suspension system JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1805 of 3039

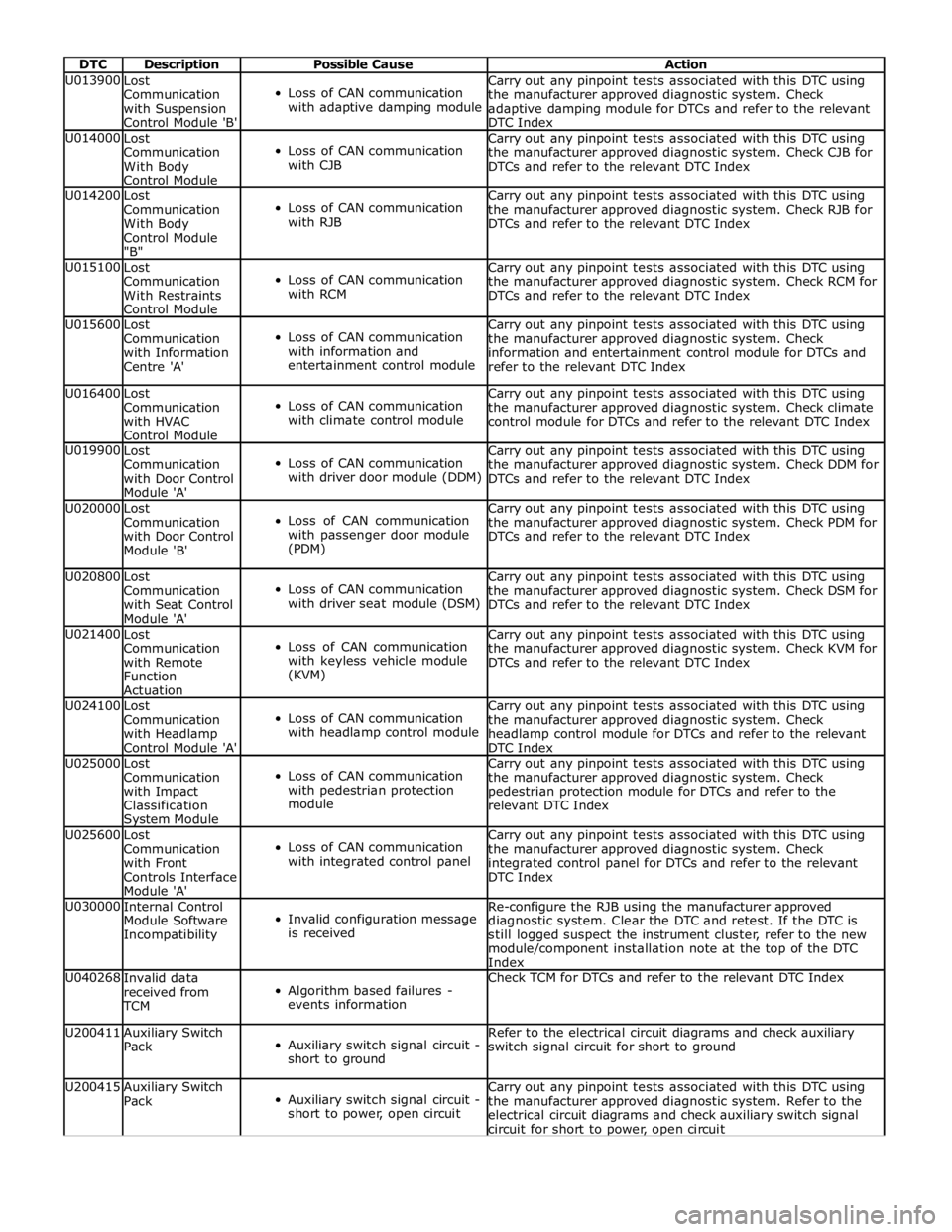

DTC Description Possible Cause Action U013900

Lost

Communication

with Suspension

Control Module 'B'

Loss of CAN communication

with adaptive damping module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

adaptive damping module for DTCs and refer to the relevant

DTC Index U014000

Lost

Communication

With Body

Control Module

Loss of CAN communication

with CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

DTCs and refer to the relevant DTC Index U014200

Lost

Communication

With Body

Control Module

"B"

Loss of CAN communication

with RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

DTCs and refer to the relevant DTC Index U015100

Lost

Communication

With Restraints

Control Module

Loss of CAN communication

with RCM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RCM for

DTCs and refer to the relevant DTC Index U015600

Lost

Communication

with Information

Centre 'A'

Loss of CAN communication

with information and

entertainment control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment control module for DTCs and

refer to the relevant DTC Index U016400

Lost

Communication

with HVAC

Control Module

Loss of CAN communication

with climate control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check climate

control module for DTCs and refer to the relevant DTC Index U019900

Lost

Communication

with Door Control

Module 'A'

Loss of CAN communication

with driver door module (DDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DDM for

DTCs and refer to the relevant DTC Index U020000

Lost

Communication

with Door Control

Module 'B'

Loss of CAN communication

with passenger door module

(PDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check PDM for

DTCs and refer to the relevant DTC Index U020800

Lost

Communication

with Seat Control

Module 'A'

Loss of CAN communication

with driver seat module (DSM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DSM for

