Supercharger JAGUAR XFR 2010 1.G Manual Online

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1342 of 3039

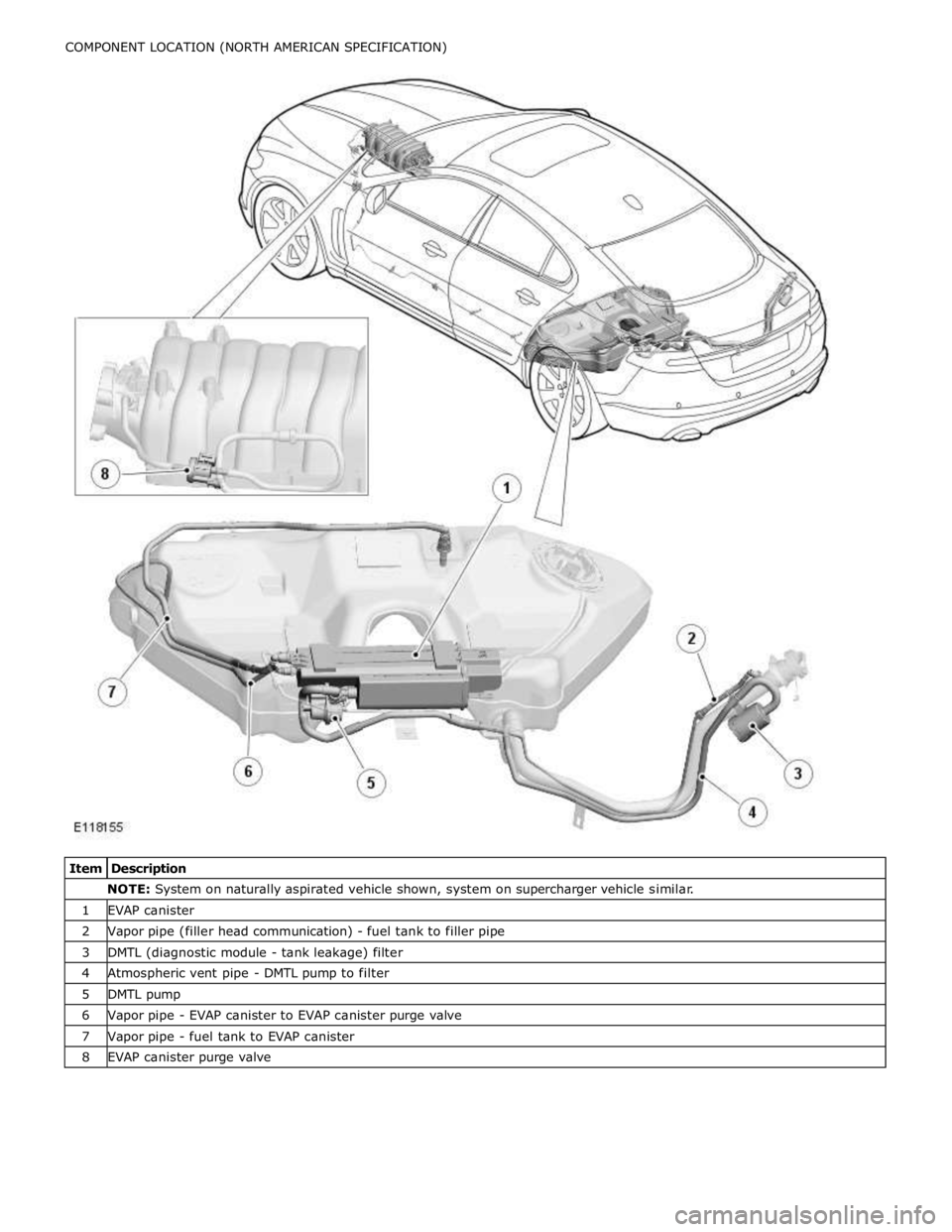

NOTE: System on naturally aspirated vehicle shown, system on supercharger vehicle similar. 1 EVAP canister 2 Vapor pipe (filler head communication) - fuel tank to filler pipe 3 DMTL (diagnostic module - tank leakage) filter 4 Atmospheric vent pipe - DMTL pump to filter 5 DMTL pump 6 Vapor pipe - EVAP canister to EVAP canister purge valve 7 Vapor pipe - fuel tank to EVAP canister 8 EVAP canister purge valve

