side mirror JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 25 of 3039

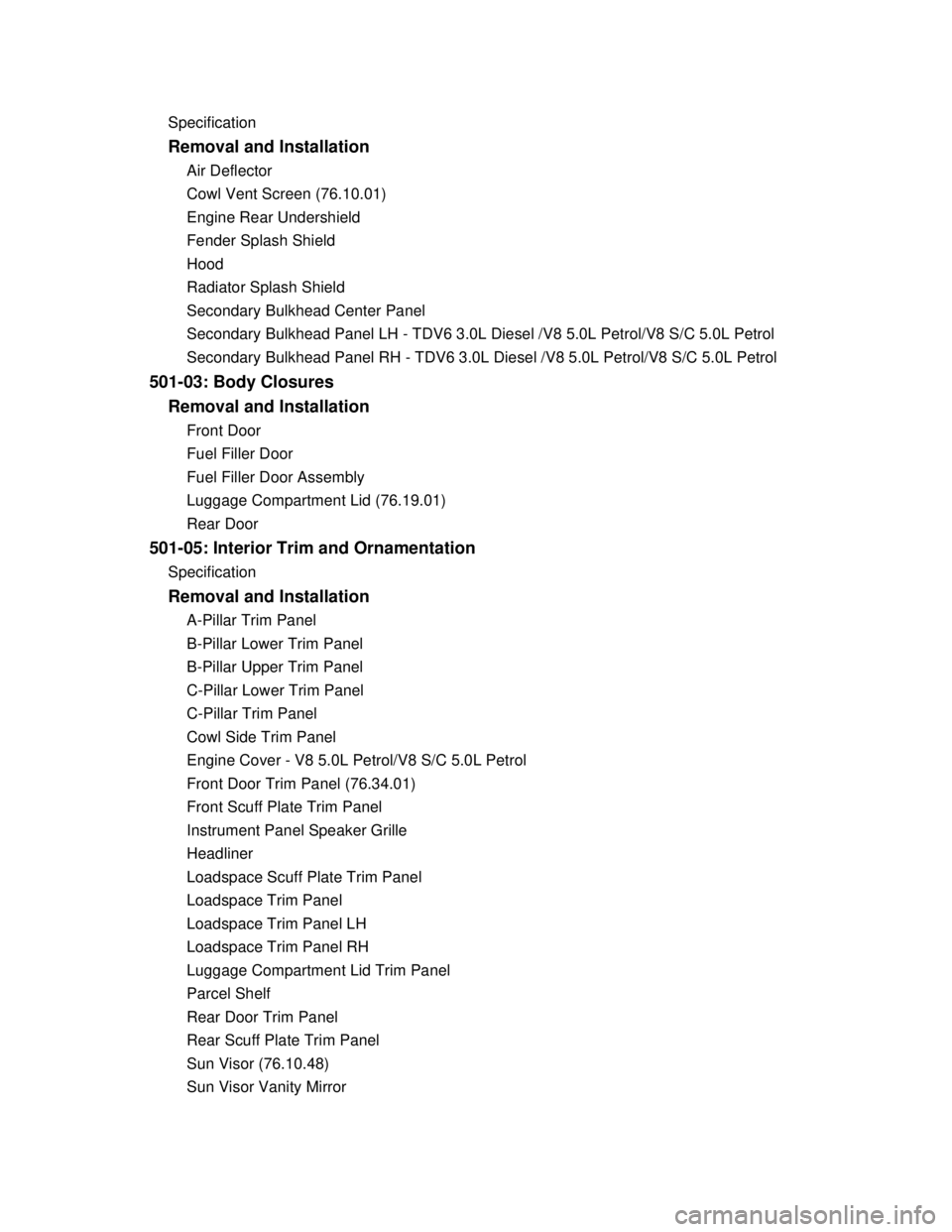

SpecificationRemoval and InstallationAir Deflector

Cowl Vent Screen (76.10.01)

Engine Rear Undershield

Fender Splash Shield

Hood

Radiator Splash Shield

Secondary Bulkhead Center Panel

Secondary Bulkhead Panel LH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Secondary Bulkhead Panel RH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol501-03: Body Closures

Removal and InstallationFront Door

Fuel Filler Door

Fuel Filler Door Assembly

Luggage Compartment Lid (76.19.01)

Rear Door501-05: Interior Trim and OrnamentationSpecificationRemoval and InstallationA-Pillar Trim Panel

B-Pillar Lower Trim Panel

B-Pillar Upper Trim Panel

C-Pillar Lower Trim Panel

C-Pillar Trim Panel

Cowl Side Trim Panel

Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Front Door Trim Panel (76.34.01)

Front Scuff Plate Trim Panel

Instrument Panel Speaker Grille

Headliner

Loadspace Scuff Plate Trim Panel

Loadspace Trim Panel

Loadspace Trim Panel LH

Loadspace Trim Panel RH

Luggage Compartment Lid Trim Panel

Parcel Shelf

Rear Door Trim Panel

Rear Scuff Plate Trim Panel

Sun Visor (76.10.48)

