Supercharger JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1270 of 3039

Firing order 1:2:7:3:4:5:6:8 Spark plug type - Vehicles with supercharger ILKAR6C-10 Spark plug type - Vehicles without supercharger ILKAR6C-10

Description Nm lb-ft lb-in Spark plugs 20 15 - Ignition coil-on-plug retaining bolts 7 5 -

Page 1278 of 3039

Published: 11-May-2011

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Ignition Coil-On-Plug V8 S/C 5.0L Petrol

Removal and Installation

Removal

NOTES:

Removal steps in this procedure may contain installation details.

Some variation in the illustrations may occur, but the essential information is always correct.

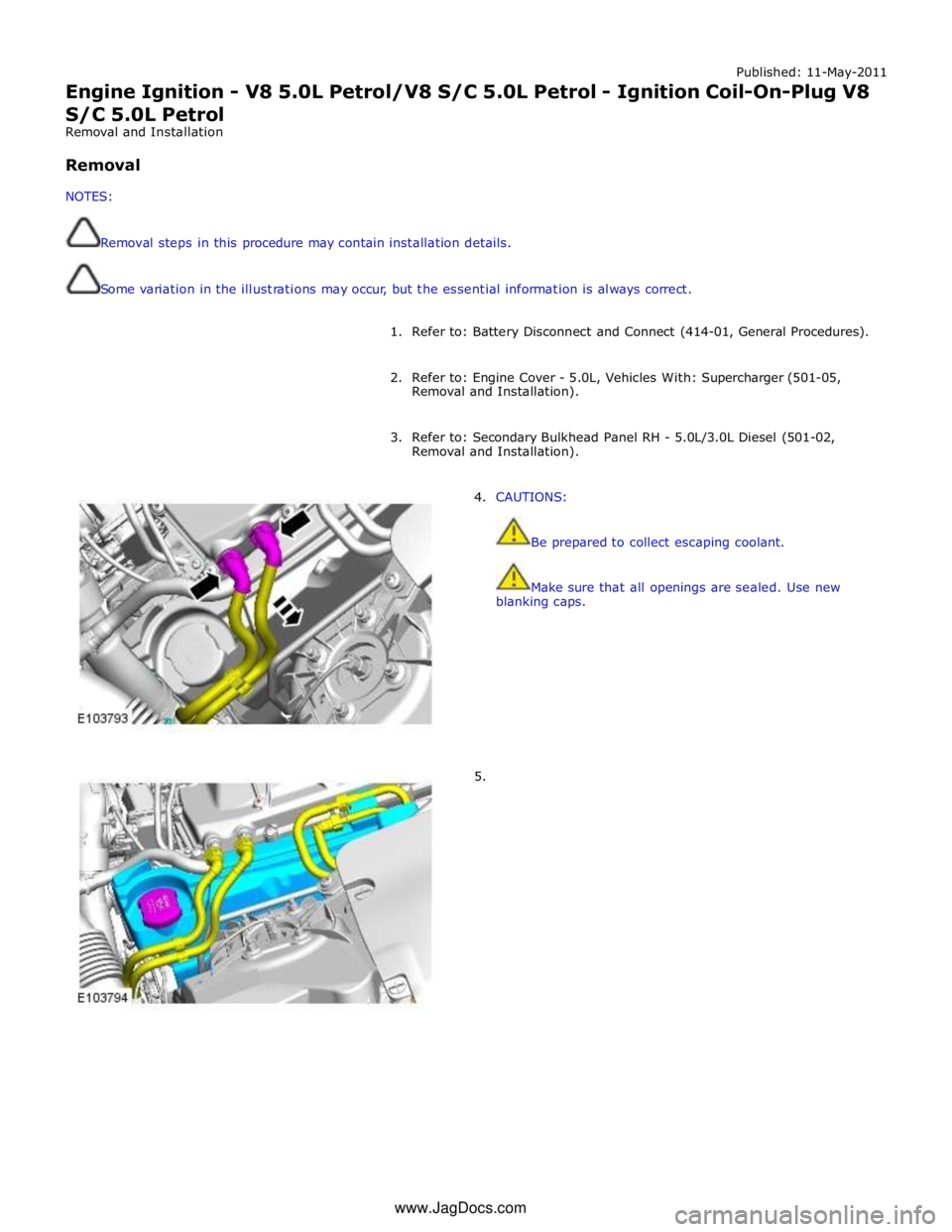

1. Refer to: Battery Disconnect and Connect (414-01, General Procedures).

2. Refer to: Engine Cover - 5.0L, Vehicles With: Supercharger (501-05,

Removal and Installation).

