key JAGUAR XJ6 1994 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 400 of 521

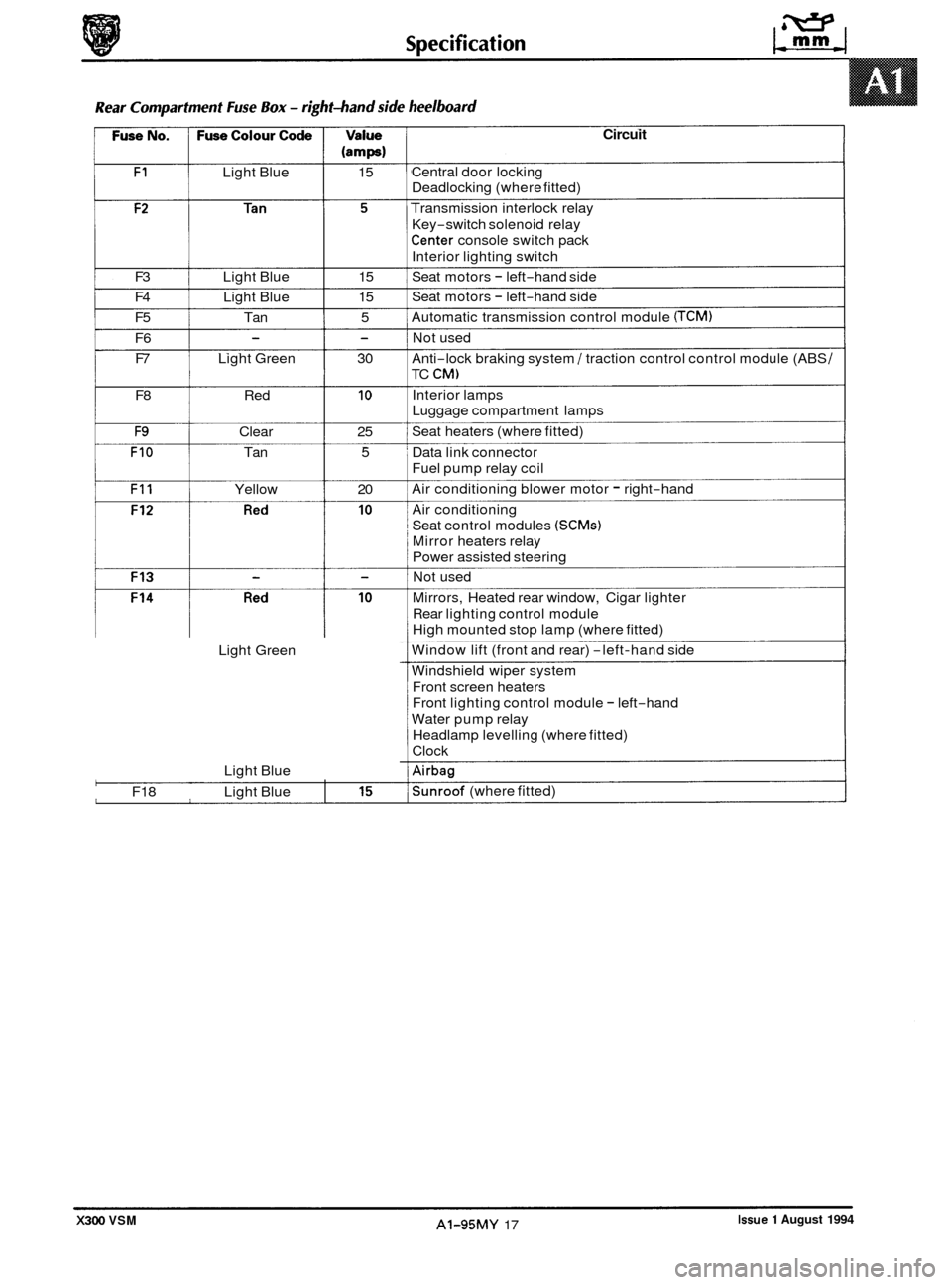

(amps)

F1 Light Blue 15

F3 Light Blue 15

F4 Light Blue 15

F5 Tan 5

F6 F7 Light Green 30

- -

F8 Red 10

F9 Clear 25

FIO Tan 5

F11 Yellow 20 0

Light Green

Light Blue

F18 Light Blue

0'

I

Circuit

Central door locking

Deadlocking (where fitted)

Transmission interlock relay

Key

-switch solenoid relay

Center console switch pack

Interior lighting switch

Seat motors

- left-hand side

Seat motors

- left-hand side

Automatic transmission control module

(TCM)

Not used

Anti

-lock braking system / traction control control module (ABS /

TC CM)

Interior lamps

Luggage compartment lamps

Seat heaters (where fitted)

Data link connector

Fuel pump relay coil

Air conditioning blower motor

- right-hand

Air conditioning

Seat control modules

(SCMs)

Mirror heaters relay

Power assisted steering

Not used

Mirrors, Heated rear window, Cigar lighter

Rear lighting control module

High mounted stop lamp (where fitted)

Window lift (front and rear)

-left-hand side

Windshield wiper system Front screen heaters

Front lighting control module

- left-hand

Water pump relay

Headlamp levelling (where fitted)

Clock

Airbag

Sunroof (where fitted)

Issue 1 August 1994 AI-95MY 17 X300 VSM

Page 410 of 521

General Fitting Instructions

SECTION CONTENTS

Subsection Title SRO Page

i ................ PreliminaryPage ..................................................................... i

A3.1 ............. Safety Precautions ................................................................... 1

A3.1.1 ........... Safety Precautions. Used Engine Oils ................................................... 1

A3.1.2 ........... Safety Precautions. Health Protection Precautions ........................................ 1

A3.1.3 ........... Safety Precautions. Environmental Protection Precautions .................................. 1

