ABS JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1341 of 1784

(5) Support sun gear on wood block (Fig. 6). Then

remove first sun gear snap ring and separate drum

from gear.

(6) Remove remaining snap ring from sun gear

(Fig. 7).

(7) Measure inside diameter of sun gear bushings

with bore gauge or inside micrometer (Fig. 8). Maxi-

mum allowable diameter is 27.08 mm (1.0661 in.).

Replace sun gear if bushing inside diameter is

greater than specified.

SUN GEAR AND CLUTCH ASSEMBLY

(1) Install first snap ring on sun gear.

(2) Install sun gear in drum and install remaining

snap ring.(3) Coat replacement seal rings with petroleum

jelly and install them on sun gear.Be sure seal

ring ends are interlocked.

(4) Install thrust washer. Be sure washer tabs are

seated in drum slots.

(5) Install one-way clutch/second brake hub assem-

bly on sun gear. Deep side of hub flange faces up-

ward (Fig. 9).

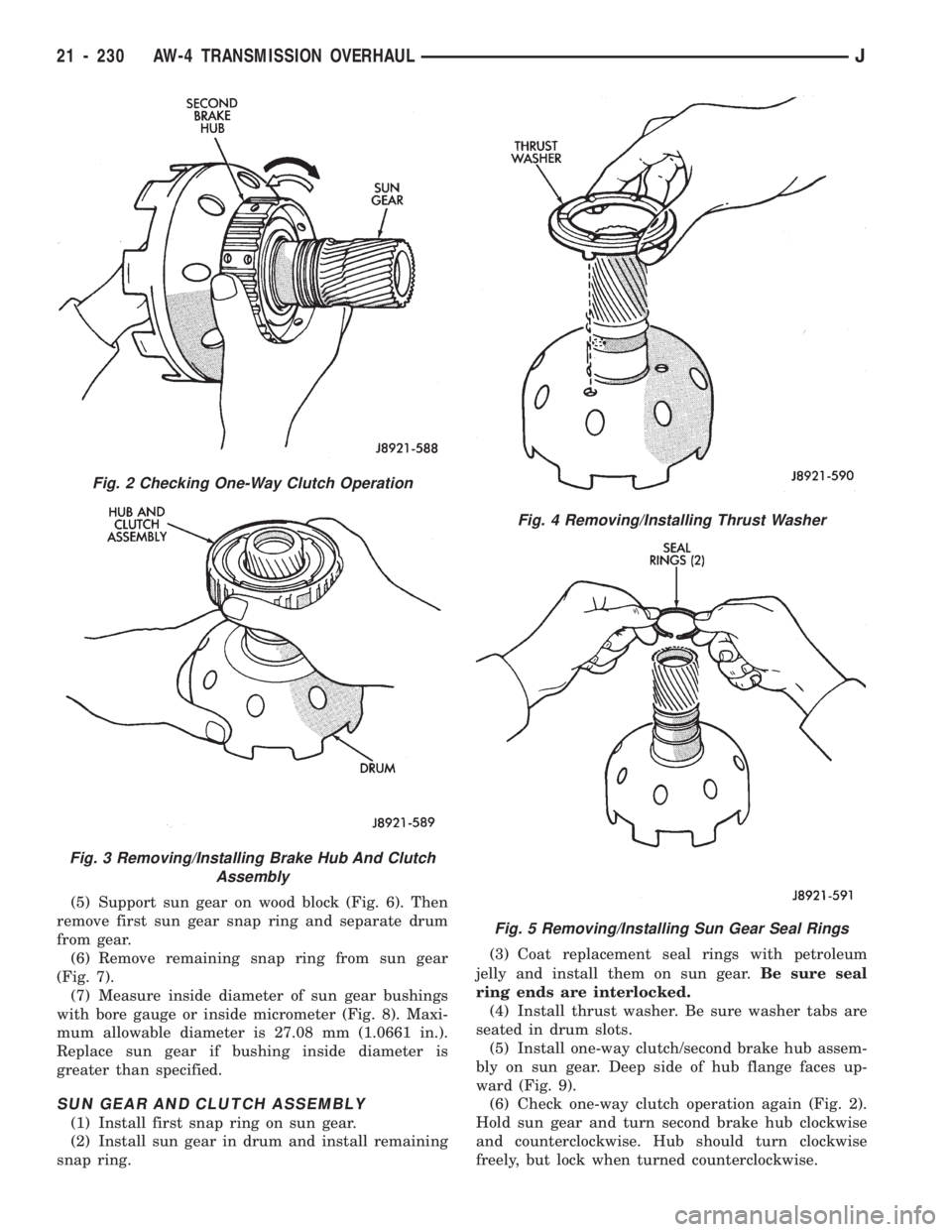

(6) Check one-way clutch operation again (Fig. 2).

Hold sun gear and turn second brake hub clockwise

and counterclockwise. Hub should turn clockwise

freely, but lock when turned counterclockwise.

