Valve JAGUAR XJ 1994 2.G AJ16 Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 2 of 73

AJ16 Engine Service Manual

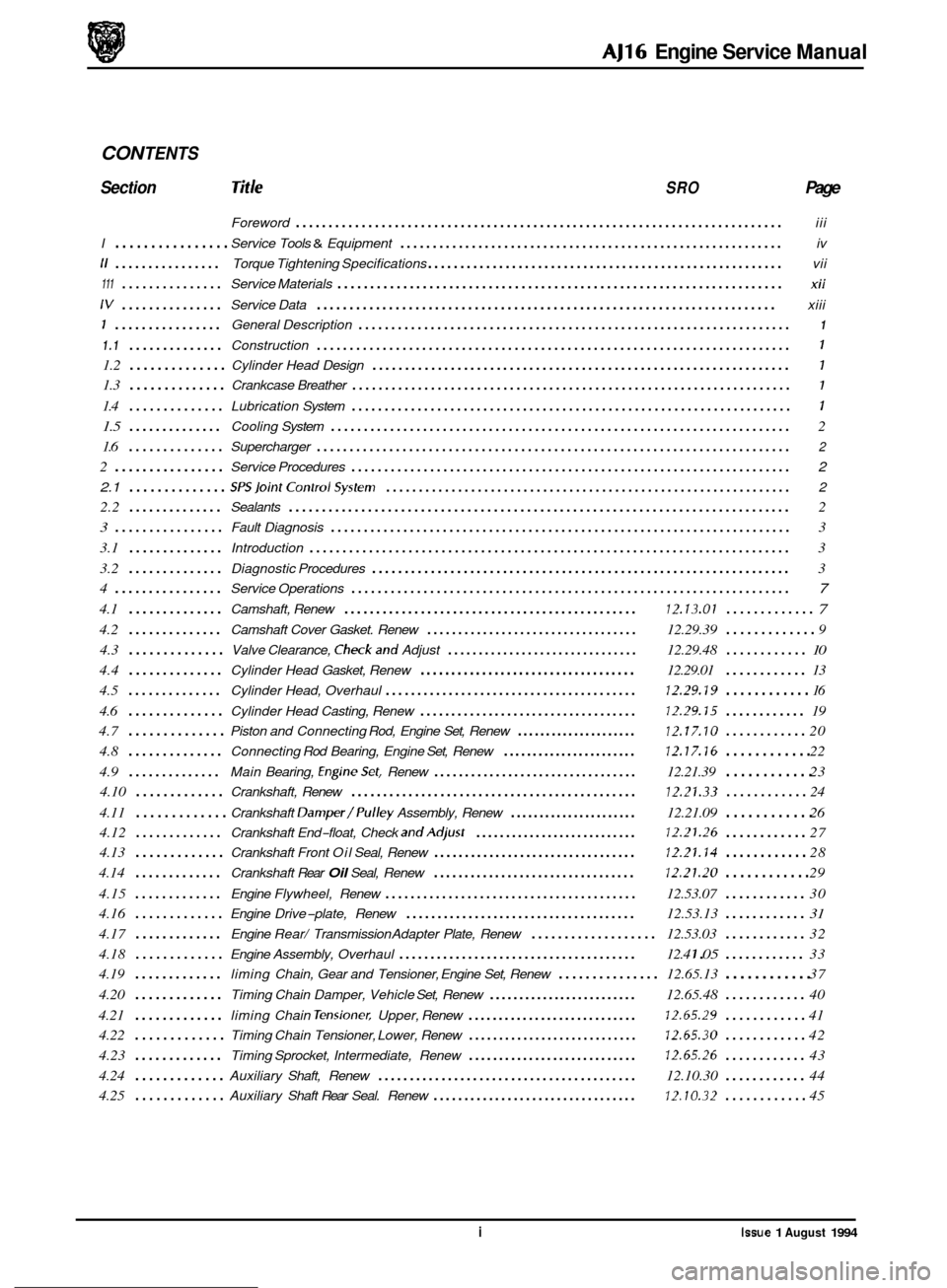

CON TENTS

Section SRO Page

Foreword ........................................................................\

.. iii

I ................ Service Tools & Equipment ........................................................... iv

I1 ................ Torque Tightening Specifications ....................................................... vii

111 ............... Service Materials .................................................................... xii

1V ............... Service Data ...................................................................... xiii

1 ................ General Description .................................................................. 1

1.1 .............. Construction ........................................................................\

1

1.2 .............. Cylinder Head Design ................................................................ 7

1.3 .............. Crankcase Breather ................................................................... 7

1.4 .............. Lubrication System ................................................................... 1

1.5 .............. Cooling System ...................................................................... 2

1.6

.............. Supercharger ........................................................................\

2

2 ................ Service Procedures ................................................................... 2

2.1 .............. SPSloint ControlSystem .............................................................. 2

2.2 .............. Sealants ........................................................................\

.... 2

3 ................ Fault Diagnosis ...................................................................... 3

3.1

.............. Introduction ........................................................................\

. 3

3.2

.............. Diagnostic Procedures ................................................................ 3

4

................ Service Operations ................................................................... 7

4.1 .............. Camshaft, Renew .............................................. 12.13.01 ............. 7

4.2 .............. Camshaft Cover Gasket. Renew .................................. 12.29.39 ............. 9

4.3

.............. Valve Clearance, Checkand Adjust ............................... 12.29.48 ............ 10

4.4 .............. Cylinder Head Gasket, Renew ................................... 12.29.01 ............ 13

4.5

.............. Cylinder Head, Overhaul ........................................ 12.29.19 ............ 16

4.6

.............. Cylinder Head Casting, Renew ................................... 12.29.15 ............ 19

4.7

.............. Piston and Connecting Rod, Engine Set, Renew ..................... 12.17.10 ............ 20

4.8

.............. Connecting Rod Bearing, Engine Set, Renew ....................... 12.17.16 ............ 22

4.9

.............. Main Bearing, Engineset, Renew ................................. 12.21.39 ............ 23

4.10 ............. Crankshaft, Renew ............................................. 12.21.33 ............ 24

4.11

............. Crankshaft Damper/Pulley Assembly, Renew ...................... 12.21.09 ............ 26

4.12

............. Crankshaft End-float, Check andAdjust ........................... 12.21.26 ............ 27

4.13

............. Crankshaft Front Oil Seal, Renew ................................. 12.21.14 ............ 28

4.14

............. Crankshaft Rear Oil Seal, Renew ................................. 72.21.20 ............ 29

4.15

............. Engine Flywheel, Renew ........................................ 12.53.07 ............ 30

4.16

............. Engine Drive-plate, Renew ..................................... 12.53.13 ............ 31

4.17 ............. Engine Rear/ Transmission Adapter Plate, Renew ................... 12.53.03 ............ 32

4.18

............. Engine Assembly, Overhaul ...................................... 12.4 7 . 05 ............ 33

4.19

............. liming Chain, Gear and Tensioner, Engine Set, Renew ............... 12.65.13 ............ 37

4.20

............. Timing Chain Damper, Vehicle Set, Renew ......................... 12.65.48 ............ 40

4.21

............. liming Chain Tensioner, Upper, Renew ............................ 12.65.29 ............ 41

4.22

............. Timing Chain Tensioner, Lower, Renew ............................ 12.65.30 ............ 42

