ABS JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1098 of 1784

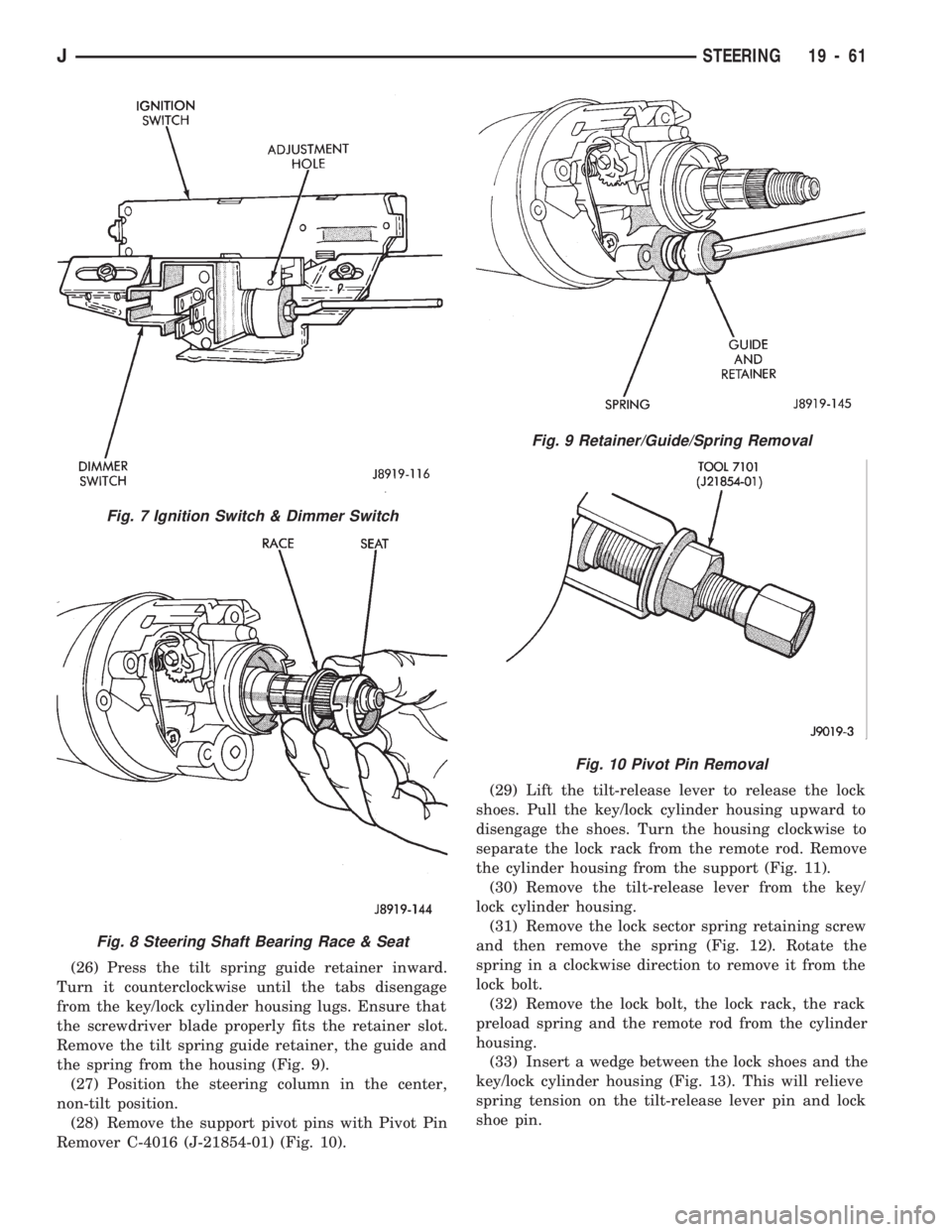

(26) Press the tilt spring guide retainer inward.

Turn it counterclockwise until the tabs disengage

from the key/lock cylinder housing lugs. Ensure that

the screwdriver blade properly fits the retainer slot.

Remove the tilt spring guide retainer, the guide and

the spring from the housing (Fig. 9).

(27) Position the steering column in the center,

non-tilt position.

(28) Remove the support pivot pins with Pivot Pin

Remover C-4016 (J-21854-01) (Fig. 10).(29) Lift the tilt-release lever to release the lock

shoes. Pull the key/lock cylinder housing upward to

disengage the shoes. Turn the housing clockwise to

separate the lock rack from the remote rod. Remove

the cylinder housing from the support (Fig. 11).

(30) Remove the tilt-release lever from the key/

lock cylinder housing.

(31) Remove the lock sector spring retaining screw

and then remove the spring (Fig. 12). Rotate the

spring in a clockwise direction to remove it from the

lock bolt.

(32) Remove the lock bolt, the lock rack, the rack

preload spring and the remote rod from the cylinder

housing.

(33) Insert a wedge between the lock shoes and the

key/lock cylinder housing (Fig. 13). This will relieve

spring tension on the tilt-release lever pin and lock

shoe pin.

Fig. 7 Ignition Switch & Dimmer Switch

Fig. 8 Steering Shaft Bearing Race & Seat

Fig. 9 Retainer/Guide/Spring Removal

Fig. 10 Pivot Pin Removal

JSTEERING 19 - 61

Page 1102 of 1784

(13) Install all support attaching screws finger-

tight. Next, tighten the screws alternately and evenly

to7Nzm (60 in. lbs.) torque.

(14) Install the remote rod in the support. Route

the rod through the upper end of the shroud and in-

sert it into the rod slot located in the support.

(15) Install the dimmer switch and ignition switch.

(16) Install the steering shaft in the steering col-

umn.

(17) Install replacement races and bearings in the

key/lock cylinder, if removed.Ensure that the bear-

ings are lubricated with chassis lubricant be-

fore installation.

(18) Install the lock shoes, the lock shoe springs

and the lock shoe pin the key/lock cylinder housing.

Use a 4.5-mm (0.18-in) diameter rod to align the

shoes and the pin during installation.

(19) Install the tilt-release lever, the lever spring

and the lever pin in the key/lock cylinder housing.

Insert a wedge between the housing and the lever to

relieve the spring tension. This will allow easier re-

lease lever pin installation.

(20) Install the lock bolt in the key/lock cylinder

housing and engage it in the lock sector cam surface.

(21) Install the lock rack, the rack preload spring

and a replacement shim in the key/lock cylinder

housing. Align and mate the square block tooth on

the lock rack and the lock sector.

(22) Install the lock spring and the spring retain-

ing screw. Tighten the screw to 4 Nzm (35 in. lbs.)

torque.

(23) Align and install the assembled key/lock cylin-

der housing on the support. Retain the lock shoes in

the disengaged position for easier housing installa-

tion.(24) Align the pivot pin holes in the housing with

those in the support. Insert the pivot pins.Press the

housing firmly downward when inserting the

pivot pins. This prevents damaging the holes in

the support.When the pivot pins are within both

the housing and the support holes, seat them fully

with a punch and a hammer.