DTCs and refer to the relevant DTC Index U021400

Lost

Communication

with Remote

Function

Actuation

Loss of CAN communication

with keyless vehicle module

(KVM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check KVM for

DTCs and refer to the relevant DTC Index U024100

Lost

Communication

with Headlamp

Control Module 'A'

Loss of CAN communication

with headlamp control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

headlamp control module for DTCs and refer to the relevant

DTC Index U025000

Lost

Communication

with Impact

Classification System Module

Loss of CAN communication

with pedestrian protection

module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

pedestrian protection module for DTCs and refer to the

relevant DTC Index U025600

Lost

Communication

with Front

Controls Interface

Module 'A'

Loss of CAN communication

with integrated control panel Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

integrated control panel for DTCs and refer to the relevant

DTC Index U030000

Internal Control

Module Software

Incompatibility

Invalid configuration message

is received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC is

still logged suspect the instrument cluster, refer to the new

module/component installation note at the top of the DTC

Index U040268

Invalid data

received from

TCM

Algorithm based failures -

events information Check TCM for DTCs and refer to the relevant DTC Index U200411

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to ground Refer to the electrical circuit diagrams and check auxiliary

switch signal circuit for short to ground U200415

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check auxiliary switch signal

circuit for short to power, open circuit

Page 1823 of 3039

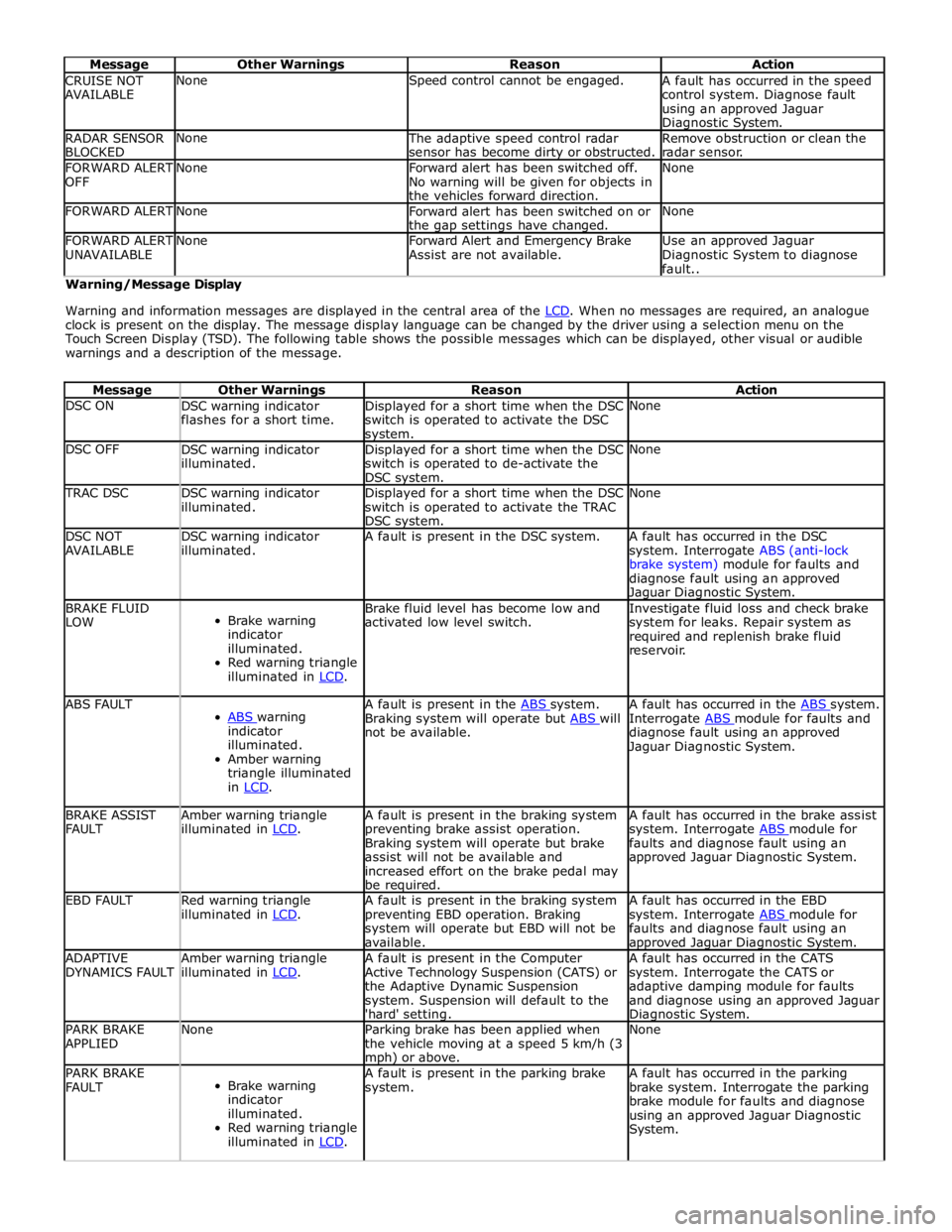

Message Other Warnings Reason Action CRUISE NOT

AVAILABLE None Speed control cannot be engaged.

