.

Remove both A-pillar trim panels.

Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

6.

Remove both B-pillar upper trim panels.

Refer to: B-Pillar Upper Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

7.

Remove both C-pillar trim panels.

Refer to: C-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

8.

Remove both front seats.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

9. Refer to: Rear Seat Cushion (501-10 Seating, Removal and Installation).

Page 2293 of 3039

Published: 04-Nov-2013

Rear View Mirrors - Rear View Mirrors - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired, N = Medium speed CAN (controller area network) bus, O = LIN (local interconnect network) bus

Item Description 1 RJB (rear junction box) 2 RH (right-hand) door module 3 RH door mirror 4 LH (left-hand)side door mirror 5 Interior mirror 6 Battery

Page 2312 of 3039

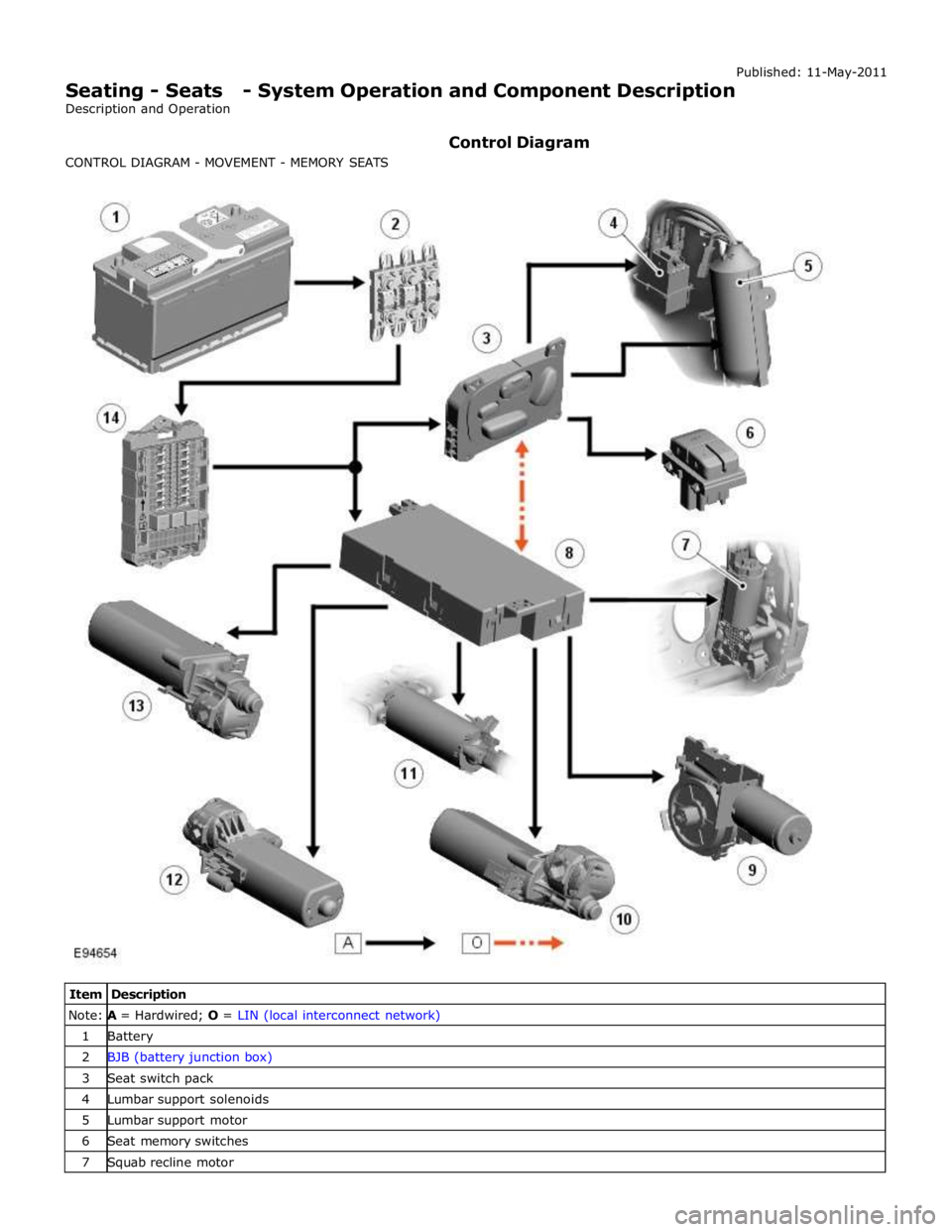

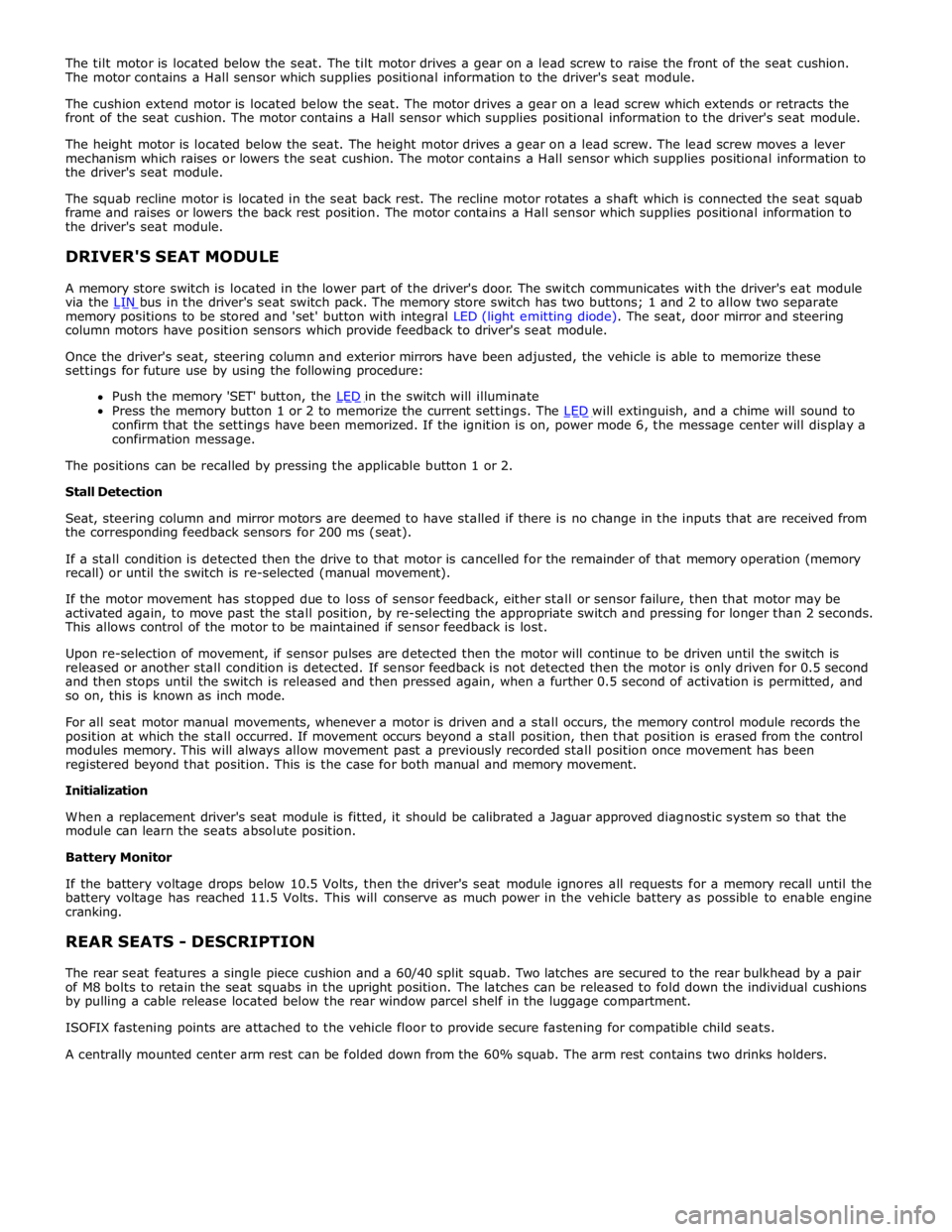

Note: A = Hardwired; O = LIN (local interconnect network) 1 Battery 2 BJB (battery junction box) 3 Seat switch pack 4 Lumbar support solenoids 5 Lumbar support motor 6 Seat memory switches 7 Squab recline motor

