heater JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1712 of 3039

bus. Temperature control for the heater element is provided by the steering wheel heater control module which receives a

temperature feedback signal from a NTC (negative temperature coefficient) thermistor located within the steering wheel.

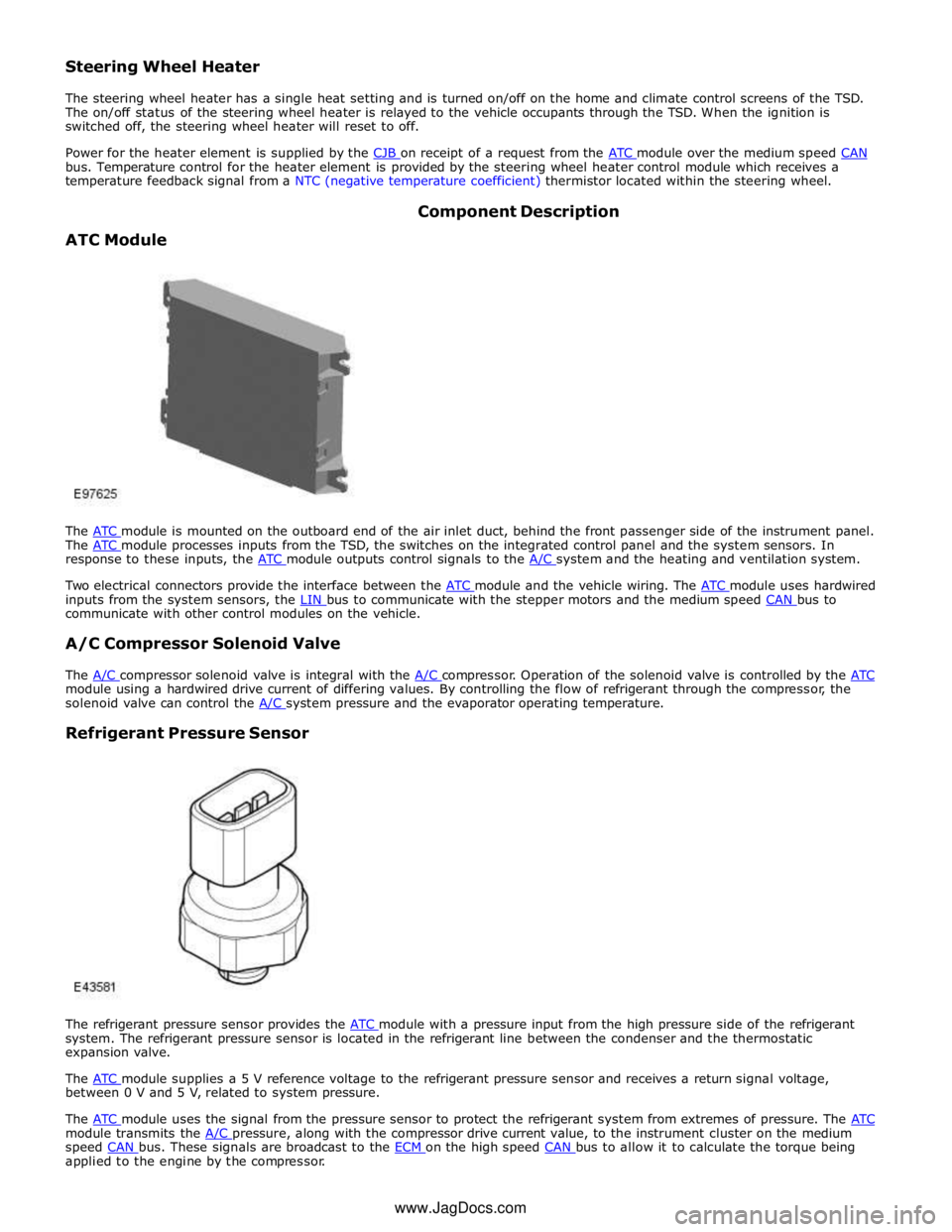

ATC Module Component Description

The ATC module is mounted on the outboard end of the air inlet duct, behind the front passenger side of the instrument panel. The ATC module processes inputs from the TSD, the switches on the integrated control panel and the system sensors. In response to these inputs, the ATC module outputs control signals to the A/C system and the heating and ventilation system.

Two electrical connectors provide the interface between the ATC module and the vehicle wiring. The ATC module uses hardwired inputs from the system sensors, the LIN bus to communicate with the stepper motors and the medium speed CAN bus to communicate with other control modules on the vehicle.

