oil dipstick JAGUAR XJ6 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 50 of 521

Engine (V12)

3.2.3 ENGINE OIL, RENEW

SRO 12.60.00

. Undo and remove the sump plug positioned at the rear of

the sump, drain the engine oil into a suitable receptacle

and dispose of

it in a safe and environmentally friendly

manner.

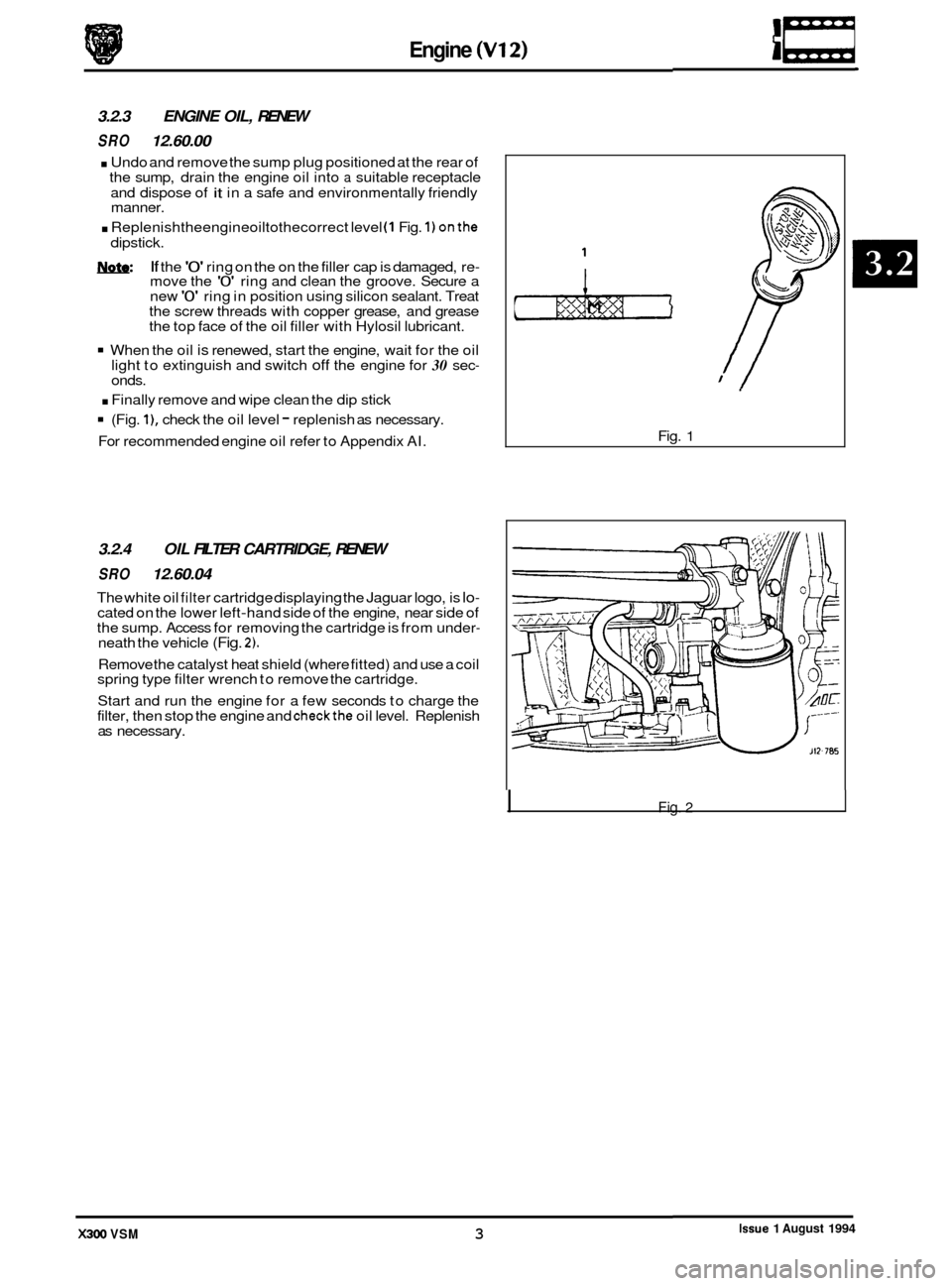

. Replenishtheengineoiltothecorrect level (1 Fig. 1) onthe

dipstick.

