key JEEP CHEROKEE 1994 Service Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1013 of 1784

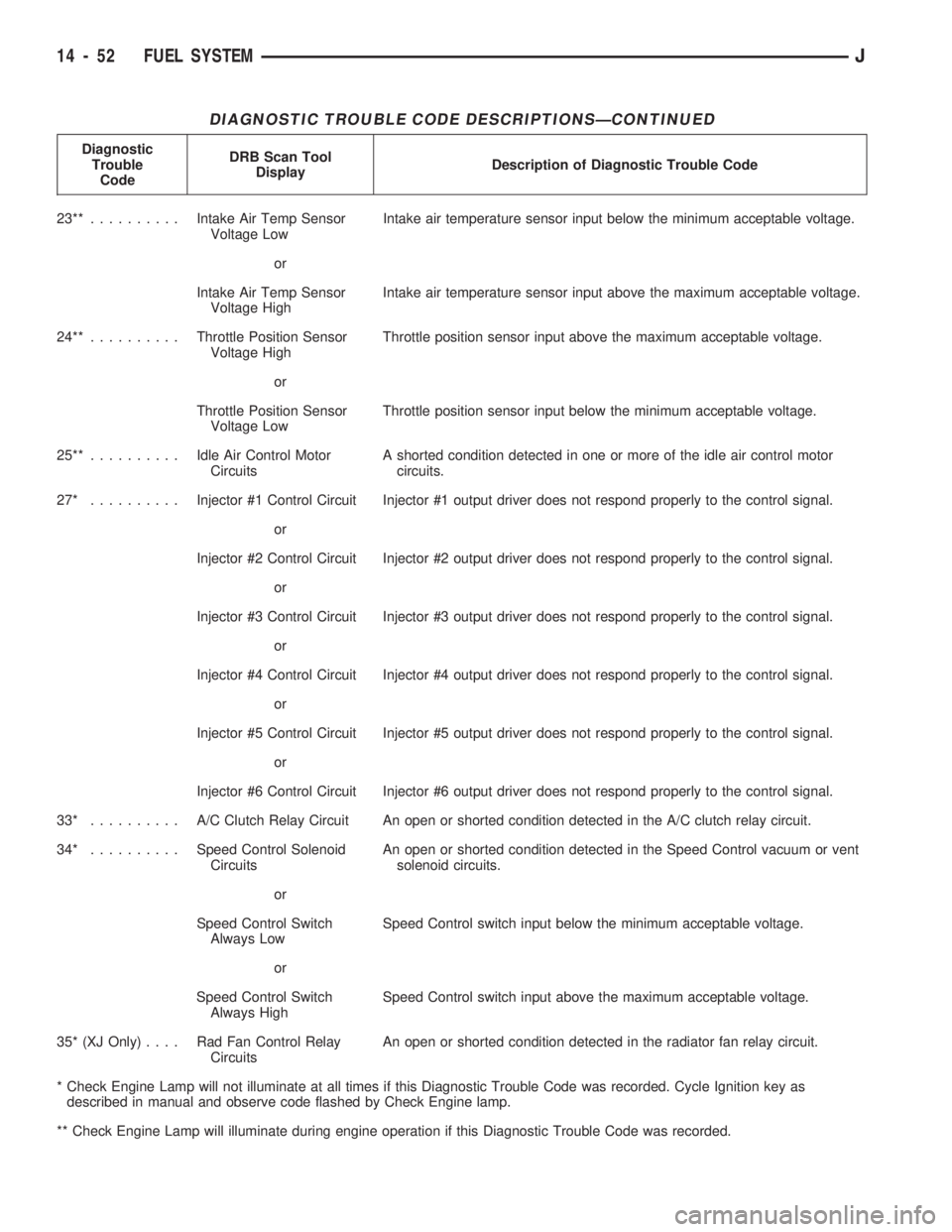

DIAGNOSTIC TROUBLE CODE DESCRIPTIONSÐCONTINUED

Diagnostic

Trouble

CodeDRB Scan Tool

DisplayDescription of Diagnostic Trouble Code

23**..........Intake Air Temp Sensor

Voltage LowIntake air temperature sensor input below the minimum acceptable voltage.

or

Intake Air Temp Sensor

Voltage HighIntake air temperature sensor input above the maximum acceptable voltage.

24**..........Throttle Position Sensor

Voltage HighThrottle position sensor input above the maximum acceptable voltage.

or

Throttle Position Sensor

Voltage LowThrottle position sensor input below the minimum acceptable voltage.

25**..........Idle Air Control Motor

CircuitsA shorted condition detected in one or more of the idle air control motor

circuits.

27* ..........Injector #1 Control Circuit Injector #1 output driver does not respond properly to the control signal.

or

Injector #2 Control Circuit Injector #2 output driver does not respond properly to the control signal.

or

Injector #3 Control Circuit Injector #3 output driver does not respond properly to the control signal.

or

Injector #4 Control Circuit Injector #4 output driver does not respond properly to the control signal.

or

Injector #5 Control Circuit Injector #5 output driver does not respond properly to the control signal.

or

Injector #6 Control Circuit Injector #6 output driver does not respond properly to the control signal.

33* .......... A/CClutch Relay Circuit An open or shorted condition detected in the A/C clutch relay circuit.

34* ..........Speed Control Solenoid

CircuitsAn open or shorted condition detected in the Speed Control vacuum or vent

solenoid circuits.

or

Speed Control Switch

Always LowSpeed Control switch input below the minimum acceptable voltage.

or

Speed Control Switch

Always HighSpeed Control switch input above the maximum acceptable voltage.

35* (XJ Only).... RadFanControl Relay

CircuitsAn open or shorted condition detected in the radiator fan relay circuit.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key as