4.23

............. Timing Sprocket, Intermediate, Renew ............................ 12.65.26 ............ 43

4.24

............. Auxiliary Shaft, Renew ......................................... 12.10.30 ............ 44

4.25

............. Auxiliary Shaft Rear Seal. Renew ................................. 12.10.32 ............ 45

0

i Issue 1 August 1994

Page 3 of 73

AJ16 Engine Service Manual

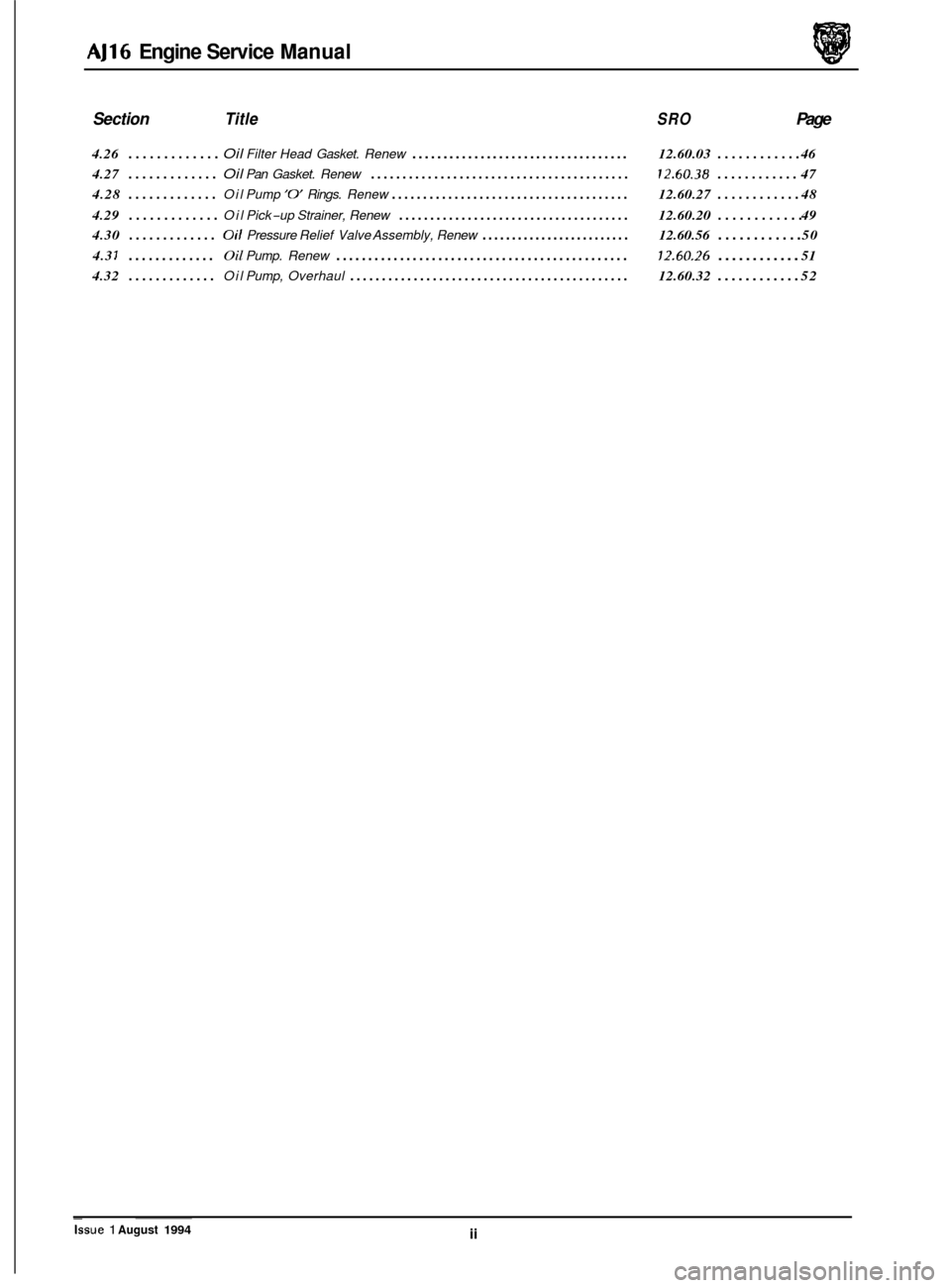

Section Title SRO Page

4.26 ............. Oil Filter Head Gasket. Renew ................................... 12.60.03 ............ 46

4.27

............. Oil Pan Gasket. Renew ......................................... 12.60.38 ............ 47

4.28

............. Oil Pump '0' Rings. Renew ...................................... 12.60.27 ............ 48

4.29

............. Oil Pick-up Strainer, Renew ..................................... 12.60.20 ............ 49

4.30

............. Oil Pressure Relief Valve Assembly, Renew ......................... 12.60.56 ............ 50

4.3

1 ............. Oil Pump. Renew .............................................. 12.60.26 ............ 51

4.32

............. Oil Pump, Overhaul ............................................ 12.60.32 ............ 52 ~

