key JEEP CHEROKEE 1994 Service Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1510 of 1784

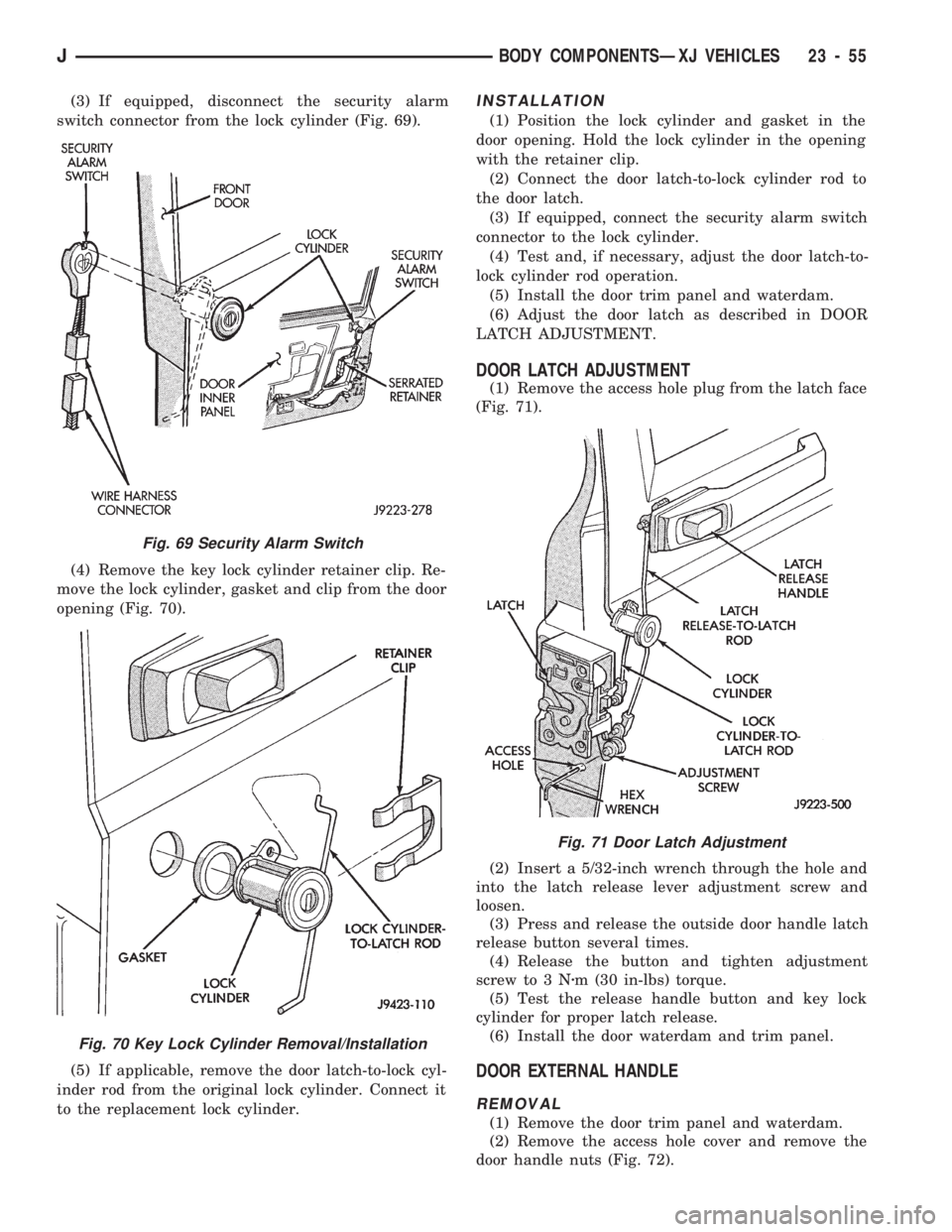

(3) If equipped, disconnect the security alarm

switch connector from the lock cylinder (Fig. 69).

(4) Remove the key lock cylinder retainer clip. Re-

move the lock cylinder, gasket and clip from the door

opening (Fig. 70).

(5) If applicable, remove the door latch-to-lock cyl-

inder rod from the original lock cylinder. Connect it

to the replacement lock cylinder.INSTALLATION

(1) Position the lock cylinder and gasket in the

door opening. Hold the lock cylinder in the opening

with the retainer clip.

(2) Connect the door latch-to-lock cylinder rod to

the door latch.

(3) If equipped, connect the security alarm switch

connector to the lock cylinder.

(4) Test and, if necessary, adjust the door latch-to-

lock cylinder rod operation.

(5) Install the door trim panel and waterdam.

(6) Adjust the door latch as described in DOOR

LATCH ADJUSTMENT.

