body JAGUAR XJ6 1997 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 95 of 227

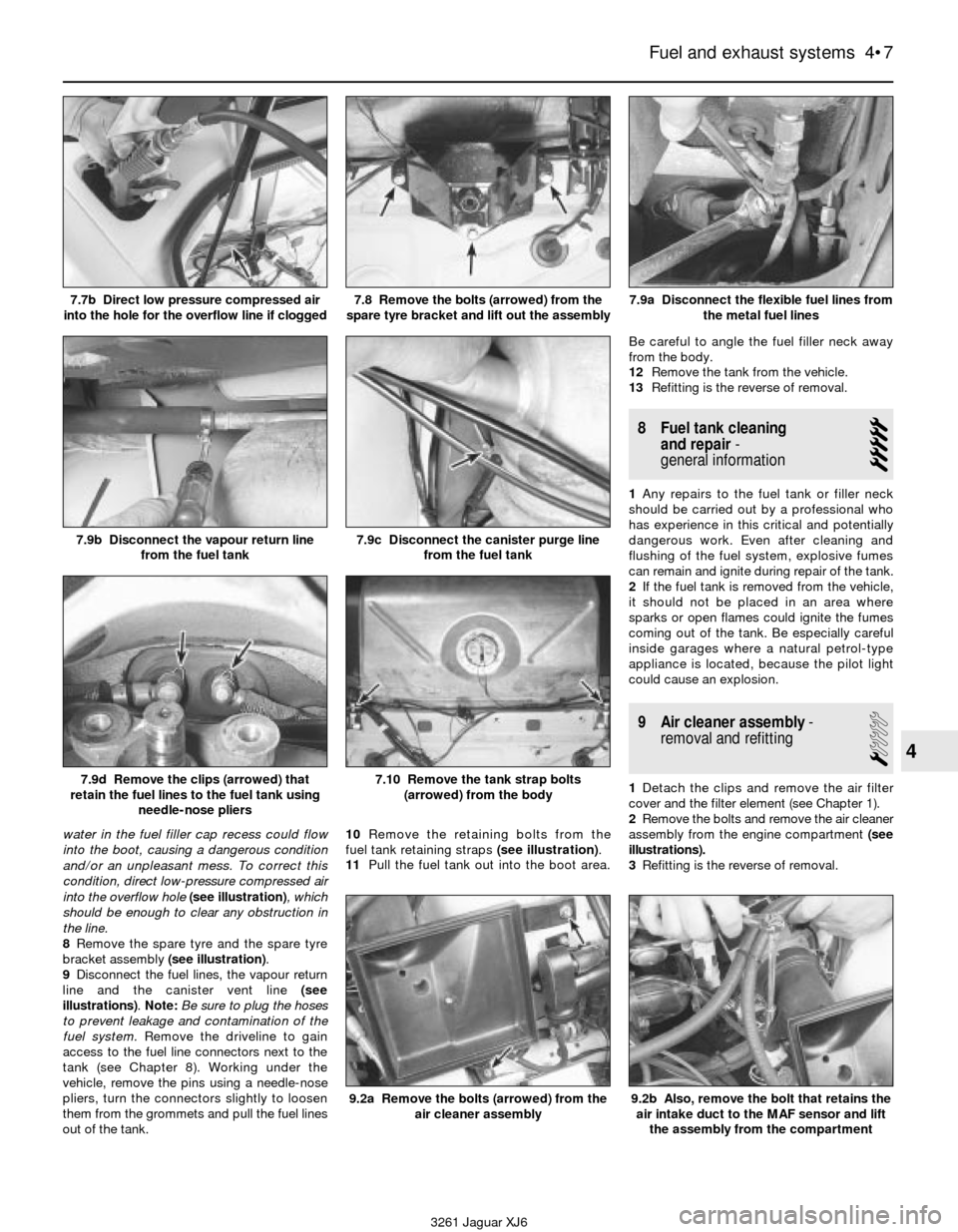

water in the fuel filler cap recess could flow

into the boot, causing a dangerous condition

and/or an unpleasant mess. To correct this

condition, direct low-pressure compressed air

into the overflow hole (see illustration), which

should be enough to clear any obstruction in

the line.

8Remove the spare tyre and the spare tyre

bracket assembly (see illustration).

9Disconnect the fuel lines, the vapour return

line and the canister vent line (see

illustrations). Note:Be sure to plug the hoses

to prevent leakage and contamination of the

fuel system.Remove the driveline to gain

access to the fuel line connectors next to the

tank (see Chapter 8). Working under the

vehicle, remove the pins using a needle-nose

pliers, turn the connectors slightly to loosen

them from the grommets and pull the fuel lines

out of the tank.10Remove the retaining bolts from the

fuel tank retaining straps (see illustration).

11Pull the fuel tank out into the boot area.Be careful to angle the fuel filler neck away

from the body.

12Remove the tank from the vehicle.

13Refitting is the reverse of removal.

8 Fuel tank cleaning

and repair-

general information

5

1Any repairs to the fuel tank or filler neck

should be carried out by a professional who

has experience in this critical and potentially

dangerous work. Even after cleaning and

flushing of the fuel system, explosive fumes

can remain and ignite during repair of the tank.

2If the fuel tank is removed from the vehicle,

it should not be placed in an area where

sparks or open flames could ignite the fumes

coming out of the tank. Be especially careful

inside garages where a natural petrol-type

appliance is located, because the pilot light

could cause an explosion.

9 Air cleaner assembly-

removal and refitting

1

1Detach the clips and remove the air filter

cover and the filter element (see Chapter 1).

2Remove the bolts and remove the air cleaner

assembly from the engine compartment (see

illustrations).

3Refitting is the reverse of removal.

Fuel and exhaust systems 4•7

4

7.7b Direct low pressure compressed air

into the hole for the overflow line if clogged7.8 Remove the bolts (arrowed) from the

spare tyre bracket and lift out the assembly7.9a Disconnect the flexible fuel lines from

the metal fuel lines

7.9b Disconnect the vapour return line

from the fuel tank7.9c Disconnect the canister purge line

from the fuel tank

7.9d Remove the clips (arrowed) that

retain the fuel lines to the fuel tank using

needle-nose pliers

3261 Jaguar XJ6

7.10 Remove the tank strap bolts

(arrowed) from the body

9.2a Remove the bolts (arrowed) from the

air cleaner assembly9.2b Also, remove the bolt that retains the

air intake duct to the MAF sensor and lift

the assembly from the compartment

Page 96 of 227

10 Accelerator cable- removal,

refitting and adjustment

3

Removal

1Detach the cable from the negative terminal

of the battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Loosen the locknut on the threaded portion

of the throttle cable at the throttle body (see

illustration).

3Rotate the throttle lever, then slip the

throttle cable end out of the slot in the lever

(see illustration).

4Detach the throttle cable from the

accelerator pedal (see illustration).

5From inside the vehicle, pull the cable

through the bulkhead.

Refitting and adjustment

6Refitting is the reverse of removal.

7To adjust the cable, fully depress the

accelerator pedal and check that the throttle

is fully opened.

