Control module JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2422 of 3039

Published: 15-Jan-2013

Glass, Frames and Mechanisms - Door Window Motor Initialization

General Procedures

NOTES:

Make sure that the vehicle battery is fully charged before carrying out this procedure.

After the battery has been disconnected or a new window regulator and motor or door module has been installed, it is

necessary to initialize each door window motor separately to operate the one-touch and anti-trap function.

In addition to this manual procedure, the approved diagnostic tool can also be used to initialize the door window motor.

1. Start the engine.

2. Operate the window control switch until the door window glass is in the

fully closed position, continue to operate the window control switch for a

further two seconds.

3. Release the window control switch.

4. Operate the window control switch in the closed position and continue to

operate the window control switch for a further two seconds.

5. Operate the window control switch until the door window glass is in the

fully open position (one-touch down).

6. NOTES:

If the door window motor initialization has been completed

correctly, when the window control switch is operated, the door window

glass should move to the fully closed position (one-touch up)

automatically.

If the door window glass does not fully close automatically

(one-touch up), repeat the complete procedure.

Operate the window control switch once to the close position.

If multiple attempts have failed to initialize the door window

motor, refer the diagnosis and testing procedure.

For additional information, refer to: Glass, Frames and Mechanisms (501-11 Glass, Frames and Mechanisms, Diagnosis and Testing).

7. Repeat the door window motor initialization for each door window motor.

Page 2490 of 3039

Note: A = Hardwired; N = Medium speed CAN (controller area network); O = LIN (local interconnect network) bus 1 Battery 2 Megafuse (250 A) 3 RJB (rear junction box) 4 Door module - front passenger 5 Door ajar switch - front passenger 6 Door latch - front passenger

