lock JAGUAR XJ 1994 2.G ZF Automatic Transmission Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 74, PDF Size: 2.66 MB

Page 48 of 74

ZF Automatic Transmissions Service Manual

2.1.6 Transmission Rotary Switch

This switch is located on a square extension of the transmission selector shaft and is linked to the shift lever via the

selector cable. The switch comprises a selector bar which moves across a series of copper segments located on the

switch quadrant. The copper segments are set out in seven bands, each band providing an electrical output or com

- bination of outputs to the TCM.

The electrical outputs to the TCM are in the form of a three

-digit code which takes up three of the seven bands of the

quadrant; the remaining four bands are used for reverse, ground and start inhibit.

2.1.7 Decoder Module

The decoder module, located on the right hand side of the J-gate assembly, is used to translate the three-digit codes

from the rotary transmission switch into single-line functions to feed the illumination module and to provide the fol-

lowing information:

. Cruise control, ie when cruise control can or cannot be engaged.

. Indication when the vehicle is not in 'P' Park.

. Provide the ECM with a Park/ Neutral signal.

2.1.8 Performance Mode Switch

This switch, located on the shift lever surround, provides two alternative shift patterns:

. 'Normal Mode' -for everyday use,

. 'Sport Mode'- gear changes take place at higher road speeds in order to enhance performance.

Note: Torque converter 'lock-up' occurs in fourth gear in each mode.

2. I. 9 'Kick-down' Mechanism

'Kick-down' is activated by the final travel of the accelerator pedal which contacts a floor-mounted switch located be- hind the pedal. Operation of the switch provides a signal to the TCM that a downward change is required. The switch

is adjustable to ensure that the pedal does not overtravel and stretch the cable.

2.1.10 Reverse Safefy Inhibit

If 'R' Reverse is selected when the vehicle is travelling forwards at more than 5 mile / h, solenoid valve MV2 will be

energised to prevent engagement of reverse gear.

2.1.11 Gearshift hterlock

A brake pedal /gearshift interlock is incorporated in the gear selector mechanism. The gear selector lever may only

be moved from the P - Park position if the ignition key switch is in position II and the foot brake is applied.

The ignition key cannot be removed from the ignition switch unless the shift lever is in

the 'P - Park position. Once

the ignition key has been removed, the shift lever is locked in the park position.

2.1.12 Starter Inhibit Switch

The starter inhibit switch prevents the starter motor from being operated when the shift lever is not in position 'P' - Park or position 'N' - Neutral. The switch is located in the gear selector housing.

issue 1 August 1994 47

Page 49 of 74

ZF Automatic Transmissions Service Manual

1

1

33

2

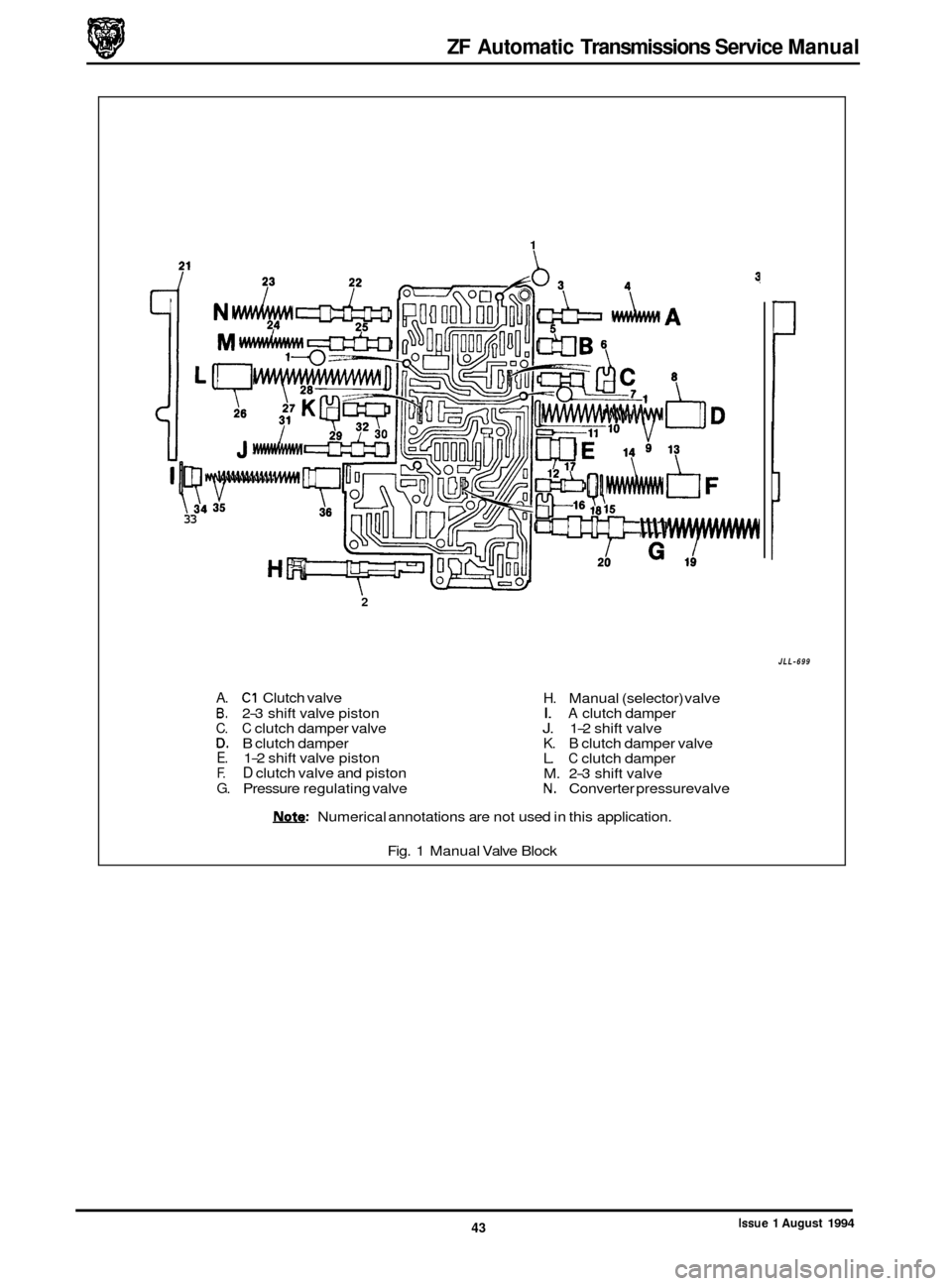

A. C1 Clutch valve

B. 2-3 shift valve piston C. C clutch damper valve D. B clutch damper E. 1-2 shift valve piston F. D clutch valve and piston

