clock JEEP CHEROKEE 1988 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1988, Model line: CHEROKEE, Model: JEEP CHEROKEE 1988Pages: 1378, PDF Size: 19.9 MB

Page 1036 of 1378

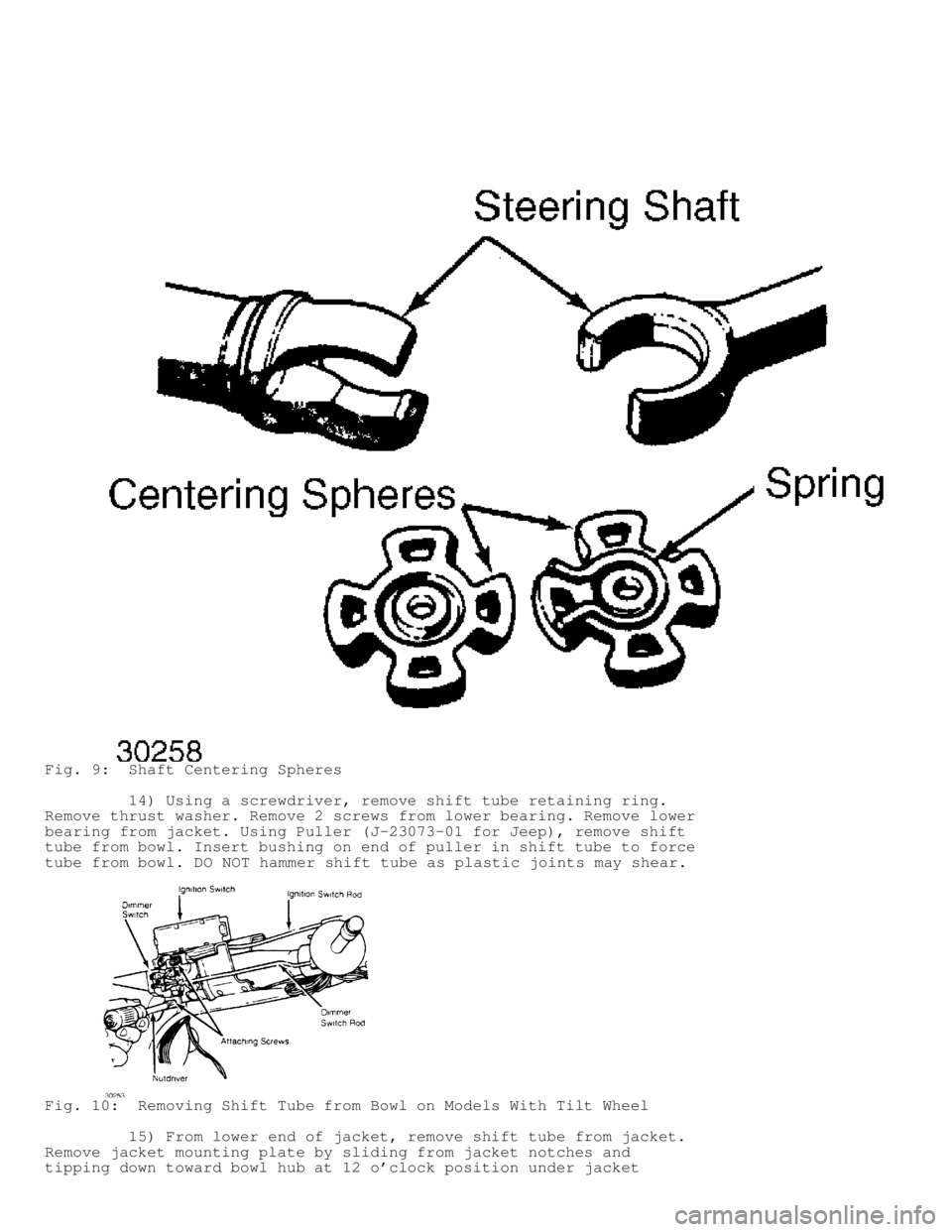

Fig. 9: Shaft Centering Spheres

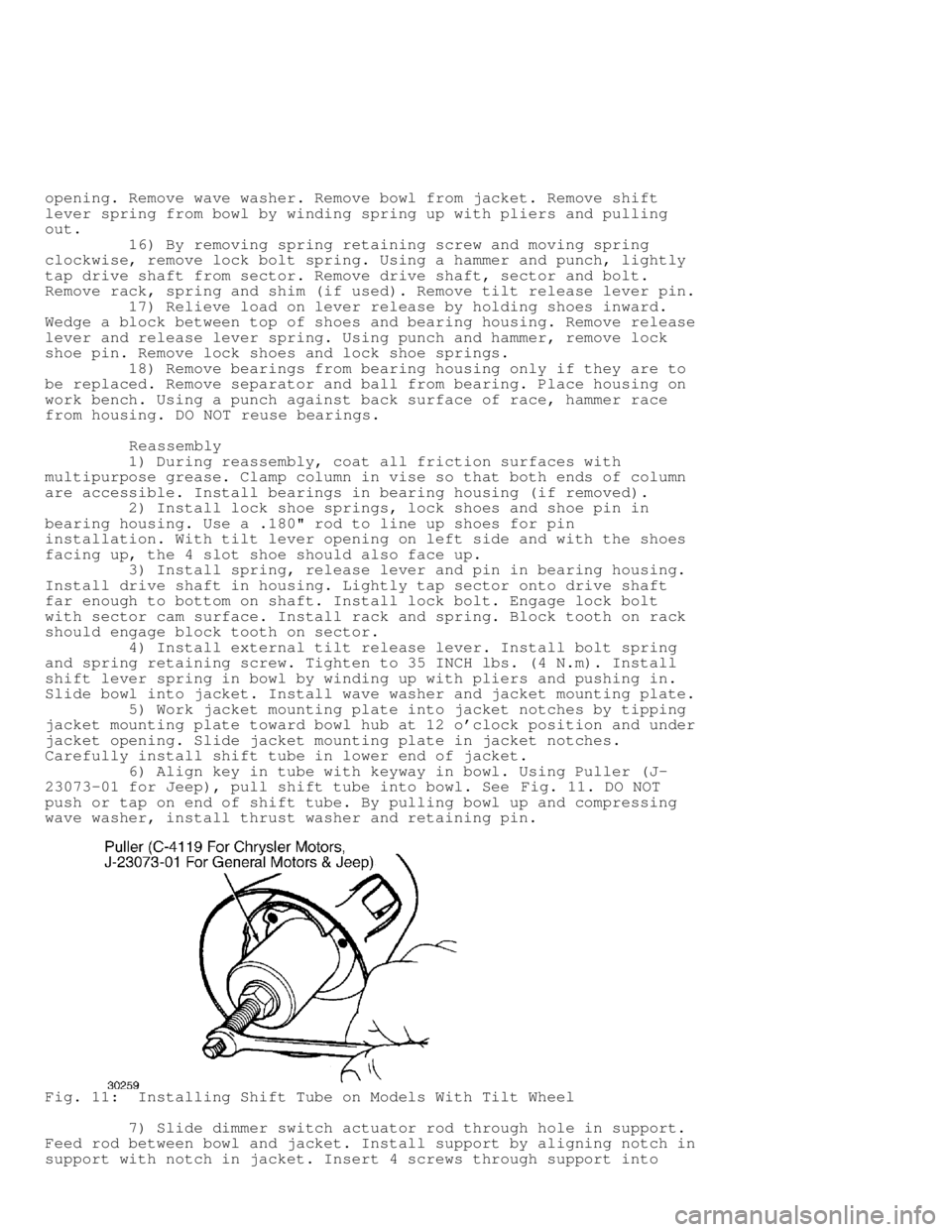

14) Using a screwdriver, remove shift tube retaining ring.