(25) Insert tilt-release lever in key/lock cylinder

housing and place housing in the full-upward tilt po-

sition.

(26) Lubricate the tilt spring guide and the tilt

spring liberally with chassis lubricant and position

the spring on the guide.

(27) Insert the tilt spring guide and the spring into

the key/lock cylinder housing. Install the guide re-

tainer over the spring. Engage the retainer lock tabs

with the housing lugs by pressing the retainer down-

ward and turning clockwise with a screwdriver.

(28) Place the cover on the key/lock cylinder hous-

ing. Align and install the cover retaining screws.

Tighten the screws to 7 Nzm (60 in. lbs.) torque.

(29) Install the gear selector indicator lamp mount-

ing bracket screw.

(30) Install the gear selector indicator cover and

retaining screws.

(31) Route the dimmer switch wire harness and

gear selector indicator down through the steering col-

umn.

(32) To install ignition switch lock, turn the key to

the LOCK position and remove the key. This will

cause the buzzer operating lever to retract in the

key/lock cylinder. Now insert the key/lock cylinder

into the housing far enough to contact the drive

shaft. Force it inward and move the ignition switch

actuator rod up and down to align the components.

When the components align, the key/lock cylinder

will move inward and the spring-loaded retainer will

snap and lock it in place (Fig. 23).

(33) Insert the ignition key in the cylinder and

turn it to the ON position. Install the key warning

buzzer switch.

(34) Install the turn signal switch. Fold the wires

against the connector. Route the wire harness and

connector down through the steering column. Posi-

tion the switch in the key/lock cylinder housing.Do

notinstall the switch retaining screws at this time.

(35) Install the windshield wiper wire harness and

switch. Route the wire harness down through steer-

ing column jacket.

(36) If equipped, install the cruise control wire har-

ness. Install the turn signal stalk by pushing it

straight into the column.

(37) Insert the hazard warning knob in the hazard

warning switch and press it inward. Align and install

the turn signal switch retaining screws. Ensure that

the turn signal switch is properly seated before tight-

ening the screws. Tighten the screws to 4 Nzm

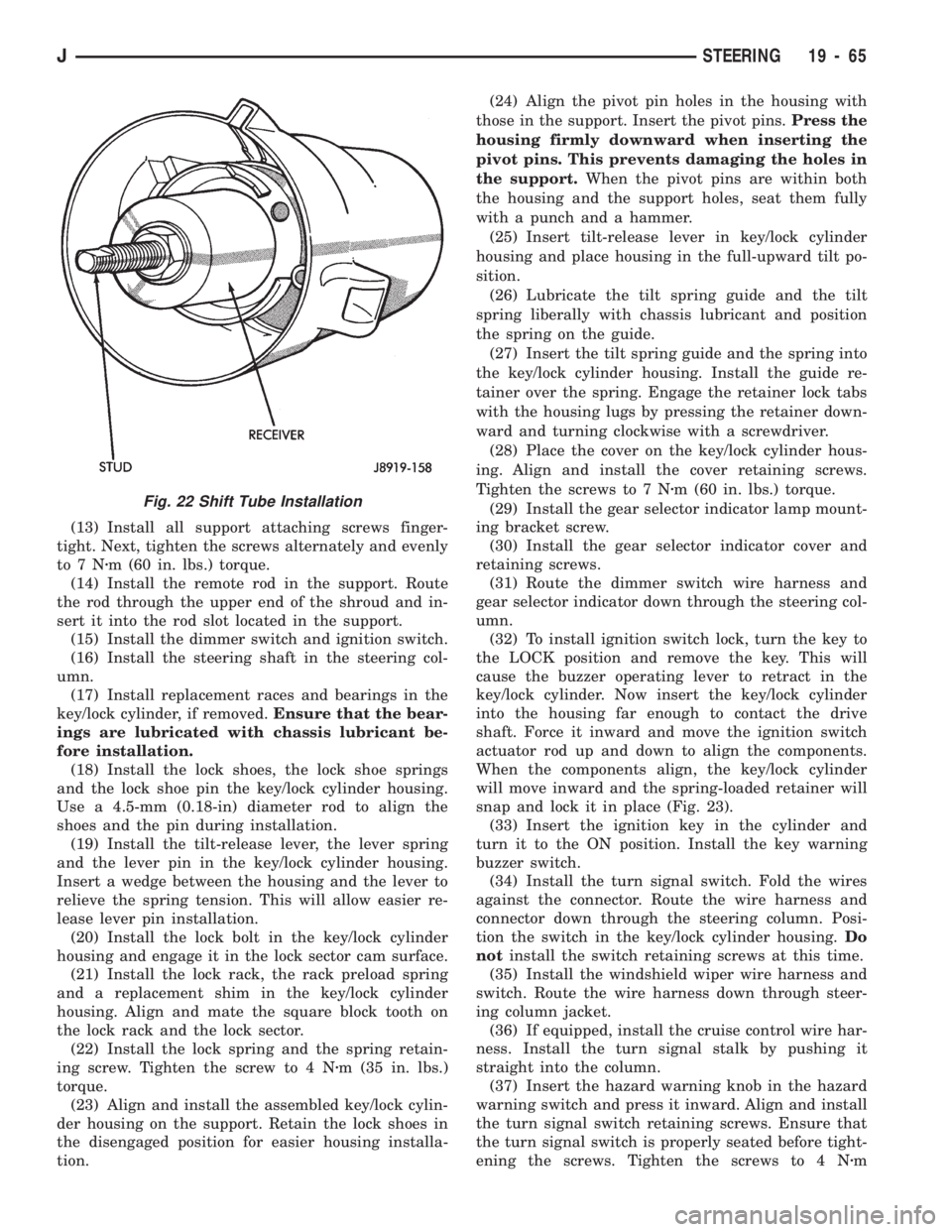

Fig. 22 Shift Tube Installation

JSTEERING 19 - 65

Page 1104 of 1784

(9) Install replacement races and bearings in the

key/lock cylinder, if removed.Ensure that the bear-

ings are lubricated with chassis lubricant be-

fore installation.

(10) Install the lock shoes, the lock shoe springs

and the lock shoe pin the key/lock cylinder housing.

Use a 4.5-mm (0.18-in) diameter rod to align the

shoes and the pin during installation.

(11) Install the tilt-release lever, the lever spring

and the lever pin in the key/lock cylinder housing.

Insert a wedge between the housing and the lever to

relieve the spring tension. This will allow easier re-

lease lever pin installation.

(12) Install the lock bolt in the key/lock cylinder

housing and engage it in the lock sector cam surface.

(13) Install the lock rack, the rack preload spring

and a replacement shim in the key/lock cylinder

housing. The square block tooth on the lock rack and

lock sector must mate.

(14) Install the lock spring and the spring retain-

ing screw. Tighten the screw to 4 Nzm (35 in. lbs.)

torque.

(15) Align and install the assembled key/lock cylin-

der housing on the support. Retain the lock shoes in

the disengaged position for easier housing installa-

tion.