Sun Visor Vanity Mirror

Page 132 of 3039

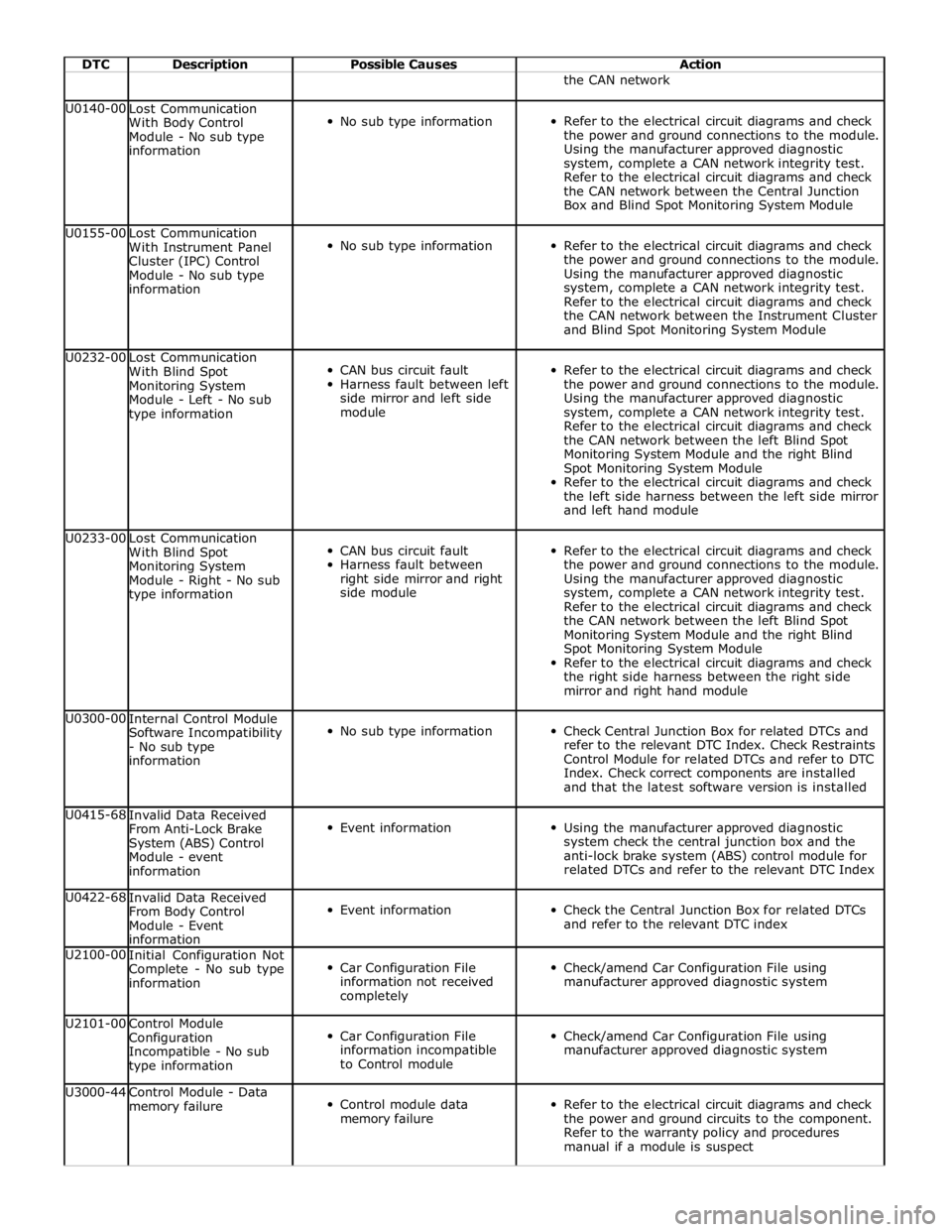

DTC Description Possible Causes Action the CAN network U0140-00

Lost Communication

With Body Control

Module - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network between the Central Junction

Box and Blind Spot Monitoring System Module U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network between the Instrument Cluster

and Blind Spot Monitoring System Module U0232-00

Lost Communication

With Blind Spot

Monitoring System

Module - Left - No sub

type information

CAN bus circuit fault

Harness fault between left

side mirror and left side

module

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network between the left Blind Spot

Monitoring System Module and the right Blind

Spot Monitoring System Module

Refer to the electrical circuit diagrams and check

the left side harness between the left side mirror

and left hand module U0233-00

Lost Communication

With Blind Spot

Monitoring System

Module - Right - No sub

type information

CAN bus circuit fault

Harness fault between

right side mirror and right

side module

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network between the left Blind Spot

Monitoring System Module and the right Blind

Spot Monitoring System Module

Refer to the electrical circuit diagrams and check

the right side harness between the right side

mirror and right hand module U0300-00

Internal Control Module

Software Incompatibility

- No sub type

information

No sub type information

Check Central Junction Box for related DTCs and

refer to the relevant DTC Index. Check Restraints

Control Module for related DTCs and refer to DTC

Index. Check correct components are installed

and that the latest software version is installed U0415-68

Invalid Data Received

From Anti-Lock Brake

System (ABS) Control

Module - event

information

Event information

Using the manufacturer approved diagnostic

system check the central junction box and the

anti-lock brake system (ABS) control module for

related DTCs and refer to the relevant DTC Index U0422-68

Invalid Data Received

From Body Control

Module - Event

information

Event information

Check the Central Junction Box for related DTCs

and refer to the relevant DTC index U2100-00

Initial Configuration Not

Complete - No sub type

information

Car Configuration File

information not received

completely

Check/amend Car Configuration File using

manufacturer approved diagnostic system U2101-00

Control Module

Configuration

Incompatible - No sub

type information

Car Configuration File

information incompatible

to Control module

Check/amend Car Configuration File using

manufacturer approved diagnostic system U3000-44

Control Module - Data

memory failure

Control module data

memory failure

Refer to the electrical circuit diagrams and check

the power and ground circuits to the component.