Page 2493 of 3039

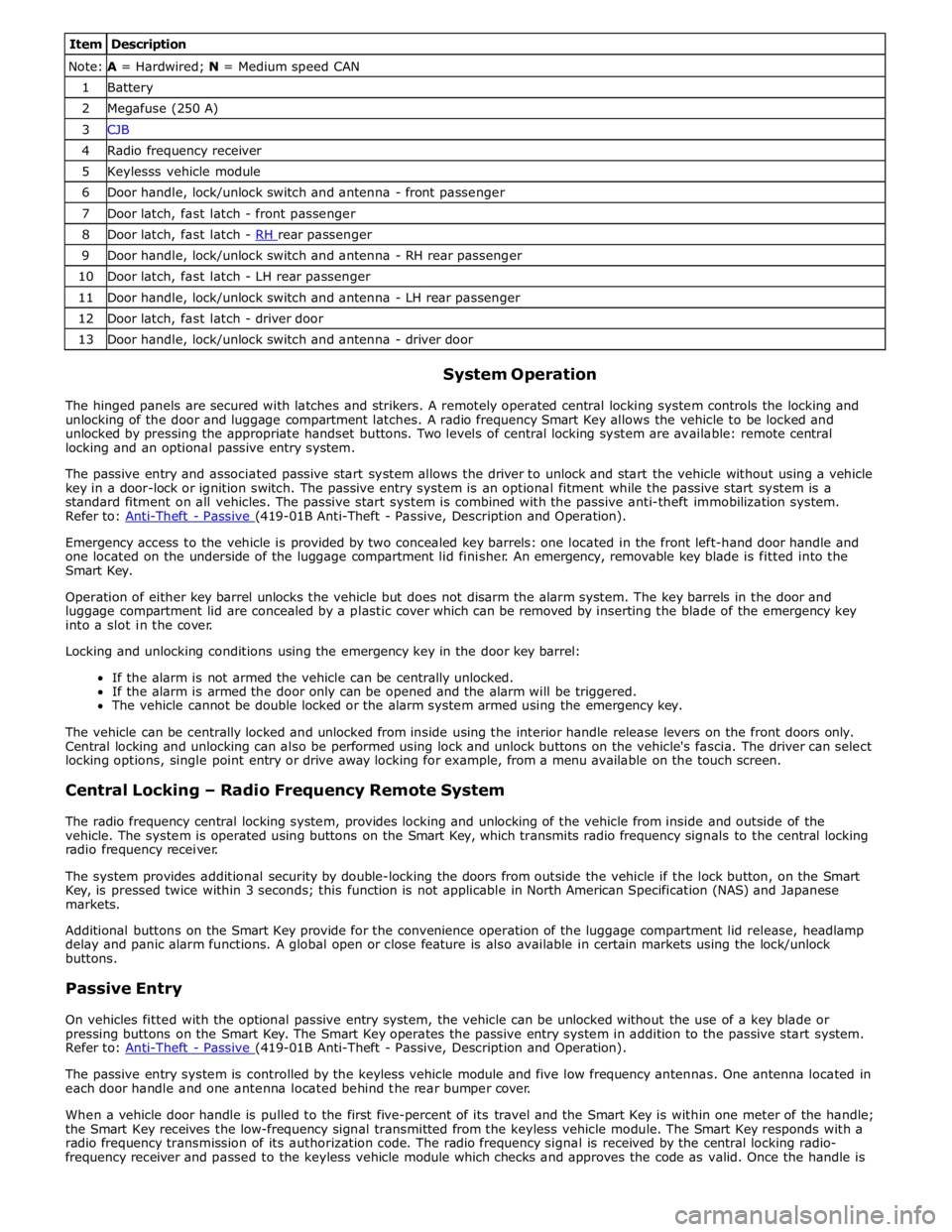

Item Description Note: A = Hardwired; N = Medium speed CAN 1 Battery 2 Megafuse (250 A) 3 CJB 4 Radio frequency receiver 5 Keylesss vehicle module 6 Door handle, lock/unlock switch and antenna - front passenger 7 Door latch, fast latch - front passenger 8 Door latch, fast latch - RH rear passenger 9 Door handle, lock/unlock switch and antenna - RH rear passenger 10 Door latch, fast latch - LH rear passenger 11 Door handle, lock/unlock switch and antenna - LH rear passenger 12 Door latch, fast latch - driver door 13 Door handle, lock/unlock switch and antenna - driver door

System Operation

The hinged panels are secured with latches and strikers. A remotely operated central locking system controls the locking and

unlocking of the door and luggage compartment latches. A radio frequency Smart Key allows the vehicle to be locked and

unlocked by pressing the appropriate handset buttons. Two levels of central locking system are available: remote central

locking and an optional passive entry system.

The passive entry and associated passive start system allows the driver to unlock and start the vehicle without using a vehicle

key in a door-lock or ignition switch. The passive entry system is an optional fitment while the passive start system is a

standard fitment on all vehicles. The passive start system is combined with the passive anti-theft immobilization system.

Refer to: Anti-Theft - Passive (419-01B Anti-Theft - Passive, Description and Operation).

Emergency access to the vehicle is provided by two concealed key barrels: one located in the front left-hand door handle and

one located on the underside of the luggage compartment lid finisher. An emergency, removable key blade is fitted into the

Smart Key.

Operation of either key barrel unlocks the vehicle but does not disarm the alarm system. The key barrels in the door and

luggage compartment lid are concealed by a plastic cover which can be removed by inserting the blade of the emergency key

into a slot in the cover.

Locking and unlocking conditions using the emergency key in the door key barrel:

If the alarm is not armed the vehicle can be centrally unlocked.

If the alarm is armed the door only can be opened and the alarm will be triggered.

The vehicle cannot be double locked or the alarm system armed using the emergency key.

The vehicle can be centrally locked and unlocked from inside using the interior handle release levers on the front doors only.

Central locking and unlocking can also be performed using lock and unlock buttons on the vehicle's fascia. The driver can select

locking options, single point entry or drive away locking for example, from a menu available on the touch screen.