Issue 1 August 1994 ii

Page 6 of 73

AJ16 Engine Service Manual

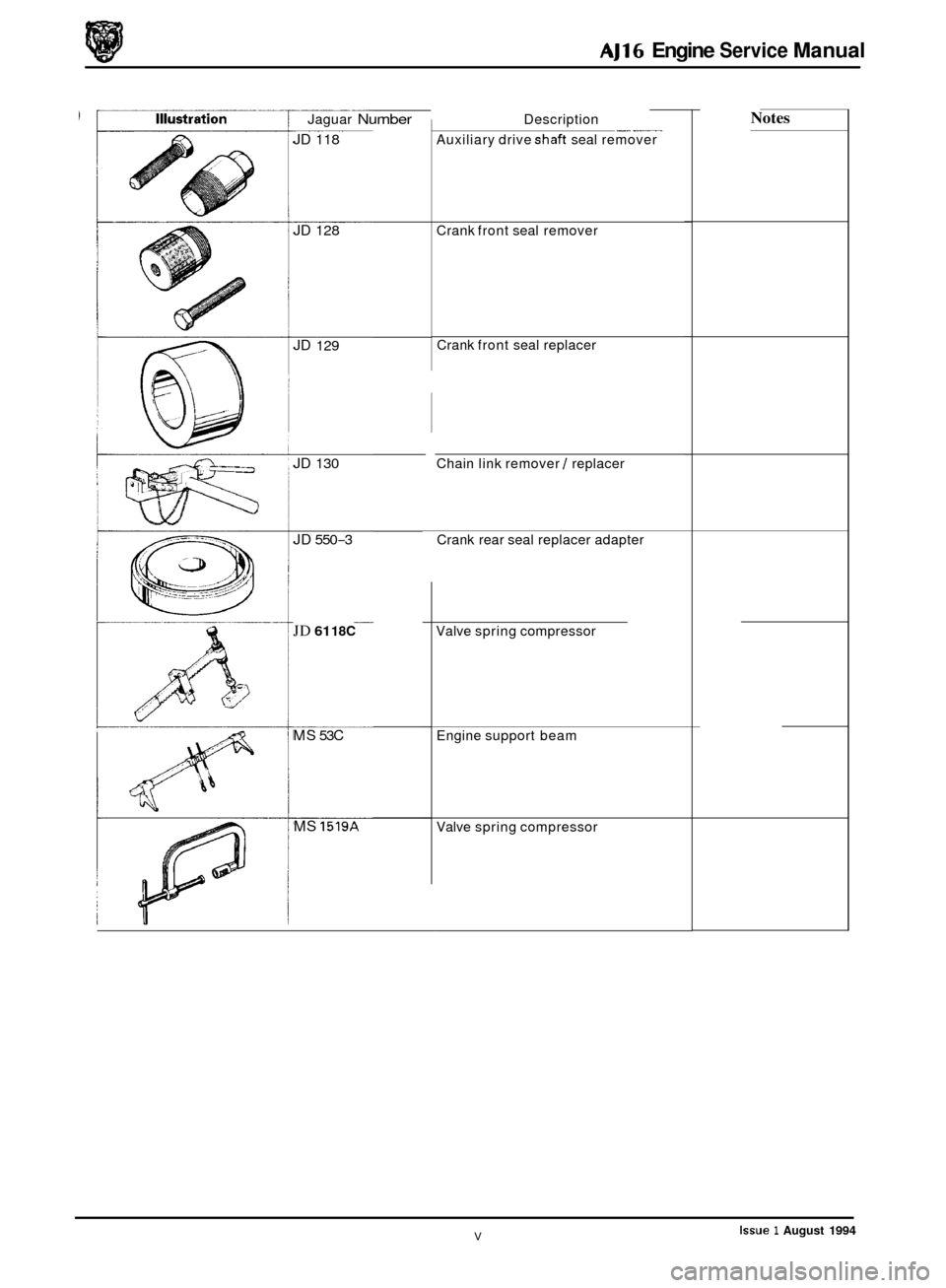

Jaguar Number ~~

JD

118

JD 128

JD

129

JD 130

JD 550

-3

JD 61 18C

MS 53C

MS 1519A

__ ~ Description

Auxiliary drive

shaft seal remover

Crank front seal remover

Crank front seal replacer

Chain link remover

/ replacer

Crank rear seal replacer adapter

Valve spring compressor

Engine support beam

Valve spring compressor

Notes

Issue 1 August 1994 V

Page 11 of 73

AJ16 Engine Service Manual

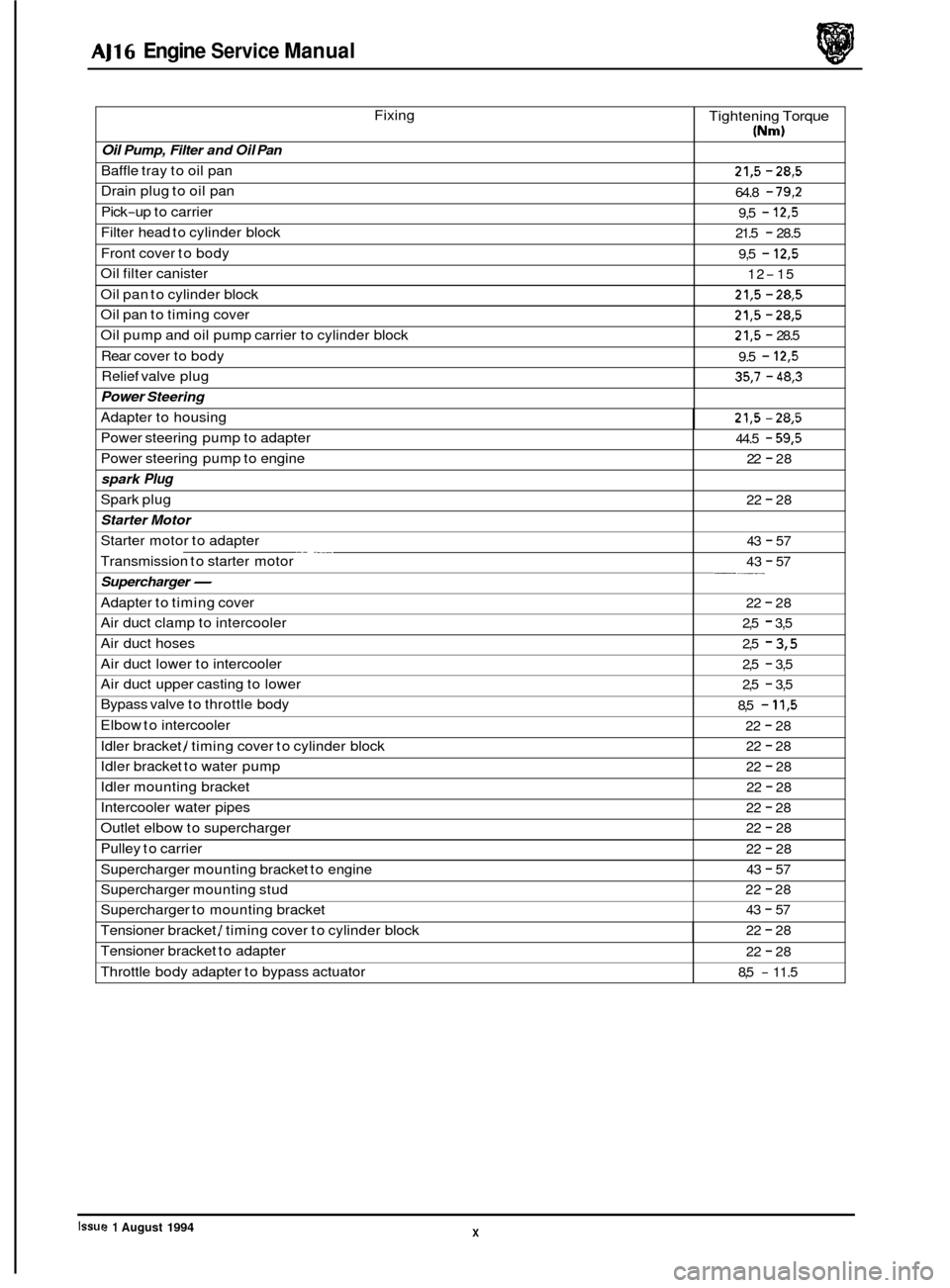

0 Fixing

Oil Pump, Filter and Oil Pan

Baffle tray to oil pan

Drain plug to oil pan

Pick

-up to carrier

Filter head to cylinder block

Front cover to body

Oil filter canister

Oil pan to cylinder block

Oil pan to timing cover

Oil pump and oil pump carrier to cylinder block

Rear cover to body

Relief valve plug Tightening

Torque

(Nm)

