ESP JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 94 of 327

Climate Control Systems

Position

Closed Open

Closed Open

14.7.11 Fault Code 32

RH Fresh / Recirc. Pofenfiomefer

Test the 5 volt supply to potentiometer between pin 1 and pin 2 (ground).

If there is no 5V supply, inspect the harness for open circuit or short circuit to ground. If no harness faults are apparent,

renew the A 1 CCM.

W: The A / CCM provides a common 5V output and ground to all servos, ie all servo potentiometers are fed by

a 5V rail. If all servos are inoperable check the A 1 CCM outputs and harness, renew the A I CCM.

Check resistance between potentiometer connector pins 1 and 2 at blower harness connector, value should be

6wl

f10% at 20°C.

Measure the resistance from the potentiometer wiper (pin

6) to pins 1 and 2 respectively. Resistances should read:

Action Value lest point

Recirc. 1 k2

Fresh 4k8 Pin 2 ground

R eci rc. 4k8

Pin 1 +5 volts

Fresh lk2

Closed Open

Closed

Open

e

I Position I Action I Valw 1 Test point I

High lk2

Low 4k8 Pin 2 ground

High 4k8

Pin

9 +5 volts

Low 1 k2

If the resistance measured falls outside the said limits, renew the potentiometer.

X300 EDM 19 Issue 1 August 1994

Page 95 of 327

Climate Control Systems

Position

Closed

Open

Closed

ODen

14.7.13 Fault Code 34

Defrost

Vent Potentiomefer

Disconnect the CENTRE VENT servo yellow, Sway connector.

Test the 5V supply to the potentiometer at the air distribution connector (black 12-way), pin 9 (positive) and pin 2

If there is no 5 volt supply, inspect the harness for open circuit or short circuit to ground. If no harness faults are appar-

ent, renew the A / CCM.

&&: The A / CCM provides a common 5V output and ground to all servos, ie all servo potentiometers are fed by a 5V rail. If all servos are inoperable check the A/ CCM outputs and harness, renew the AI CCM.

Check resistance between potentiometer connector pins

9 and 2 at air distribution box connector (black 12-way), value

should be

6w1 +10% at 20°C.

Measure the resistance from the potentiometer wiper (pin

6) to pins 9 and 2 respectively. Resistances should read:

(ground).

Action Value Test

point

Defrost 4k8 Pin 2 ground

Feet 4k8

Pin 9 +5 volts

Defrost 1 k2

Feet

lk2

Position Action Value

Closed Feet

lk2

4k8

Open Face

Closed

Feet 4k8

Open Face

lk2

If the resistance measured falls outside the said limits, renew the potentiometer.

Test point

Pin 2 ground

Pin

9 +5 volts

14.7.14 Fault Code 35

Centre Vent Potentiometer

Disconnect the DEFROST VENT servo yellow, Sway connector.

Test the 5V supply to the potentiometer at the air distribution connector (black 12-way), pin 9 (positive) and pin 2

If there is no 5 volt supply, inspect the harness for open circuit or short circuit to ground. If no harness faults are appar- ent, renew the A/ CCM.

The

A / CCM provides a common 5V output and ground to all servos, ie all servo potentiometers are fed by

a 5V rail. If all servos are inoperable check the A/ CCM outputs and harness, renew the A / CCM.

Check resistance between potentiometerconnector pins

9 and 2 at air distribution box connector (black 12-way),value

should be 6wZ +10% at 20°C.

Measure the resistance from the potentiometer wiper (pin

3) to pins 9 and 2 respectively. Resistances should read:

(ground).

If the

resistance measured falls outside the said limits, renew the potentiometer.

Issue 1 August 1994 20 X300 EDM

Page 96 of 327

Climate Control Systems

Position Action Value Test point

Closed Face 1 k2

Open Foot

4k8

Closed Face

4k8

Open Foot

1 k2

Pin 2 ground

Pin

9 +5 volts

14.7.15 Fault Code 36

Foot Vent

Potentiometer

Disconnect the COOL AIR BYPASS yellow, Sway connector.