Page 2314 of 3039

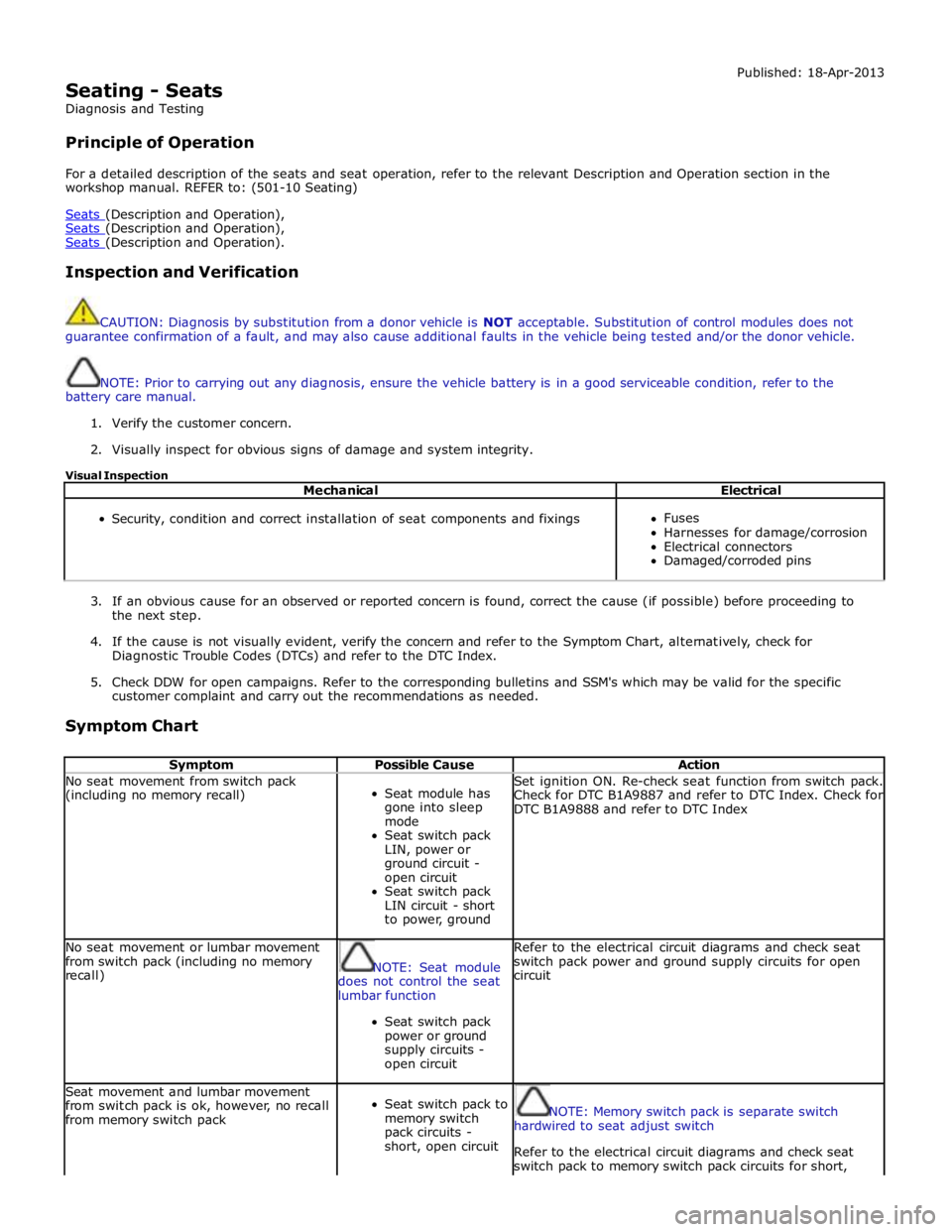

Note:

A =

Hardwired;

N

=

Medium

speed

CAN

(controller

area

network) bus;

P

=

MOST

ring

1

Battery

2

BJB

3

ATC

(automatic

temperature

control) module

4

RJB

(rear

junction

box)

5

Touch Screen

Display

(TSD)