8If not fully opened, loosen the locknuts,

depress accelerator pedal and adjust the

cable until the throttle is fully open.

9Tighten the locknuts and recheck the

adjustment. Make sure the throttle closes fully

when the pedal is released (see illustration).

10After the cable is adjusted, check the

adjustment of the bellcrank. Use a small

clamp and a straight rod or stiff wire (coat

hanger) and attach it to the brake master

cylinder in such a way that the tip acts as a

pointer. Align the pointer with “A” (automatic

transmission) or “M” (manual transmission) on

the bellcrank (see illustration),depending on

what type of transmission is installed in the

vehicle.

11Slowly rotate the bellcrank until it reaches

the throttle stop (wide open throttle) andcheck to make sure the pointer aligns with the

notch in the bellcrank (see illustration).

12If necessary, adjust the position of

the throttle stop using a spanner and turn the

throttle stop screw until the bellcrank reaches

the correct position. Lock the throttle stop

screw in place.

4•8 Fuel and exhaust systems

3261 Jaguar XJ6 10.4 Remove circlip (arrowed) and separate cable from the

accelerator pedal by pulling the pin from the pedal assembly

10.2 Loosen the locknuts on the accelerator cable10.3 Rotate the bellcrank and remove the cable end from the slot

10.9 Make sure the throttle closes completely and there is a

slight amount of flex in the cable

10.10 Attach a strong wire (coat hanger)

to the master cylinder using a clamp and

align it with the notch on the bellcrank

Page 97 of 227

13Allow the bellcrank to return to the idle

position and test the adjustment once again

until the correct adjustment has been attained.

11 Electronic Fuel Injection

(EFI) system-

general information

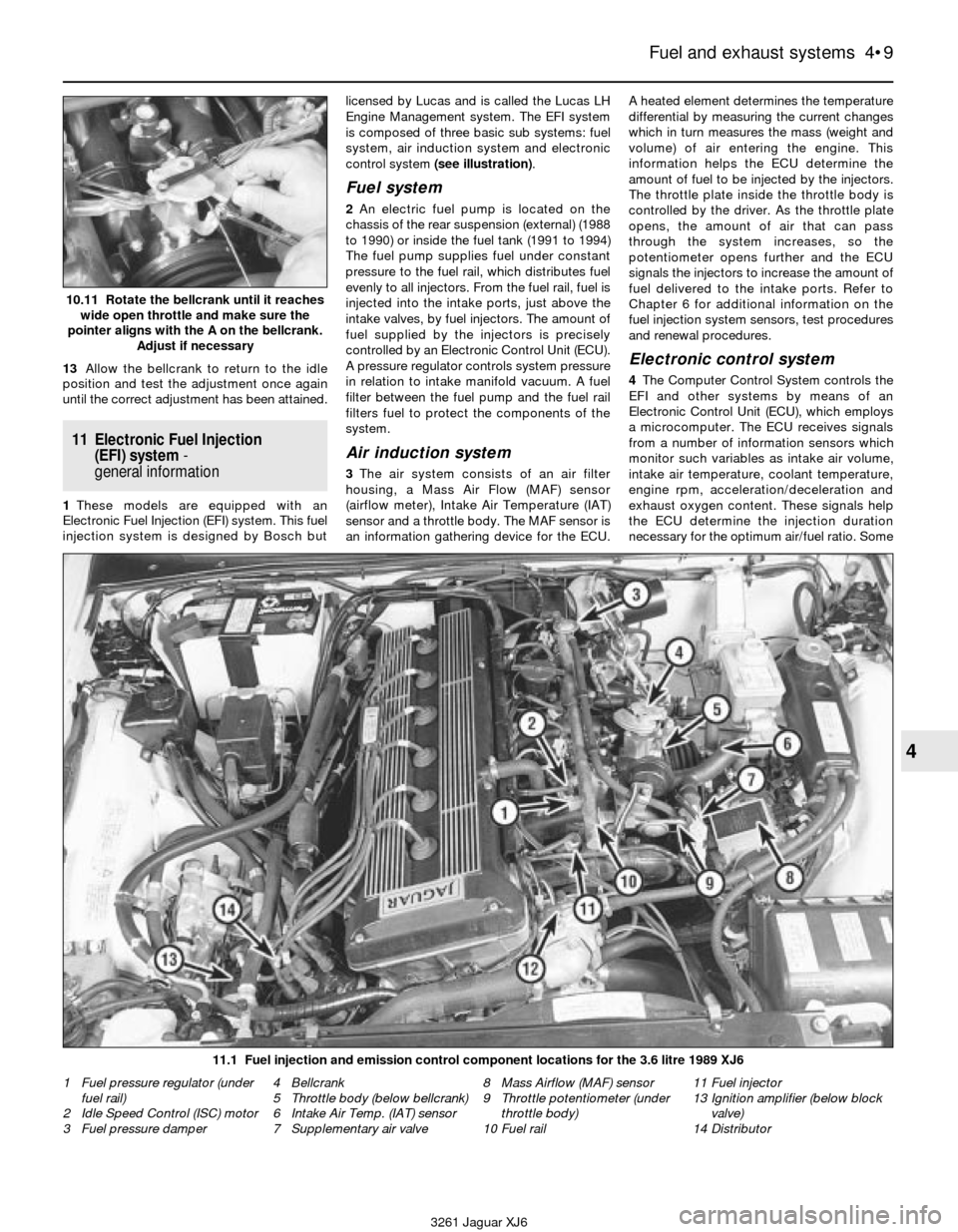

1These models are equipped with an

Electronic Fuel Injection (EFI) system. This fuel

injection system is designed by Bosch butlicensed by Lucas and is called the Lucas LH

Engine Management system. The EFI system

is composed of three basic sub systems: fuel

system, air induction system and electronic

control system (see illustration).

Fuel system

2An electric fuel pump is located on the

chassis of the rear suspension (external) (1988

to 1990) or inside the fuel tank (1991 to 1994)

The fuel pump supplies fuel under constant

pressure to the fuel rail, which distributes fuel

evenly to all injectors. From the fuel rail, fuel is

injected into the intake ports, just above the

intake valves, by fuel injectors. The amount of

fuel supplied by the injectors is precisely

controlled by an Electronic Control Unit (ECU).

A pressure regulator controls system pressure

in relation to intake manifold vacuum. A fuel

filter between the fuel pump and the fuel rail

filters fuel to protect the components of the

system.

Air induction system

3The air system consists of an air filter

housing, a Mass Air Flow (MAF) sensor

(airflow meter), Intake Air Temperature (IAT)

sensor and a throttle body. The MAF sensor is

an information gathering device for the ECU.A heated element determines the temperature

differential by measuring the current changes

which in turn measures the mass (weight and

volume) of air entering the engine. This

information helps the ECU determine the

amount of fuel to be injected by the injectors.

The throttle plate inside the throttle body is

controlled by the driver. As the throttle plate

opens, the amount of air that can pass

through the system increases, so the

potentiometer opens further and the ECU

signals the injectors to increase the amount of

fuel delivered to the intake ports. Refer to

Chapter 6 for additional information on the

fuel injection system sensors, test procedures

and renewal procedures.