Refer to the warranty policy and procedures

manual if a module is suspect

Page 148 of 3039

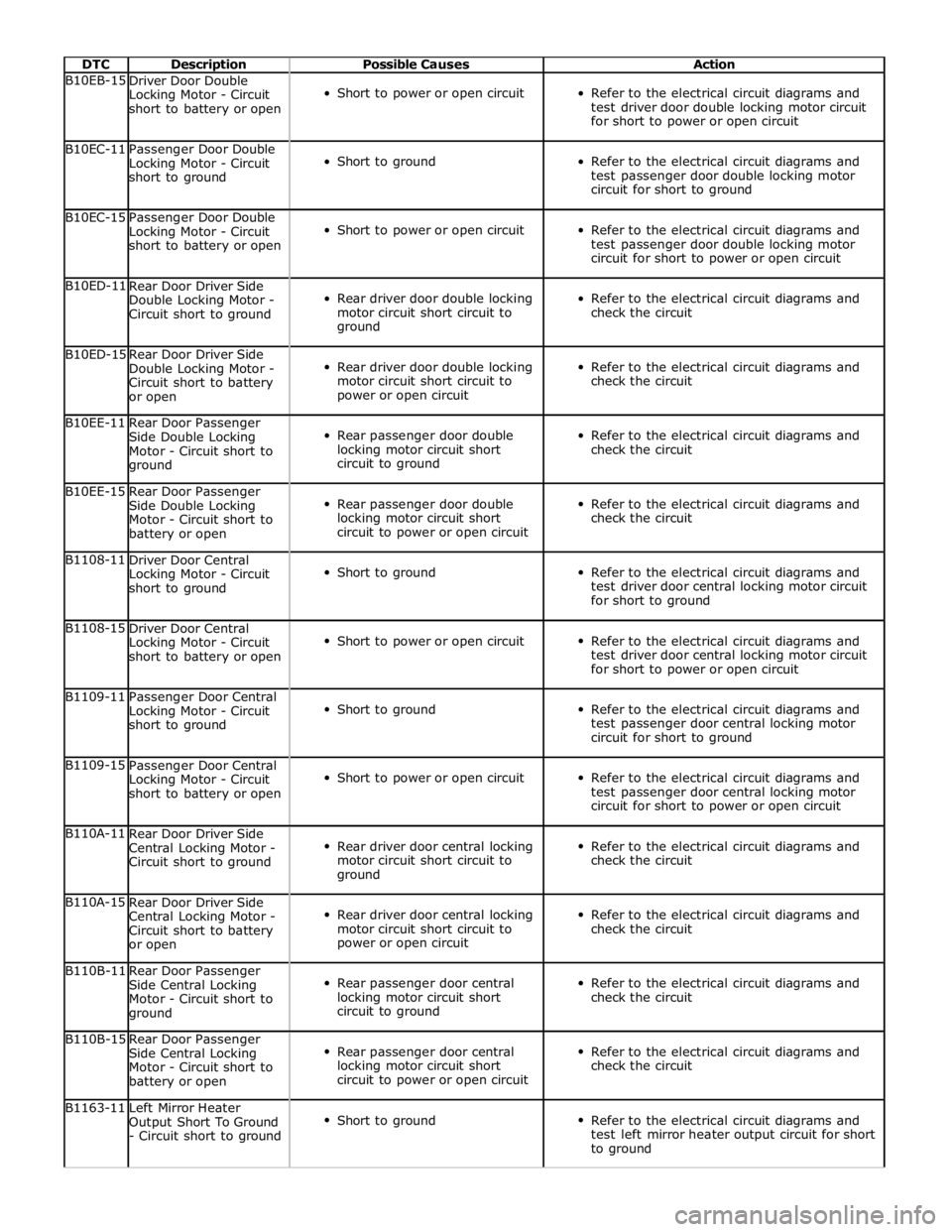

DTC Description Possible Causes Action B10EB-15

Driver Door Double

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test driver door double locking motor circuit

for short to power or open circuit B10EC-11

Passenger Door Double

Locking Motor - Circuit

short to ground

Short to ground

Refer to the electrical circuit diagrams and

test passenger door double locking motor

circuit for short to ground B10EC-15

Passenger Door Double

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test passenger door double locking motor

circuit for short to power or open circuit B10ED-11

Rear Door Driver Side

Double Locking Motor -

Circuit short to ground

Rear driver door double locking

motor circuit short circuit to

ground

Refer to the electrical circuit diagrams and

check the circuit B10ED-15

Rear Door Driver Side

Double Locking Motor -

Circuit short to battery

or open

Rear driver door double locking

motor circuit short circuit to

power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B10EE-11

Rear Door Passenger

Side Double Locking

Motor - Circuit short to

ground

Rear passenger door double

locking motor circuit short

circuit to ground

Refer to the electrical circuit diagrams and

check the circuit B10EE-15

Rear Door Passenger

Side Double Locking

Motor - Circuit short to

battery or open

Rear passenger door double

locking motor circuit short

circuit to power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B1108-11

Driver Door Central

Locking Motor - Circuit

short to ground

Short to ground

Refer to the electrical circuit diagrams and

test driver door central locking motor circuit

for short to ground B1108-15

Driver Door Central

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test driver door central locking motor circuit

for short to power or open circuit B1109-11

Passenger Door Central

Locking Motor - Circuit

short to ground

Short to ground

Refer to the electrical circuit diagrams and

test passenger door central locking motor

circuit for short to ground B1109-15

Passenger Door Central

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test passenger door central locking motor