Remove thrust washer. Remove 2 screws from lower bearing. Remove lower

bearing from jacket. Using Puller (J-23073-01 for Jeep), remove shift

tube from bowl. Insert bushing on end of puller in shift tube to force

tube from bowl. DO NOT hammer shift tube as plastic joints may shear.

Fig. 10: Removing Shift Tube from Bowl on Models With Tilt Wheel

15) From lower end of jacket, remove shift tube from jacket.

Remove jacket mounting plate by sliding from jacket notches and

tipping down toward bowl hub at 12 o'clock position under jacket

Page 1037 of 1378

opening. Remove wave washer. Remove bowl from jacket. Remove shift

lever spring from bowl by winding spring up with pliers and pulling

out.

16) By removing spring retaining screw and moving spring

clockwise, remove lock bolt spring. Using a hammer and punch, lightly

tap drive shaft from sector. Remove drive shaft, sector and bolt.

Remove rack, spring and shim (if used). Remove tilt release lever pin.\

17) Relieve load on lever release by holding shoes inward.

Wedge a block between top of shoes and bearing housing. Remove release

lever and release lever spring. Using punch and hammer, remove lock

shoe pin. Remove lock shoes and lock shoe springs.

18) Remove bearings from bearing housing only if they are to

be replaced. Remove separator and ball from bearing. Place housing on

work bench. Using a punch against back surface of race, hammer race

from housing. DO NOT reuse bearings.

Reassembly

1) During reassembly, coat all friction surfaces with

multipurpose grease. Clamp column in vise so that both ends of column

are accessible. Install bearings in bearing housing (if removed).

2) Install lock shoe springs, lock shoes and shoe pin in

bearing housing. Use a .180" rod to line up shoes for pin

installation. With tilt lever opening on left side and with the shoes

facing up, the 4 slot shoe should also face up.

3) Install spring, release lever and pin in bearing housing.

Install drive shaft in housing. Lightly tap sector onto drive shaft

far enough to bottom on shaft. Install lock bolt. Engage lock bolt

with sector cam surface. Install rack and spring. Block tooth on rack

should engage block tooth on sector.

4) Install external tilt release lever. Install bolt spring

and spring retaining screw. Tighten to 35 INCH lbs. (4 N.m). Install

shift lever spring in bowl by winding up with pliers and pushing in.

Slide bowl into jacket. Install wave washer and jacket mounting plate.

5) Work jacket mounting plate into jacket notches by tipping

jacket mounting plate toward bowl hub at 12 o'clock position and under

jacket opening. Slide jacket mounting plate in jacket notches.

Carefully install shift tube in lower end of jacket.

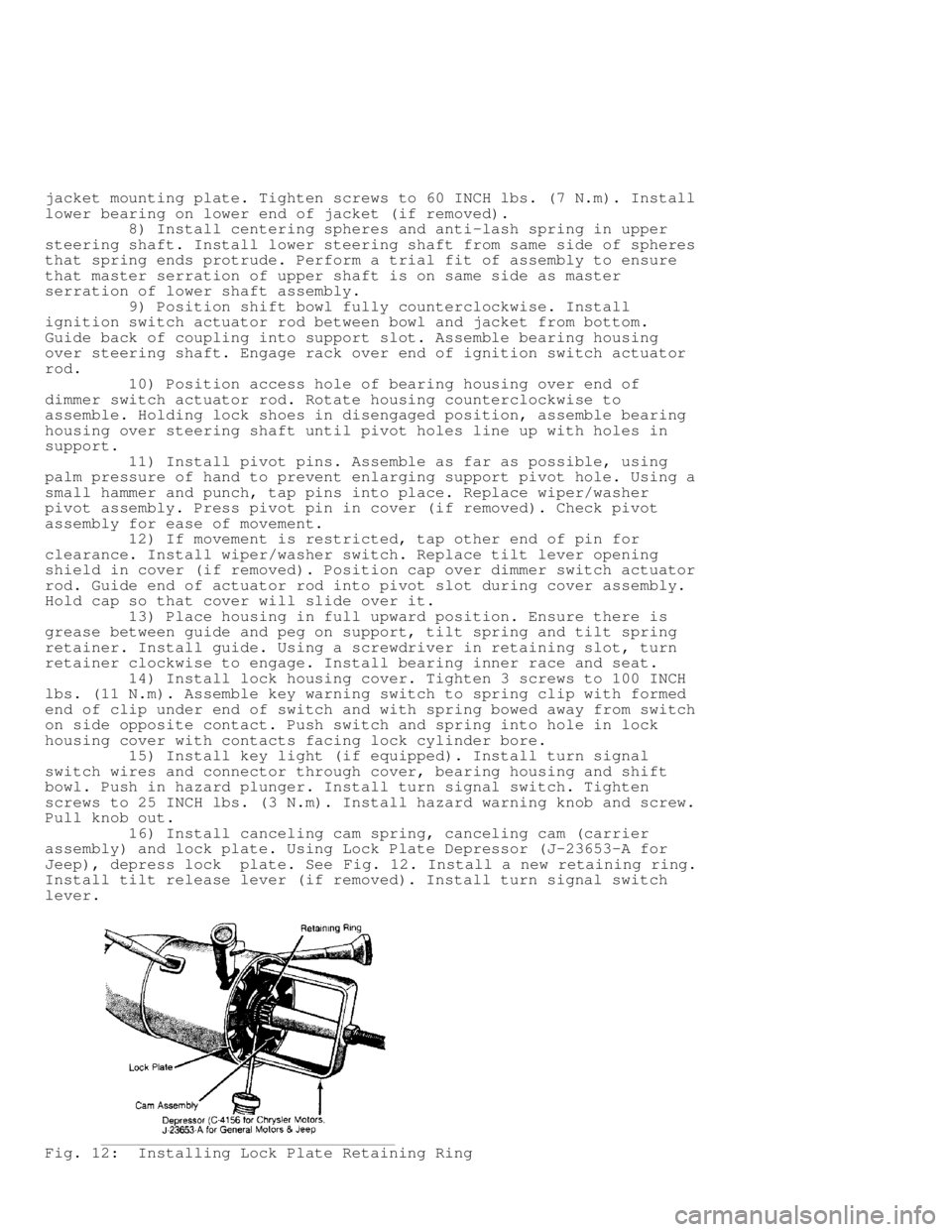

6) Align key in tube with keyway in bowl. Using Puller (J-

23073-01 for Jeep), pull shift tube into bowl. See Fig. 11. DO NOT

push or tap on end of shift tube. By pulling bowl up and compressing

wave washer, install thrust washer and retaining pin.