A/C Compressor Solenoid Valve

The A/C compressor solenoid valve is integral with the A/C compressor. Operation of the solenoid valve is controlled by the ATC module using a hardwired drive current of differing values. By controlling the flow of refrigerant through the compressor, the

solenoid valve can control the A/C system pressure and the evaporator operating temperature.

Refrigerant Pressure Sensor

The refrigerant pressure sensor provides the ATC module with a pressure input from the high pressure side of the refrigerant system. The refrigerant pressure sensor is located in the refrigerant line between the condenser and the thermostatic

expansion valve.

The ATC module supplies a 5 V reference voltage to the refrigerant pressure sensor and receives a return signal voltage, between 0 V and 5 V, related to system pressure.

The ATC module uses the signal from the pressure sensor to protect the refrigerant system from extremes of pressure. The ATC module transmits the A/C pressure, along with the compressor drive current value, to the instrument cluster on the medium speed CAN bus. These signals are broadcast to the ECM on the high speed CAN bus to allow it to calculate the torque being applied to the engine by the compressor. www.JagDocs.com

Page 1733 of 3039

Climate Control - Evaporator

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

All vehicles Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Heater Core and Evaporator Core Housing (412-01 Climate Control, Removal and Installation).

3. Refer to: Thermostatic Expansion Valve (412-01 Climate Control, Removal and Installation).

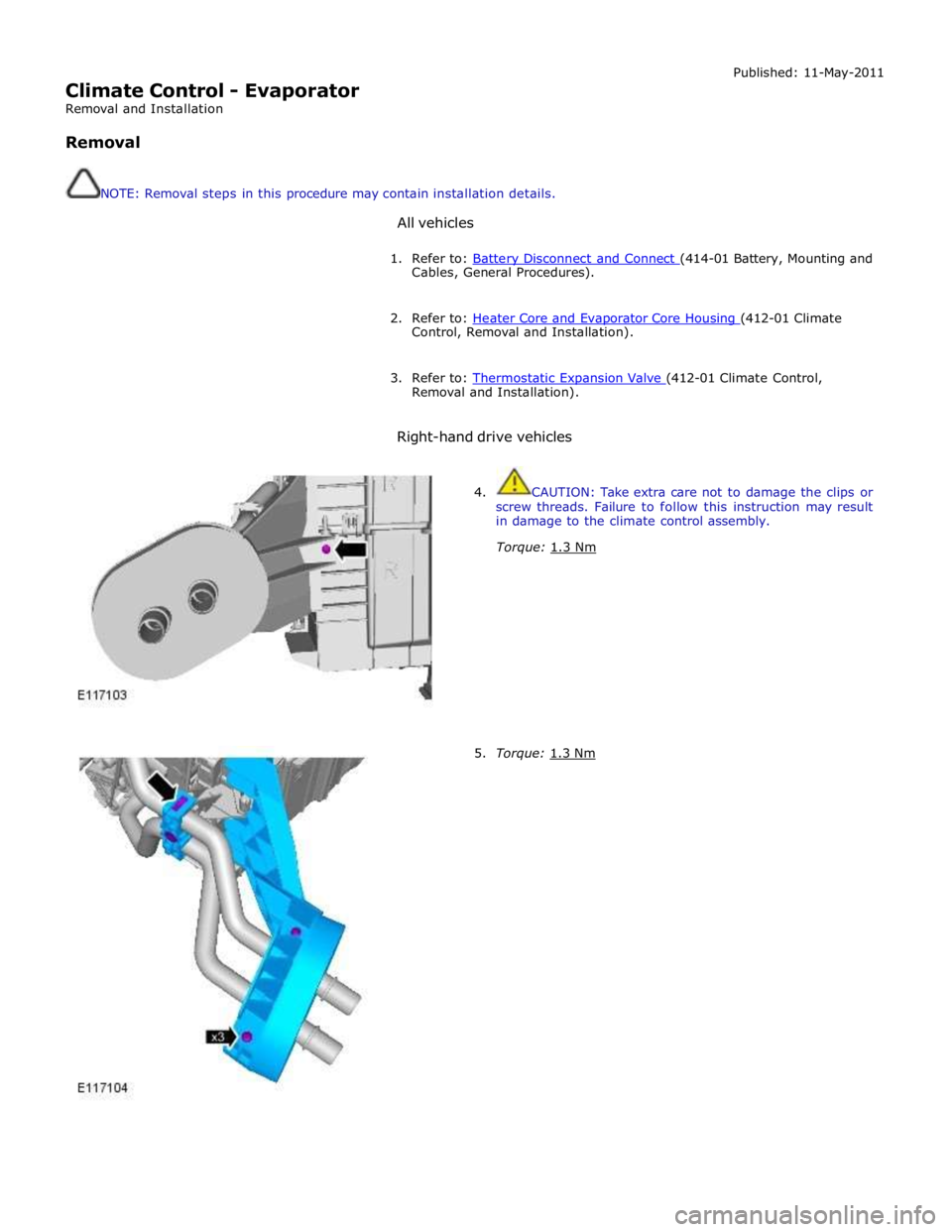

Right-hand drive vehicles

4. CAUTION: Take extra care not to damage the clips or

screw threads. Failure to follow this instruction may result

in damage to the climate control assembly.