A fault has occurred in the speed

control system. Diagnose fault

using an approved Jaguar Diagnostic System. RADAR SENSOR

BLOCKED None

The adaptive speed control radar

sensor has become dirty or obstructed. Remove obstruction or clean the

radar sensor. FORWARD ALERT

OFF None

Forward alert has been switched off.

No warning will be given for objects in

the vehicles forward direction. None FORWARD ALERT None

Forward alert has been switched on or

the gap settings have changed. None FORWARD ALERT

UNAVAILABLE None

Forward Alert and Emergency Brake

Assist are not available. Use an approved Jaguar

Diagnostic System to diagnose

fault.. Warning/Message Display

Warning and information messages are displayed in the central area of the LCD. When no messages are required, an analogue clock is present on the display. The message display language can be changed by the driver using a selection menu on the

Touch Screen Display (TSD). The following table shows the possible messages which can be displayed, other visual or audible

warnings and a description of the message.

Message Other Warnings Reason Action DSC ON

DSC warning indicator

flashes for a short time. Displayed for a short time when the DSC

switch is operated to activate the DSC system. None DSC OFF

DSC warning indicator

illuminated. Displayed for a short time when the DSC

switch is operated to de-activate the

DSC system. None TRAC DSC

DSC warning indicator

illuminated. Displayed for a short time when the DSC

switch is operated to activate the TRAC

DSC system. None DSC NOT

AVAILABLE DSC warning indicator

illuminated. A fault is present in the DSC system.

A fault has occurred in the DSC

system. Interrogate ABS (anti-lock

brake system) module for faults and

diagnose fault using an approved Jaguar Diagnostic System. BRAKE FLUID

LOW

Brake warning

indicator

illuminated.

Red warning triangle

illuminated in LCD. Brake fluid level has become low and

activated low level switch. Investigate fluid loss and check brake

system for leaks. Repair system as

required and replenish brake fluid

reservoir. ABS FAULT

ABS warning indicator

illuminated.

Amber warning

triangle illuminated

in LCD. A fault is present in the ABS system. Braking system will operate but ABS will not be available. A fault has occurred in the ABS system. Interrogate ABS module for faults and diagnose fault using an approved

Jaguar Diagnostic System. BRAKE ASSIST

FAULT Amber warning triangle

illuminated in LCD. A fault is present in the braking system

preventing brake assist operation.

Braking system will operate but brake

assist will not be available and

increased effort on the brake pedal may

be required. A fault has occurred in the brake assist

system. Interrogate ABS module for faults and diagnose fault using an

approved Jaguar Diagnostic System. EBD FAULT

Red warning triangle

illuminated in LCD. A fault is present in the braking system

preventing EBD operation. Braking

system will operate but EBD will not be

available. A fault has occurred in the EBD

system. Interrogate ABS module for faults and diagnose fault using an approved Jaguar Diagnostic System. ADAPTIVE

DYNAMICS FAULT Amber warning triangle

illuminated in LCD. A fault is present in the Computer

Active Technology Suspension (CATS) or

the Adaptive Dynamic Suspension

system. Suspension will default to the

'hard' setting. A fault has occurred in the CATS

system. Interrogate the CATS or

adaptive damping module for faults

and diagnose using an approved Jaguar Diagnostic System. PARK BRAKE

APPLIED None

Parking brake has been applied when

the vehicle moving at a speed 5 km/h (3 mph) or above. None PARK BRAKE

FAULT

Brake warning

indicator

illuminated.

Red warning triangle

illuminated in LCD. A fault is present in the parking brake

system. A fault has occurred in the parking

brake system. Interrogate the parking

brake module for faults and diagnose

using an approved Jaguar Diagnostic

System.

Page 2022 of 3039

The lighting system has an 'auto' lights function which is controlled by the CJB on receipt of signals from the rain/light sensor located at the top of the windscreen. The exterior lights are turned on or off in response to ambient light signals from the

rain/light sensor on a LIN (local interconnect network) bus connection to the CJB . The auto lights can also be activated when the windshield wipers are activated by signals from the rain sensor, which is located at the top of the windshield or when the

driver activates the wipers in the fast wipe position.

Two levels of headlamp specification are available; halogen or xenon. In certain markets the headlamps feature a cornering

lamp or a static bending lamp which illuminates the area at the side of the vehicle when turning into driveways for example.

North American Specification (NAS) vehicles have a side marker lamp installed in the headlamp assembly. Replacement of any

of the headlamp bulbs requires removal of the headlamp assembly.

The tail lamp comprises two separate lamp assemblies. The turn signal indicator, side and stop lamps and reverse lamps are

located in each rear fender tail lamp assembly. The rear fog lamps are located in separate units attached to the luggage

compartment lid. A side marker lamp is fitted to the rear fender tail lamp assembly and is fitted in all markets.

Two systems of headlamp leveling are available; manual leveling which is only available on halogen headlamps and static

dynamic leveling which is available on xenon headlamps. The manual system uses a thumbwheel rheostat to adjust the

vertical alignment of the headlamps to compensate for differing vehicle loading. The static dynamic system uses height

sensors fitted to the front and rear suspension and a headlamp leveling module which periodically monitors the vehicle

attitude and adjusts the headlamp vertical alignment accordingly.

