VIN JAGUAR XJ6 1997 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 132 of 227

6Carefully check to make sure the

suspension and steering components do not

make contact with the hoses. Have an

assistant push on the vehicle and also turn the

steering wheel from lock-to-lock during

inspection.

7Bleed the brake system (see Section 9).

Metal brake line renewal

8When replacing brake lines, use the proper

parts only. Do not use copper line for any

brake system connections. Purchase steel

brake lines from a dealer or motor factors..

9Unless you’re using factory renewal brake

lines, you may need a tubing bender to bend

the lines to the proper shape.

10First, remove the line you intend to renew,

lay it on a clean workbench and measure it

carefully. Obtain a new line of the same length

and bend it to match the pattern of the old

line.

Warning: Do not crimp or

damage the line. No bend should

have a smaller radius than

9/16-inch. Make sure the

protective coating on the new line is

undamaged at the bends.

11When refitting the new line, make sure it’s

well supported by the brackets, the routing

matches the original and there’s plenty of

clearance between moving or hot

components.

12After refitting, check the master cylinder

fluid level and add fluid as necessary. Bleed

the brake system as outlined in Section 9 and

test the brakes carefully before driving the

vehicle. Be sure there are no leaks.

9 Brake hydraulic system-

bleeding

2

Warning: Wear eye protection

when bleeding the brake

system. If the fluid comes in

contact with your eyes,

immediately rinse them with water and

seek medical attention.Note:Bleeding the hydraulic system is

necessary to remove any air which has entered

the system during removal and refitting of a

hose, line, caliper or master cylinder.

1It will probably be necessary to bleed the

system at all four brakes if air has entered the

system due to low fluid level or if the brake

lines have been disconnected at the master

cylinder.

2If a brake line was disconnected at only one

wheel, then only that caliper or wheel cylinder

must be bled.

3If a brake line is disconnected at a fitting

located between the master cylinder and any

of the brakes, that part of the system served

by the disconnected line must be bled.

4Bleed the right rear, the left rear, the right

front and the left front caliper, in that order,

when the entire system is involved.

5Remove any residual vacuum from the

servo and pressure in the anti-lock braking

system (if equipped) by applying the brake

about 30 times with the engine off.

6Remove the master cylinder reservoir cover

and fill the reservoir with brake fluid. Refit the

cover. Note:Check the fluid level often during

the bleeding operation and add fluid as

necessary to prevent the fluid level from falling

low enough to allow air into the master

cylinder.

7Have an assistant on hand, as well as a

supply of new brake fluid, an empty clear

plastic container, a length of 3/16-inch clear

tubing to fit over the bleed screws and a

spanner to open and close the bleed screws.

8Beginning at the right rear wheel, loosen the

bleed screw slightly, then tighten it to a point

where it is snug but can still be loosened

quickly and easily.

9Place one end of the tubing over the bleed

valve and submerge the other end in brake

fluid in the container (see illustration).

10Have the assistant pump the brakes a few

times to build pressure in the system, then

hold the pedal firmly depressed.

11While the pedal is held depressed, open

the bleed screw just enough to allow fluid to

flow from the caliper. Watch for air bubbles toexit the submerged end of the tube. When the

fluid flow slows after a couple of seconds,

close the screw and have your assistant

release the pedal.

12Repeat Steps 10 and 11 until no more air

is seen leaving the tube, then tighten the

bleed screw and proceed to the left rear

wheel, the right front wheel and the left

front wheel, in that order, and perform the

same procedure. Be sure to check the fluid in

the master cylinder reservoir frequently.

13Never reuse old brake fluid. It contains

contaminates and moisture which could

damage the braking system.

14Refill the master cylinder with fluid at the

end of the operation.

15Check the operation of the brakes. The

pedal should feel solid when depressed, with

no sponginess. If necessary, repeat the entire

process.

Warning: Do not drive the car if

in doubt about the effectiveness

of the brake system.

10 Handbrake cable-

adjustment

1

1Slowly apply the handbrake and count the

number of clicks at the lever. It should be fully

applied within three to five clicks. If the lever is

still not fully applied by the fifth click, adjust

the handbrake cable as follows:

2Raise the vehicle and place it securely on

axle stands.

3Loosen the locknut (see illustration)and

tighten the cable adjuster until all slack has

been removed. Tighten the locknut. Make

sure the wheels turn freely with the handbrake

lever released

4Lower the vehicle and recheck the

handbrake lever. It should now be properly

adjusted. If it’s now fully applied within three

to five clicks, raise the vehicle again and

readjust the cable at the adjuster.

5Make sure the handbrake holds the vehicle

on an incline.