. Test the 5V supply to the potentiometer at the main unit, pin 9 (positive) and pin 2 (ground).

If there is no 5 volt supply, inspect the harness for open circuit or short circuit to ground. If no harness faults are appar- ent, renew the A I CCM.

&&: The A I CCM provides a common 5V output and ground to all servos, ie all servo potentiometers are fed by a 5V rail. If all servos are inoperable check the A 1 CCM outputs and harness, renew the A 1 CCM.

Check resistance between potentiometer connector pins9 and

2 at blower motor connector, value should be 6kn +10%

at 20°C.

Measure the resistance from the potentiometer wiper (pin

6) to pins 9 and 2 respectively. Resistances should read:

14.7.16 Fault Code 4 1

1 H Fresh / Recirc. Motor

The resistance between pins 1 and 3, servo unit Sway connector, should read 4.8 - 7.2 kn.

If the resistance is outside of the set limits, renew the servo unit.

The motor operation can be checked by applying battery voltage to pin

5, motor %way connector, and ground to pin 4 of the connector. The motor arm should rotate smoothly in a clockwise direction. Renew the motor if the arm does

not rotate smoothly.

Apply battery voltage to pin

4, servo unit %ay connector, and ground to pin 5. The motor arm should rotate smoothly

in a anti-clockwise direction. Renew the motor if the arm does not rotate smoothly.

Inspect the harness for open circuit or short circuit to ground. Rectify as necessary.

If no harness faults are apparent,

renew the AI CCM.

14.7.17 Fault Code 42

RH Fresh / Recirc. Motor

The resistance between pins 1 and 3, servo unit Sway connector, should read 4.8 - 7.2 kn.

If the resistance is outside of the set limits, renew the servo unit.

The motor operation can be checked by applying battery voltage to pin

5, motor Sway connector, and ground to pin 4 of the connector. The motor arm should rotate smoothly in a clockwise direction. Renew the motor if the arm does

not rotate smoothly.

Apply battery voltage to pin

4, servo unit Sway connector, and ground to pin 5. The motor arm should rotate smoothly

in a anti-clockwise direction. Renew the motor if the arm does not rotate smoothly.

Inspect the harness for open circuit or short circuit to ground. Rectify as necessary.

If no harness faults are apparent,

renew the A I CCM.

21 Issue 1 August 1994

Page 181 of 327

I3 E I ect r ical

15.3.2.5 Throttle Linkage and Bellows

The throttle linkage and bellows are located adjacent to the throttle body (below supercharger, where fitted) on 6cylin-

der vehicles, or centrally below the injector cover on 12 cylinder vehicles. The bellows expand I contract according

to the pressure drop created by the pump I control valve module, causing the linkage to act upon the throttle body,

controlling vehicle speed.

15.3.2.6

The brake and clutch pedal switches are mounted below the relevant foot pedals. Operation of a pedal, causes subse- quent switch operation, either interrupting the+12Vsupplytothe pneumaticcircuit, orsignalling tothe SC CMto disen- gage speed control, causing the dump valve to open and vent the system, returning speed control to the driver.