Fig. 11: Installing Shift Tube on Models With Tilt Wheel

7) Slide dimmer switch actuator rod through hole in support.

Feed rod between bowl and jacket. Install support by aligning notch in

support with notch in jacket. Insert 4 screws through support into

Page 1038 of 1378

jacket mounting plate. Tighten screws to 60 INCH lbs. (7 N.m). Install\

lower bearing on lower end of jacket (if removed).

8) Install centering spheres and anti-lash spring in upper

steering shaft. Install lower steering shaft from same side of spheres

that spring ends protrude. Perform a trial fit of assembly to ensure

that master serration of upper shaft is on same side as master

serration of lower shaft assembly.

9) Position shift bowl fully counterclockwise. Install

ignition switch actuator rod between bowl and jacket from bottom.

Guide back of coupling into support slot. Assemble bearing housing

over steering shaft. Engage rack over end of ignition switch actuator

rod.

10) Position access hole of bearing housing over end of

dimmer switch actuator rod. Rotate housing counterclockwise to

assemble. Holding lock shoes in disengaged position, assemble bearing

housing over steering shaft until pivot holes line up with holes in

support.

11) Install pivot pins. Assemble as far as possible, using

palm pressure of hand to prevent enlarging support pivot hole. Using a

small hammer and punch, tap pins into place. Replace wiper/washer

pivot assembly. Press pivot pin in cover (if removed). Check pivot

assembly for ease of movement.

12) If movement is restricted, tap other end of pin for

clearance. Install wiper/washer switch. Replace tilt lever opening

shield in cover (if removed). Position cap over dimmer switch actuator\

rod. Guide end of actuator rod into pivot slot during cover assembly.

Hold cap so that cover will slide over it.

13) Place housing in full upward position. Ensure there is

grease between guide and peg on support, tilt spring and tilt spring

retainer. Install guide. Using a screwdriver in retaining slot, turn

retainer clockwise to engage. Install bearing inner race and seat.

14) Install lock housing cover. Tighten 3 screws to 100 INCH

lbs. (11 N.m). Assemble key warning switch to spring clip with formed

end of clip under end of switch and with spring bowed away from switch

on side opposite contact. Push switch and spring into hole in lock

housing cover with contacts facing lock cylinder bore.

15) Install key light (if equipped). Install turn signal

switch wires and connector through cover, bearing housing and shift

bowl. Push in hazard plunger. Install turn signal switch. Tighten

screws to 25 INCH lbs. (3 N.m). Install hazard warning knob and screw.\

Pull knob out.

16) Install canceling cam spring, canceling cam (carrier

assembly) and lock plate. Using Lock Plate Depressor (J-23653-A for

Jeep), depress lock plate. See Fig. 12. Install a new retaining ring.

Install tilt release lever (if removed). Install turn signal switch

lever.

Fig. 12: Installing Lock Plate Retaining Ring

Page 1042 of 1378

shaft nut. Place reference mark in relation of pitman arm-to-sector

shaft. Using puller, remove pitman arm.

2) Remove sector shaft cover retaining bolts. Lift sector

shaft and cover from housing. Using a screwdriver, pry sector shaft

seal from housing. Use care not to damage housing area. Note direction

of seal installation.

3) Loosen sector shaft adjusting screw lock nut. Rotate

adjusting screw clockwise and remove cover from sector shaft. Inspect

gear lubricant for contamination. Steering gear must be overhauled if

contamination exists.

4) Lubricate new sector shaft seal with steering gear

lubricant. Position seal in housing bore. Using proper sized socket,

tap seal into housing until it bottoms.

5) Install sector shaft so center tooth of sector shaft

enters center tooth of ball nut. Fill housing with lubricant. Install

new sector shaft cover gasket on gear housing (if equipped). Apply a

thin bead of sealant to sector shaft cover on models which do not use

a gasket.