3. Refer to: Secondary Bulkhead Panel RH - 5.0L/3.0L Diesel (501-02,

Removal and Installation).

4. CAUTIONS:

Be prepared to collect escaping coolant.

Make sure that all openings are sealed. Use new

blanking caps.

5. www.JagDocs.com

Page 1280 of 3039

Published: 11-May-2011

Engine Emission Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Emission Control - Component Location

Description and Operation

www.JagDocs.com ItemDescription1Partloadbreather2FullloadbreatherCOMPONENTLOCATION-SUPERCHARGERVEHICLES

Page 1281 of 3039

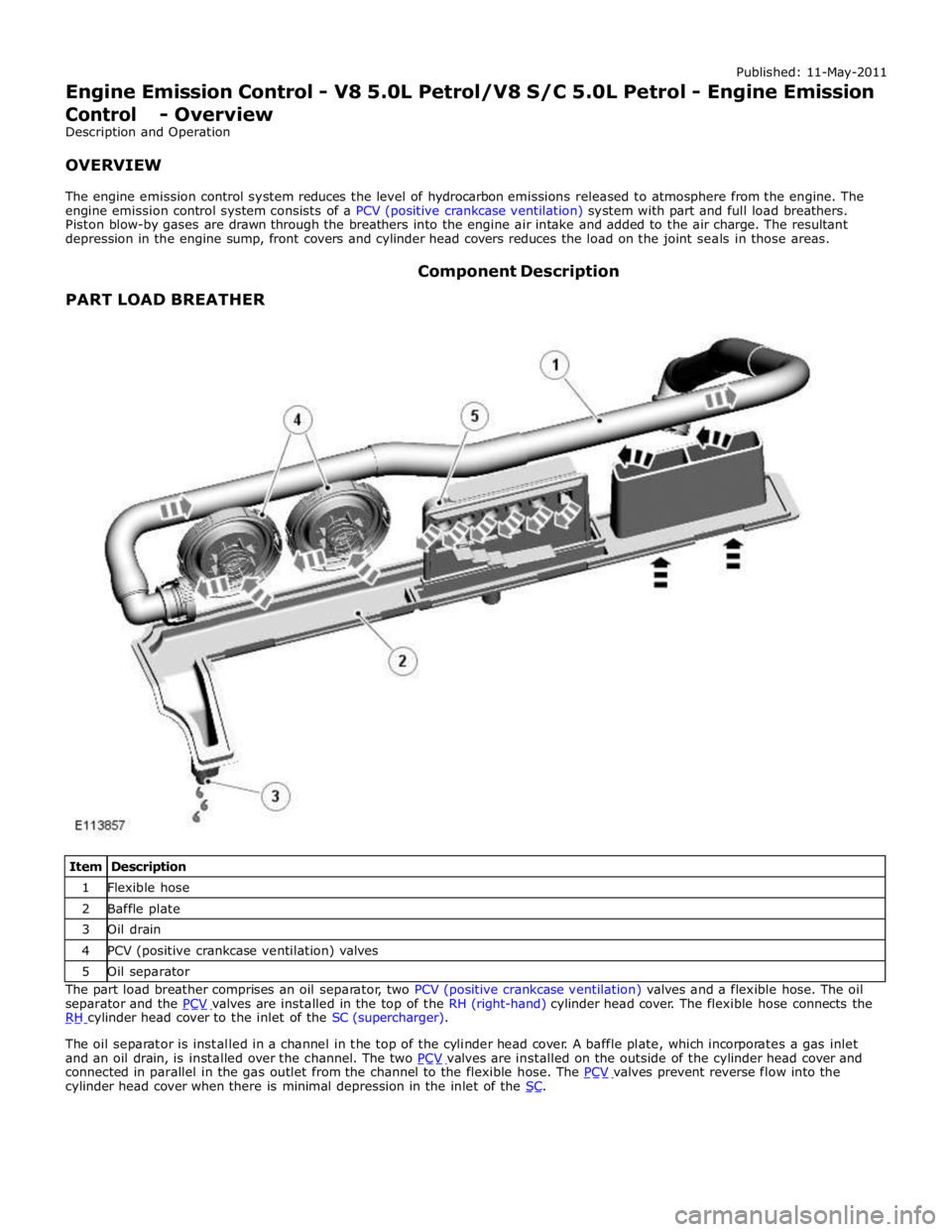

PARTLOADBREATHERComponentDescription

ItemDescription1Flexiblehose2Baffleplate3Oildrain4PCV(positivecrankcaseventilation)valves5OilseparatorThepartloadbreathercomprisesan oilseparator,twoPCV(positivecrankcaseventilation) valvesand aflexiblehose.Theoil