9•10 Braking system

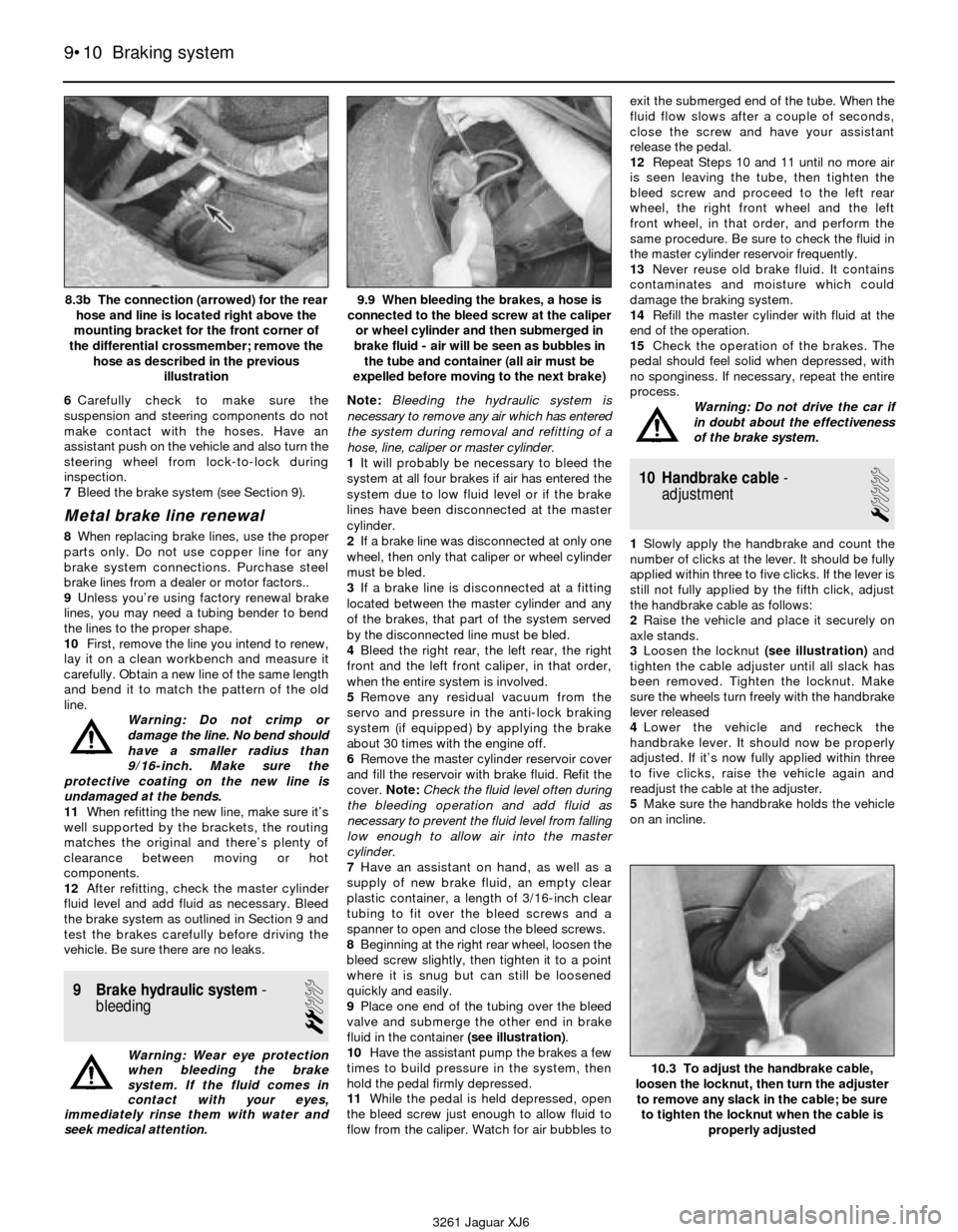

8.3b The connection (arrowed) for the rear

hose and line is located right above the

mounting bracket for the front corner of

the differential crossmember; remove the

hose as described in the previous

illustration9.9 When bleeding the brakes, a hose is

connected to the bleed screw at the caliper

or wheel cylinder and then submerged in

brake fluid - air will be seen as bubbles in

the tube and container (all air must be

expelled before moving to the next brake)

10.3 To adjust the handbrake cable,

loosen the locknut, then turn the adjuster

to remove any slack in the cable; be sure

to tighten the locknut when the cable is

properly adjusted

3261 Jaguar XJ6

Page 136 of 227

bulbs (open-circuit between the switch and

the bulbs), or the switch is defective.

5To remove the switch, reach up under the

dash and unplug the two electrical connectors

- one for the brake lights and one for the

cruise control system. Locate the two pairs of

leads coming down the pedal box and trace

them to their connectors on or near the

steering column.

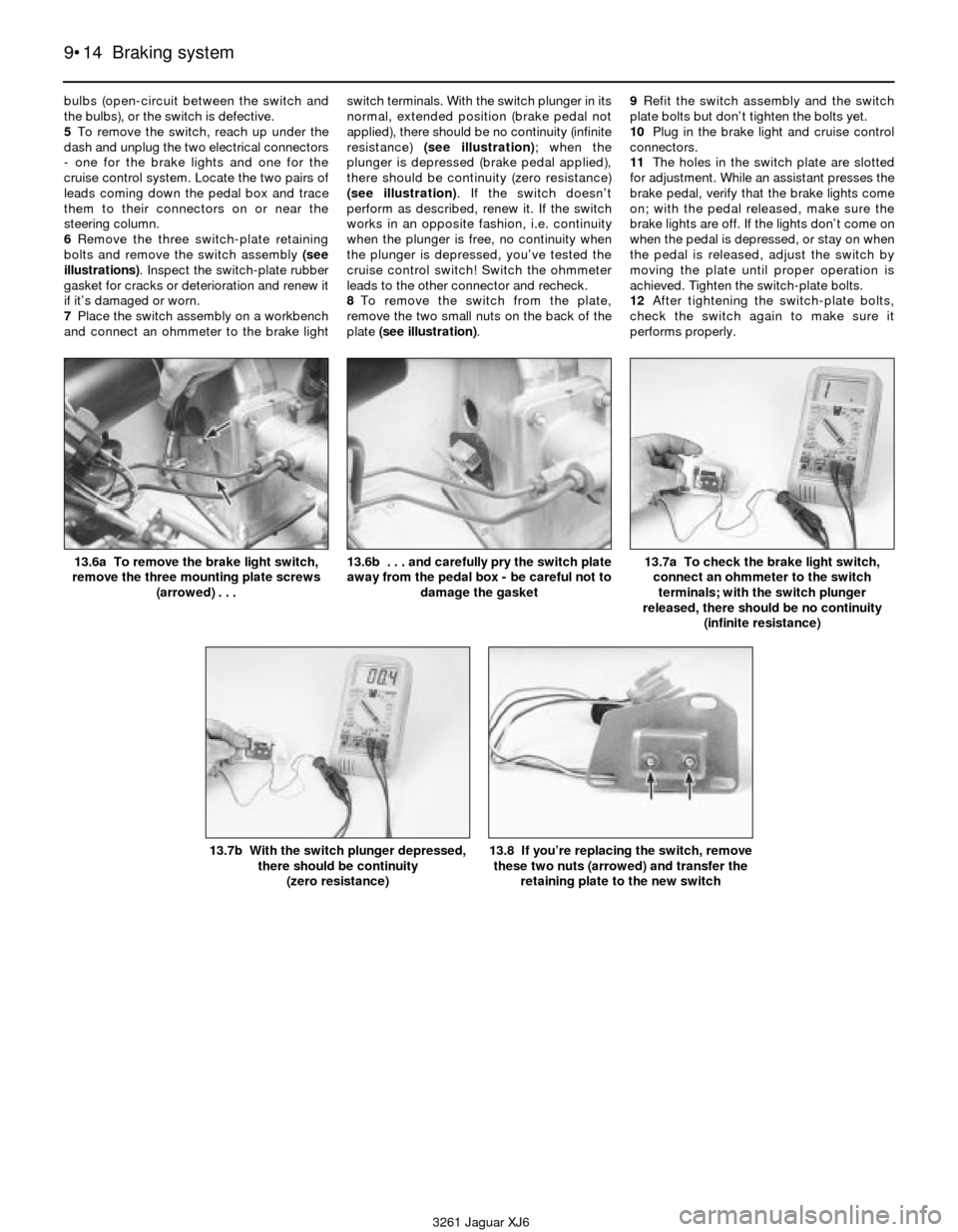

6Remove the three switch-plate retaining

bolts and remove the switch assembly (see

illustrations). Inspect the switch-plate rubber

gasket for cracks or deterioration and renew it

if it’s damaged or worn.

7Place the switch assembly on a workbench

and connect an ohmmeter to the brake lightswitch terminals. With the switch plunger in its

normal, extended position (brake pedal not

applied), there should be no continuity (infinite

resistance) (see illustration); when the

plunger is depressed (brake pedal applied),

there should be continuity (zero resistance)

(see illustration). If the switch doesn’t

perform as described, renew it. If the switch

works in an opposite fashion, i.e. continuity

when the plunger is free, no continuity when

the plunger is depressed, you’ve tested the

cruise control switch! Switch the ohmmeter

leads to the other connector and recheck.

8To remove the switch from the plate,

remove the two small nuts on the back of the

plate (see illustration).9Refit the switch assembly and the switch

plate bolts but don’t tighten the bolts yet.

10Plug in the brake light and cruise control

connectors.

11The holes in the switch plate are slotted

for adjustment. While an assistant presses the

brake pedal, verify that the brake lights come

on; with the pedal released, make sure the

brake lights are off. If the lights don’t come on

when the pedal is depressed, or stay on when

the pedal is released, adjust the switch by

moving the plate until proper operation is

achieved. Tighten the switch-plate bolts.

12After tightening the switch-plate bolts,

check the switch again to make sure it

performs properly.