Page 1348 of 3039

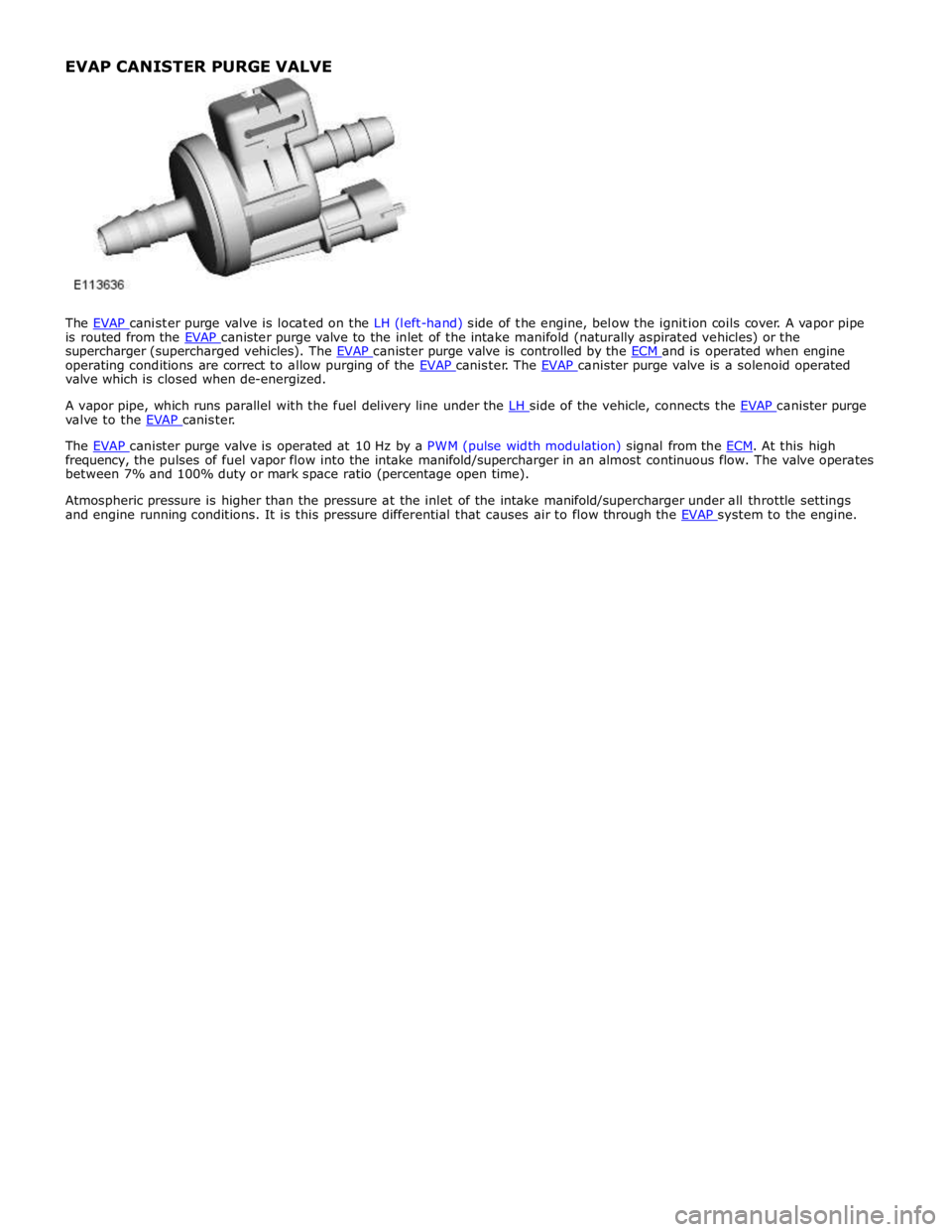

is routed from the EVAP canister purge valve to the inlet of the intake manifold (naturally aspirated vehicles) or the supercharger (supercharged vehicles). The EVAP canister purge valve is controlled by the ECM and is operated when engine operating conditions are correct to allow purging of the EVAP canister. The EVAP canister purge valve is a solenoid operated valve which is closed when de-energized.