(16) Align the pivot pin holes in the key/lock cylin-

der housing with those in the support and insert the

pivot pins.Press the housing firmly downward

when inserting the pivot pins to prevent dam-

aging the holes in the support.When the pivot

pins are within both the housing and the support

holes, seat them fully with a punch and a hammer.(17) Insert the tilt-release lever in the key/lock cyl-

inder housing and place the housing in the full-up-

ward tilt position.

(18) Lubricate tilt spring guide and tilt spring lib-

erally with chassis lubricant. Then position spring on

guide.

(19) Insert the tilt spring guide and the spring into

the key/lock cylinder housing. Install the guide re-

tainer over the spring. Engage the retainer lock tabs

with the housing lugs by pressing the retainer down-

ward and turning clockwise with a screwdriver.

(20) Place the cover on the key/lock cylinder hous-

ing. Align and install the cover retaining screws.

Tighten the screws to 7 Nzm (60 in. lbs.) torque.

(21) Route the dimmer switch wire harness down

through the steering column.

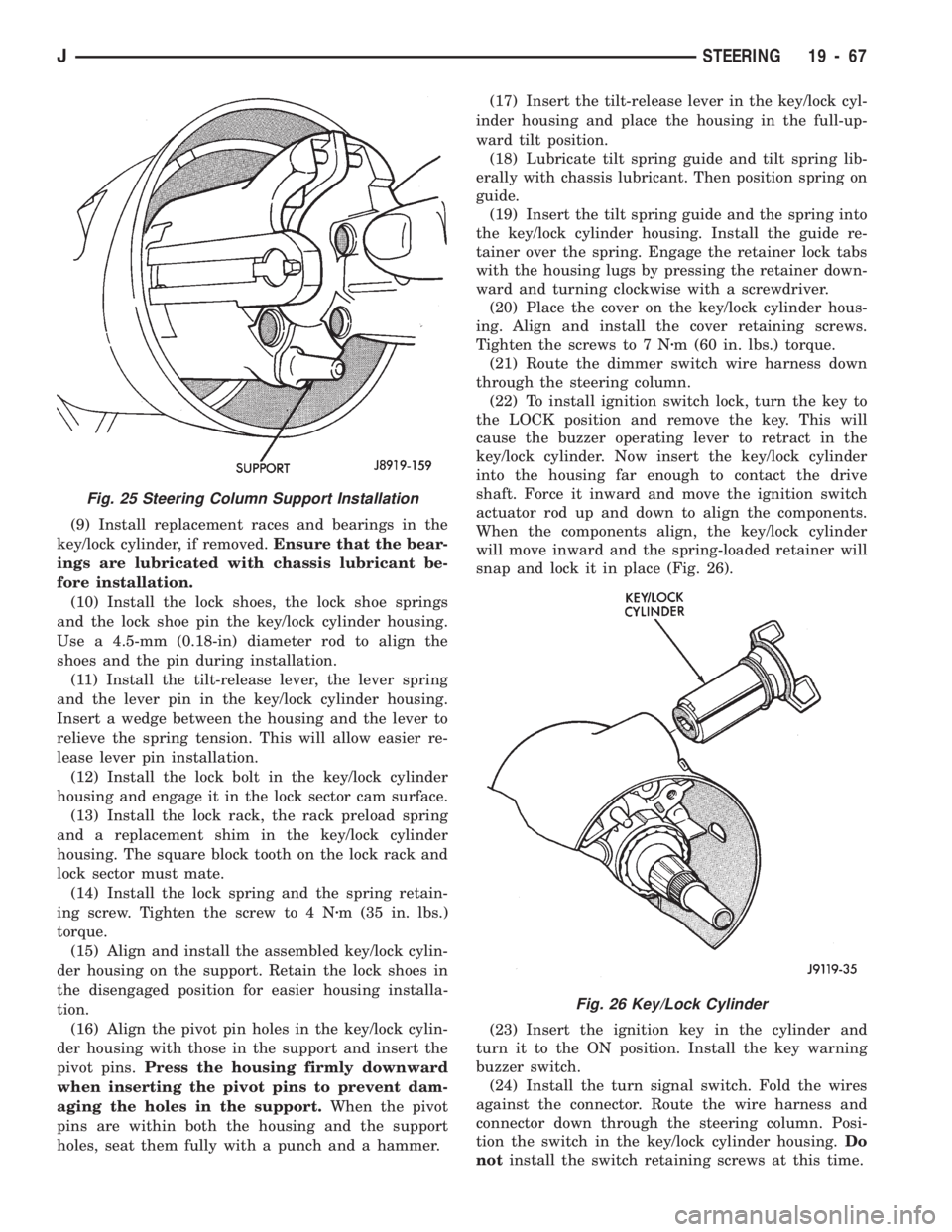

(22) To install ignition switch lock, turn the key to

the LOCK position and remove the key. This will

cause the buzzer operating lever to retract in the

key/lock cylinder. Now insert the key/lock cylinder

into the housing far enough to contact the drive

shaft. Force it inward and move the ignition switch

actuator rod up and down to align the components.

When the components align, the key/lock cylinder

will move inward and the spring-loaded retainer will

snap and lock it in place (Fig. 26).

(23) Insert the ignition key in the cylinder and

turn it to the ON position. Install the key warning

buzzer switch.

(24) Install the turn signal switch. Fold the wires

against the connector. Route the wire harness and

connector down through the steering column. Posi-

tion the switch in the key/lock cylinder housing.Do

notinstall the switch retaining screws at this time.

Fig. 26 Key/Lock Cylinder

Fig. 25 Steering Column Support Installation

JSTEERING 19 - 67

Page 1238 of 1784

able. It will be necessary to replace the retainer

if either bushing is scored, or worn.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

FRONT CLUTCH ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seals on piston and in hub of re-

tainer. Be sure lip of each seal faces interior of clutch

retainer.

(3) Lubricate lips of piston and retainer seals with

liberal quantity of Door Eze, or petroleum jelly. Then

lubricate retainer hub, bore and piston with trans-

mission fluid.

(4) Install clutch piston in retainer (Fig. 61). Use

twisting motion to seat piston in bottom of retainer.

Do not attempt to push the piston straight in.

This could fold the seals over causing leakage

and clutch slip.

(5) Position spring in clutch piston (Fig. 62).(6) Position spring retainer on top of piston spring

(Fig. 63).Make sure retainer is properly in-

stalled. Small raised tabs should be facing up-

ward. Semicircular lugs on underside of retainer

are for positioning retainer in spring.

(7) Compress piston spring and retainer with Com-

pressor Tool C-3575-A (Fig. 64). Then install new

snap ring to secure spring retainer and spring.

(8) Install clutch plates and discs (Fig. 57). Install steel

plate then disc until all plates and discs are installed.

(9) Install pressure plate and waved snap ring

(Fig. 57).

(10) Check clutch plate clearance (Fig. 64). Clear-

ance should be 1.70 to 3.40 mm (0.067 to 0.134 in.).