9•14 Braking system

13.6a To remove the brake light switch,

remove the three mounting plate screws

(arrowed) . . .13.6b . . . and carefully pry the switch plate

away from the pedal box - be careful not to

damage the gasket13.7a To check the brake light switch,

connect an ohmmeter to the switch

terminals; with the switch plunger

released, there should be no continuity

(infinite resistance)

13.7b With the switch plunger depressed,

there should be continuity

(zero resistance)13.8 If you’re replacing the switch, remove

these two nuts (arrowed) and transfer the

retaining plate to the new switch

3261 Jaguar XJ6

Page 139 of 227

1 General information

Warning: Whenever any of the

suspension or steering fasteners

are loosened or removed, they

must be inspected and if

necessary, replaced with new ones of the

same part number or of original equipment

quality and design. Torque wrench settings

must be followed for proper reassembly

and component retention. Never attempt

to heat, straighten or weld any suspension

or steering component. Instead, renew any

bent or damaged part.

The front suspension (see illustrations)

consists of unequal-length upper and lower

control arms, shock absorbers and coil

springs. The upper ends of the shocks are

attached to the body; the lower ends

are attached to the lower control arms. The

upper ends of the coil springs are seated

against the suspension crossmember; the

lower ends are seated against removable

plates which are bolted to the lower control

arms. The steering knuckles are attached to

balljoints in the upper and lower control arms.

An anti-roll bar is attached to the suspension

crossmember with a pair of bushing brackets

and to the lower control arms via a connecting

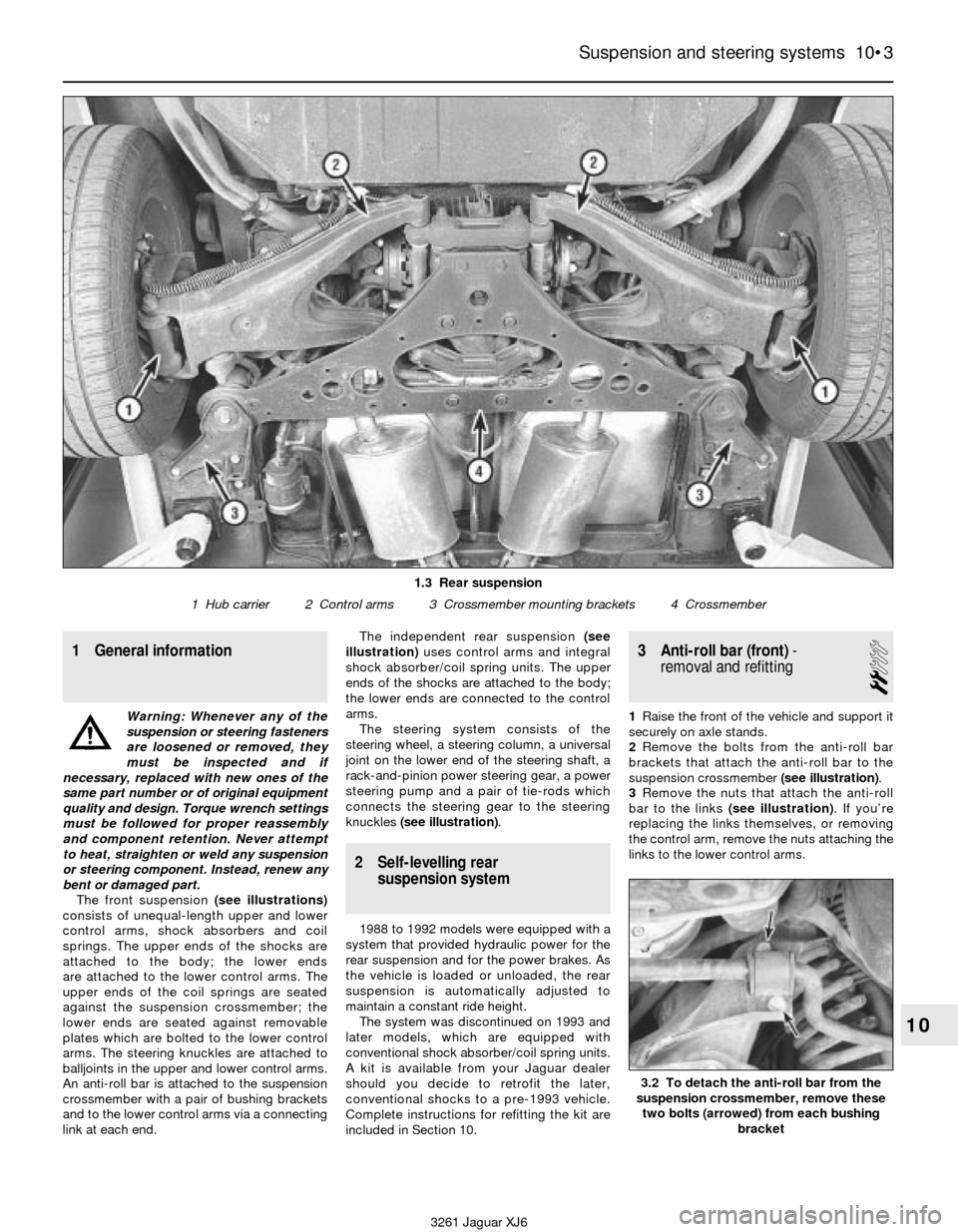

link at each end.The independent rear suspension (see

illustration)uses control arms and integral

shock absorber/coil spring units. The upper

ends of the shocks are attached to the body;

the lower ends are connected to the control

arms.

The steering system consists of the

steering wheel, a steering column, a universal

joint on the lower end of the steering shaft, a

rack-and-pinion power steering gear, a power

steering pump and a pair of tie-rods which

connects the steering gear to the steering

knuckles (see illustration).

2 Self-levelling rear

suspension system

1988 to 1992 models were equipped with a

system that provided hydraulic power for the

rear suspension and for the power brakes. As

the vehicle is loaded or unloaded, the rear

suspension is automatically adjusted to

maintain a constant ride height.

The system was discontinued on 1993 and

later models, which are equipped with

conventional shock absorber/coil spring units.

A kit is available from your Jaguar dealer

should you decide to retrofit the later,

conventional shocks to a pre-1993 vehicle.

Complete instructions for refitting the kit are

included in Section 10.

3 Anti-roll bar (front)-

removal and refitting

2

1Raise the front of the vehicle and support it

securely on axle stands.

2Remove the bolts from the anti-roll bar

brackets that attach the anti-roll bar to the

suspension crossmember (see illustration).

3Remove the nuts that attach the anti-roll

bar to the links (see illustration). If you’re

replacing the links themselves, or removing

the control arm, remove the nuts attaching the

links to the lower control arms.