separatorandthePCVvalvesareinstalledinthetopoftheRH(right-hand)cylinderhead cover.TheflexiblehoseconnectstheRHcylinderheadcovertotheinletoftheSC(supercharger).Theoilseparatorisinstalledinachannelin thetopofthecylinderheadcover.Abaffleplate,whichincorporatesagasinlet

andanoildrain,isinstalledoverthechannel.ThetwoPCVvalvesareinstalledontheoutsideofthecylinderheadcoverandconnectedinparallelinthegasoutletfromthechannelto theflexiblehose.ThePCVvalvespreventreverseflowintothecylinderheadcoverwhen thereisminimaldepressionintheinletoftheSC.

Page 1285 of 3039

Air cleaner retaining bolts 8 - 71 Supercharger retaining bolts 25 18 - Charge air cooler lower assembly retaining bolts 20 15 - Throttle body retaining studs 10 7 - Charge air cooler top assembly retaining bolts 25 18 - Manifold absolute pressure and temperature (MAPT) sensor 5 - 44 Coolant outlet pipe 11 8 -

Page 1286 of 3039

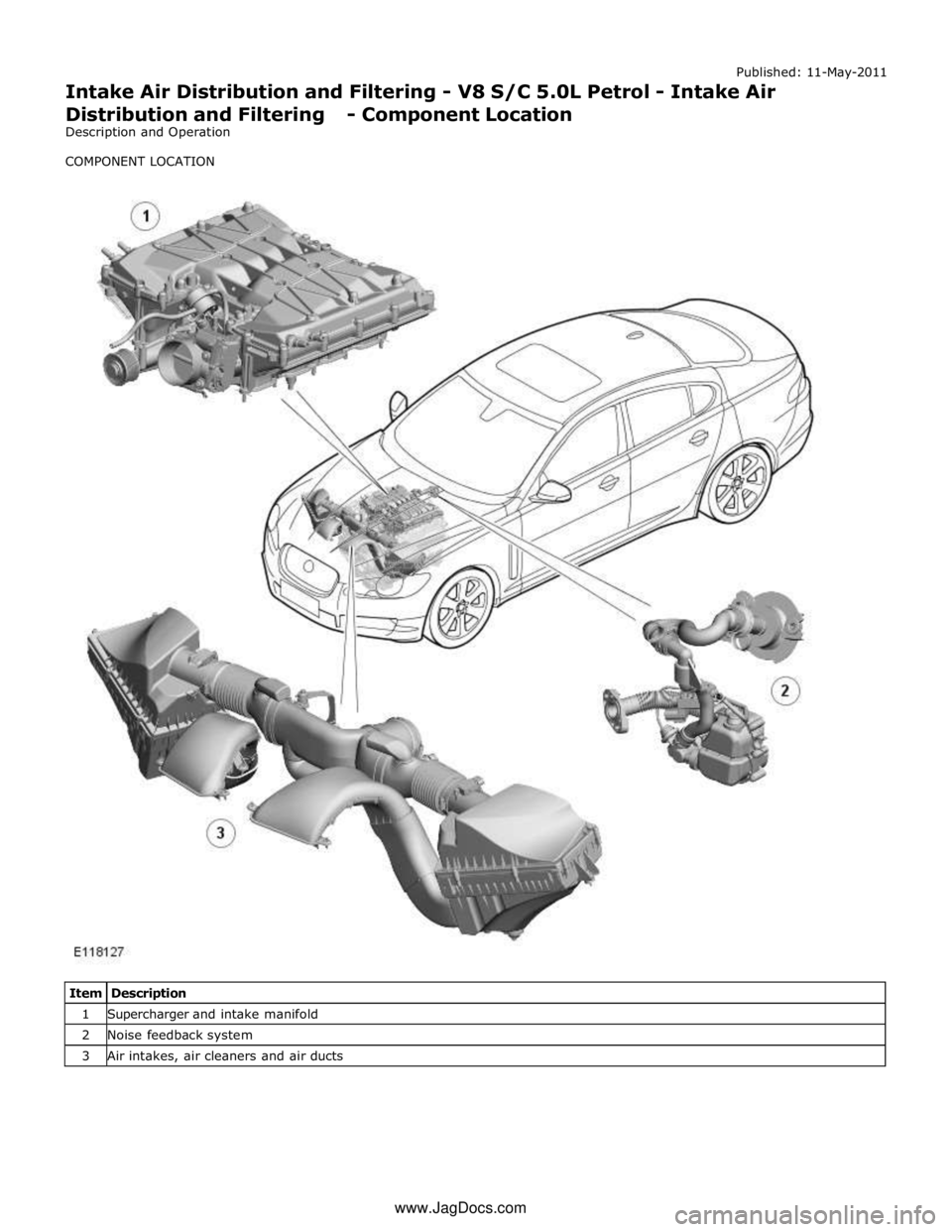

1 Supercharger and intake manifold 2 Noise feedback system 3 Air intakes, air cleaners and air ducts www.JagDocs.com

Page 1287 of 3039

Published: 11-May-2011

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Intake Air

Distribution and Filtering - Overview

Description and Operation

OVERVIEW

The intake air distribution and filtering system comprises:

Dual air intakes, air cleaners and air ducts.

A SC (supercharger) and intake manifolds.

A noise feedback system.

Page 1289 of 3039

SUPERCHARGER System Operation

At closed or partially open throttle positions, the bypass valve is fully open, allowing a flow of air from the SC (supercharger)

outlet back to the inlet side. This results in little or no pressure increase across the SC. Progressive opening of the throttle reduces the depression downstream of the electric throttle. This is sensed by the pneumatic actuator, which moves to close

the bypass valve. As the bypass valve closes there is a corresponding increase in the outlet pressure from the SC, which increases engine power output.

NOISE FEEDBACK SYSTEM

Sound waves from the RH (right-hand) intake manifold are filtered by the calibrated orifice in the inlet pipe connection on the

symposer. The sound waves make the paddle oscillate and generate pulsations in the outlet chambers. When the pneumatic

valve is open, the pulsations are transmitted through the outlet pipe and feedback tube to the resonator in the passenger

compartment.