If clearance is incorrect, clutch discs, plates pressure

plates and snap ring may have to be changed.

Fig. 59 Front Clutch Piston Retainer Check Ball Location

Fig. 60 Retainer Bushing Locations

Fig. 61 Front Clutch Piston Installation

Fig. 62 Clutch Piston Spring Installation

Fig. 63 Correct Spring Retainer Installed Position

J30RH/32RH TRANSMISSION OVERHAUL 21 - 127

Page 1243 of 1784

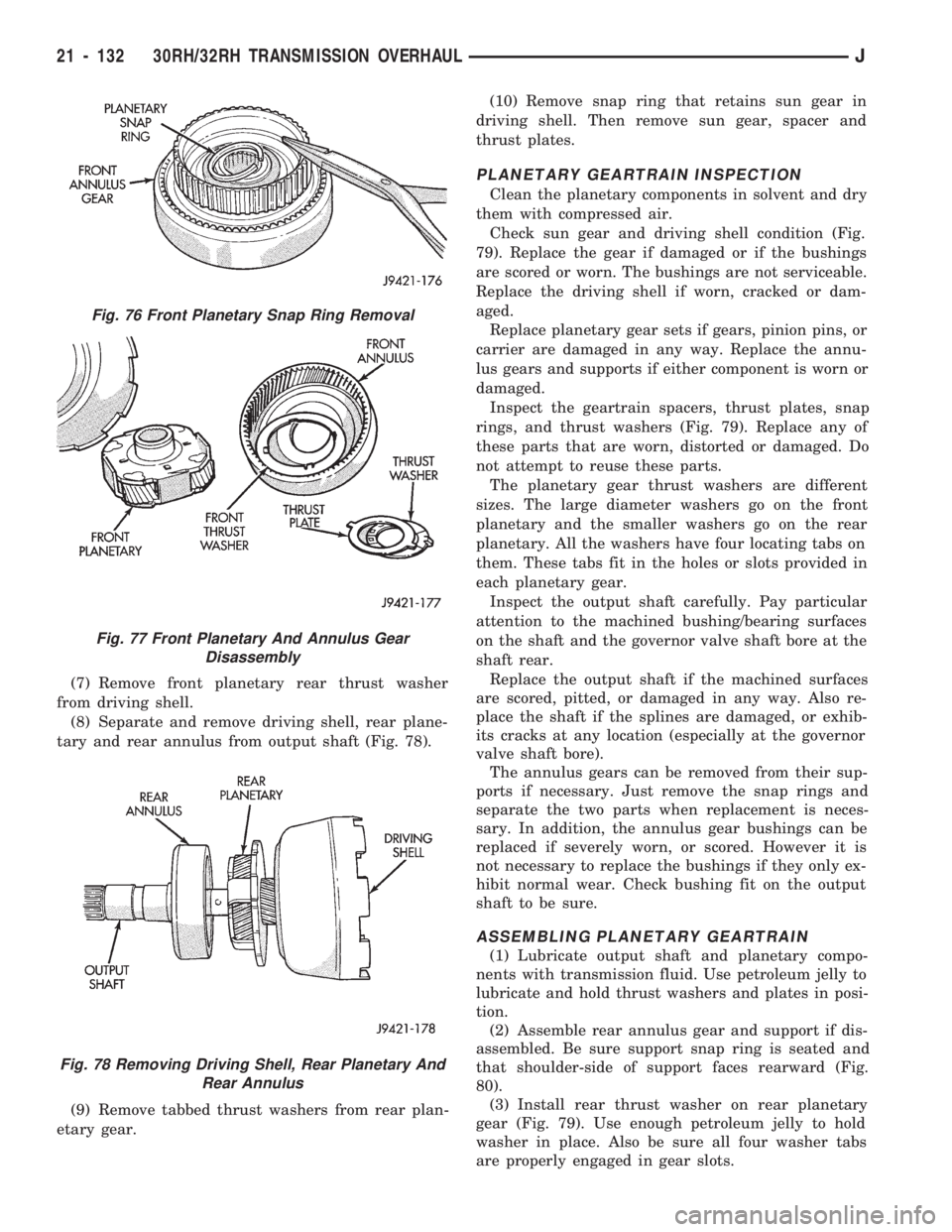

(7) Remove front planetary rear thrust washer

from driving shell.

(8) Separate and remove driving shell, rear plane-

tary and rear annulus from output shaft (Fig. 78).

(9) Remove tabbed thrust washers from rear plan-

etary gear.(10) Remove snap ring that retains sun gear in

driving shell. Then remove sun gear, spacer and

thrust plates.