Suspension and steering systems 10•3

10

1.3 Rear suspension

1 Hub carrier 2 Control arms 3 Crossmember mounting brackets 4 Crossmember

3.2 To detach the anti-roll bar from the

suspension crossmember, remove these

two bolts (arrowed) from each bushing

bracket

3261 Jaguar XJ6

Page 141 of 227

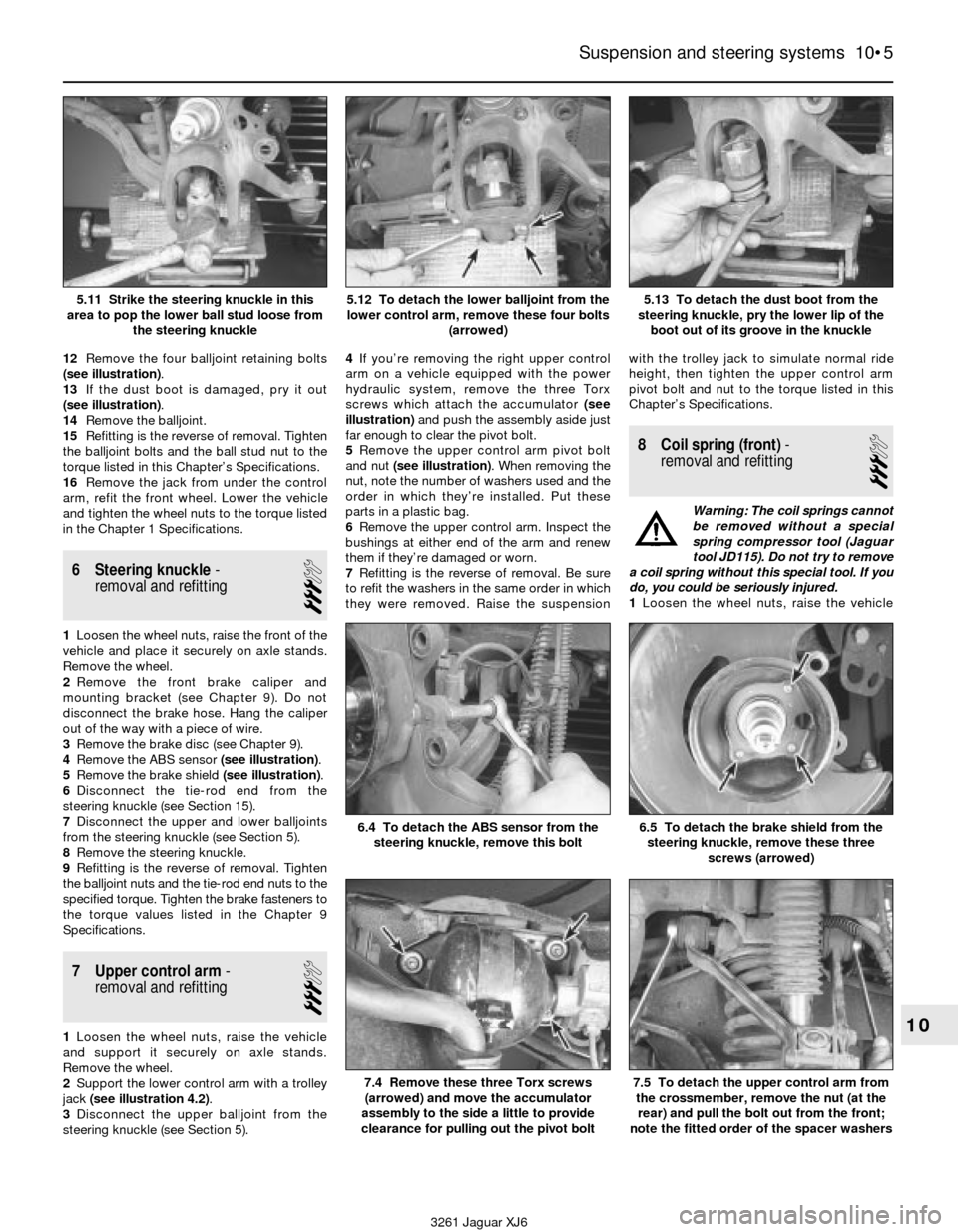

12Remove the four balljoint retaining bolts

(see illustration).

13If the dust boot is damaged, pry it out

(see illustration).

14Remove the balljoint.

15Refitting is the reverse of removal. Tighten

the balljoint bolts and the ball stud nut to the

torque listed in this Chapter’s Specifications.

16Remove the jack from under the control

arm, refit the front wheel. Lower the vehicle

and tighten the wheel nuts to the torque listed

in the Chapter 1 Specifications.

6 Steering knuckle-

removal and refitting

3

1Loosen the wheel nuts, raise the front of the

vehicle and place it securely on axle stands.

Remove the wheel.

2Remove the front brake caliper and

mounting bracket (see Chapter 9). Do not

disconnect the brake hose. Hang the caliper

out of the way with a piece of wire.

3Remove the brake disc (see Chapter 9).

4Remove the ABS sensor (see illustration).

5Remove the brake shield (see illustration).

6Disconnect the tie-rod end from the

steering knuckle (see Section 15).

7Disconnect the upper and lower balljoints

from the steering knuckle (see Section 5).

8Remove the steering knuckle.

9Refitting is the reverse of removal. Tighten

the balljoint nuts and the tie-rod end nuts to the

specified torque. Tighten the brake fasteners to

the torque values listed in the Chapter 9

Specifications.

7 Upper control arm-

removal and refitting

3

1Loosen the wheel nuts, raise the vehicle

and support it securely on axle stands.

Remove the wheel.

2Support the lower control arm with a trolley

jack (see illustration 4.2).

3Disconnect the upper balljoint from the

steering knuckle (see Section 5).4If you’re removing the right upper control

arm on a vehicle equipped with the power

hydraulic system, remove the three Torx

screws which attach the accumulator (see

illustration)and push the assembly aside just

far enough to clear the pivot bolt.

5Remove the upper control arm pivot bolt

and nut (see illustration). When removing the

nut, note the number of washers used and the

order in which they’re installed. Put these

parts in a plastic bag.

6Remove the upper control arm. Inspect the

bushings at either end of the arm and renew

them if they’re damaged or worn.

7Refitting is the reverse of removal. Be sure

to refit the washers in the same order in which

they were removed. Raise the suspensionwith the trolley jack to simulate normal ride

height, then tighten the upper control arm

pivot bolt and nut to the torque listed in this

Chapter’s Specifications.

8 Coil spring (front)-

removal and refitting

3

Warning: The coil springs cannot

be removed without a special

spring compressor tool (Jaguar

tool JD115). Do not try to remove

a coil spring without this special tool. If you

do, you could be seriously injured.

1Loosen the wheel nuts, raise the vehicle

Suspension and steering systems 10•5

10

5.11 Strike the steering knuckle in this

area to pop the lower ball stud loose from

the steering knuckle5.12 To detach the lower balljoint from the

lower control arm, remove these four bolts

(arrowed)5.13 To detach the dust boot from the

steering knuckle, pry the lower lip of the

boot out of its groove in the knuckle

6.5 To detach the brake shield from the

steering knuckle, remove these three

screws (arrowed)6.4 To detach the ABS sensor from the

steering knuckle, remove this bolt

7.4 Remove these three Torx screws

(arrowed) and move the accumulator

assembly to the side a little to provide

clearance for pulling out the pivot bolt7.5 To detach the upper control arm from

the crossmember, remove the nut (at the

rear) and pull the bolt out from the front;

note the fitted order of the spacer washers

3261 Jaguar XJ6

Page 142 of 227

and support it securely on axle stands.

Remove the wheel.