circuit for short to power or open circuit B110A-11

Rear Door Driver Side

Central Locking Motor -

Circuit short to ground

Rear driver door central locking

motor circuit short circuit to

ground

Refer to the electrical circuit diagrams and

check the circuit B110A-15

Rear Door Driver Side

Central Locking Motor -

Circuit short to battery

or open

Rear driver door central locking

motor circuit short circuit to

power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B110B-11

Rear Door Passenger

Side Central Locking

Motor - Circuit short to

ground

Rear passenger door central

locking motor circuit short

circuit to ground

Refer to the electrical circuit diagrams and

check the circuit B110B-15

Rear Door Passenger

Side Central Locking

Motor - Circuit short to

battery or open

Rear passenger door central

locking motor circuit short

circuit to power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B1163-11

Left Mirror Heater

Output Short To Ground

- Circuit short to ground

Short to ground

Refer to the electrical circuit diagrams and

test left mirror heater output circuit for short

to ground

Page 1706 of 3039

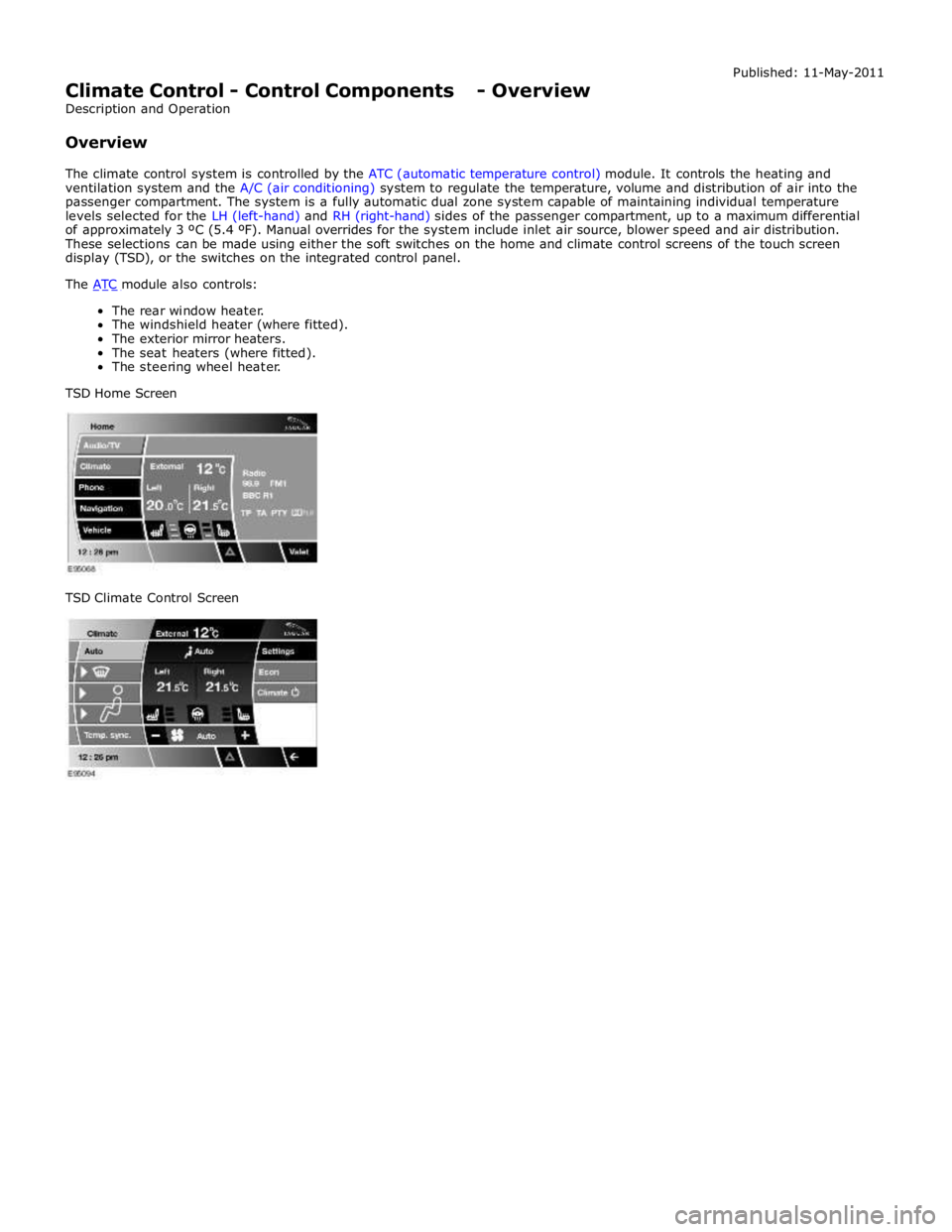

Climate Control - Control Components - Overview

Description and Operation

Overview Published: 11-May-2011

The climate control system is controlled by the ATC (automatic temperature control) module. It controls the heating and

ventilation system and the A/C (air conditioning) system to regulate the temperature, volume and distribution of air into the

passenger compartment. The system is a fully automatic dual zone system capable of maintaining individual temperature

levels selected for the LH (left-hand) and RH (right-hand) sides of the passenger compartment, up to a maximum differential

of approximately 3 ºC (5.4 ºF). Manual overrides for the system include inlet air source, blower speed and air distribution.

These selections can be made using either the soft switches on the home and climate control screens of the touch screen

display (TSD), or the switches on the integrated control panel.

The ATC module also controls: The rear window heater.

The windshield heater (where fitted).

The exterior mirror heaters.

The seat heaters (where fitted).

The steering wheel heater.

TSD Home Screen

TSD Climate Control Screen

Page 1827 of 3039

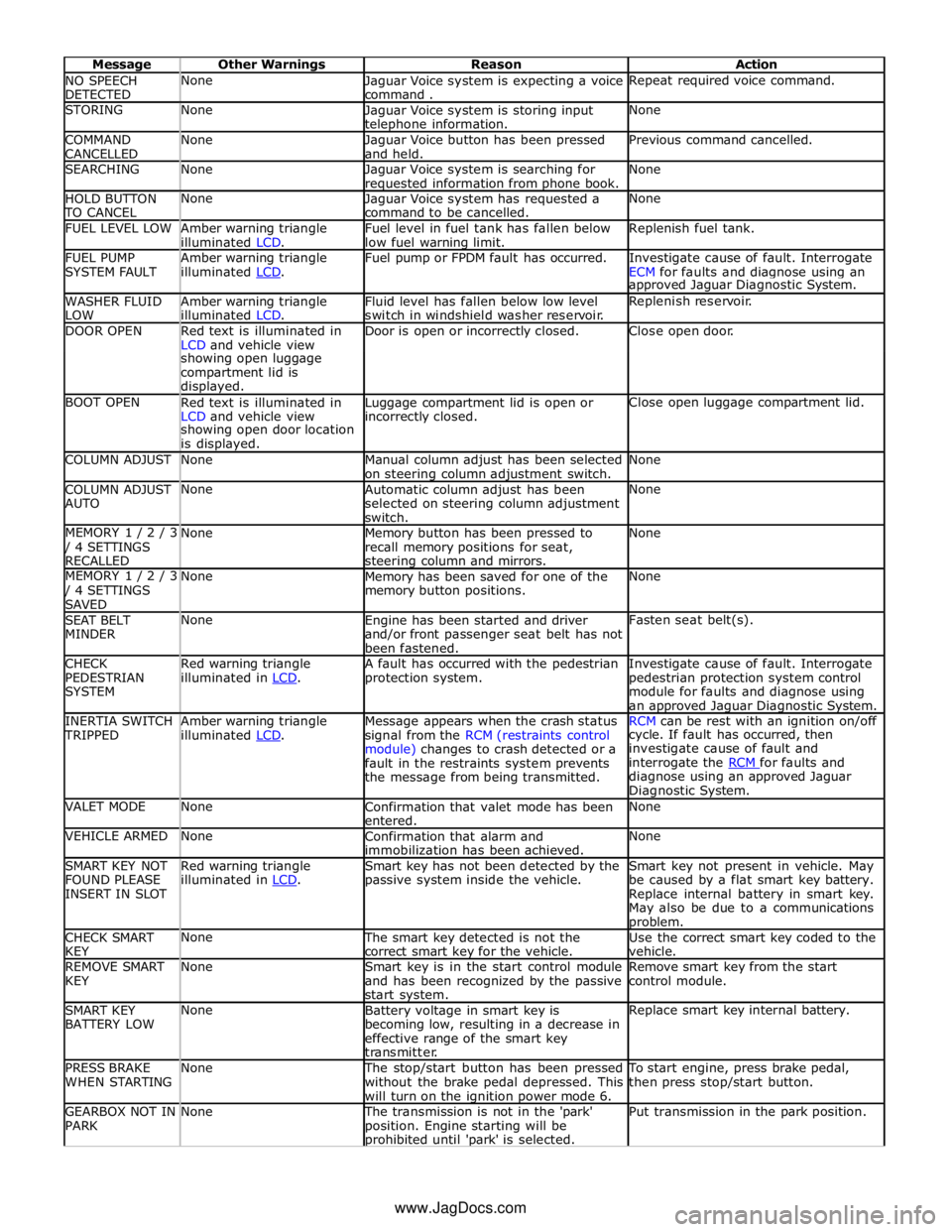

NO SPEECH

DETECTED None

Jaguar Voice system is expecting a voice

command . Repeat required voice command. STORING None

Jaguar Voice system is storing input telephone information. None COMMAND

CANCELLED None

Jaguar Voice button has been pressed

and held. Previous command cancelled. SEARCHING None

Jaguar Voice system is searching for requested information from phone book. None HOLD BUTTON TO CANCEL None

Jaguar Voice system has requested a

command to be cancelled. None FUEL LEVEL LOW

Amber warning triangle

illuminated LCD. Fuel level in fuel tank has fallen below

low fuel warning limit. Replenish fuel tank. FUEL PUMP

SYSTEM FAULT Amber warning triangle

illuminated LCD. Fuel pump or FPDM fault has occurred.