A3.2 ............. General Fitting Instructions ............................................................ 2

A3.2.1

........... General Fitting Instructions. Precautions Against Damage To The Vehicle ..................... 2

A3.2.2

........... General Fitting Instructions. Preparation ................................................. 2

A3.2.3

........... General Fitting Instructions. Dismantling ................................................ 2

A3.2.4

........... General Fitting Instructions. Inspection .................................................. 2

A3.2.5

........... General Fitting Instructions. Ball And Roller Bearings ...................................... 3

A3.2.6

........... General Fitting Instructions. Oil Seals ................................................... 3

A3.2.7

........... General Fitting Instructions. Joints And Joint Faces ......................................... 4

A3.2.8

........... General Fitting instructions. Hydraulic Flexible Pipes And Hoses ............................ 4

A3.2.9

........... General Fitting Instructions. Metric Bolt identification ...................................... 4

A3.2.10

.......... General Fitting instructions. Metric Nut Identification ...................................... 4

A3.2.11

.......... General Fitting Instructions. Hydraulic Fittings -Metrification ............................... 5

A3.2.12

.......... General Fitting Instructions. Keys And Keyways ........................................... 6

A3.2.13

.......... General Fitting Instructions. Split Pins ................................................... 6

A3.2.14

.......... General Fitting instructions. Tab Washers ................................................ 6

A3.2.15

.......... General Fitting instructions. Special Fixings .............................................. 6

A3.2.16

.......... General Fitting Instructions. Nuts ....................................................... 7

A3.2.17 .......... General Fitting Instructions. Locking Wire ................................................ 7

A3.2.18 .......... General Fitting Instructions. Screw Threads ............................................... 7

A3.2.19 .......... General Fitting Instructions. Unified Thread Identification - Bolts ............................ 7

A3.2.20 .......... General Fitting Instructions. Unified Thread Identification - Nuts ............................ 7

A3.2.21 .......... General Fitting Instructions. Unified Thread Identification - Studs. Brake Rods. etc .............. 7

A3.3 ............. Taper Roller Bearings - Fault Diagnosis .................................................. 8

X300 VSM i Issue 1 August 1994

Page 417 of 521

General Fitting Instructions

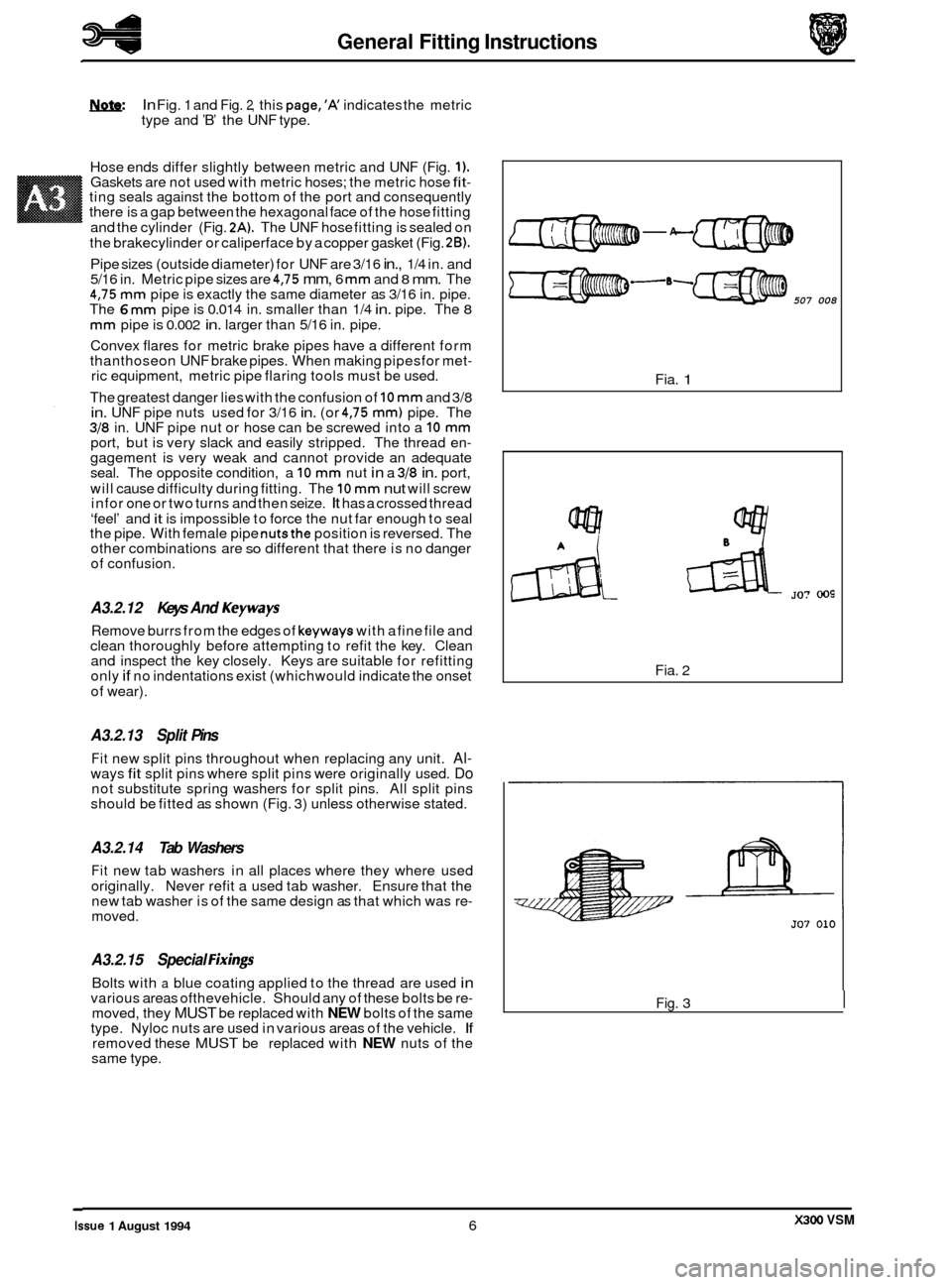

In Fig. 1 and Fig. 2, this page,’K indicates the metric

type and ’B’ the UNF type.