Fig. 2 Checking One-Way Clutch Operation

Fig. 3 Removing/Installing Brake Hub And Clutch

Assembly

Fig. 4 Removing/Installing Thrust Washer

Fig. 5 Removing/Installing Sun Gear Seal Rings

21 - 230 AW-4 TRANSMISSION OVERHAULJ

Page 1344 of 1784

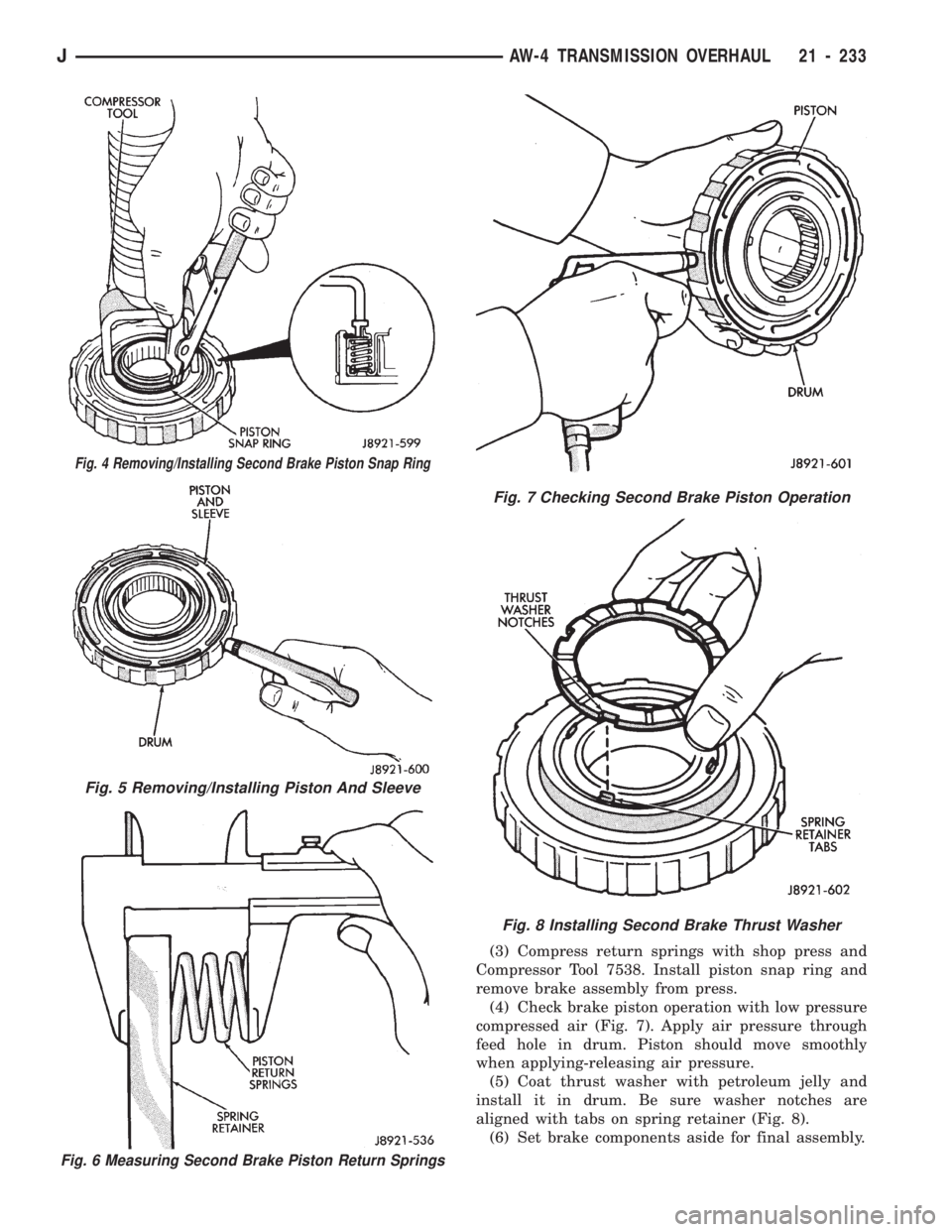

(3) Compress return springs with shop press and

Compressor Tool 7538. Install piston snap ring and

remove brake assembly from press.

(4) Check brake piston operation with low pressure

compressed air (Fig. 7). Apply air pressure through

feed hole in drum. Piston should move smoothly

when applying-releasing air pressure.

(5) Coat thrust washer with petroleum jelly and

install it in drum. Be sure washer notches are

aligned with tabs on spring retainer (Fig. 8).

(6) Set brake components aside for final assembly.