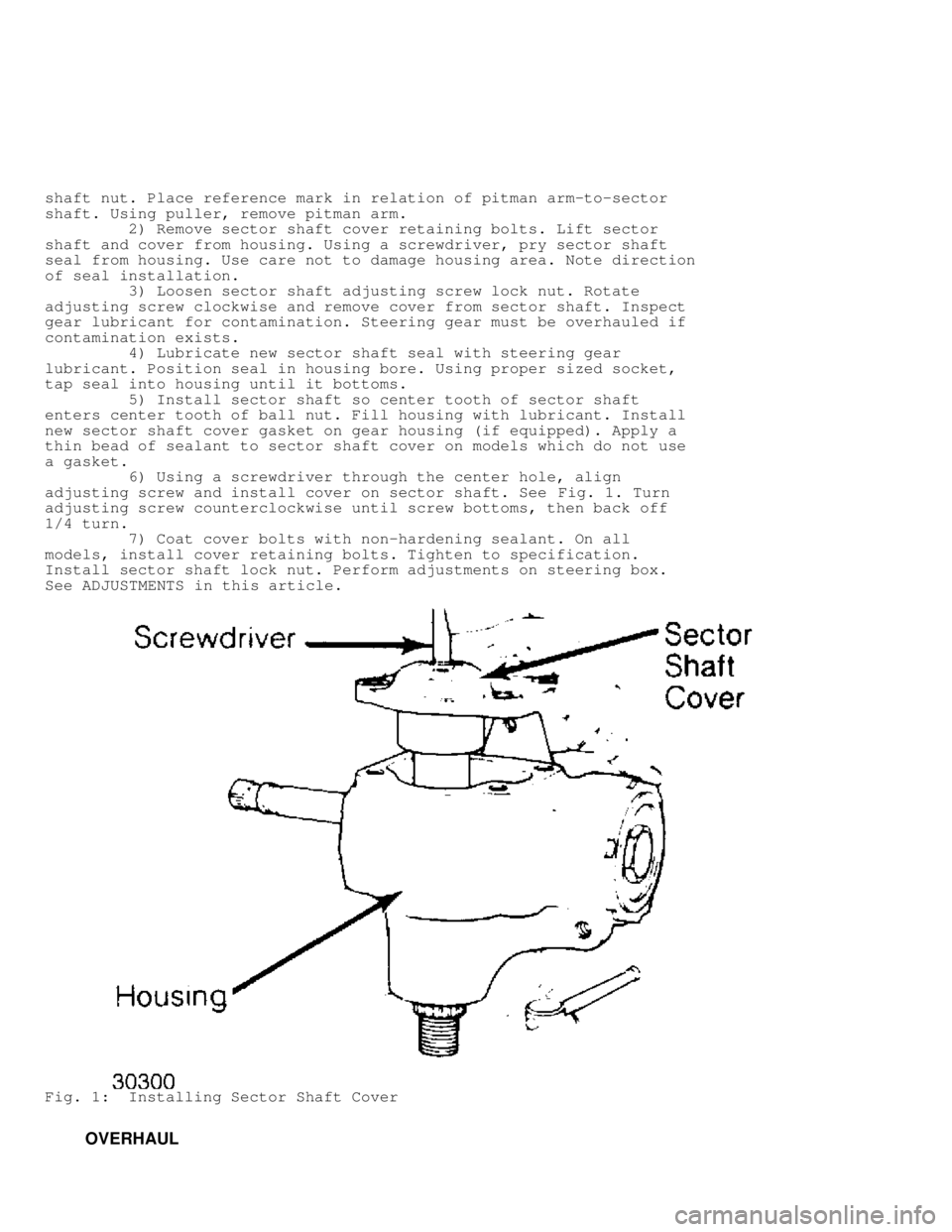

6) Using a screwdriver through the center hole, align

adjusting screw and install cover on sector shaft. See Fig. 1. Turn

adjusting screw counterclockwise until screw bottoms, then back off

1/4 turn.

7) Coat cover bolts with non-hardening sealant. On all

models, install cover retaining bolts. Tighten to specification.

Install sector shaft lock nut. Perform adjustments on steering box.

See ADJUSTMENTS in this article.

Fig. 1: Installing Sector Shaft Cover

OVERHAUL

Page 1043 of 1378

STEERING GEAR

Disassembly

1) Place steering gear in a holding fixture. Worm shaft

should be centered in steering gear. Remove sector shaft cover bolts.

Remove sector shaft and cover from housing.

2) Remove sector shaft adjusting screw lock nut. Rotate

adjusting screw clockwise to remove cover from shaft. DO NOT lose shim

located on adjusting screw.

3) Loosen worm bearing adjuster lock nut. Remove worm bearing

adjuster and worm shaft lower bearing. Remove worm shaft and ball nut

assembly from housing. Remove upper bearing.

CAUTION: DO NOT allow ball nut to rotate down worm shaft as ball

guides may be damaged.

4) If ball nut fails to rotate smoothly on worm shaft,

disassembly is required. Remove ball guide clamp and guides. Rotate

worm shaft in both directions to remove balls. Note and record number

of balls in each circuit area of the ball nut.

5) Note direction of ball nut on worm shaft prior to removal.

Remove ball nut from worm shaft.

CAUTION: Note and record number of balls removed from each circuit of

ball nut during disassembly. Determine location of ball nut

on worm shaft prior to removal. Ball nut must be installed

on worm shaft with shallow teeth in proper direction.

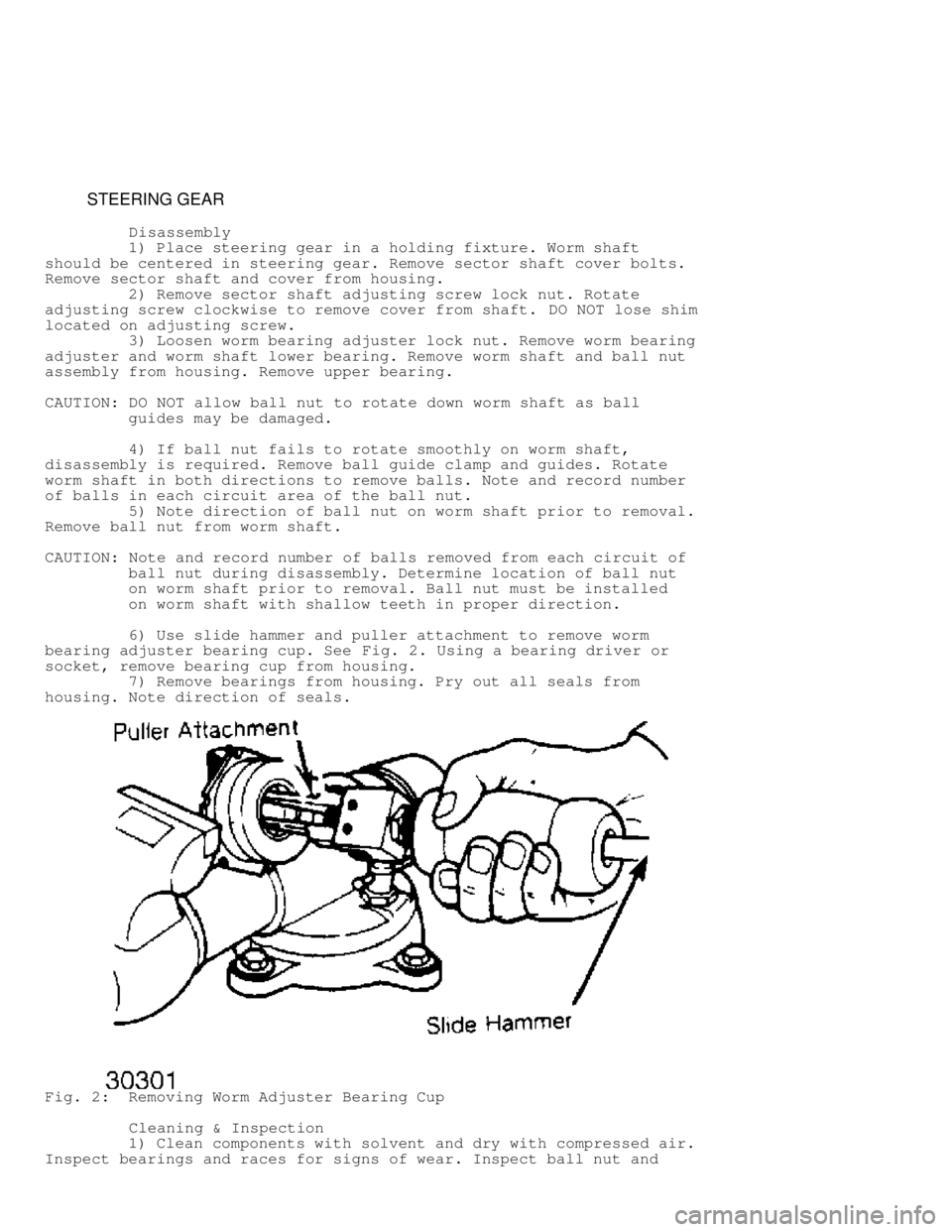

6) Use slide hammer and puller attachment to remove worm

bearing adjuster bearing cup. See Fig. 2. Using a bearing driver or

socket, remove bearing cup from housing.

7) Remove bearings from housing. Pry out all seals from

housing. Note direction of seals.

Fig. 2: Removing Worm Adjuster Bearing Cup

Cleaning & Inspection

1) Clean components with solvent and dry with compressed air.