A vapor pipe, which runs parallel with the fuel delivery line under the LH side of the vehicle, connects the EVAP canister purge valve to the EVAP canister.

The EVAP canister purge valve is operated at 10 Hz by a PWM (pulse width modulation) signal from the ECM. At this high frequency, the pulses of fuel vapor flow into the intake manifold/supercharger in an almost continuous flow. The valve operates

between 7% and 100% duty or mark space ratio (percentage open time).

Atmospheric pressure is higher than the pressure at the inlet of the intake manifold/supercharger under all throttle settings

and engine running conditions. It is this pressure differential that causes air to flow through the EVAP system to the engine. EVAP CANISTER PURGE VALVE

Page 1351 of 3039

Published: 11-May-2011

Evaporative Emissions - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Evaporative

Emission Canister Purge Valve V8 S/C 5.0L Petrol

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions (100-00 General Information, Description and Operation).

2. Refer to: Engine Cover - 5.0L, Vehicles With: Supercharger (501-05,

Removal and Installation).

3. Refer to: Secondary Bulkhead Panel LH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-02 Front End Body Panels, Removal and Installation).

4. CAUTION: Be prepared to collect escaping coolant.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

5. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Page 1364 of 3039

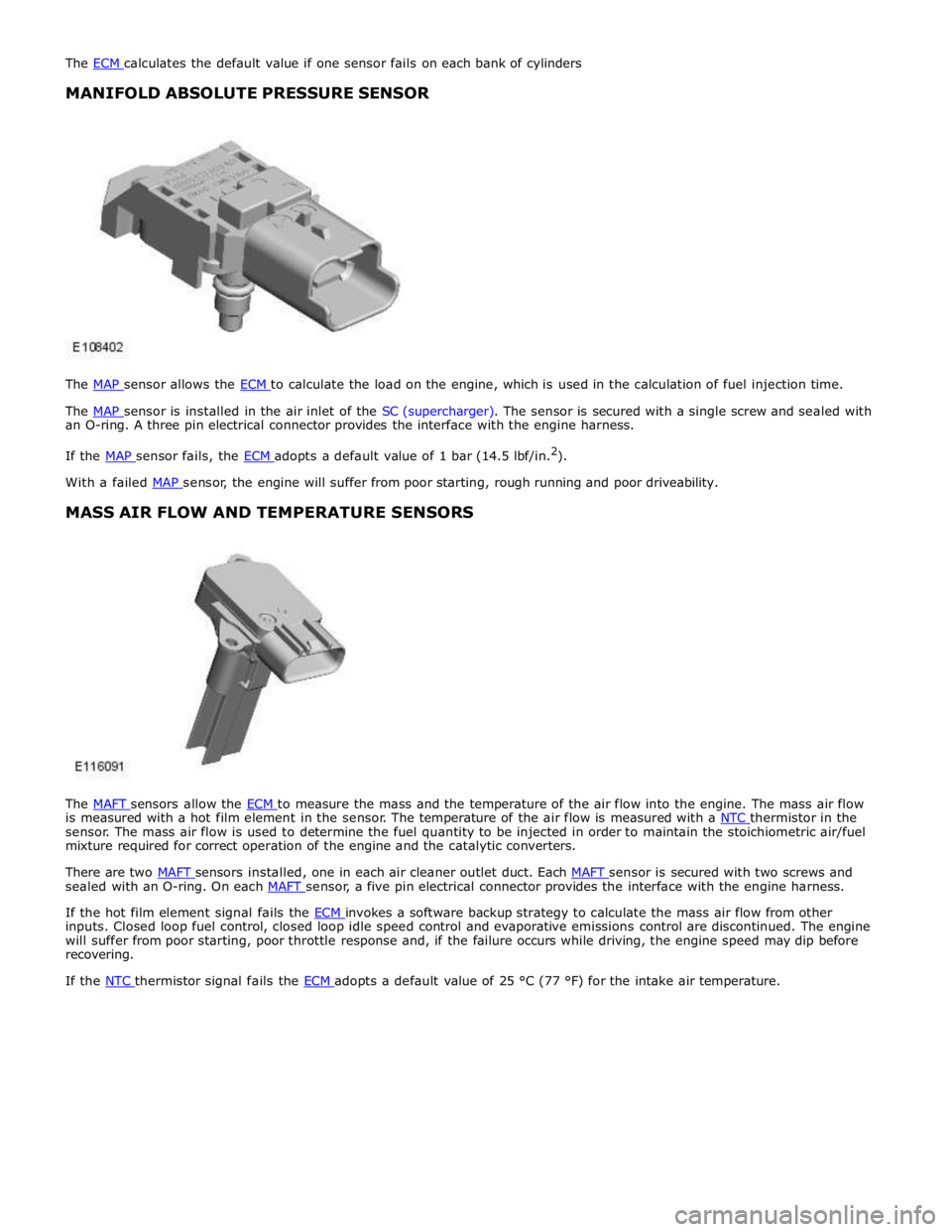

MANIFOLD ABSOLUTE PRESSURE SENSOR

The MAP sensor allows the ECM to calculate the load on the engine, which is used in the calculation of fuel injection time.