Fig. 6 Measuring Second Brake Piston Return Springs

Fig. 7 Checking Second Brake Piston Operation

Fig. 8 Installing Second Brake Thrust Washer

Fig. 4 Removing/Installing Second Brake Piston Snap Ring

Fig. 5 Removing/Installing Piston And Sleeve

JAW-4 TRANSMISSION OVERHAUL 21 - 233

Page 1370 of 1784

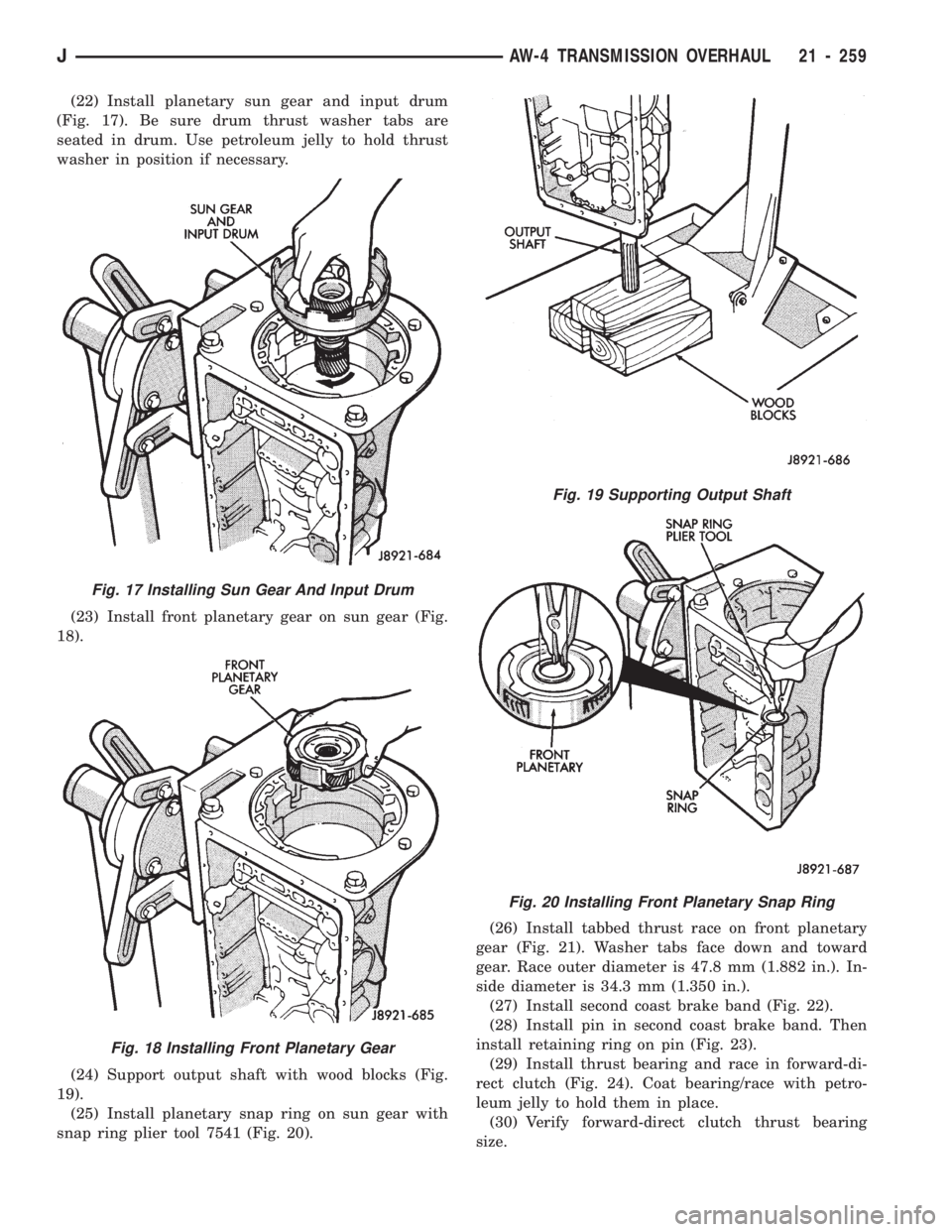

(22) Install planetary sun gear and input drum

(Fig. 17). Be sure drum thrust washer tabs are

seated in drum. Use petroleum jelly to hold thrust

washer in position if necessary.

(23) Install front planetary gear on sun gear (Fig.

18).

(24) Support output shaft with wood blocks (Fig.

19).

(25) Install planetary snap ring on sun gear with

snap ring plier tool 7541 (Fig. 20).(26) Install tabbed thrust race on front planetary

gear (Fig. 21). Washer tabs face down and toward

gear. Race outer diameter is 47.8 mm (1.882 in.). In-

side diameter is 34.3 mm (1.350 in.).

(27) Install second coast brake band (Fig. 22).

(28) Install pin in second coast brake band. Then

install retaining ring on pin (Fig. 23).

(29) Install thrust bearing and race in forward-di-

rect clutch (Fig. 24). Coat bearing/race with petro-

leum jelly to hold them in place.

(30) Verify forward-direct clutch thrust bearing

size.

Fig. 17 Installing Sun Gear And Input Drum

Fig. 18 Installing Front Planetary Gear

Fig. 19 Supporting Output Shaft

Fig. 20 Installing Front Planetary Snap Ring

JAW-4 TRANSMISSION OVERHAUL 21 - 259

Page 1381 of 1784

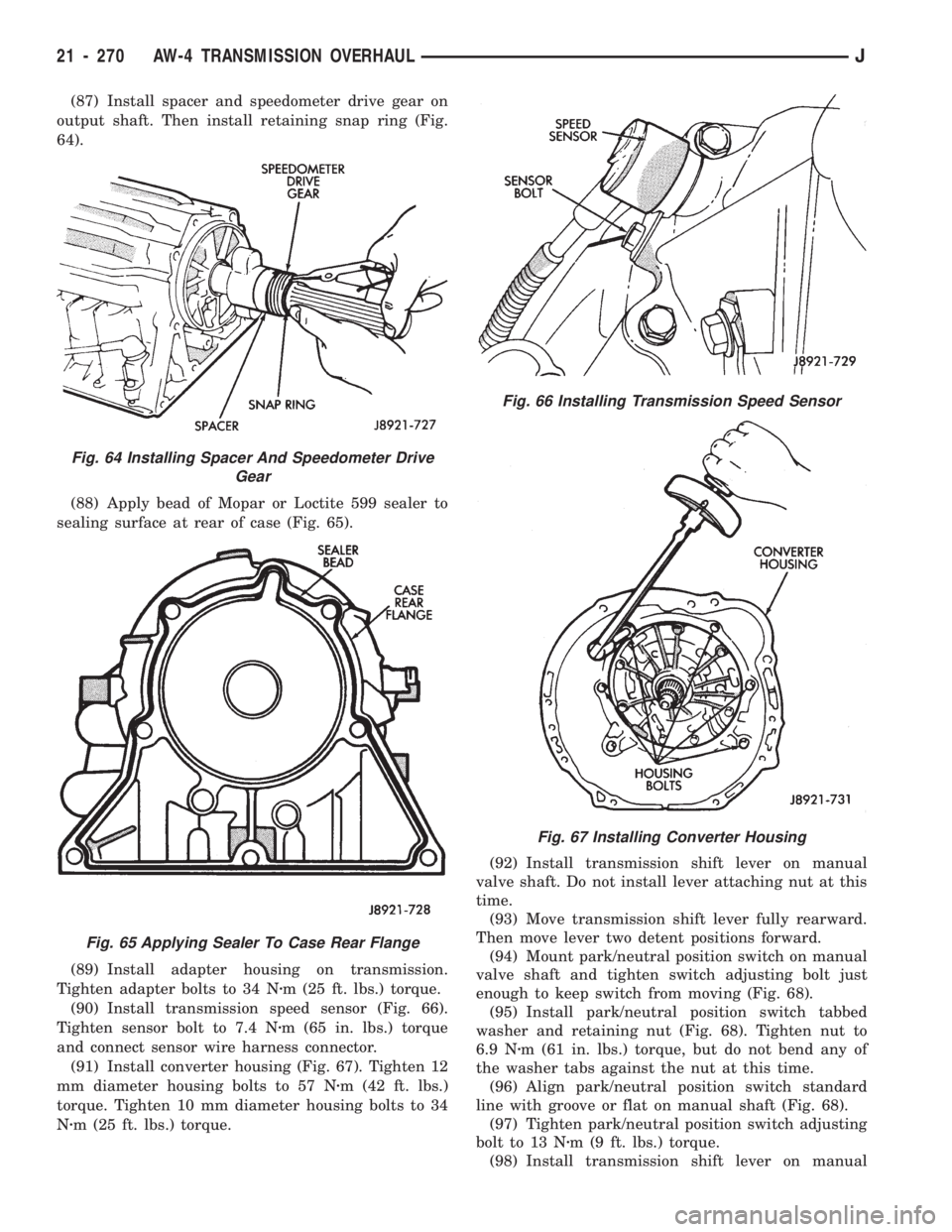

(87) Install spacer and speedometer drive gear on

output shaft. Then install retaining snap ring (Fig.

64).

(88) Apply bead of Mopar or Loctite 599 sealer to

sealing surface at rear of case (Fig. 65).

(89) Install adapter housing on transmission.

Tighten adapter bolts to 34 Nzm (25 ft. lbs.) torque.