Central Locking – Radio Frequency Remote System

The radio frequency central locking system, provides locking and unlocking of the vehicle from inside and outside of the

vehicle. The system is operated using buttons on the Smart Key, which transmits radio frequency signals to the central locking

radio frequency receiver.

The system provides additional security by double-locking the doors from outside the vehicle if the lock button, on the Smart

Key, is pressed twice within 3 seconds; this function is not applicable in North American Specification (NAS) and Japanese

markets.

Additional buttons on the Smart Key provide for the convenience operation of the luggage compartment lid release, headlamp

delay and panic alarm functions. A global open or close feature is also available in certain markets using the lock/unlock

buttons.

Passive Entry

On vehicles fitted with the optional passive entry system, the vehicle can be unlocked without the use of a key blade or

pressing buttons on the Smart Key. The Smart Key operates the passive entry system in addition to the passive start system.

Refer to: Anti-Theft - Passive (419-01B Anti-Theft - Passive, Description and Operation).

The passive entry system is controlled by the keyless vehicle module and five low frequency antennas. One antenna located in

each door handle and one antenna located behind the rear bumper cover.

When a vehicle door handle is pulled to the first five-percent of its travel and the Smart Key is within one meter of the handle;

the Smart Key receives the low-frequency signal transmitted from the keyless vehicle module. The Smart Key responds with a

radio frequency transmission of its authorization code. The radio frequency signal is received by the central locking radio-

frequency receiver and passed to the keyless vehicle module which checks and approves the code as valid. Once the handle is

Page 2494 of 3039

door modules.

Locking of the vehicle is performed by pressing one of the buttons located on each exterior door handle, with the Smart Key

within a one meter range of the vehicle. When the door handle button is pressed, the keyless vehicle module transmits a

low-frequency signal via the low-frequency handle antenna to the Smart Key. The Smart Key transmits a radio frequency signal

which is verified by the keyless vehicle module and allows the doors to be locked or double locked and the alarm system to be

armed.

To double lock the vehicle, the button on the exterior door handle must be pressed twice within three seconds, with the Smart

Key within one meter range of the vehicle.

If a door, engine-compartment lid or the luggage compartment lid is ajar when an attempt to lock the vehicle is made, an error

tone is emitted and no locking action will occur.

Refer to: Anti-Theft - Active (419-01A Anti-Theft - Active, Description and Operation).

Engine Compartment Lid Latches Component Description

Two engine-compartment lid latches are located on the front crossmember. An engine-compartment lid release lever is located

below the instrument panel on the left-hand 'A' pillar and is connected with a cable to the latches. An engine-compartment lid

ajar switch is integrated in the engine-compartment lid latch.

Door Latches

The door latches are located at the rear of each door and engage with a striker on the adjacent pillar. Each door latch motor

assembly contains micro-switches for lock, unlock and door ajar. Motors provide for the central door locking and the double

locking feature. The electrical control for the door latch components is provided by the CJB and RJB via the driver's and

passenger door modules.

The interior door handles are connected by a cable to the latch release mechanisms. The interior door handles also incorporate

a locking facility to allow the doors to be locked from inside the vehicle when all the doors are closed. If a door is ajar the

locking feature is inhibited.

Luggage Compartment Lid Latch

The luggage compartment latch is attached to the bottom of the lid. The latch can be released electrically by pressing the

interior release button located on the outboard side of driver's lower knee bolster; a release button is also provided on the

Smart Key. There is also a release switch on the underside of the luggage compartment lid finisher.

On NAS vehicles an emergency release cable is attached to the latch. This allows the latch to be manually opened by pulling a

handle located in the luggage compartment lid interior trim.