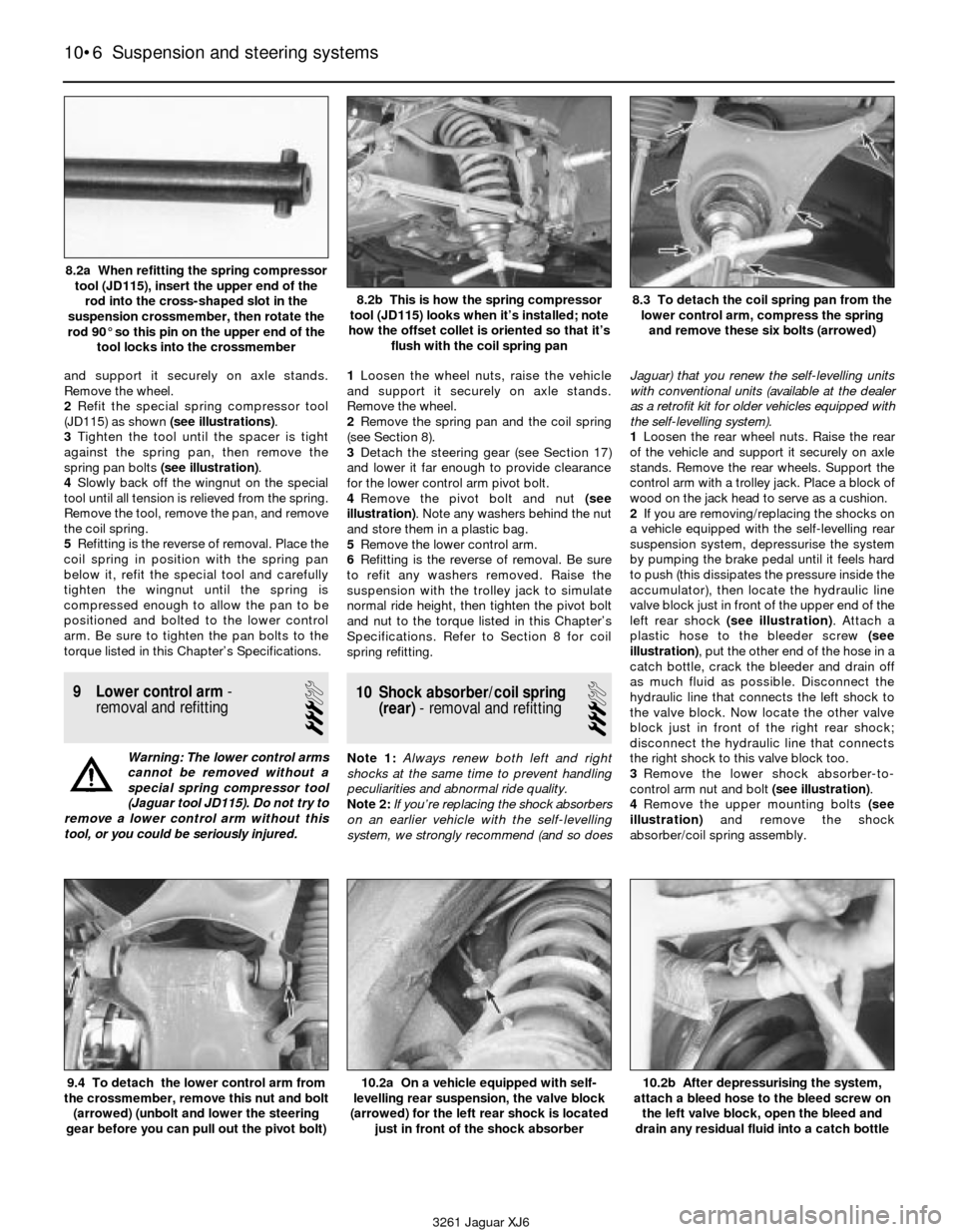

2Refit the special spring compressor tool

(JD115) as shown (see illustrations).

3Tighten the tool until the spacer is tight

against the spring pan, then remove the

spring pan bolts (see illustration).

4Slowly back off the wingnut on the special

tool until all tension is relieved from the spring.

Remove the tool, remove the pan, and remove

the coil spring.

5Refitting is the reverse of removal. Place the

coil spring in position with the spring pan

below it, refit the special tool and carefully

tighten the wingnut until the spring is

compressed enough to allow the pan to be

positioned and bolted to the lower control

arm. Be sure to tighten the pan bolts to the

torque listed in this Chapter’s Specifications.

9 Lower control arm-

removal and refitting

3

Warning: The lower control arms

cannot be removed without a

special spring compressor tool

(Jaguar tool JD115). Do not try to

remove a lower control arm without this

tool, or you could be seriously injured.1Loosen the wheel nuts, raise the vehicle

and support it securely on axle stands.

Remove the wheel.

2Remove the spring pan and the coil spring

(see Section 8).

3Detach the steering gear (see Section 17)

and lower it far enough to provide clearance

for the lower control arm pivot bolt.

4Remove the pivot bolt and nut (see

illustration). Note any washers behind the nut

and store them in a plastic bag.

5Remove the lower control arm.

6Refitting is the reverse of removal. Be sure

to refit any washers removed. Raise the

suspension with the trolley jack to simulate

normal ride height, then tighten the pivot bolt

and nut to the torque listed in this Chapter’s

Specifications. Refer to Section 8 for coil

spring refitting.

10 Shock absorber/coil spring

(rear)- removal and refitting

3

Note 1: Always renew both left and right

shocks at the same time to prevent handling

peculiarities and abnormal ride quality.

Note 2:If you’re replacing the shock absorbers

on an earlier vehicle with the self-levelling

system, we strongly recommend (and so doesJaguar) that you renew the self-levelling units

with conventional units (available at the dealer

as a retrofit kit for older vehicles equipped with

the self-levelling system).