21,5 - 28,5

64.8 - 79,2

9,5 - 12,5

21.5 - 28.5

9,5

- 12,5

12-15

21,5 - 28,5

21,5 - 28,5

21,5 - 28.5

9.5

- 12,5

35,7 - 48,3

Power Steering

Adapter to housing 21,5 - 28,5

Power steering pump to adapter

Power steering pump to engine

spark Plug

Starter Motor

Starter motor to adapter

Transmission to starter motor

Supercharger-

Spark plug

--

44.5 - 59,5

22 - 28

22

- 28

43

- 57

43

- 57 -___

Adapter to timing cover

Air duct clamp to intercooler

Air duct hoses

Air duct lower to intercooler 22 - 28

2,5

- 3,5

2,5

- 3,5

2,5 - 3,5

Air duct upper casting to lower

Bypass valve to throttle body

Elbow to intercooler

Idler bracket

/ timing cover to cylinder block

Idler bracket to water pump

X Issue 1 August 1994

2,5 - 3,5

8,5

- 11,5

22 - 28

22

- 28

22

- 28

Idler mounting bracket

Intercooler water pipes

Outlet elbow to supercharger

Pulley to carrier

Supercharger mounting bracket to engine

Supercharger mounting stud 22 - 28

22

- 28

22

- 28

22

- 28

43

- 57

22

- 28

Supercharger to mounting bracket 43 - 57

Tensioner bracket / timing cover to cylinder block 22 - 28

Tensioner bracket to adapter

Throttle body adapter to bypass actuator 22 - 28

8,5

- 11.5

Page 16 of 73

AJ16 Engine Service Manual

Item

Type

Length

Outside diameter

Inside diameter

Material ~

Application

Specification

Chamfer locking

3,2

liter: 68,37 to 68,50 mm

4,O liter: 77,12 to 77,25 mm

23,807 to 23,812 mm

14,30 to 14.81 mm

Cast iron

'iston pin

2amshaft

dalve

Number of journals

Nominal

lift

Permissible end float

4djustment of valve clearance 7

9,95 mm

0.13 mm

rlalve Guide

Valve

stem diameter

Valve clearance

Jalve seat Intake

and exhaust: 6,947 to 6,960

mm

Intake and exhaust: 0,30 to 0,36 mm

Jalve seat insert outside diameter Outside

diameter

rappet

lalve spring Standard

- no

groove: 10,993 to

11,005 mm

1st oversize - 1 groove: 11,043 to

11,055

mm (production only)

2nd oversize

- 2 grooves: 1 1,143 to

11,155 mm

:amshaft sprocket

:rankshaft sprocket Diametrical

clearance

Free length

Number

of teeth

ntermediate sprocket

0,02 to 0,05 mm

43,5 mm

30

xv Issue 1 August 1994

Page 17 of 73

AJ16 Engine Service Manual

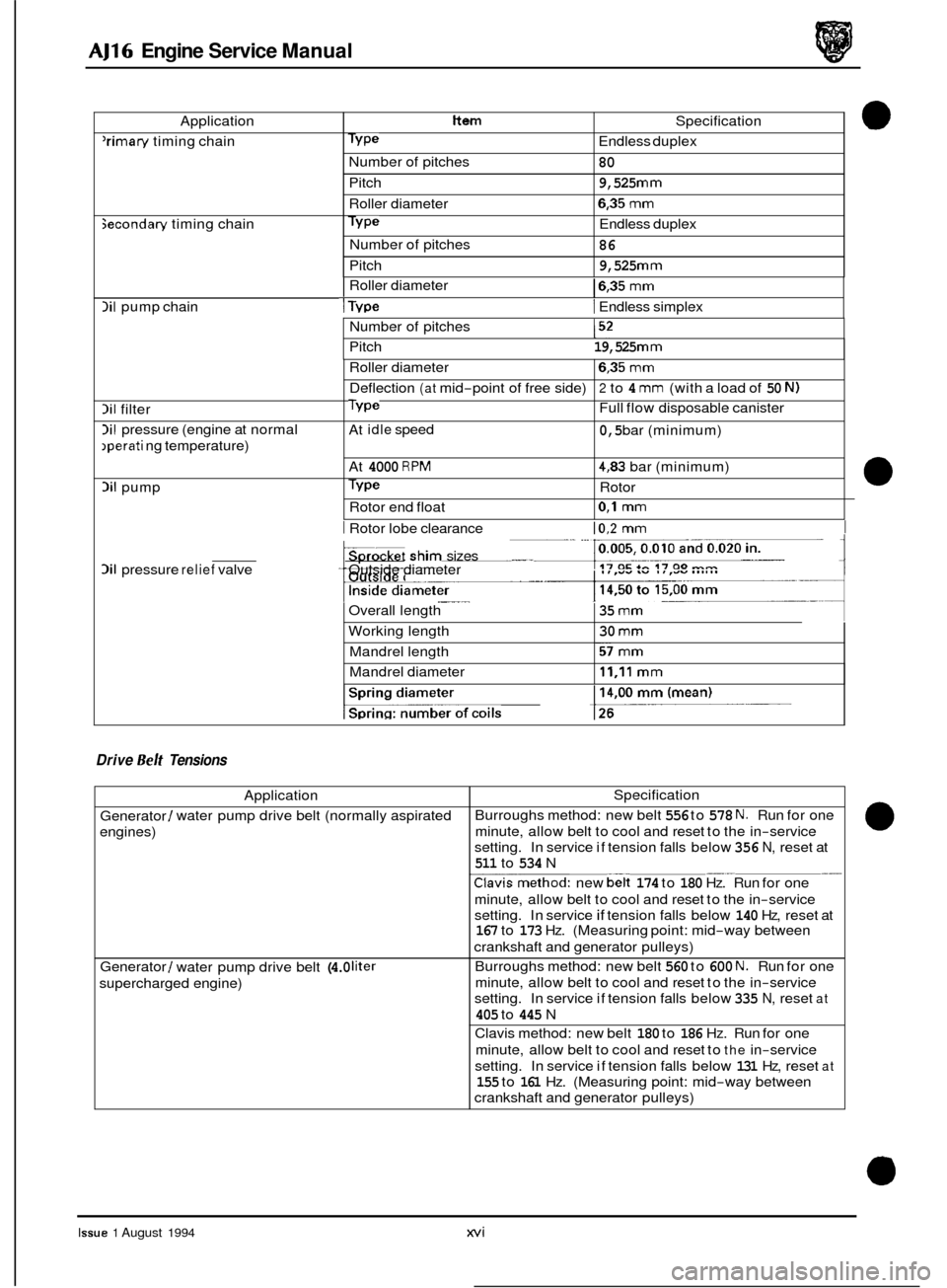

0 Application Item

'rimary timing chain Type

Pitch

Roller diameter

secondan/ timing chain Type

Number of pitches

Pitch

Number of

pitches Specification

Endless duplex

80

9,525

mm

6,35 mm

Endless duplex

86

9,525

mm

lil pump chain

lil filter

lil pressure (engine at normal

,perati ng temperature)

Si1 pump

I Roller diameter 16,35 mm

I Type I Endless simplex

Roller diameter

6,35 mm

Deflection (at mid-point of free side) 2 to 4 mm (with a load of 50 N)

Type Full flow disposable canister

At

idle speed 0,5 bar (minimum)

At

4000 RPM 4,83 bar (minimum)

Type Rotor

Rotor end float

0,l mm

Number of pitches I52

Pitch 19,525 mm

___ Overall length

Working length Mandrel length

Mandrel diameter 35 mm

30 mm

57 mm

11,ll mm

Si1 pressure relief valve

Application

Generator

/ water pump drive belt (normally aspirated

engines)

Generator

/ water pump drive belt (4.0 liter

supercharged engine)