Brake and Clutch Pedal Switches

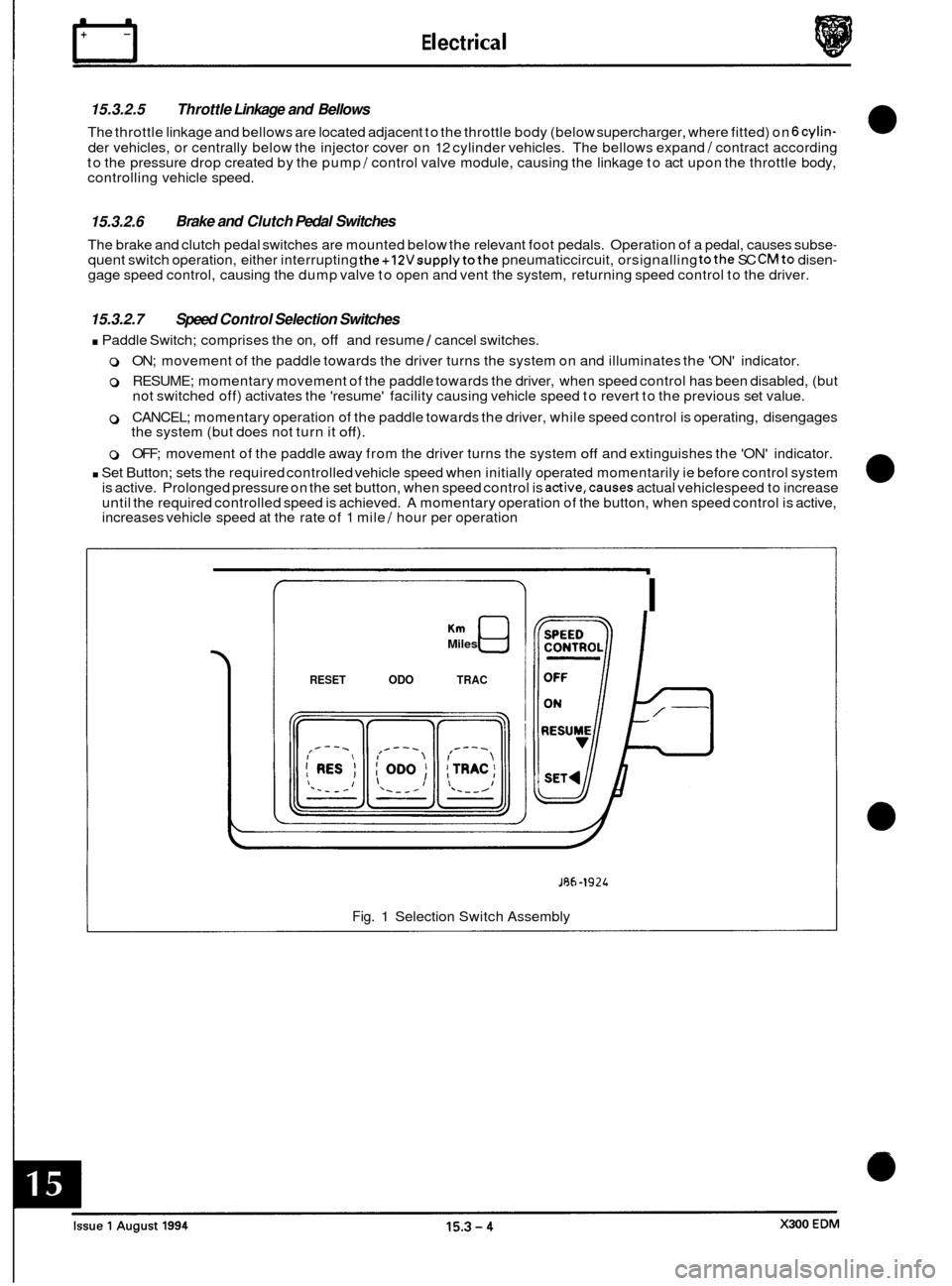

15.3.2.7 Speed Control Selection Switches

. Paddle Switch; comprises the on, off and resume 1 cancel switches.

0 ON; movement of the paddle towards the driver turns the system on and illuminates the 'ON' indicator.

0 RESUME; momentary movement of the paddle towards the driver, when speed control has been disabled, (but

not switched off) activates the 'resume' facility causing vehicle speed to revert to the previous set value.

0 CANCEL; momentary operation of the paddle towards the driver, while speed control is operating, disengages

the system (but does not turn it off).