Electronic control system

4The Computer Control System controls the

EFI and other systems by means of an

Electronic Control Unit (ECU), which employs

a microcomputer. The ECU receives signals

from a number of information sensors which

monitor such variables as intake air volume,

intake air temperature, coolant temperature,

engine rpm, acceleration/deceleration and

exhaust oxygen content. These signals help

the ECU determine the injection duration

necessary for the optimum air/fuel ratio. Some

Fuel and exhaust systems 4•9

4

10.11 Rotate the bellcrank until it reaches

wide open throttle and make sure the

pointer aligns with the A on the bellcrank.

Adjust if necessary

11.1 Fuel injection and emission control component locations for the 3.6 litre 1989 XJ6

3261 Jaguar XJ6 1 Fuel pressure regulator (under

fuel rail)

2 Idle Speed Control (ISC) motor

3 Fuel pressure damper4 Bellcrank

5 Throttle body (below bellcrank)

6 Intake Air Temp. (IAT) sensor

7 Supplementary air valve8 Mass Airflow (MAF) sensor

9 Throttle potentiometer (under

throttle body)

10 Fuel rail11 Fuel injector

13 Ignition amplifier (below block

valve)

14 Distributor

Page 98 of 227

of these sensors and their corresponding

ECU-controlled relays are not contained

within EFI components, but are located

throughout the engine compartment. For

further information regarding the ECU and its

relationship to the engine electrical and

ignition system, see Chapter 6.

12 Electronic Fuel Injection

(EFI) system- check

2

1Check the earth wire connections for

tightness. Check all wiring and electrical

connectors that are related to the system.

Loose electrical connectors and poor grounds

can cause many problems that resemble

more serious malfunctions.

2Check to see that the battery is fully

charged, as the control unit and sensors

depend on an accurate supply voltage in

order to properly meter the fuel.

3Check the air filter element - a dirty or

partially blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for a shorted

wire in the harness related to the system.

5Check the air intake duct from the MAF

sensor to the intake manifold for leaks, which

will result in an excessively lean mixture. Also

check the condition of the vacuum hoses

connected to the intake manifold.

6Remove the air intake duct from the throttle

body and check for carbon and residue build-

up. If it’s dirty, clean with aerosol carburettor

cleaner (make sure the can says it’s safe for

use with oxygen sensors and catalytic

converters) and a toothbrush.

7With the engine running, place a

stethoscope against each injector, one at a

time, and listen for a clicking sound, indicating

operation (see illustration).8If there is a problem with an injector,

purchase a special injector test light (noid

light) and refit it into the injector electrical

connector (see illustration). Start the engine

and make sure that each injector connector

flashes the noid light. This will test for the

proper voltage signal to the injector.Caution:

If the engine will not start and the noid

light indicates that each injector is

receiving the proper signal, there is a good

possibility that the injector(s) is stuck open

and allowing fuel into the combustion

chamber in excessive amounts. If the spark

plugs are fouled, detach the primary (low

voltage) wires from the ignition coil, disable

the fuel pump by removing the fuel pump

relay (see Section 2), remove the spark plugs

and crank the engine over. If fuel sprays from

the spark plug holes, the engine is flooded

and the fuel must be removed from the

combustion chambers.

9With the engine OFF and the fuel injector

electrical connectors disconnected, measure

the resistance of each injector (see

illustration). Each injector should measure

about 2.0 to 3.0 ohms. If not, the injector is

probably faulty.10The remainder of the system checks

should be left to a Jaguar service department

or other qualified repair workshop, as there is

a chance that the control unit may be

damaged if not performed properly.

13 Electronic Fuel Injection

(EFI) system- component

check and renewal

3

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. See

the Warning in Section 2.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

Throttle body

Check

1Verify that the throttle linkage operates

smoothly.

2Start the engine, detach each vacuum hose

and, using your finger, check the vacuum at

each port on the throttle body with the engine

at idle and above idle. The vacuum available

from the throttle body is ported. Raise the

engine rpm and watch as vacuum increases.

It may be necessary to use a vacuum gauge.

Refer to Chapter 2B for additional information

concerning vacuum checks.

Renewal

Warning: Wait until the engine is

completely cool before

beginning this procedure.

3Detach the cable from the negative terminal

of the battery (see the Cautionat the

beginning of this Section).

4Drain the radiator (see Chapter 1).

4•10 Fuel and exhaust systems

12.9 Using an ohmmeter, measure the

resistance across both terminals

of the injector

3261 Jaguar XJ6 12.7 Use a stethoscope or a screwdriver to determine if the

injectors are working properly - they should make a steady

clicking sound that rises and falls with engine speed changes

12.8 Refit the “noid” light into the fuel injector electrical

connector and check to see that it blinks with the engine running

Page 99 of 227

5Remove the air cleaner (see Chapter 1) and

the air cleaner housing (see Section 9).

6Remove the air intake duct.

7Detach the electrical connector from the

MAF sensor (see illustration).

8Remove the clamp that retains the MAF

sensor to the air intake duct (see illustration)

and lift the MAF sensor assembly from the

engine compartment.

9Detach the throttle cable from the bellcrank

(see Section 10), then remove the bellcrank

assembly from the throttle body (see

illustration).

10Detach the kickdown cable from the

bellcrank and set the cable and brackets

aside (see Chapter 7).

11Clearly label, then detach, all vacuum and

coolant hoses from the throttle body.

12Disconnect the electrical connector from

the throttle potentiometer.

13Remove the four throttle body mounting

bolts and detach the throttle body from the

intake manifold.

14Using a soft brush and carburettor

cleaner, thoroughly clean the throttle body

casting, then blow out all passages with

compressed air.

Caution: Do not clean the throttle position

sensor with any solvents or sprays. Just

wipe it off with a clean, soft cloth.

15Refitting of the throttle body is the reverse

of removal.

16Be sure to tighten the throttle body

mounting bolts to the torque listed in this

Chapter’s Specifications.

Adjustment

17Remove the air intake duct to expose the

throttle body and butterfly valve.

18Make sure the throttle body is clean and

free of burrs, nicks or carbon build-up (see

illustration).

19Measure the clearance between the

butterfly valve (throttle plate) and the wall of

the throttle body (see illustration). It should

be 0.05 mm (0.002 inch). 20If the gap is incorrect, loosen the throttle

stop locknut (see illustration)and turn the

throttle stop screw until the correct clearance

is attained.

21Refit the air intake duct and surrounding

components.