I Rotor lobe clearance 10,2 mm I

Specification

Burroughs method: new belt

556 to 578 N. Run for one

minute, allow belt to cool and reset to the in

-service

setting. In service if tension falls below

356 N, reset at

511 to 534 N

.Clavismethod: new belt 174 to 180 Hz. Run for one

minute, allow belt to cool and reset to the in

-service

setting. In service

if tension falls below 140 Hz, reset at 167 to 173 Hz. (Measuring point: mid-way between

crankshaft and generator pulleys)

Burroughs method: new belt

560 to 600 N. Run for one

minute, allow belt to cool and reset to the in

-service

setting. In service if tension falls below

335 N, reset at

405 to 445 N

Clavis method: new belt

180 to 186 Hz. Run for one

minute, allow belt to cool and reset to

the in-service

setting. In service if tension falls below

131 Hz, reset at

155 to 161 Hz. (Measuring point: mid-way between

crankshaft and generator pulleys)

__ ___

.- ...

pket she sizes ___ Outside diameter

1

1

Drive Belt Tensions

0

Issue 1 August 1994 xvi

Page 20 of 73

AJ16 Engine Service Manual

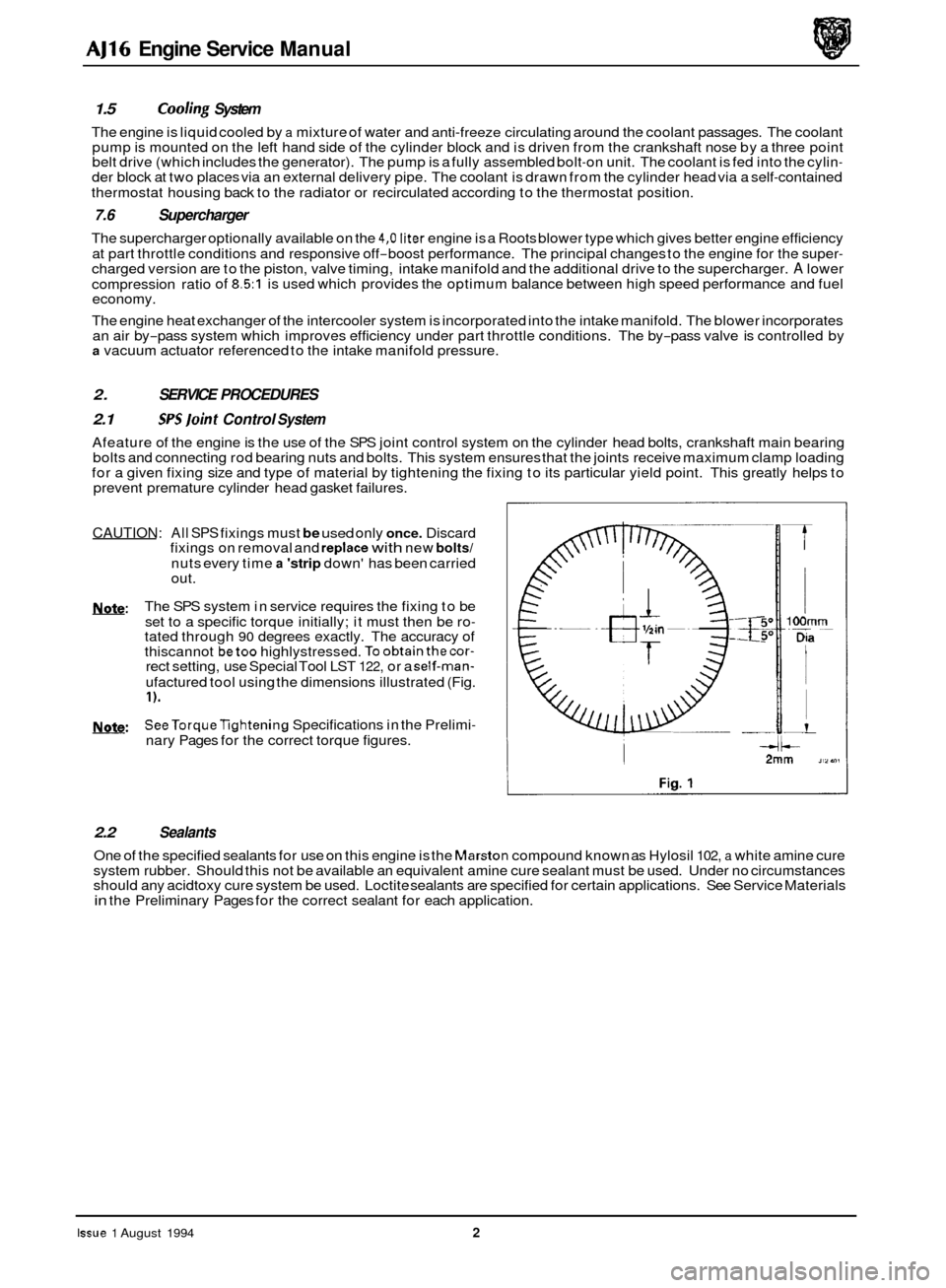

0 GENERAL DESCRIPTION - The engine is available as a 3,2 and 4,O liter unit. A 4,O liter supercharged version is also available. Fuel is supplied

to each cylinder via an injector fed from a regulated fuel rail. To comply with statutory regulations in some countries

and to reduce emissions during the warm

-up period, secondary air is delivered to the exhaust manifold by an electri- cally operated air injection pump. This improves oxidation until the catalytic converters are fully effective. All engine

functions are controlled by an integrated engine management system, which incorporates the on-board diagnostic

system (OBDII).

1.1 Construction

The skirted design crankcase is manufactured in cast aluminum alloy with shrink fit dry cast iron cylinder sleeves.

Thecrankshaft ismanufactured from cast

ironforthe3,2 literengine,forged steel forthe 4,O liter engineand is nitro-car-

burize treated to give a very high quality finish on the bearing surfaces and increase the life of the journals.

The crankshaft is supported by seven iron bearing caps having bearings, which are lead bronze on split steel backed

shells with a lead indium overlay.

Crankshaft end

-float is controlled by half thrust washers fitted on each side of the center main bearing journal. The

connecting rods are manufactured from carbon manganese steel, forged in an 'H' section. The small end bushes are

lead bronze with steel backing, machined to size after being pressed into the connecting rods. The connecting rod bear- ings are of a lead bronze alloy on split steel backed shells and with lead indium overlay.

The pistons are of monometal construction (aluminum) and have a spring assisted micro

-land oil control ring situated

below a barrel-faced internally tapered chrome plated compression ring and an externally stepped taper-faced second-

ary ring.

The cylinder head is cast from aluminum alloy with pent

-roof shaped combustion chambers with cross-flow valve

porting. Running directly in the cylinder head are

twocast iron camshafts retained by machined aluminumcaps. Each

camshaft uses chilled cams to drive two valves per cylinder via chilled cast iron bucket tappets with shim adjustment.

Control of each of the four valves per cylinder is maintained by single valve springs.

The camshafts are operated by a two stage 'duplex' chain drive from the crankshaft. Each stage is controlled by a hy

- draulic tensioner operating through a pivoted rubber-faced curved tensioner blade. The first stage incorporates a three

point drive via the crankshaft, intermediate shaft and auxiliary shaft. The intermediate shaft is live and provides a 0.75 x crank speed drive through the timing cover. This drive access is blanked off. The 'live' auxiliary shaft is driven at

crankshaft speed and is situated on the right hand side of the engine (looking from rear). In addition to driving the

engine position sensor via a set of 2 : 1 reduction spiral gears, it provides an external drive for the power assisted steer- ing pump at the rear. The second stage is a three point drive via the intermediate shaft and two camshafts. The 2:l reduction ratio from crank speed is achieved by the combined ratio of the intermediate and camshaft sprockets sizes.