Hose ends differ slightly between metric and UNF (Fig.

1). Gaskets are not used with metric hoses; the metric hose fit- ting seals against the bottom of the port and consequently

there is a gap between the hexagonal face of the hose fitting

and the cylinder (Fig.

2A). The UNF hose fitting is sealed on

the brakecylinder or caliperface by a copper gasket (Fig.

2B).

Pipe sizes (outside diameter) for UNF are 3/16 in., 1/4 in. and

5/16 in. Metric pipe sizes are 4,75 mm, 6 mm and 8 mm. The 4,75 mm pipe is exactly the same diameter as 3/16 in. pipe.

The 6 mm pipe is 0.014 in. smaller than 1/4 in. pipe. The 8

mm pipe is 0.002 in. larger than 5/16 in. pipe.

Convex flares for metric brake pipes have a different form

thanthoseon UNF brake pipes. When making pipesfor met

- ric equipment, metric pipe flaring tools must be used.

The greatest danger lies with the confusion of

10 mm and 3/8 in. UNF pipe nuts used for 3/16 in. (or 4,75 mm) pipe. The 318 in. UNF pipe nut or hose can be screwed into a 10 mm port, but is very slack and easily stripped. The thread en- gagement is very weak and cannot provide an adequate

seal. The opposite condition, a 10 mm nut in a 318 in. port,

will cause difficulty during fitting. The

10 mm nut will screw

in for one or two turns and then seize. It has a crossed thread

‘feel’ and

it is impossible to force the nut far enough to seal

the pipe. With female pipe nutsthe position is reversed. The

other combinations are so different that there is no danger

of confusion.

A3.2.12 Keys And Keyways

Remove burrs from the edges of keyways with a fine file and

clean thoroughly before attempting to refit the key. Clean

and inspect the key closely. Keys are suitable for refitting

only

if no indentations exist (which would indicate the onset

of wear).

A3.2.13 Split Pins

Fit new split pins throughout when replacing any unit. Al- ways fit split pins where split pins were originally used. Do not substitute spring washers for split pins. All split pins

should be fitted as shown (Fig. 3) unless otherwise stated.

A3.2.14 Tab Washers

Fit new tab washers in all places where they where used

originally. Never refit a used tab washer. Ensure that the

new tab washer is of the same design as that which was re

- moved.

A3.2.15 Special Fixing

Bolts with a blue coating applied to the thread are used in various areas ofthevehicle. Should any of these bolts be re- moved, they MUST be replaced with NEW bolts of the same

type. Nyloc nuts are used in various areas of the vehicle. If removed these MUST be replaced with NEW nuts of the

same type.

-A

507 008

Fia. 1

Fia. 2

Fig. 3 I

X300 VSM Issue 1 August 1994 6

Page 424 of 521

SECTION CON TENTS

Suh-Section Title SRO Page

i Toiii ............ PreliminaryPages ................................................................ i Toiii

A4.1

............. Body Repair, Introduction ............................................................. 1

A4.1.1 ........... Health And Safety .................................................................... 1

A4.1.2 ........... Notification Of Hazards ............................................................... 2

A4.1.3 ........... Potential Risks ....................................................................... \

3

A4.1.3.1

.......... Potential Risks. Paint ................................................................. 3

A4.1.3.2

.......... Potential Risks. Applied Heat (Welding) .................................................. 3

A4.1.3.3 .......... Potential Risks. Metal Repair ........................................................... 3

A4.1.4 ........... Precautions ........................................................................\

. 3

A4.1.4.1 ..........

A4.1.4.2 ..........

A4.1.4.3 ..........

A4.1.5 ...........

A4.1.5.1 ..........

A4.1.6 ...........

A4.1.6.1 ..........

A4.1.6.2 ..........

A4.1.6.3 ..........

A4.1.6.4 ..........

A4.1.6.5 ..........

A4.1.6.6. .........

Precautions. Paint .................................................................... 3

Precautions. Applied Heat

............................................................. 3

Precautions. Metal Repair ............................................................. 3

General Repair Notes ................................................................. 4

Welding & Gas Processes. Special Notes ................................................. 4

Plastic Component & Trim Materials. - Table ............................................. 5

Plastics. Explanatory Notes ............................................................ 5

Plastics. Handling Notes .............................................................. 5

Recycled Materials

................................................................... 5

Plastics. Component Location & Type - External. Illustration ................................. 6

Plastics. Component Location

& Type - Internal. Illustration ................................. 7

Plastics. Component Location & Type - Underhood. Illustration .............................. 8

A4.2 ............. Body Structure. ...................................................................... 9

A4.2.1 ........... Body Structure. Introduction ........................................................... 9

A4.2.2.1 .......... Body Alignment. Datum Location ...................................................... 10

A4.2.2.2 .......... Body Alignment. Plan View - Key to Illustration .......................................... 10

A4.2.2.3 .......... Body Alignment. Side View - Key to Illustration .......................................... 12

A4.2.3 ........... Zinc Coated Panels .................................................................. 14

A4.2.3.1 .......... Zinc Coated Panels. Description ....................................................... 14

A4.2.3.2

.......... Zinc Coated Panels. Welding Preparation ............................................... 14

A4.2.3.3

.......... Zinc Coated Panels. Body Fillers ....................................................... 14

A4.2.3.4

.......... Zinc Coated Panels. Refinishing ....................................................... 14

A4.2.4

........... Panels -Associated. Renew ..................................... 77.10.02 ............ 15

A4.2.5

........... Surfaces (Old). Prepare .......................................... 77.10.03 ............ 16

A4.2.5.1 .......... Surfaces (New). Prepare ......................................... 77.10.04 ............ 16

A4.2.5.2 .......... Panels -Align And Weld ........................................ 77.10.05 & 06 ....... 17

A4.2.6 ........... Cutting And Welding Symbols ......................................................... 18

A4.3.1 ........... Adhesive. Sealers and Body Protection - Approved Systems ................................ 19

A4.3.