0 OFF; movement of the paddle away from the driver turns the system off and extinguishes the 'ON' indicator.

. Set Button; sets the required controlled vehicle speed when initially operated momentarily ie before control system

is active. Prolonged pressure on the set button, when speed control is active,causes actual vehiclespeed to increase

until the required controlled speed is achieved. A momentary operation of the button, when speed control is active,

increases vehicle speed at the rate of 1 mile

/ hour per operation

Miles

RESET ODO TRAC

I

JRh-1924

Fig. 1 Selection Switch Assembly

Page 187 of 327

rl E I ect r ica I

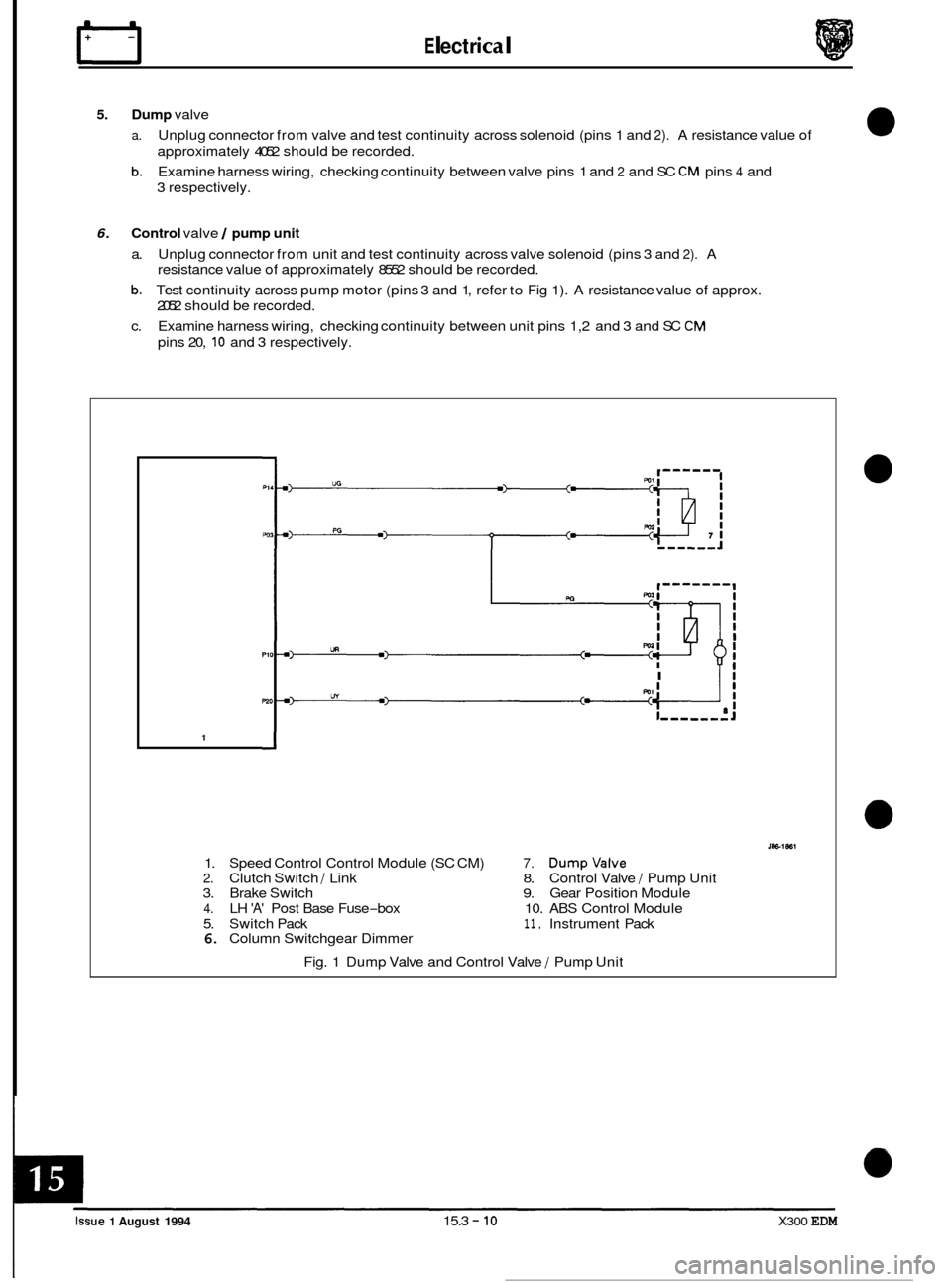

5. Dump valve

a.

b.