Investigate cause of fault. Interrogate

ECM for faults and diagnose using an approved Jaguar Diagnostic System. WASHER FLUID

LOW Amber warning triangle

illuminated LCD. Fluid level has fallen below low level

switch in windshield washer reservoir. Replenish reservoir. DOOR OPEN

Red text is illuminated in

LCD and vehicle view Door is open or incorrectly closed. Close open door. showing open luggage

compartment lid is

displayed. BOOT OPEN

Red text is illuminated in

LCD and vehicle view Luggage compartment lid is open or incorrectly closed. Close open luggage compartment lid. showing open door location

is displayed. COLUMN ADJUST None

Manual column adjust has been selected

on steering column adjustment switch. None COLUMN ADJUST

AUTO None

Automatic column adjust has been

selected on steering column adjustment

switch. None MEMORY 1 / 2 / 3 / 4 SETTINGS

RECALLED None

Memory button has been pressed to

recall memory positions for seat, steering column and mirrors. None MEMORY 1 / 2 / 3 / 4 SETTINGS

SAVED None

Memory has been saved for one of the

memory button positions. None SEAT BELT

MINDER None

Engine has been started and driver

and/or front passenger seat belt has not

been fastened. Fasten seat belt(s). CHECK

PEDESTRIAN

SYSTEM Red warning triangle

illuminated in LCD. A fault has occurred with the pedestrian

protection system. Investigate cause of fault. Interrogate

pedestrian protection system control

module for faults and diagnose using

an approved Jaguar Diagnostic System. INERTIA SWITCH TRIPPED Amber warning triangle

illuminated LCD. Message appears when the crash status

signal from the RCM (restraints control

module) changes to crash detected or a

fault in the restraints system prevents

the message from being transmitted. RCM can be rest with an ignition on/off cycle. If fault has occurred, then

investigate cause of fault and

interrogate the RCM for faults and diagnose using an approved Jaguar

Diagnostic System. VALET MODE None

Confirmation that valet mode has been

entered. None VEHICLE ARMED None

Confirmation that alarm and

immobilization has been achieved. None SMART KEY NOT

FOUND PLEASE

INSERT IN SLOT Red warning triangle

illuminated in LCD. Smart key has not been detected by the

passive system inside the vehicle. Smart key not present in vehicle. May

be caused by a flat smart key battery.

Replace internal battery in smart key.

May also be due to a communications problem. CHECK SMART

KEY None The smart key detected is not the

correct smart key for the vehicle. Use the correct smart key coded to the

vehicle. REMOVE SMART

KEY None

Smart key is in the start control module

and has been recognized by the passive

start system. Remove smart key from the start

control module. SMART KEY

BATTERY LOW None

Battery voltage in smart key is

becoming low, resulting in a decrease in

effective range of the smart key

transmitter. Replace smart key internal battery. PRESS BRAKE

WHEN STARTING None The stop/start button has been pressed

without the brake pedal depressed. This

will turn on the ignition power mode 6. To start engine, press brake pedal,

then press stop/start button. GEARBOX NOT IN

PARK None The transmission is not in the 'park'

position. Engine starting will be prohibited until 'park' is selected. Put transmission in the park position. www.JagDocs.com

Page 1832 of 3039

Warning Devices - Blindspot Monitoring System - Overview

Description and Operation

OVERVIEW Published: 11-May-2011

Eliminating blind spots is a major element in vehicle body design, but because of the structural requirements of B, C and D

posts, blind spots cannot be entirely eliminated. Statistics show that some accidents are directly attributable to drivers moving

across into the path of overtaking vehicles that have not been seen in conventional mirrors. New mirror designs have improved

the situation, but by remotely covering areas that cannot be seen either directly or by the vehicle mirrors, have led to the

introduction of a radar-based blind spot monitoring system.

The blind spot monitoring system comprises:

LH (left-hand) Blind spot monitoring sensor

RH (right-hand) Blind spot monitoring sensor

LH door mirror RH door mirror

The system uses two radar modules operating at a frequency of 24 GHz and each combining the radar face and electronic

module in a single unit. The modules are located behind the rear bumper surface, symmetrically, one on each side of the car

behind the rear wheels. They are side facing and inclined rearwards at an angle of 16 degrees, which is dictated by the shape

at the rear of the vehicle. Each module is calibrated to detect a vehicle in the driver’s blind spot. Once a vehicle is detected

the module illuminates an amber warning ‘alert icon’ LED (light emitting diode) in the relevant exterior door mirror. If there is a

fault or blockage with the blind spot monitoring system an amber warning indicator dot LED is displayed in the exterior mirror and the message ‘blind spot monitoring not available’ is displayed in the instrument cluster message center.

When the system initiates, it performs a self-check, during which the warning icons in the mirrors illuminate alternately for a

short period of time. Each module does a left/right determination check when the ignition is switched on. Each mirror has a

different circuit configuration so that the modules can determine which mirror they are connected to. If a module detects the

wrong mirror it will go into a fault condition.

The blind spot monitoring modules receive vehicle speed on the medium speed CAN (controller area network) and are inactive

until the vehicle reaches 16kph (10mph). Each blind spot monitor module emits a radar field greater than the blind spot area.

Each Blind Spot Monitor module emits a radar field greater than the blind spot area. The actual blind spot area is calibrated

into the module during its manufacture.

CAUTION: The blind spot monitoring system is designed as a driver aid not a safety device. The driver should always