G. Pressure regulating valve

H. Manual (selector) valve I. A clutch damper J. 1-2 shift valve K. B clutch damper valve L. C clutch damper

M. 2-3 shift valve N. Converter pressure valve

!!Me: Numerical annotations are not used in this application.

Fig. 1 Manual Valve Block

&

JLL-699

Issue 1 August 1994 43

Page 50 of 74

ZF Automatic Transmissions Service Manual

2 1.

I

Jh

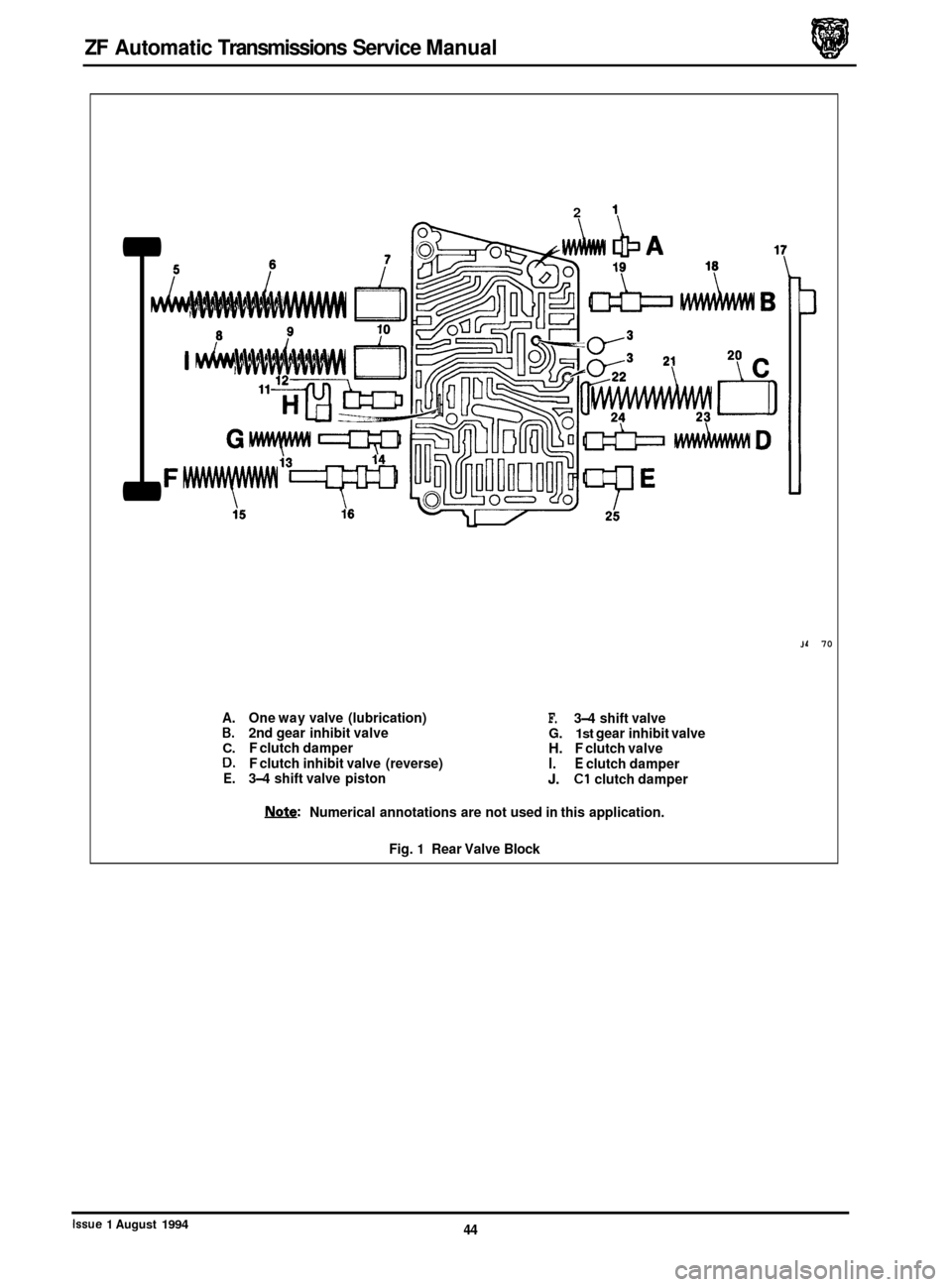

A. One way valve (lubrication) B. 2nd gear inhibit valve C. F clutch damper D. F clutch inhibit valve (reverse) E. 3-4 shift valve piston

F. 3-4 shift valve G. 1st gear inhibit valve H. F clutch valve

I. E clutch damper

J. C1 clutch damper

IWQ: Numerical annotations are not used in this application.

Fig.