1ynfa: If the '0' ring on the on the filler cap is damaged, re- move the '0' ring and clean the groove. Secure a

new '0' ring in position using silicon sealant. Treat

the screw threads with copper grease, and grease

the top face of the oil filler with Hylosil lubricant.

When the oil is renewed, start the engine, wait for the oil

light to extinguish and switch off the engine for 30 sec- onds.

. Finally remove and wipe clean the dip stick

(Fig. l), check the oil level - replenish as necessary.

For recommended engine oil refer to Appendix AI. Fig.

1

3.2.4

OIL FILTER CARTRIDGE, RENEW

SRO 12.60.04

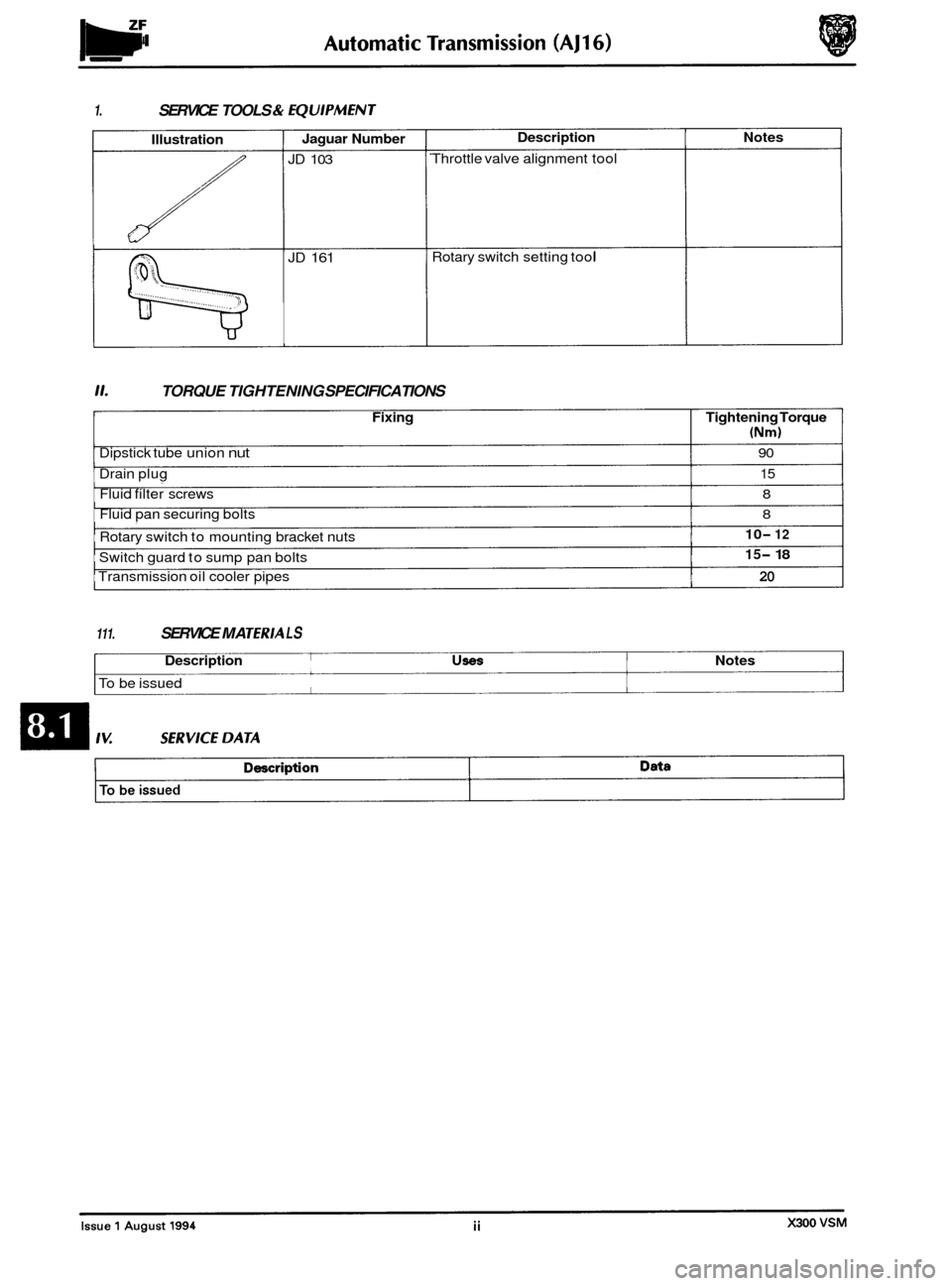

The white oil filter cartridge displaying the Jaguar logo, is lo- cated on the lower left-hand side of the engine, near side of

the sump. Access for removing the cartridge is from under- neath the vehicle (Fig. 2).

Remove the catalyst heat shield (where fitted) and use a coil

spring type filter wrench to remove the cartridge.

Start and run the engine for a few seconds to charge the

filter, then stop the engine and

checkthe oil level. Replenish

as necessary.

I Fig. 2

Issue 1 August 1994 X300 VSM 3

r

Page 137 of 521

1. SERVICE TOOLS & fQUlPMENT

Illustration

::(())(((((

Jaguar Number

JD 103

JD 161

Description Notes

Throttle valve alignment tool

Rotary switch setting tool

11. TORQUE TIGHTENING SPECIFICATIONS

Fixing Tightening Torque

(Nm)

Dipstick tube union nut 90

Drain plug 15

Fluid filter screws 8

Fluid pan securing bolts 8

Rotary switch to mounting bracket nuts

Transmission oil cooler pipes

20

10- 12

15- 18 Switch guard to sump pan bolts

111. SERVICE MA TERlA L S

Description USeS Notes

To be issued

Page 138 of 521

Automatic Transmission (AJ16)