described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

14 - 52 FUEL SYSTEMJ

Page 1014 of 1784

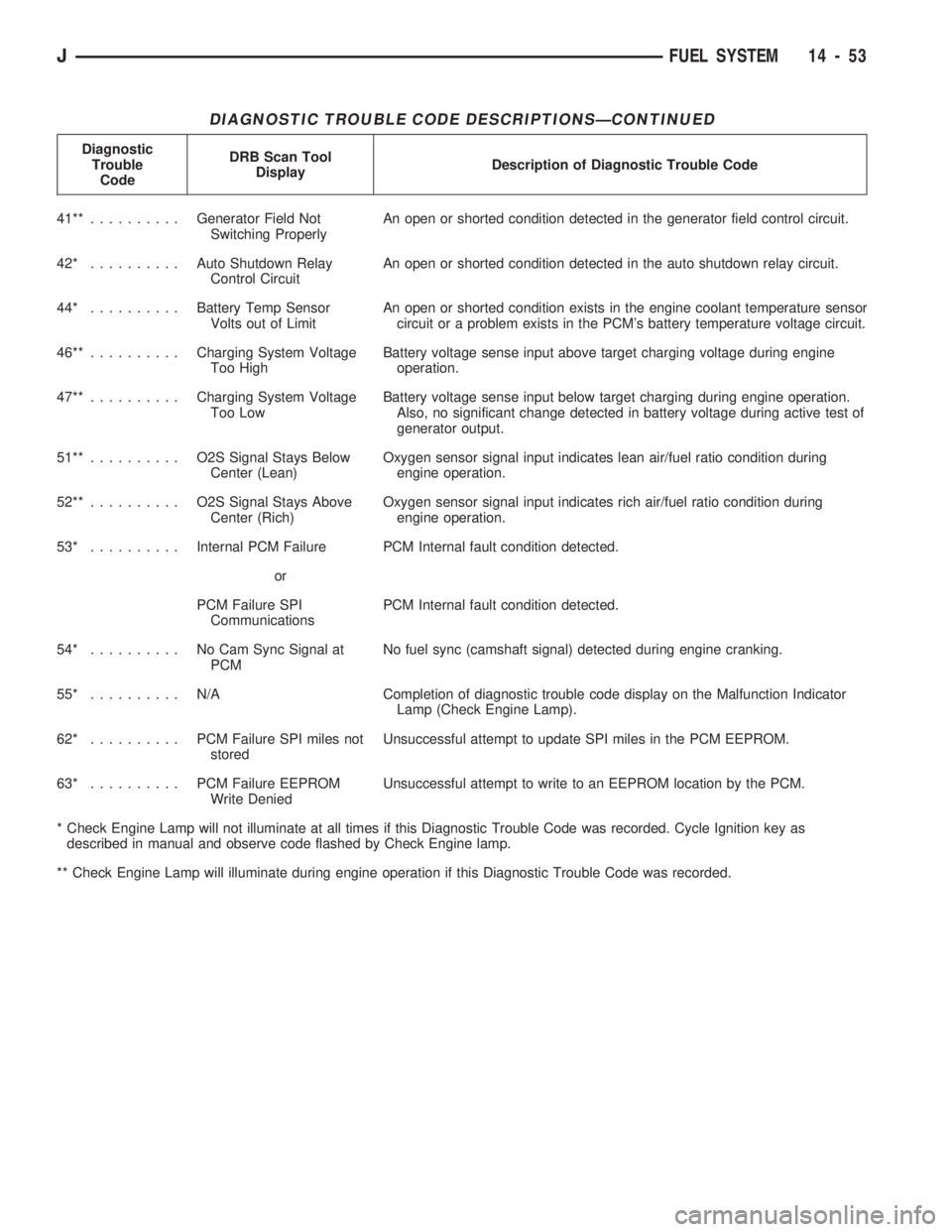

DIAGNOSTIC TROUBLE CODE DESCRIPTIONSÐCONTINUED

Diagnostic

Trouble

CodeDRB Scan Tool

DisplayDescription of Diagnostic Trouble Code

41**..........Generator Field Not

Switching ProperlyAn open or shorted condition detected in the generator field control circuit.

42* ..........Auto Shutdown Relay

Control CircuitAn open or shorted condition detected in the auto shutdown relay circuit.

44* ..........Battery Temp Sensor

Volts out of LimitAn open or shorted condition exists in the engine coolant temperature sensor

circuit or a problem exists in the PCM's battery temperature voltage circuit.

46**..........Charging System Voltage

Too HighBattery voltage sense input above target charging voltage during engine

operation.

47**..........Charging System Voltage

Too LowBattery voltage sense input below target charging during engine operation.

Also, no significant change detected in battery voltage during active test of

generator output.

51**.......... O2SSignal Stays Below

Center (Lean)Oxygen sensor signal input indicates lean air/fuel ratio condition during

engine operation.

52**.......... O2SSignal Stays Above

Center (Rich)Oxygen sensor signal input indicates rich air/fuel ratio condition during

engine operation.

53* ..........Internal PCM Failure PCM Internal fault condition detected.

or

PCM Failure SPI

CommunicationsPCM Internal fault condition detected.

54* .......... NoCamSync Signal at

PCMNo fuel sync (camshaft signal) detected during engine cranking.

55* .......... N/ACompletion of diagnostic trouble code display on the Malfunction Indicator

Lamp (Check Engine Lamp).

62* .......... PCMFailure SPI miles not

storedUnsuccessful attempt to update SPI miles in the PCM EEPROM.

63* .......... PCMFailure EEPROM

Write DeniedUnsuccessful attempt to write to an EEPROM location by the PCM.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key as