6

Information

and

Entertainment

module

www.JagDocs.com

Page 2315 of 3039

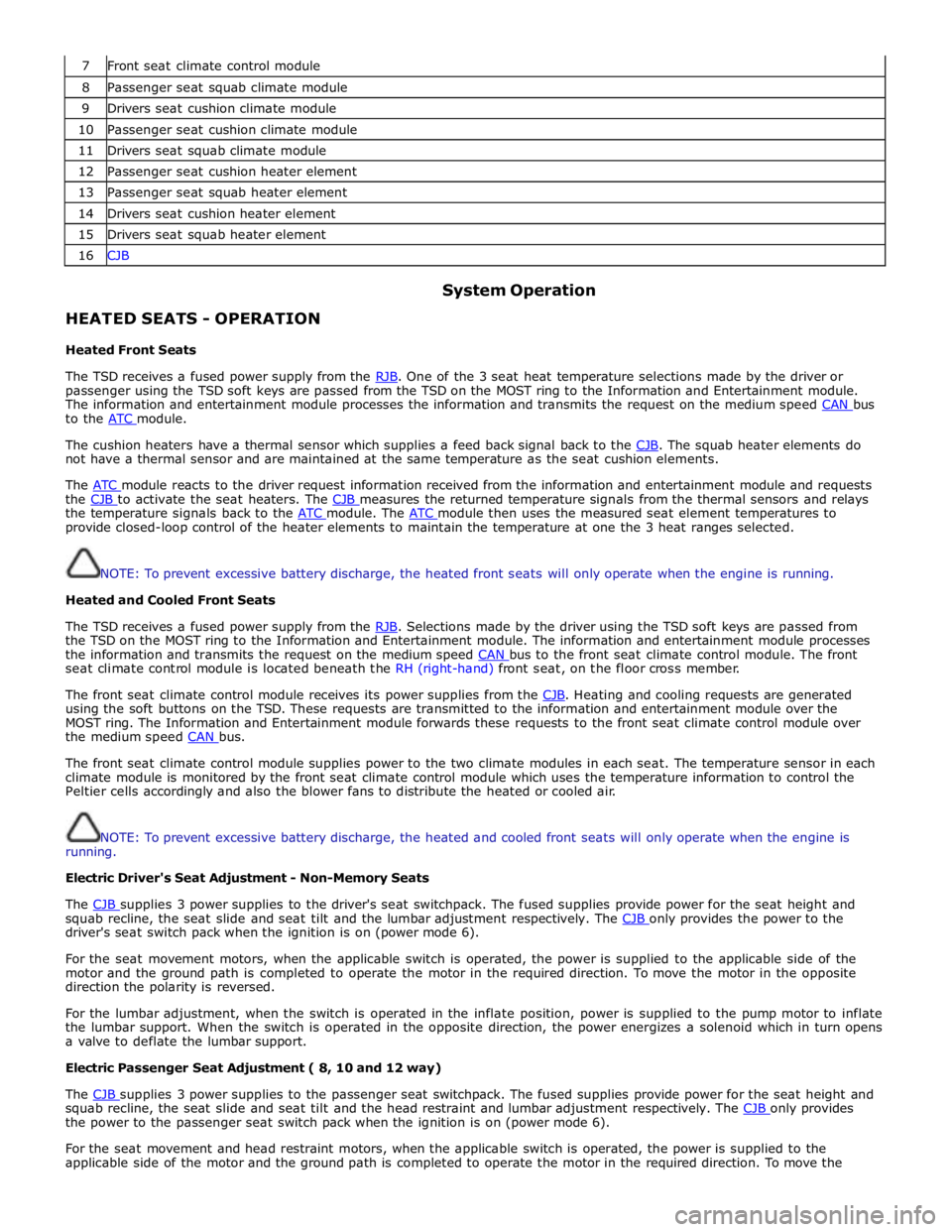

7 Front seat climate control module 8 Passenger seat squab climate module 9 Drivers seat cushion climate module 10 Passenger seat cushion climate module 11 Drivers seat squab climate module 12 Passenger seat cushion heater element 13 Passenger seat squab heater element 14 Drivers seat cushion heater element 15 Drivers seat squab heater element 16 CJB

HEATED SEATS - OPERATION

Heated Front Seats System Operation

The TSD receives a fused power supply from the RJB. One of the 3 seat heat temperature selections made by the driver or passenger using the TSD soft keys are passed from the TSD on the MOST ring to the Information and Entertainment module.

The information and entertainment module processes the information and transmits the request on the medium speed CAN bus to the ATC module.

The cushion heaters have a thermal sensor which supplies a feed back signal back to the CJB. The squab heater elements do not have a thermal sensor and are maintained at the same temperature as the seat cushion elements.

The ATC module reacts to the driver request information received from the information and entertainment module and requests the CJB to activate the seat heaters. The CJB measures the returned temperature signals from the thermal sensors and relays the temperature signals back to the ATC module. The ATC module then uses the measured seat element temperatures to provide closed-loop control of the heater elements to maintain the temperature at one the 3 heat ranges selected.

NOTE: To prevent excessive battery discharge, the heated front seats will only operate when the engine is running.

Heated and Cooled Front Seats

The TSD receives a fused power supply from the RJB. Selections made by the driver using the TSD soft keys are passed from the TSD on the MOST ring to the Information and Entertainment module. The information and entertainment module processes

the information and transmits the request on the medium speed CAN bus to the front seat climate control module. The front seat climate control module is located beneath the RH (right-hand) front seat, on the floor cross member.

The front seat climate control module receives its power supplies from the CJB. Heating and cooling requests are generated using the soft buttons on the TSD. These requests are transmitted to the information and entertainment module over the

MOST ring. The Information and Entertainment module forwards these requests to the front seat climate control module over

the medium speed CAN bus.

The front seat climate control module supplies power to the two climate modules in each seat. The temperature sensor in each

climate module is monitored by the front seat climate control module which uses the temperature information to control the

Peltier cells accordingly and also the blower fans to distribute the heated or cooled air.