Torque: 1.3 Nm

5. Torque: 1.3 Nm

Page 1740 of 3039

Climate Control - Heater Core

Removal and Installation

Removal

NOTES:

Removal steps in this procedure may contain installation details.

Some variation in the illustrations may occur, but the essential information is always correct.

All vehicles Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Heater Core and Evaporator Core Housing (412-01 Climate Control, Removal and Installation).

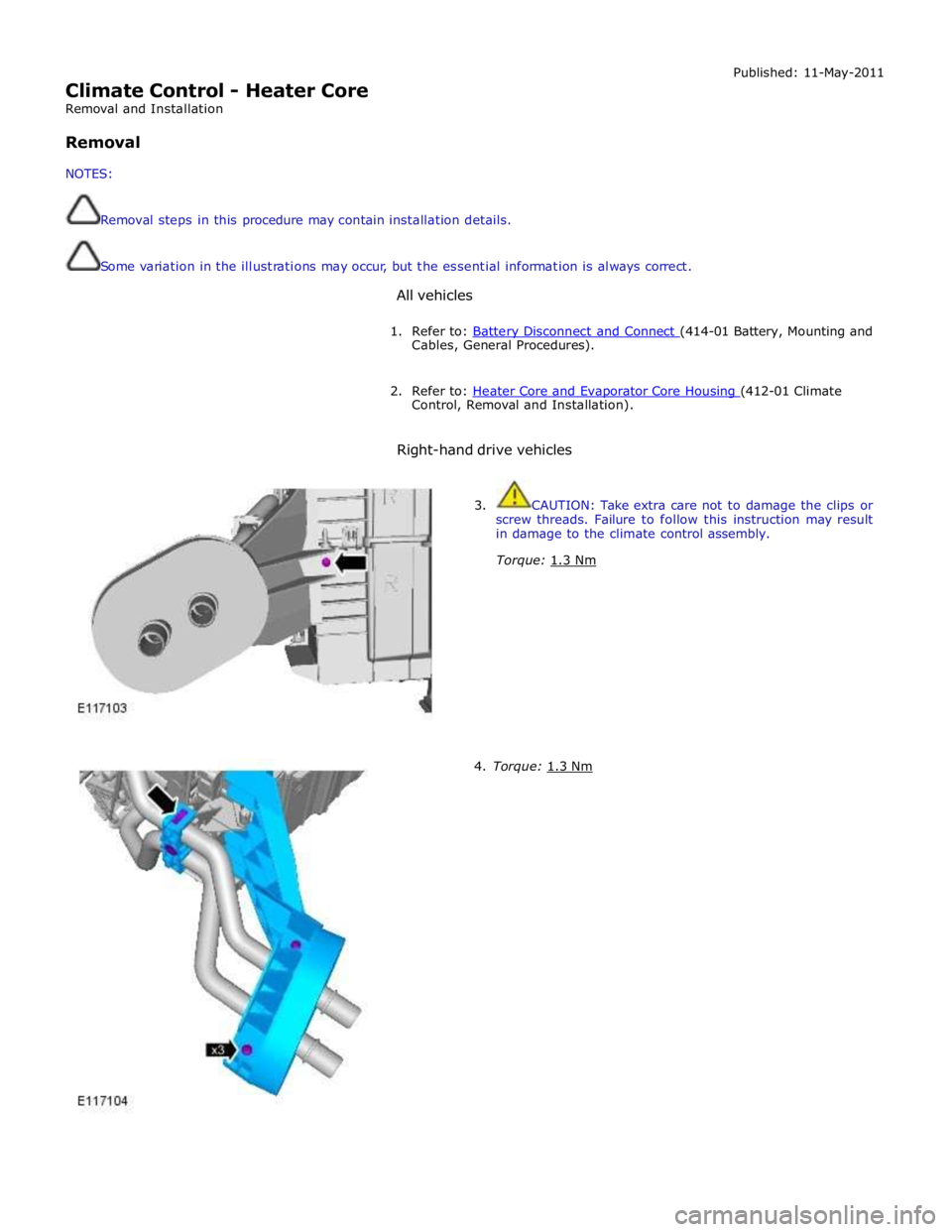

Right-hand drive vehicles

3. CAUTION: Take extra care not to damage the clips or

screw threads. Failure to follow this instruction may result

in damage to the climate control assembly.