exercise due care and attention whilst driving. www.JagDocs.com

Page 1834 of 3039

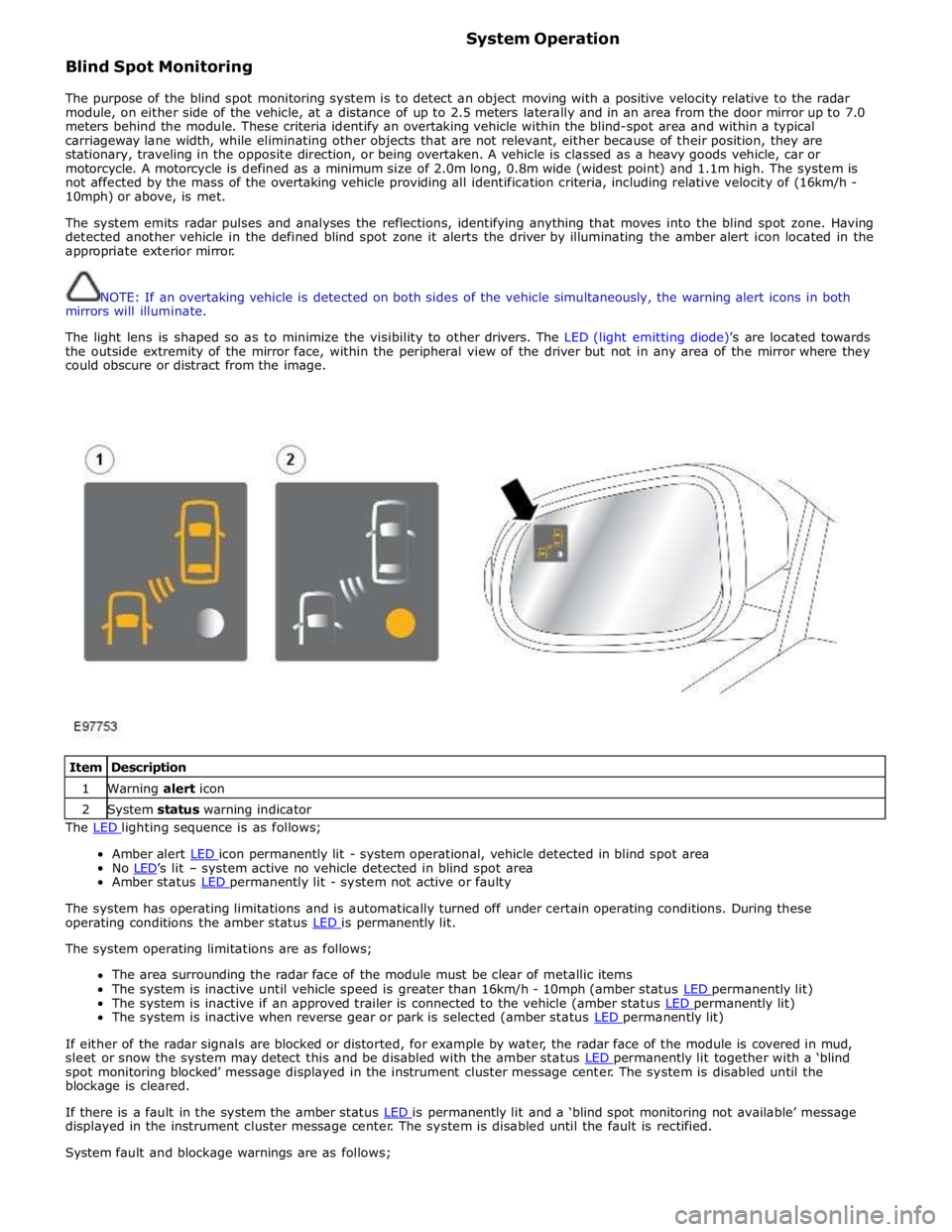

Blind Spot Monitoring System Operation

The purpose of the blind spot monitoring system is to detect an object moving with a positive velocity relative to the radar

module, on either side of the vehicle, at a distance of up to 2.5 meters laterally and in an area from the door mirror up to 7.0

meters behind the module. These criteria identify an overtaking vehicle within the blind-spot area and within a typical

carriageway lane width, while eliminating other objects that are not relevant, either because of their position, they are

stationary, traveling in the opposite direction, or being overtaken. A vehicle is classed as a heavy goods vehicle, car or

motorcycle. A motorcycle is defined as a minimum size of 2.0m long, 0.8m wide (widest point) and 1.1m high. The system is

not affected by the mass of the overtaking vehicle providing all identification criteria, including relative velocity of (16km/h -

10mph) or above, is met.

The system emits radar pulses and analyses the reflections, identifying anything that moves into the blind spot zone. Having

detected another vehicle in the defined blind spot zone it alerts the driver by illuminating the amber alert icon located in the

appropriate exterior mirror.

NOTE: If an overtaking vehicle is detected on both sides of the vehicle simultaneously, the warning alert icons in both

mirrors will illuminate.

The light lens is shaped so as to minimize the visibility to other drivers. The LED (light emitting diode)’s are located towards

the outside extremity of the mirror face, within the peripheral view of the driver but not in any area of the mirror where they

could obscure or distract from the image.

Item Description 1 Warning alert icon 2 System status warning indicator The LED lighting sequence is as follows;

Amber alert LED icon permanently lit - system operational, vehicle detected in blind spot area No LED’s lit – system active no vehicle detected in blind spot area Amber status LED permanently lit - system not active or faulty

The system has operating limitations and is automatically turned off under certain operating conditions. During these

operating conditions the amber status LED is permanently lit. The system operating limitations are as follows;

The area surrounding the radar face of the module must be clear of metallic items

The system is inactive until vehicle speed is greater than 16km/h - 10mph (amber status LED permanently lit) The system is inactive if an approved trailer is connected to the vehicle (amber status LED permanently lit) The system is inactive when reverse gear or park is selected (amber status LED permanently lit)

If either of the radar signals are blocked or distorted, for example by water, the radar face of the module is covered in mud,

sleet or snow the system may detect this and be disabled with the amber status LED permanently lit together with a ‘blind spot monitoring blocked’ message displayed in the instrument cluster message center. The system is disabled until the

blockage is cleared.

If there is a fault in the system the amber status LED is permanently lit and a ‘blind spot monitoring not available’ message displayed in the instrument cluster message center. The system is disabled until the fault is rectified.

System fault and blockage warnings are as follows;