Idle Speed Control (ISC) motor

Note:The minimum idle speed is pre-set at

the factory and should not require adjustment

under normal operating conditions; however ifthe throttle body has been replaced or you

suspect the minimum idle speed has been

tampered with (for example, if the idle speed

screw was removed from the throttle body)

have the vehicle checked by a dealer service

department or a qualified automotive repair

workshop.Check

22Start the engine and allow it to reach

normal operating temperature. Switch on the

Fuel and exhaust systems 4•11

4

13.9 Remove the bellcrank assembly bolts

(arrowed) and separate it from the

throttle body13.18 The area inside the throttle body

near the throttle plate suffers from sludge

build-up because the PCV hose vents

crankcase vapour into the intake duct

13.19 Measure clearance between the

butterfly valve and the throttle body

3261 Jaguar XJ6 13.7 Push up on the clip and remove the harness connector from

the MAF sensor

13.8 Remove the air intake duct clamp from the

MAF sensor housing

13.20 Adjust the butterfly angle by

loosening the locknut on the throttle stop

and turning the adjustment bolt

Page 101 of 227

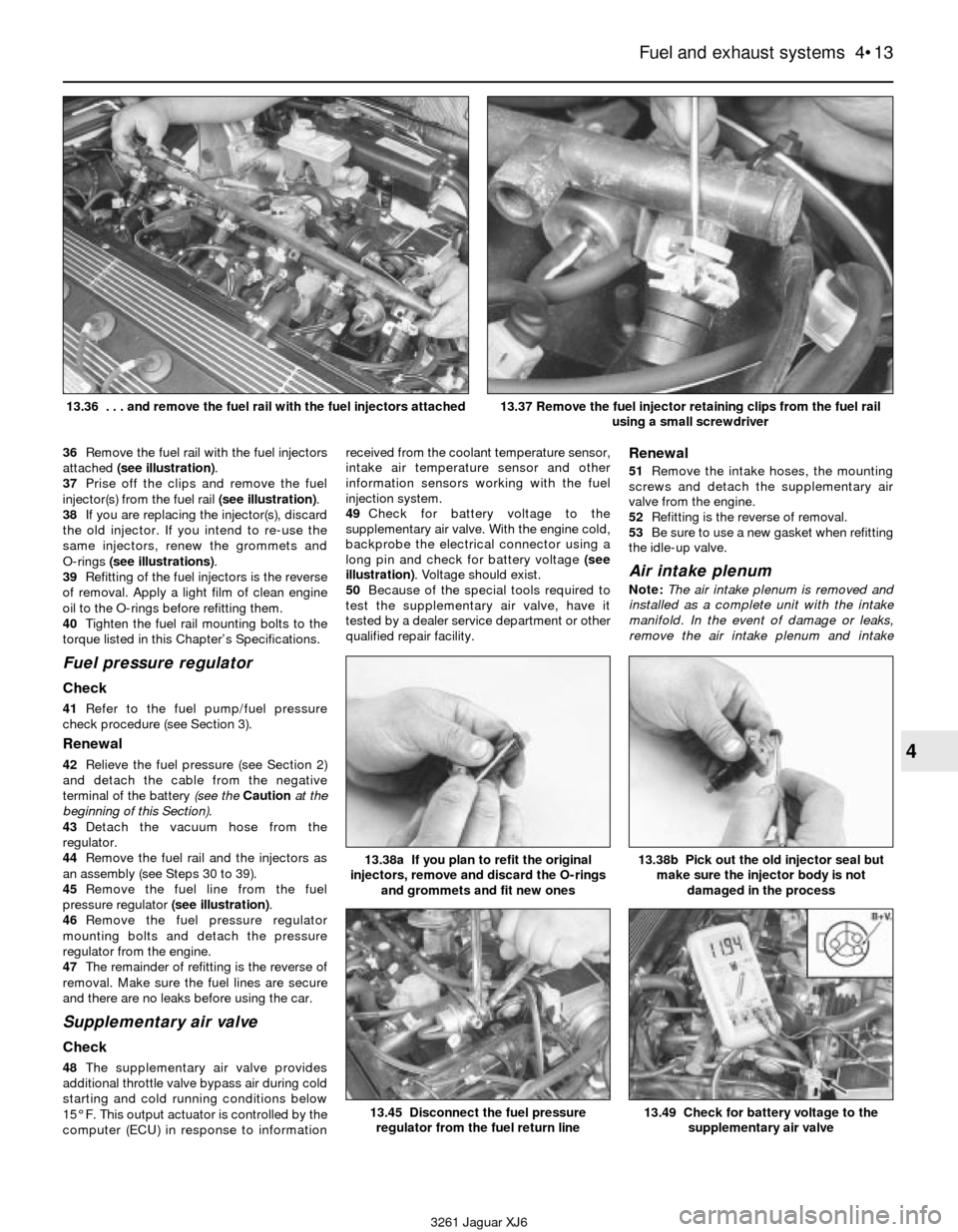

36Remove the fuel rail with the fuel injectors

attached (see illustration).

37Prise off the clips and remove the fuel

injector(s) from the fuel rail (see illustration).

38If you are replacing the injector(s), discard

the old injector. If you intend to re-use the

same injectors, renew the grommets and

O-rings (see illustrations).

39Refitting of the fuel injectors is the reverse

of removal. Apply a light film of clean engine

oil to the O-rings before refitting them.

40Tighten the fuel rail mounting bolts to the

torque listed in this Chapter’s Specifications.

Fuel pressure regulator

Check

41Refer to the fuel pump/fuel pressure

check procedure (see Section 3).

Renewal

42Relieve the fuel pressure (see Section 2)

and detach the cable from the negative

terminal of the battery (see the Cautionat the

beginning of this Section).

43Detach the vacuum hose from the

regulator.

44Remove the fuel rail and the injectors as

an assembly (see Steps 30 to 39).

45Remove the fuel line from the fuel

pressure regulator (see illustration).

46Remove the fuel pressure regulator

mounting bolts and detach the pressure

regulator from the engine.

47The remainder of refitting is the reverse of

removal. Make sure the fuel lines are secure

and there are no leaks before using the car.

Supplementary air valve

Check

48The supplementary air valve provides

additional throttle valve bypass air during cold

starting and cold running conditions below

15° F. This output actuator is controlled by the

computer (ECU) in response to informationreceived from the coolant temperature sensor,

intake air temperature sensor and other

information sensors working with the fuel

injection system.

49Check for battery voltage to the

supplementary air valve. With the engine cold,

backprobe the electrical connector using a

long pin and check for battery voltage (see

illustration). Voltage should exist.

50Because of the special tools required to

test the supplementary air valve, have it

tested by a dealer service department or other

qualified repair facility.

Renewal

51Remove the intake hoses, the mounting

screws and detach the supplementary air

valve from the engine.

52Refitting is the reverse of removal.

53Be sure to use a new gasket when refitting

the idle-up valve.

Air intake plenum

Note:The air intake plenum is removed and

installed as a complete unit with the intake

manifold. In the event of damage or leaks,

remove the air intake plenum and intake

Fuel and exhaust systems 4•13

4

3261 Jaguar XJ6 13.36 . . . and remove the fuel rail with the fuel injectors attached

13.37 Remove the fuel injector retaining clips from the fuel rail

using a small screwdriver

13.45 Disconnect the fuel pressure

regulator from the fuel return line

13.38b Pick out the old injector seal but

make sure the injector body is not

damaged in the process13.38a If you plan to refit the original

injectors, remove and discard the O-rings

and grommets and fit new ones

13.49 Check for battery voltage to the

supplementary air valve

Page 102 of 227

manifold as a single unit and have it repaired

by a dealer service department. Refer to

Chapter 2 for removal and refitting procedures.

