check engine JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1011 of 1784

Excessive Oil Consumption: Although the PCM

monitors exhaust stream oxygen content through ox-

ygen sensor (closed loop), it cannot determine exces-

sive oil consumption.

Throttle Body Air Flow: The PCM cannot detect

a clogged or restricted air cleaner inlet or air filter

element.

Evaporative System: The PCM will not detect a

restricted, plugged or loaded EVAP canister.

Vacuum Assist: Leaks or restrictions in the vac-

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. However,

a vacuum leak at the MAP sensor will be monitored

and a diagnostic trouble code (DTC) will be gener-

ated by the PCM.

Powertrain Control Module (PCM) System

Ground: The PCM cannot determine a poor system

ground. However, a DTC may be generated as a re-

sult of this condition.

Powertrain Control Module (PCM) Connector

Engagement: The PCM cannot determine spread or

damaged connector pins. However, a DTC may be

generated as a result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device. It will es-

tablish high and low limits that are programmed into

it for that device. If the input voltage is not within

specifications and other Diagnostic Trouble Code

(DTC) criteria are met, a DTC will be stored in mem-

ory. Other DTC criteria might include engine rpm

limits or input voltages from other sensors or

switches. The other inputs might have to be sensed

by the PCM when it senses a high or low input volt-

age from the control system device in question.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