Page 2034 of 3039

dependant on a particular ignition mode status. The side lamps will also be illuminated when the lighting control switch is in

the AUTO position and a 'lights on' signal is received by the CJB from the rain/light sensor Side Marker Lamps (NAS only)

The side marker lamp is located in the outer part of the headlamp assembly. The side marker lamp uses a W5W wedge fitting

bulb. The bulb is fitted into a holder which connects with contacts in the headlamp housing. The holder is fitted into an

aperture which connects with contacts in the headlamp housing. The side marker lamp is active at all times when the side

lamps are active.

AUTOMATIC HEADLAMP OPERATION

The automatic headlamp function is a driver assistance system. The driver can override the system operation by selection of

side lamp or headlamp on if the ambient light conditions require front and rear lighting to be active. The automatic headlamp

system uses a light sensor and the CJB, which are connected via a LIN (local interconnect network) bus to control the headlamp functionality. The light sensor is incorporated in the rain/light sensor located on the inside of the windshield, below

the rear view mirror. The wiper system also uses the rain/light sensor for automatic wiper operation.

The light sensor measures the ambient light around the vehicle in a vertical direction and also the angular light level from the

front of the vehicle. The rain/light sensor uses vehicle speed signals, wiper switch position and the park position of the front

wipers to control the system. The automatic headlamp operation uses ambient light levels which are monitored by photodiode

incorporated in the rain/light sensor. The rain/light sensor sends a lights on/off request to the CJB on the LIN bus, which responds by switching on the low beam headlamps, front side lamps and rear tail lamps. The automatic headlamps are

activated under the following conditions:

Twilight

Darkness

Rain

Snow

Tunnels

Underground or multistoried car parks.

Operation of the automatic headlamps requires the ignition to be in ignition mode 6, the lighting control switch to be in the

'AUTO' position and a lights on request signal from the light sensor. If the rain sensor signal activates the fast speed wipers,

the low beam headlamps are activated, providing the lighting control switch is in the 'AUTO' position.

HEADLAMP LEVELING

Headlamp leveling provides for the adjustment of the vertical aim of the headlamps. The leveling system is primarily required

to minimise glare to other road users when a heavy load is in the rear of the vehicle. Two systems of headlamp leveling are

available; manual and static dynamic.

Manual Headlamp Leveling

The manual system uses a thumbwheel rheostat to adjust the vertical alignment of the headlamps to compensate for differing

vehicle loading. The rotary thumbwheel is located on the auxiliary lighting switch, adjacent to the illumination dimmer

thumbwheel. Three positions are available to adjust the headlamps to a position to prevent glare to other road users.

Static Dynamic Headlamp Leveling

The static dynamic headlamp leveling system uses the following components:

Front and rear vehicle height sensors

Two headlamp leveling, vertical adjustment motors

Headlamp leveling module

Ignition in mode 6

Vehicle speed information from ABS module.

The static dynamic system uses height sensors fitted to the front and rear suspension and a headlamp leveling module which

periodically monitors the vehicle attitude and adjusts the headlamp vertical alignment accordingly.

Static dynamic headlamp leveling is controlled by a headlamp leveling module located in the lower instrument panel, behind

the glovebox.

The height sensors are both located on the RH side of the vehicle. The front sensor is attached to the front suspension lower arm with a strap and to the front sub frame with a bracket and 2 bolts. The rear sensor is attached to the rear suspension

upper control arm with a cable tied clip and to the rear sub frame with a bracket and 2 bolts. Each sensor has 3 connections to

the headlamp leveling module; power, ground and signal.

DAYTIME RUNNING LAMPS (DRL)

Refer to DRL section for details. Refer to: Daytime Running Lamps (DRL) (417-04 Daytime Running Lamps (DRL), Description and Operation).

REAR LAMP ASSEMBLY

The rear lamp assembly is a 2 piece unit, with one part located in the rear quarter panel and the second part attached to the

luggage compartment lid. The outer rear lamp assembly is located in a recess in the vehicle body. The lamp is secured with 2

studs inboard studs on the lamp body which are secured to the vehicle body with 2 nuts. A third outboard stud and nut secures

Page 2785 of 3039

Transmission (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Removal) /

Transmission - 4.2L (307-01, Removal) /

Transmission - V8 5.0L Petrol/V8 S/C 5.0L Petrol (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Removal) /

Front Shock Absorber (204-01 Front Suspension, Removal and Installation) /

Front Subframe - 2.7L Diesel (502-00, Removal and Installation) /

Front Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation) /

Front Subframe - 4.2L, Vehicles Without: Supercharger (502-00, Removal

and Installation) /

Front Subframe - 4.2L, Vehicles With: Supercharger (502-00, Removal

and Installation).

8. Remove the pedestrian protection hood actuator.

For additional information, refer to: Pedestrian Protection Hood Actuator LH (501-20C Pedestrian Protection System, Removal and Installation) / Pedestrian Protection Hood Actuator RH (501-20C Pedestrian Protection System, Removal and Installation).

9. If the drivers side front side member and suspension top mount is to be

repaired, remove the brake master cylinder and reservoir.

For additional information, refer to: Brake Master Cylinder (206-06 Hydraulic Brake Actuation, Removal and Installation) /

Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

10. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the fuel supply and return lines.