1 Rear Valve Block

70

44 Issue 1 August 1994

Page 51 of 74

ZF Automatic Transmissions Service Manual

3

C

? a

12 L?-'

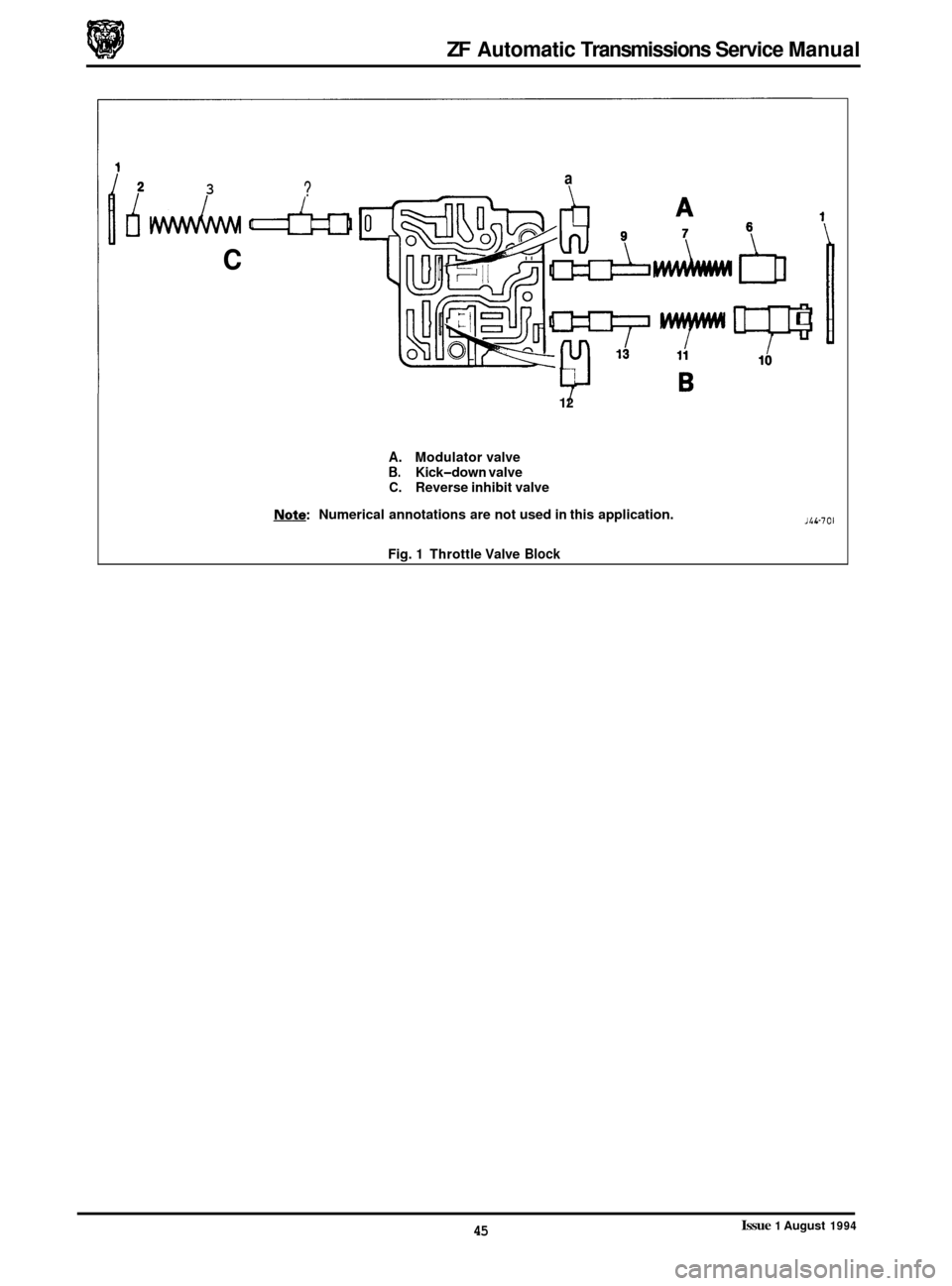

A. Modulator valve B. Kick-down valve C. Reverse inhibit valve

Note: Numerical annotations are not used in this application.