Fuel Filler Door

The fuel filler door is electrically locked by a motor located on the fuel door housing. The fuel door is locked when the vehicle

is locked and alarmed. The fuel door can be opened when the vehicle is unlocked or locked:

via an interior handle,

via drive-a-way locking,

via the lock switch on the fascia,

via the external door key barrel. www.JagDocs.com

Page 2495 of 3039

Published: 18-Mar-2014

Handles, Locks, Latches and Entry Systems - Locks, Latches and Entry Systems

Diagnosis and Testing

Principle of Operation

For a detailed description of the locks, latches and entry systems and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to: Handles, Locks, Latches and Entry Systems (501-14, Description and

Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

1. Verify the customer concern, to be sure the correct issue is investigated

2. Visually inspect for obvious signs of damage and system integrity

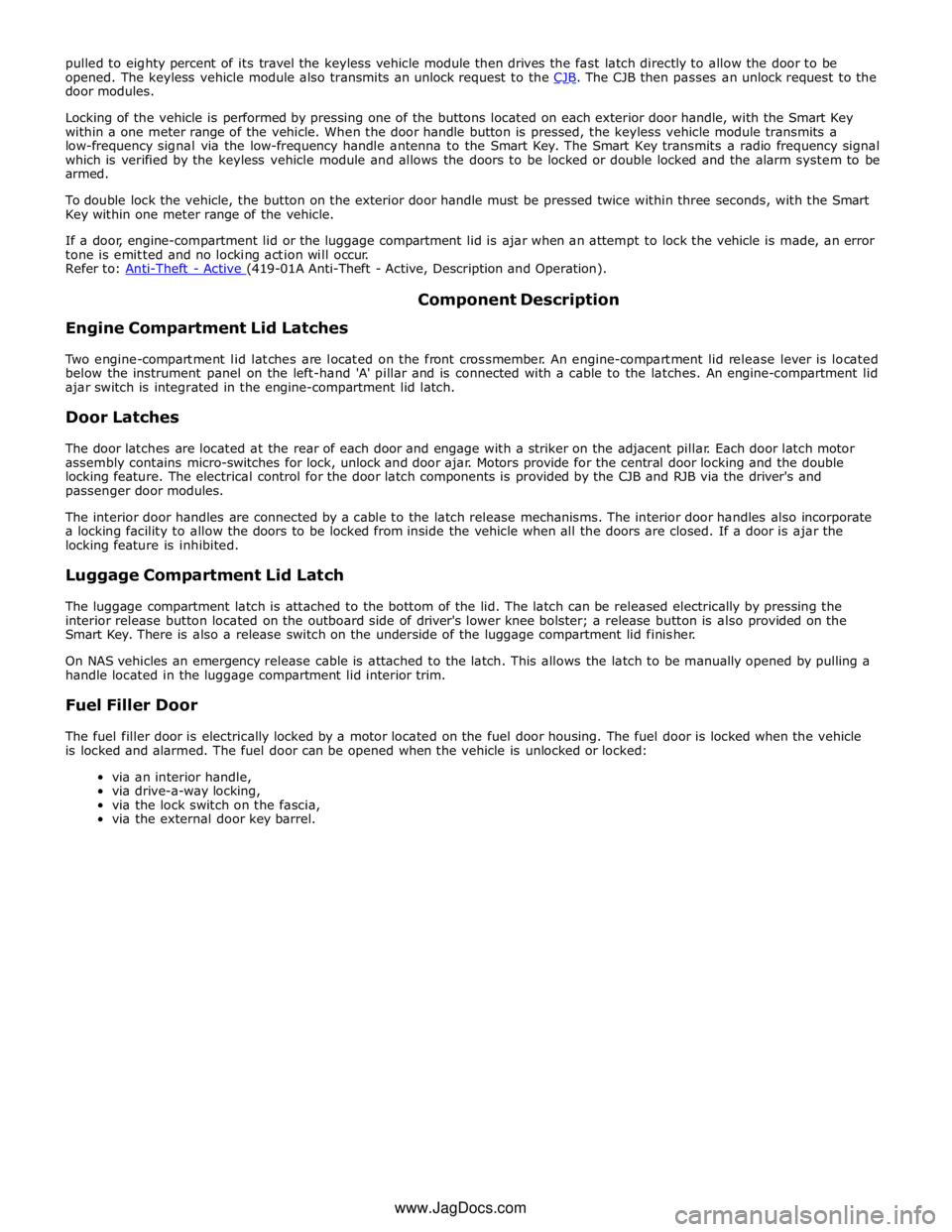

Visual Inspection

Mechanical Electrical

Incorrectly aligned door(s), hood or tailgate

Fuel filler door lock actuator

Hood release handle

Hood release cables

Hood latch(es)