The MAP sensor is installed in the air inlet of the SC (supercharger). The sensor is secured with a single screw and sealed with an O-ring. A three pin electrical connector provides the interface with the engine harness.

If the MAP sensor fails, the ECM adopts a default value of 1 bar (14.5 lbf/in.2

). With a failed MAP sensor, the engine will suffer from poor starting, rough running and poor driveability.

MASS AIR FLOW AND TEMPERATURE SENSORS

The MAFT sensors allow the ECM to measure the mass and the temperature of the air flow into the engine. The mass air flow is measured with a hot film element in the sensor. The temperature of the air flow is measured with a NTC thermistor in the sensor. The mass air flow is used to determine the fuel quantity to be injected in order to maintain the stoichiometric air/fuel

mixture required for correct operation of the engine and the catalytic converters.

There are two MAFT sensors installed, one in each air cleaner outlet duct. Each MAFT sensor is secured with two screws and sealed with an O-ring. On each MAFT sensor, a five pin electrical connector provides the interface with the engine harness.

If the hot film element signal fails the ECM invokes a software backup strategy to calculate the mass air flow from other inputs. Closed loop fuel control, closed loop idle speed control and evaporative emissions control are discontinued. The engine

will suffer from poor starting, poor throttle response and, if the failure occurs while driving, the engine speed may dip before

recovering.

If the NTC thermistor signal fails the ECM adopts a default value of 25 °C (77 °F) for the intake air temperature.