The tuning valve of the noise feedback system receives a power feed from the power distribution box and is connected to

ground through the ECM (engine control module). At lower engine loads and speeds the ECM keeps the ground open circuit and the tuning valve is de-energized closed. Atmospheric pressure is sensed at the pneumatic valve through the vent cap on the

tuning valve, which keeps the pneumatic valve closed and prevents sound from the symposer entering the feedback system.

At higher engine loads and speeds the ECM connects the tuning valve to ground. The tuning valve energizes, blanks off the atmospheric vent and opens the vacuum line between the brake vacuum system and the pneumatic valve. The depression in

the brake vacuum system is sensed at the pneumatic valve, which opens and allows sound from the symposer into the

feedback system.

The status of the pneumatic valve at various engine loads and speeds is given below:

Pneumatic Valve Status

NOTE: Values are for valve opening with increasing engine load and speed. Deduct 0.05 g/rev and 50 rev/min for valve

closing with decreasing engine load and speed.

Engine Load: g/rev Engine Speed: rev/min 0 500 1000 2500 3000 4000 5800 6500 1.30 Closed Closed Closed Closed Closed Closed Closed Closed 1.35 Closed Closed Closed Closed Closed Closed Closed Closed 1.40 Closed Closed Closed Closed Closed Closed Closed Open 1.60 Closed Closed Closed Closed Closed Closed Closed Open 1.80 Closed Closed Closed Closed Closed Closed Closed Open 2.50 Closed Closed Closed Closed Closed Open Open Open 3.00 Closed Closed Closed Closed Closed Open Open Open 3.50 Closed Closed Closed Open Open Open Open Open

Page 1292 of 3039

9 Support 10 Inlet connection 11 Outlet connection 12 MAFT sensor The outlet tubes and T-piece duct direct the air from the air cleaners to the electric throttle. Hose clamps connect the outlet

tubes and T-piece duct together, and to the air cleaners and the electric throttle. A grommet and bracket attached the T-piece

duct to a bracket on the RH cylinder head. The two outlet tubes and the T-piece duct each incorporate a quarter wave resonator to reduce air induction noise.

The LH (left-hand) outlet tube incorporates a connector stub for the engine full load breather pipe.

The T-piece duct incorporates a connector stub for the vacuum tube of the bypass valve actuator on the supercharger.