The oil pump is a rotor

-type mounted on the underside of the front of the crankcase and driven by a 'simplex' chain

from the crankshaft nose. The pump incorporates a built-in pressure relief valve. Below the line of the crankcase, but

abovetheoil pan

oillevel aretwowindagetrays; these prevent oil beingsucked upand thrown into thecrankcasethere- by alleviating windage and power losses through oil surge.

At the rear of the crankshaft is

a new design of lip-type PTFE oil seal which provides a high degree of oil retention. It also allows the use of higher engine speeds and easier serviceability.

1.2 Cylinder Head Design

The four valves per cylinder are smaller in diameter than on a conventional two valve per cylinder engine and have a greater combined effective area. They are also lighter and apply less stress to the operating gear. The design in- creases the power at high engine speeds and allows an efficient combustion of the fuel. It also allows the spark plug

to besituated in its ideal central position which creates efficient combustion and consequently enhancesfuel economy.

1.3 Crankcase Breather

Blow-by gases are recycled via the air intake system to maintain a crankcase depression and so prevent their escape

to the atmosphere. A baffled vent from the camshaft cover is used for both full and part load breathing. For full load

breathing,

a connection is made direct to the clean side ofthe air filter upstream ofthe throttle disc. Part load breathing is provided by a spur off the full load pipe to downstream ofthe throttle disc via the water heated restrictor. In this way,

a crankcase depression is maintained at all throttle settings.

1.4 Lubrication System

Oil is drawn from the oil pan via a gauze filter. Pressurized oil, having been regulated by a relief valve, is then fed via

internal galleries on the left hand side of the cylinder block. Pressurized and filtered oil is fed into the main oil gallery,

the seven main bearings are fed and thence via crankshaft drillings to the connecting rod bearings. The intermediate

shaft, auxiliary shaft and camshaft bearings are pressure lubricated by means of internal drillings directly fed from the

front of the main oil gallery. For some markets an oil cooler is fitted to vehicles with

4,O liter supercharged engines.

The pistons run on hardened steel piston pins offset from the center line of the piston towards the thrust face.

Issue 1 August 1994 1

Page 21 of 73

AJ16 Engine Service Manual

1.5 Coohg System

The engine is liquid cooled by a mixture of water and anti-freeze circulating around the coolant passages. The coolant

pump is mounted on the left hand side of the cylinder block and is driven from the crankshaft nose by a three point

belt drive (which includes the generator). The pump is a fully assembled bolt

-on unit. The coolant is fed into the cylin- der block at two places via an external delivery pipe. The coolant is drawn from the cylinder head via a self-contained

thermostat housing back to the radiator or recirculated according to the thermostat position.

7.6 Supercharger

The supercharger optionally available on the 4,O liter engine is a Roots blower type which gives better engine efficiency

at part throttle conditions and responsive off

-boost performance. The principal changes to the engine for the super- charged version are to the piston, valve timing, intake manifold and the additional drive to the supercharger. A lower

compression ratio

of 8.5:l is used which provides the optimum balance between high speed performance and fuel

economy.

The engine heat exchanger of the intercooler system is incorporated into the intake manifold. The blower incorporates

an air by

-pass system which improves efficiency under part throttle conditions. The by-pass valve is controlled by a vacuum actuator referenced to the intake manifold pressure.

2. SERVICE PROCEDURES

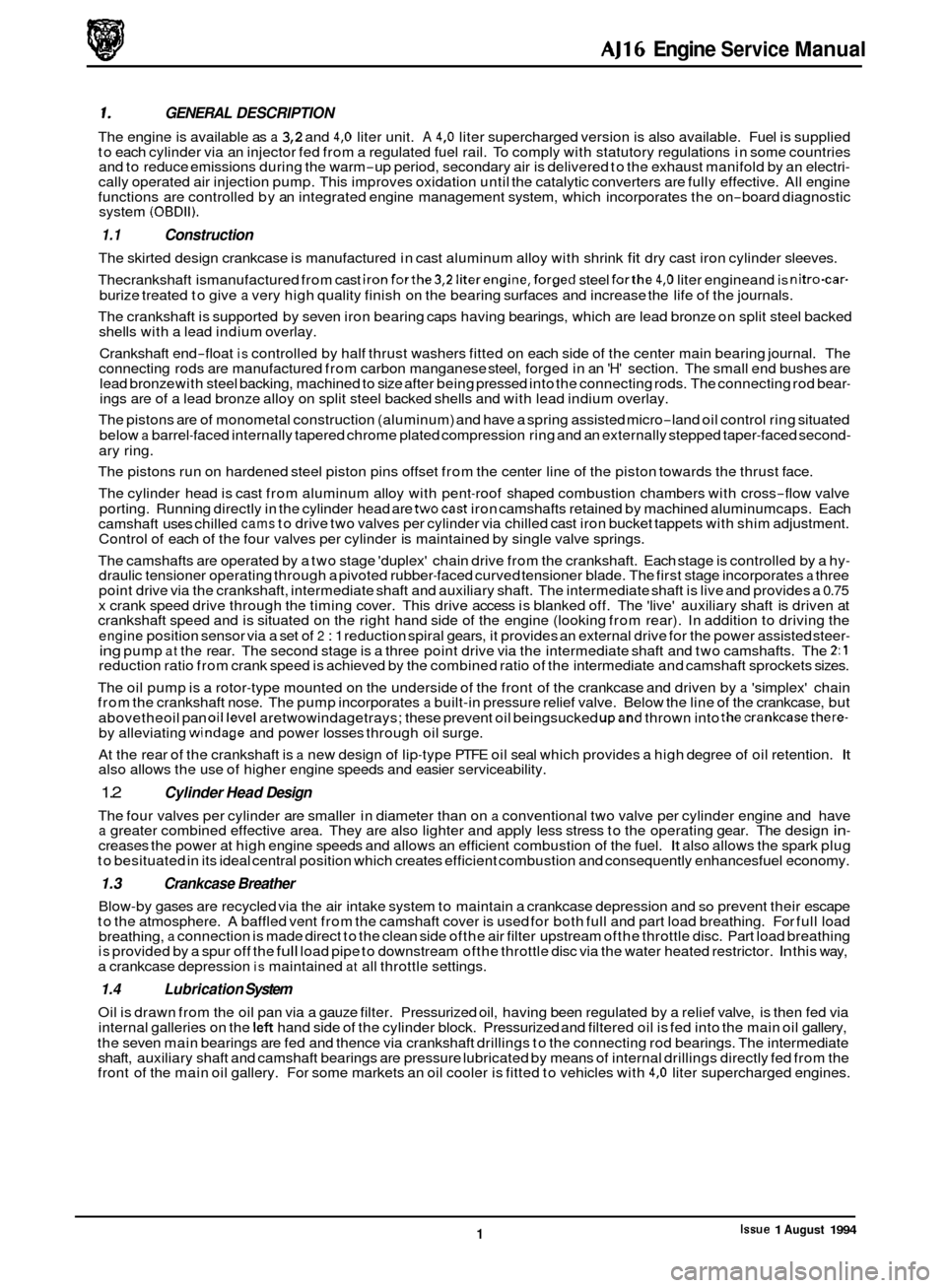

2.1 SPS )oint Control System

Afeature of the engine is the use of the SPS joint control system on the cylinder head bolts, crankshaft main bearing

bolts and connecting rod bearing nuts and bolts. This system ensures that the joints receive maximum clamp loading

for a given fixing size and type of material by tightening the fixing to its particular yield point. This greatly helps to

prevent premature cylinder head gasket failures.