Inspect bearings and races for signs of wear. Inspect ball nut and

Page 1045 of 1378

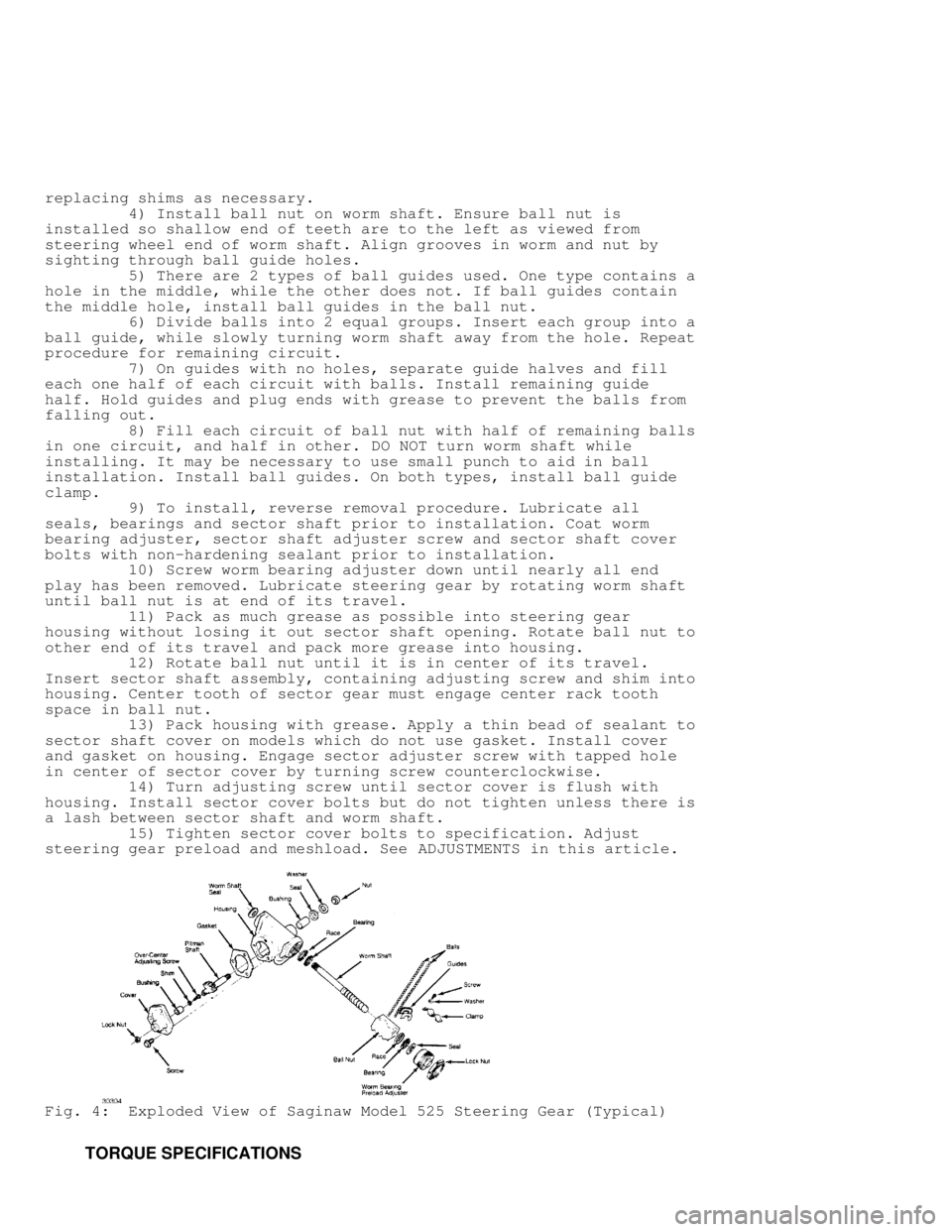

replacing shims as necessary.

4) Install ball nut on worm shaft. Ensure ball nut is

installed so shallow end of teeth are to the left as viewed from

steering wheel end of worm shaft. Align grooves in worm and nut by

sighting through ball guide holes.

5) There are 2 types of ball guides used. One type contains a

hole in the middle, while the other does not. If ball guides contain

the middle hole, install ball guides in the ball nut.

6) Divide balls into 2 equal groups. Insert each group into a

ball guide, while slowly turning worm shaft away from the hole. Repeat

procedure for remaining circuit.

7) On guides with no holes, separate guide halves and fill

each one half of each circuit with balls. Install remaining guide

half. Hold guides and plug ends with grease to prevent the balls from

falling out.

8) Fill each circuit of ball nut with half of remaining balls

in one circuit, and half in other. DO NOT turn worm shaft while

installing. It may be necessary to use small punch to aid in ball

installation. Install ball guides. On both types, install ball guide

clamp.

9) To install, reverse removal procedure. Lubricate all

seals, bearings and sector shaft prior to installation. Coat worm

bearing adjuster, sector shaft adjuster screw and sector shaft cover

bolts with non-hardening sealant prior to installation.

10) Screw worm bearing adjuster down until nearly all end

play has been removed. Lubricate steering gear by rotating worm shaft

until ball nut is at end of its travel.

11) Pack as much grease as possible into steering gear

housing without losing it out sector shaft opening. Rotate ball nut to

other end of its travel and pack more grease into housing.

12) Rotate ball nut until it is in center of its travel.

Insert sector shaft assembly, containing adjusting screw and shim into

housing. Center tooth of sector gear must engage center rack tooth

space in ball nut.

13) Pack housing with grease. Apply a thin bead of sealant to

sector shaft cover on models which do not use gasket. Install cover

and gasket on housing. Engage sector adjuster screw with tapped hole

in center of sector cover by turning screw counterclockwise.

14) Turn adjusting screw until sector cover is flush with

housing. Install sector cover bolts but do not tighten unless there is

a lash between sector shaft and worm shaft.

15) Tighten sector cover bolts to specification. Adjust

steering gear preload and meshload. See ADJUSTMENTS in this article.

Fig. 4: Exploded View of Saginaw Model 525 Steering Gear (Typical)