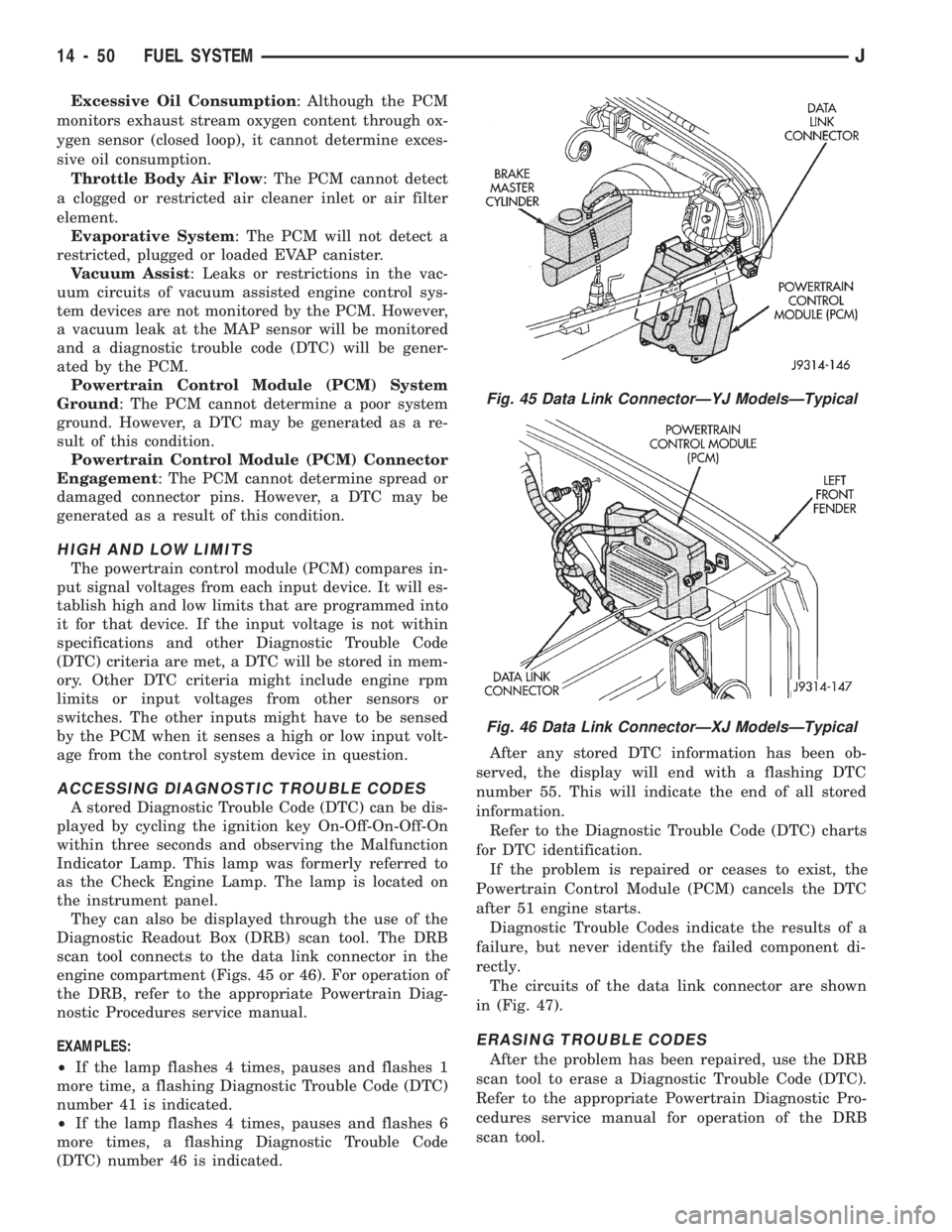

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

scan tool connects to the data link connector in the

engine compartment (Figs. 45 or 46). For operation of

the DRB, refer to the appropriate Powertrain Diag-

nostic Procedures service manual.

EXAMPLES:

²If the lamp flashes 4 times, pauses and flashes 1

more time, a flashing Diagnostic Trouble Code (DTC)

number 41 is indicated.

²If the lamp flashes 4 times, pauses and flashes 6

more times, a flashing Diagnostic Trouble Code

(DTC) number 46 is indicated.After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

Refer to the Diagnostic Trouble Code (DTC) charts

for DTC identification.

If the problem is repaired or ceases to exist, the

Powertrain Control Module (PCM) cancels the DTC

after 51 engine starts.

Diagnostic Trouble Codes indicate the results of a

failure, but never identify the failed component di-

rectly.