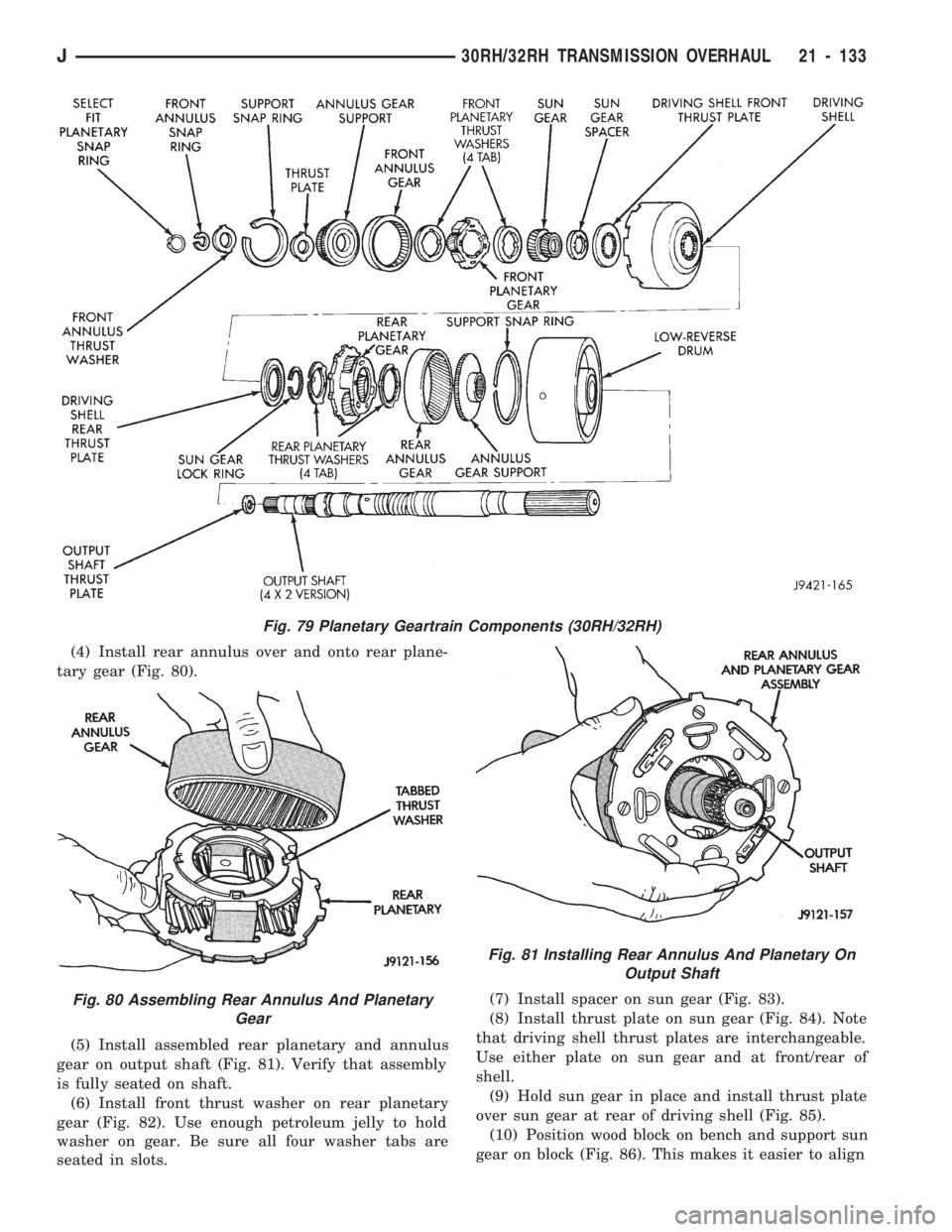

PLANETARY GEARTRAIN INSPECTION

Clean the planetary components in solvent and dry

them with compressed air.

Check sun gear and driving shell condition (Fig.

79). Replace the gear if damaged or if the bushings

are scored or worn. The bushings are not serviceable.

Replace the driving shell if worn, cracked or dam-

aged.

Replace planetary gear sets if gears, pinion pins, or

carrier are damaged in any way. Replace the annu-

lus gears and supports if either component is worn or

damaged.

Inspect the geartrain spacers, thrust plates, snap

rings, and thrust washers (Fig. 79). Replace any of

these parts that are worn, distorted or damaged. Do

not attempt to reuse these parts.

The planetary gear thrust washers are different

sizes. The large diameter washers go on the front

planetary and the smaller washers go on the rear

planetary. All the washers have four locating tabs on

them. These tabs fit in the holes or slots provided in

each planetary gear.

Inspect the output shaft carefully. Pay particular

attention to the machined bushing/bearing surfaces

on the shaft and the governor valve shaft bore at the

shaft rear.

Replace the output shaft if the machined surfaces

are scored, pitted, or damaged in any way. Also re-

place the shaft if the splines are damaged, or exhib-

its cracks at any location (especially at the governor

valve shaft bore).

The annulus gears can be removed from their sup-

ports if necessary. Just remove the snap rings and

separate the two parts when replacement is neces-

sary. In addition, the annulus gear bushings can be

replaced if severely worn, or scored. However it is

not necessary to replace the bushings if they only ex-

hibit normal wear. Check bushing fit on the output

shaft to be sure.

ASSEMBLING PLANETARY GEARTRAIN

(1) Lubricate output shaft and planetary compo-

nents with transmission fluid. Use petroleum jelly to

lubricate and hold thrust washers and plates in posi-

tion.

(2) Assemble rear annulus gear and support if dis-

assembled. Be sure support snap ring is seated and

that shoulder-side of support faces rearward (Fig.

80).

(3) Install rear thrust washer on rear planetary

gear (Fig. 79). Use enough petroleum jelly to hold

washer in place. Also be sure all four washer tabs

are properly engaged in gear slots.

Fig. 76 Front Planetary Snap Ring Removal

Fig. 77 Front Planetary And Annulus Gear

Disassembly

Fig. 78 Removing Driving Shell, Rear Planetary And

Rear Annulus

21 - 132 30RH/32RH TRANSMISSION OVERHAULJ

Page 1244 of 1784

(4) Install rear annulus over and onto rear plane-

tary gear (Fig. 80).

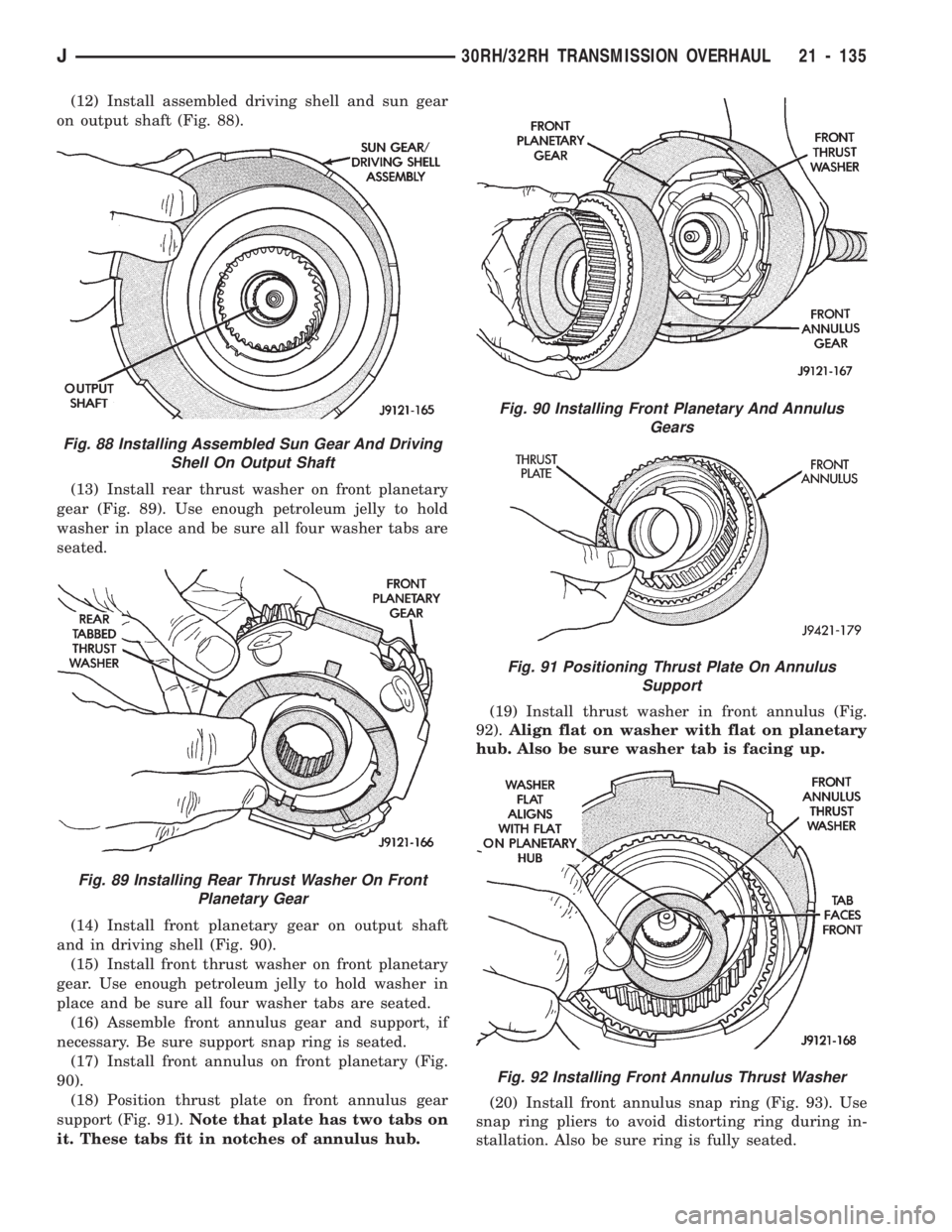

(5) Install assembled rear planetary and annulus

gear on output shaft (Fig. 81). Verify that assembly

is fully seated on shaft.