TORQUE SPECIFICATIONS

Page 1048 of 1378

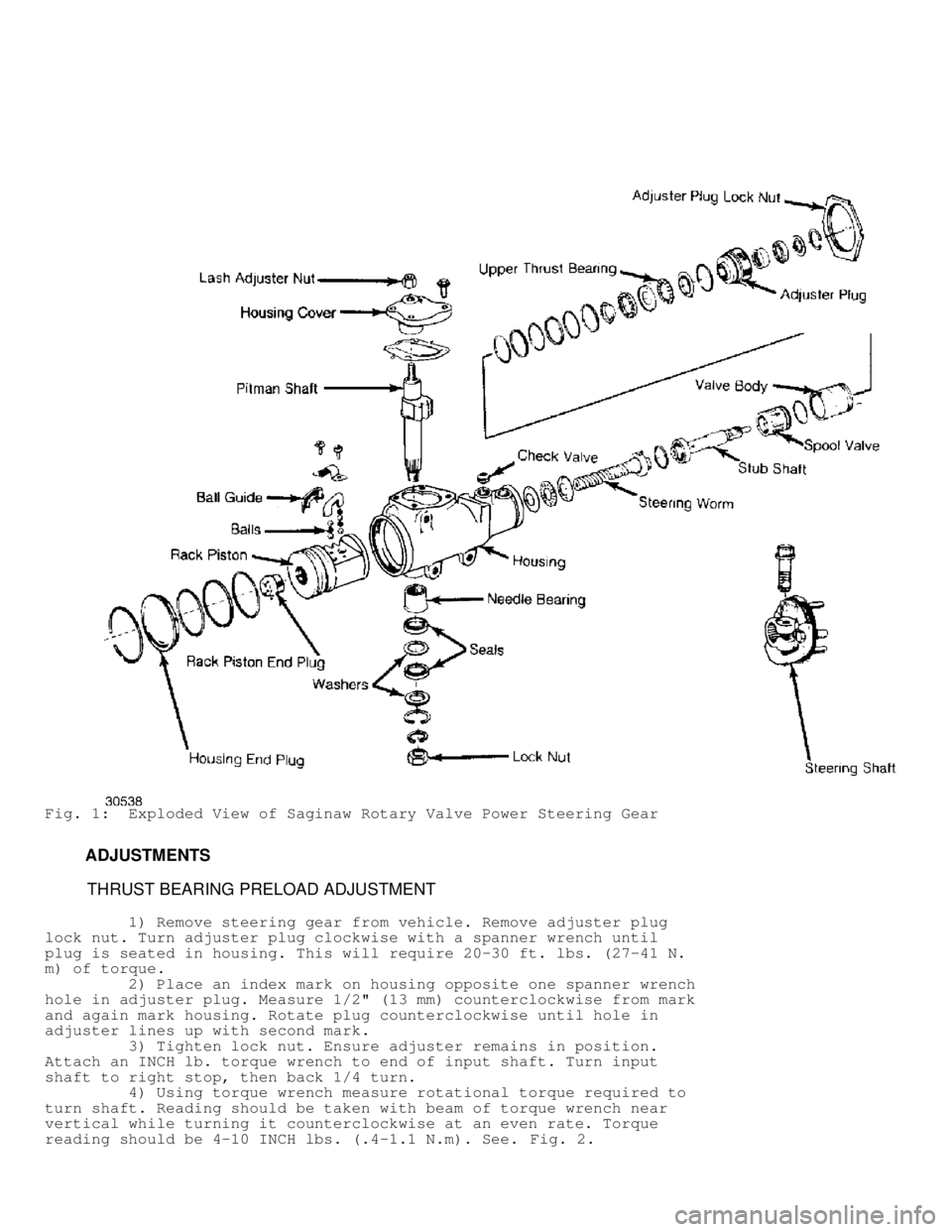

Fig. 1: Exploded View of Saginaw Rotary Valve Power Steering Gear

ADJUSTMENTS

THRUST BEARING PRELOAD ADJUSTMENT

1) Remove steering gear from vehicle. Remove adjuster plug

lock nut. Turn adjuster plug clockwise with a spanner wrench until

plug is seated in housing. This will require 20-30 ft. lbs. (27-41 N.

m) of torque.

2) Place an index mark on housing opposite one spanner wrench

hole in adjuster plug. Measure 1/2" (13 mm) counterclockwise from mark\

and again mark housing. Rotate plug counterclockwise until hole in

adjuster lines up with second mark.

3) Tighten lock nut. Ensure adjuster remains in position.

Attach an INCH lb. torque wrench to end of input shaft. Turn input

shaft to right stop, then back 1/4 turn.

4) Using torque wrench measure rotational torque required to

turn shaft. Reading should be taken with beam of torque wrench near

vertical while turning it counterclockwise at an even rate. Torque

reading should be 4-10 INCH lbs. (.4-1.1 N.m). See. Fig. 2.

Page 1055 of 1378

Cleaning & Inspection

1) Clean all pump components in solvent, and blow dry.

Inspect flow control valve assembly for wear, scoring, burrs and other

damage. Inspect seal bore for burrs, nicks and score marks.

2) Inspect machined surfaces of body for scratches and burrs.

Check "O" ring mating surfaces. Inspect drive shaft and sleeve for

wear.

3) Inspect pump ring for roughness. Check thrust plate and

pressure plate for scoring and wear. Ensure vanes slide freely but fit

snugly into slots. If vanes are loose in slots, replace rotor and/or

vanes.

Reassembly

1) Lubricate all "O" rings, seals, pump ring, rotor and vanes

with petroleum jelly. Install sleeve. Ensure sleeve is fully seated.

2) Install "O" ring in sleeve seat. Install small dowel pin

in pump housing. Install pressure plate spring and "O" ring. Install

pressure plate with dowel pin hole aligned with dowel pin holes.

Install dowel pins.

3) Install pump ring with identification marks located

adjacent to one dowel pin. Install rotor with counterbore toward drive

shaft end of housing.

4) Install vanes with rounded edges toward pump ring. Install

thrust plate "O" ring. Install thrust plate with indentations aligned

with bolt holes of housing. Install retaining ring.

CAUTION: Pump ring must be installed with identification marks

located adjacent to dowel pins. Thrust plate must be

installed so indentations in thrust plate align with bolt

holes of housing and thrust plate engages with pump ring

dowel pins.

5) Using a socket, install drive shaft seal in housing until

seal bottoms. Support drive shaft bearing on inner race, and press

drive shaft into bearing. Install drive shaft and bearing in pump

housing.

6) Rotate drive shaft during installation to align with rotor

serrations. Ensure bearing is fully seated in pump housing. Snap ring

should be installed with large lug area (near snap ring pliers hole)

positioned right of small lug (near snap ring pliers hole), ensuring

beveled area of snap ring is properly positioned.

7) Install spring, flow control valve and "O" rings. Install

return tube with new "O" ring. Install pulley.