s

JbI-701

Fig. 1 Throttle Valve Block

Issue 1 August 1994 45

Page 56 of 74

ZF Automatic Transmissions Service Manual

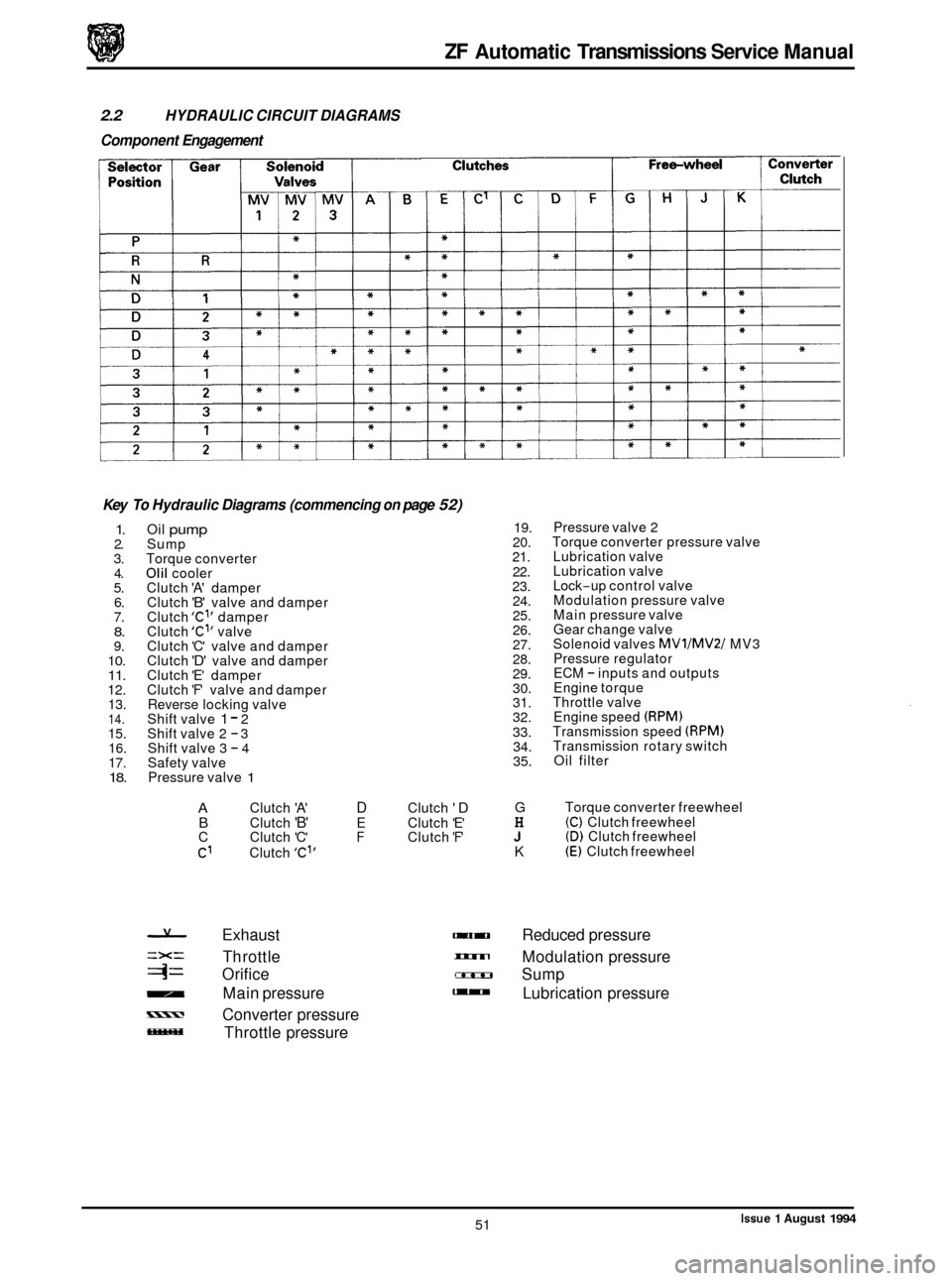

2.2 HYDRAULIC CIRCUIT DIAGRAMS

Component Engagement

Key

To Hydraulic Diagrams (commencing on page 52)

1. 2.

3. 4.

5. 6.

7.

8. 9. 10. 11. 12. 13.

14. 15. 16.

17.

18.

Oil pump Sump

Torque converter

Olil cooler

Clutch 'A' damper

Clutch 'B' valve and damper

Clutch 'Cl' damper

Clutch 'Cl' valve

Clutch 'C' valve and damper

Clutch

'D' valve and damper

Clutch 'E' damper

Clutch

'F' valve and damper

Reverse locking valve

Shift valve

1 - 2

Shift valve 2 - 3

Shift valve 3 - 4

Safety valve

Pressure valve

1

A Clutch 'A' D Clutch 'D B Clutch 'B' E Clutch 'E'

C Clutch 'C' F Clutch 'F'

C1 Clutch 'C"

19.

20.

21.

22.

23. 24.

25.

26.

27.

28.

29.

30.

31.

32.

33. 34.

35.