Torque: 1.3 Nm

4. Torque: 1.3 Nm

Page 1743 of 3039

Climate Control - Heater Core and Evaporator Core Housing

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Climate Control Assembly (412-01 Climate Control, Removal and Installation).

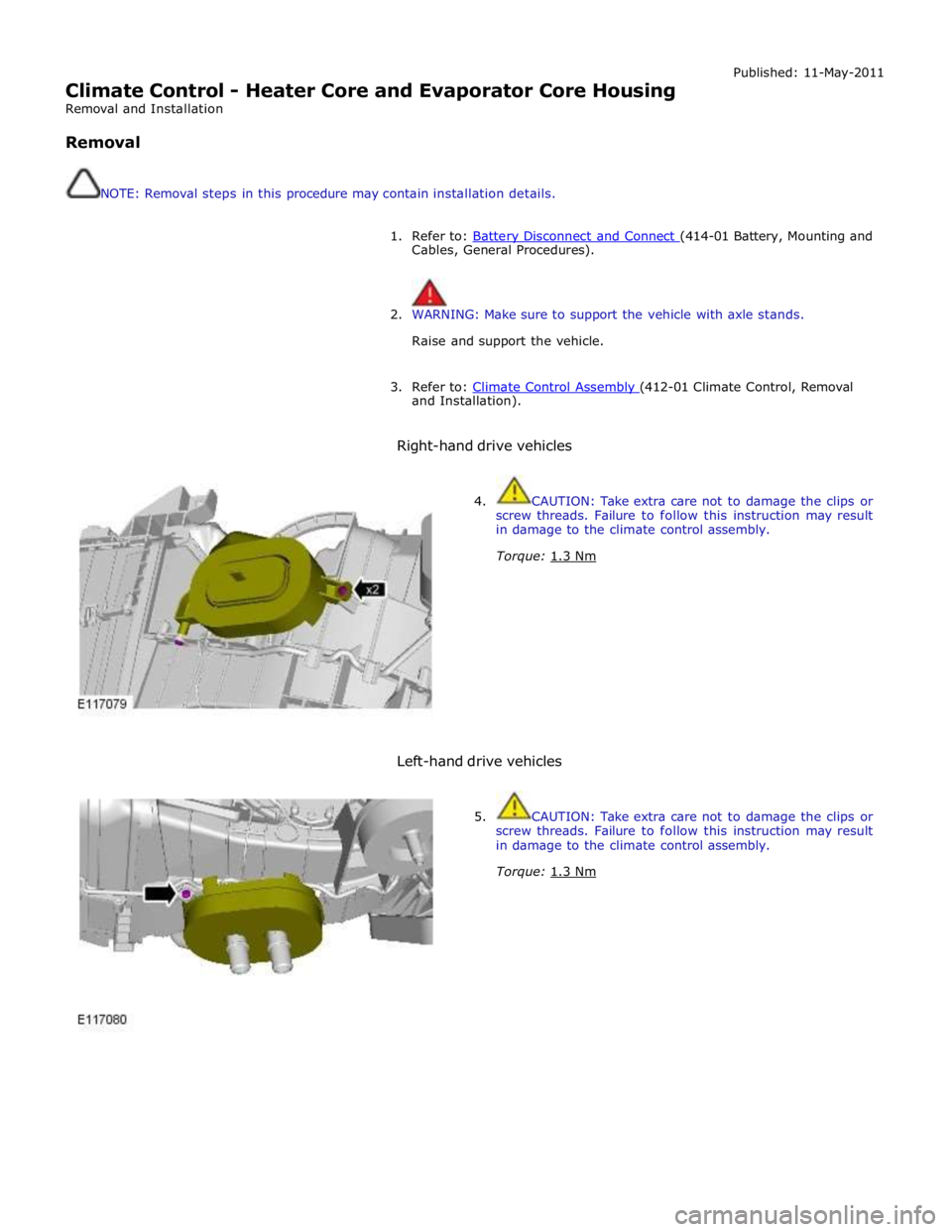

Right-hand drive vehicles

4. CAUTION: Take extra care not to damage the clips or

screw threads. Failure to follow this instruction may result

in damage to the climate control assembly.

Torque: 1.3 Nm

Left-hand drive vehicles

5. CAUTION: Take extra care not to damage the clips or

screw threads. Failure to follow this instruction may result

in damage to the climate control assembly.