described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

JFUEL SYSTEM 14 - 53

Page 1039 of 1784

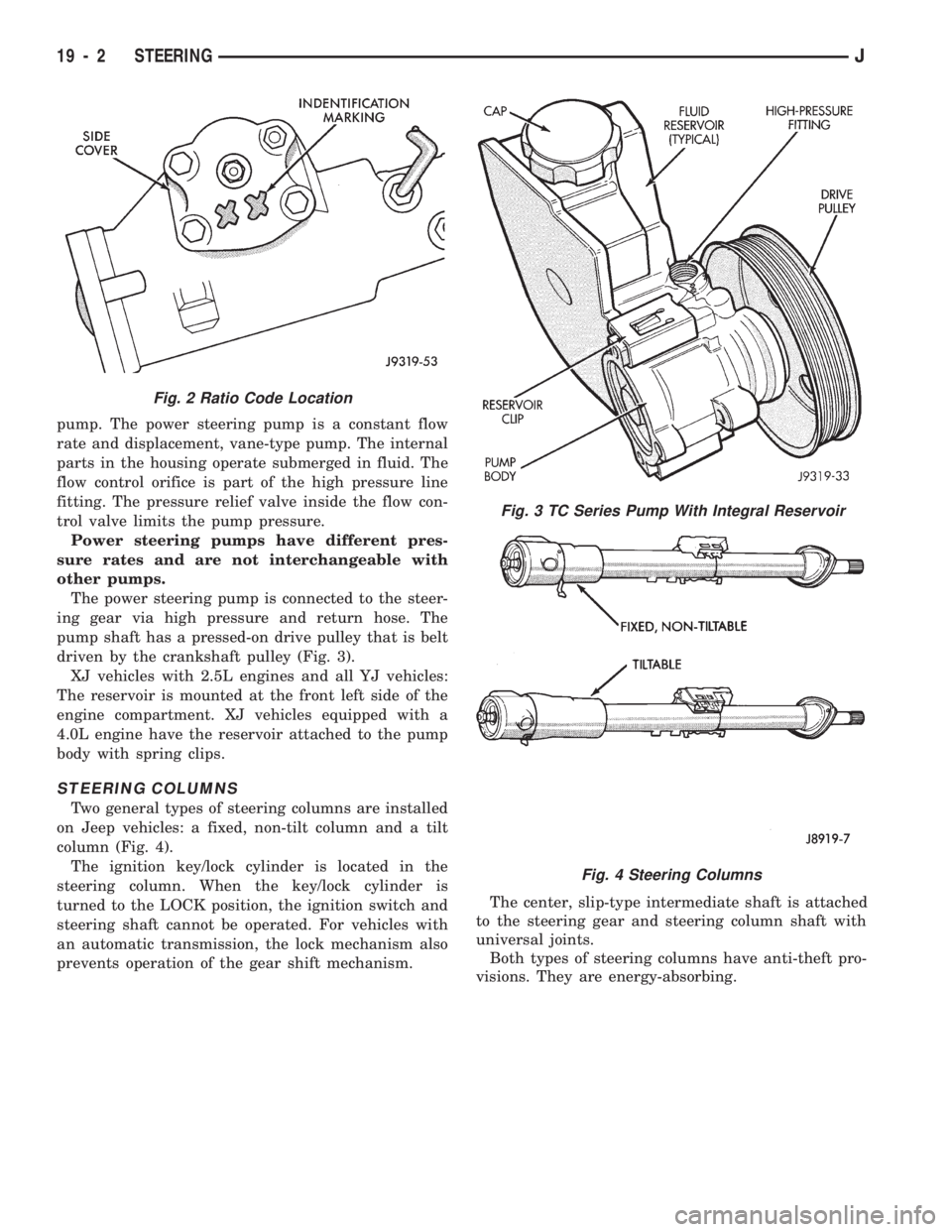

pump. The power steering pump is a constant flow

rate and displacement, vane-type pump. The internal

parts in the housing operate submerged in fluid. The

flow control orifice is part of the high pressure line

fitting. The pressure relief valve inside the flow con-

trol valve limits the pump pressure.

Power steering pumps have different pres-

sure rates and are not interchangeable with

other pumps.

The power steering pump is connected to the steer-

ing gear via high pressure and return hose. The

pump shaft has a pressed-on drive pulley that is belt

driven by the crankshaft pulley (Fig. 3).

XJ vehicles with 2.5L engines and all YJ vehicles:

The reservoir is mounted at the front left side of the

engine compartment. XJ vehicles equipped with a

4.0L engine have the reservoir attached to the pump

body with spring clips.

STEERING COLUMNS

Two general types of steering columns are installed

on Jeep vehicles: a fixed, non-tilt column and a tilt

column (Fig. 4).

The ignition key/lock cylinder is located in the

steering column. When the key/lock cylinder is

turned to the LOCK position, the ignition switch and

steering shaft cannot be operated. For vehicles with

an automatic transmission, the lock mechanism also

prevents operation of the gear shift mechanism.The center, slip-type intermediate shaft is attached

to the steering gear and steering column shaft with

universal joints.

Both types of steering columns have anti-theft pro-

visions. They are energy-absorbing.

Fig. 3 TC Series Pump With Integral Reservoir

Fig. 4 Steering Columns

Fig. 2 Ratio Code Location

19 - 2 STEERINGJ

Page 1083 of 1784

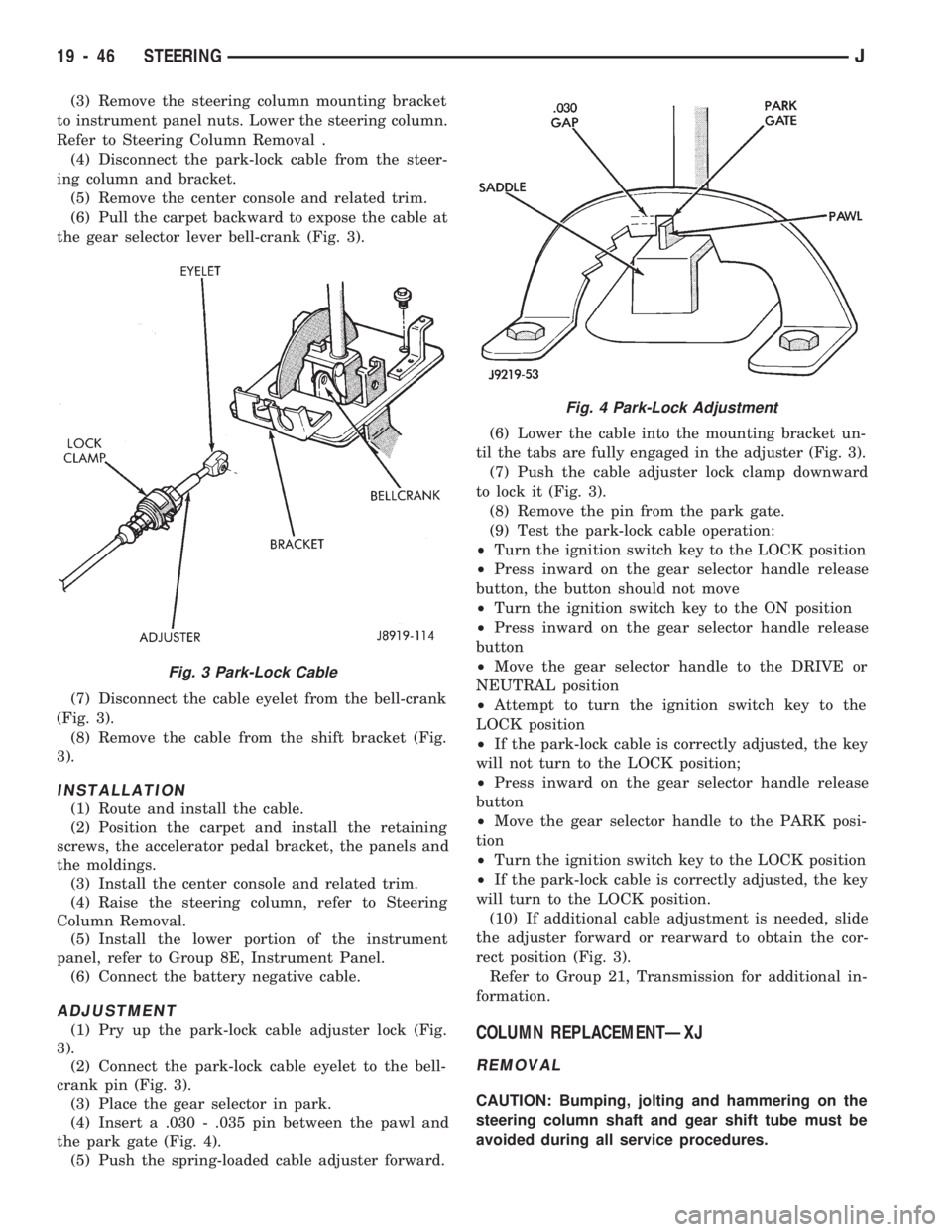

(3) Remove the steering column mounting bracket

to instrument panel nuts. Lower the steering column.