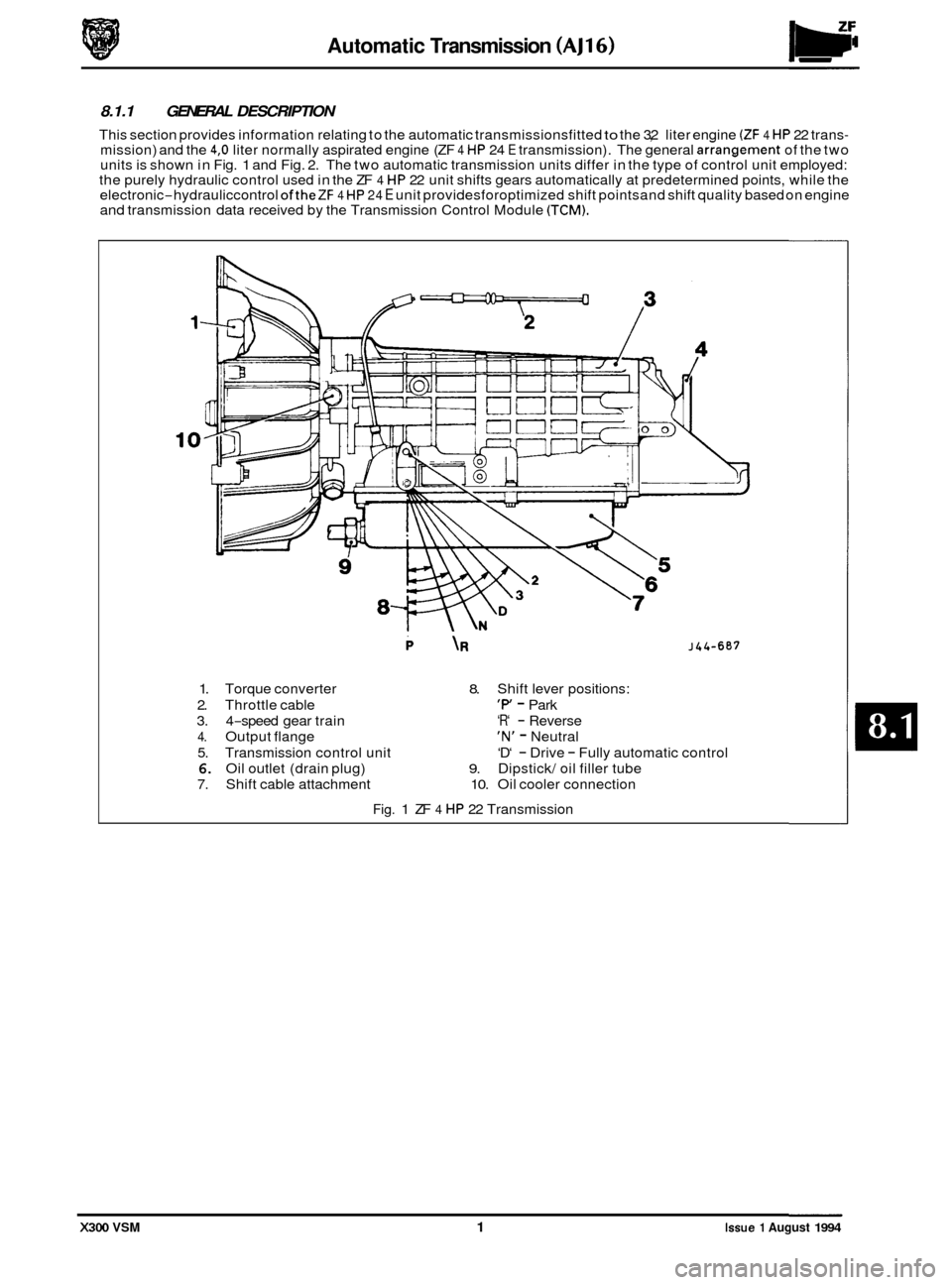

8.1.1 GENERAL DESCRIPTION

’ This section provides information relating to the automatic transmissionsfitted to the 3,2 liter engine (ZF 4 HP 22 trans- mission) and the 4,O liter normally aspirated engine (ZF 4 HP 24 E transmission). The general arrangement of the two

units is shown in Fig. 1 and Fig. 2. The two automatic transmission units differ in the type of control unit employed:

the purely hydraulic control used in the ZF 4 HP 22 unit shifts gears automatically at predetermined points, while the

electronic-hydrauliccontrol oftheZF 4 HP 24 E unit providesforoptimized shift point sand shift quality based on engine

and transmission data received by the Transmission Control Module (TCM).

