power steering JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 59 of 327

Steering 69

SECTION CONTENTS

Sub

-Section Title SRO Page

10.1 ............. System Description ................................................................... 1

10.2.1 ............ Power Steering Control Module ........................................................ 1

10.2.2. ........... Steering Rack Transducer .............................................................. 1

10.2 ............. Component Descriptions .............................................................. 1

10.3 ............. Diagnostics ........................................................................\

. 3

X300 EDM i Issue 1 August 1994

Page 61 of 327

Q Steering

I86 177L

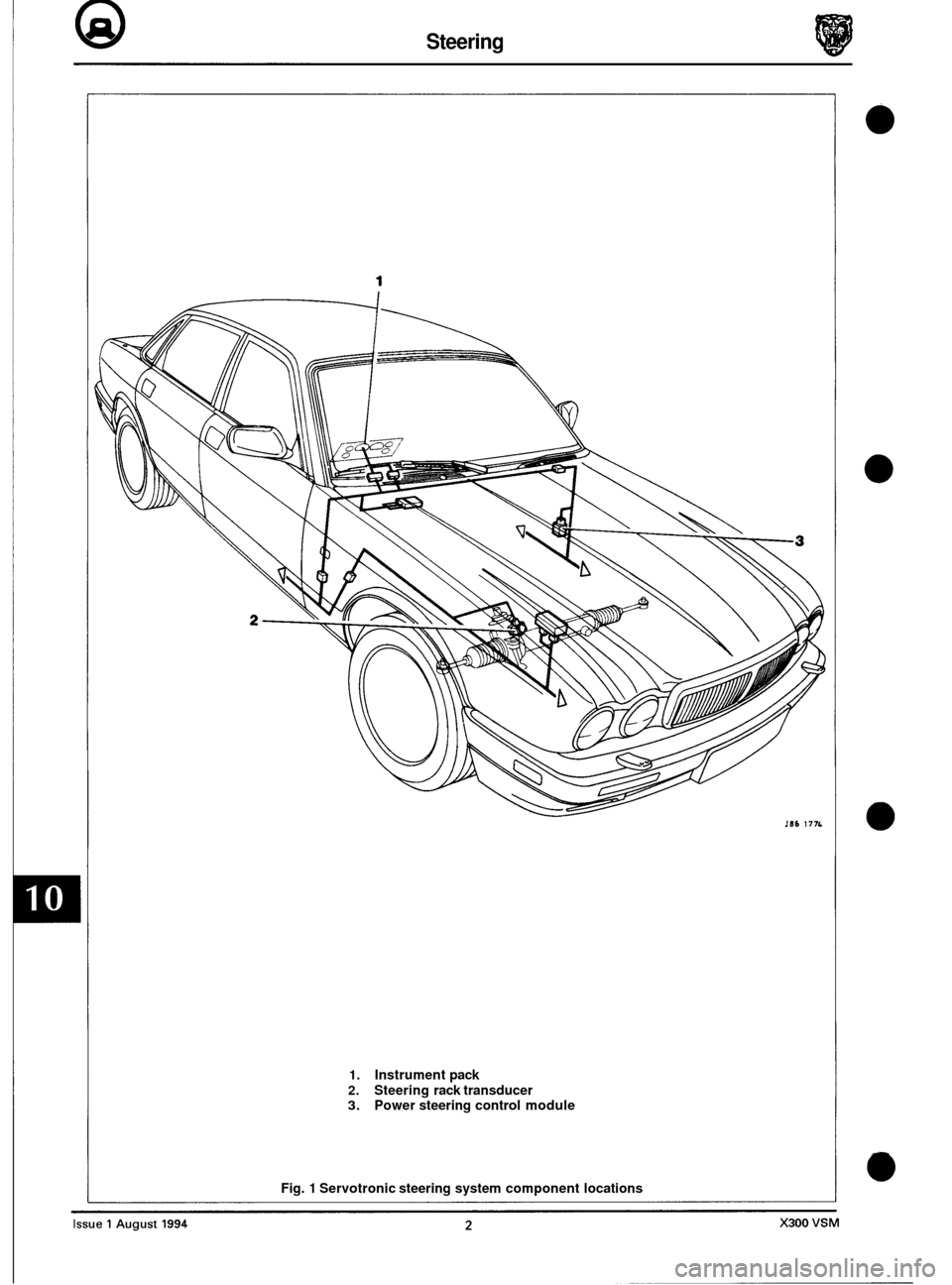

1. Instrument pack

2. Steering rack transducer 3. Power steering control module

Fig.