Page 1390 of 3039

Published: 11-May-2011

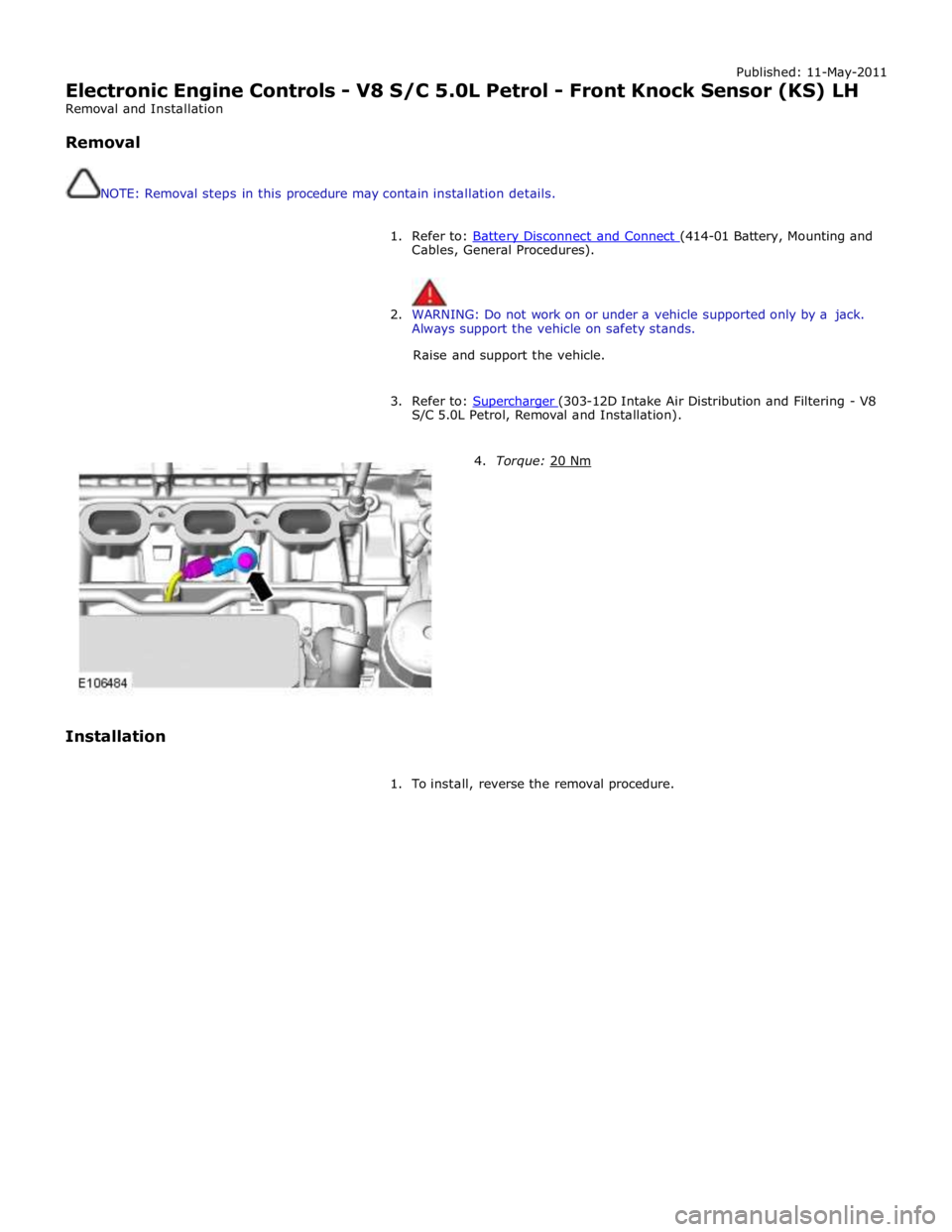

Electronic Engine Controls - V8 S/C 5.0L Petrol - Front Knock Sensor (KS) LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Supercharger (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