(90) Install transmission speed sensor (Fig. 66).

Tighten sensor bolt to 7.4 Nzm (65 in. lbs.) torque

and connect sensor wire harness connector.

(91) Install converter housing (Fig. 67). Tighten 12

mm diameter housing bolts to 57 Nzm (42 ft. lbs.)

torque. Tighten 10 mm diameter housing bolts to 34

Nzm (25 ft. lbs.) torque.(92) Install transmission shift lever on manual

valve shaft. Do not install lever attaching nut at this

time.

(93) Move transmission shift lever fully rearward.

Then move lever two detent positions forward.

(94) Mount park/neutral position switch on manual

valve shaft and tighten switch adjusting bolt just

enough to keep switch from moving (Fig. 68).

(95) Install park/neutral position switch tabbed

washer and retaining nut (Fig. 68). Tighten nut to

6.9 Nzm (61 in. lbs.) torque, but do not bend any of

the washer tabs against the nut at this time.

(96) Align park/neutral position switch standard

line with groove or flat on manual shaft (Fig. 68).

(97) Tighten park/neutral position switch adjusting

bolt to 13 Nzm (9 ft. lbs.) torque.

(98) Install transmission shift lever on manual

Fig. 66 Installing Transmission Speed Sensor

Fig. 67 Installing Converter Housing

Fig. 64 Installing Spacer And Speedometer Drive

Gear

Fig. 65 Applying Sealer To Case Rear Flange

21 - 270 AW-4 TRANSMISSION OVERHAULJ

Page 1477 of 1784

(2) Carefully pry the applique off the license plate

visor and tailgate (Fig. 62).

INSTALLATION

(1) Align the moulding with the visor and then

press the applique into place.

(2) Install the rivets to attach the outboard tabs on

applique to the tailgate.

WOODGRAIN OVERLAY

SERVICE INFORMATION

Exterior woodgrain overlay is a weather-resistant

vinyl. The adhesive backing is protected by a paper

liner until removed for installation.

OVERLAY REPAIR

Small nicks and scratches on an overlay can be

touched-up with paint.

To eliminate blisters and air bubbles, pierce them

with a needle or pin. Force the trapped air out of the

hole and press firmly on the overlay. Heat also can

be applied to remove small wrinkles.

Whenever an overlay must be stretched, do

not slit or cut it. Instead, apply heat and press

or squeegee the overlay into place.

INSTALLATION REQUIREMENTS

Overlay replacement requires metal repair and

paint refinish to be completed before the overlay is

installed.

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A woodgrain overlay

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for overlay installation:

²a commercial woodgrain overlay removal solution;

²a commercial adhesive removal solution;

²liquid dish detergent (for wetting solution);

²a mixture of wetting solution;

²a commercial wax and silicone removal solution;

²isopropyl alcohol (rubbing alcohol);

²a squeegee (4 to 5 inches wide, plastic or hard rub-

ber);

²a water bucket and sponge;

²sandpaper (no. 360 or no. 400, wet or dry type);

²a heat gun (or infra-red heat bulb);

²clean wiping rags or paper towels;

²a pair of scissors;

²a needle or pin; and

²a wax pencil.

Using a wetting solution helps the installation of

an overlay. Prepare a solution by mixing two or three

teaspoons of dish detergent with 1 gallon of water.

Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

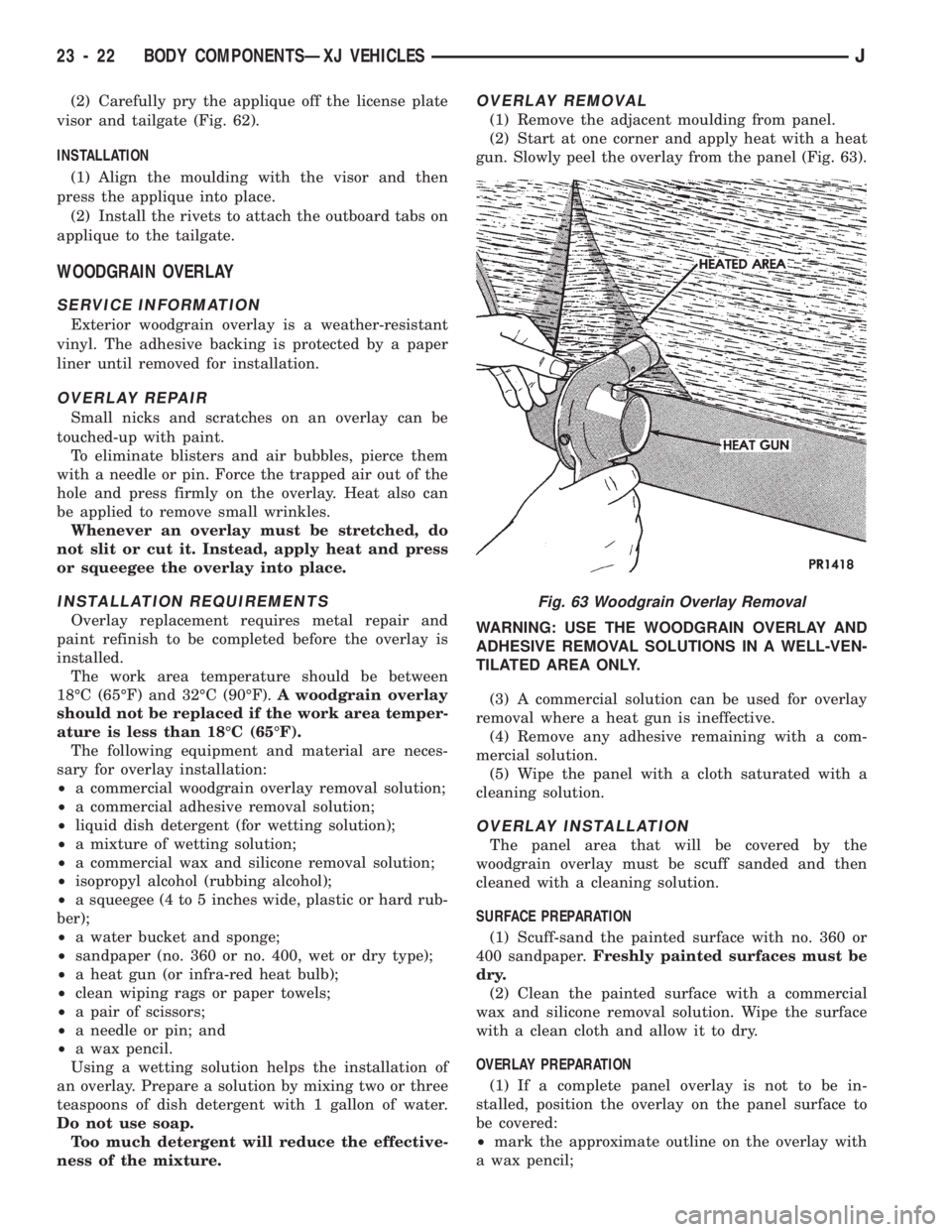

OVERLAY REMOVAL

(1) Remove the adjacent moulding from panel.