1 Servotronic steering system component locations

Page 63 of 327

@ Steering

R

. WIP

+ Y

1- -------q I I +I" I

*Ti m) wp I

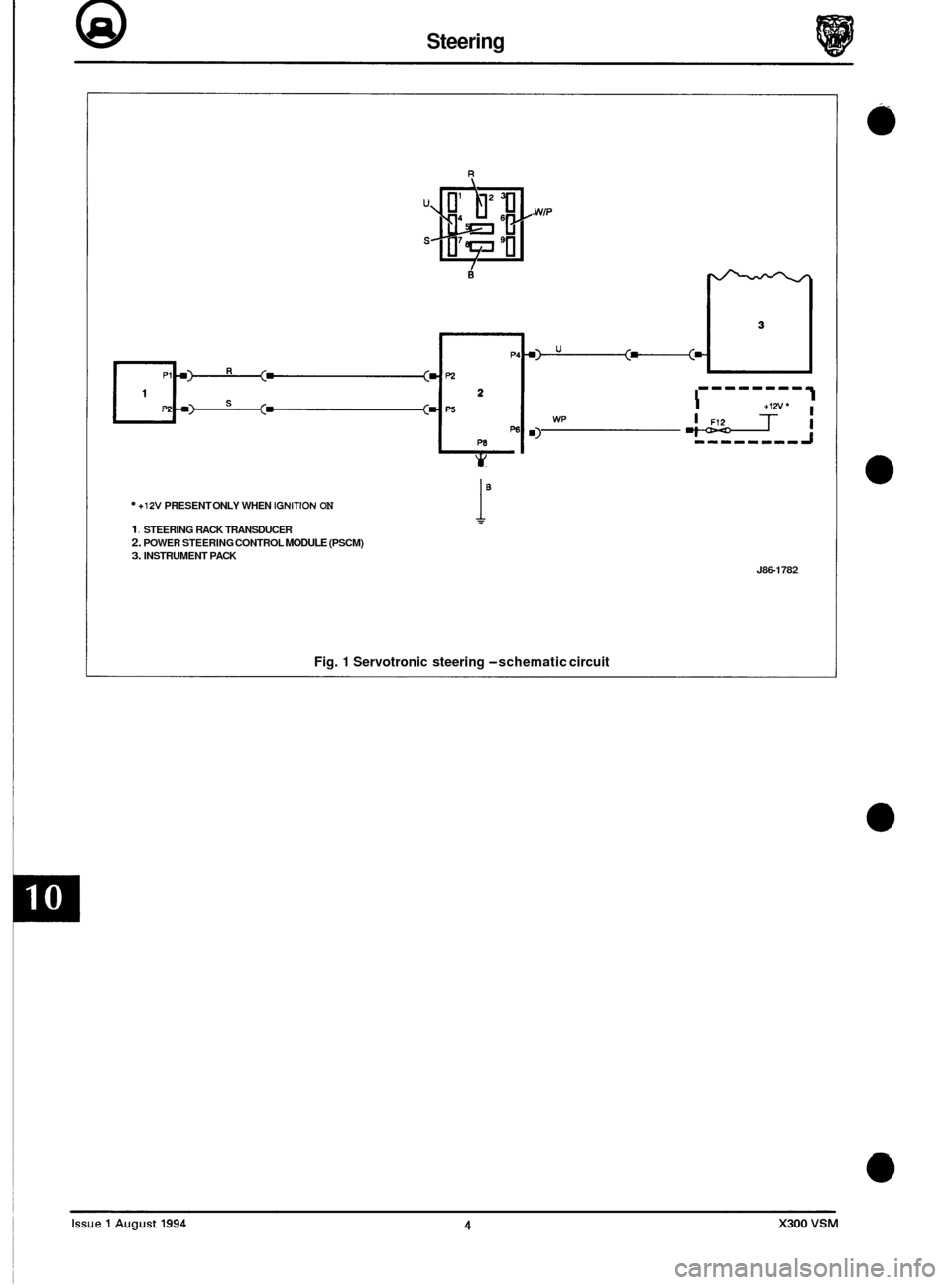

+12V PRESENT ONLY WHEN IGNITION ON

1. STEERING RACK TRANSDUCER 2. POWER STEERING CONTROL MODULE (PSCM) 3. INSTRUMENT PACK

i"