Refer to Steering Column Removal .

(4) Disconnect the park-lock cable from the steer-

ing column and bracket.

(5) Remove the center console and related trim.

(6) Pull the carpet backward to expose the cable at

the gear selector lever bell-crank (Fig. 3).

(7) Disconnect the cable eyelet from the bell-crank

(Fig. 3).

(8) Remove the cable from the shift bracket (Fig.

3).

INSTALLATION

(1) Route and install the cable.

(2) Position the carpet and install the retaining

screws, the accelerator pedal bracket, the panels and

the moldings.

(3) Install the center console and related trim.

(4) Raise the steering column, refer to Steering

Column Removal.

(5) Install the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

(6) Connect the battery negative cable.

ADJUSTMENT

(1) Pry up the park-lock cable adjuster lock (Fig.

3).

(2) Connect the park-lock cable eyelet to the bell-

crank pin (Fig. 3).

(3) Place the gear selector in park.

(4) Insert a .030 - .035 pin between the pawl and

the park gate (Fig. 4).

(5) Push the spring-loaded cable adjuster forward.(6) Lower the cable into the mounting bracket un-

til the tabs are fully engaged in the adjuster (Fig. 3).

(7) Push the cable adjuster lock clamp downward

to lock it (Fig. 3).

(8) Remove the pin from the park gate.

(9) Test the park-lock cable operation:

²Turn the ignition switch key to the LOCK position

²Press inward on the gear selector handle release

button, the button should not move

²Turn the ignition switch key to the ON position

²Press inward on the gear selector handle release

button

²Move the gear selector handle to the DRIVE or

NEUTRAL position

²Attempt to turn the ignition switch key to the

LOCK position

²If the park-lock cable is correctly adjusted, the key

will not turn to the LOCK position;

²Press inward on the gear selector handle release

button

²Move the gear selector handle to the PARK posi-

tion

²Turn the ignition switch key to the LOCK position

²If the park-lock cable is correctly adjusted, the key

will turn to the LOCK position.

(10) If additional cable adjustment is needed, slide

the adjuster forward or rearward to obtain the cor-

rect position (Fig. 3).

Refer to Group 21, Transmission for additional in-

formation.COLUMN REPLACEMENTÐXJ

REMOVAL

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

Fig. 3 Park-Lock Cable

Fig. 4 Park-Lock Adjustment

19 - 46 STEERINGJ

Page 1087 of 1784

NON-TILT STEERING COLUMN

DISASSEMBLYÐCOLUMN OR CONSOLE SHIFT

Steering column removal from the vehicle is not

necessary for;

²Lockplate cover

²Lockplate

²Steering shaft retaining ring

²Canceling cam

²Turn signal switch

²Upper bearing preload spring

²Ignition key/lock cylinder service

The steering column must be removed from

the vehicle to service any other component.

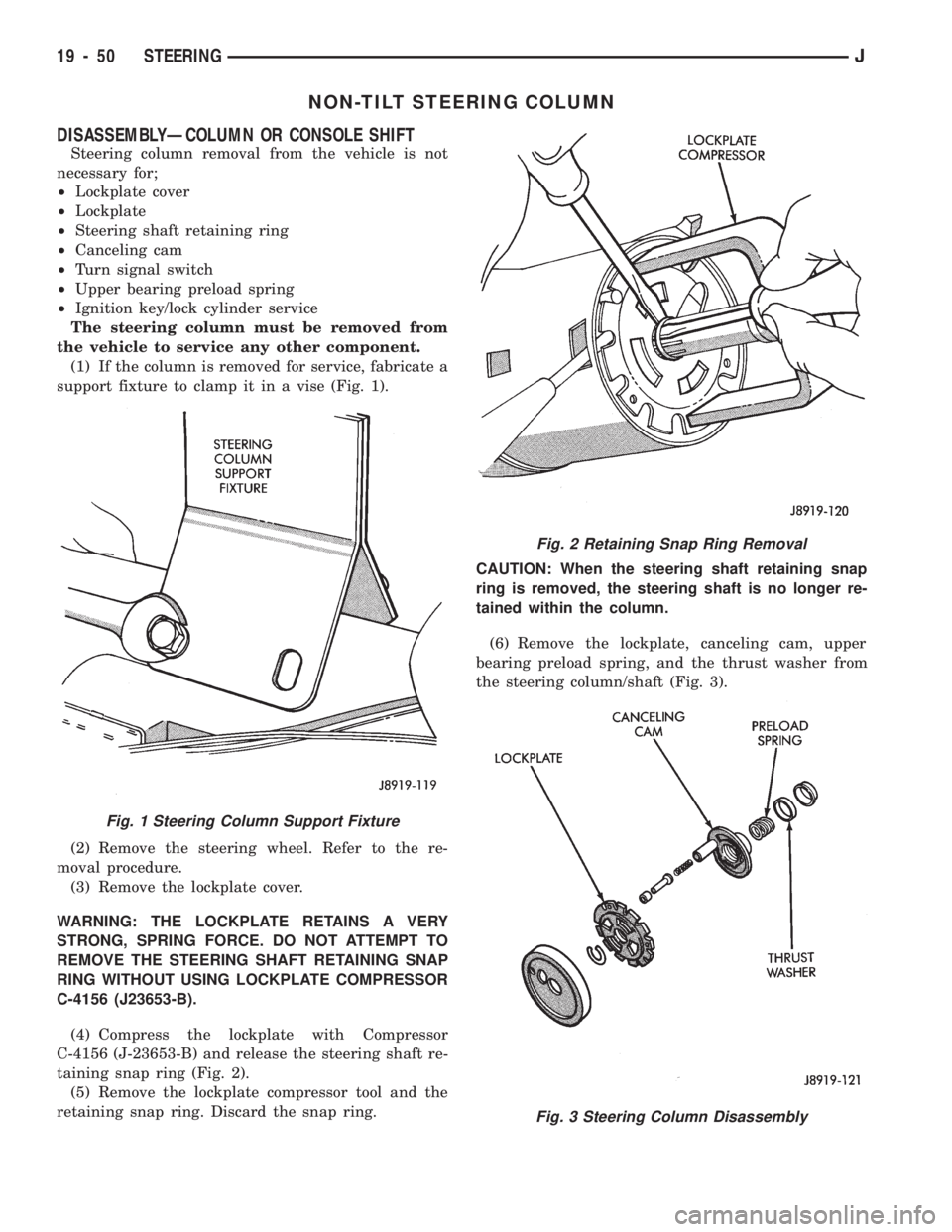

(1) If the column is removed for service, fabricate a

support fixture to clamp it in a vise (Fig. 1).

(2) Remove the steering wheel. Refer to the re-

moval procedure.