Exterior door handle(s)

Interior door handle(s)

Cable(s)

Tailgate release switch

Rear window release switch

Fuses

Wiring harness

Wiring connector(s)

Door lock actuator(s)

Remote transmitter (key-fob or smart key)

Central locking switches

Controller Area Network (CAN) circuits

Radio frequency (RF) receiver

Central junction box (CJB)

Loose or corroded connections

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

Symptom Chart

NOTE: Complete the diagnostic steps below to confirm any concern prior to replacing any component

Symptom Possible Causes Action The message center indicates that the

hood, the luggage compartment is

open when it appears to be closed

Incorrect striker

alignment/adjustment

Ajar switch circuit short circuit to

ground

Ajar switch failure

Check/adjust the strikers as

necessary

Check for DTCs indicating an ajar

switch fault. Refer to the DTC index Vehicle indicates a miss-lock when the

hood, luggage compartment appear to

be closed Fuel flap does not lock/unlock

Fuel flap cable detached from body

Fuel flap actuator detached from

mounting bracket

Fuel flap actuator disconnected

Fuel flap actuator failure

Check the condition and installation

of the fuel flap cable

Check the security of the fuel flap

actuator and bracket

Check the security of the actuator

electrical connector

Check for DTCs indicating a fuel flap

actuator fault. Refer to the DTC

index Door(s) will not unlatch/open when

using outside door handle

Exterior door handle

condition/installation

Exterior release cable disconnected

from exterior door handle or door

latch

Check the exterior door handle

condition and installation

Check the condition and security of

the exterior release cable

Single door will not open from the

Page 2505 of 3039

Body wiring harness / connectors

Door wiring harness / connectors

Alarm control module

Central junction box (CJB)

Door Latch ajar switch

To investigate the functioning of the door ajar switch contained within the door latch, to prove or eliminate the door

latch mounted door ajar switch as the root cause, follow the process below. This will prevent the unnecessary replacement of

a correctly functioning door latch 1 Remove door trim from door 2 Disconnect door harness from latch for access to connector pins for latch electrical testing 3 Inspect latch module for any visual damage NOTES:

Figure 1 - Unlatched position shown

Figure 2 - First safety latched position shown

Figure 3 - Fully latched position shown

Test will not work if latch is only in first safety latch position 4 Using a small screw driver or similar, rotate latch claw to the second fully latched position (figure 3)

5 Carry out continuity test between terminals 1 and 4 (left side) or 8 and 4 (right side) with claw closed Does the continuity test pass? Yes

The latch ajar switch is working correctly. Do not replace latch.

Investigate for fault elsewhere in vehicle system

Page 2543 of 3039

Wipers and Washers - Wipers and Washers

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the wipers and washers, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: (501-16 Wipers and Washers)

Wipers and Washers (Description and Operation), Wipers and Washers (Description and Operation), Wipers and Washers (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