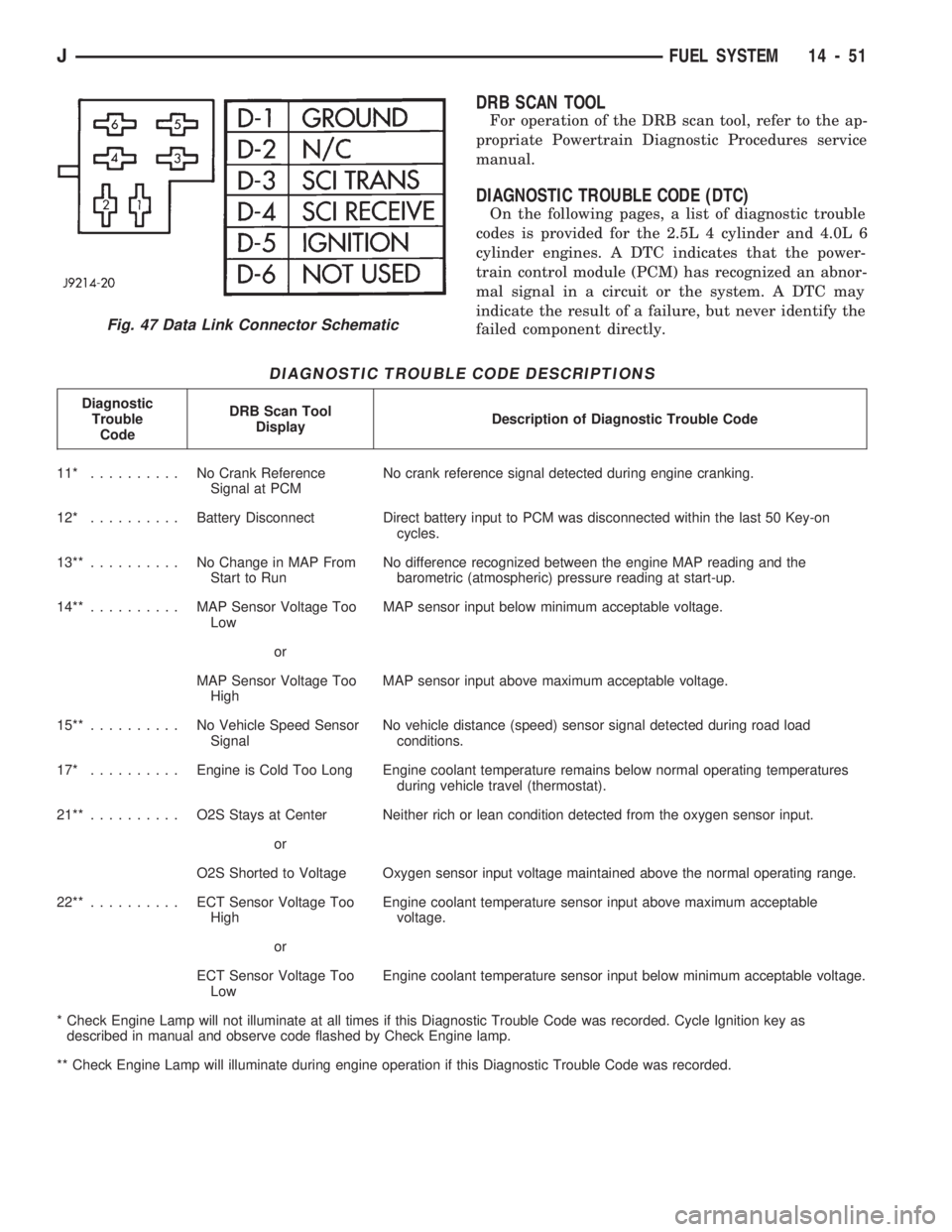

The circuits of the data link connector are shown

in (Fig. 47).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a Diagnostic Trouble Code (DTC).

Refer to the appropriate Powertrain Diagnostic Pro-

cedures service manual for operation of the DRB

scan tool.

Fig. 45 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 46 Data Link ConnectorÐXJ ModelsÐTypical

14 - 50 FUEL SYSTEMJ

Page 1012 of 1784

DRB SCAN TOOL

For operation of the DRB scan tool, refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual.