(3) Remove the lockplate cover.

WARNING: THE LOCKPLATE RETAINS A VERY

STRONG, SPRING FORCE. DO NOT ATTEMPT TO

REMOVE THE STEERING SHAFT RETAINING SNAP

RING WITHOUT USING LOCKPLATE COMPRESSOR

C-4156 (J23653-B).

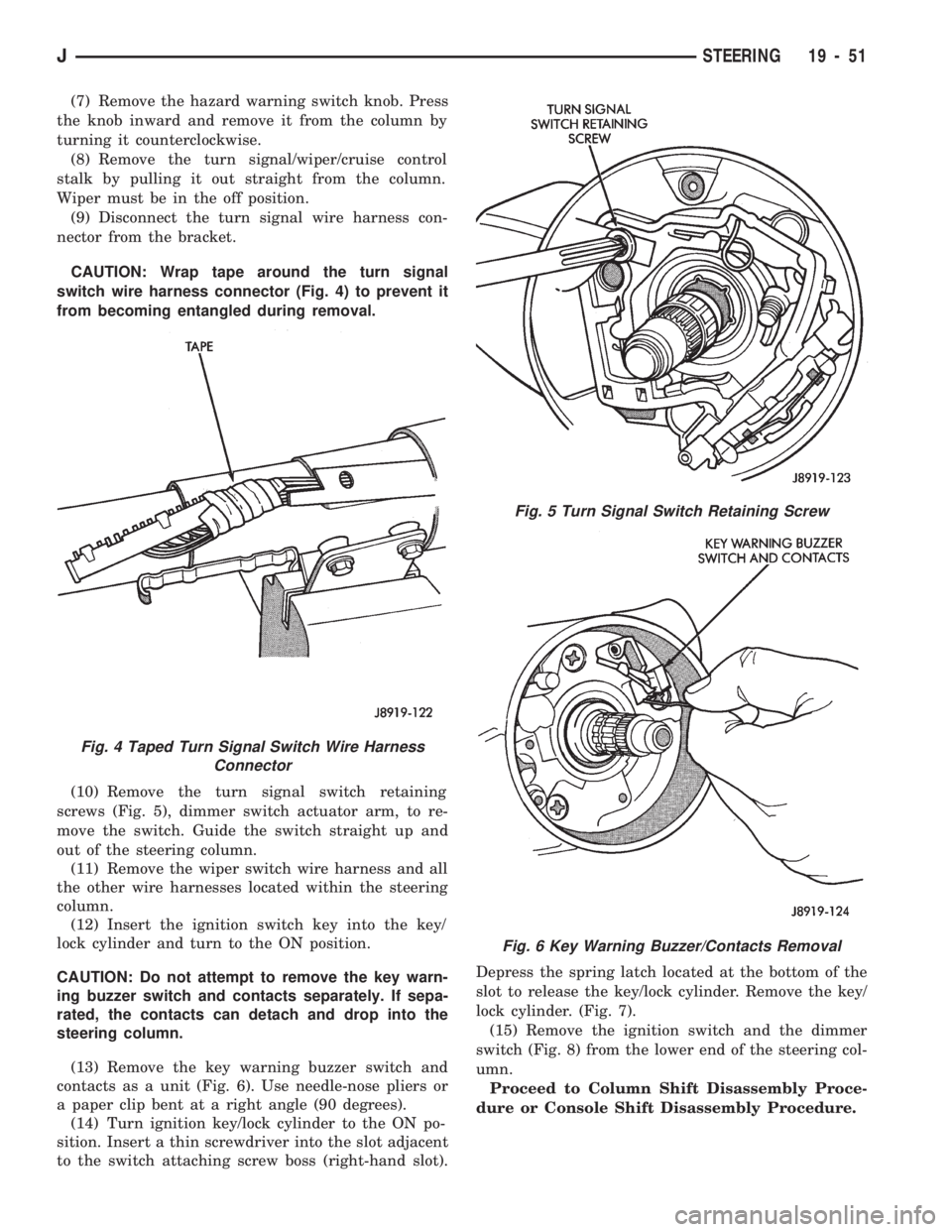

(4) Compress the lockplate with Compressor

C-4156 (J-23653-B) and release the steering shaft re-

taining snap ring (Fig. 2).

(5) Remove the lockplate compressor tool and the

retaining snap ring. Discard the snap ring.CAUTION: When the steering shaft retaining snap

ring is removed, the steering shaft is no longer re-

tained within the column.

(6) Remove the lockplate, canceling cam, upper

bearing preload spring, and the thrust washer from

the steering column/shaft (Fig. 3).

Fig. 2 Retaining Snap Ring Removal

Fig. 3 Steering Column Disassembly

Fig. 1 Steering Column Support Fixture

19 - 50 STEERINGJ

Page 1088 of 1784

(7) Remove the hazard warning switch knob. Press

the knob inward and remove it from the column by

turning it counterclockwise.

(8) Remove the turn signal/wiper/cruise control

stalk by pulling it out straight from the column.

Wiper must be in the off position.

(9) Disconnect the turn signal wire harness con-

nector from the bracket.