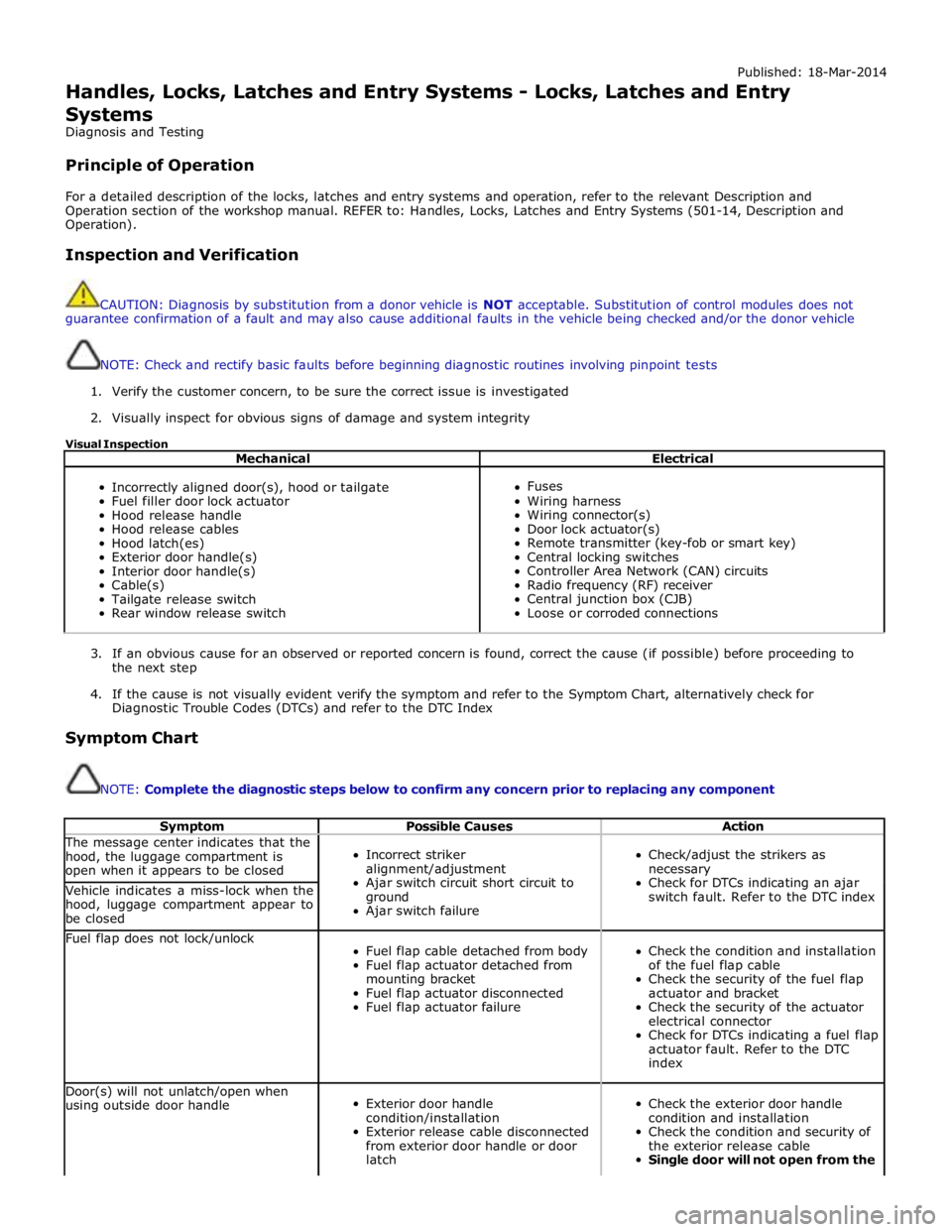

Visual Inspection

Mechanical Electrical

Wiper blade(s)

Wiper pivot arm shaft

Washer reservoir

Hose(s)

Washer jet(s)

Fuse(s)

Wiring harness

Electrical connector(s)

Washer pump(s)

Wiper motor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B109512

Wiper On/Off

Relay

Wiper On/Off relay control Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

Page 2559 of 3039

Published: 11-May-2011

Roof Opening Panel - Roof Opening Panel - Component Location

Description and Operation

Component Location

Item Description 1 CJB (central junction box) 2 Roof opening panel, rocker switch 3 Rear window sunblind, switch 4 Roof opening panel, motor 5 Roof opening panel, control module 6 Roof opening panel 7 Rear window sunblind 8 Rear window sunblind, motor assembly 9 Drain tubes (4 off) 10 ABS (anti-lock brake system) module www.JagDocs.com

Page 2561 of 3039

Published: 11-May-2011

Roof Opening Panel - Roof Opening Panel - System Operation and

Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 Megafuse (250 A) 3 Rear window sunblind, switch 4 Rear window sunblind, motor 5 ABS (anti-lock brake system) module 6 Roof opening panel, control module 7 Roof opening panel, rocker switch 8 CJB (central junction box)

Page 2562 of 3039

Roof opening panel System Operation

Operation of the roof opening panel is controlled by the roof opening panel control module, which is integral with the motor.