J86-1782

Fig. 1 Servotronic steering -schematic circuit

Page 98 of 327

Climate Control Systems

14.7.22 BLOWER MOTORS

Disconnect the blower motors (LH & RH) multi-plugs and check motor operation by applying battery voltage (+12V) across pin 5 (+vel and pin 9 (-ve).

Non-functioning of both L H and RH motors *

Cause:

1. Loss of ignition voltage.

Remedy:

1.

2.

*

Examine fuse F12 in RH heelboard fuse-box. If fuse is blown determine reason for failure and renew.

Examine harness wiring from

RH heelboard fuse-box connection CA044/010 to splice CAS53. Repair or renew

wiring as necessary.

This fault will also affect the operation of seat control modules, power steering control module and door mirror

heaters.

Non-functioning of RH blower motor only

Cause:

1. Faulty relay operation.

2. Faulty harness wiring.

Remedy:

1. Ensure 12Vsupply between relay pin 1 and ground.

Ensure continuity between pins 3 and

5 when relay operated.

Ensure relay coil impedance of

7552 to 135Q across pins 1 and 2.

Ensure correct seating of relay on base. Examine pins for damage or deformity.

Check continuity of wiring from fuse F12

(RH heelboard fuse-box) to relay pin 1 and from relay pin 2 to A / CCM

pin 53 (26-way connector).

Check continuity of wiring from fuse

F11 (RH heelboard fuse-box) to relay pin 3, from relay pin 5 to motor pin 5, from motor pin 13 to A / CCM pin 41 (16-way connector), from motor pin 8 to ground and from motor pin 10 to A / CCM pin 42 (16-way connector).

2.

Non-functioning of L H blower motor only

Cause:

1. Faulty relay operation.

2. Faulty harness wiring.

Remedy:

1. Ensure 12V supply between relay pin 1 and ground.

Ensure continuity between pins 3 and

5 when relay operated.

Ensure relay coil impedance

of 7552 to 135Q across pins 1 and 2.

Ensure correct seating of relay on base. Examine pins for damage or deformity.

2. Check continuity of wiring from fuse F12 (RH heelboard fuse-box) to relay pin 1 and from relay pin 2 to A / CCM

pin 66 (26-way connector).

Check continuity of wiring from fuse

F11 (LH heelboard fuse box) to relay pin 3, from relay pin 5 to motor pin 5, from motor pin 13 to A / CCM pin 49 (16-way connector), from motor pin 8 to ground and from motor pin 10 to

A / CCM pin 50 (16-way connector).

X300 EDM 23 Issue 1 August 1994

Page 107 of 327

E I ect r ica I

15.1 SUPPLEMENTAL RESTRAINT SYSTEM

15.1.1 System Description

The Supplemental Restraint System (SRS) installation comprises:

0 electronic Diagnostic Module (DM)

0 driver and passenger-side air bag modules (including firing mechanisms)

0 two front impact sensors (left and right)

0 one safing sensor

0 dedicated wiring harness

0 two cable reel cassettes (integral part of the steering column harness)

0 Malfunction Indicator Lamp (MIL) and driver information message

The system is designed to provide protection for both driver and front seat passenger by automatically deploying air

bags in the event of a collision during forward travel. The driver

-side air bag is located in the centre of the steering

wheel assembly and the passenger-side air bag in the fascia panel.

In the event of a collision the impact

/ safing sensors operate, completing the electrical firing circuit and causing the

air bags to inflate within 32 milliseconds. At least two of the three sensors (at least one impact, and the safing sensor)

.must be activated to initiate firing. System operation is dependent upon battery voltage supplied directly, and via the

ignition switch, to the DM and the correct installation and operation of all system components, including the wiring

harness. Faults in system components, installation or wiring will be indicated by the MIL Lamp, located on the instru

- ment panel, which will illuminate 'SRS AIR BAG'. Indication is also given by the driver information message'AIR BAG'

displayed on the LCD panel below the speedometer.