Torque: 1.3 Nm

Page 1764 of 3039

Electric booster heater retaining screws 1.3 - 11

Page 1765 of 3039

Published: 11-May-2011

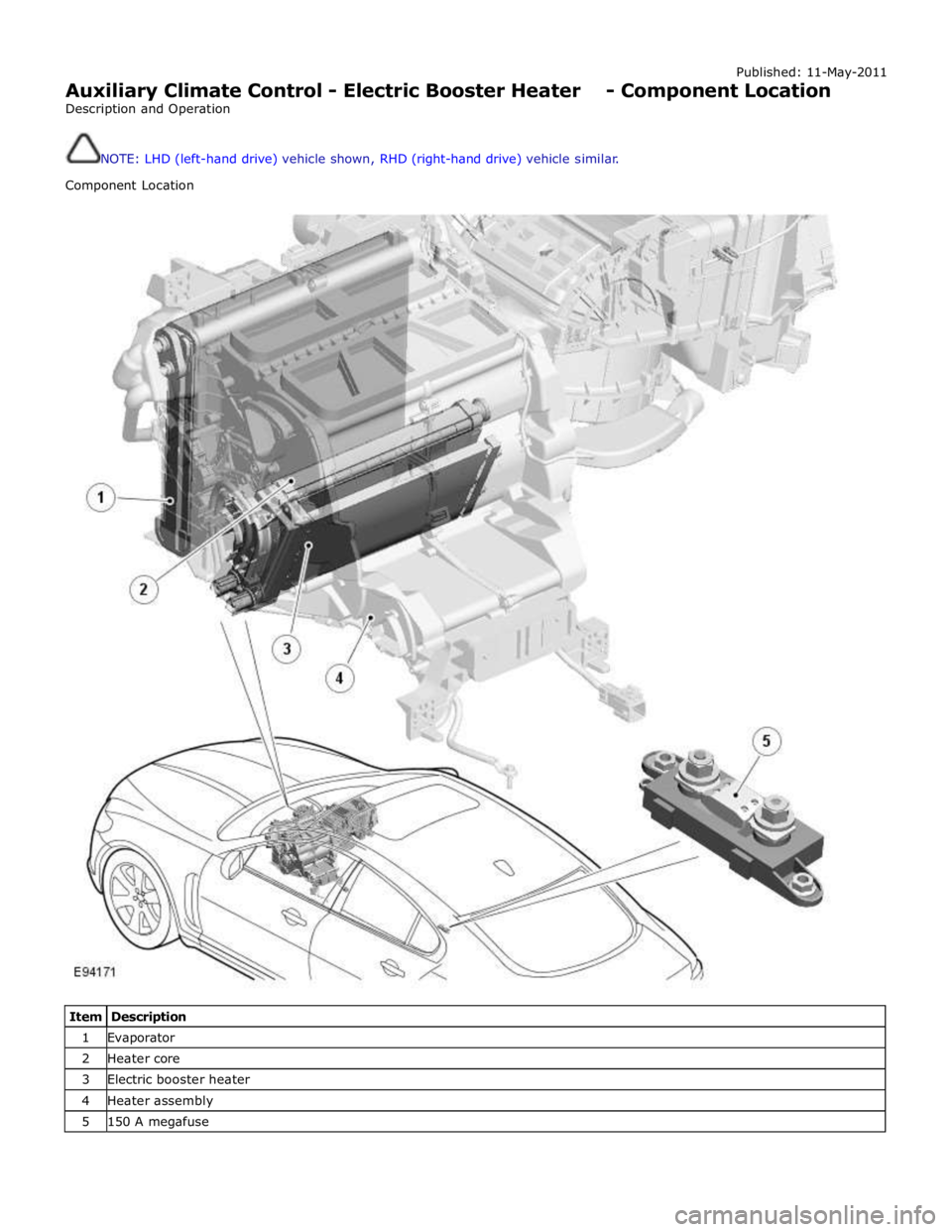

Auxiliary Climate Control - Electric Booster Heater - Component Location

Description and Operation

NOTE: LHD (left-hand drive) vehicle shown, RHD (right-hand drive) vehicle similar.