Installation

4. Torque: 20 Nm

1. To install, reverse the removal procedure.

Page 1391 of 3039

Published: 11-May-2011

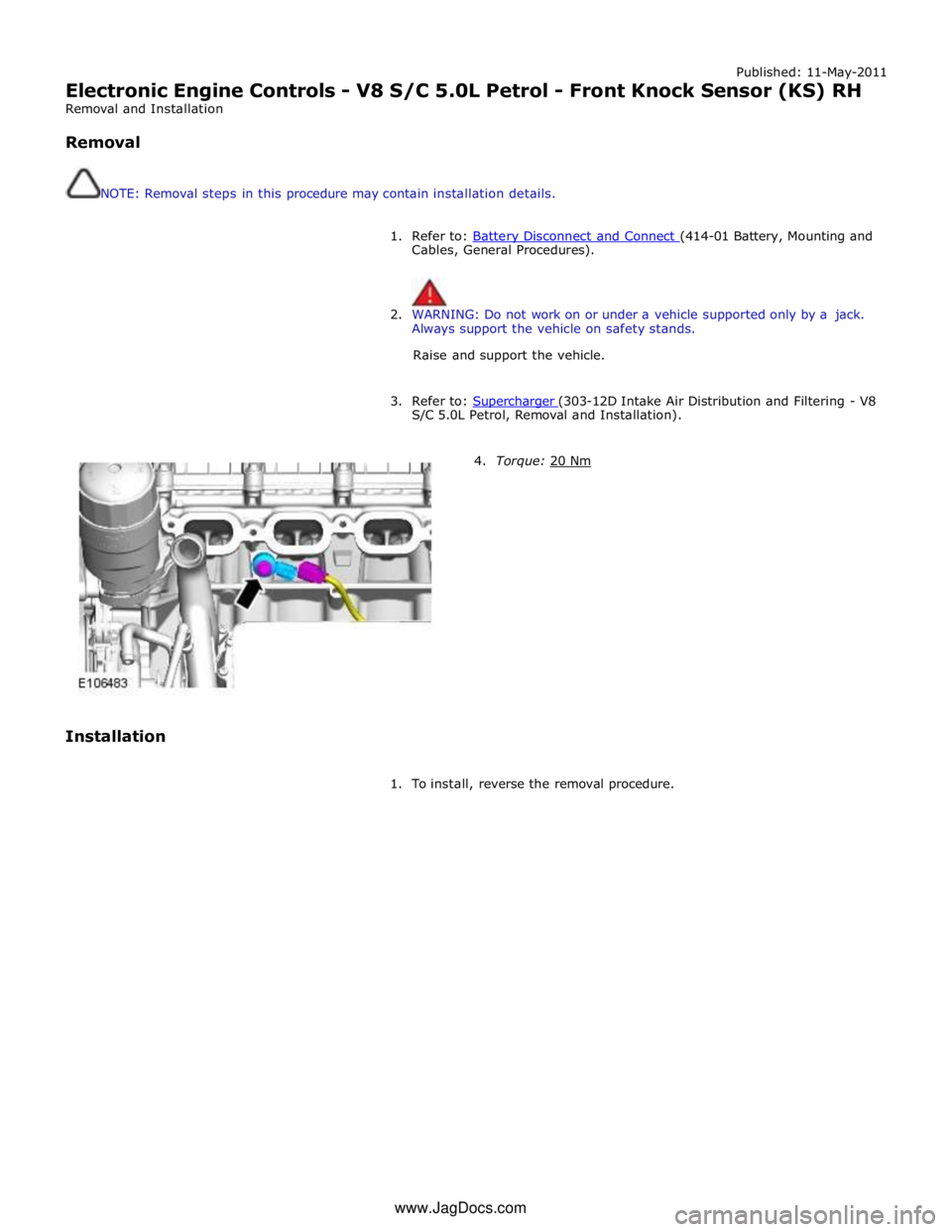

Electronic Engine Controls - V8 S/C 5.0L Petrol - Front Knock Sensor (KS) RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Supercharger (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