(6) Install front thrust washer on rear planetary

gear (Fig. 82). Use enough petroleum jelly to hold

washer on gear. Be sure all four washer tabs are

seated in slots.(7) Install spacer on sun gear (Fig. 83).

(8) Install thrust plate on sun gear (Fig. 84). Note

that driving shell thrust plates are interchangeable.

Use either plate on sun gear and at front/rear of

shell.

(9) Hold sun gear in place and install thrust plate

over sun gear at rear of driving shell (Fig. 85).

(10) Position wood block on bench and support sun

gear on block (Fig. 86). This makes it easier to align

Fig. 79 Planetary Geartrain Components (30RH/32RH)

Fig. 80 Assembling Rear Annulus And Planetary

Gear

Fig. 81 Installing Rear Annulus And Planetary On

Output Shaft

J30RH/32RH TRANSMISSION OVERHAUL 21 - 133

Page 1246 of 1784

(12) Install assembled driving shell and sun gear

on output shaft (Fig. 88).

(13) Install rear thrust washer on front planetary

gear (Fig. 89). Use enough petroleum jelly to hold

washer in place and be sure all four washer tabs are

seated.

(14) Install front planetary gear on output shaft

and in driving shell (Fig. 90).

(15) Install front thrust washer on front planetary

gear. Use enough petroleum jelly to hold washer in

place and be sure all four washer tabs are seated.

(16) Assemble front annulus gear and support, if

necessary. Be sure support snap ring is seated.

(17) Install front annulus on front planetary (Fig.

90).

(18) Position thrust plate on front annulus gear

support (Fig. 91).Note that plate has two tabs on

it. These tabs fit in notches of annulus hub.(19) Install thrust washer in front annulus (Fig.

92).Align flat on washer with flat on planetary

hub. Also be sure washer tab is facing up.

(20) Install front annulus snap ring (Fig. 93). Use

snap ring pliers to avoid distorting ring during in-

stallation. Also be sure ring is fully seated.

Fig. 88 Installing Assembled Sun Gear And Driving

Shell On Output Shaft

Fig. 89 Installing Rear Thrust Washer On Front

Planetary Gear

Fig. 90 Installing Front Planetary And Annulus

Gears

Fig. 91 Positioning Thrust Plate On Annulus

Support

Fig. 92 Installing Front Annulus Thrust Washer

J30RH/32RH TRANSMISSION OVERHAUL 21 - 135

Page 1285 of 1784

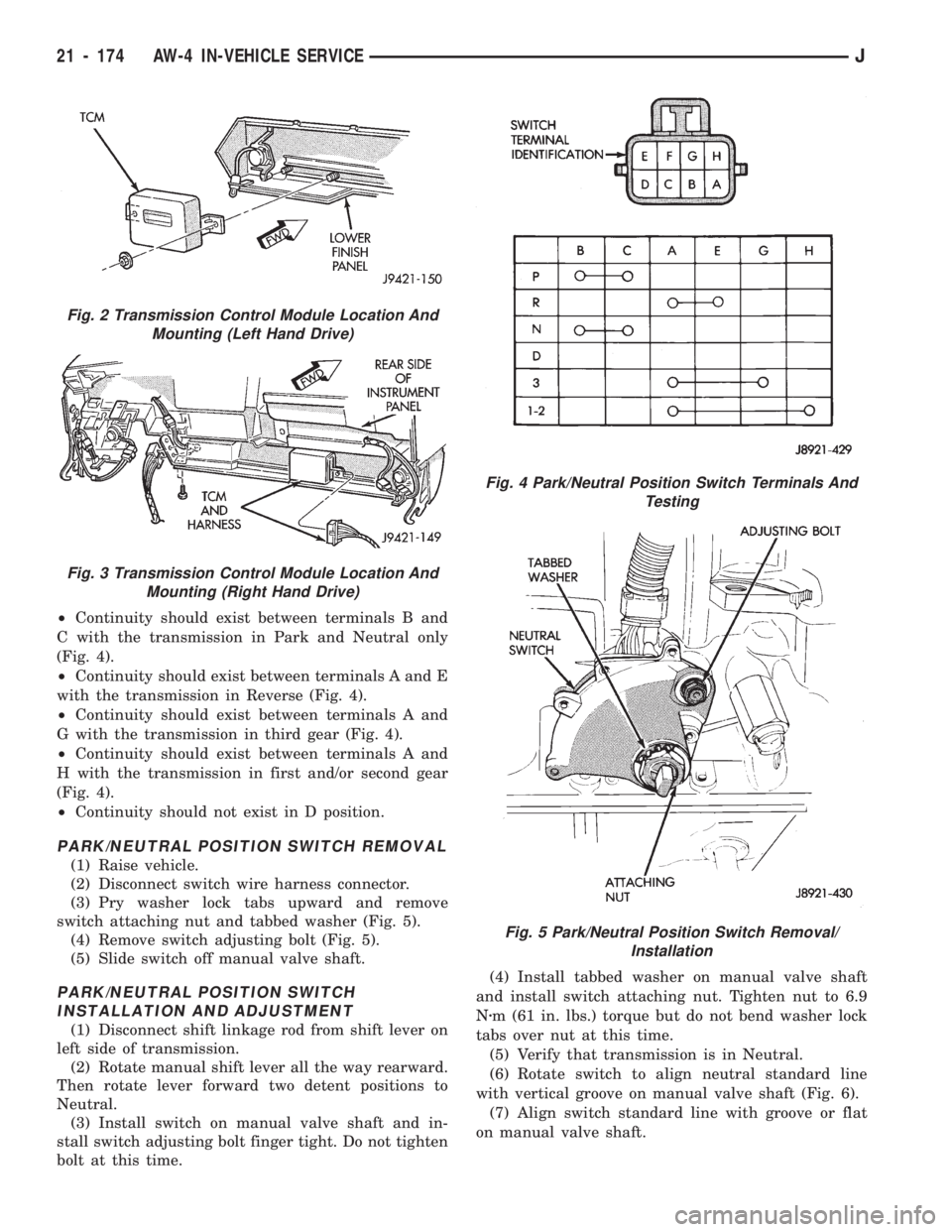

²Continuity should exist between terminals B and

C with the transmission in Park and Neutral only

(Fig. 4).

²Continuity should exist between terminals A and E

with the transmission in Reverse (Fig. 4).