Component Location

Item Description 1 Evaporator 2 Heater core 3 Electric booster heater 4 Heater assembly 5 150 A megafuse

Page 1766 of 3039

Published: 11-May-2011

Auxiliary Climate Control - Electric Booster Heater - System Operation and

Component Description

Description and Operation

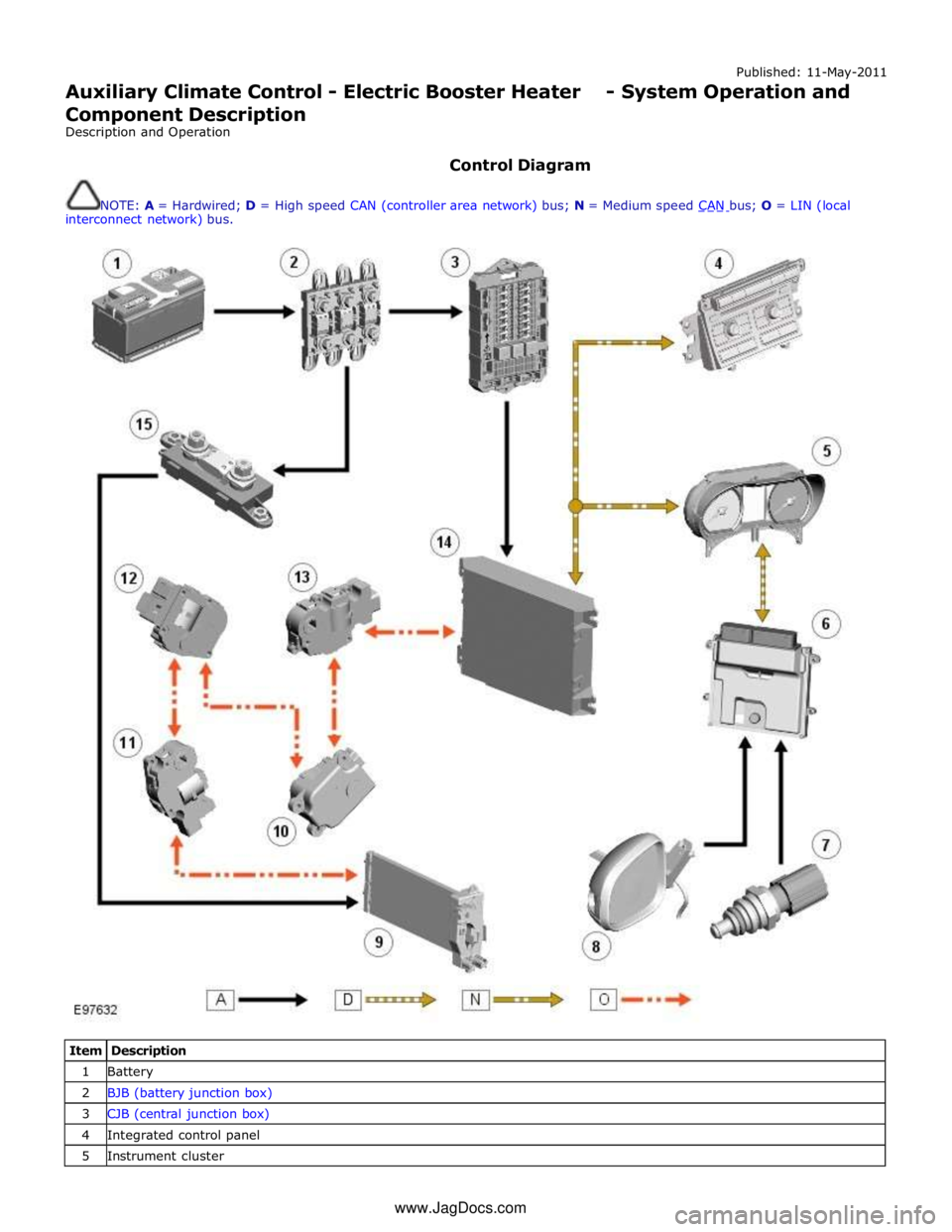

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus; N = Medium speed CAN bus; O = LIN (local interconnect network) bus.

Item Description 1 Battery 2 BJB (battery junction box) 3 CJB (central junction box) 4 Integrated control panel 5 Instrument cluster www.JagDocs.com

Page 1767 of 3039

7 ECT (engine coolant temperature) sensor 8 Ambient temperature sensor 9 Electric booster heater 10 Face/Feet distribution stepper motor 11 RH (right-hand) temperature blend stepper motor 12 LH (left-hand) temperature blend stepper motor 13 Windshield (defrost) distribution stepper motor 14 ATC (automatic temperature control) module 15 150 A megafuse

General System Operation

Operation of the electric booster heater is controlled by the ATC module, which communicates with the micro-controller in the booster heater using the LIN bus. The temperature requested by the ATC module is based on:

The ambient air temperature.

The engine coolant temperature.

The temperatures selected on the integrated control panel.

The blower must be running for the electric booster heater to operate.