1 . 1 .......... Body Sealing & Preservation Manual - Section Relevance ................................. 19 A4.3.2 ........... Cavity Wax Injection ................................................................ 19

A4.3.2.1

.......... Cavity Wax Injection Points - Front. Illustration .......................................... 20

A4.3.2.2. ......... Cavity Wax Injection Points - Rear, Illustration ........................................... 21

A4.3.3 ........... Underseal. Application Area .......................................................... 22

A4.3.4

........... Insulation Pads. Location ............................................................. 23

A4.3.5

........... Foamlnjection ..................................................................... 24

A4.4.1 ........... Paint Systems - Approved. Table ...................................................... 25

A4.4.1.1

.......... General Recommendations (Paint Refinishing Manual) .................................... 25

A4.4.1.2

.......... Paint Refinishing Manual. Section Relevance ............................................ 25

A4.4.2

........... ‘Black-Out’ Areas. Illustration ......................................................... 26

A4.4.3 ........... Anti-theft labels .................................................................... 27

A4.4.3.1

.......... Anti-theft labels. Original Components ................................................ 27

A4.4.3.2

.......... Anti-theft Labels. Replacement Components ............................................ 27

A4.4.3.3 .......... Anti-theft Labels. Procurement ........................................................ 27

A4.4.3.4

.......... Anti-theft Labels. Location -Front ..................................................... 28

A4.4.3.5

.......... Anti-theft Labels. Location - Rear ...................................................... 29

A4.4.3.7.

......... Anti-theft Labels. Fitting Process ....................................................... 31

A4.2.1.1

.......... Body Structure.

Constructional Steel Classification - Table .................................. 9

A4.2.2 ........... BodyAlignment ..................................................................... 9

A4.4.3.6 .......... Anti-theft Labels. Location -Power unit & Transmission ................................... 30

Page 437 of 521

Body Systems & Body Repair

Location

Centre line of the front crossmember rear mounting, at the

main floor

RH longitudinal

A4.2.2.1 Datum location, Example

The FRONT MASTER DATUM (front crossmember rear mounting at the inner face ofthe main floor RH longitudi- nal) is nominally 359,5mm to the right-hand side of the body center line. The LH side front datum is measured 717,0/ 721,Omm from the RH. Please refer to the illustration on the following page.

Expressed as

a true position in three planes, the front master datum is:

Position

X 300,O

Y 359.5 Z -50.0

0

Datum

Front Master Datum

Plan

A4.2.2.2 Key, Plan View

Please refer to the illustration on the opposite page.

Key Location

1

2

3

4

5 Driveshaft centre bearing fixings

6

7

8

9

10 Front

face body

- bumper strut / mounting point

Rearmost hole, Vee

-mount to crush tube

Front Master Datum Plan, centre line

of the front crossmember rear mounting at the main floor RH longi-

tudinal

Rearmost hole, transmission mounting

at the main floor RH longitudinal

Rear Master Datum Plan, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear suspension differential strut mounting

Rear face body

- bumper strut / mounting point

X300 VSM Issue 1 August 1994 10

Page 439 of 521

E 12

Rear face bodv - bumDer strut / mountina Doint

Body Systems

I

& Body

side vww

the illustration on the opposite page.

Repair

Location

Front face body - bumper strut / mounting point

Front Master Datum Vertical. centre line of the front crossmember rear mountina

Front

face body - bumper strut / mounting point

Front Master Datum Vertical, centre line of the front crossmember rear mounting

Transmission mountings

at the main floor longitudinal

Driveshaft centre bearing fixings

Rear Master Datum

Vertical, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear suspension differential strut mounting

Rear face body

- bumper strut / mounting point

Transmission

mountings

at the main floor longitudinal

Driveshaft centre bearing fixings

Rear Master Datum

Vertical, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear

susoension differential strut mounting

Wheel centre to

bummr cover face I

Wheel base I

Wheel centre to bumper cover face

Body Systems & Body Repair

A4.2.2.3 Key, Side Vww

Please refer to the illustration on the opposite page.