Unplug connector from valve and test continuity across solenoid (pins 1 and 2). A resistance value of

approximately 4052 should be recorded.

Examine harness wiring, checking continuity between valve pins 1 and

2 and SC CM pins 4 and

3 respectively.

6. Control valve / pump unit

a. Unplug connector from unit and test continuity across valve solenoid (pins 3 and 2). A

resistance value of approximately 8552 should be recorded.

b. Test continuity across pump motor (pins 3 and 1, refer to Fig 1). A resistance value of approx.

2052 should be recorded.

c. Examine harness wiring, checking continuity between unit pins 1,2 and 3 and SC

CM

pins 20, 10 and 3 respectively.

I Ii

1

1. Speed Control Control Module (SC CM) 7. Dumpvalve

2. Clutch Switch / Link 8. Control Valve / Pump Unit

3. Brake Switch 9. Gear Position Module

4. LH 'A' Post Base Fuse-box 10. ABS Control Module

5. Switch Pack

11. Instrument Pack 6. Column Switchgear Dimmer

Fig. 1 Dump Valve and Control Valve

/ Pump Unit

0

0

0

0

Issue 1 August 1994 15.3 - 10 X300 EDM

Page 200 of 327

15.4.1.4 Remote Recall

Remote activation of memory positions 1 and 2 can be achieved using the key fob transmitters (one per set of keys).

lfthe vehicle is unlocked using the remote transmitter the stored driving position will be adopted automatically. If the

vehicle is unlocked using the remote transmitter and an exit position is already set the corresponding entry position

will be adopted until the ignition key is inserted, the stored driving position will then be restored. 0 ~

15.4.1.5

Reverse Mirror Dip

On selection of reverse gear and operation of the mirror toggle switch downwards, the passenger side rear view mirror

will automatically tilt downwards to assist reverse parking. Upward adjustment disables reverse dip, a further down- ward adjustment when still in reverse gear reinstates reverse dip. The mirror will return to normal position when any

other gear position is selected.

15.4.2 SYSTEM COMPONENTS

15.4.2.1 Seats

- Driver and Passenger

The driver and passenger seat adjustment systems comprises the following components:

o Fore / aft motor

o Front raise / lower motor

o Rear raise / lower motor

0 Squab recline motor

0 Headrest motor

0 Lumbarpump

0 Squab heater

0 Inner cushion heater

0 Outer cushion heater

0 Heater thermostat

0 Switch pack

o Seat Control Module (SCM)

o Wiring harness

15.4.2.2 Motors

The five seat position adjustment motors are located below the seat cushions (horizontal and vertical adjustment) and

behind the squab (recline and headrest adjustment). Each motor unit incorporates a potentiometer which provides

directional movement position control via feedbackvoltage variations to the SCM. Positional variations are activated

by the SCM in response to signals from switches mounted on the seat switch pack.

15.4.2.3 Lumbar Pump

The lumbar pump, located behind the seat squab allows adjustment of seat rigidity by increasing/decreasing air pres- sure in the lumbar pad. The pump motor is controlled from a switch on theseat switch pack and governed by an in-line

pressure switch.

A solenoid valve is used to regulate air flow to the lumbar pad.

15.4.2.4 Heaters and Thermostats

The two cushion heaters and squab heater are regulated by a single in-line thermostat and operated by a switch

mounted on thecenter console switch pack. Operation of this switch causesthe Body Processor Unit (BPU) to energize a timed input to SCM (for 11 minute f 1) which in turn causes SCM to energize the heater supply. The supply will

remain on until timed out, although the heater circuit will be broken by the thermostat if the set temperature is ex- ceeded.

Note: Heatingcan only occur when the ignition switch is position I1 and the ambient temperature is belowthe thermo- stat pre-set value of 26°C.