If electrical load management is in force, electric booster heater performance is reduced. For additional information, refer to:

Electronic Engine Controls (303-14A, Description and Operation),

Electronic Engine Controls (303-14B Electronic Engine Controls - V6 3.0L Petrol, Description and Operation), Electronic Engine Controls (303-14C, Description and Operation).

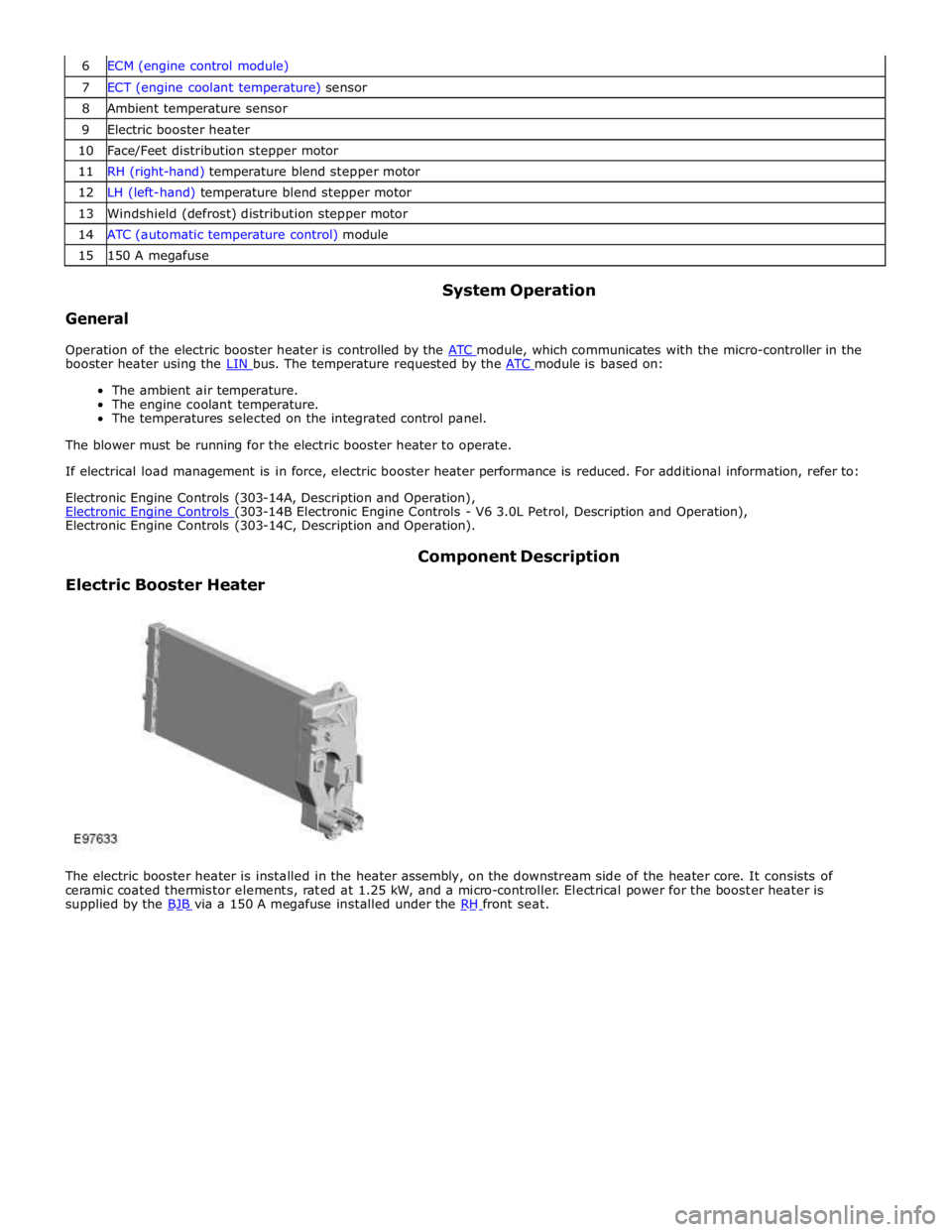

Electric Booster Heater Component Description

The electric booster heater is installed in the heater assembly, on the downstream side of the heater core. It consists of

ceramic coated thermistor elements, rated at 1.25 kW, and a micro-controller. Electrical power for the booster heater is

supplied by the BJB via a 150 A megafuse installed under the RH front seat.