NOTE: To prevent excessive battery discharge, the heated and cooled front seats will only operate when the engine is

running.

Electric Driver's Seat Adjustment - Non-Memory Seats

The CJB supplies 3 power supplies to the driver's seat switchpack. The fused supplies provide power for the seat height and squab recline, the seat slide and seat tilt and the lumbar adjustment respectively. The CJB only provides the power to the driver's seat switch pack when the ignition is on (power mode 6).

For the seat movement motors, when the applicable switch is operated, the power is supplied to the applicable side of the

motor and the ground path is completed to operate the motor in the required direction. To move the motor in the opposite

direction the polarity is reversed.

For the lumbar adjustment, when the switch is operated in the inflate position, power is supplied to the pump motor to inflate

the lumbar support. When the switch is operated in the opposite direction, the power energizes a solenoid which in turn opens

a valve to deflate the lumbar support.

Electric Passenger Seat Adjustment ( 8, 10 and 12 way)

The CJB supplies 3 power supplies to the passenger seat switchpack. The fused supplies provide power for the seat height and squab recline, the seat slide and seat tilt and the head restraint and lumbar adjustment respectively. The CJB only provides the power to the passenger seat switch pack when the ignition is on (power mode 6).

For the seat movement and head restraint motors, when the applicable switch is operated, the power is supplied to the

applicable side of the motor and the ground path is completed to operate the motor in the required direction. To move the

Page 2317 of 3039

memory positions to be stored and 'set' button with integral LED (light emitting diode). The seat, door mirror and steering

column motors have position sensors which provide feedback to driver's seat module.

Once the driver's seat, steering column and exterior mirrors have been adjusted, the vehicle is able to memorize these

settings for future use by using the following procedure:

Push the memory 'SET' button, the LED in the switch will illuminate Press the memory button 1 or 2 to memorize the current settings. The LED will extinguish, and a chime will sound to confirm that the settings have been memorized. If the ignition is on, power mode 6, the message center will display a

confirmation message.

The positions can be recalled by pressing the applicable button 1 or 2.

Stall Detection

Seat, steering column and mirror motors are deemed to have stalled if there is no change in the inputs that are received from

the corresponding feedback sensors for 200 ms (seat).

If a stall condition is detected then the drive to that motor is cancelled for the remainder of that memory operation (memory

recall) or until the switch is re-selected (manual movement).

If the motor movement has stopped due to loss of sensor feedback, either stall or sensor failure, then that motor may be

activated again, to move past the stall position, by re-selecting the appropriate switch and pressing for longer than 2 seconds.

This allows control of the motor to be maintained if sensor feedback is lost.

Upon re-selection of movement, if sensor pulses are detected then the motor will continue to be driven until the switch is

released or another stall condition is detected. If sensor feedback is not detected then the motor is only driven for 0.5 second

and then stops until the switch is released and then pressed again, when a further 0.5 second of activation is permitted, and

so on, this is known as inch mode.

For all seat motor manual movements, whenever a motor is driven and a stall occurs, the memory control module records the

position at which the stall occurred. If movement occurs beyond a stall position, then that position is erased from the control

modules memory. This will always allow movement past a previously recorded stall position once movement has been

registered beyond that position. This is the case for both manual and memory movement.

Initialization

When a replacement driver's seat module is fitted, it should be calibrated a Jaguar approved diagnostic system so that the

module can learn the seats absolute position.

Battery Monitor

If the battery voltage drops below 10.5 Volts, then the driver's seat module ignores all requests for a memory recall until the

battery voltage has reached 11.5 Volts. This will conserve as much power in the vehicle battery as possible to enable engine

cranking.

REAR SEATS - DESCRIPTION

The rear seat features a single piece cushion and a 60/40 split squab. Two latches are secured to the rear bulkhead by a pair

of M8 bolts to retain the seat squabs in the upright position. The latches can be released to fold down the individual cushions

by pulling a cable release located below the rear window parcel shelf in the luggage compartment.

ISOFIX fastening points are attached to the vehicle floor to provide secure fastening for compatible child seats.

A centrally mounted center arm rest can be folded down from the 60% squab. The arm rest contains two drinks holders.