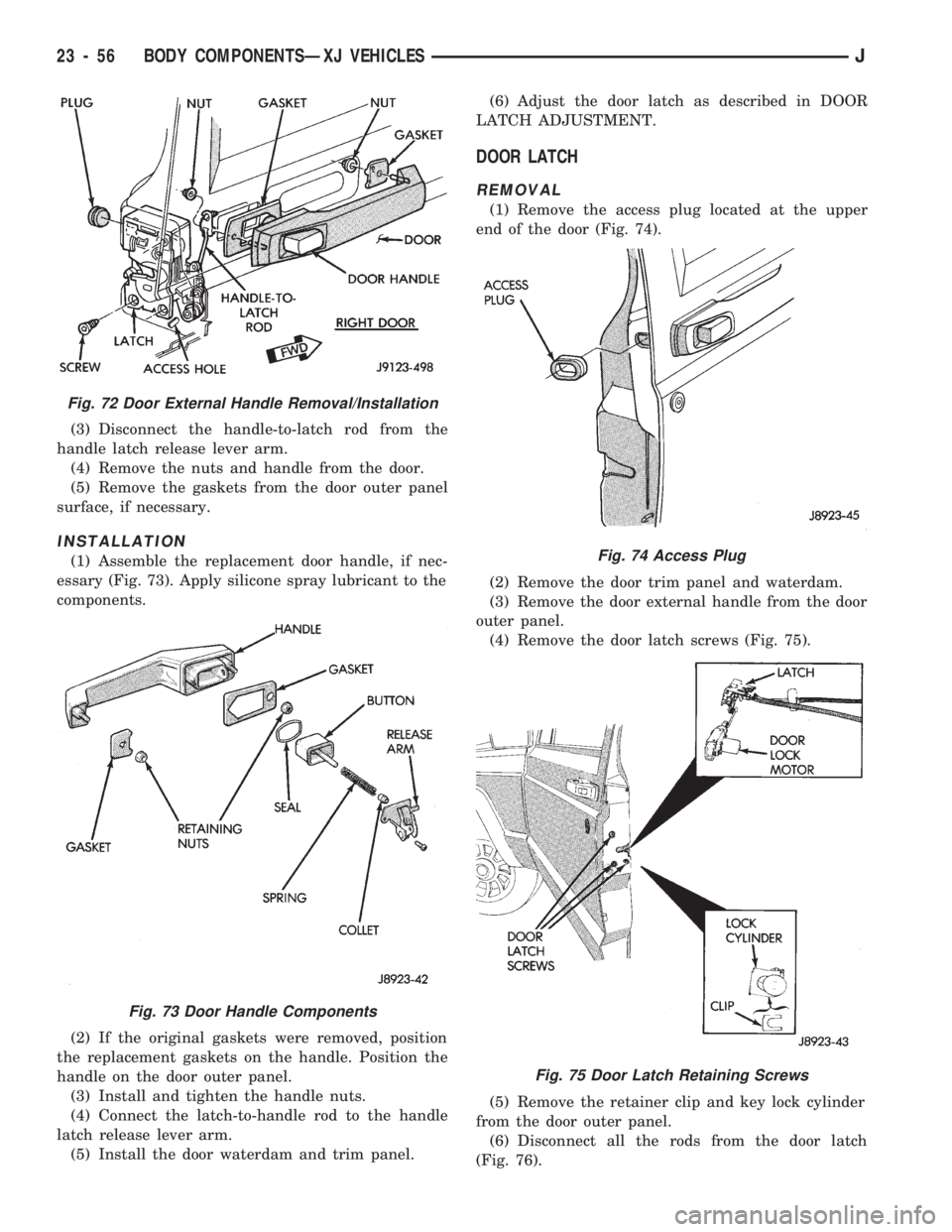

DOOR LATCH ADJUSTMENT

(1) Remove the access hole plug from the latch face

(Fig. 71).

(2) Insert a 5/32-inch wrench through the hole and

into the latch release lever adjustment screw and

loosen.

(3) Press and release the outside door handle latch

release button several times.

(4) Release the button and tighten adjustment

screw to 3 Nzm (30 in-lbs) torque.

(5) Test the release handle button and key lock

cylinder for proper latch release.

(6) Install the door waterdam and trim panel.

DOOR EXTERNAL HANDLE

REMOVAL

(1) Remove the door trim panel and waterdam.

(2) Remove the access hole cover and remove the

door handle nuts (Fig. 72).

Fig. 71 Door Latch Adjustment

Fig. 69 Security Alarm Switch

Fig. 70 Key Lock Cylinder Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 55

Page 1511 of 1784

(3) Disconnect the handle-to-latch rod from the

handle latch release lever arm.

(4) Remove the nuts and handle from the door.

(5) Remove the gaskets from the door outer panel

surface, if necessary.

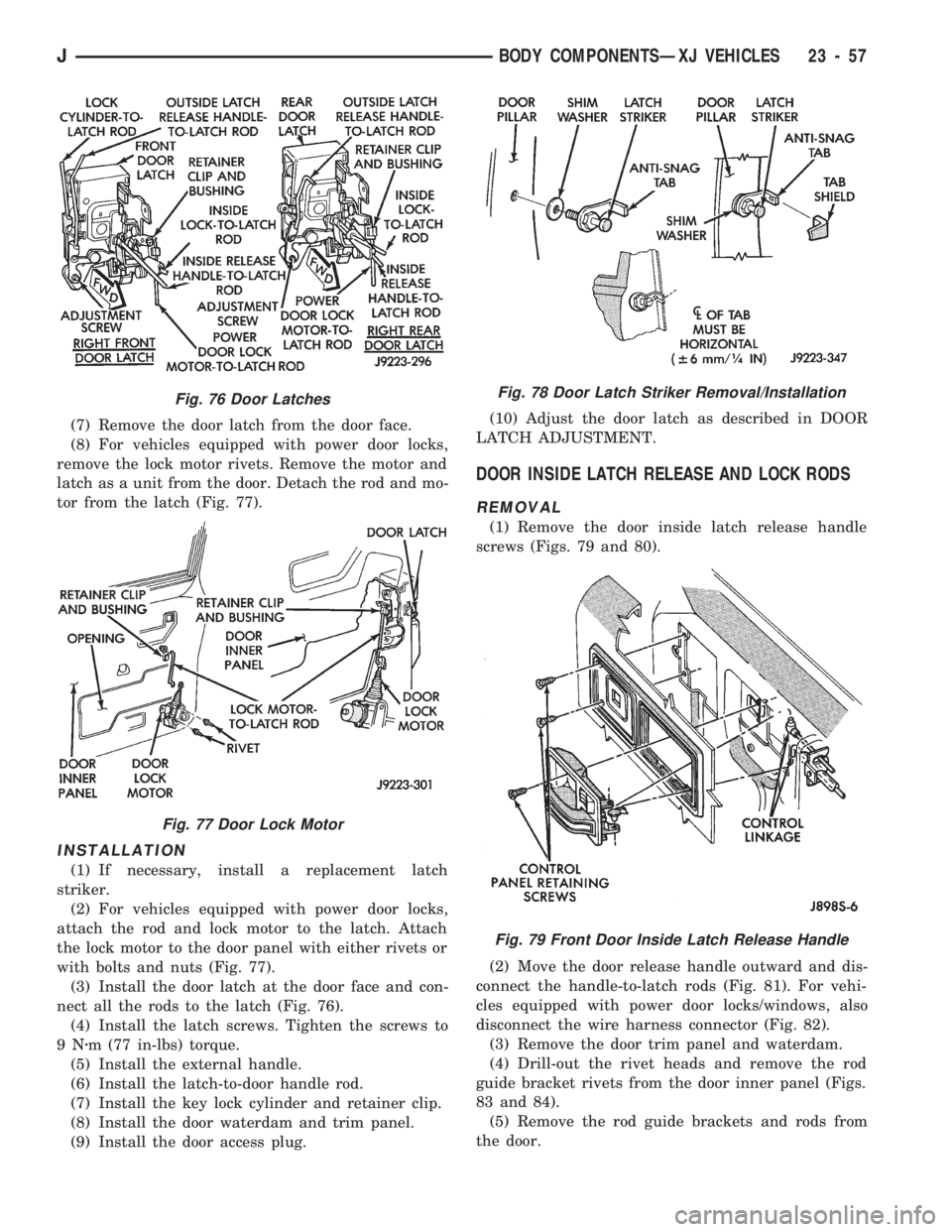

INSTALLATION

(1) Assemble the replacement door handle, if nec-

essary (Fig. 73). Apply silicone spray lubricant to the

components.