²Continuity should exist between terminals A and

G with the transmission in third gear (Fig. 4).

²Continuity should exist between terminals A and

H with the transmission in first and/or second gear

(Fig. 4).

²Continuity should not exist in D position.

PARK/NEUTRAL POSITION SWITCH REMOVAL

(1) Raise vehicle.

(2) Disconnect switch wire harness connector.

(3) Pry washer lock tabs upward and remove

switch attaching nut and tabbed washer (Fig. 5).

(4) Remove switch adjusting bolt (Fig. 5).

(5) Slide switch off manual valve shaft.

PARK/NEUTRAL POSITION SWITCH

INSTALLATION AND ADJUSTMENT

(1) Disconnect shift linkage rod from shift lever on

left side of transmission.

(2) Rotate manual shift lever all the way rearward.

Then rotate lever forward two detent positions to

Neutral.

(3) Install switch on manual valve shaft and in-

stall switch adjusting bolt finger tight. Do not tighten

bolt at this time.(4) Install tabbed washer on manual valve shaft

and install switch attaching nut. Tighten nut to 6.9

Nzm (61 in. lbs.) torque but do not bend washer lock

tabs over nut at this time.

(5) Verify that transmission is in Neutral.

(6) Rotate switch to align neutral standard line

with vertical groove on manual valve shaft (Fig. 6).

(7) Align switch standard line with groove or flat

on manual valve shaft.

Fig. 2 Transmission Control Module Location And

Mounting (Left Hand Drive)

Fig. 3 Transmission Control Module Location And

Mounting (Right Hand Drive)

Fig. 4 Park/Neutral Position Switch Terminals And

Testing

Fig. 5 Park/Neutral Position Switch Removal/

Installation

21 - 174 AW-4 IN-VEHICLE SERVICEJ

Page 1286 of 1784

(8) Tighten switch adjusting bolt to 13 Nzm(9ft.

lbs.) torque.

(9) Bend at least two washer lock tabs over switch

attaching nut to secure it.

(10) Connect shift linkage rod to shift lever on left

side of case.

(11) Connect switch wires to harness and lower ve-

hicle.

(12) Check switch operation. Engine should start

in Park and Neutral only.

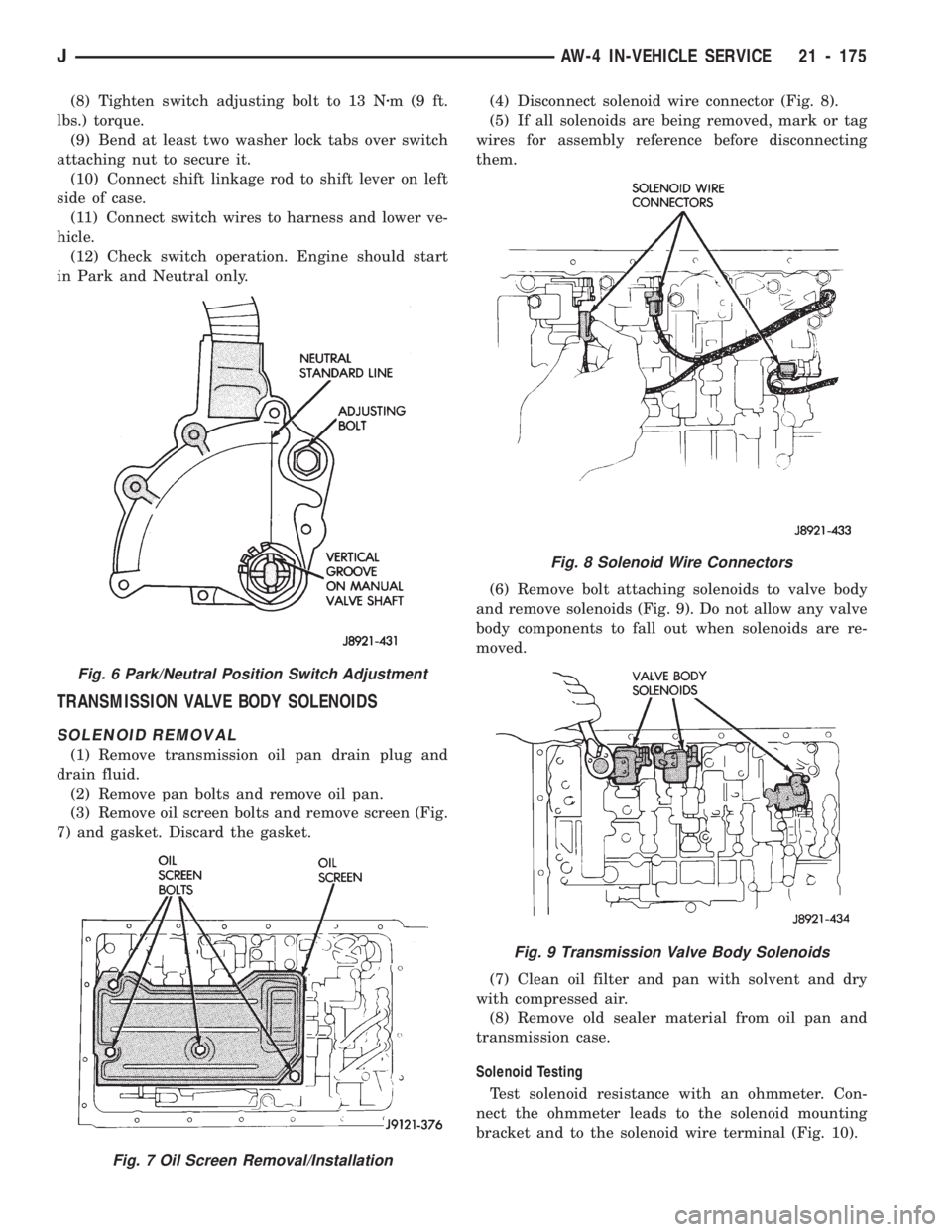

TRANSMISSION VALVE BODY SOLENOIDS

SOLENOID REMOVAL

(1) Remove transmission oil pan drain plug and

drain fluid.

(2) Remove pan bolts and remove oil pan.

(3) Remove oil screen bolts and remove screen (Fig.

7) and gasket. Discard the gasket.(4) Disconnect solenoid wire connector (Fig. 8).

(5) If all solenoids are being removed, mark or tag

wires for assembly reference before disconnecting

them.

(6) Remove bolt attaching solenoids to valve body

and remove solenoids (Fig. 9). Do not allow any valve

body components to fall out when solenoids are re-

moved.

(7) Clean oil filter and pan with solvent and dry

with compressed air.

(8) Remove old sealer material from oil pan and

transmission case.

Solenoid Testing

Test solenoid resistance with an ohmmeter. Con-

nect the ohmmeter leads to the solenoid mounting

bracket and to the solenoid wire terminal (Fig. 10).