G

H J K

Pressure valve 2

Torque converter pressure valve

Lubrication valve

Lubrication valve

Lock

-up control valve

Modulation pressure valve

Main pressure valve

Gear change valve

Solenoid valves

MVllMV2l MV3

Pressure regulator

ECM

- inputs and outputs

Engine torque

Throttle valve Engine speed

(RPM) Transmission speed (RPM) Transmission rotary switch

Oil filter

Torque converter freewheel

(C) Clutch freewheel (D) Clutch freewheel (E) Clutch freewheel

Exhaust - Reduced pressure

=X= Th rott le - Modulation pressure

4= Orifice 2- Sump

- Main pressure - Lubrication pressure

- Converter pressure

Throttle pressure

Issue 1 August 1994 51

Page 66 of 74

ZF Automatic Transmissions Service Manual

Problem Possible Cause

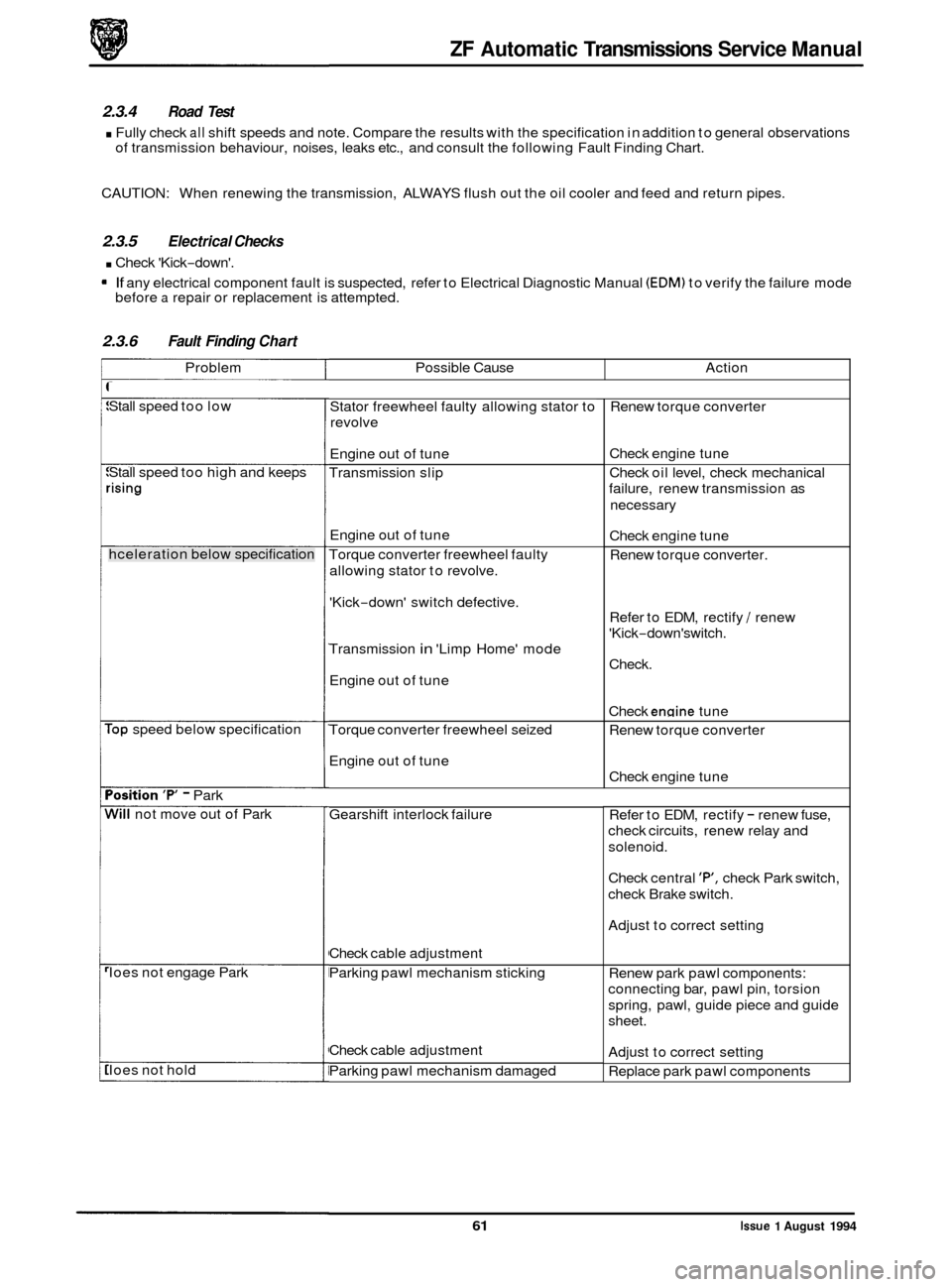

2.3.4 Road Test

. Fully check all shift speeds and note. Compare the results with the specification in addition to general observations of transmission behaviour, noises, leaks etc., and consult the following Fault Finding Chart.

Action

CAUTION:

When renewing the transmission, ALWAYS flush out the oil cooler and feed and return pipes.

2.3.5 Electrical Checks

. Check 'Kick-down'.

If any electrical component fault is suspected, refer to Electrical Diagnostic Manual (EDM) to verify the failure mode

before a repair or replacement is attempted.

2.3.6 Fault Finding Chart

Stall speed too low

Stall speed too high and keeps

,ising

hceleration below specification

Top speed below specification

'osition 'P - Park

Nil1 not move out of Park

Ioes not engage Park

Ioes not hold Stator

freewheel faulty allowing stator to

revolve

Engine out of tune

Transmission slip

Engine out of tune

Torque converter freewheel faulty

allowing stator to revolve.

'Kick

-down' switch defective.

Transmission

in 'Limp Home' mode

Engine out of tune

Torque converter freewheel seized

Engine out of tune

Gearshift interlock failure

Check cable adjustment

Parking pawl mechanism sticking

Check cable adjustment

Parking pawl mechanism damaged Renew

torque converter

Check engine tune

Check oil level, check mechanical

failure, renew transmission as

necessary

Check engine tune

Renew torque converter.

Refer to EDM, rectify

I renew

'Kick

-down'switch.

Check.

Check

engine tune

Renew torque converter

Check engine tune

Refer to EDM, rectify

- renew fuse,

check circuits, renew relay and

solenoid.

Check central

'P, check Park switch,

check Brake switch.

Adjust to correct setting

Renew park pawl components:

connecting bar, pawl pin, torsion

spring, pawl, guide piece and guide

sheet.