0

0

0

X300 VSM Issue 1 August 1994 12

Page 445 of 521

Body Systems & Body Repair

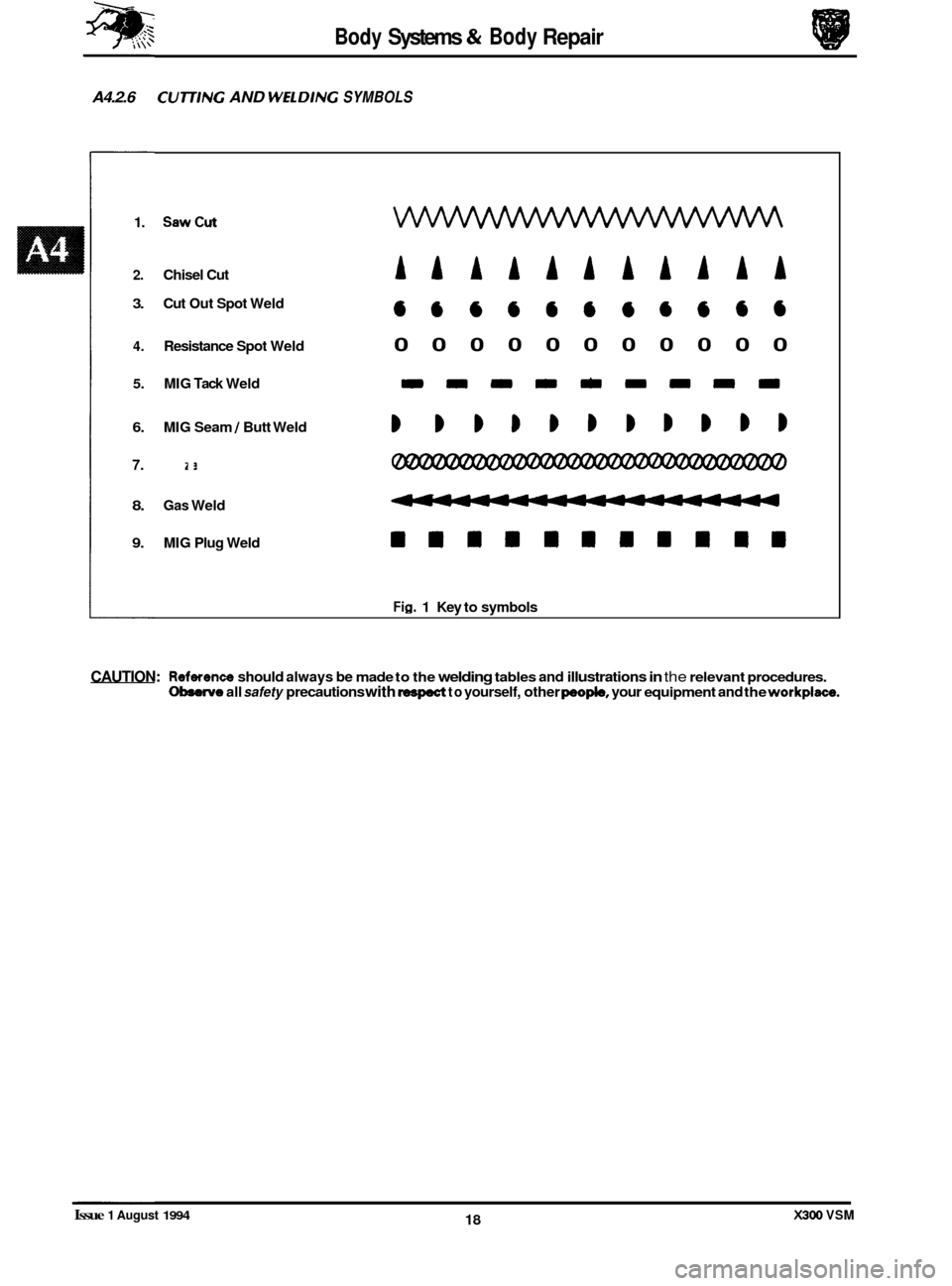

A4.2.6 CU77/NG AND WELDlNG SYMBOLS

1. SawCut

2. Chisel Cut AkAAAkAAkAA

666666@6646

4. Resistance Spot Weld 00000000000

3. Cut Out Spot Weld

5. MIG Tack Weld DmmDmm=m=

6. MIG Seam / Butt Weld BBBBBBBBBBB

7. Braze

8. Gas Weld

9. MIG Plug Weld WIIBIIBBIII

Fig. 1 Key to symbols

CAUTION: Reference should always be made to the welding tables and illustrations in the relevant procedures. Obsenfo all safety precautions with respect to yourself, other peopIe, your equipment and the workplace.