(2) If the original gaskets were removed, position

the replacement gaskets on the handle. Position the

handle on the door outer panel.

(3) Install and tighten the handle nuts.

(4) Connect the latch-to-handle rod to the handle

latch release lever arm.

(5) Install the door waterdam and trim panel.(6) Adjust the door latch as described in DOOR

LATCH ADJUSTMENT.

DOOR LATCH

REMOVAL

(1) Remove the access plug located at the upper

end of the door (Fig. 74).

(2) Remove the door trim panel and waterdam.

(3) Remove the door external handle from the door

outer panel.

(4) Remove the door latch screws (Fig. 75).

(5) Remove the retainer clip and key lock cylinder

from the door outer panel.

(6) Disconnect all the rods from the door latch

(Fig. 76).

Fig. 72 Door External Handle Removal/Installation

Fig. 73 Door Handle Components

Fig. 74 Access Plug

Fig. 75 Door Latch Retaining Screws

23 - 56 BODY COMPONENTSÐXJ VEHICLESJ

Page 1512 of 1784

(7) Remove the door latch from the door face.

(8) For vehicles equipped with power door locks,

remove the lock motor rivets. Remove the motor and

latch as a unit from the door. Detach the rod and mo-

tor from the latch (Fig. 77).

INSTALLATION

(1) If necessary, install a replacement latch

striker.

(2) For vehicles equipped with power door locks,

attach the rod and lock motor to the latch. Attach

the lock motor to the door panel with either rivets or

with bolts and nuts (Fig. 77).

(3) Install the door latch at the door face and con-

nect all the rods to the latch (Fig. 76).

(4) Install the latch screws. Tighten the screws to

9Nzm (77 in-lbs) torque.

(5) Install the external handle.

(6) Install the latch-to-door handle rod.

(7) Install the key lock cylinder and retainer clip.

(8) Install the door waterdam and trim panel.

(9) Install the door access plug.(10) Adjust the door latch as described in DOOR

LATCH ADJUSTMENT.

DOOR INSIDE LATCH RELEASE AND LOCK RODS

REMOVAL

(1) Remove the door inside latch release handle

screws (Figs. 79 and 80).

(2) Move the door release handle outward and dis-

connect the handle-to-latch rods (Fig. 81). For vehi-

cles equipped with power door locks/windows, also

disconnect the wire harness connector (Fig. 82).

(3) Remove the door trim panel and waterdam.

(4) Drill-out the rivet heads and remove the rod

guide bracket rivets from the door inner panel (Figs.

83 and 84).

(5) Remove the rod guide brackets and rods from

the door.

Fig. 76 Door Latches

Fig. 77 Door Lock Motor

Fig. 78 Door Latch Striker Removal/Installation

Fig. 79 Front Door Inside Latch Release Handle

JBODY COMPONENTSÐXJ VEHICLES 23 - 57

Page 1523 of 1784

(2) Install and tighten hinge-to-roof panel nuts to 9

Nzm (7 ft-lbs) torque.

(3) Install the liftgate-to-hinge screws. Tighten

screws to 9 Nzm (7 ft-lbs) torque.

(4) Install the liftgate (headliner) upper trim moul-

ding (Fig. 111).

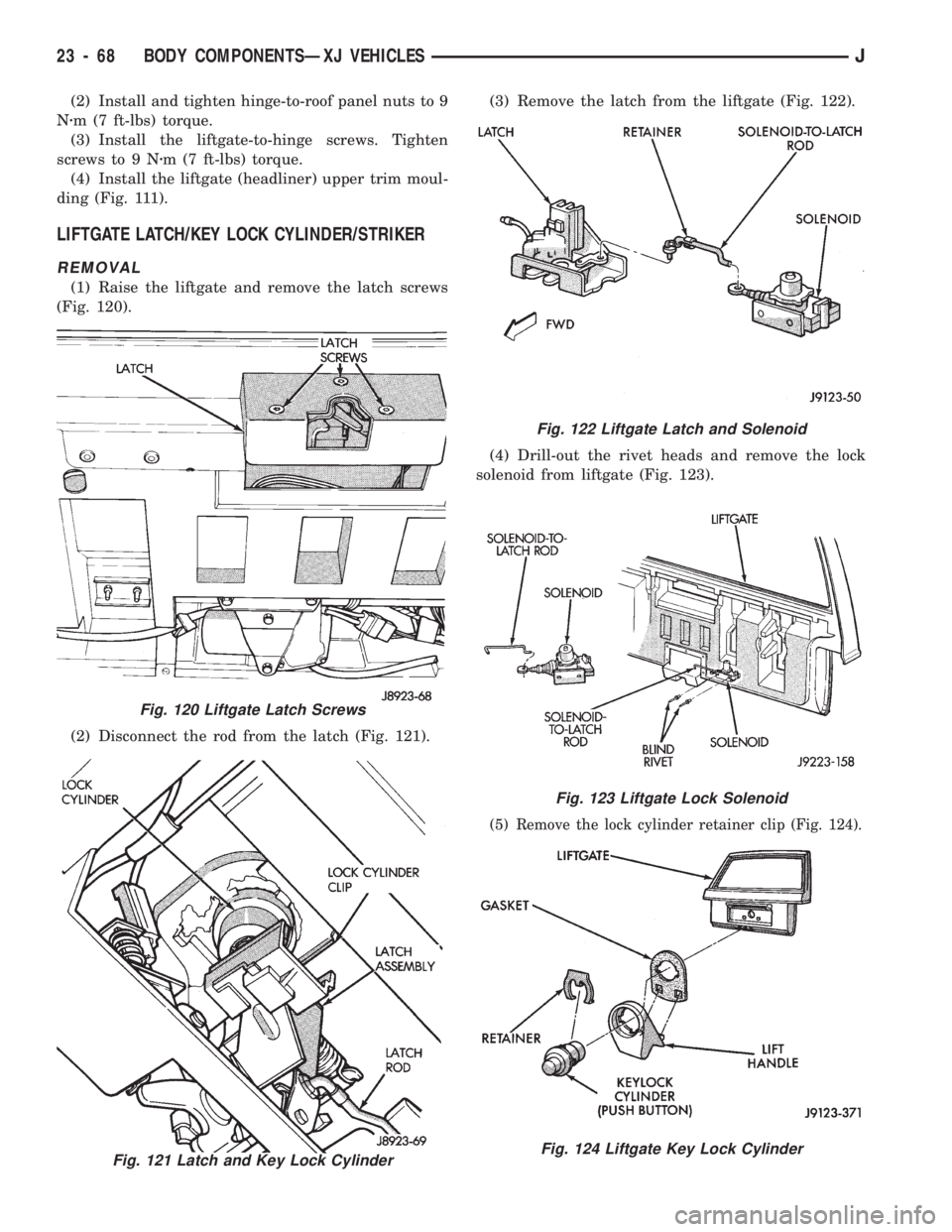

LIFTGATE LATCH/KEY LOCK CYLINDER/STRIKER

REMOVAL

(1) Raise the liftgate and remove the latch screws

(Fig. 120).