Adjust to correct setting

Replace park pawl components

61 Issue 1 August 1994

Page 67 of 74

ZF Automatic Transmissions Service Manual

a

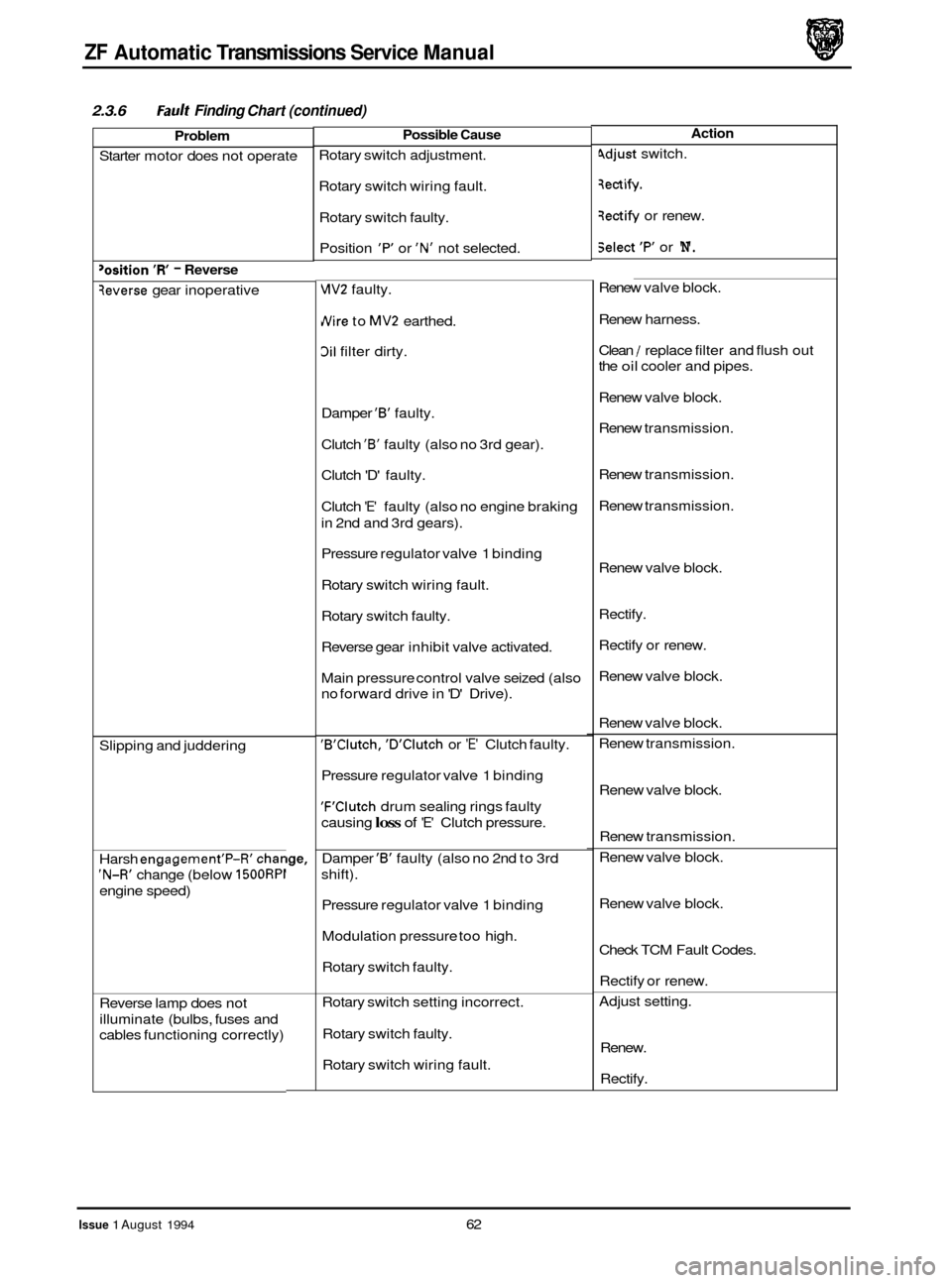

2.3.6 Fault Finding Chart (continued)

Problem

Starter motor does not operate

'osition 'R' - Reverse

3everse gear inoperative

Slipping and juddering

Harsh

engagement'p-R' chan

'N-R' change (below 1500RPF

engine speed)

Reverse lamp does not

illuminate (bulbs, fuses and

cables functioning correctly)

Possible Cause

Rotary switch adjustment.

Rotary switch wiring fault.

Rotary switch faulty.

Position

'P or 'N' not selected.

vIV2 faulty.

rNire to MV2 earthed.

3il filter dirty.

Damper

'6' faulty.

Clutch

'6' faulty (also no 3rd gear).

Clutch 'D' faulty.

Clutch

'E' faulty (also no engine braking

in 2nd and 3rd gears).

Pressure regulator valve 1 binding

Rotary switch wiring fault.

Rotary switch faulty.

Reverse gear inhibit valve activated.

Main pressure control valve seized (also

no forward drive in 'D' Drive).

'B'Clutch, 'D'Clutch or 'E' Clutch faulty.

Pressure regulator valve 1 binding

'F'Clutch drum sealing rings faulty

causing

loss of 'E' Clutch pressure.

Damper

'6' faulty (also no 2nd to 3rd

shift).

Pressure regulator valve 1 binding

Modulation pressure too high.

Rotary switch faulty.

Rotary switch setting incorrect.

Rotary switch faulty.

Rotary switch wiring fault.

Action

4djust switch.

qectify.

3ectify or renew.

Select 'F" or 'N'.

Renew valve block.

Renew harness.

Clean

/ replace filter and flush out

the

oil cooler and pipes.

Renew valve block.

Renew transmission.

Renew transmission.

Renew transmission.

Renew valve block.

Rectify.

Rectify or renew.

Renew valve block.

Renew valve block.

Renew transmission.

Renew valve block.

Renew transmission.

Renew valve block.

Renew valve block.

Check TCM Fault Codes.

Rectify or renew.

Adjust setting.

Renew.

Rectify.