11. Release and position the front side member wiring harness to one side.

12. Remove any remaining miscellaneous components from the repair area.

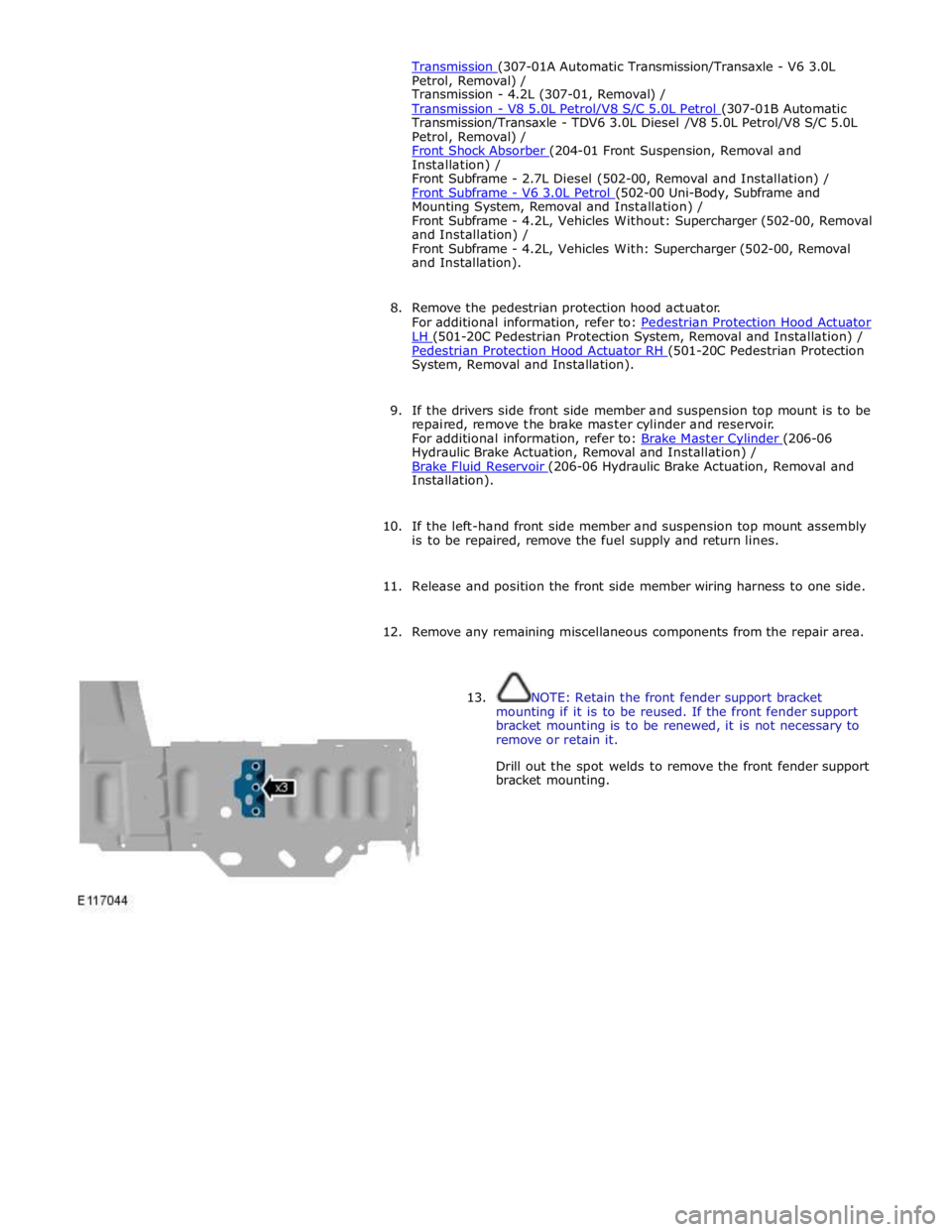

13. NOTE: Retain the front fender support bracket

mounting if it is to be reused. If the front fender support

bracket mounting is to be renewed, it is not necessary to

remove or retain it.

Drill out the spot welds to remove the front fender support

bracket mounting.

Page 2797 of 3039

(100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

5. Remove the fender apron panel front extension.

For additional information, refer to: Fender Apron Panel Front Extension (501-27 Front End Sheet Metal Repairs, Removal and Installation).

6. Remove the front fender support bracket.

For additional information, refer to: Front Fender Support Bracket (501-27 Front End Sheet Metal Repairs, Removal and Installation).

7. Remove the fender apron panel.

For additional information, refer to: Fender Apron Panel (501-27 Front End Sheet Metal Repairs, Removal and Installation).

8. Remove the engine, transmission / transaxle, front subframe and front

suspension, as an assembly.