Fig. 8 Solenoid Wire Connectors

Fig. 9 Transmission Valve Body Solenoids

Fig. 6 Park/Neutral Position Switch Adjustment

Fig. 7 Oil Screen Removal/Installation

JAW-4 IN-VEHICLE SERVICE 21 - 175

Page 1300 of 1784

AW-4 TRANSMISSION REMOVAL AND INSTALLATION

INDEX

page page

Oil Pump Seal Replacement............... 189

Torque Converter Stator Clutch Inspection..... 189Transmission and Torque Converter Installation . 190

Transmission and Torque Converter Removal . . 189

TRANSMISSION AND TORQUE CONVERTER

REMOVAL

(1) Raise vehicle.

(2) Drain transmission fluid and reinstall oil pan

drain plug.

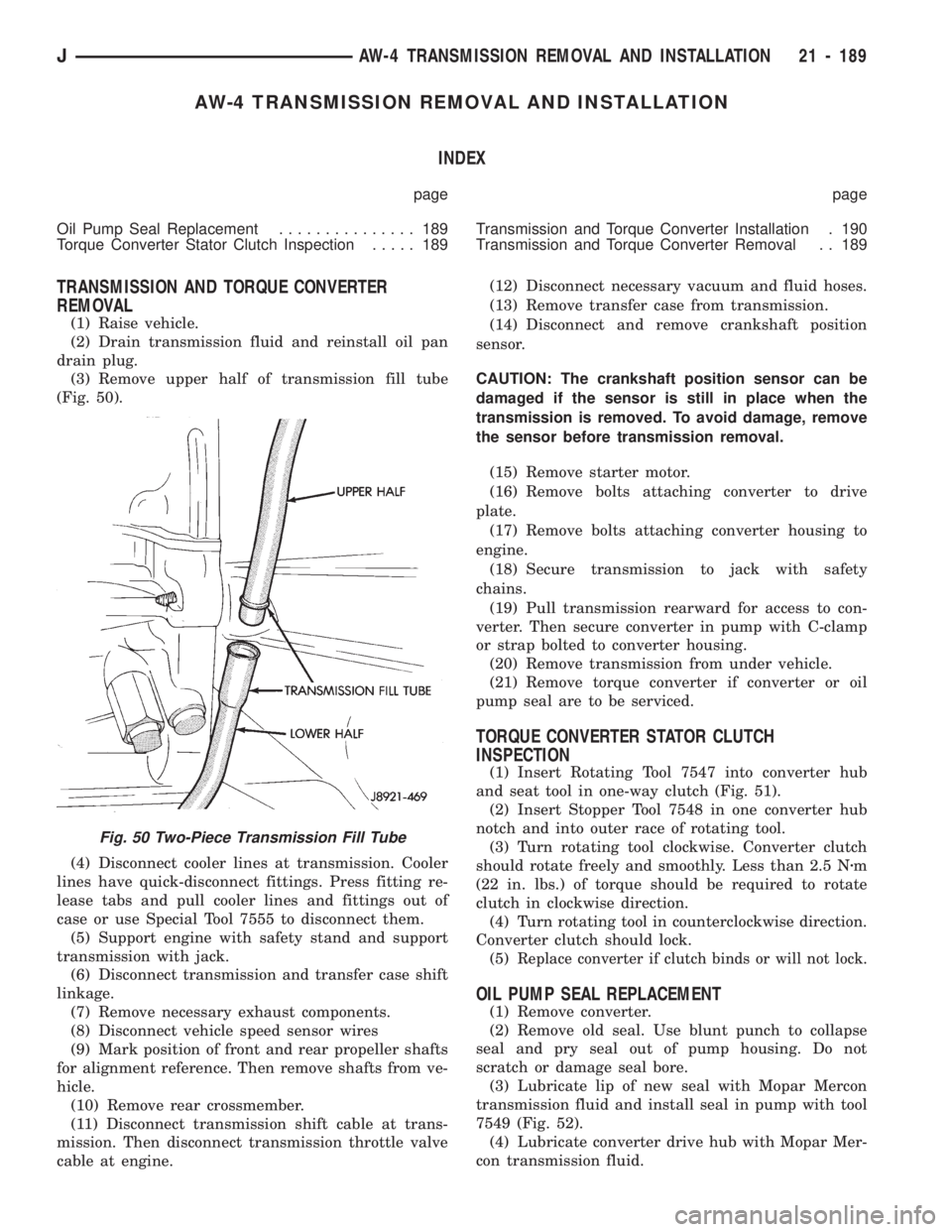

(3) Remove upper half of transmission fill tube

(Fig. 50).

(4) Disconnect cooler lines at transmission. Cooler

lines have quick-disconnect fittings. Press fitting re-

lease tabs and pull cooler lines and fittings out of

case or use Special Tool 7555 to disconnect them.

(5) Support engine with safety stand and support

transmission with jack.

(6) Disconnect transmission and transfer case shift

linkage.

(7) Remove necessary exhaust components.

(8) Disconnect vehicle speed sensor wires

(9) Mark position of front and rear propeller shafts

for alignment reference. Then remove shafts from ve-

hicle.

(10) Remove rear crossmember.

(11) Disconnect transmission shift cable at trans-

mission. Then disconnect transmission throttle valve

cable at engine.(12) Disconnect necessary vacuum and fluid hoses.

(13) Remove transfer case from transmission.

(14) Disconnect and remove crankshaft position

sensor.

CAUTION: The crankshaft position sensor can be

damaged if the sensor is still in place when the

transmission is removed. To avoid damage, remove

the sensor before transmission removal.

(15) Remove starter motor.

(16) Remove bolts attaching converter to drive

plate.

(17) Remove bolts attaching converter housing to

engine.

(18) Secure transmission to jack with safety

chains.

(19) Pull transmission rearward for access to con-

verter. Then secure converter in pump with C-clamp

or strap bolted to converter housing.

(20) Remove transmission from under vehicle.

(21) Remove torque converter if converter or oil

pump seal are to be serviced.

TORQUE CONVERTER STATOR CLUTCH

INSPECTION

(1) Insert Rotating Tool 7547 into converter hub

and seat tool in one-way clutch (Fig. 51).

(2) Insert Stopper Tool 7548 in one converter hub

notch and into outer race of rotating tool.

(3) Turn rotating tool clockwise. Converter clutch

should rotate freely and smoothly. Less than 2.5 Nzm

(22 in. lbs.) of torque should be required to rotate

clutch in clockwise direction.

(4) Turn rotating tool in counterclockwise direction.

Converter clutch should lock.

(5)

Replace converter if clutch binds or will not lock.

OIL PUMP SEAL REPLACEMENT

(1) Remove converter.

(2) Remove old seal. Use blunt punch to collapse

seal and pry seal out of pump housing. Do not

scratch or damage seal bore.

(3) Lubricate lip of new seal with Mopar Mercon

transmission fluid and install seal in pump with tool

7549 (Fig. 52).

(4) Lubricate converter drive hub with Mopar Mer-

con transmission fluid.

Fig. 50 Two-Piece Transmission Fill Tube

JAW-4 TRANSMISSION REMOVAL AND INSTALLATION 21 - 189