0

CAUTION: All SPS fixings must be used only once. Discard

fixings on removal and replace with new bolts/

nuts every time a 'strip down' has been carried

out.

The SPS system in service requires the fixing to be

set to a specific torque initially; it must then be ro

- tated through 90 degrees exactly. The accuracy of

thiscannot betoo highlystressed. Toobtainthecor- rect setting, use Special Tool LST 122, or a self-man-

ufactured tool using the dimensions illustrated (Fig.

I).

SeeTorqueTightening Specifications in the Prelimi-

nary Pages for the correct torque figures.

b:

w:

2.2 Sealants

One of the specified sealants for use on this engine is the Marston compound known as Hylosil 102, a white amine cure

system rubber. Should this not be available an equivalent amine cure sealant must be used. Under no circumstances

should any acidtoxy cure system be used. Loctite sealants are specified for certain applications. See Service Materials

in the Preliminary Pages for the correct sealant for each application.

Issue 1 August 1994 2

Page 22 of 73

AJ16 Engine Service Manual

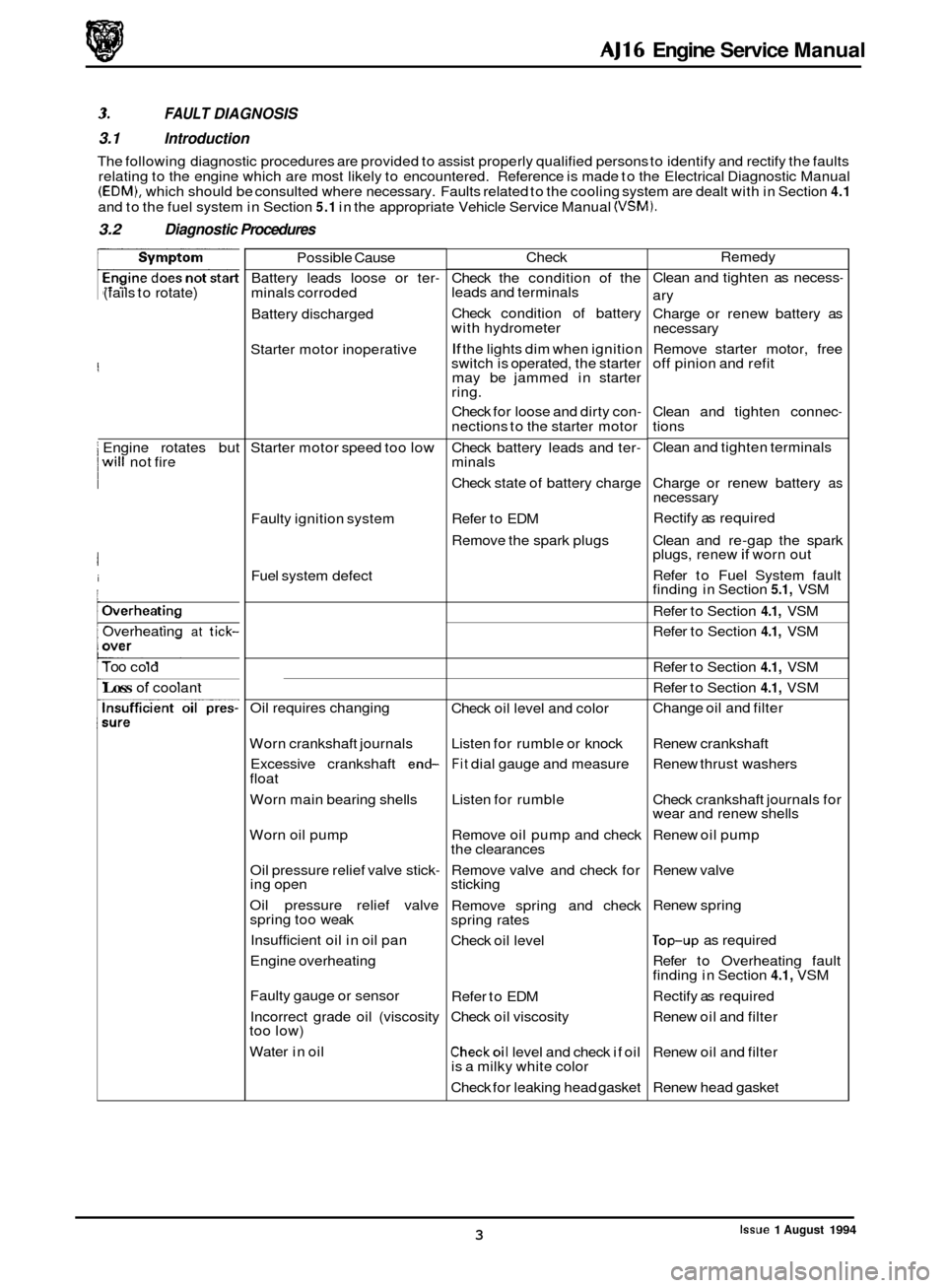

FAULT DIAGNOSIS

3.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults

relating to the engine which are most likely to encountered. Reference is made to the Electrical Diagnostic Manual

(EDM), which should be consulted where necessary. Faults related to the cooling system are dealt with in Section 4.1

and to the fuel system in Section 5.1 in the appropriate Vehicle Service Manual (VSM).

3.2 Diagnostic Procedures

(fails to rotate)

I Engine rotates but 0 I will not fire

I

i

/Overheating

Overheating at tick-

Too cold

Loss of coolant Possible

Cause

Battery leads loose or ter

- minals corroded

Battery discharged

Starter motor inoperative

Starter motor speed too

low

Faulty ignition system

Fuel system defect

Oil requires changing

Worn crankshaft journals

Excessive crankshaft

end- float

Worn main bearing shells

Worn oil pump Oil pressure relief valve stick

- ing open

Oil pressure relief valve

spring too weak

Insufficient oil in oil pan

Engine overheating

Faulty gauge or sensor

Incorrect grade oil (viscosity

too low)

Water in oil Check

Check the condition of the

leads and terminals

Check condition of battery

with hydrometer

If the lights dim when ignition

switch is operated, the starter

may be jammed in starter

ring.