Page 1837 of 3039

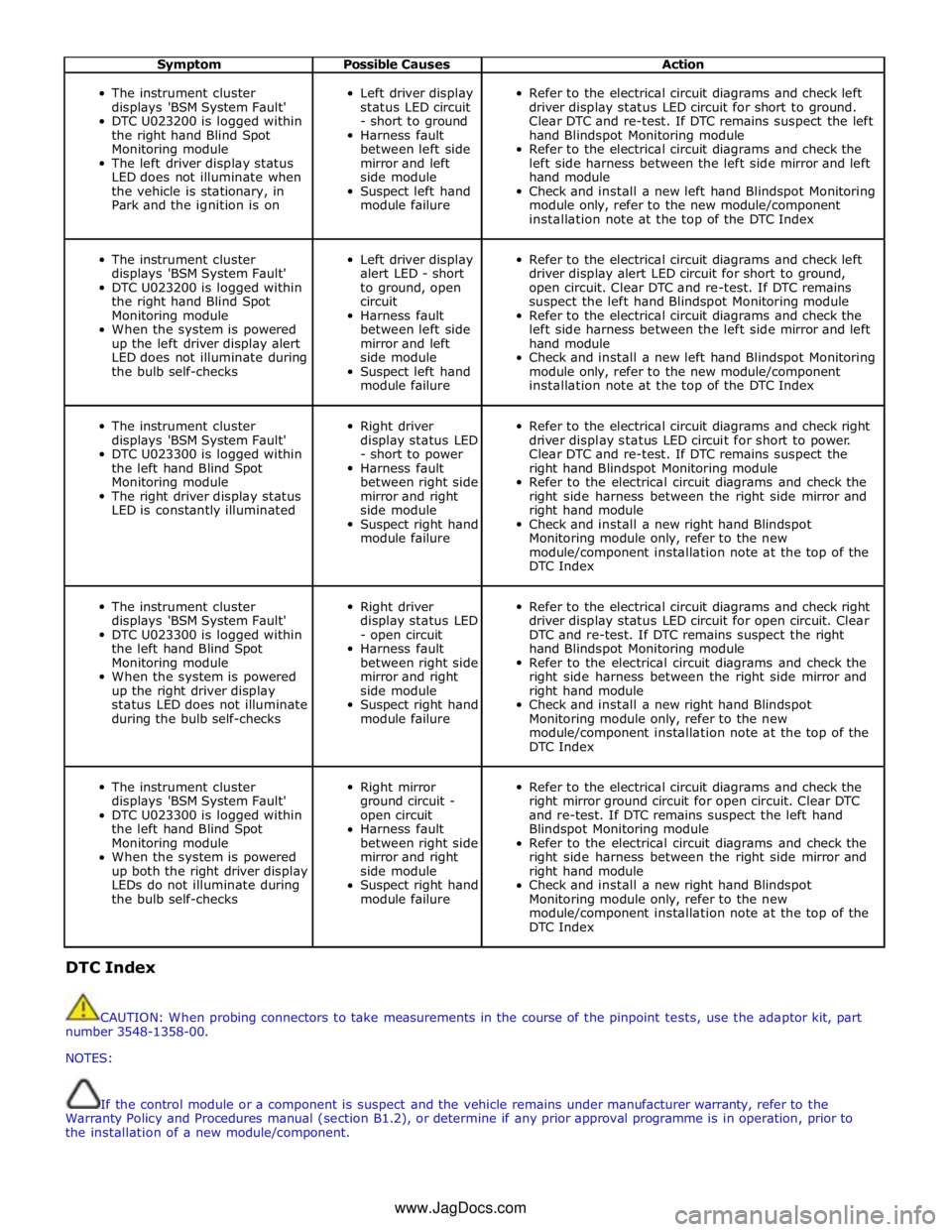

Symptom Possible Causes Action

The instrument cluster

displays 'BSM System Fault'

DTC U023200 is logged within

the right hand Blind Spot

Monitoring module

The left driver display status

LED does not illuminate when

the vehicle is stationary, in

Park and the ignition is on

Left driver display

status LED circuit

- short to ground

Harness fault

between left side

mirror and left

side module

Suspect left hand

module failure

Refer to the electrical circuit diagrams and check left

driver display status LED circuit for short to ground.

Clear DTC and re-test. If DTC remains suspect the left

hand Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

left side harness between the left side mirror and left

hand module

Check and install a new left hand Blindspot Monitoring

module only, refer to the new module/component

installation note at the top of the DTC Index

The instrument cluster

displays 'BSM System Fault'

DTC U023200 is logged within

the right hand Blind Spot

Monitoring module

When the system is powered

up the left driver display alert

LED does not illuminate during

the bulb self-checks

Left driver display

alert LED - short

to ground, open

circuit

Harness fault

between left side

mirror and left

side module

Suspect left hand

module failure

Refer to the electrical circuit diagrams and check left

driver display alert LED circuit for short to ground,

open circuit. Clear DTC and re-test. If DTC remains

suspect the left hand Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

left side harness between the left side mirror and left

hand module

Check and install a new left hand Blindspot Monitoring

module only, refer to the new module/component

installation note at the top of the DTC Index

The instrument cluster

displays 'BSM System Fault'

DTC U023300 is logged within

the left hand Blind Spot

Monitoring module

The right driver display status

LED is constantly illuminated

Right driver

display status LED

- short to power

Harness fault

between right side

mirror and right

side module

Suspect right hand

module failure

Refer to the electrical circuit diagrams and check right

driver display status LED circuit for short to power.

Clear DTC and re-test. If DTC remains suspect the

right hand Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module

Check and install a new right hand Blindspot

Monitoring module only, refer to the new

module/component installation note at the top of the

DTC Index

The instrument cluster

displays 'BSM System Fault'

DTC U023300 is logged within

the left hand Blind Spot

Monitoring module

When the system is powered

up the right driver display

status LED does not illuminate

during the bulb self-checks

Right driver

display status LED

- open circuit

Harness fault

between right side

mirror and right

side module

Suspect right hand

module failure

Refer to the electrical circuit diagrams and check right

driver display status LED circuit for open circuit. Clear

DTC and re-test. If DTC remains suspect the right

hand Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module

Check and install a new right hand Blindspot

Monitoring module only, refer to the new

module/component installation note at the top of the

DTC Index

The instrument cluster

displays 'BSM System Fault'

DTC U023300 is logged within

the left hand Blind Spot

Monitoring module

When the system is powered

up both the right driver display

LEDs do not illuminate during

the bulb self-checks

Right mirror

ground circuit -

open circuit

Harness fault

between right side

mirror and right

side module

Suspect right hand

module failure

Refer to the electrical circuit diagrams and check the

right mirror ground circuit for open circuit. Clear DTC

and re-test. If DTC remains suspect the left hand

Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module

Check and install a new right hand Blindspot

Monitoring module only, refer to the new

module/component installation note at the top of the

DTC Index DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

www.JagDocs.com

Page 1838 of 3039

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

When carrying out repair/diagnosis of the system, on removal of the front or rear bumper inspect the sensor connectors

to ensure they were correctly latched and check fly leads for signs of chaffing or trapped wires.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