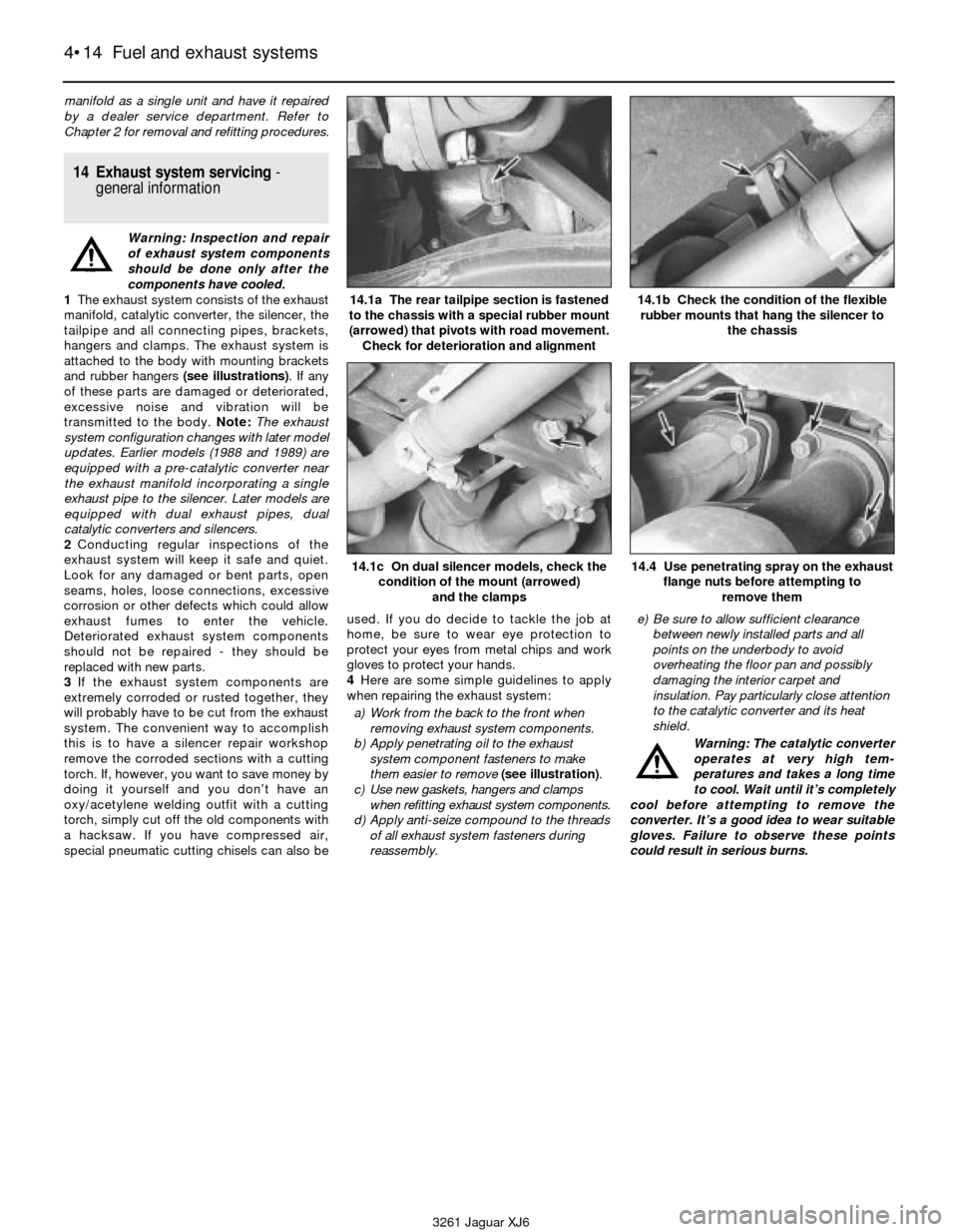

14 Exhaust system servicing-

general information

Warning: Inspection and repair

of exhaust system components

should be done only after the

components have cooled.

1The exhaust system consists of the exhaust

manifold, catalytic converter, the silencer, the

tailpipe and all connecting pipes, brackets,

hangers and clamps. The exhaust system is

attached to the body with mounting brackets

and rubber hangers (see illustrations). If any

of these parts are damaged or deteriorated,

excessive noise and vibration will be

transmitted to the body. Note:The exhaust

system configuration changes with later model

updates. Earlier models (1988 and 1989) are

equipped with a pre-catalytic converter near

the exhaust manifold incorporating a single

exhaust pipe to the silencer. Later models are

equipped with dual exhaust pipes, dual

catalytic converters and silencers.

2Conducting regular inspections of the

exhaust system will keep it safe and quiet.

Look for any damaged or bent parts, open

seams, holes, loose connections, excessive

corrosion or other defects which could allow

exhaust fumes to enter the vehicle.

Deteriorated exhaust system components

should not be repaired - they should be

replaced with new parts.

3If the exhaust system components are

extremely corroded or rusted together, they

will probably have to be cut from the exhaust

system. The convenient way to accomplish

this is to have a silencer repair workshop

remove the corroded sections with a cutting

torch. If, however, you want to save money by

doing it yourself and you don’t have an

oxy/acetylene welding outfit with a cutting

torch, simply cut off the old components with

a hacksaw. If you have compressed air,

special pneumatic cutting chisels can also beused. If you do decide to tackle the job at

home, be sure to wear eye protection to

protect your eyes from metal chips and work

gloves to protect your hands.

4Here are some simple guidelines to apply

when repairing the exhaust system:

a) Work from the back to the front when

removing exhaust system components.

b) Apply penetrating oil to the exhaust

system component fasteners to make

them easier to remove(see illustration).

c) Use new gaskets, hangers and clamps

when refitting exhaust system components.

d) Apply anti-seize compound to the threads

of all exhaust system fasteners during

reassembly.e) Be sure to allow sufficient clearance

between newly installed parts and all

points on the underbody to avoid

overheating the floor pan and possibly

damaging the interior carpet and

insulation. Pay particularly close attention

to the catalytic converter and its heat

shield.

Warning: The catalytic converter

operates at very high tem-

peratures and takes a long time

to cool. Wait until it’s completely

cool before attempting to remove the

converter. It’s a good idea to wear suitable

gloves. Failure to observe these points

could result in serious burns.

4•14 Fuel and exhaust systems

14.1c On dual silencer models, check the

condition of the mount (arrowed)

and the clamps

14.1a The rear tailpipe section is fastened

to the chassis with a special rubber mount

(arrowed) that pivots with road movement.

Check for deterioration and alignment14.1b Check the condition of the flexible

rubber mounts that hang the silencer to

the chassis

14.4 Use penetrating spray on the exhaust

flange nuts before attempting to

remove them

3261 Jaguar XJ6

Page 104 of 227

same dimensions, amperage rating, cold

cranking rating, etc. as the original.