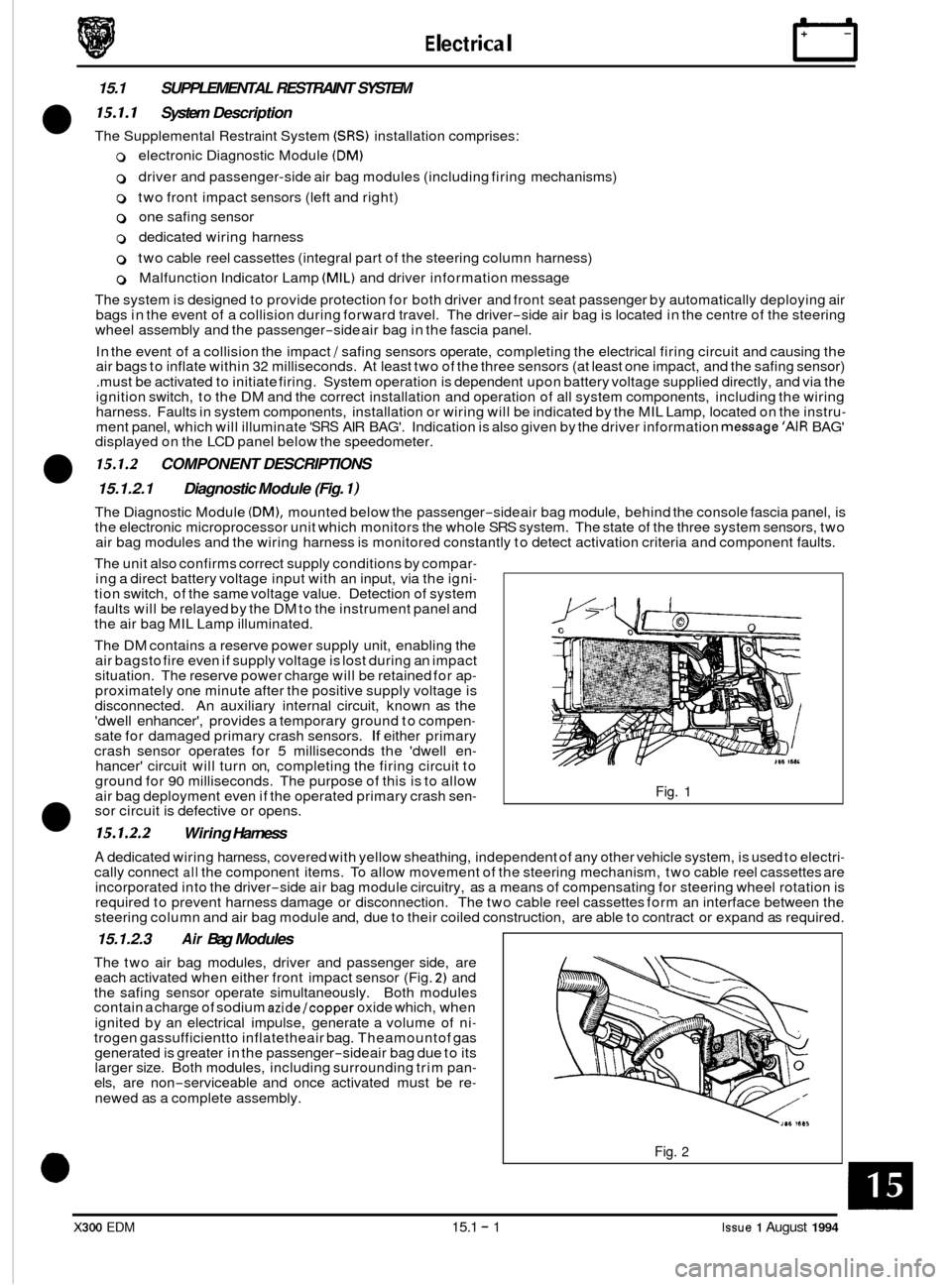

15.1.2.1 Diagnostic Module (Fig. I)

The Diagnostic Module (DM), mounted below the passenger-side air bag module, behind the console fascia panel, is

the electronic microprocessor unit which monitors the whole SRS system. The state of the three system sensors, two

air bag modules and the wiring harness is monitored constantly to detect activation criteria and component faults.