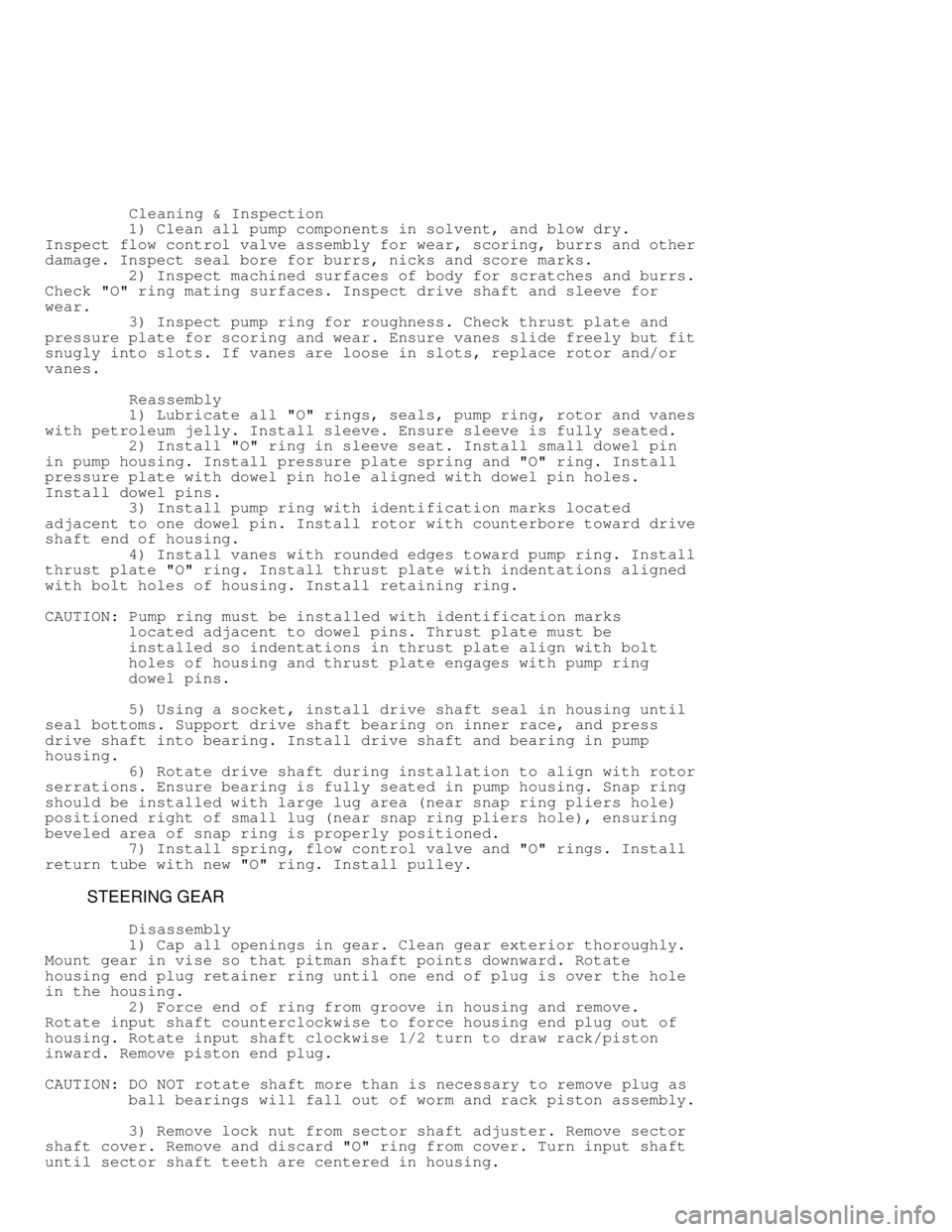

STEERING GEAR

Disassembly

1) Cap all openings in gear. Clean gear exterior thoroughly.

Mount gear in vise so that pitman shaft points downward. Rotate

housing end plug retainer ring until one end of plug is over the hole

in the housing.

2) Force end of ring from groove in housing and remove.

Rotate input shaft counterclockwise to force housing end plug out of

housing. Rotate input shaft clockwise 1/2 turn to draw rack/piston

inward. Remove piston end plug.

CAUTION: DO NOT rotate shaft more than is necessary to remove plug as

ball bearings will fall out of worm and rack piston assembly.

3) Remove lock nut from sector shaft adjuster. Remove sector

shaft cover. Remove and discard "O" ring from cover. Turn input shaft

until sector shaft teeth are centered in housing.

Page 1056 of 1378

4) Tap end of sector shaft with a soft-faced hammer to free

shaft from housing, then remove sector shaft. Remove adjuster plug

lock nut. Remove adjuster plug with a spanner wrench.

5) Insert a rack/piston arbor into end of rack/piston until

arbor just contacts worm shaft. Turn stub shaft counterclockwise to

force rack/piston onto arbor. Remove rack/piston and arbor as an

assembly.

6) Take care to keep arbor fully inserted so ball bearings

will not fall out. Remove input shaft and control valve assembly from

housing. Remove worm, wormshaft lower thrust bearing, and races from

housing.

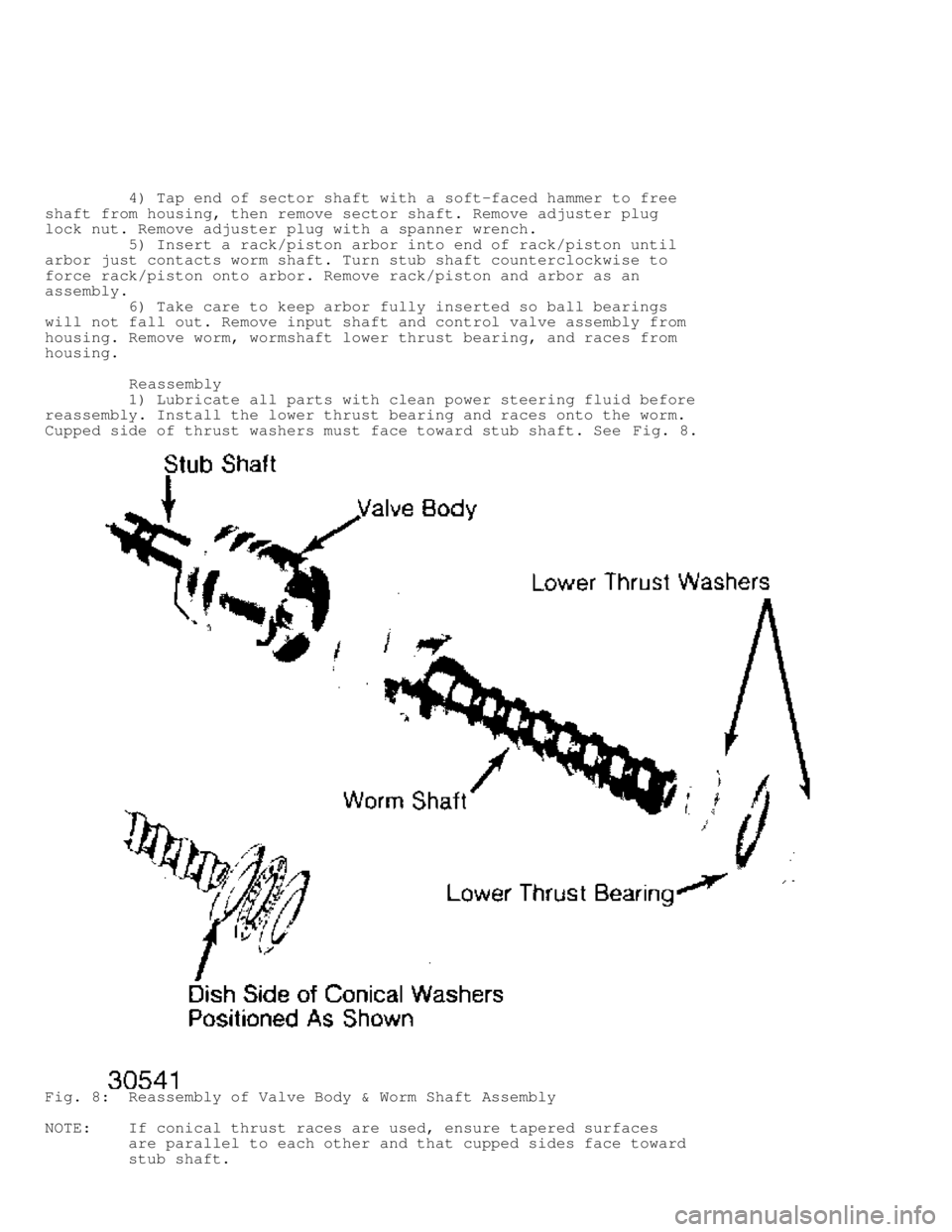

Reassembly

1) Lubricate all parts with clean power steering fluid before

reassembly. Install the lower thrust bearing and races onto the worm.