6Refitting is the reverse of removal.

4 Battery cables-

check and renewal

1

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

1Periodically inspect the entire length of

each battery cable for damage, cracked or

burned insulation and corrosion. Poor battery

cable connections can cause starting

problems and decreased engine performance.

2Check the cable-to-terminal connections at

the ends of the cables for cracks, loose wire

strands and corrosion. The presence of white,

fluffy deposits under the insulation at the

cable terminal connection is a sign that the

cable is corroded and should be renewed.

Check the terminals for distortion, missing

mounting bolts and corrosion.

3When removing the cables, always

disconnect the negative cable first and hook it

up last or the battery may be shorted by the

tool used to loosen the cable clamps. Even if

only the positive cable is being renewed, be

sure to disconnect the negative cable from

the battery first (see Chapter 1 for further

information regarding battery cable removal).

4Disconnect the cables from the battery,

then trace each of them to their opposite ends

and detach them from the starter solenoid

and earth terminals. Note the routing of each

cable to ensure correct refitting.

5If you are replacing either or both of the old

cables, take them with you when buying new

items. It is vitally important that you replace

the cables with identical parts. Cables have

characteristics that make them easy to

identify: positive cables are usually red, larger

in cross-section and have a larger diameter

battery post clamp; earth cables are usually

black, smaller in cross-section and have a

slightly smaller diameter clamp for the

negative post.

6Clean the threads of the solenoid or earth

connection with a wire brush to remove rust

and corrosion. Apply a light coat of battery

terminal corrosion inhibitor, or petroleum jelly,

to the threads to prevent future corrosion.

7Attach the cable to the solenoid or earth

connection and tighten the mounting nut/bolt

securely.

8Before connecting a new cable to the

battery, make sure that it reaches the battery

post without having to be stretched.

9Connect the positive cable first, followed by

the negative cable.

5 Ignition system- general

information and precautions

1All models are equipped with a computerised

ignition system. The ignition system consists of

the ignition coil, the crankshaft position sensor,

the amplifier and the electronic control unit

(ECU). The ignition ECU controls the ignition

timing and advance characteristics for the

engine. The ignition timing is not adjustable,

therefore, changing the position of the distributor

will not change the timing in any way. Note:In

the event the distributor must be removed from

the engine, be sure to follow the precautions

described in Section 9 and mark the engine and

distributor with paint to ensure correct refitting. If

the distributor is not marked and Ihe crankshaft is

turned while the distributor is out of the engine,

have the distributor installed by a dealer service

department. The distributor must be installed

using a special alignment tool.

2The distributor is driven by the intermediate

shaft which also drives the power steering pump.

The crankshaft position sensor is located on the

front timing cover. It detects crank position by

pulsing an electronic signal to the ECU. This

signal is sent to the ECU to provide ignition

timing specifications.

3The computerised ignition system provides

complete control of the ignition timing by

determining the optimum timing in response to

engine speed, coolant temperature, throttle

position and vacuum pressure in the intake

manifold. These parameters are relayed to the

ECU by the crankshaft position sensor, throttle

potentiometer, coolant temperature sensor and

MAF sensor. Ignition timing is altered during

warm-up, idling and warm running conditions by

the ECU. This electronic ignition system also

consists of the ignition switch, battery, coil,

distributor, spark plug leads and spark plugs.

4Refer to a dealer parts department or car

accessory outlet for any questions concerning

the availability of the distributor parts and

assemblies. Testing the crankshaft position

sensor is covered in Chapter 6.

5When working on the ignition system, take

the following precautions:

a) Do not keep the ignition switch on for

more than 10 seconds if the engine will

not start.

b) Always connect a tachometer in

accordance with the manufacturer’s

instructions. Some tachometers may be

incompatible with this ignition system.

Consult a dealer service department

before buying a tachometer for use with

this vehicle.

c) Never allow the ignition coil terminals to

touch earth. Earthing the coil could result

in damage to the igniter and/or the

ignition coil.

d) Do not disconnect the battery when the

engine is running.

6 Ignition system- check

2

Warning: Because of the high

voltage generated by the

ignition system, extreme care

should be taken when working

on the ignition components. This not only

includes the amplifier, coil, distributor and

spark plug leads, but related components

such as connectors, tachometer and other

test equipment also.

1With the ignition switch turned to the “ON”

position, a “Battery” light or an “Oil Pressure”

light is a basic check for ignition and battery

supply to the ECU.

2Check all ignition wiring connections for

tightness, cuts, corrosion or any other signs of a

bad connection.