X300 EDM 15.4 - 3 Issue 1 August 1994

Page 205 of 327

rl Electrical

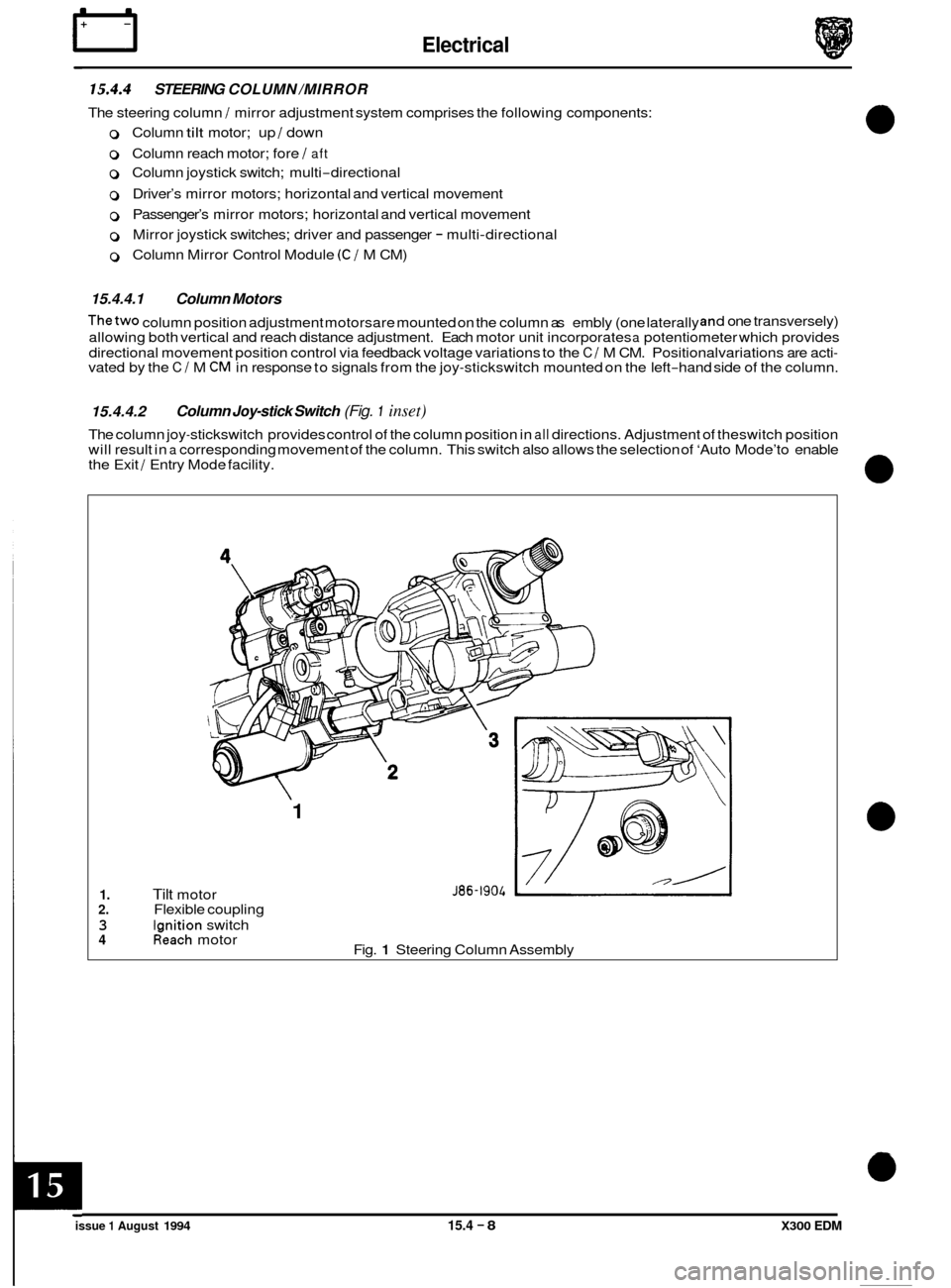

15.4.4 STEERING COLUMN /MIRROR

The steering column / mirror adjustment system comprises the following components:

0 Column tilt motor; up / down

0 Column reach motor; fore / aft

0 Column joystick switch; multi-directional

0 Driver’s mirror motors; horizontal and vertical movement

0 Passenger’s mirror motors; horizontal and vertical movement

0 Mirror joystick switches; driver and passenger - multi-directional

0 Column Mirror Control Module (C / M CM)

15.4.4.1 Column Motors

Thetwo column position adjustment motorsare mounted on the column as embly (one laterally d

one transversely)

allowing both vertical and reach distance adjustment. Each motor unit incorporates a potentiometer which provides

directional movement position control via feedback voltage variations to the

C / M CM. Positional variations are acti- vated by the C / M CM in response to signals from the joy-stickswitch mounted on the left-hand side of the column.

15.4.4.2

The column joy-stickswitch provides control of the column position in all directions. Adjustment of theswitch position

will result in a corresponding movement of the column. This switch also allows the selection of ‘Auto Mode’to enable

the Exit / Entry Mode facility.

Column Joy-stick Switch (Fig. 1 inset)

1. Tilt motor 2. Flexible coupling

3 lanition switch

1

J86-1904

Ifeach motor

Fig. 1 Steering Column Assembly 4

issue 1 August 1994 15.4 - 8 X300 EDM

Page 210 of 327

E I ect r ica I

15.4.7 SYMPTOM FLOW CHARTS

The following test procedures are designed to test the system as a whole, identifying faulty areas and indicating poss- ible solutions by functional operations.

During all test procedures the entry

/ exit mode switch must be OFF.

The first three test procedures listed i.e. drivers seat position adjustments, steering column position adjustments, rear

view mirror position adjustments must be carried out four times, each time under one of the conditions stated below:

Key in ignition barrel

Ignition key in auxiliary position

Driver’s door open with ignition key out

Driver’s door closed within the last 30 seconds with ignition key out.

0

Driver‘s seat position adjustments

1.

2.

3.

0

4.

5.

6.

7.

0

Locate seat switch pack on the side of the seat cushion.

Operate the fore

/ aft movement control switch. Does the seat respond in the correct

manner?

Yes: Proceed to step 3.

No:

Operate front and rear, raise / lower movement control switches. Does seat respond in the

correct manner in each case?

Yes: Proceed to step 4.

No:

Operate squab recline / incline movement control switch. Does squab respond in correct

manner?

Yes: Proceed to step 5.

No:

Operate lumbar pump inflate / deflate control switch. Does lumbar pad stiffen and slacken

according

I y?

Yes: Proceed to step 6

No:

Operate headrest raise / lower switch. Does headrest respond in correct manner?

Yes: proceed to step

7.

No:

Remove key from ignition, close driver‘s door and allow 30 seconds to elapse. Repeat

steps

1 - 6 and check that adjustment cannot be made.

Test complete; proceed to Memory Position Set.

Abort

test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Steering column position adjustments

1.

2.

Locate steering column joystick switch the LH side of the column.

Operate switch to give fore

/ aft movement. Does the column respond in correct manner?

Yes: Proceed to step 3.

No:

Operate the switch to give raise / lower movement. Does column respond in the correct

manner in each case?

Yes: Proceed to step 4.

No:

Remove key from ignition, close driver’s door and allow 30 seconds to elapse. Repeat

steps 1

- 3 and check that adjustment cannot be made.

Test complete; proceed to Memory Position Set.

Abort

test and refer to Diagnostic Sub

-Routines.

3.

Abort test and refer to Diagnostic Sub-Routines.

4.

5.

X300 EDM 15.4 - 13 Issue 1 August 1994

Page 211 of 327

Rear view mirror position adjustments

1. Locate mirror select switch on driver's door switch pack and select driver's side mirror, ie

rotate switch towards the door.

2. Locate rear view mirror joystick switch on driver's door pack.

Operate the switch to give left

/ right and up / down movement. Does the mirror respond

in the correct manner?

3. Yes: Proceed to step 4 or 5.

No:

Japanese market vehicles only

Operate the switch to action 'fold away mode'. Does mirror respond in the correct manner

in each case?