For additional information, refer to: Engine (303-01A, Removal) /

Engine (303-01B Engine - V6 3.0L Petrol, Removal) / Engine (303-01D, Removal) /

Engine (303-01E, Removal) /

Transmission - 2.7L Diesel (307-01, Removal) /

Transmission - TDV6 3.0L Diesel (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Removal) /

Transmission (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Removal) /

Transmission - 4.2L (307-01, Removal) /

Transmission - V8 5.0L Petrol/V8 S/C 5.0L Petrol (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Removal) /

Front Shock Absorber (204-01 Front Suspension, Removal and Installation) /

Front Subframe - 2.7L Diesel (502-00, Removal and Installation) /

Front Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation) /

Front Subframe - 4.2L, Vehicles Without: Supercharger (502-00, Removal

and Installation) /

Front Subframe - 4.2L, Vehicles With: Supercharger (502-00, Removal

and Installation).

9. Remove the pedestrian protection hood actuator.

For additional information, refer to: Pedestrian Protection Hood Actuator LH (501-20C Pedestrian Protection System, Removal and Installation) / Pedestrian Protection Hood Actuator RH (501-20C Pedestrian Protection System, Removal and Installation).

10. If the drivers side front side member and suspension top mount is to be

repaired, remove the brake master cylinder and reservoir.

For additional information, refer to: Brake Master Cylinder (206-06 Hydraulic Brake Actuation, Removal and Installation) /

Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

11. If the drivers side front side member and suspension top mount is to be

repaired, remove the brake booster.

Page 2798 of 3039

Actuation, Removal and Installation).

12. Remove the left-hand and right-hand front seats.

For additional information, refer to: Front Seat (501-10 Seating, Removal and Installation).

13. Remove the heater core and evaporator core housing.

For additional information, refer to: Heater Core and Evaporator Core Housing (412-01 Climate Control, Removal and Installation).

14. Remove the front safety belt retractor.

For additional information, refer to: Front Safety Belt Retractor (501-20A Safety Belt System, Removal and Installation).

15. Remove the B-pillar side impact sensor.

For additional information, refer to: B-Pillar Side Impact Sensor (501-20B Supplemental Restraint System, Removal and Installation).

16. Remove the left-hand and right-hand front floor covering.

17. Remove the rear floor covering.

18. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the left-hand rear foot well duct.

19. If the right-hand front side member and suspension top mount assembly

is to be repaired, remove the right-hand rear foot well duct.

20. If the drivers side front side member and suspension top mount is being

repaired, remove the pedal box.

21. Release and position the insulating material at the inner bulkhead to

one side.

22. Release and position the inner bulkhead and floor panel wiring harness

to one side.

23. Drain the fuel tank.

For additional information, refer to: Fuel Tank Draining (310-00 Fuel System - General Information, General Procedures).

24. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the left-hand under shield.

25. If the right-hand front side member and suspension top mount assembly

is to be repaired, remove the right-hand under shield.

26. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the fuel supply and return pipes.

27. For diesel engine vehicles only, if the left-hand front side member and

suspension top mount assembly is to be repaired, remove the fuel

cooler.

28. If the right-hand front side member and suspension top mount assembly

is to be repaired, release and position the underfloor wiring harness to

Page 2993 of 3039

5. Disconnect the generator electrical connectors.

6. Disconnect the battery positive cable and position it to one side.

7. Remove the rear subframe and rear suspension, as an assembly.

For additional information, refer to: Rear Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and

Installation).

8. Remove the fuel tank filler pipe.

For additional information, refer to: Fuel Tank Filler Pipe (310-01B,

Removal and Installation).

9. Release the left-hand and right-hand luggage floor wiring harnesses and

position them to one side.

10. Make sure that the rear seats are covered to prevent any damage during

this repair procedure.

11. NOTE: If undamaged, the left-hand and right-hand rear bumper

retaining brackets should be reinstalled.

Remove the left-hand and right-hand rear bumper retaining brackets.