0

0

X300 VSM 18 Issue 1 August 1994

Page 477 of 521

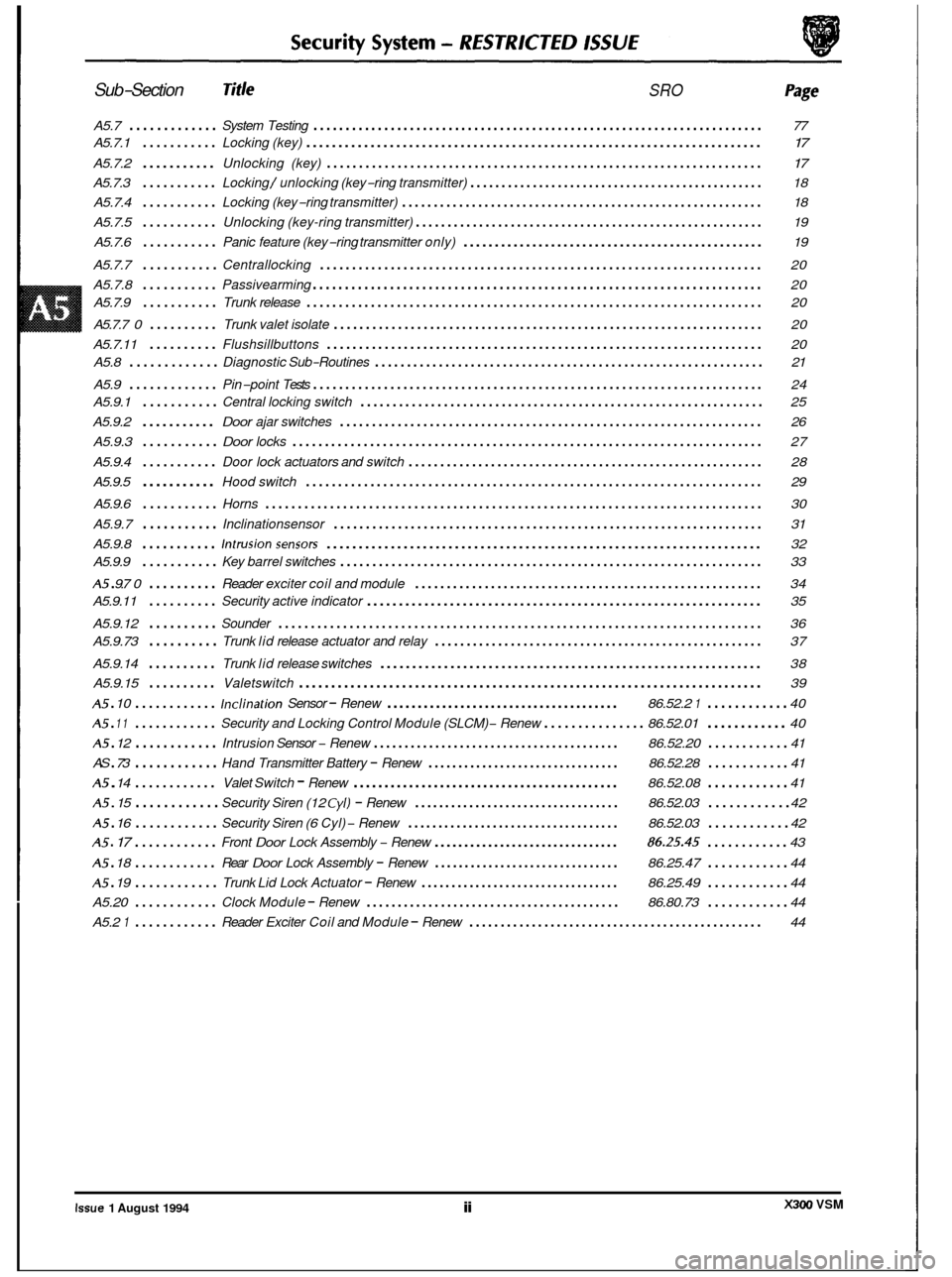

page e

Sub-Section Title SRO

A5.7 ............. System Testing ...................................................................... 77

A5.7.1

........... Locking (key) ....................................................................... \

17

A5.7.2 ........... Unlocking (key) .................................................................... 17

A5.7.3 ........... Locking / unlocking (key-ring transmitter) ............................................... 18

A5.7.4

........... Locking (key-ring transmitter) ......................................................... 18

A5.7.5

........... Unlocking (key-ring transmitter) ....................................................... 19

A5.7.6

........... Panic feature (key-ring transmitter only) ................................................ 19

A5.7.7

........... Centrallocking ..................................................................... 20

A5.7.8

........... Passivearming ...................................................................... 20

A5.7.9

........... Trunk release ....................................................................... \

20

A5.7.7

0 .......... Trunk valet isolate ................................................................... 20

A5.7.11

.......... Flushsillbuttons .................................................................... 20

A5.9

............. Pin-point Tests ...................................................................... 24

A5.8

............. Diagnostic

Sub-Routines ............................................................. 21

A5.9.1

........... Central locking switch ............................................................... 25

A5.9.2

........... Door ajar switches .................................................................. 26

A5.9.3

........... Door locks ........................................................................\

. 27

A5.9.4

........... Door lock actuators and switch ........................................................ 28

A5.9.5

........... Hood switch ....................................................................... \

29 e

A5.9.6 ........... Horns ........................................................................\

..... 30

A5.9.7

........... Inclinationsensor ................................................................... 31

A5.9.8

........... Intrusionsensors .................................................................... 32

A5 . 9.7 0 .......... Reader exciter coil and module ....................................................... 34

A5.9.12

.......... Sounder ........................................................................\

... 36

A5.9.14

.......... Trunk lid release switches ............................................................ 38

A5.9.15

.......... Valetswitch ........................................................................\

39

A5 . 10 ............ Inclination Sensor - Renew ...................................... 86.52.2 1 ............ 40

A5 . 12 ............ Intrusion Sensor - Renew ........................................ 86.52.20 ............ 41

A5 . 14 ............ Valet Switch - Renew ........................................... 86.52.08 ............ 41

A5.9.9

........... Key

barrel switches .................................................................. 33

A5.9.11

.......... Security active indicator .............................................................. 35

A5.9.73

.......... Trunk lid release actuator and relay .................................................... 37

A5 . 11 ............ Security and Locking Control Module (SLCM) - Renew ............... 86.52.01 ............ 40

AS

. 73 ............ Hand Transmitter Battery - Renew ................................ 86.52.28 ............ 41

A5 . 15 ............ Security Siren (12 Cyl) - Renew .................................. 86.52.03 ............ 42

A5 . 16 ............ Security Siren (6 Cyl) - Renew ................................... 86.52.03 ............ 42

A5 . 17 ............ Front Door Lock Assembly - Renew ............................... 86.25.45 ............ 43

A5 . 18 ............ Rear Door Lock Assembly - Renew ............................... 86.25.47 ............ 44

Trunk Lid Lock Actuator - Renew ................................. 86.25.49 ............ 44

Clock Module - Renew ......................................... 86.80.73 ............ 44

Reader Exciter Coil and Module - Renew ............................................... 44

e

A5 . 19 ............

A5.20 ............

A5.2 1 ............

e

X300 VSM Issue 1 August 1994 ii

Page 478 of 521

0

c

doors, windows, trunk, hood and sliding roof.