(2) Disconnect the rod from the latch (Fig. 121).(3) Remove the latch from the liftgate (Fig. 122).

(4) Drill-out the rivet heads and remove the lock

solenoid from liftgate (Fig. 123).

(5) Remove the lock cylinder retainer clip (Fig. 124).

Fig. 121 Latch and Key Lock Cylinder

Fig. 122 Liftgate Latch and Solenoid

Fig. 123 Liftgate Lock Solenoid

Fig. 124 Liftgate Key Lock Cylinder

Fig. 120 Liftgate Latch Screws

23 - 68 BODY COMPONENTSÐXJ VEHICLESJ

Page 1524 of 1784

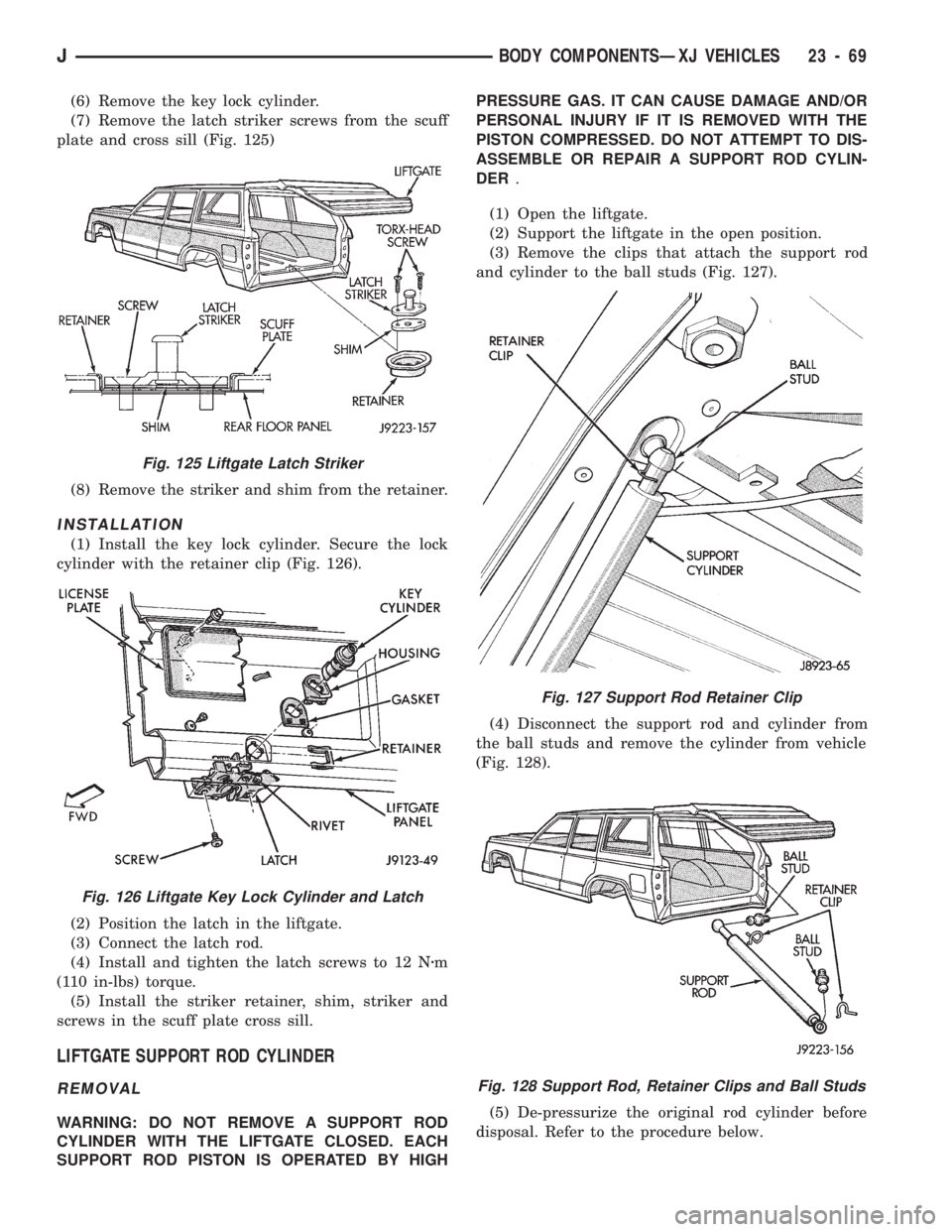

(6) Remove the key lock cylinder.

(7) Remove the latch striker screws from the scuff

plate and cross sill (Fig. 125)

(8) Remove the striker and shim from the retainer.

INSTALLATION

(1) Install the key lock cylinder. Secure the lock

cylinder with the retainer clip (Fig. 126).

(2) Position the latch in the liftgate.

(3) Connect the latch rod.

(4) Install and tighten the latch screws to 12 Nzm

(110 in-lbs) torque.

(5) Install the striker retainer, shim, striker and

screws in the scuff plate cross sill.