Check for loose and dirty con

- nections to the starter motor

Check battery leads and ter

- minals

Check state of battery charge

Refer to EDM

Remove the spark plugs

Check oil level and color

Listen for rumble or knock

Fit dial gauge and measure

Listen for rumble

Remove oil pump and check

the clearances

Remove valve and check for

sticking

Remove spring and check

spring rates

Check oil level

Refer to EDM

Check oil viscosity

Checkoil level and check if oil

is a milky white color

Check for leaking head gasket Remedy

Clean and tighten as necess

-

ary

Charge or renew battery as

necessary

Remove starter motor, free

off pinion and refit

Clean and tighten connec

- tions

Clean and tighten terminals

Charge or renew battery

as necessary

Rectify as required

Clean and re

-gap the spark

plugs, renew if worn out

Refer to Fuel System fault

finding in Section

5.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Change oil and filter

Renew crankshaft

Renew thrust washers

Check crankshaft journals for

wear and renew shells

Renew oil pump

Renew valve

Renew spring

lop-up as required

Refer to Overheating fault

finding in Section

4.1, VSM

Rectify as required

Renew oil and filter

Renew oil and filter

Renew head gasket

Issue 1 August 1994 3

Page 23 of 73

AJ16 Engine Service Manual

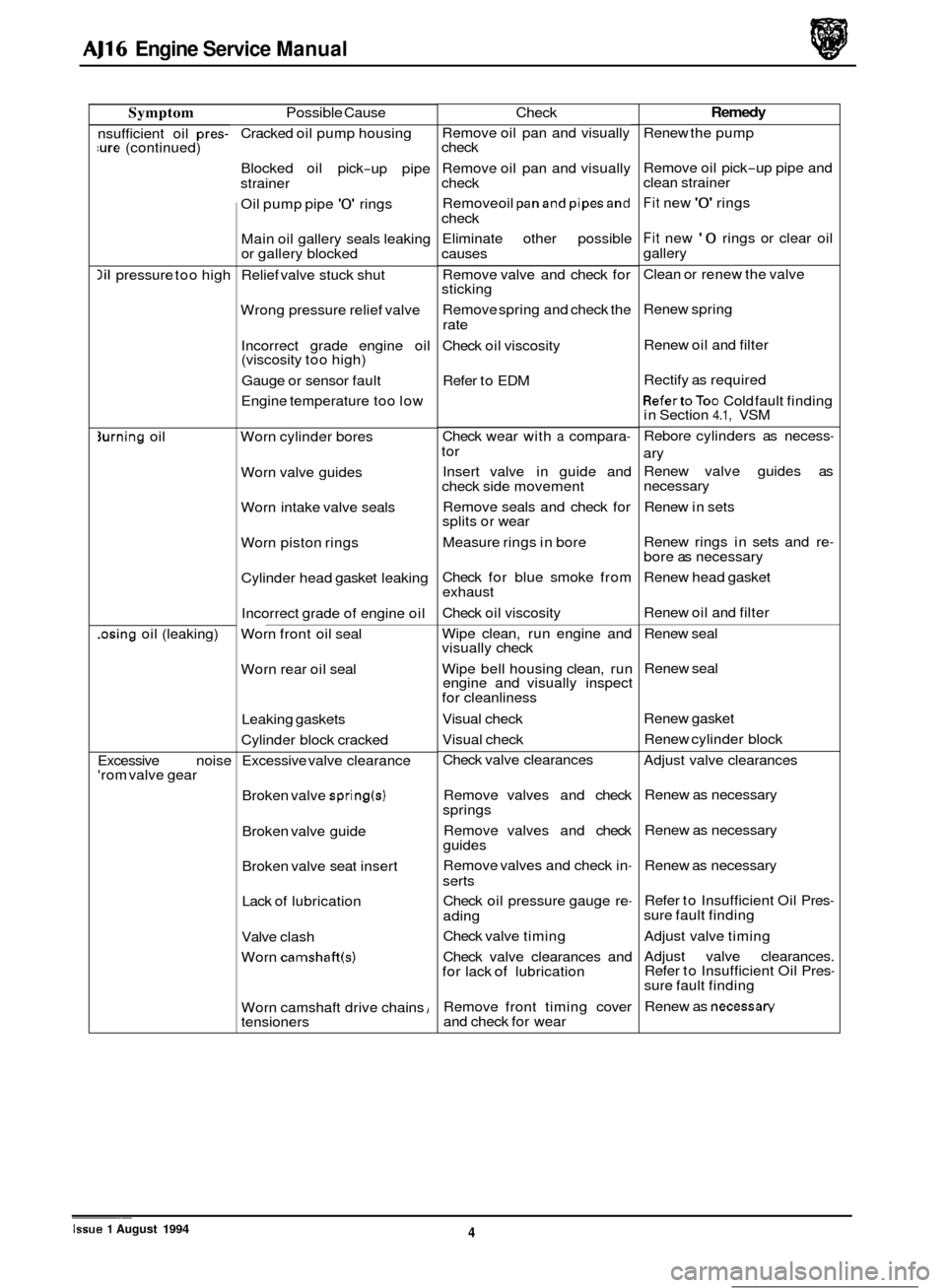

Symptom Possible Cause ~~

nsufficient

oil pres- ure (continued)

lil pressure too high

3urning oil

.osing oil (leaking)

Excessive noise

'rom valve gear Cracked

oil pump housing

Blocked oil pick

-up pipe

strainer

Oil pump pipe

'0' rings

Main oil gallery seals leaking

or gallery blocked

Relief valve stuck shut

Wrong pressure relief valve

Incorrect grade engine oil

(viscosity too high)

Gauge or sensor fault

Engine temperature too low

Worn cylinder bores

Worn valve guides

Worn intake valve seals

Worn piston rings

Cylinder head gasket leaking

Incorrect grade of engine oil

Worn front oil seal

Worn rear oil seal

Leaking gaskets

Cylinder block cracked

Excessive valve clearance

Broken valve

spring(s)

Broken valve guide

Broken valve seat insert

Lack of lubrication

Valve clash

Worn

camshaft(s)

Worn camshaft drive chains i tensioners

Check

Remove oil pan and visually

check

Remove oil pan and visually

check

Removeoil

panand pipesand check Eliminate other possible

causes

Remove valve and check for

sticking

Remove spring and check the

rate

Check oil viscosity

Refer to EDM

Check wear with

a compara- tor

Insert valve in guide and

check side movement

Remove seals and check for

splits or wear

Measure rings in bore

Check for blue smoke from

exhaust

Check oil viscosity

Wipe clean, run engine and

visually check

Wipe bell housing clean, run

engine and visually inspect

for cleanliness

Visual check

Visual check

Check valve clearances

Remove valves and check

springs

Remove valves and check

guides

Remove valves and check in

- serts

Check oil pressure gauge re

- ading

Check valve timing

Check valve clearances and

for lack

of lubrication

Remove front timing cover

and check for wear

Remedy

Renew the pump

Remove oil pick

-up pipe and

clean strainer

Fit new '0' rings

Fit new '0 rings or clear oil

gallery

Clean or renew the valve

Renew spring

Renew oil and filter

Rectify as required

RefertoToo Cold fault finding

in Section 4.1, VSM

Rebore cylinders as necess

-

ary

Renew valve guides as

necessary

Renew in sets

Renew rings in sets and re

- bore as necessary

Renew head gasket

Renew oil and filter

Renew seal

Renew seal

Renew gasket Renew cylinder block

Adjust valve clearances

Renew as necessary

Renew as necessary

Renew as necessary

Refer to Insufficient Oil Pres

- sure fault finding

Adjust valve timing

Adjust valve clearances.

Refer to Insufficient Oil Pres

- sure fault finding

Renew as

necessaw

0

0

0 ~~~

Issue 1 August 1994 4