I Method I UK / EUROPE

of IXJ16I1SOVIIDAIM

Operation Sport XJ12 /DD6

Locking

Central locking Key X X X

Remote central locking Remote X X X

Deadlocking Remote/ X X X

Two stage unlock Remote/

- - - Key

Key

Drive away locks Auto X/DD X/DD X/DD

Switch

close

Interior trunk lid release Switch

Flush

sill buttons /

intrusion override

security

Security system (base)

Intrusion sensing (full)

Inclination sensing

Passive arming

Panic alarm

Audible tones (error

/

deadlock)

Engine immobilization

*

Auto

.,,,

Remote

Auto

1 XI X X

X D

D D

X/ DD

X

-~~

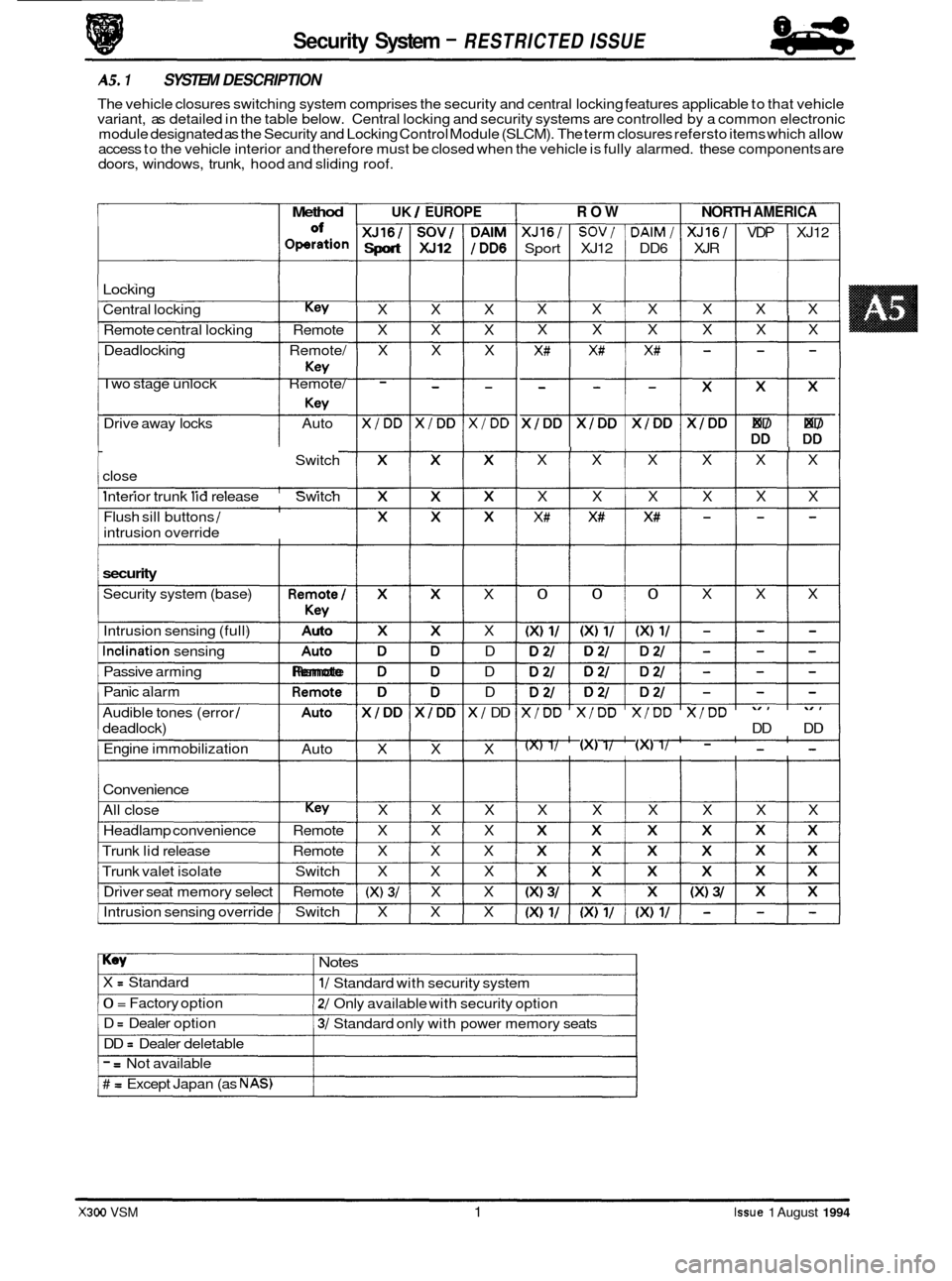

Security System - RESTRICTED ISSUE

AS. 1 SYSTEM DESCRIPTION

The vehicle closures switching system comprises the security and central locking features applicable to that vehicle

variant, as detailed in the table below. Central locking and security systems are controlled by a common electronic

module designated as the Security and Locking Control Module (SLCM). The term closures refersto items which allow

access to the vehicle interior and therefore must be closed when the vehicle is fully alarmed. these components are

Convenience

All close Key X X X

Headlamp convenience Remote X X X

Trunk lid release Remote X X X

Trunk valet isolate Switch X X X

Driver seat memory select Remote

(X) 3/ X X

Intrusion sensing override Switch X X X

ROW NORTH AMERICA

XJ16/ SOV/ DAlM/ XJ16/ VDP XJ12

Sport XJ12 DD6 XJR

X X X X X X

I X X X X X X

X# X# X# - - -

$$$$$ DD DD

I I I I I X X X X X X

X X X X X X

X# X# X# - - -

I 0 0 0 X X X

X/DD X/DD X/DD X/DD

DD DD

(X) 1/ (XI 1/ (XI 1/ - - -

X X X X X X

Key Notes

X = Standard

0 = Factory option

D

= Dealer option

DD

= Dealer deletable

1/ Standard with security system

2/ Only available with security option

3/ Standard only with power memory seats

- = Not available

# = Except Japan (as NAS)

X300 VSM 1 Issue 1 August 1994

Page 480 of 521

I 03 I Door lock actuators (4 off) 1 part of door assemblv I I

Issue 1 August 1994 X300 VSM 3 I

1 04 I Door lock switches (2 off) I part of door latch assembly I I

1 05 IHoodswitch 1 located above siren I I

1 06 IHorn 1 located on front RH side of en(

1 07 I Inclination sensor I behind luggage compartment LH liner I I

I 08 I Intrusion sensor (LH) I located above LH door behind roof lining I

I 09 I intrusion sensor (RH) 1 located above LH door behind roof lining I

I

1 1 part of door latch assembly I 10 I Key barrel switches (2 off)