Installation

4. Torque: 20 Nm

1. To install, reverse the removal procedure. www.JagDocs.com

Page 1402 of 3039

Published: 11-May-2011

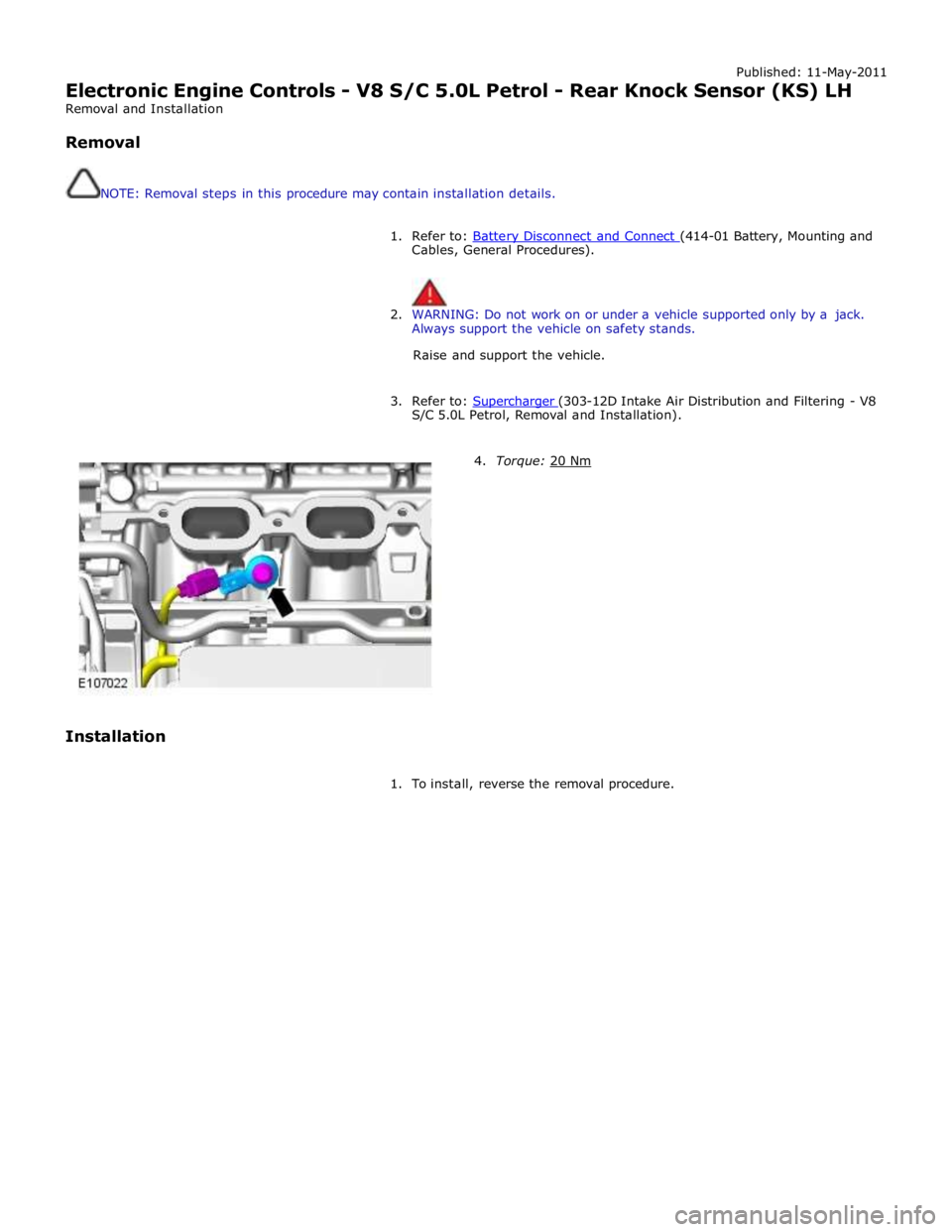

Electronic Engine Controls - V8 S/C 5.0L Petrol - Rear Knock Sensor (KS) LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Supercharger (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