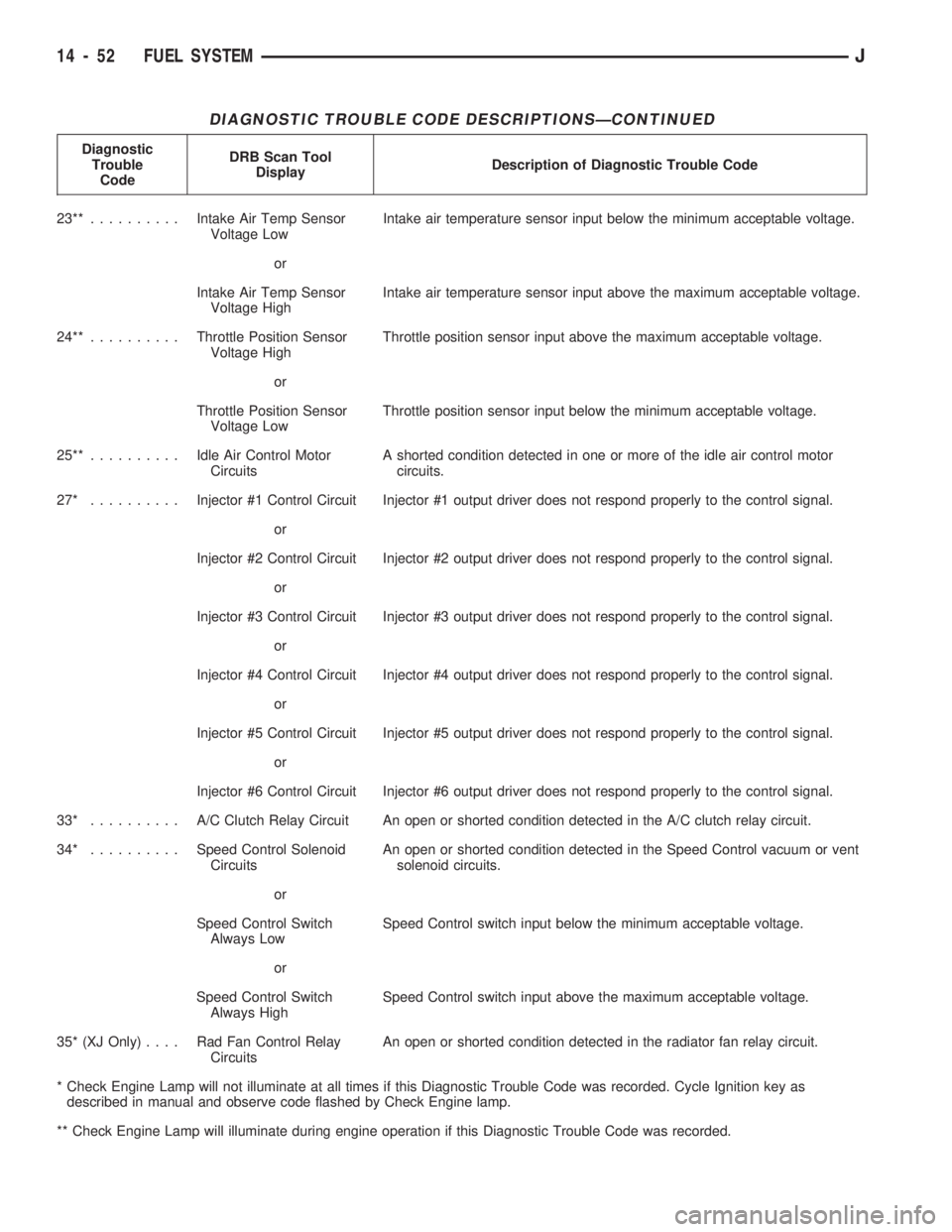

DIAGNOSTIC TROUBLE CODE (DTC)

On the following pages, a list of diagnostic trouble

codes is provided for the 2.5L 4 cylinder and 4.0L 6

cylinder engines. A DTC indicates that the power-

train control module (PCM) has recognized an abnor-

mal signal in a circuit or the system. A DTC may

indicate the result of a failure, but never identify the

failed component directly.

DIAGNOSTIC TROUBLE CODE DESCRIPTIONS

Diagnostic

Trouble

CodeDRB Scan Tool

DisplayDescription of Diagnostic Trouble Code

11* .......... NoCrank Reference

Signal at PCMNo crank reference signal detected during engine cranking.

12* ..........Battery Disconnect Direct battery input to PCM was disconnected within the last 50 Key-on

cycles.

13**.......... NoChange in MAP From

Start to RunNo difference recognized between the engine MAP reading and the

barometric (atmospheric) pressure reading at start-up.

14**.......... MAPSensor Voltage Too

LowMAP sensor input below minimum acceptable voltage.

or

MAP Sensor Voltage Too

HighMAP sensor input above maximum acceptable voltage.

15**.......... NoVehicle Speed Sensor

SignalNo vehicle distance (speed) sensor signal detected during road load

conditions.

17* ..........Engine is Cold Too Long Engine coolant temperature remains below normal operating temperatures

during vehicle travel (thermostat).

21**.......... O2SStays at Center Neither rich or lean condition detected from the oxygen sensor input.

or

O2S Shorted to Voltage Oxygen sensor input voltage maintained above the normal operating range.