1 11 I Key fob transmitter 1 part of key fob I I

I 12 I Key transponder 1 part of key I I

I 13 I Reader exciter coil 1 part of ignition switch I I

I 14 I Reader exciter module 1 part of steering column assembly I I

1 15 I Relays (deadlock) I I I

1 18 I Security active indicator part of central locking switch I I

I 19 I Securitv and lockina control module (SLCM) located in luaaaae compartment behind LH liner I I

1 20 ISounder , located on front RH side of engine bay I I

1 25 IValet switch 1 in centre console compartment I I

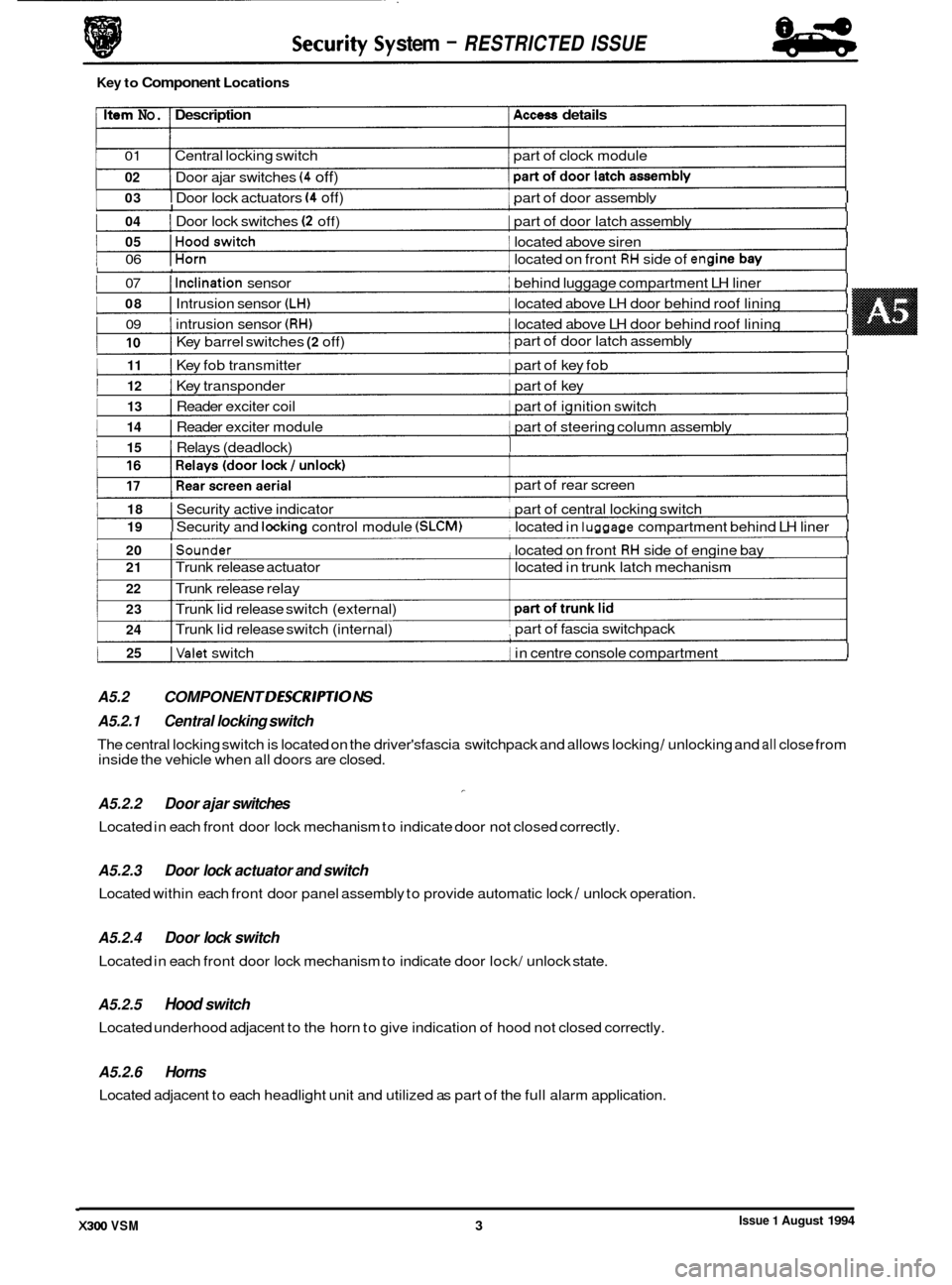

A5.2 COMPONENT DESCR/PT/O NS I

stem - RESTRICTED ISSUE

Key to Component Locations

Item No. Description Access details

01 Central locking switch part of clock module

02

1 I

Door ajar switches (4 off)

I I

part of rear screen

I 21 I Trunk release actuator located in trunk latch mechanism

22 I Trunk release relay

23

24 I Trunk lid release switch (external)

I Trunk lid release switch (internal) part of

fascia switchpack ,

A5.2.1 Central locking switch

A5.2.2 Door ajar switches

Located in each front door lock mechanism to indicate door not closed correctly.

-

The central locking switch is located on the driver'sfascia switchpack and allows locking / unlocking and all close from

inside the vehicle when all doors are closed.

A5.2.3

Located within each front door panel assembly to provide automatic lock / unlock operation.

Door lock actuator and switch

A5.2.4 Door lock switch

Located in each front door lock mechanism to indicate door lock/ unlock state.

A5.2.5 Hood switch

Located underhood adjacent to the horn to give indication of hood not closed correctly.

A5.2.6 Horns

Located adjacent to each headlight unit and utilized as part of the full alarm application.