The control module receives inputs from the CJB, which provides an 'open' or 'close' signal for remote handset operation, and

an 'enable' signal when the vehicle enters power mode 6.

The control module also receives a vehicle speed signal from the ABS module. The vehicle speed signal is used by the control

module to calibrate the anti-trap feature.

If the battery is disconnected, or the power supply is interrupted while the roof opening panel is in a partially open position,

the motor and control module will need to be calibrated to restore full functionality. To recalibrate:

1. Switch ignition on.

2. Press the front of the switch, so the roof opening panel is the tilt position, and then release the switch.

3. Press the front of the switch and hold for thirty seconds.

4. After thirty seconds the roof opening panel will begin to move. Keep the front of the switch pressed until the roof

opening panel has fully opened and then closed.

5. Once the open/close cycle has completed and the roof opening panel has stopped moving, release the switch.

6. The roof opening panel can now be operated as normal.

Drain hoses are connected to the front and rear corners of the roof opening panel frame. The drain hoses are located inside of

the cabin on the 'A' and 'D' post pillars to allow water, which has collected in the frame, to escape. One-way valves fitted to

the end of each drain hose, prevent the ingress of dirt and moisture.

Rear window sunblind

The powered rear window sunblind is operated through a switch in the roof console. Power to the sunblind motor is provided by

a pair of relays located in the CJB when the vehicle enters power mode 4. The sunblind motor is located beneath the rear parcel

shelf and is supplied as a sealed unit with the sunblind mechanism.

If the battery is disconnected or a replacement sunblind is fitted, the motor will require re-calibrating. To re-calibrate the

motor the sunblind should be powered through two-full cycles of movement.

Roof opening panel, motor Component Description

The roof opening panel motor has a worm drive which drives a gear in the cast housing attached to the end of the motor. The

gear has a small pinion gear attached to the outer part of its spindle. The pinion engages with two cables to form a rack and

pinion drive. Rotation of the motor turns the pinion which in turn drives the cables in the required direction.

The two cables are attached either side of the pinion. One end of each cable is attached to the guide; the opposite end of

each cable is held in position on the pinion by a metal insert in the frame. The cables run in channels, in the panel frame to

the guides. As the panel is closed the cables are pushed through channels in the front of the frame. The displaced cable is

guided into a further two channels in the frame, which protect the cable and prevent it from snagging. The cables

manufactured from rigid spring steel can pull as well as push the panel along the guides.

The motor contains a micro-switch and Hall effect sensor. Signals received from these components enable the control module

to calculate the exact position of the roof opening panel. The Hall effect sensor is also responsible for the operation of the

anti-trap function.

If the anti-trap feature is activated while the roof opening panel is closing, the panel is reversed for 200mm or as far as

possible. The Hall effect sensor, located in the motor, monitors the speed of the motor and if the speed decreases below a set

threshold, indicating an obstruction, the power feed to the motor is reversed so the panel goes back. In an emergency the

anti-trap function can be overridden by holding the switch in the closed position.

Roof opening panel, control module

The roof opening panel control module is integrated within the motor. The control module receives inputs from the CJB, which

provides an 'open' or 'close' signal for remote handset operation, and an 'enable' signal when the vehicle enters power mode 6.

The control module also contains the algorithm for the anti-trap system and receives a vehicle speed signal from the ABS

module. The vehicle speed signal is used by the control module to calibrate the anti-trap feature.