P \R J44-607

1. Torque converter 8. Shift lever positions:

2. Throttle cable

‘P - Park

3. 4

-speed gear train ‘R‘ - Reverse

4. Output flange ‘N’ - Neutral

5. Transmission control unit

6. Oil outlet (drain plug) 9. Dipstick/ oil filler tube

7. Shift cable attachment 10. Oil cooler connection

‘D‘

- Drive - Fully automatic

control

Fig. 1 ZF 4 HP 22 Transmission

X300 VSM 1 Issue 1 August 1994

Page 139 of 521

I 1 I

8-

/ /

7, 6

'4 '5

J4L- 688

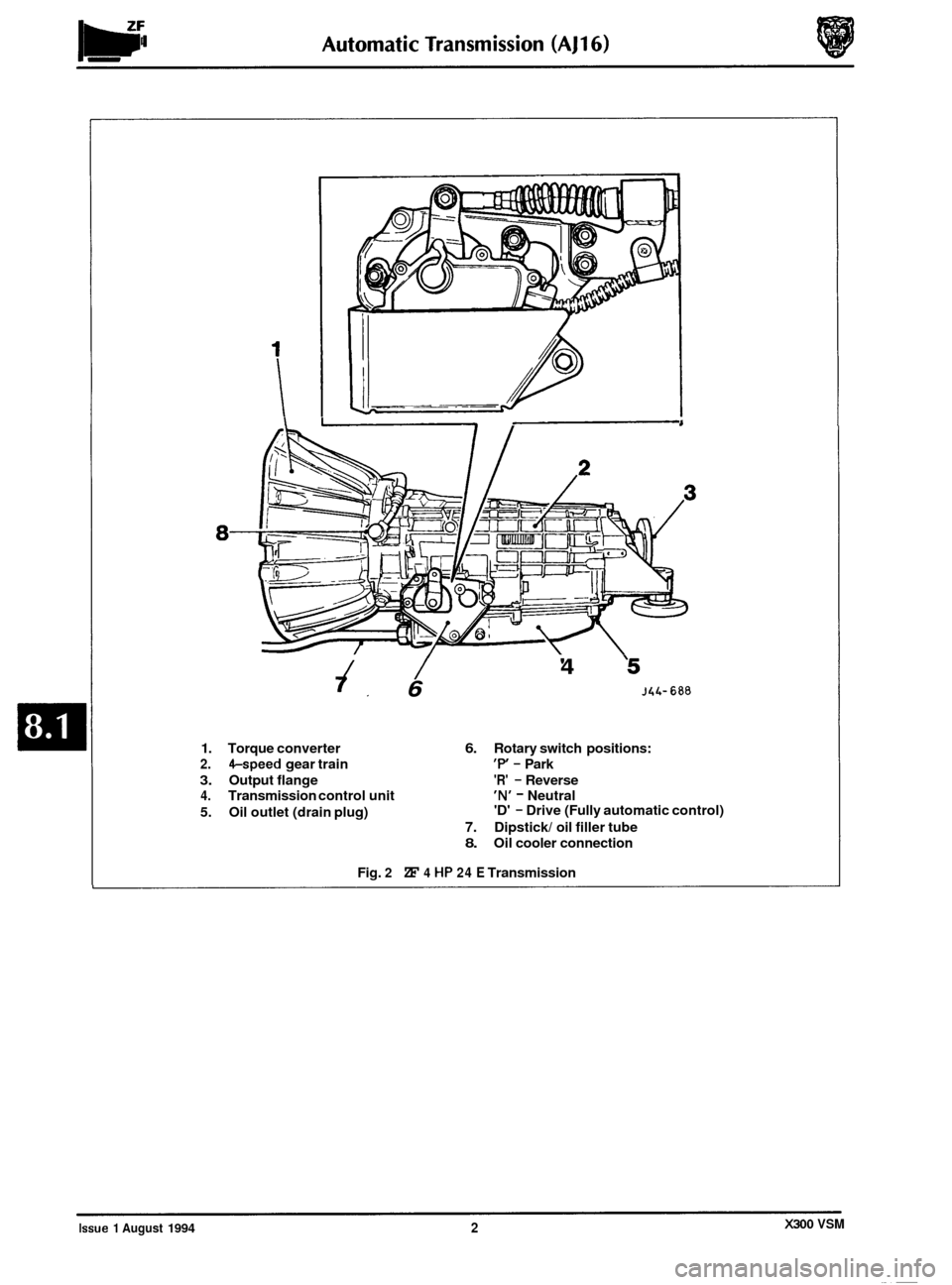

1. Torque converter 6. Rotary switch positions:

2. &speed gear train 'P - Park

3. Output flange 'R' - Reverse

4. Transmission control unit 'N' - Neutral

5. Oil outlet (drain plug) 'D' - Drive

(Fully automatic control)

7. Dipstick/ oil filler tube

8. Oil cooler connection

Fig.

2 ZF 4 HP 24 E Transmission

X300 VSM Issue 1 August 1994 2