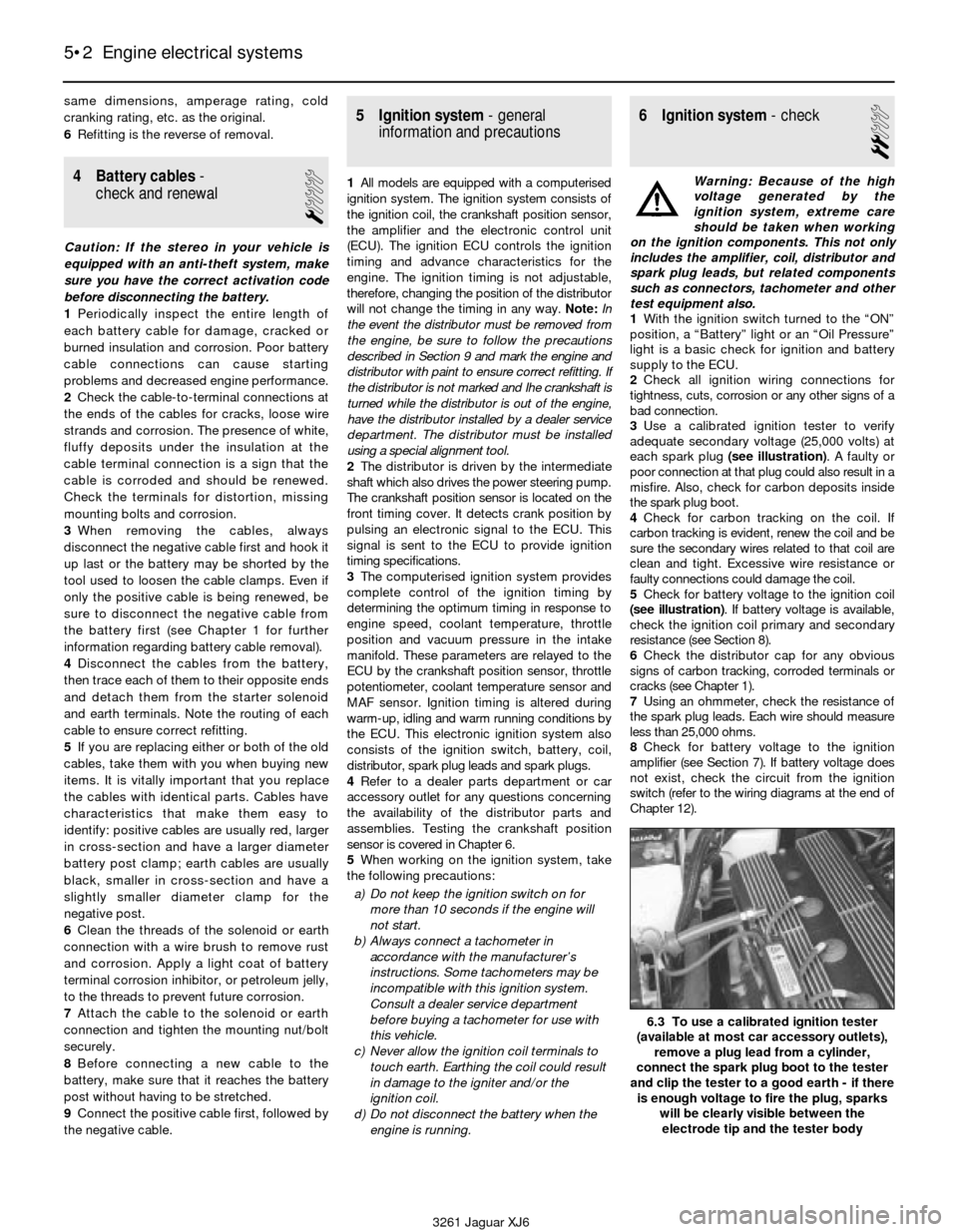

3Use a calibrated ignition tester to verify

adequate secondary voltage (25,000 volts) at

each spark plug (see illustration). A faulty or

poor connection at that plug could also result in a

misfire. Also, check for carbon deposits inside

the spark plug boot.

4Check for carbon tracking on the coil. If

carbon tracking is evident, renew the coil and be

sure the secondary wires related to that coil are

clean and tight. Excessive wire resistance or

faulty connections could damage the coil.

5Check for battery voltage to the ignition coil

(see illustration). If battery voltage is available,

check the ignition coil primary and secondary

resistance (see Section 8).

6Check the distributor cap for any obvious

signs of carbon tracking, corroded terminals or

cracks (see Chapter 1).

7Using an ohmmeter, check the resistance of

the spark plug leads. Each wire should measure

less than 25,000 ohms.

8Check for battery voltage to the ignition

amplifier (see Section 7). If battery voltage does

not exist, check the circuit from the ignition

switch (refer to the wiring diagrams at the end of

Chapter 12).

5•2 Engine electrical systems

6.3 To use a calibrated ignition tester

(available at most car accessory outlets),

remove a plug lead from a cylinder,

connect the spark plug boot to the tester

and clip the tester to a good earth - if there

is enough voltage to fire the plug, sparks

will be clearly visible between the

electrode tip and the tester body

3261 Jaguar XJ6

Page 106 of 227

sure you have the correct activation code

before disconnecting the battery.

2Disconnect the electrical connectors and

the coil wire from the coil.

3Using an ohmmeter, check the coil

resistance:

a) Measure the resistance between the

positive and negative terminals (see

illustration). Compare your reading with

the specified coil primary resistance listed

in this Chapter’s Specifications.

b) Measure the resistance between the

positive terminal and the high tension (HT)

terminal(see illustration). Compare your

reading with the specified coil secondary

resistance listed in this Chapter’s

Specifications.

4If either of the above tests yield resistance

values outside the specified amount, renew

the coil.

Renewal

5Detach the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery. 6Label and disconnect the electrical wires

from the coil terminals.

7Remove the coil mounting fasteners (see

illustration).

8Refitting is the reverse of removal.

9 Distributor-

removal and refitting

2

Note:The timing on this ignition system cannot

be adjusted by turning the distributor. Ignition

timing is maintained by the ECU at all times. In

the event the distributor must be removed from

the engine, be sure to follow the precautions

described in this section and mark the engine

and distributor with paint to ensure correct

refitting. If the distributor is not marked, and the

crankshaft is turned while the distributor is out of

the engine, have the distributor installed by a

dealer service department. The distributor must

be installed using a special alignment tool.

Removal

1Detach the battery negative cable. Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Disconnect the electrical connectors from

the distributor.

3Look for a raised “1” on the distributor cap.

This marks the location for the number one

cylinder spark plug lead terminal. If the cap

does not have a mark for the number one

terminal, locate the number one spark plug

and trace the wire back to the terminal on the

cap.

4Remove the distributor cap (see Chapter 1)

and rotate the engine until the rotor is pointing

toward the number one spark plug terminal.

5Make a mark on the edge of the distributor

base directly below the rotor tip and in line

with it. Also, mark the distributor base and the

engine block to ensure that the distributor is

installed correctly (see illustrations).

6Remove the distributor hold-down bolt,

then pull the distributor out to remove it.

Caution: DO NOT turn the crankshaft while

the distributor is out of the engine, or the

alignment marks will be useless.

5•4 Engine electrical systems

8.3a To check the primary resistance of

the coil, measure the resistance between

the positive and the negative terminals8.3b To check the secondary resistance of

the coil, measure the resistance between

the positive terminal and the HT terminal8.7 Remove the nuts from the coil

mounting bracket (arrowed)

3261 Jaguar XJ6

9.5a Paint or scribe a mark (arrowed) on the edge of the

distributor housing below the rotor tip to ensure that the rotor is

pointing in the same direction when the distributor is reinstalled9.5b Paint or scribe another mark across the cylinder head and

the distributor body (arrowed) to ensure that the distributor is

aligned correctly when it is reinstalled

Page 109 of 227

8After the alternator is installed, adjust the

drivebelt tension (see Chapter 1).

9Check the charging voltage to verify proper

operation of the alternator (see Section 11).

13 Starting system- general

information and precautions

The sole function of the starting system is

to crank the engine over quickly enough to

allow it to start.

The starting system consists of the battery,

the starter motor, the starter solenoid, the

starter relay and the electrical circuit

connecting the components. The solenoid is

mounted directly on the starter motor.

The solenoid/starter motor assembly is

installed on the upper part of the engine, next

to the transmission bellhousing.

When the ignition key is turned to the

START position, the starter solenoid is

actuated through the starter control circuit.

The starter solenoid then connects the battery

to the starter. The battery supplies the

electrical energy to the starter motor, which

does the actual work of cranking the engine.

The starter on a vehicle equipped with an

automatic transmission can be operated only

when the transmission selector lever is in Park

or Neutral.

These vehicles are equipped with either a

Bosch or Lucas starter assembly. The Lucas

unit is distinguished by the separate earth

strap from the solenoid to the starter body.

Bosch starter assemblies are equipped with a

solid metal earthing bar.

The starting system circuit is equipped with

a relay. The relay allows the ignition switch to

power the starter solenoid.

Always observe the following precautions

when working on the starting system:

a) Excessive cranking of the starter motor

can overheat it and cause serious

damage. Never operate the starter motor

for more than 15 seconds at a time

without pausing to allow it to cool for at

least two minutes.

b) The starter is connected directly to the

battery and could arc or cause a fire if

mishandled, overloaded or short circuited.

c) Always detach the cable from the

negative terminal of the battery before

working on the starting system.