22**.......... ECTSensor Voltage Too

HighEngine coolant temperature sensor input above maximum acceptable

voltage.

or

ECT Sensor Voltage Too

LowEngine coolant temperature sensor input below minimum acceptable voltage.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key as

described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

Fig. 47 Data Link Connector Schematic

JFUEL SYSTEM 14 - 51

Page 1013 of 1784

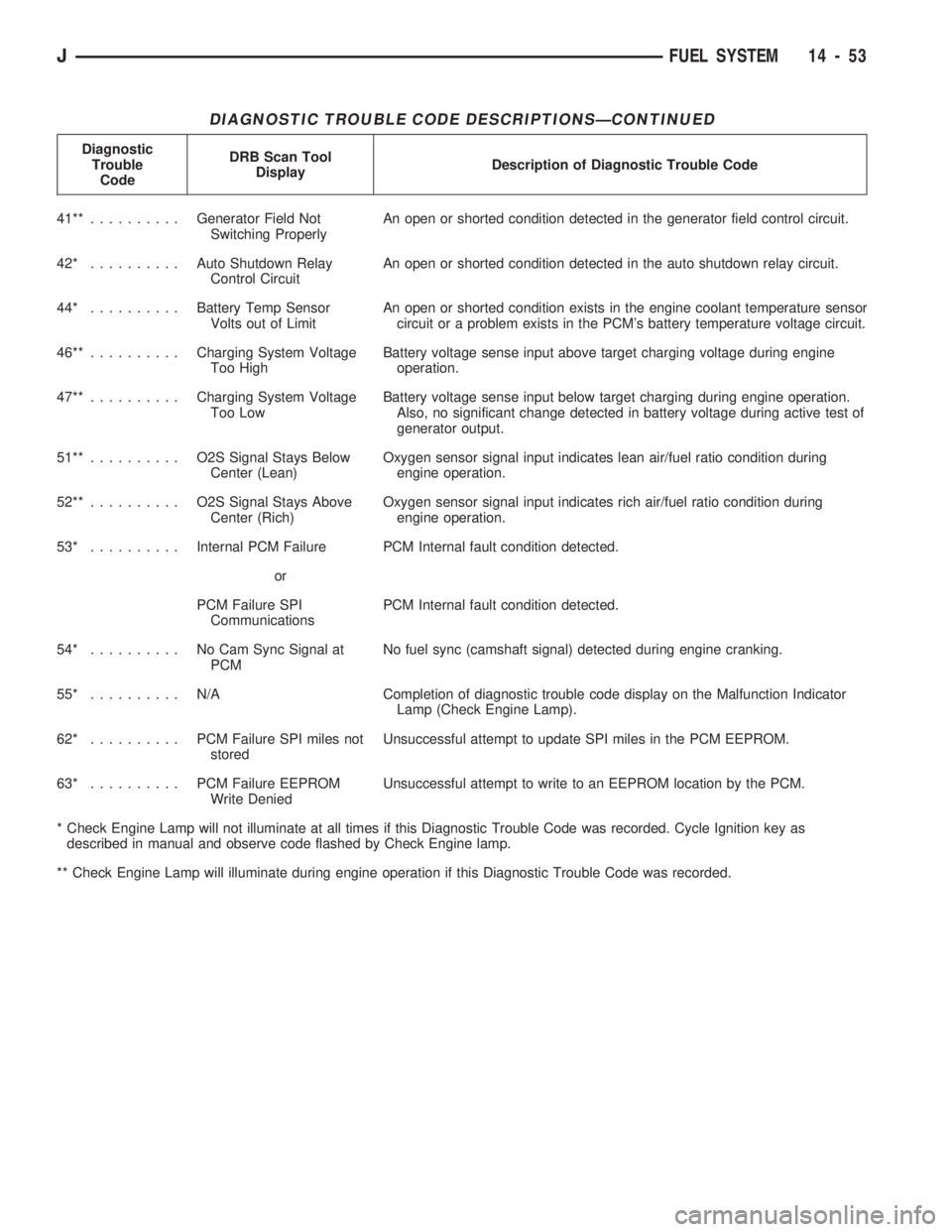

DIAGNOSTIC TROUBLE CODE DESCRIPTIONSÐCONTINUED

Diagnostic

Trouble

CodeDRB Scan Tool

DisplayDescription of Diagnostic Trouble Code

23**..........Intake Air Temp Sensor

Voltage LowIntake air temperature sensor input below the minimum acceptable voltage.

or

Intake Air Temp Sensor

Voltage HighIntake air temperature sensor input above the maximum acceptable voltage.

24**..........Throttle Position Sensor

Voltage HighThrottle position sensor input above the maximum acceptable voltage.

or

Throttle Position Sensor

Voltage LowThrottle position sensor input below the minimum acceptable voltage.

25**..........Idle Air Control Motor

CircuitsA shorted condition detected in one or more of the idle air control motor

circuits.

27* ..........Injector #1 Control Circuit Injector #1 output driver does not respond properly to the control signal.

or

Injector #2 Control Circuit Injector #2 output driver does not respond properly to the control signal.

or

Injector #3 Control Circuit Injector #3 output driver does not respond properly to the control signal.

or

Injector #4 Control Circuit Injector #4 output driver does not respond properly to the control signal.

or

Injector #5 Control Circuit Injector #5 output driver does not respond properly to the control signal.

or

Injector #6 Control Circuit Injector #6 output driver does not respond properly to the control signal.

33* .......... A/CClutch Relay Circuit An open or shorted condition detected in the A/C clutch relay circuit.

34* ..........Speed Control Solenoid

CircuitsAn open or shorted condition detected in the Speed Control vacuum or vent

solenoid circuits.

or

Speed Control Switch