Issue 1 August 1994 62

Page 68 of 74

ZF Automatic Transmissions Service Manual

Problem Possible Cause

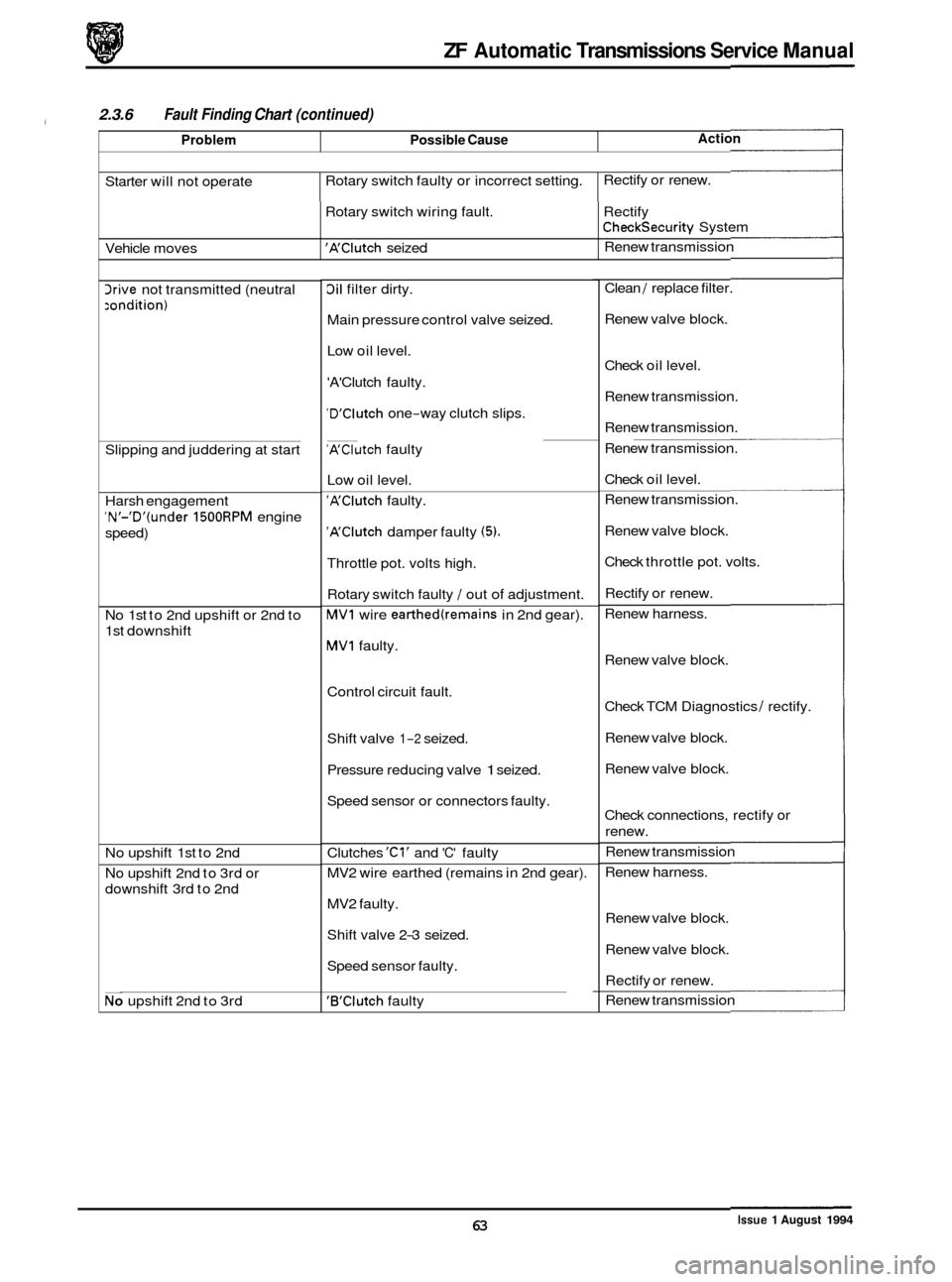

2.3.6 Fault Finding Chart (continued)

e Action

Starter will not operate Rotary

switch faulty or incorrect setting. Rectify

or renew.

3rive not transmitted (neutral

:ondition)

Vehicle moves

Slipping and juddering at start Rotary

switch wiring fault. Rectify 'A'Clutch seized Renew

transmission

Checksecurity System

Harsh engagement

'N'-'D'(under 1500RPM engine

speed)

No 1st to 2nd upshift or 2nd to

1st downshift

No upshift 1st to 2nd

No upshift 2nd to 3rd or

downshift 3rd to 2nd

No upshift 2nd to 3rd

3il filter dirty.

Main pressure control valve seized.

Low oil level.

'A'Clutch faulty.

'D'Clutch one-way clutch slips. ~

'A'Clutch faulty

Low oil level.

'A'Clutch faulty.

'A'Clutch damper faulty (5).

Throttle pot. volts high.

Rotary switch faulty

/ out of adjustment.

MVI wire earthed(remains in 2nd gear).

MVI faulty.

Control circuit fault.

Shift valve

1-2 seized.

Pressure reducing valve

1 seized.

Speed sensor or connectors faulty.

Clutches

'Cl' and 'C' faulty

MV2 wire earthed (remains in 2nd gear).

MV2 faulty.

Shift valve 2

-3 seized.

Speed sensor faulty.

'B'Clutch faulty Clean

/ replace

filter.

Renew valve block.

Check oil level.

Renew transmission.

Renew transmission.

Renew transmission.

Check oil level.

Renew transmission.

Renew valve block.

Check throttle pot. volts.

Rectify or renew.

Renew harness.

Renew valve block.

Check TCM Diagnostics

/ rectify.

Renew valve block.

Renew valve block.

Check connections, rectify or

renew.

Renew transmission

Renew harness.

Renew valve block.

Renew valve block.

Rectify or renew.

Renew transmission

Issue 1 August 1994 63

Page 69 of 74

ZF Automatic Transmissions Service Manual

0

2.3.6 Fault Finding Chart (continued)

Problem

Uo upshift 3rd to 4th or

lownshift 4th to 3rd

Vo upshift 3rd to 4th

lownshift 4th to 3rd too hard

Manual gearshift D to 3rd too

lard

Manual gearshift 3rd to 2nd too

9ard

Vo 1st gear; 2nd gear start only.

No 1st or 2nd gear; 3rd gear

start only

No 2nd gear; transmission shifts

1st to 3rd gear

Light throttle gear change

speeds incorrect

Up to 'kick

-down' detent, gear

change speeds not to

specification

Possible Cause

Shift valve 3-4 seized.

MVl wire earthed.

MV1 faulty.

Speed sensor faulty.

'F'Clutch faulty

3rain orifice 'F' partially blocked.

Damper

'E' faulty.

Damper

'E' faulty.

Drain orifice

'F' partially blocked.

Damper

'Cl' faulty

Speed sensor faulty.

MV1 faulty.

MV1 wire earthed.

Shift valve 1

-2 seized.

'1st Gear Inhibit' circuit operated or

'Performance Mode' switch faulty.

Transmission 'Limp Home' mode.

Speed sensor faulty.

MV1 or MV2 faulty.

Shift valves 1

-2 and 2-3 seized.

Speed sensor faulty.

Shift valve 2

-3 seized.

Shift valves sticking.

Speed sensor faulty.

Throttle pot. volts incorrect.

Transmission Control Module

(TCM).

'Kick-down' switch out of adjustment

3enew valve block.

3enew harness.

Renew valve block.

Rectify or renew.

Renew transmission

Renew valve block.

Renew valve block.

Renew valve block.

Renew valve block.

Renew valve block

Check or renew speed sensor.

Renew valve block.

Renew harness.

Renew valve block.

Operate 'Performance Mode' switch

to correct function or renew switch.

Check Diagnostics

1 JDS.

Renew speed sensor.

Renew valve block.

Renew valve block.

Check or

recheck Diagnostics,

renew speed sensor.

Renew valve block.