15.1.2 COMPONENT DESCRIPTIONS

The unit also confirms correct supply conditions by compar- ing a direct battery voltage input with an input, via the igni- tion switch, of the same voltage value. Detection of system

faults will be relayed by the DM to the instrument panel and

the air bag MIL Lamp illuminated.

The DM contains a reserve power supply unit, enabling the

air bagsto fire even if supply voltage is lost during an impact

situation. The reserve power charge will be retained for ap

- proximately one minute after the positive supply voltage is

disconnected. An auxiliary internal circuit, known as the

'dwell enhancer', provides a temporary ground to compen

- sate for damaged primary crash sensors. If either primary

crash sensor operates for 5 milliseconds the 'dwell en- hancer' circuit will turn on, completing the firing circuit to

ground for 90 milliseconds. The purpose of this is to allow

air bag deployment even if the operated primary crash sen- sor circuit is defective or opens.

15.1.2.2 Wiring Harness

Fig. 1

A dedicated wiring harness, covered with yellow sheathing, independent of any other vehicle system, is used to electri- cally connect all the component items. To allow movement of the steering mechanism, two cable reel cassettes are

incorporated into the driver-side air bag module circuitry, as a means of compensating for steering wheel rotation is

required to prevent harness damage or disconnection. The two cable reel cassettes form an interface between the

steering column and air bag module and, due to their coiled construction, are able to contract or expand as required.