Cupped side of thrust washers must face toward stub shaft. See Fig. 8.

Fig. 8: Reassembly of Valve Body & Worm Shaft Assembly

NOTE: If conical thrust races are used, ensure tapered surfaces

are parallel to each other and that cupped sides face toward

stub shaft.

Page 1057 of 1378

2) Install stub shaft cap "O" ring in valve body. Align valve

body drive pin on worm with narrow pin slot in valve body. Worm drive

lugs must engage in stub shaft cap.

3) Install valve body and worm assembly into housing. Perform

installation by pressing directly on valve body only. This will

prevent stub shaft "O" ring from disengaging from valve body.

4) Valve body is correctly seated when fluid return port in

housing is fully visible. Ensure worm locating pin is fully engaged in

valve body. Place seal protector over input shaft, install a new

adjuster plug "O" ring, then install adjuster plug.

5) Remove seal protector from housing and loosely install

adjuster plug lock nut. Insert arbor and rack/piston into housing.

Align worm and rack/piston and turn stub shaft clockwise to engage

worm. Maintain pressure on arbor until worm is fully engaged.

6) Turn input shaft clockwise until middle rack groove in

rack/piston is aligned with center of sector shaft roller bearing.

Remove arbor. Install a new sector shaft cover gasket.

7) Thread sector shaft cover onto adjuster screw until

bottomed. Back off 1 1/2 turns. Install sector shaft so that center

gear tooth meshes with center groove in rack/piston. Install cover

attaching bolts.

8) Install adjuster lock nut halfway onto sector shaft.

Install piston and plug in rack/piston. Install housing end plug "O"

ring, end plug and retainer ring. Adjust worm bearing preload and

over-center preload at this time.

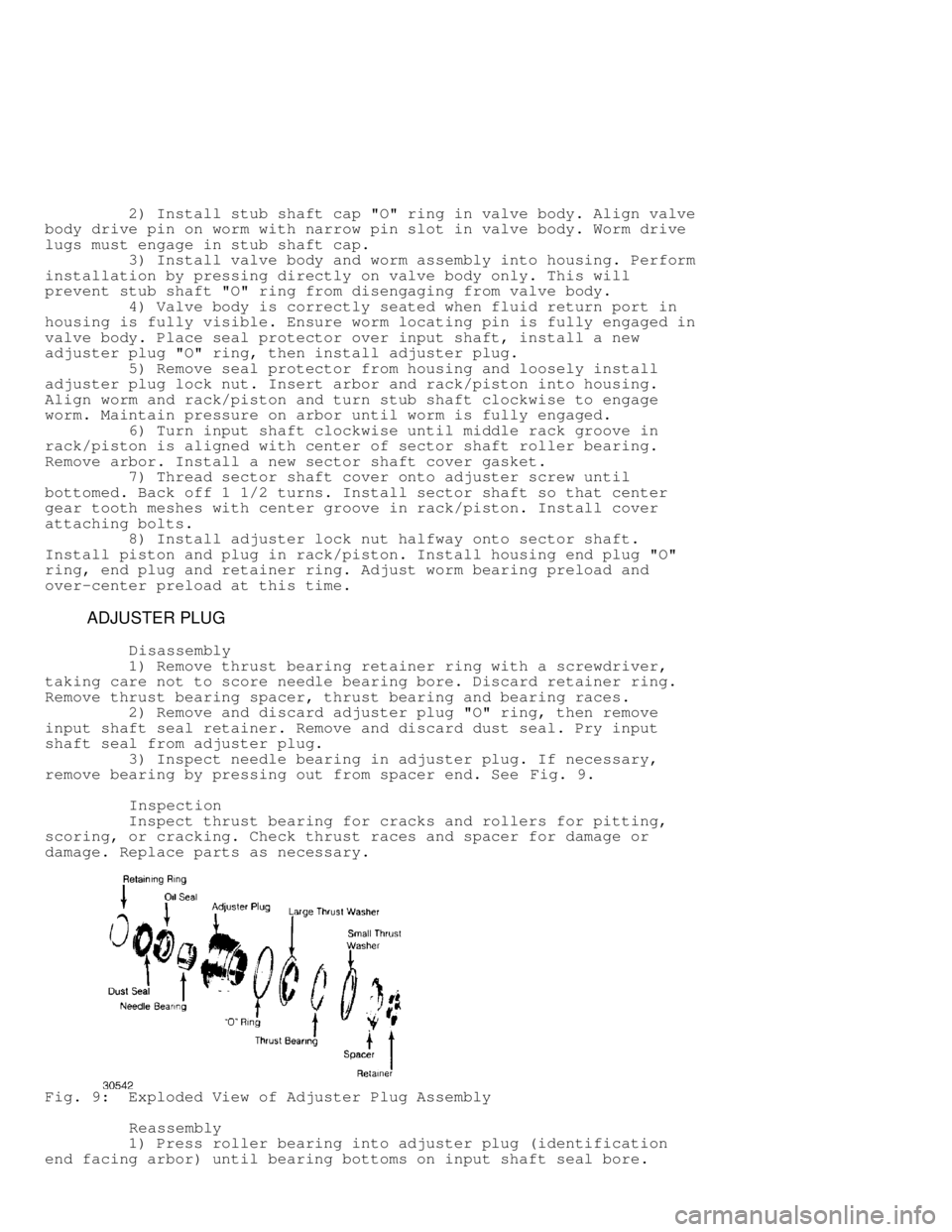

ADJUSTER PLUG

Disassembly

1) Remove thrust bearing retainer ring with a screwdriver,

taking care not to score needle bearing bore. Discard retainer ring.

Remove thrust bearing spacer, thrust bearing and bearing races.

2) Remove and discard adjuster plug "O" ring, then remove

input shaft seal retainer. Remove and discard dust seal. Pry input

shaft seal from adjuster plug.

3) Inspect needle bearing in adjuster plug. If necessary,

remove bearing by pressing out from spacer end. See Fig. 9.

Inspection

Inspect thrust bearing for cracks and rollers for pitting,

scoring, or cracking. Check thrust races and spacer for damage or

damage. Replace parts as necessary.

Fig. 9: Exploded View of Adjuster Plug Assembly

Reassembly

1) Press roller bearing into adjuster plug (identification

end facing arbor) until bearing bottoms on input shaft seal bore.