Installation

4. Torque: 20 Nm

1. To install, reverse the removal procedure.

Page 1403 of 3039

Published: 11-May-2011

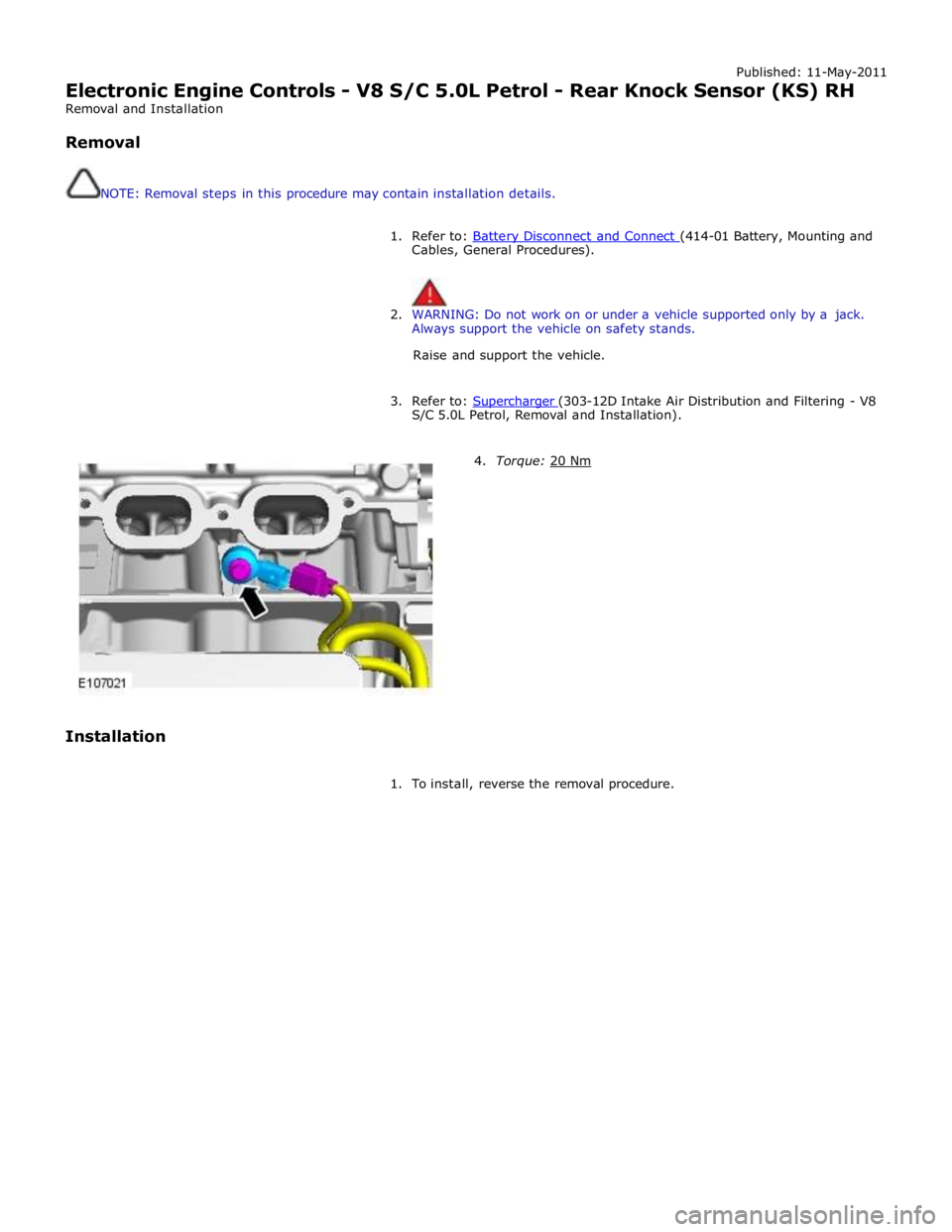

Electronic Engine Controls - V8 S/C 5.0L Petrol - Rear Knock Sensor (KS) RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Supercharger (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

Installation

4. Torque: 20 Nm

1. To install, reverse the removal procedure.

Page 1404 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Variable Valve Timing (VVT)

Oil Control Solenoid LH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Disconnect the battery ground cable.

Refer to: Specifications (414-00, Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Thermostat Housing - Vehicles With: Supercharger (303-03,

Removal and Installation).

4. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

Torque: 10 Nm

5. CAUTION: Evenly and progressively, remove the VVT

units from each side.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Page 1406 of 3039

Published: 11-May-2011

Electronic Engine Controls - V8 S/C 5.0L Petrol - Variable Valve Timing (VVT)

Oil Control Solenoid RH

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Disconnect the battery ground cable.

Refer to: Specifications (414-00, Specifications).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Thermostat Housing - Vehicles With: Supercharger (303-03,

Removal and Installation).

4. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

5. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Torque: 10 Nm www.JagDocs.com