Page 3031 of 3039

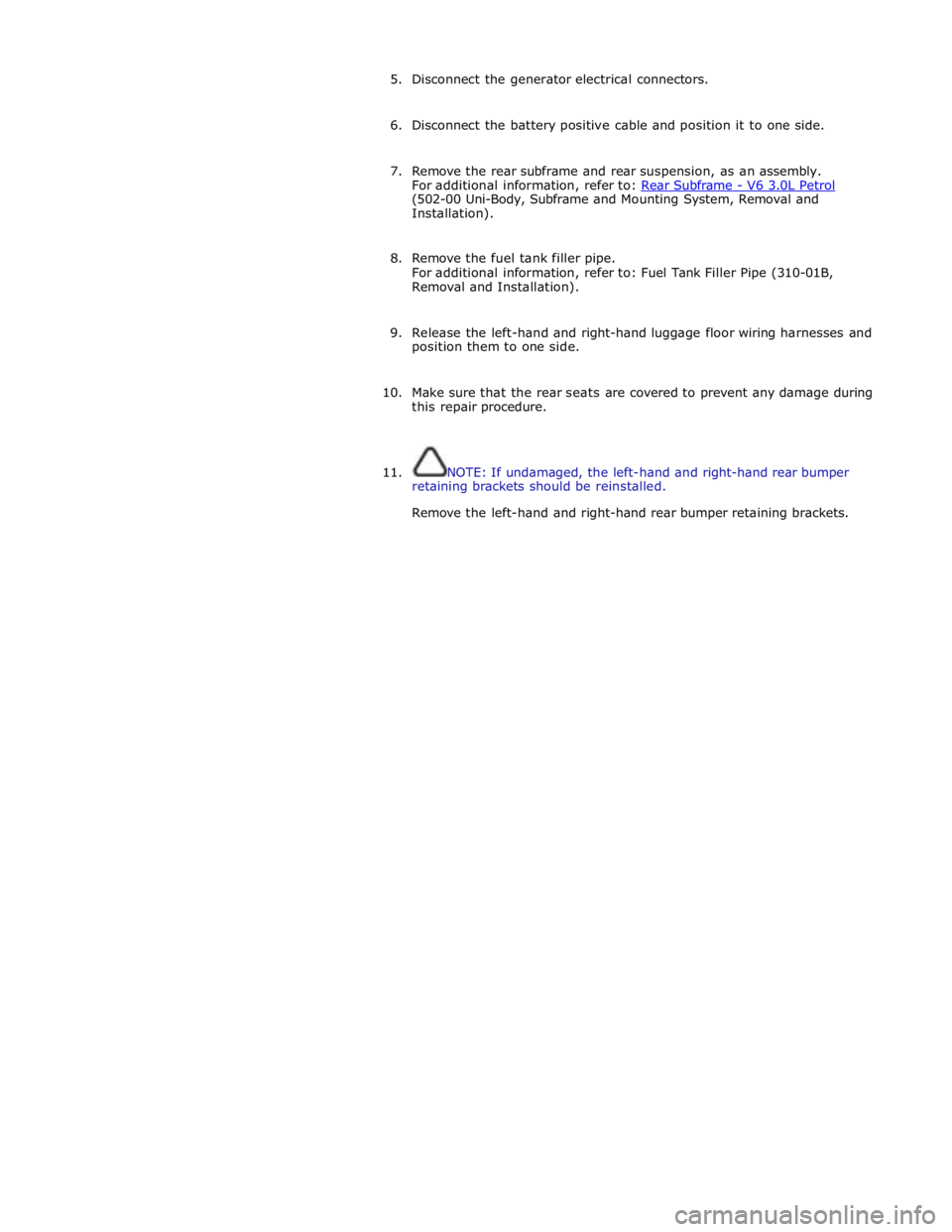

27. Release the radiator assembly.

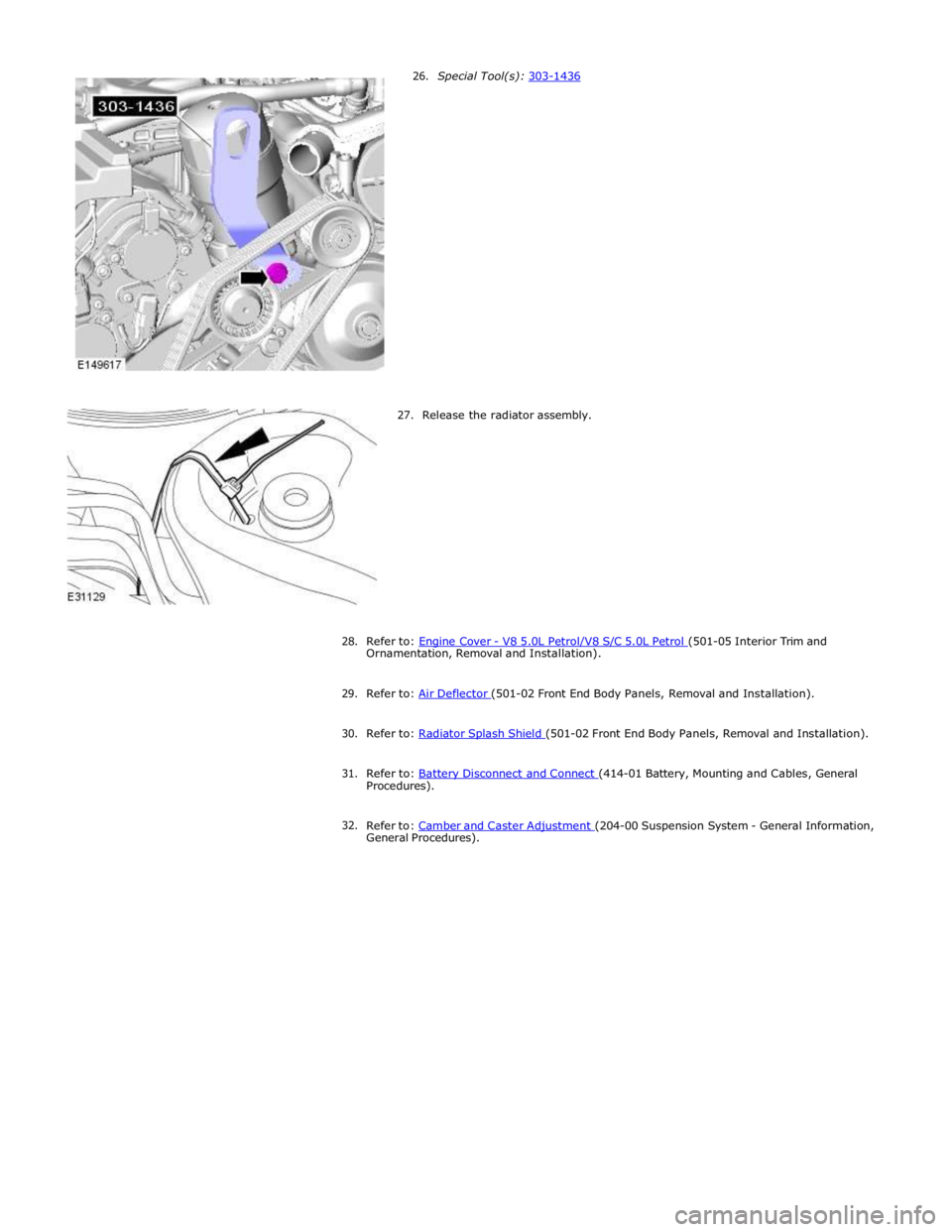

28.