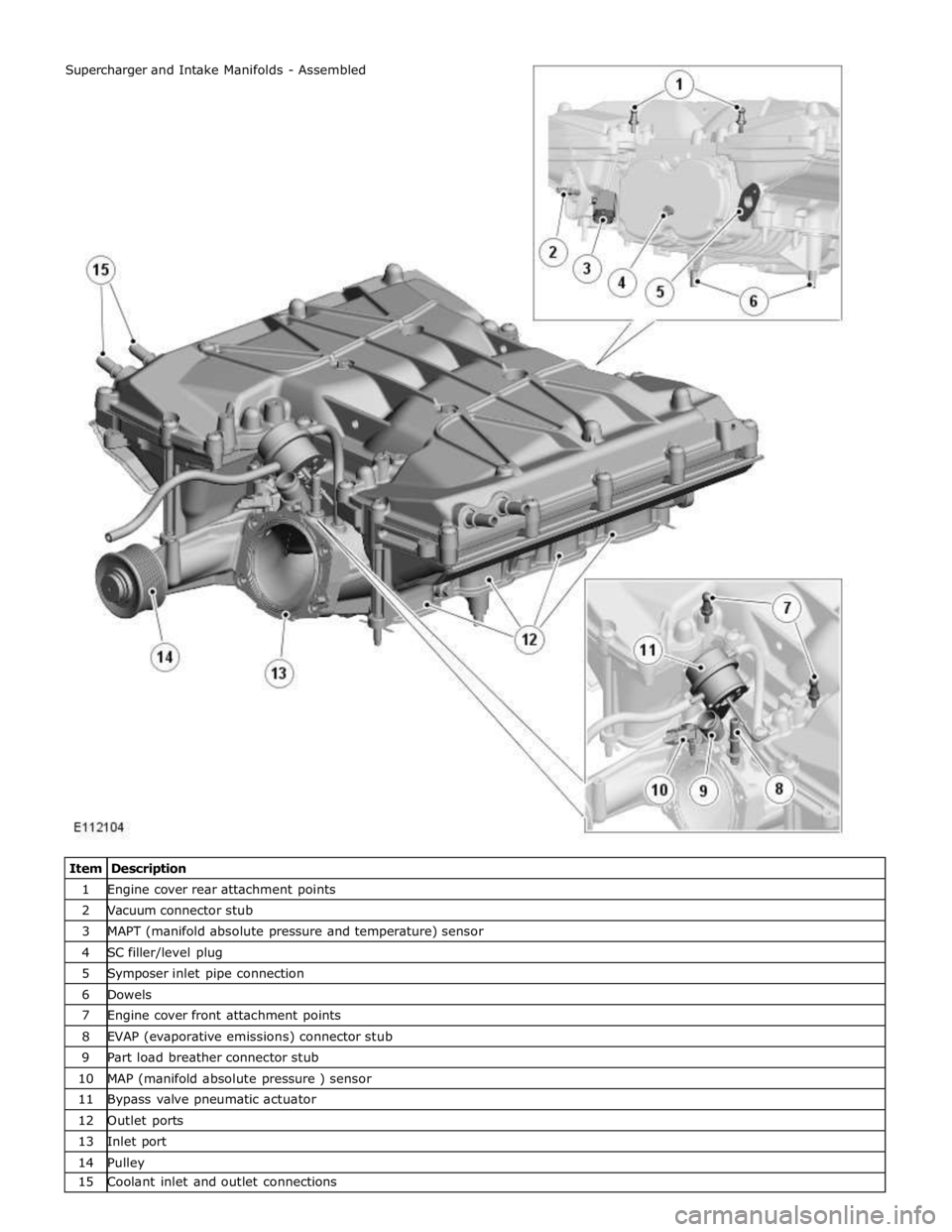

SUPERCHARGER AND INTAKE MANIFOLDS

The SC increases the pressure, and thus mass, of the air supplied to the engine, to increase the engine's power output. Two separate intake manifolds direct air from the SC to the cylinder inlet ports.

The intake manifolds are attached to their related cylinder heads and the sides of the SC. Two dowels locate the SC in position on the cylinder block. A charge air cooler tank top is installed on top of the SC and intake manifolds to form the air duct from the SC outlet to the intake manifolds. A charge air cooler is installed in each intake manifold.

The charge air cooler tank top incorporates four studs for the attachment of the engine cover. A NVH (noise, vibration and

harshness) pad is attached to the side of each intake manifold.

Page 1293 of 3039

1 Engine cover rear attachment points 2 Vacuum connector stub 3 MAPT (manifold absolute pressure and temperature) sensor 4 SC filler/level plug 5 Symposer inlet pipe connection 6 Dowels 7 Engine cover front attachment points 8 EVAP (evaporative emissions) connector stub 9 Part load breather connector stub 10 MAP (manifold absolute pressure ) sensor 11 Bypass valve pneumatic actuator 12 Outlet ports 13 Inlet port 14 Pulley 15 Coolant inlet and outlet connections Supercharger and Intake Manifolds - Assembled