Page 2328 of 3039

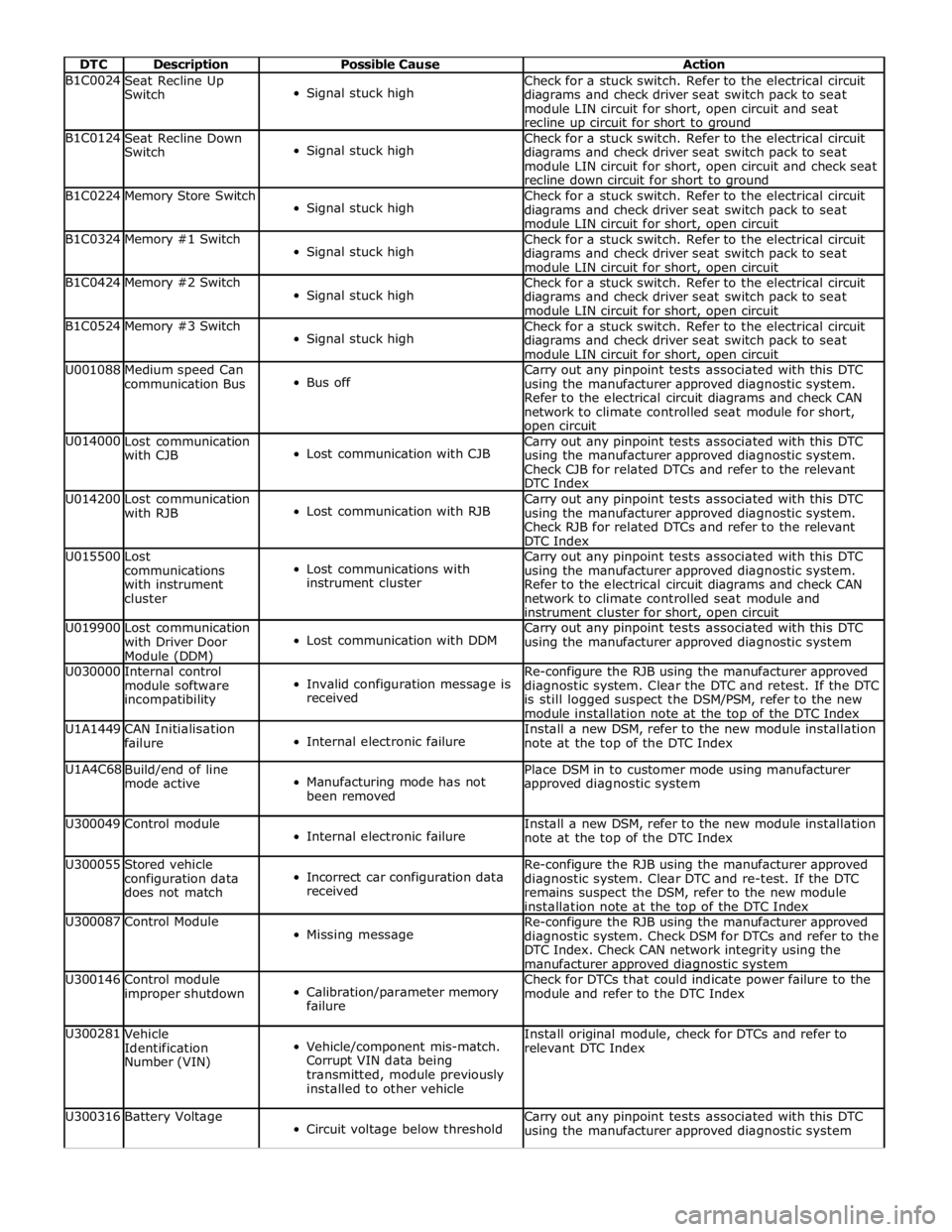

Seating - Seats

Diagnosis and Testing

Principle of Operation Published: 18-Apr-2013

For a detailed description of the seats and seat operation, refer to the relevant Description and Operation section in the

workshop manual. REFER to: (501-10 Seating)

Seats (Description and Operation), Seats (Description and Operation), Seats (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTE: Prior to carrying out any diagnosis, ensure the vehicle battery is in a good serviceable condition, refer to the

battery care manual.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Security, condition and correct installation of seat components and fixings

Fuses

Harnesses for damage/corrosion

Electrical connectors

Damaged/corroded pins

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the concern and refer to the Symptom Chart, alternatively, check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSM's which may be valid for the specific

customer complaint and carry out the recommendations as needed.

Symptom Chart

Symptom Possible Cause Action No seat movement from switch pack

(including no memory recall)

Seat module has

gone into sleep

mode

Seat switch pack

LIN, power or

ground circuit -

open circuit

Seat switch pack

LIN circuit - short

to power, ground Set ignition ON. Re-check seat function from switch pack.