(2) Start at one corner and apply heat with a heat

gun. Slowly peel the overlay from the panel (Fig. 63).

WARNING: USE THE WOODGRAIN OVERLAY AND

ADHESIVE REMOVAL SOLUTIONS IN A WELL-VEN-

TILATED AREA ONLY.

(3) A commercial solution can be used for overlay

removal where a heat gun is ineffective.

(4) Remove any adhesive remaining with a com-

mercial solution.

(5) Wipe the panel with a cloth saturated with a

cleaning solution.

OVERLAY INSTALLATION

The panel area that will be covered by the

woodgrain overlay must be scuff sanded and then

cleaned with a cleaning solution.

SURFACE PREPARATION

(1) Scuff-sand the painted surface with no. 360 or

400 sandpaper.Freshly painted surfaces must be

dry.

(2) Clean the painted surface with a commercial

wax and silicone removal solution. Wipe the surface

with a clean cloth and allow it to dry.

OVERLAY PREPARATION

(1) If a complete panel overlay is not to be in-

stalled, position the overlay on the panel surface to

be covered:

²mark the approximate outline on the overlay with

a wax pencil;

Fig. 63 Woodgrain Overlay Removal

23 - 22 BODY COMPONENTSÐXJ VEHICLESJ

Page 1551 of 1784

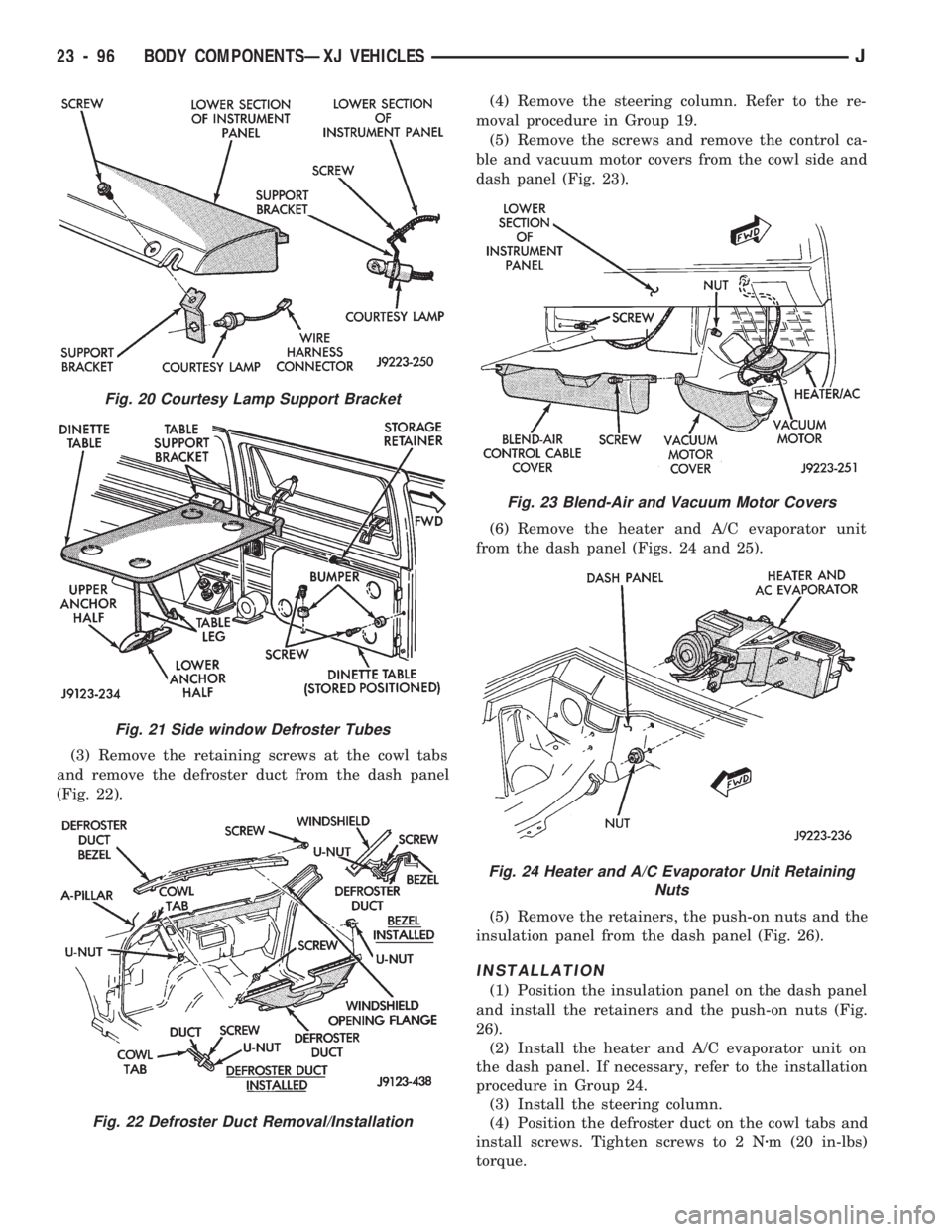

(3) Remove the retaining screws at the cowl tabs

and remove the defroster duct from the dash panel

(Fig. 22).(4) Remove the steering column. Refer to the re-

moval procedure in Group 19.

(5) Remove the screws and remove the control ca-

ble and vacuum motor covers from the cowl side and

dash panel (Fig. 23).

(6) Remove the heater and A/C evaporator unit

from the dash panel (Figs. 24 and 25).

(5) Remove the retainers, the push-on nuts and the

insulation panel from the dash panel (Fig. 26).