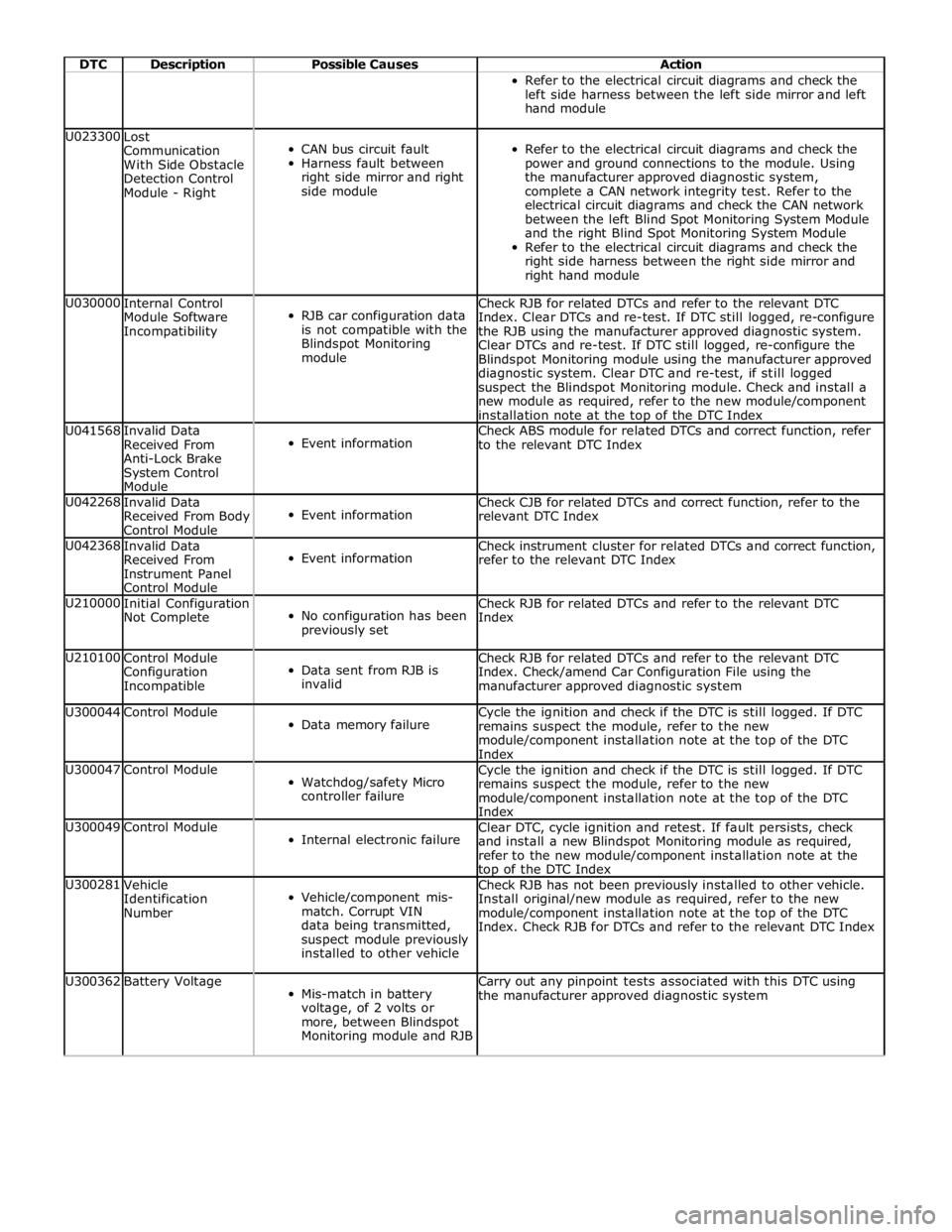

DTC Description Possible Causes Action B11C911

Driver Display

Status LED

Driver Display Status LED

circuit - short to ground Refer to the electrical circuit diagrams and check driver display

status LED circuit for short to ground B11C915

Driver Display

Status LED

Driver Display Status LED

circuit - short to power,

open circuit Refer to the electrical circuit diagrams and check driver display

status LED circuit for short to power, open circuit B11D611

Driver Display Alert

LED

Driver Display Alert LED

circuit - short to ground Refer to the electrical circuit diagrams and check driver display

alert LED circuit for short to ground B11D615

Driver Display Alert

LED

Driver Display Alert LED

circuit - short to power,

open circuit Refer to the electrical circuit diagrams and check driver display

alert LED circuit for short to power, open circuit U001000

Medium Speed CAN

Communication Bus

No sub type information Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check MS CAN

bus state, carry out CAN network integrity tests using the

manufacturer approved diagnostic system U014000

Lost

Communication

With Body Control

Module

Lost communication with

CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

related DTCs and correct function, refer to the relevant DTC

Index U014200

Lost

Communication

With Body Control

Module "B"

Lost communication with

RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

related DTCs and correct function, refer to the relevant DTC

Index U014600

Lost

Communication

With Gateway "A"

Lost communication with

information and

entertainment module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment module for related DTCs and

correct function, refer to the relevant DTC Index U015500

Lost

Communication

With Instrument

Panel Cluster (IPC)

Control Module

Lost communication with

instrument cluster Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

instrument cluster for related DTCs and correct function, refer

to the relevant DTC Index U023200

Lost

Communication

With Side Obstacle

Detection Control

Module - Left

CAN bus circuit fault

Harness fault between left

side mirror and left side

module

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using

the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the left Blind Spot Monitoring System Module

and the right Blind Spot Monitoring System Module

Page 1839 of 3039

DTC Description Possible Causes Action Refer to the electrical circuit diagrams and check the

left side harness between the left side mirror and left

hand module U023300

Lost

Communication

With Side Obstacle

Detection Control

Module - Right

CAN bus circuit fault

Harness fault between

right side mirror and right

side module

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using

the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the left Blind Spot Monitoring System Module

and the right Blind Spot Monitoring System Module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module U030000

Internal Control

Module Software

Incompatibility

RJB car configuration data

is not compatible with the

Blindspot Monitoring

module Check RJB for related DTCs and refer to the relevant DTC

Index. Clear DTCs and re-test. If DTC still logged, re-configure

the RJB using the manufacturer approved diagnostic system.

Clear DTCs and re-test. If DTC still logged, re-configure the

Blindspot Monitoring module using the manufacturer approved

diagnostic system. Clear DTC and re-test, if still logged

suspect the Blindspot Monitoring module. Check and install a

new module as required, refer to the new module/component

installation note at the top of the DTC Index U041568

Invalid Data

Received From

Anti-Lock Brake

System Control

Module

Event information Check ABS module for related DTCs and correct function, refer

to the relevant DTC Index U042268

Invalid Data

Received From Body

Control Module

Event information Check CJB for related DTCs and correct function, refer to the

relevant DTC Index U042368

Invalid Data

Received From

Instrument Panel

Control Module

Event information Check instrument cluster for related DTCs and correct function,

refer to the relevant DTC Index U210000

Initial Configuration

Not Complete

No configuration has been

previously set Check RJB for related DTCs and refer to the relevant DTC

Index U210100

Control Module

Configuration

Incompatible

Data sent from RJB is

invalid Check RJB for related DTCs and refer to the relevant DTC

Index. Check/amend Car Configuration File using the

manufacturer approved diagnostic system U300044 Control Module

Data memory failure Cycle the ignition and check if the DTC is still logged. If DTC

remains suspect the module, refer to the new

module/component installation note at the top of the DTC

Index U300047 Control Module

Watchdog/safety Micro

controller failure Cycle the ignition and check if the DTC is still logged. If DTC

remains suspect the module, refer to the new

module/component installation note at the top of the DTC

Index U300049 Control Module

Internal electronic failure Clear DTC, cycle ignition and retest. If fault persists, check

and install a new Blindspot Monitoring module as required,

refer to the new module/component installation note at the top of the DTC Index U300281

Vehicle

Identification

Number

Vehicle/component mis-

match. Corrupt VIN

data being transmitted,

suspect module previously

installed to other vehicle Check RJB has not been previously installed to other vehicle.

Install original/new module as required, refer to the new

module/component installation note at the top of the DTC

Index. Check RJB for DTCs and refer to the relevant DTC Index U300362 Battery Voltage

Mis-match in battery

voltage, of 2 volts or

more, between Blindspot

Monitoring module and RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system