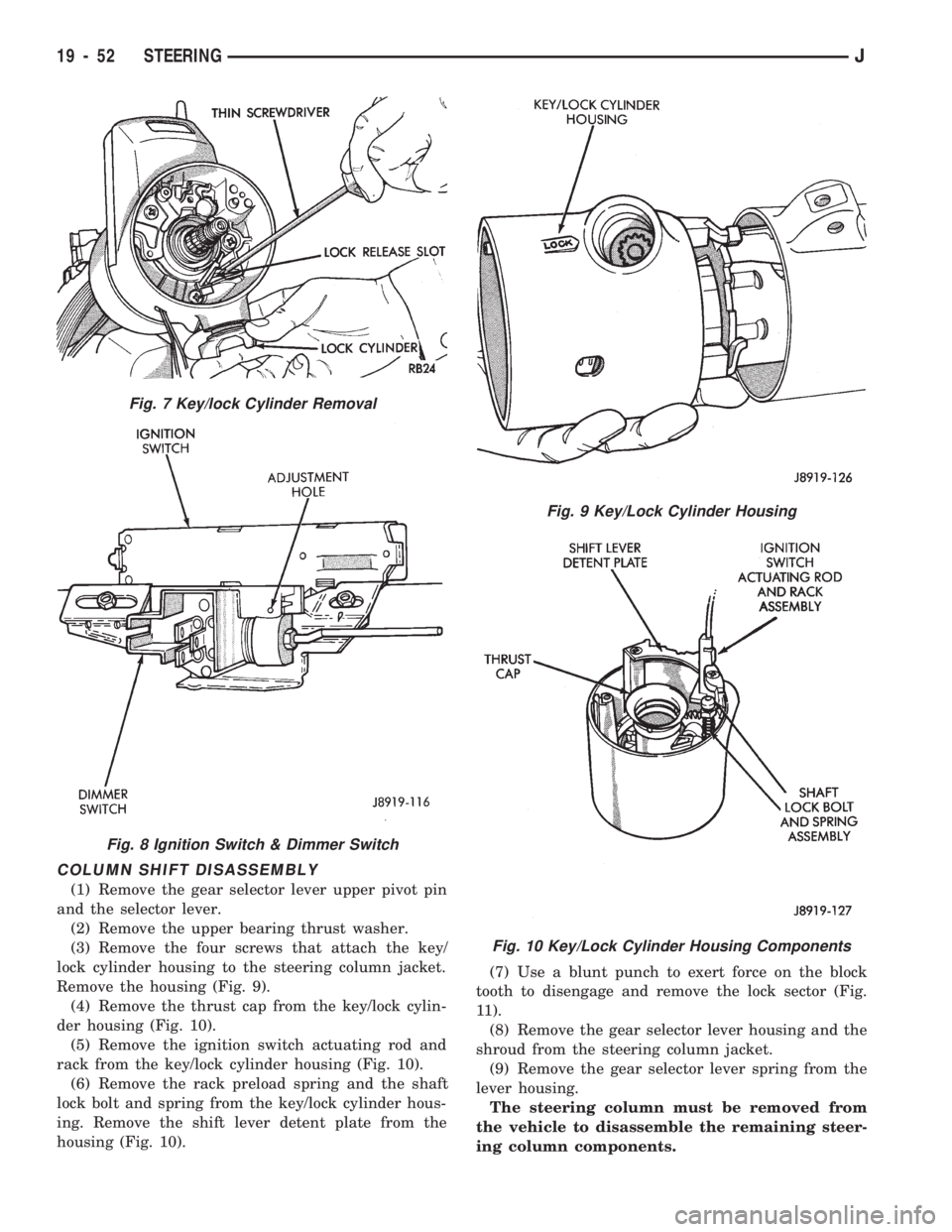

CAUTION: Wrap tape around the turn signal

switch wire harness connector (Fig. 4) to prevent it

from becoming entangled during removal.

(10) Remove the turn signal switch retaining

screws (Fig. 5), dimmer switch actuator arm, to re-

move the switch. Guide the switch straight up and

out of the steering column.

(11) Remove the wiper switch wire harness and all

the other wire harnesses located within the steering

column.

(12) Insert the ignition switch key into the key/

lock cylinder and turn to the ON position.

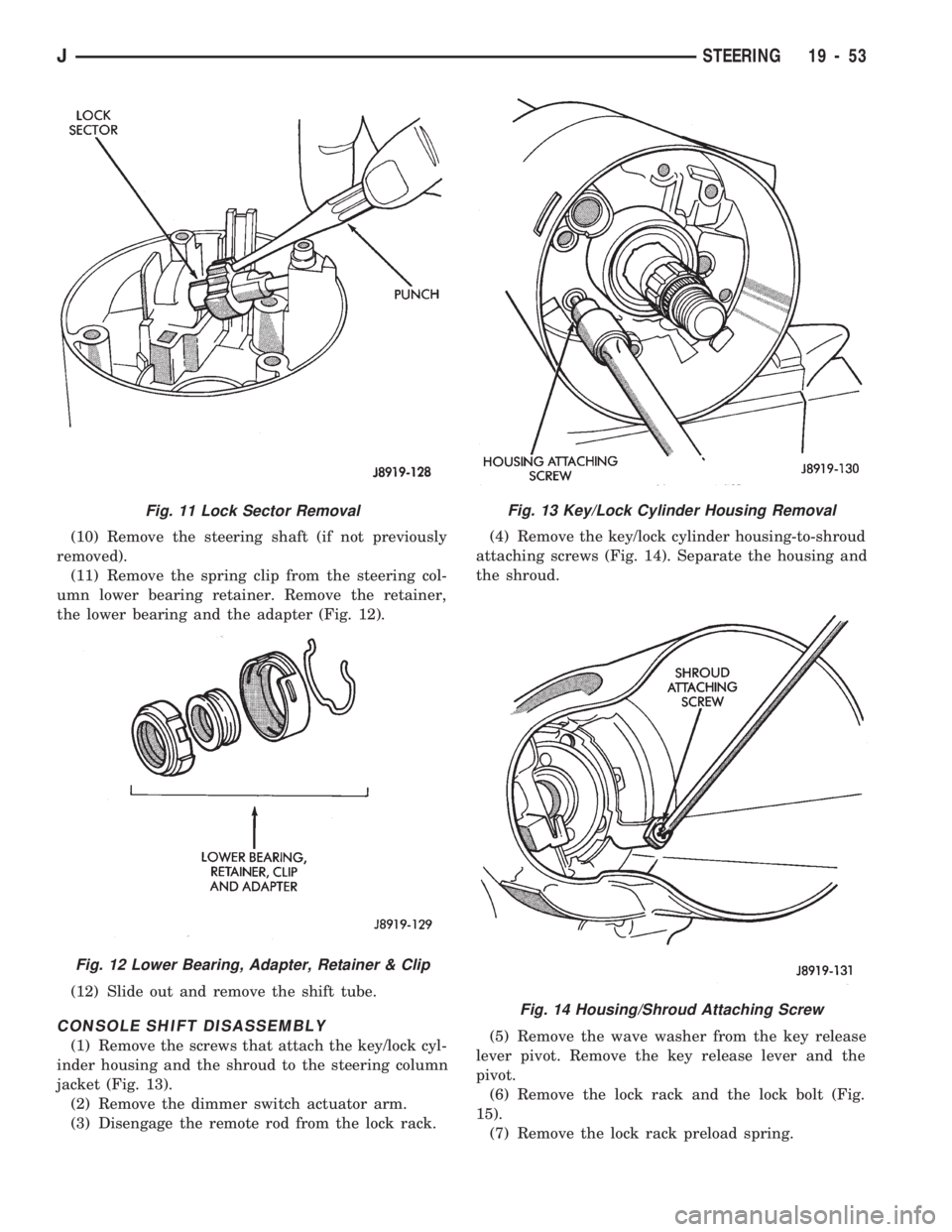

CAUTION: Do not attempt to remove the key warn-

ing buzzer switch and contacts separately. If sepa-

rated, the contacts can detach and drop into the

steering column.

(13) Remove the key warning buzzer switch and

contacts as a unit (Fig. 6). Use needle-nose pliers or

a paper clip bent at a right angle (90 degrees).

(14) Turn ignition key/lock cylinder to the ON po-

sition. Insert a thin screwdriver into the slot adjacent

to the switch attaching screw boss (right-hand slot).Depress the spring latch located at the bottom of the

slot to release the key/lock cylinder. Remove the key/

lock cylinder. (Fig. 7).