INSTALLATION

(1) Position the insulation panel on the dash panel

and install the retainers and the push-on nuts (Fig.

26).

(2) Install the heater and A/C evaporator unit on

the dash panel. If necessary, refer to the installation

procedure in Group 24.

(3) Install the steering column.

(4) Position the defroster duct on the cowl tabs and

install screws. Tighten screws to 2 Nzm (20 in-lbs)

torque.

Fig. 20 Courtesy Lamp Support Bracket

Fig. 21 Side window Defroster Tubes

Fig. 22 Defroster Duct Removal/Installation

Fig. 23 Blend-Air and Vacuum Motor Covers

Fig. 24 Heater and A/C Evaporator Unit Retaining

Nuts

23 - 96 BODY COMPONENTSÐXJ VEHICLESJ

Page 1564 of 1784

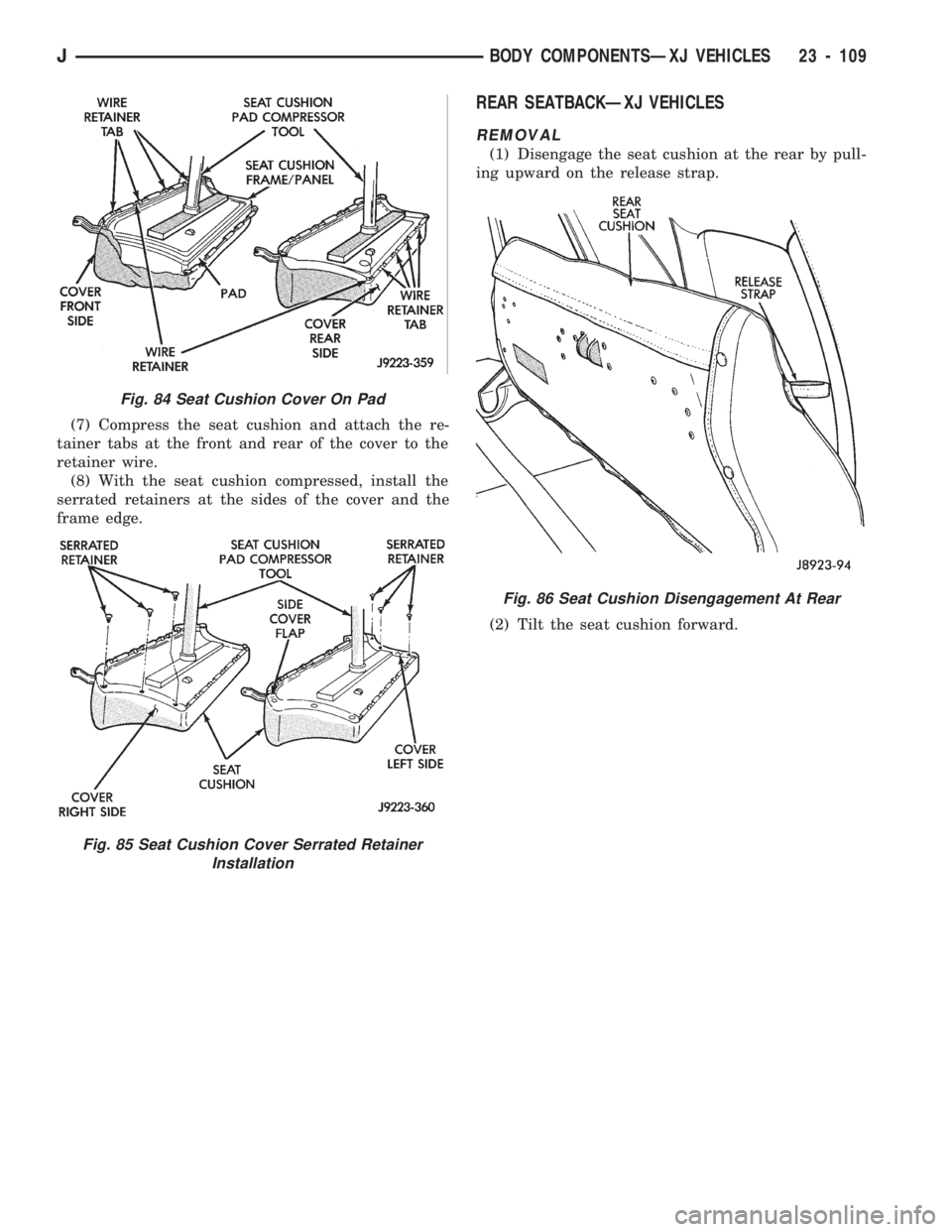

(7) Compress the seat cushion and attach the re-

tainer tabs at the front and rear of the cover to the

retainer wire.

(8) With the seat cushion compressed, install the

serrated retainers at the sides of the cover and the

frame edge.

REAR SEATBACKÐXJ VEHICLES

REMOVAL

(1) Disengage the seat cushion at the rear by pull-

ing upward on the release strap.

(2) Tilt the seat cushion forward.