Check for DTC B1A9887 and refer to DTC Index. Check for

DTC B1A9888 and refer to DTC Index No seat movement or lumbar movement

from switch pack (including no memory

recall)

NOTE: Seat module

does not control the seat

lumbar function

Seat switch pack

power or ground

supply circuits -

open circuit Refer to the electrical circuit diagrams and check seat

switch pack power and ground supply circuits for open

circuit Seat movement and lumbar movement

from switch pack is ok, however, no recall

from memory switch pack

Seat switch pack to

memory switch

pack circuits -

short, open circuit

NOTE: Memory switch pack is separate switch

hardwired to seat adjust switch

Refer to the electrical circuit diagrams and check seat

switch pack to memory switch pack circuits for short,

Page 2333 of 3039

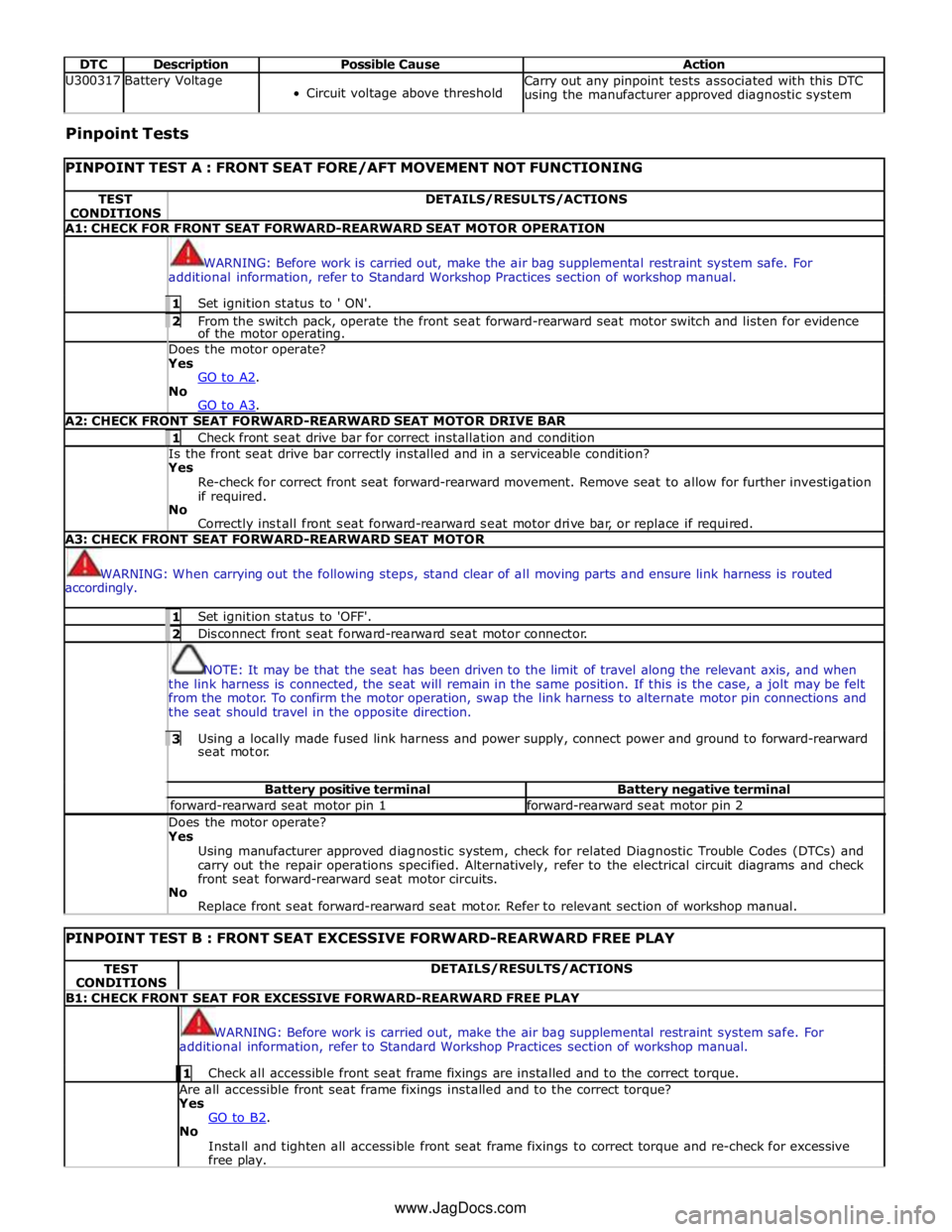

DTC Description Possible Cause Action B1C0024

Seat Recline Up

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and seat

recline up circuit for short to ground B1C0124

Seat Recline Down

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and check seat

recline down circuit for short to ground B1C0224 Memory Store Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit B1C0324 Memory #1 Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit B1C0424 Memory #2 Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit B1C0524 Memory #3 Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit U001088

Medium speed Can

communication Bus

Bus off Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check CAN

network to climate controlled seat module for short, open circuit U014000

Lost communication

with CJB

Lost communication with CJB Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Check CJB for related DTCs and refer to the relevant