(15) Remove the ignition switch and the dimmer

switch (Fig. 8) from the lower end of the steering col-

umn.

Proceed to Column Shift Disassembly Proce-

dure or Console Shift Disassembly Procedure.

Fig. 4 Taped Turn Signal Switch Wire Harness

Connector

Fig. 5 Turn Signal Switch Retaining Screw

Fig. 6 Key Warning Buzzer/Contacts Removal

JSTEERING 19 - 51

Page 1089 of 1784

COLUMN SHIFT DISASSEMBLY

(1) Remove the gear selector lever upper pivot pin

and the selector lever.

(2) Remove the upper bearing thrust washer.

(3) Remove the four screws that attach the key/

lock cylinder housing to the steering column jacket.

Remove the housing (Fig. 9).

(4) Remove the thrust cap from the key/lock cylin-

der housing (Fig. 10).

(5) Remove the ignition switch actuating rod and

rack from the key/lock cylinder housing (Fig. 10).

(6) Remove the rack preload spring and the shaft

lock bolt and spring from the key/lock cylinder hous-

ing. Remove the shift lever detent plate from the

housing (Fig. 10).(7) Use a blunt punch to exert force on the block

tooth to disengage and remove the lock sector (Fig.

11).

(8) Remove the gear selector lever housing and the

shroud from the steering column jacket.

(9) Remove the gear selector lever spring from the

lever housing.

The steering column must be removed from

the vehicle to disassemble the remaining steer-

ing column components.

Fig. 7 Key/lock Cylinder Removal

Fig. 8 Ignition Switch & Dimmer Switch

Fig. 9 Key/Lock Cylinder Housing

Fig. 10 Key/Lock Cylinder Housing Components

19 - 52 STEERINGJ

Page 1090 of 1784

(10) Remove the steering shaft (if not previously

removed).

(11) Remove the spring clip from the steering col-

umn lower bearing retainer. Remove the retainer,

the lower bearing and the adapter (Fig. 12).

(12) Slide out and remove the shift tube.

CONSOLE SHIFT DISASSEMBLY

(1) Remove the screws that attach the key/lock cyl-

inder housing and the shroud to the steering column

jacket (Fig. 13).

(2) Remove the dimmer switch actuator arm.

(3) Disengage the remote rod from the lock rack.(4) Remove the key/lock cylinder housing-to-shroud

attaching screws (Fig. 14). Separate the housing and

the shroud.

(5) Remove the wave washer from the key release

lever pivot. Remove the key release lever and the

pivot.

(6) Remove the lock rack and the lock bolt (Fig.

15).

(7) Remove the lock rack preload spring.

Fig. 11 Lock Sector Removal

Fig. 12 Lower Bearing, Adapter, Retainer & Clip

Fig. 13 Key/Lock Cylinder Housing Removal

Fig. 14 Housing/Shroud Attaching Screw

JSTEERING 19 - 53

Page 1091 of 1784

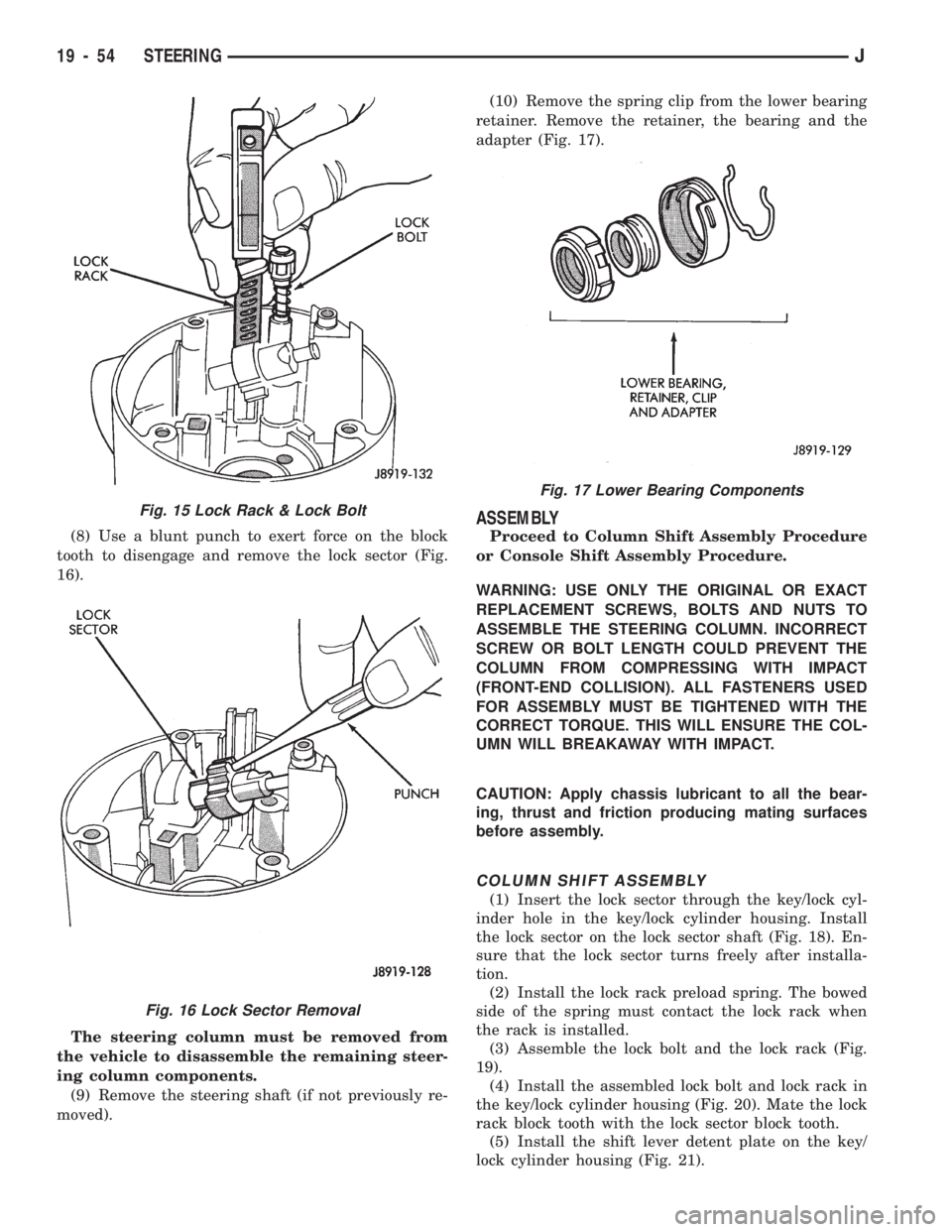

(8) Use a blunt punch to exert force on the block

tooth to disengage and remove the lock sector (Fig.

16).