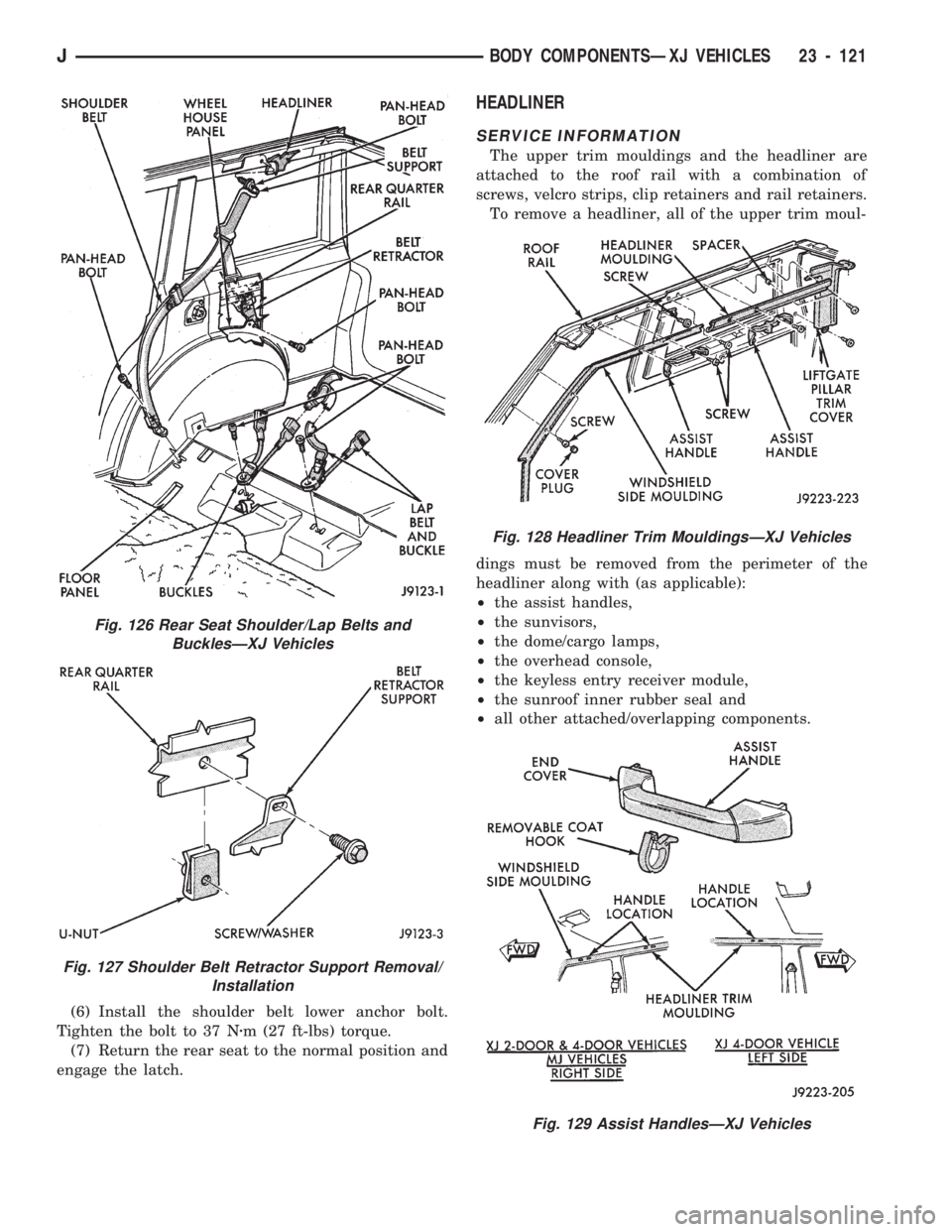

LIFTGATE SUPPORT ROD CYLINDER

REMOVAL

WARNING: DO NOT REMOVE A SUPPORT ROD

CYLINDER WITH THE LIFTGATE CLOSED. EACH

SUPPORT ROD PISTON IS OPERATED BY HIGHPRESSURE GAS. IT CAN CAUSE DAMAGE AND/OR

PERSONAL INJURY IF IT IS REMOVED WITH THE

PISTON COMPRESSED. DO NOT ATTEMPT TO DIS-

ASSEMBLE OR REPAIR A SUPPORT ROD CYLIN-

DER.

(1) Open the liftgate.

(2) Support the liftgate in the open position.

(3) Remove the clips that attach the support rod

and cylinder to the ball studs (Fig. 127).

(4) Disconnect the support rod and cylinder from

the ball studs and remove the cylinder from vehicle

(Fig. 128).

(5) De-pressurize the original rod cylinder before

disposal. Refer to the procedure below.

Fig. 127 Support Rod Retainer Clip

Fig. 128 Support Rod, Retainer Clips and Ball Studs

Fig. 125 Liftgate Latch Striker

Fig. 126 Liftgate Key Lock Cylinder and Latch

JBODY COMPONENTSÐXJ VEHICLES 23 - 69

Page 1576 of 1784

(6) Install the shoulder belt lower anchor bolt.

Tighten the bolt to 37 Nzm (27 ft-lbs) torque.

(7) Return the rear seat to the normal position and

engage the latch.