Fig. 84 Seat Cushion Cover On Pad

Fig. 85 Seat Cushion Cover Serrated Retainer

Installation

Fig. 86 Seat Cushion Disengagement At Rear

JBODY COMPONENTSÐXJ VEHICLES 23 - 109

Page 1658 of 1784

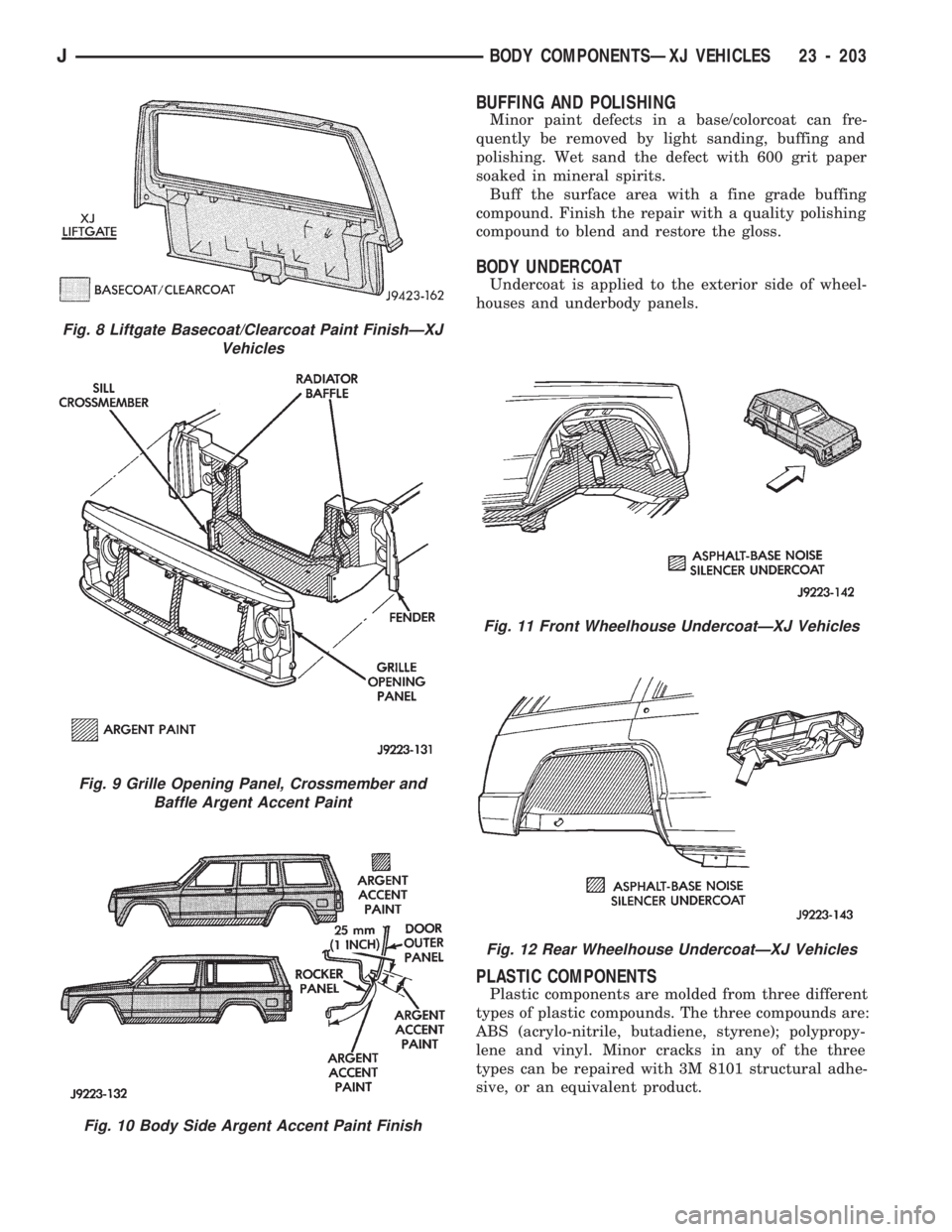

BUFFING AND POLISHING

Minor paint defects in a base/colorcoat can fre-

quently be removed by light sanding, buffing and

polishing. Wet sand the defect with 600 grit paper

soaked in mineral spirits.

Buff the surface area with a fine grade buffing

compound. Finish the repair with a quality polishing

compound to blend and restore the gloss.

BODY UNDERCOAT

Undercoat is applied to the exterior side of wheel-

houses and underbody panels.

PLASTIC COMPONENTS

Plastic components are molded from three different

types of plastic compounds. The three compounds are:

ABS (acrylo-nitrile, butadiene, styrene); polypropy-

lene and vinyl. Minor cracks in any of the three

types can be repaired with 3M 8101 structural adhe-

sive, or an equivalent product.

Fig. 8 Liftgate Basecoat/Clearcoat Paint FinishÐXJ

Vehicles

Fig. 9 Grille Opening Panel, Crossmember and

Baffle Argent Accent Paint

Fig. 10 Body Side Argent Accent Paint Finish

Fig. 11 Front Wheelhouse UndercoatÐXJ Vehicles

Fig. 12 Rear Wheelhouse UndercoatÐXJ Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 203