Renew valve block.

Check or renew speed sensor.

Check voltage

- JDS.

Check TCM Diagnostics.

Readjust 'kick

-down' switch

Issue 1 August 1994 64

Page 70 of 74

ZF Automatic Transmissions Service Manual

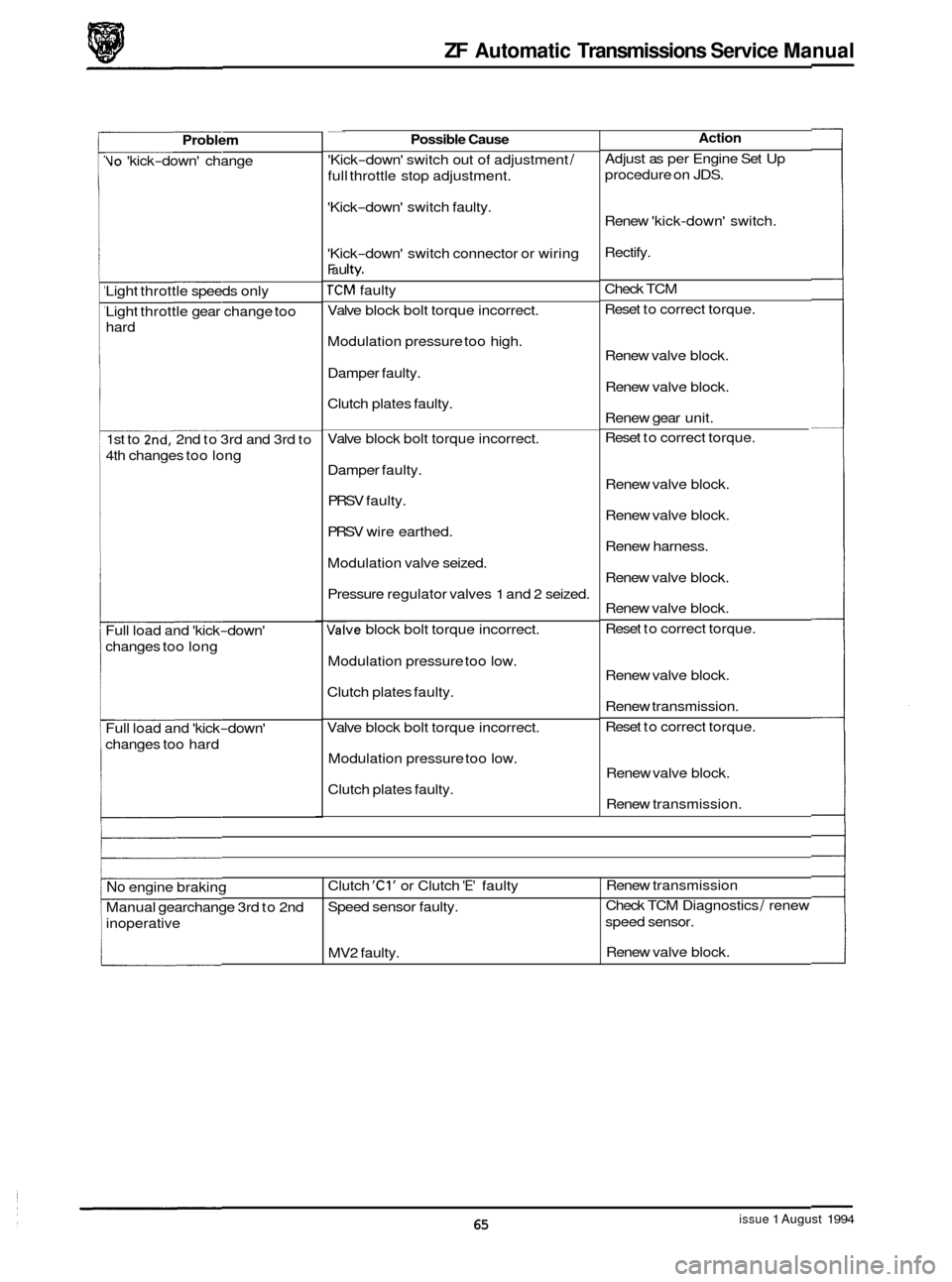

No engine braking

Manual gearchange 3rd to 2nd

inoperative Clutch 'Cl' or

Clutch 'E' faulty

Speed sensor faulty.

MV2 faulty.

a

Renew transmission

Check TCM Diagnostics

1 renew

speed sensor.

Renew valve block.

a

0

Problem

Vo 'kick-down' change

Light throttle speeds only

Light throttle gear change too

hard

1st to

2nd, 2nd to 3rd and 3rd to

4th changes too long

Full load and 'kick

-down'

changes too long

Full load and 'kick

-down'

changes too hard ~

Possible Cause

'Kick-down'

switch out of adjustment 1

full throttle stop adjustment.

'Kick

-down' switch faulty.

'Kick

-down' switch connector or wiring

Fa u Ity.

TCM faulty

Valve block bolt torque incorrect.

Modulation pressure too high.

Damper faulty.

Clutch plates faulty.

Valve block bolt torque incorrect.

Damper faulty.

PRSV faulty.

PRSV wire earthed.

Modulation valve seized.

Pressure regulator valves

1 and 2 seized.

mve block bolt torque incorrect.

Modulation pressure too low.

Clutch plates faulty.

Valve block bolt torque incorrect.

Modulation pressure too low.

Clutch plates faulty.

Action

Adjust as per Engine Set Up

procedure on JDS.

Renew 'kick

-down' switch.

Rectify.

Check TCM

Reset to correct torque.

Renew valve block.

Renew valve block.

Renew gear unit.

Reset to correct torque.

Renew valve block.

Renew valve block.

Renew harness.

Renew valve block.

Renew valve block.

Reset to correct torque.

Renew valve block.

Renew transmission.

Reset to correct torque.

Renew valve block.

Renew transmission.

issue 1 August 1994 65