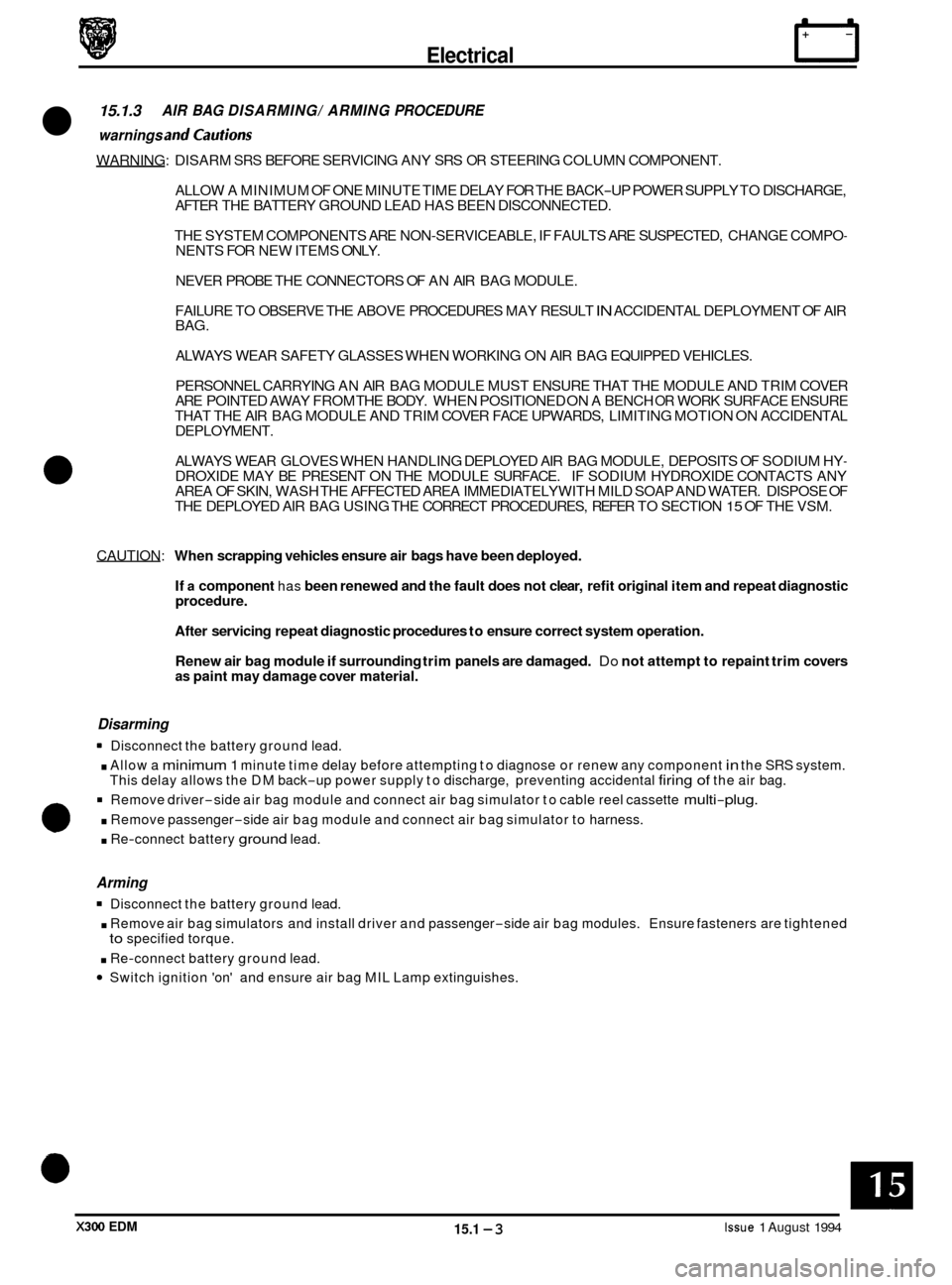

15.1.2.3 Air Bag Modules

The two air bag modules, driver and passenger side, are

each activated when either front impact sensor (Fig. 2) and

the safing sensor operate simultaneously. Both modules

contain a charge of sodium

azide/copper oxide which, when

ignited by an electrical impulse, generate a volume of ni

- trogen gassufficientto inflatetheair bag. Theamountof gas

generated is greater in the passenger-side air bag due to its

larger size. Both modules, including surrounding trim pan- els, are non-serviceable and once activated must be re-

newed as a complete assembly.

Fig. 2

X300 EDM 15.1 - 1 Issue 1 August 1994

Page 109 of 327

Electrical rl

15.1.3 AIR BAG DISARMING/ ARMING PROCEDURE

warnings and cautions

WARNING: DISARM SRS BEFORE SERVICING ANY SRS OR STEERING COLUMN COMPONENT.

ALLOW A MINIMUM OF ONE MINUTE TIME DELAY FOR THE BACK

-UP POWER SUPPLY TO DISCHARGE,

AFTER THE BATTERY GROUND LEAD HAS BEEN DISCONNECTED.

THE SYSTEM COMPONENTS ARE NON

-SERVICEABLE, IF FAULTS ARE SUSPECTED, CHANGE COMPO- NENTS FOR NEW ITEMS ONLY.

NEVER PROBE THE CONNECTORS OF AN AIR BAG MODULE.

FAILURE TO OBSERVE THE ABOVE PROCEDURES MAY RESULT

IN ACCIDENTAL DEPLOYMENT OF AIR

BAG.

ALWAYS WEAR SAFETY GLASSES WHEN WORKING ON AIR BAG EQUIPPED VEHICLES.

PERSONNEL CARRYING AN AIR BAG MODULE MUST ENSURE THAT THE MODULE AND TRIM COVER

ARE POINTED AWAY FROM THE BODY. WHEN POSITIONED ON A BENCH

OR WORK SURFACE ENSURE

THAT THE AIR BAG MODULE AND TRIM COVER FACE UPWARDS, LIMITING MOTION ON ACCIDENTAL

DEPLOYMENT.

ALWAYS WEAR GLOVES WHEN HANDLING DEPLOYED AIR BAG MODULE, DEPOSITS OF SODIUM HY

- DROXIDE MAY BE PRESENT ON THE MODULE SURFACE. IF SODIUM HYDROXIDE CONTACTS ANY

AREA OF SKIN, WASH THE AFFECTED AREA IMMEDIATELY WITH MILD SOAP AND WATER. DISPOSE OF

THE DEPLOYED AIR BAG USING THE CORRECT PROCEDURES, REFER TO SECTION

15 OF THE VSM.

CAUTION:

When scrapping vehicles ensure air bags have been deployed.

If

a component has been renewed and the fault does not clear, refit original item and repeat diagnostic

procedure.

After servicing repeat diagnostic procedures to ensure correct system operation.

Renew air bag module if surrounding trim panels are damaged.

Do not attempt to repaint trim covers as paint may damage cover material.

Disarming

. Allow a minimum 1 minute time delay before attempting to diagnose or renew any component in the SRS system.