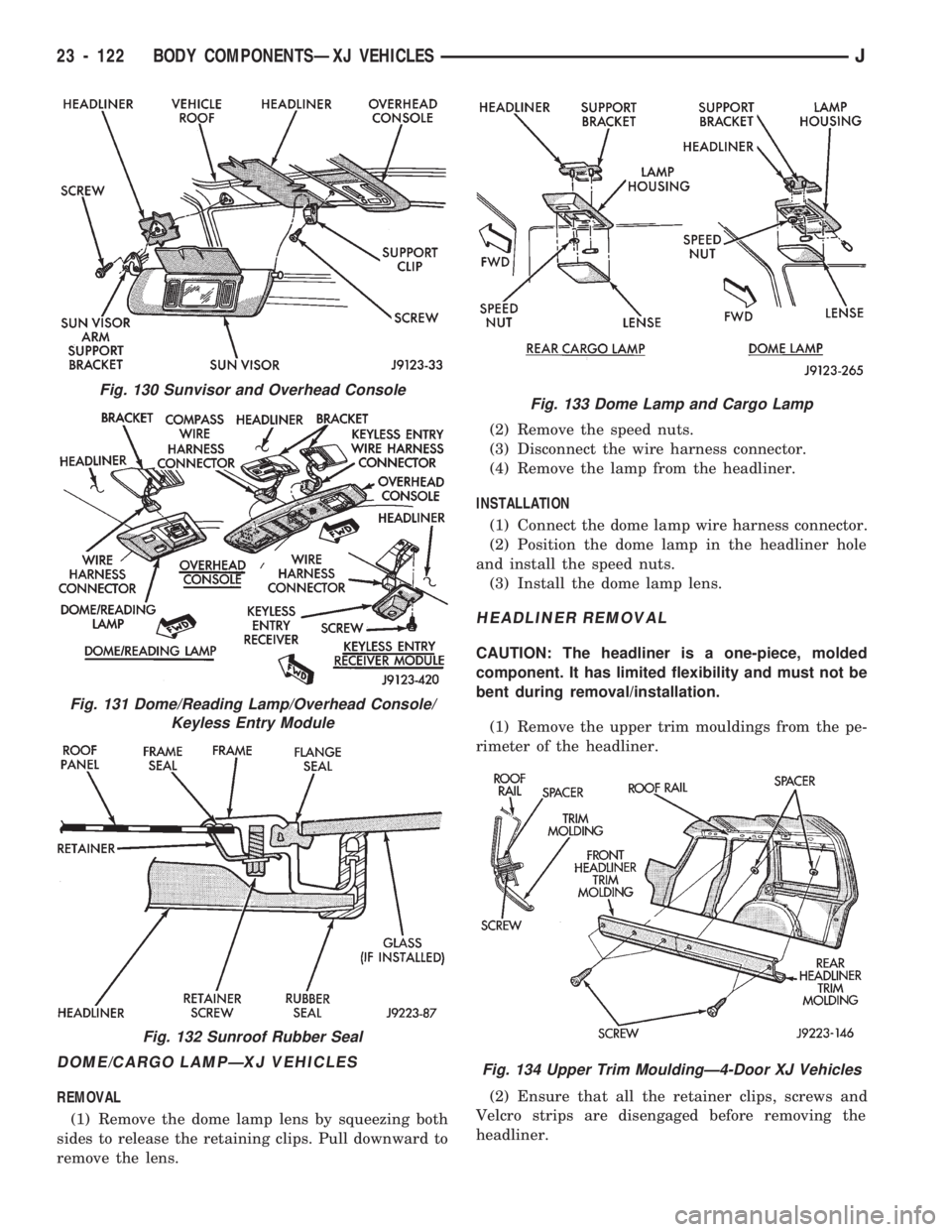

HEADLINER

SERVICE INFORMATION

The upper trim mouldings and the headliner are

attached to the roof rail with a combination of

screws, velcro strips, clip retainers and rail retainers.

To remove a headliner, all of the upper trim moul-

dings must be removed from the perimeter of the

headliner along with (as applicable):

²the assist handles,

²the sunvisors,

²the dome/cargo lamps,

²the overhead console,

²the keyless entry receiver module,

²the sunroof inner rubber seal and

²all other attached/overlapping components.

Fig. 128 Headliner Trim MouldingsÐXJ Vehicles

Fig. 129 Assist HandlesÐXJ Vehicles

Fig. 126 Rear Seat Shoulder/Lap Belts and

BucklesÐXJ Vehicles

Fig. 127 Shoulder Belt Retractor Support Removal/

Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 121

Page 1577 of 1784

DOME/CARGO LAMPÐXJ VEHICLES

REMOVAL

(1) Remove the dome lamp lens by squeezing both

sides to release the retaining clips. Pull downward to

remove the lens.(2) Remove the speed nuts.

(3) Disconnect the wire harness connector.

(4) Remove the lamp from the headliner.

INSTALLATION

(1) Connect the dome lamp wire harness connector.

(2) Position the dome lamp in the headliner hole

and install the speed nuts.

(3) Install the dome lamp lens.

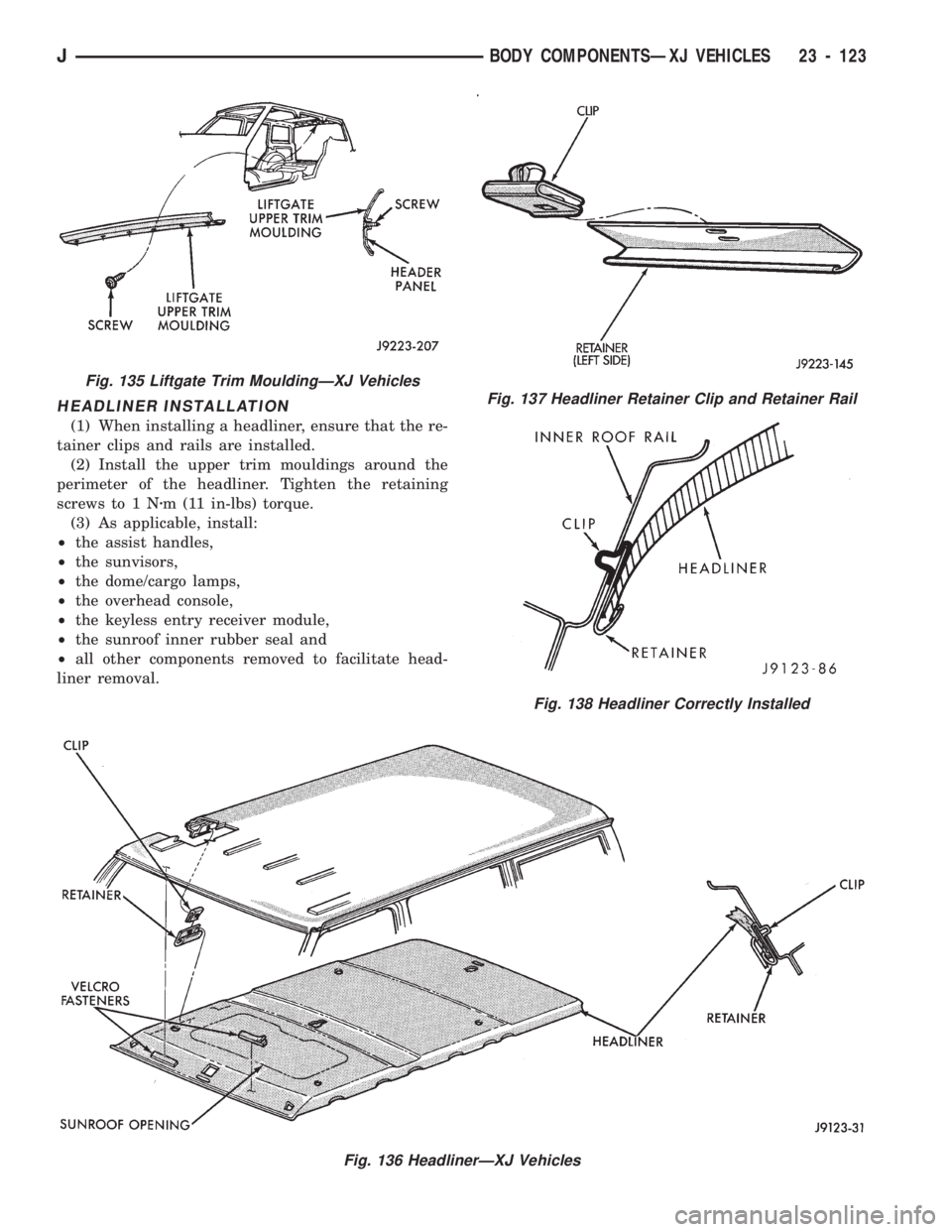

HEADLINER REMOVAL

CAUTION: The headliner is a one-piece, molded

component. It has limited flexibility and must not be

bent during removal/installation.