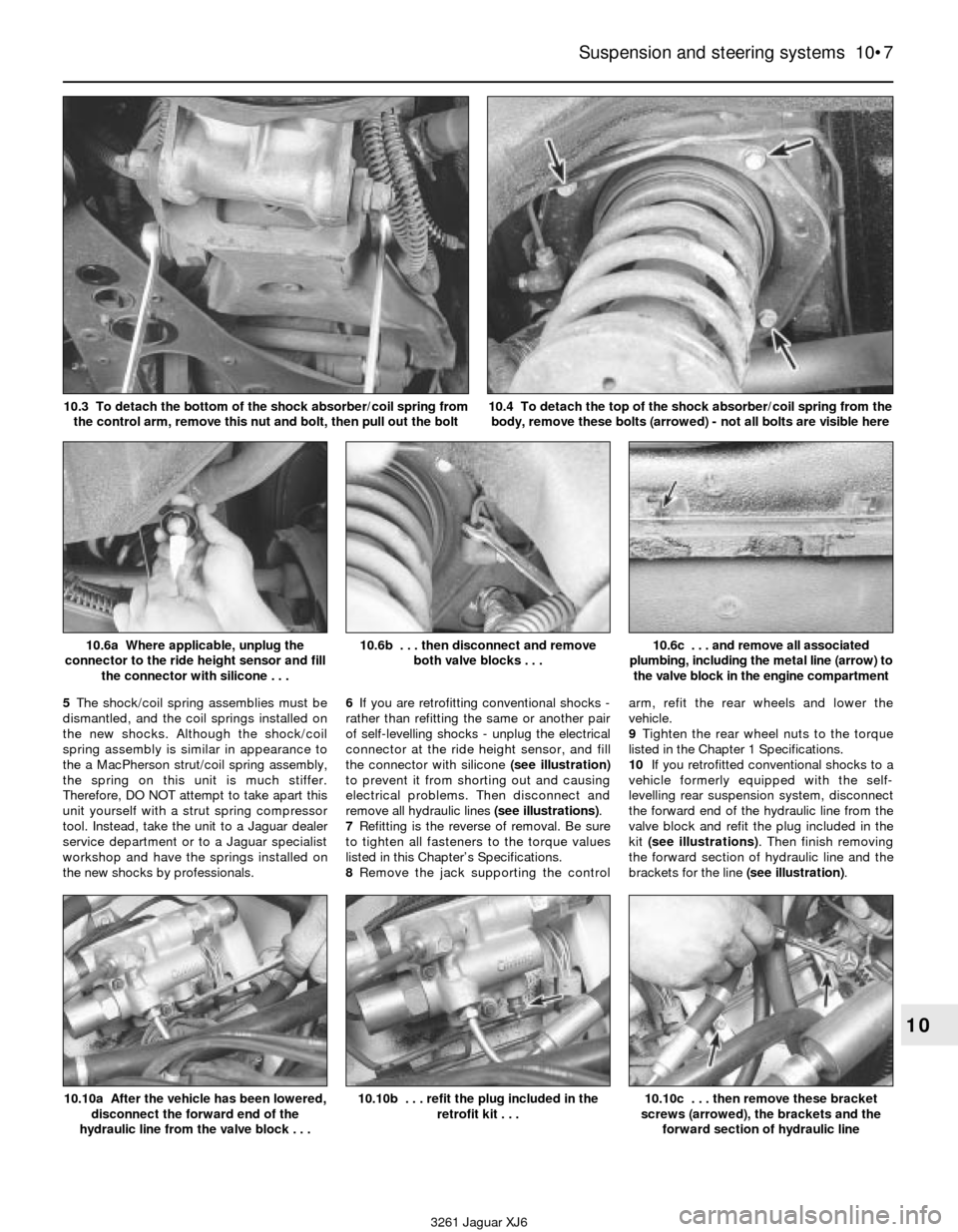

1Loosen the rear wheel nuts. Raise the rear

of the vehicle and support it securely on axle

stands. Remove the rear wheels. Support the

control arm with a trolley jack. Place a block of

wood on the jack head to serve as a cushion.

2If you are removing/replacing the shocks on

a vehicle equipped with the self-levelling rear

suspension system, depressurise the system

by pumping the brake pedal until it feels hard

to push (this dissipates the pressure inside the

accumulator), then locate the hydraulic line

valve block just in front of the upper end of the

left rear shock (see illustration). Attach a

plastic hose to the bleeder screw (see

illustration), put the other end of the hose in a

catch bottle, crack the bleeder and drain off

as much fluid as possible. Disconnect the

hydraulic line that connects the left shock to

the valve block. Now locate the other valve

block just in front of the right rear shock;

disconnect the hydraulic line that connects

the right shock to this valve block too.

3Remove the lower shock absorber-to-

control arm nut and bolt (see illustration).

4Remove the upper mounting bolts (see

illustration)and remove the shock

absorber/coil spring assembly.

10•6 Suspension and steering systems

9.4 To detach the lower control arm from

the crossmember, remove this nut and bolt

(arrowed) (unbolt and lower the steering

gear before you can pull out the pivot bolt)10.2a On a vehicle equipped with self-

levelling rear suspension, the valve block

(arrowed) for the left rear shock is located

just in front of the shock absorber10.2b After depressurising the system,

attach a bleed hose to the bleed screw on

the left valve block, open the bleed and

drain any residual fluid into a catch bottle

3261 Jaguar XJ6 8.2a When refitting the spring compressor

tool (JD115), insert the upper end of the

rod into the cross-shaped slot in the

suspension crossmember, then rotate the

rod 90° so this pin on the upper end of the

tool locks into the crossmember

8.2b This is how the spring compressor

tool (JD115) looks when it’s installed; note

how the offset collet is oriented so that it’s

flush with the coil spring pan8.3 To detach the coil spring pan from the

lower control arm, compress the spring

and remove these six bolts (arrowed)

Page 143 of 227

5The shock/coil spring assemblies must be

dismantled, and the coil springs installed on

the new shocks. Although the shock/coil

spring assembly is similar in appearance to

the a MacPherson strut/coil spring assembly,

the spring on this unit is much stiffer.

Therefore, DO NOT attempt to take apart this

unit yourself with a strut spring compressor

tool. Instead, take the unit to a Jaguar dealer

service department or to a Jaguar specialist

workshop and have the springs installed on

the new shocks by professionals.6If you are retrofitting conventional shocks -

rather than refitting the same or another pair

of self-levelling shocks - unplug the electrical

connector at the ride height sensor, and fill

the connector with silicone (see illustration)

to prevent it from shorting out and causing

electrical problems. Then disconnect and

remove all hydraulic lines (see illustrations).

7Refitting is the reverse of removal. Be sure

to tighten all fasteners to the torque values

listed in this Chapter’s Specifications.

8Remove the jack supporting the controlarm, refit the rear wheels and lower the

vehicle.

9Tighten the rear wheel nuts to the torque

listed in the Chapter 1 Specifications.

10If you retrofitted conventional shocks to a

vehicle formerly equipped with the self-

levelling rear suspension system, disconnect

the forward end of the hydraulic line from the

valve block and refit the plug included in the

kit (see illustrations). Then finish removing

the forward section of hydraulic line and the

brackets for the line (see illustration).

Suspension and steering systems 10•7

10

10.6a Where applicable, unplug the

connector to the ride height sensor and fill

the connector with silicone . . .10.6b . . . then disconnect and remove

both valve blocks . . .10.6c . . . and remove all associated

plumbing, including the metal line (arrow) to

the valve block in the engine compartment

3261 Jaguar XJ6 10.3 To detach the bottom of the shock absorber/coil spring from

the control arm, remove this nut and bolt, then pull out the bolt

10.4 To detach the top of the shock absorber/coil spring from the

body, remove these bolts (arrowed) - not all bolts are visible here

10.10a After the vehicle has been lowered,

disconnect the forward end of the

hydraulic line from the valve block . . .10.10b . . . refit the plug included in the

retrofit kit . . .10.10c . . . then remove these bracket

screws (arrowed), the brackets and the

forward section of hydraulic line

Page 145 of 227

sure you have the correct activation code

before disconnecting the battery.

2Pry off the centre pad (see illustration).

3Remove the steering wheel nut and mark

the relationship of the steering wheel hub to

the shaft (see illustration).

4Slide the steering wheel off the steering

shaft (see illustration).

5Refitting is the reverse of removal. Make

sure you align the match marks you made on

the steering wheel and the shaft. Tighten the

steering wheel nut to the torque listed in this

Chapter’s Specifications.

15 Tie-rod ends-

removal and refitting

2

1Loosen the wheel nuts, raise the front of the

vehicle and support it securely on axle stands.

Remove the front wheel.

2Back off the locknut that locks the tie-rod

end to the tie-rod, then paint an alignment

mark on the threads to ensure the new tie-rod

end is installed in the same position (see

illustration).

3Loosen the nut on the tie-rod ball stud, then

fit a small puller and pop the ball stud loose

(see illustration). Remove the nut and

separate the ball stud from the steering

knuckle. Unscrew the tie-rod end from the tie-

rod.