Caution:If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

14 Starter motor-

testing in vehicle

2

1Make sure that the battery is charged and

that all cables, both at the battery and starter

solenoid terminals, are clean and secure.2If the starter motor does not turn at all when

the switch is operated, make sure that the

shift lever is in Neutral or Park (automatic

transmission) or that the clutch pedal is

depressed (manual transmission).

3If the starter motor spins but the engine is

not cranking, the overrunning clutch in the

starter motor is slipping and the starter motor

must be renewed.

4If, when the switch is actuated, the starter

motor does not operate at all but the solenoid

clicks, then the problem lies with either the

battery, the main solenoid contacts or the

starter motor itself (or the engine is seized).

5If the solenoid plunger cannot be heard

when the switch is actuated, the battery is

bad, the in-line fuse is burned (the circuit is

open), the starter relay (see illustration)is

defective or the starter solenoid itself is

defective.

6To check the solenoid, connect a jumper

lead between the battery (+) and the ignition

switch terminal (the small terminal) on the

solenoid. If the starter motor now operates,

the solenoid is OK and the problem is in the

ignition switch, linear switch (1988 to 1992),

rotary switch (1993 and 1994) or in the wiring.

7If the starter motor still does not operate,

remove the starter/solenoid assembly for

dismantling, testing and repair.

8If the starter motor cranks the engine at an

abnormally slow speed, first make sure that

the battery is charged and that all terminalconnections are tight. If the engine is partially

seized, or has the wrong viscosity oil in it, it

will crank slowly.

9Run the engine until normal operating

temperature is reached, then disconnect the

coil wire from the distributor cap and earth it

on the engine.

10Connect a voltmeter positive lead to the

battery positive post and connect the

negative lead to the negative post.

11Crank the engine and take the voltmeter

readings as soon as a steady figure is

indicated. Do not allow the starter motor to

turn for more than 15 seconds at a time. A

reading of nine volts or more, with the starter

motor turning at normal cranking speed, is

normal. If the reading is nine volts or more but

the cranking speed is slow, the motor is faulty.

If the reading is less than nine volts and the

cranking speed is slow, the solenoid contacts

are probably burned, the starter motor is bad,

the battery is discharged or there is a bad

connection.

15 Starter motor-

removal and refitting

2

1Detach the cable from the negative terminal

of the battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Raise the vehicle and support it securely

using axle stands.

3Drain the transmission fluid (see Chapter 7)

and remove the transmission fluid filler tube

from the transmission.

4Detach the electrical connectors from the

starter/solenoid assembly (see illustrations).

5Place a trolley jack under the tail section of

the transmission, remove the rear trans-

mission mount (see Chapter 7) and lower the

transmission slightly to gain access to the

upper transmission bellhousing bolts. Using

an extension with a swivel socket, remove the

upper starter mounting bolt (see illustration).

Engine electrical systems 5•7

5

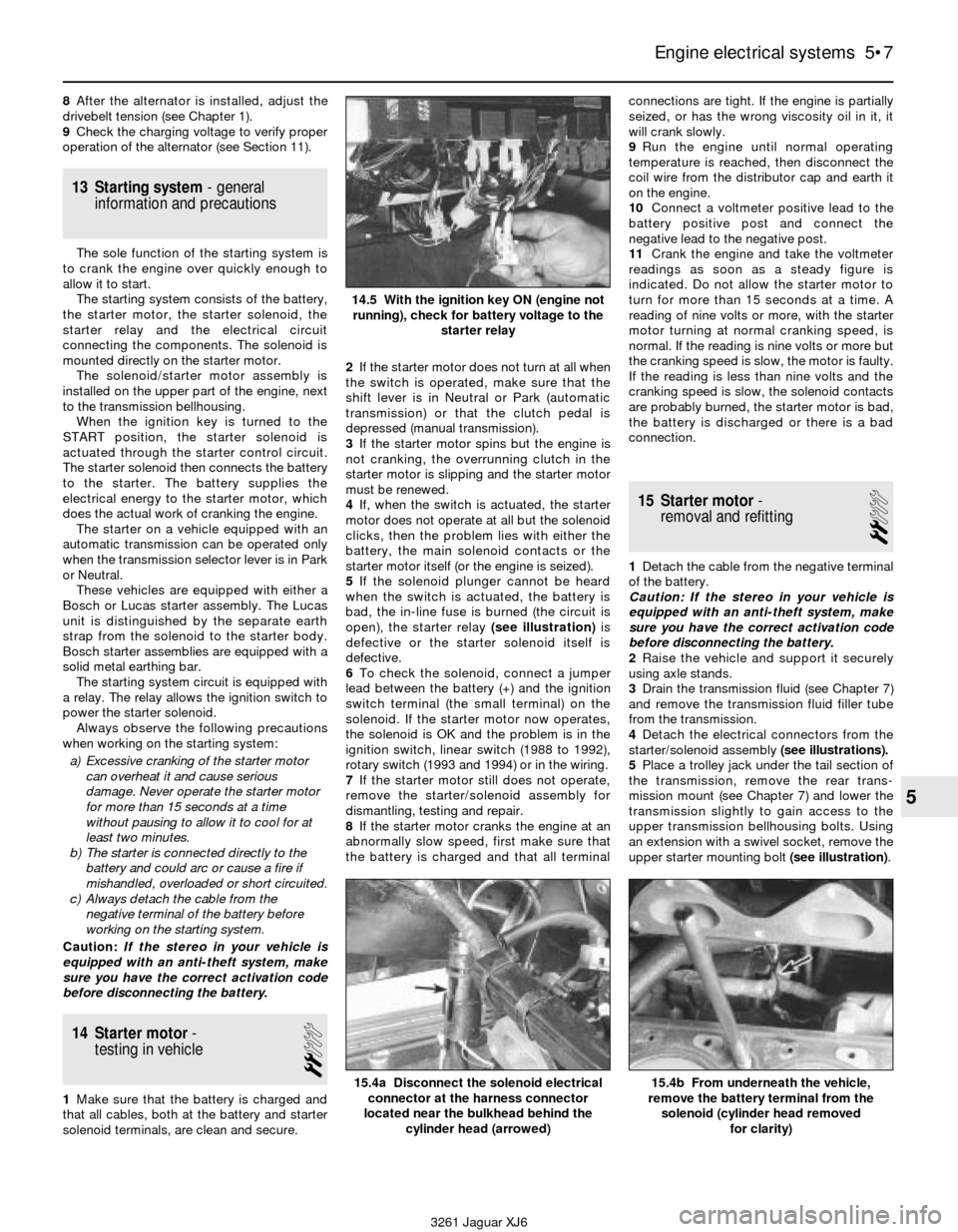

14.5 With the ignition key ON (engine not

running), check for battery voltage to the

starter relay

15.4a Disconnect the solenoid electrical

connector at the harness connector

located near the bulkhead behind the

cylinder head (arrowed)15.4b From underneath the vehicle,

remove the battery terminal from the

solenoid (cylinder head removed

for clarity)

3261 Jaguar XJ6