(1) Remove the upper trim mouldings from the pe-

rimeter of the headliner.

(2) Ensure that all the retainer clips, screws and

Velcro strips are disengaged before removing the

headliner.

Fig. 130 Sunvisor and Overhead Console

Fig. 131 Dome/Reading Lamp/Overhead Console/

Keyless Entry Module

Fig. 132 Sunroof Rubber Seal

Fig. 133 Dome Lamp and Cargo Lamp

Fig. 134 Upper Trim MouldingÐ4-Door XJ Vehicles

23 - 122 BODY COMPONENTSÐXJ VEHICLESJ

Page 1578 of 1784

HEADLINER INSTALLATION

(1) When installing a headliner, ensure that the re-

tainer clips and rails are installed.

(2) Install the upper trim mouldings around the

perimeter of the headliner. Tighten the retaining

screws to 1 Nzm (11 in-lbs) torque.

(3) As applicable, install:

²the assist handles,

²the sunvisors,

²the dome/cargo lamps,

²the overhead console,

²the keyless entry receiver module,

²the sunroof inner rubber seal and

²all other components removed to facilitate head-

liner removal.

Fig. 136 HeadlinerÐXJ Vehicles

Fig. 137 Headliner Retainer Clip and Retainer Rail

Fig. 138 Headliner Correctly Installed

Fig. 135 Liftgate Trim MouldingÐXJ Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 123

Page 1587 of 1784

BODY COMPONENTSÐYJ VEHICLES

CONTENTS

page page

ADD-A-TRUNK........................ 198

DOORS.............................. 172

EXTERIOR COMPONENTS............... 134FIXED WINDOW GLASS................ 181

GENERAL SERVICE INFORMATION........ 132

INTERIOR COMPONENTS............... 188

GENERAL SERVICE INFORMATION

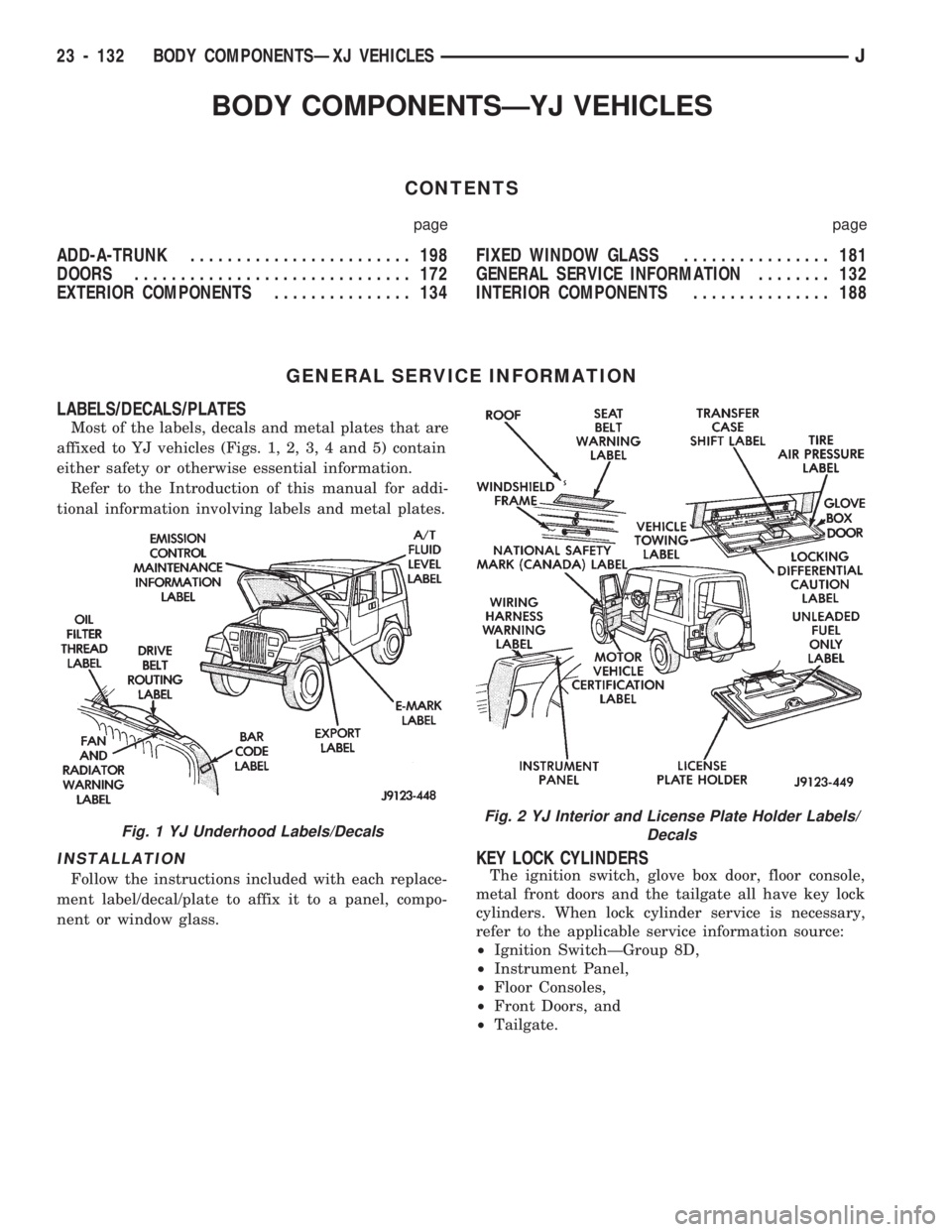

LABELS/DECALS/PLATES

Most of the labels, decals and metal plates that are

affixed to YJ vehicles (Figs. 1, 2, 3, 4 and 5) contain

either safety or otherwise essential information.

Refer to the Introduction of this manual for addi-

tional information involving labels and metal plates.

INSTALLATION

Follow the instructions included with each replace-

ment label/decal/plate to affix it to a panel, compo-

nent or window glass.