Refer to: Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-05 Interior Trim and Ornamentation, Removal and Installation).

29. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation). 30. Refer to: Radiator Splash Shield (501-02 Front End Body Panels, Removal and Installation). 31. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

32.

Refer to: Camber and Caster Adjustment (204-00 Suspension System - General Information, General Procedures).

Page 3037 of 3039

Installation

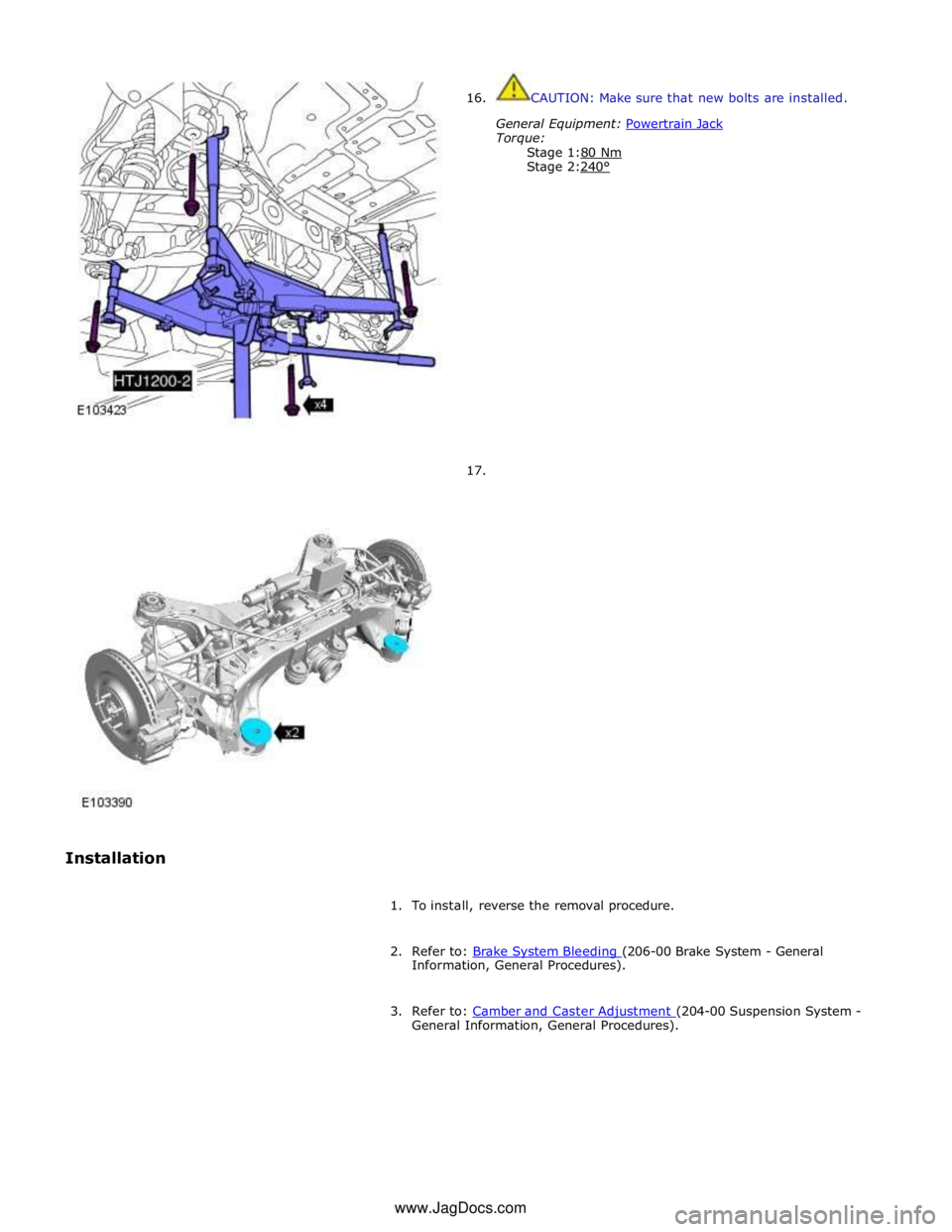

16.

17.

CAUTION: Make sure that new bolts are installed.

General Equipment: Powertrain Jack Torque:

Stage 1:80 Nm Stage 2:240°

1. To install, reverse the removal procedure.

2. Refer to: Brake System Bleeding (206-00 Brake System - General Information, General Procedures).

3. Refer to: Camber and Caster Adjustment (204-00 Suspension System - General Information, General Procedures). www.JagDocs.com