Remove driver-side air bag module and connect air bag simulator to cable reel cassette multi-plug.

. Remove passenger-side air bag module and connect air bag simulator to harness.

. Re-connect battery ground lead.

Disconnect

the battery ground lead.

This delay allows the DM back

-up power supply to discharge, preventing accidental firing of the air bag.

0

Arming

Disconnect the battery ground lead.

. Remove air bag simulators and install driver and passenger-side air bag modules. Ensure fasteners are tightened

. Re-connect battery ground lead.

Switch ignition 'on' and ensure air bag MIL Lamp extinguishes.

to specified torque.

X300 EDM 15.1 -3 Issue 1 August 1994

Page 157 of 327

E I ect r ical

15.2.3 COMPONENT DESCRIPTION

15.2.3.1 Speedometer

The speed indication input signal, sent as a pulse rate, is generated by an open collectortransistor within the ABS con- trol module. The instrument pack converts the frequency of this signal to drive the speedometer and to provide two

road speed outputs:

Speed output

1 (pin 2,48 way connector)

This output is connected to the radio head unit, security control module and the power steering module.

Speed output 2 (pin

3,48 way connector)

This output is connected to the body processor unit, cruise control control module, air conditioning control module

and the engine management system.

15.2.3.2 Tachometer

The tachometer input, all engine variants, is provided by the engine management control module. When the engine

is running the control module generates three high state pulses per engine revolution.

15.2.3.3

This signal comes direct from the variable resistance type oil pressure sensor, mounted on the engine. The sensor

resistance values range from 75Q (8 Bar) to 330Q (0 Bar).

When the gauge reaches

a pre-determined reading the instrument pack illuminates the warning light.

Engine Oil Pressure and Warning lamp

15.2.3.4 Engine Coolant Temperature

This signal comes direct from the coolant temperature sensor (variable resistance type), mounted on the engine. The

sensor resistance values range from 34Q (hot) to 241Q (cold), when disconnected from the vehicle.

Note: The coolant temperature gauge is calibrated to indicate at approximately 'Normal' for a wide range of normal

engine operating temperatures.

15.2.3.5 Fuel Tank level Gauge and Warning lamp

This signal (pin 20,24-way connector) comes direct from the variable resistor type fuel level sensor. The sensor resis- tance values range from 80 ohms (full tank) to 900 ohms (empty tank).

When the gauge reaches a pre

-determined reading, the instrument pack illuminates the warning lamp.

15.2.3.6

Battery voltage is displayed on the gauge by measuring the ignition voltage.

The red charge warning lamp will illuminate if either the voltage is too low (below

10.5V) or too high (above 15.5V). In addition, the generator provides a low signal to the instrument pack (pin 9,48-way connector) when battery charging

is unsatisfactory.

Battery Voltage Gauge and Warning lamp

15.2.3.7 Liquid Crystal Display

A single line, six digit, 7 segment display with six trip function flags used for odometer, trip computer and driver mess- ages.

!Y,Q&: If the instrument pack has not been PECUS programmed, the back illumination of the LCD will not switch on.

Check that a PECUS label is attached to the back of the pack.

Issue 1 August 1994 15.2 - 4 X300 EDM

Page 190 of 327

15.4 DRIVER ERGONOMICS

15.4.1 System Description

Adjustment of the seats, steering column and exterior rear view mirrors position is effected by means of control

switches. The switches maintain the adjustment facility while depressed, movement ceasing when the switch is re- leased.

Manual adjustment can be achieved either with the ignition key in place or with the driver‘s door open, or having been

closed within the last

30 seconds.

The system offers the following facilities:

Entry

/ Exit mode; an automatic seat /column position setting for ease of driver entry into / exit from the vehicle.

Driving position set; automatic recall of up to three preferred settings.

Passenger seat set; automatic recall of up to three preferred settings.

Remote recall; automatic recall of up to two memory positions from

a remote transmitter (in key fob).

Reverse mirror dip; automatic adjustment of passenger rear view mirror when reversing.

U: Vehicles intended for the Japanese market are fitted with an additional ‘fold away’ mirror function. This func- tion allows mirrors to fold flat against the car when parking in enclosed areas.