Yes: Proceed to step

5.

No:

All markets

Operate mirror select switch to opposite position and repeat steps

1 to 4 for passenger side

mirror.

With ignition switched to auxiliary, select reverse gear and operate mirror joy

-stick

downwards. Does passenger side mirror dip automatically?

Yes: Proceed to step

7.

No:

Remove key from ignition, close driver's door and allow 30 seconds to elapse. Repeat

steps

1 - 6 and check that adjustment cannot be made.

Test complete; proceed to Memory Position Set.

Abort

test and refer to Diagnostic Sub

-Routines.

4.

Abort test and refer to Diagnostic Sub-Routines.

5.

6.

Abort test and refer to Diagnostic Sub-Routines.

7.

8.

Memory set position - drivefs side

1.

2.

3.

4.

5.

6.

7.

8.

Position the entry / exit switch, located on the LH side of the steering column, to off and

insert the key in the ignition.

Operate switches to position column, mirrors and seats to preferred positions.

Select 'memory' on the driver's door switch pack. Check that switch illuminates.

Depress desired memory button,

1,2 or 3, on door switch pack within 4 seconds of

memory select. Check that a chime sounds to confirm memory storage.

Operate the switches

so that memorized positions are changed. Depress relevant memory

option button,

1,2 or 3 and check that all positional settings are restored as memorized.

Remove key from ignition, close all doors and allow

30 seconds to elapse. Repeat steps 1

to 4 and check that adjustment cannot be made.

Readjust settings so that memorized positions are changed, leave the vehicle and operate

remote memory recall by locking and unlocking using the remote transmitter. Use both

transmitters to check both memory positions. Check all positional settings are restored as

memorized.

Yes: Proceed to step

8.

No:

Test complete. Abort

test and refer to Diagnostic Sub

-Routines.

X300 EDM Issue 1 August 1994 15.4 - 14

Page 212 of 327

Carry out the passenger seat position adjustments procedure below under each of the conditions stated below:

Key in ignition barrel

. Passenger's door open

. Passenger's closed within the last 30 seconds

0 . Auxiliary ON

Passenger seat position adjustments

1.

2.

3.

4.

5.

0

6.

7.

8.

Locate seat switch pack on the side of the seat cushion.

Operate the fore

/ aft movement control switch. Does the seat respond in the correct manner?

Yes: Proceed to step

3.

No:

Operate front and rear, raise / lower movement control switches. Does seat respond in the

correct manner in each case?

Yes: Proceed to step

4.

No:

Operate squab recline / incline movement control switch. Does squab respond in correct

manner?

Yes: Proceed to step

5.

No:

Operate lumbar pump inflate / deflate control switch. Does lumbar pad stiffen and slacken

accordingly?

Yes: Proceed to step

6

No:

Operate headrest raise / lower switch. Does headrest respond in correct manner?

Yes: Proceed to step

7.

No:

Remove key from ignition, close passenger's door and allow 30 seconds to elapse. Repeat

steps

1 - 6 and check that adjustment cannot be made.

Test complete; proceed to Memory Position Set

Abort

test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Memory

set position - passenger's side

1.

2.

0 3.

4.

5.

6.

7.

0

Insert the key in the ignition.

Operate switches to adjust seat to preferred positions.

Select 'memory' on the passenger's door switch pack. Check that switch surround

i I I um i nates.

Depress desired memory button,

1,2 or 3, on door switch pack within 4 seconds of

memory select. Check that

a chime sounds to confirm memory storage.

Operate the switches

so that memorized positions are changed. Depress relevant memory

option button,

1, 2 or 3 and check that all positional settings are restored as memorized.

Yes: Proceed to step

6.

No:

Remove key from ignition, close door and allow 30 seconds to elapse. Repeat steps 1 - 4

and check that adjustment cannot be made.

Test complete. Abort

test and refer to Diagnostic Sub

-Routines.

X300 EDM 15.4 - 15 Issue 1 August 1994