DTC Index U014200

Lost communication

with RJB

Lost communication with RJB Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Check RJB for related DTCs and refer to the relevant

DTC Index U015500

Lost

communications

with instrument

cluster

Lost communications with

instrument cluster Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check CAN

network to climate controlled seat module and

instrument cluster for short, open circuit U019900

Lost communication

with Driver Door

Module (DDM)

Lost communication with DDM Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U030000

Internal control

module software

incompatibility

Invalid configuration message is

received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC

is still logged suspect the DSM/PSM, refer to the new

module installation note at the top of the DTC Index U1A1449

CAN Initialisation

failure

Internal electronic failure Install a new DSM, refer to the new module installation

note at the top of the DTC Index U1A4C68

Build/end of line

mode active

Manufacturing mode has not

been removed Place DSM in to customer mode using manufacturer

approved diagnostic system U300049 Control module

Internal electronic failure Install a new DSM, refer to the new module installation

note at the top of the DTC Index U300055

Stored vehicle

configuration data

does not match

Incorrect car configuration data

received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear DTC and re-test. If the DTC

remains suspect the DSM, refer to the new module

installation note at the top of the DTC Index U300087 Control Module

Missing message Re-configure the RJB using the manufacturer approved

diagnostic system. Check DSM for DTCs and refer to the

DTC Index. Check CAN network integrity using the

manufacturer approved diagnostic system U300146

Control module

improper shutdown

Calibration/parameter memory

failure Check for DTCs that could indicate power failure to the

module and refer to the DTC Index U300281

Vehicle

Identification

Number (VIN)

Vehicle/component mis-match.

Corrupt VIN data being

transmitted, module previously

installed to other vehicle Install original module, check for DTCs and refer to

relevant DTC Index U300316 Battery Voltage

Circuit voltage below threshold Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system

Page 2334 of 3039

DTC Description Possible Cause Action U300317 Battery Voltage

Circuit voltage above threshold Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system Pinpoint Tests

PINPOINT TEST A : FRONT SEAT FORE/AFT MOVEMENT NOT FUNCTIONING TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK FOR FRONT SEAT FORWARD-REARWARD SEAT MOTOR OPERATION

WARNING: Before work is carried out, make the air bag supplemental restraint system safe. For

additional information, refer to Standard Workshop Practices section of workshop manual. 1 Set ignition status to ' ON'. 2 From the switch pack, operate the front seat forward-rearward seat motor switch and listen for evidence of the motor operating. Does the motor operate? Yes

GO to A2. No

GO to A3. A2: CHECK FRONT SEAT FORWARD-REARWARD SEAT MOTOR DRIVE BAR 1 Check front seat drive bar for correct installation and condition Is the front seat drive bar correctly installed and in a serviceable condition? Yes

Re-check for correct front seat forward-rearward movement. Remove seat to allow for further investigation

if required.

No

Correctly install front seat forward-rearward seat motor drive bar, or replace if required. A3: CHECK FRONT SEAT FORWARD-REARWARD SEAT MOTOR

WARNING: When carrying out the following steps, stand clear of all moving parts and ensure link harness is routed

accordingly. 1 Set ignition status to 'OFF'. 2 Disconnect front seat forward-rearward seat motor connector.

NOTE: It may be that the seat has been driven to the limit of travel along the relevant axis, and when

the link harness is connected, the seat will remain in the same position. If this is the case, a jolt may be felt

from the motor. To confirm the motor operation, swap the link harness to alternate motor pin connections and

the seat should travel in the opposite direction. 3 Using a locally made fused link harness and power supply, connect power and ground to forward-rearward seat motor. Battery positive terminal Battery negative terminal forward-rearward seat motor pin 1 forward-rearward seat motor pin 2 Does the motor operate? Yes

Using manufacturer approved diagnostic system, check for related Diagnostic Trouble Codes (DTCs) and

carry out the repair operations specified. Alternatively, refer to the electrical circuit diagrams and check

front seat forward-rearward seat motor circuits.

No

Replace front seat forward-rearward seat motor. Refer to relevant section of workshop manual.

PINPOINT TEST B : FRONT SEAT EXCESSIVE FORWARD-REARWARD FREE PLAY TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: CHECK FRONT SEAT FOR EXCESSIVE FORWARD-REARWARD FREE PLAY

WARNING: Before work is carried out, make the air bag supplemental restraint system safe. For

additional information, refer to Standard Workshop Practices section of workshop manual. 1 Check all accessible front seat frame fixings are installed and to the correct torque. Are all accessible front seat frame fixings installed and to the correct torque?

Yes

GO to B2. No

Install and tighten all accessible front seat frame fixings to correct torque and re-check for excessive

free play. www.JagDocs.com