Page 1659 of 1784

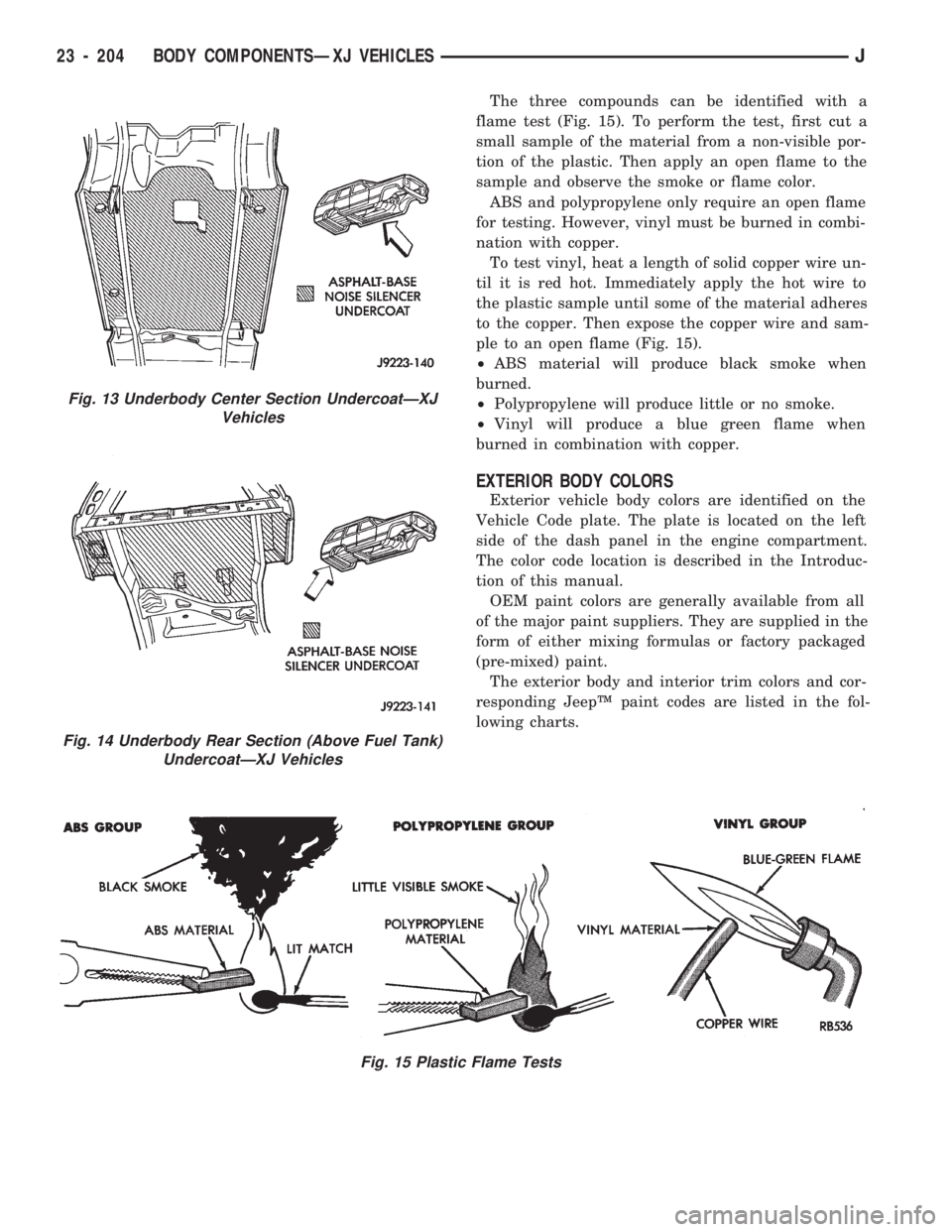

The three compounds can be identified with a

flame test (Fig. 15). To perform the test, first cut a

small sample of the material from a non-visible por-

tion of the plastic. Then apply an open flame to the

sample and observe the smoke or flame color.

ABS and polypropylene only require an open flame

for testing. However, vinyl must be burned in combi-

nation with copper.

To test vinyl, heat a length of solid copper wire un-

til it is red hot. Immediately apply the hot wire to

the plastic sample until some of the material adheres

to the copper. Then expose the copper wire and sam-

ple to an open flame (Fig. 15).

²ABS material will produce black smoke when

burned.

²Polypropylene will produce little or no smoke.

²Vinyl will produce a blue green flame when

burned in combination with copper.

EXTERIOR BODY COLORS

Exterior vehicle body colors are identified on the

Vehicle Code plate. The plate is located on the left

side of the dash panel in the engine compartment.

The color code location is described in the Introduc-

tion of this manual.

OEM paint colors are generally available from all

of the major paint suppliers. They are supplied in the

form of either mixing formulas or factory packaged

(pre-mixed) paint.

The exterior body and interior trim colors and cor-

responding JeepŸ paint codes are listed in the fol-

lowing charts.

Fig. 15 Plastic Flame Tests

Fig. 13 Underbody Center Section UndercoatÐXJ

Vehicles

Fig. 14 Underbody Rear Section (Above Fuel Tank)

UndercoatÐXJ Vehicles

23 - 204 BODY COMPONENTSÐXJ VEHICLESJ

Page 1664 of 1784

HEATING AND AIR CONDITIONING

CONTENTS

page page

CLIMATE CONTROL SYSTEMÐXJ VEHICLES . 22

CLIMATE CONTROL SYSTEMÐYJ VEHICLES . 37

COMPRESSOR OVERHAUL............... 17

GENERAL INFORMATION.................. 1SERVICE DIAGNOSISÐELECTRICAL........ 14

SERVICE DIAGNOSISÐMECHANICAL........ 8

TORQUE SPECIFICATIONS................ 45

GENERAL INFORMATION

INDEX

page page

A/C Operation............................ 1

Compressor Oil Level...................... 6

Pressure Gauge and Manifold Assembly........ 2

Refrigerant (R-12)......................... 1

Service Precautions........................ 2Service Valves........................... 3

System Charge........................... 5

System Discharge......................... 4

System Evacuation........................ 4

A/C OPERATION

The compressor increases the pressure and temper-

ature of the refrigerant. The heated refrigerant vapor

is then pumped into the condenser where it cools by

the air passing over the condenser fins. As the refrig-

erant cools in the condenser, it condenses into a liq-

uid. Still under high pressure, the liquid refrigerant

passes into the receiver. The receiver acts as a reser-

voir to furnish refrigerant to the expansion (H) valve

at all times. From the receiver, the high pressure liq-

uid refrigerant passes to the expansion (H) valve.

The expansion (H) valve meters refrigerant into the

evaporator where a low pressure is maintained by

the suction side of the compressor. As it enters the

evaporator, the refrigerant immediately begins to

boil by absorbing heat from the air passing over the

evaporator core. Having given up its heat to boil the

refrigerant, the air is cooled and passes into the pas-

senger compartment of the vehicle. From the evapo-

rator the vaporized refrigerant is drawn back to the

compressor to repeat the cycle.

REFRIGERANT (R-12)

It is illegal to release R-12 into the atmosphere.

SAFETY PRECAUTIONS

WARNING: EXTREME CARE MUST BE TAKEN TO

PREVENT ANY LIQUID REFRIGERANT FROM COM-

ING IN CONTACT WITH THE SKIN AND ESPE-

CIALLY THE EYES. ALWAYS WEAR SAFETYGOGGLES WHEN SERVICING ANY PART OF THE

REFRIGERANT SYSTEM. IF EYE CONTACT IS

MADE, APPLY A FEW DROPS OF MINERAL OIL TO

THE EYES AND FLUSH WITH WATER FOR SEV-

ERAL MINUTES. SEEK MEDICAL ATTENTION IMME-

DIATELY.

The refrigerant used in the air conditioner system

is Refrigerant-12 (R-12). R-12 is nonexplosive, non-

flammable, non-corrosive, has practically no odor and

is heavier than air. Although it is classified as a safe

refrigerant, certain precautions must be observed to

protect the parts involved and the person who is

working on the unit. Liquid R-12, at normal atmo-

sphere pressures and temperatures, evaporates so

quickly that it has the tendency to freeze anything it

contacts.

WARNING: TO AVOID A DANGEROUS EXPLOSION,

NEVER WELD OR STEAM CLEAN NEAR AIR CON-

DITIONING LINES OR COMPONENTS. DO NOT

HEAT R-12 ABOVE 52ÉC (125ÉF).

The R-12 in the system is always under pressure.

Because the system is tightly sealed, heat applied to

any part could cause this pressure to build up exces-

sively.

JHEATING AND AIR CONDITIONING 24 - 1