15.4.1.1 Entry/ Exit Mode

Entry / Exit mode is designed to give easier vehicle entry and exit for the driver. The facility is selected by positioning

the mode switch, located on the LH side of the column cowl, to ‘auto’ which designates the current seat / column posi- tion, ie driving positions, as the memorized position. On removal of ignition key or opening of driver‘s door, with igni- tion key still in place, the driver’s seat will move to the rear (current position allowing) and the column will adopt ‘tilt

away’ mode automatically creating additional space for driver exit

/ entry. Insertion of key in ignition or closure of

driver‘s door (with ignition key in place) returns seat / column positions to the memorized (previous) position.

Operation of eitherthe brake pedal or

seat/column manual controls during entry/exit mode execution will abort posi- tional adjustments. Setting the mode switch to OFF disables operation of entry / exit mode.

15.4.1.2 Driving Position Set

Setting of seat, column and external rear view mirrors to preferred driving position is available using the memory but- tons located on the drivers door switch pack. With the ignition key in place enter settings to be memorized as follows:

Adjust seat, column and mirrors to desired positions.

Press the ’memory’ button

so that it becomes illuminated.

Press button

1,2 or 3 to store configuration within four seconds of memory button operation. Memory light will extin- guish and a chime will sound, indicating procedure complete.

The above procedure may be repeated two more times until each button

(1,2 & 3) has a preferred position stored in

memory, accommodating different driver settings. Operation of any push-button (1,2 or 3) will re-position seat col-

umn and mirrors to the stored settings.

Memory recall will operate under the following conditions:

. Ignition key in and gear selector in park.

8 Ignition key in and handbrake on.

8 Ignition key out and driver’s door open (or having been closed within the last 30 seconds).

Re

-setting the preferred position on any setting button automatically erases previously stored information. Memory

information is not erased if power supply to the seat and column / mirror control modules is lost (e.g. battery discon- nected).

15.4.1.3 Passenger Seat Set

The procedure for setting and recalling a preferred passenger seat position is identical to that for a driving position.

Memory recall will only operate with ignition key in auxiliary position or passenger door open, or having been closed

within the last

30 seconds.

X300 EDM 15.4 - 1 Issue 1 August 1994

Page 215 of 327

Electrical IT

Fault:

Possible causes:

Remedy:

Fault: Possible causes:

Remedy:

Fault:

Possible causes:

Remedy:

Fault:

Possible causes:

Remedy:

Fault:

Possible causes:

Remedy: Steering

column positional adjustment inoperative

1. No power supply.

2. Wiring harness or connector fault.

3. Switch faulty.

4. Mechanical failure.

1. 2. Examine harness and connectors between S 1 CM -

3. Renew switch.

4.

Check fuses in 'A' post base fuse boxes.

fuse,

S I C CM - joy-stick switch and SI C CM - motors.

Identify and repair mechanical faults.

Steering column positional adjustment restricted

1. Wiring harness or connector fault.

2. Motor faulty.

3. Switch faulty.

4.

1.

2. Renew faulty motor.

3. Renew faulty switch.

4.

M echa n ica I mechanism fa i I u re.

Examine harness and connectors between

S 1 C CM -

motors and SI C CM and switch.

Identify and repair mechanical faults.

Rear view mirror positional adjustment inoperative or restricted

1. No power supply.

2.

3. Motor faulty.

4. Switch faulty.

5. Mechanical mechanism failure.

1.

2.

3. Renew faulty motor.

4. Renew faulty switch.

5.

Wiring harness or connector fault.

Check fuses in

'A' post base fuse boxes.

Examine harness and connectors between

S 1 C CM -

motors and SI C CM and switch.

Identify and repair mechanical faults.

Recall / Memory set facility inoperative or incorrect

1. Wiring harness or connector fault.

2. Potentiometers out of range or faulty.

3. Switches faulty.

1. Examine harness and connectors between SCM, S I C

CM and switches.

2. PDU only to check.

3. Renew faulty switches.

Exit \Entry facility inoperative or incorrect

1. Wiring harness or connector fault.

2. Potentiometers out of range or faulty.

3. Switch faulty.

1. Examine harness and connectors between SCM, S 1 C

CM and switches.

2.. PDU only to check.

3. Renew faulty switches. ~

Issue 1 August 1994 15.4 - 18 X300 EDM