The steering column must be removed from

the vehicle to disassemble the remaining steer-

ing column components.

(9) Remove the steering shaft (if not previously re-

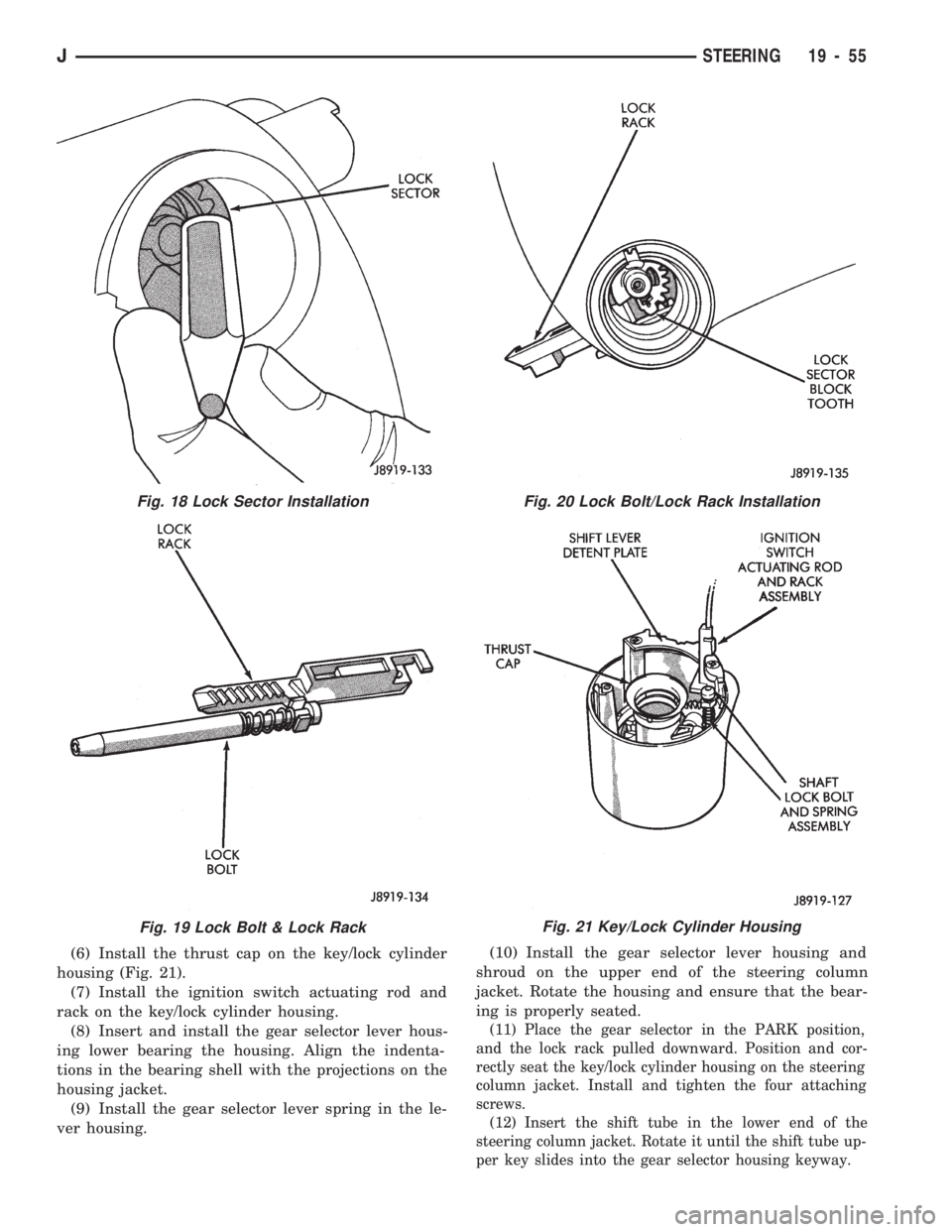

moved).(10) Remove the spring clip from the lower bearing

retainer. Remove the retainer, the bearing and the

adapter (Fig. 17).

ASSEMBLY

Proceed to Column Shift Assembly Procedure

or Console Shift Assembly Procedure.

WARNING: USE ONLY THE ORIGINAL OR EXACT

REPLACEMENT SCREWS, BOLTS AND NUTS TO

ASSEMBLE THE STEERING COLUMN. INCORRECT

SCREW OR BOLT LENGTH COULD PREVENT THE

COLUMN FROM COMPRESSING WITH IMPACT

(FRONT-END COLLISION). ALL FASTENERS USED

FOR ASSEMBLY MUST BE TIGHTENED WITH THE

CORRECT TORQUE. THIS WILL ENSURE THE COL-

UMN WILL BREAKAWAY WITH IMPACT.

CAUTION: Apply chassis lubricant to all the bear-

ing, thrust and friction producing mating surfaces

before assembly.

COLUMN SHIFT ASSEMBLY

(1) Insert the lock sector through the key/lock cyl-

inder hole in the key/lock cylinder housing. Install

the lock sector on the lock sector shaft (Fig. 18). En-

sure that the lock sector turns freely after installa-

tion.

(2) Install the lock rack preload spring. The bowed

side of the spring must contact the lock rack when

the rack is installed.

(3) Assemble the lock bolt and the lock rack (Fig.

19).

(4) Install the assembled lock bolt and lock rack in

the key/lock cylinder housing (Fig. 20). Mate the lock

rack block tooth with the lock sector block tooth.

(5) Install the shift lever detent plate on the key/

lock cylinder housing (Fig. 21).

Fig. 17 Lower Bearing Components

Fig. 15 Lock Rack & Lock Bolt

Fig. 16 Lock Sector Removal

19 - 54 STEERINGJ

Page 1092 of 1784

(6) Install the thrust cap on the key/lock cylinder

housing (Fig. 21).

(7) Install the ignition switch actuating rod and

rack on the key/lock cylinder housing.

(8) Insert and install the gear selector lever hous-

ing lower bearing the housing. Align the indenta-

tions in the bearing shell with the projections on the

housing jacket.

(9) Install the gear selector lever spring in the le-

ver housing.(10) Install the gear selector lever housing and

shroud on the upper end of the steering column

jacket. Rotate the housing and ensure that the bear-

ing is properly seated.

(11) Place the gear selector in the PARK position,

and the lock rack pulled downward. Position and cor-

rectly seat the key/lock cylinder housing on the steering

column jacket. Install and tighten the four attaching

screws.

(12) Insert the shift tube in the lower end of the

steering column jacket. Rotate it until the shift tube up-

per key slides into the gear selector housing keyway.

Fig. 18 Lock Sector Installation

Fig. 19 Lock Bolt & Lock Rack

Fig. 20 Lock Bolt/Lock Rack Installation

Fig. 21 Key/Lock Cylinder Housing

JSTEERING 19 - 55