Page 1772 of 3039

Auxiliary Climate Control - Electric Booster Heater

Removal and Installation

Removal

NOTES:

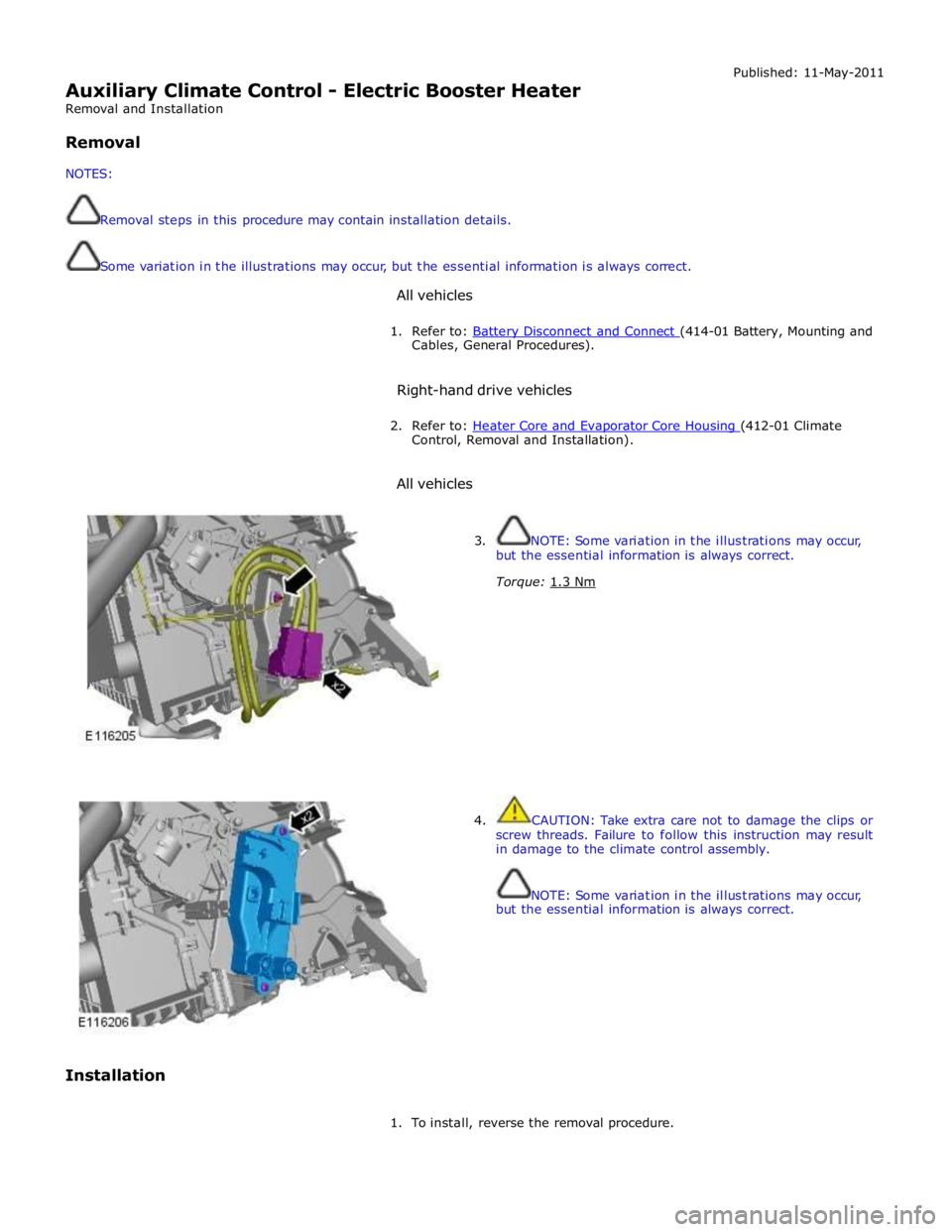

Removal steps in this procedure may contain installation details.

Some variation in the illustrations may occur, but the essential information is always correct.

All vehicles Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

Right-hand drive vehicles

2. Refer to: Heater Core and Evaporator Core Housing (412-01 Climate Control, Removal and Installation).

All vehicles

Installation

3. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Torque: 1.3 Nm

4. CAUTION: Take extra care not to damage the clips or

screw threads. Failure to follow this instruction may result

in damage to the climate control assembly.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

1. To install, reverse the removal procedure.

Page 2070 of 3039

O = LIN bus 1 ATC (automatic temperature control) module 2 Stepper motor - Windshield defrost 3 Stepper motor - Face/feet distribution 4 Stepper motor - LH (left-hand) temperature blend 5 Stepper motor - RH (right-hand) temperature blend 6 Electric booster heater 7 Stepper motor - RH outer face level vent 8 Stepper motor - RH inner face level vent 9 Stepper motor - LH inner face level vent 10 Stepper motor - LH outer face level vent CONTROL DIAGRAM - LIN BUS - SHEET 2 OF 2

www.JagDocs.com