4Refitting is the reverse of removal. Make

sure you thread the tie-rod end all the way up

to the mark on the threads, but no further.

Tighten the ball stud nut to the torque listed in

this Chapter’s Specifications. Tighten the

locknut securely.

5Have the toe-in checked and, if necessary,

adjusted at a dealer service department or

alignment workshop.

16 Steering gear boots- renewal

2

1Remove the tie-rod ends (see Section 15).

2Cut the boot clamps at both ends of the old

boots (see illustration)and slide off the

boots.3While the boots are removed, inspect the

seals in the end of the steering gear. If they’re

leaking, have them replaced by a dealer

service department or other qualified repair

workshop, or replace the steering gear with a

new or rebuilt unit (see Section 17).

4Slide the new boots into place and refit new

boot clamps.

5Refit the tie-rod ends (see Section 15).

Suspension and steering systems 10•9

10

14.4 To remove the steering wheel,

simply pull it straight off15.2 Back off this locknut and mark the

threads to ensure that the new tie-rod end

is installed properly

15.3 Loosen the ball stud nut, fit a small

puller and pop the ball stud loose from the

steering knuckle

3261 Jaguar XJ6 14.2 To remove the centre pad from the steering wheel,

simply pry it off

14.3 After removing the steering wheel nut, make a pair of

alignment marks on the steering wheel and steering shaft to

ensure proper reassembly

16.2 Cut off the boot clamps (arrowed)

and slide the boot off the steering gear

Page 148 of 227

None of these three angles are adjustable on

the rear wheels. Even the non-adjustable

angles should be checked to determine if any

of the suspension components are bent.

Getting the proper wheel alignment is a

very exacting process, one in which

complicated and expensive machines are

necessary to perform the job properly.

Because of this, you should have a technician

with the proper equipment perform these

tasks. We will, however, use this space to give

you a basic idea of what is involved with a

wheel alignment so you can better understand

the process and deal intelligently with the

workshop that does the work.Toe-in is the turning in of the wheels. The

purpose of a toe specification is to ensure

parallel rolling of the wheels. In a vehicle with

zero toe-in, the distance between the front

edges of the wheels will be the same as the

distance between the rear edges of the

wheels. The actual amount of toe-in is

normally only a fraction of an inch. Toe-in is

controlled by the tie-rod end position on the

tie-rod. Incorrect toe-in will cause the tyres to

wear improperly by making them scrub

against the road surface.

Camber is the tilting of the wheels from

vertical when viewed from one end of the

vehicle. When the wheels tilt out at the top, the camber is said to be positive (+). When

the wheels tilt in at the top the camber is

negative (-). The amount of tilt is measured in

degrees from vertical and this measurement is

called the camber angle. This angle affects the

amount of tyre tread which contacts the road

and compensates for changes in the suspension

geometry when the vehicle is cornering or

travelling over an undulating surface.

Caster is the tilting of the front steering axis

from the vertical. A tilt toward the rear is

positive caster and a tilt toward the front is

negative caster. Caster is adjusted by moving

shims from one side of the upper control arm

balljoint to the other.

10•12 Suspension and steering systems

3261 Jaguar XJ6

Page 149 of 227

3261 Jaguar XJ6

11

Chapter 11

Bodywork and fittings

Body - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Body repair - major damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Body repair - minor damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . 10

Bonnet and boot lid support struts - removal and refitting . . . . . . . . 9

Bonnet release latch and cable - removal and refitting . . . . . . . . . . . 11

Boot lid - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . 16

Boot lid latch and lock cylinder - removal and refitting . . . . . . . . . . . 17

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 24

Cowl cover - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Dashboard trim panels - removal and refitting . . . . . . . . . . . . . . . . . 26

Door - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . 19

Door latch, lock cylinder and handles - removal and refitting . . . . . . 20

Door trim panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 18Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 22

Door window glass regulator - removal and refitting . . . . . . . . . . . . . 21

Front spoiler - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front wing - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hinges and locks - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Instrument cluster housing - removal and refitting . . . . . . . . . . . . . . 25

Outside mirrors - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 23

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 12

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Steering column cover - removal and refitting . . . . . . . . . . . . . . . . . 27

Upholstery and carpets - maintenance . . . . . . . . . . . . . . . . . . . . . . . 4

Vinyl trim - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Windscreen and fixed glass - replacement . . . . . . . . . . . . . . . . . . . . 8

11•1

Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

These models feature a “unibody”

construction, using a floor pan with front and

rear frame side rails which support the body

components, front and rear suspension

systems and other mechanical components.

Certain components are particularly vulnerable

to accident damage and can be unbolted and

repaired or replaced. Among these parts are

the body mouldings, bumpers, front wings,

bonnet and boot lids and all glass.

Only general body maintenance practices

and body panel repair procedures within the

scope of the do-it-yourselfer are included in

this Chapter.

2 Body- maintenance

1

1The condition of your vehicle’s body is very

important, because the resale value depends

a great deal on it. It’s much more difficult to

repair a neglected or damaged body than it is

to repair mechanical components. The hidden

areas of the body, such as the wheel wells,

the frame and the engine compartment, areequally important, although they don’t require

as frequent attention as the rest of the body.

2Once a year, or every 12,000 miles, it’s a

good idea to have the underside of the body

steam cleaned. All traces of dirt and oil will be

removed and the area can then be inspected

carefully for rust, damaged brake lines, frayed

electrical wires, damaged cables and other

problems. The front suspension components

should be greased after completion of this job.

3At the same time, clean the engine and the

engine compartment with a steam cleaner or

water soluble degreaser.

4The wheel wells should be given close

attention, since undercoating can peel away

and stones and dirt thrown up by the tyres

can cause the paint to chip and flake, allowing

rust to set in. If rust is found, clean down to

the bare metal and apply an anti-rust paint.

5The body should be washed about once a

week. Wet the vehicle thoroughly to soften the

dirt, then wash it down with a soft sponge and

plenty of clean soapy water. If the surplus dirt

is not washed off very carefully, it can wear

down the paint.

6Spots of tar or asphalt thrown up from the

road should be removed with a cloth soaked

in solvent.

7Once every six months, wax the body and

chrome trim. If a chrome cleaner is used to

remove rust from any of the vehicle’s plated

parts, remember that the cleaner also removes

part of the chrome, so use it sparingly.

3 Vinyl trim- maintenance

1

Don’t clean vinyl trim with detergents,

caustic soap or petroleum-based cleaners.

Plain soap and water works just fine, with a

soft brush to clean dirt that may be ingrained.

Wash the vinyl as frequently as the rest of the

vehicle.

After cleaning, application of a high quality

rubber and vinyl protectant will help prevent

oxidation and cracks. The protectant can also

be applied to weather-stripping, vacuum lines

and rubber hoses (which often fail as a result

of chemical degradation) and to the tyres.

4 Upholstery and carpets-

maintenance

1

1Every three months remove the carpets or

mats and clean the interior of the vehicle

(more frequently if necessary). Vacuum the

upholstery and carpets to remove loose dirt

and dust.

2Leather upholstery requires special care.

Stains should be removed with warm water

and a very mild soap solution. Use a clean,

damp cloth to remove the soap, then wipe

Page 151 of 227

spray painting technique is mastered. Cover

the repair area with a thick coat of primer. The

thickness should be built up using several thin

layers of primer rather than one thick one.