KEY LOCK CYLINDERS

The ignition switch, glove box door, floor console,

metal front doors and the tailgate all have key lock

cylinders. When lock cylinder service is necessary,

refer to the applicable service information source:

²Ignition SwitchÐGroup 8D,

²Instrument Panel,

²Floor Consoles,

²Front Doors, and

²Tailgate.

Fig. 1 YJ Underhood Labels/DecalsFig. 2 YJ Interior and License Plate Holder Labels/

Decals

23 - 132 BODY COMPONENTSÐXJ VEHICLESJ

Page 1609 of 1784

The following equipment and material are neces-

sary for body stripe/decal removal and installation:

²a commercial tape stripe/decal removal solution;

²a commercial adhesive removal solution;

²liquid dish detergent (for the wetting solution);

²a mixture of wetting solution;

²a commercial wax and silicone removal solution;

²isopropyl (rubbing) alcohol;

²a small squeegee (plastic or hard rubber);

²a water bucket and sponge;

²clean wiping rags or paper towels;

²a heat gun (or infra-red heat bulb);

²a wax pencil;

²a sharp knife, single edge razor blade or X-acto

knife;

²a pair of scissors; and

²a needle or pin.

A wetting solution assures a better bond between

the painted surface of the body and the tape stripe/

decal. Prepare a supply of wetting solution by mixing

two or three teaspoons of dish detergent with 1 gal-

lon of water.Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

REMOVAL

The key to successful tape stripe/decal re-

moval is to apply heat to area and slowly peel

stripe/decal from panel.

(1) Clean the repaired surface, adjacent panels and

door openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from the panel.

WARNING: USE THE TAPE STRIPE/DECAL RE-

MOVAL SOLUTION IN A WELL-VENTILATED AREA

ONLY.

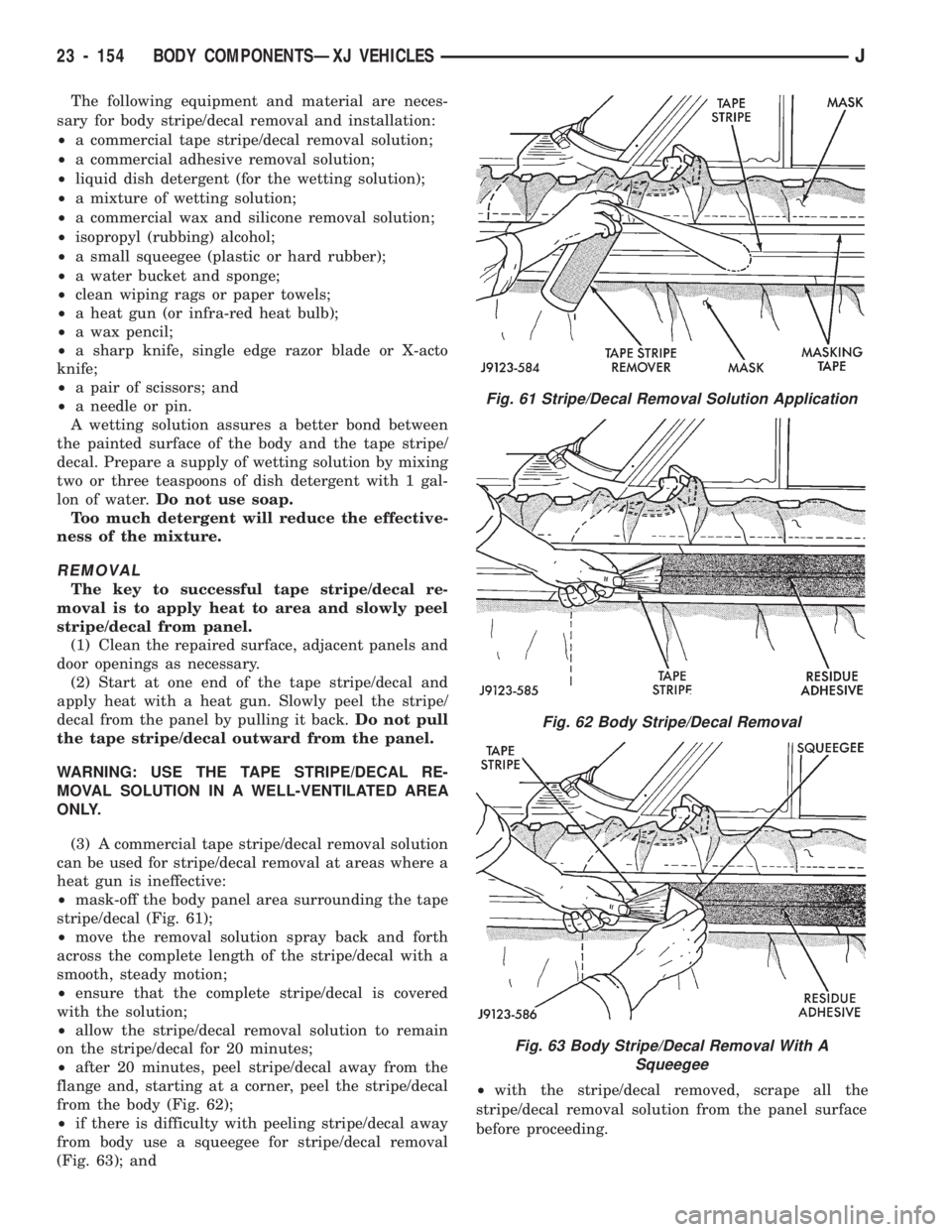

(3) A commercial tape stripe/decal removal solution

can be used for stripe/decal removal at areas where a

heat gun is ineffective:

²mask-off the body panel area surrounding the tape

stripe/decal (Fig. 61);

²move the removal solution spray back and forth

across the complete length of the stripe/decal with a

smooth, steady motion;

²ensure that the complete stripe/decal is covered

with the solution;

²allow the stripe/decal removal solution to remain

on the stripe/decal for 20 minutes;

²after 20 minutes, peel stripe/decal away from the

flange and, starting at a corner, peel the stripe/decal

from the body (Fig. 62);

²if there is difficulty with peeling stripe/decal away

from body use a squeegee for stripe/decal removal

(Fig. 63); and²with the stripe/decal removed, scrape all the

stripe/decal removal solution from the panel surface

before proceeding.

Fig. 61 Stripe/Decal Removal Solution Application

Fig. 62 Body Stripe/Decal Removal

Fig. 63 Body Stripe/Decal Removal With A

Squeegee

23 - 154 BODY COMPONENTSÐXJ VEHICLESJ