Using 600-grit wet-or-dry sandpaper, rub

down the surface of the primer until it is very

smooth. While doing this, the work area

should be thoroughly rinsed with water and

the wet-or-dry sandpaper periodically rinsed

as well. Allow the primer to dry before

spraying additional coats.

21Spray on the top coat, again building up

the thickness by using several thin layers of

paint. Begin spraying at the top of the repair

area and then, using a side-to-side motion,

work down until the whole repair area and

about two inches of the surrounding original

paint is covered. Remove all masking material

10 to 15 minutes after spraying on the final

coat of paint. Allow the new paint at least two

weeks to harden, then use a very fine rubbing

compound to blend the edges of the new

paint into the existing paint. Finally, apply a

coat of wax.

6 Body repair- major damage

5

1Major damage must be repaired by an auto

body workshop specifically equipped to

perform unibody repairs. These workshops

have the specialised equipment required to

do the job properly.

2If the damage is extensive, the body must

be checked for proper alignment or the

vehicle’s handling characteristics may be

adversely affected and other components

may wear at an accelerated rate.

3Due to the fact that most of the major body

components (bonnet, front wings, etc.) are

separate and replaceable units, any seriously

damaged components should be replaced

rather than repaired. Sometimes thecomponents can be found in a scrapyard that

specialises in used vehicle components, often

at considerable savings over the cost of new

parts.

7 Hinges and locks-

maintenance

1

Once every 3000 miles, or every three

months, the hinges and latch assemblies on

the doors, bonnet and boot should be given a

few drops of light oil or lock lubricant. The

door latch strikers should also be lubricated

with a thin coat of grease to reduce wear and

ensure free movement. Lubricate the door

and boot locks with spray-on graphite

lubricant.

8 Windscreen and fixed glass-

replacement

5

Replacement of the windscreen and fixed

glass requires the use of special fast-setting

adhesive/caulk materials and some

specialised tools. It is recommended that

these operations be left to a dealer or a

workshop specialising in glass work.

9 Bonnet and boot lid support

struts- removal and refitting

1

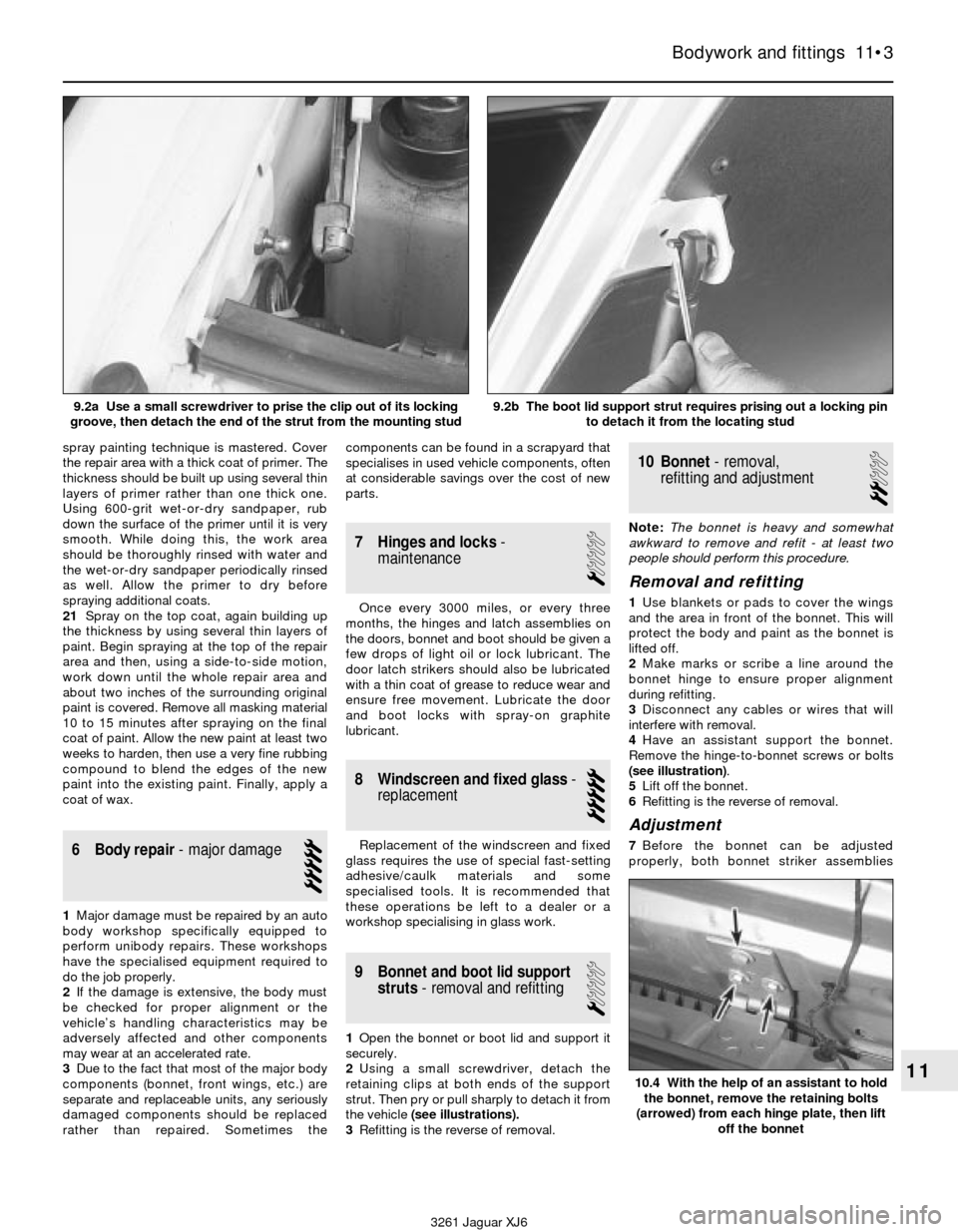

1Open the bonnet or boot lid and support it

securely.

2Using a small screwdriver, detach the

retaining clips at both ends of the support

strut. Then pry or pull sharply to detach it from

the vehicle(see illustrations).

3Refitting is the reverse of removal.

10 Bonnet- removal,

refitting and adjustment

2

Note:The bonnet is heavy and somewhat

awkward to remove and refit - at least two

people should perform this procedure.

Removal and refitting

1Use blankets or pads to cover the wings

and the area in front of the bonnet. This will

protect the body and paint as the bonnet is

lifted off.

2Make marks or scribe a line around the

bonnet hinge to ensure proper alignment

during refitting.

3Disconnect any cables or wires that will

interfere with removal.

4Have an assistant support the bonnet.

Remove the hinge-to-bonnet screws or bolts

(see illustration).

5Lift off the bonnet.

6Refitting is the reverse of removal.

Adjustment

7Before the bonnet can be adjusted

properly, both bonnet striker assemblies

Bodywork and fittings 11•3

1110.4 With the help of an assistant to hold

the bonnet, remove the retaining bolts

(arrowed) from each hinge plate, then lift

off the bonnet

3261 Jaguar XJ69.2b The boot lid support strut requires prising out a locking pin

to detach it from the locating stud

9.2a Use a small screwdriver to prise the clip out of its locking

groove, then detach the end of the strut from the mounting stud