Always LowSpeed Control switch input below the minimum acceptable voltage.

or

Speed Control Switch

Always HighSpeed Control switch input above the maximum acceptable voltage.

35* (XJ Only).... RadFanControl Relay

CircuitsAn open or shorted condition detected in the radiator fan relay circuit.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key as

described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

14 - 52 FUEL SYSTEMJ

Page 1014 of 1784

DIAGNOSTIC TROUBLE CODE DESCRIPTIONSÐCONTINUED

Diagnostic

Trouble

CodeDRB Scan Tool

DisplayDescription of Diagnostic Trouble Code

41**..........Generator Field Not

Switching ProperlyAn open or shorted condition detected in the generator field control circuit.

42* ..........Auto Shutdown Relay

Control CircuitAn open or shorted condition detected in the auto shutdown relay circuit.

44* ..........Battery Temp Sensor

Volts out of LimitAn open or shorted condition exists in the engine coolant temperature sensor

circuit or a problem exists in the PCM's battery temperature voltage circuit.

46**..........Charging System Voltage

Too HighBattery voltage sense input above target charging voltage during engine

operation.

47**..........Charging System Voltage

Too LowBattery voltage sense input below target charging during engine operation.

Also, no significant change detected in battery voltage during active test of

generator output.

51**.......... O2SSignal Stays Below

Center (Lean)Oxygen sensor signal input indicates lean air/fuel ratio condition during

engine operation.

52**.......... O2SSignal Stays Above

Center (Rich)Oxygen sensor signal input indicates rich air/fuel ratio condition during

engine operation.

53* ..........Internal PCM Failure PCM Internal fault condition detected.

or

PCM Failure SPI

CommunicationsPCM Internal fault condition detected.

54* .......... NoCamSync Signal at

PCMNo fuel sync (camshaft signal) detected during engine cranking.

55* .......... N/ACompletion of diagnostic trouble code display on the Malfunction Indicator

Lamp (Check Engine Lamp).

62* .......... PCMFailure SPI miles not

storedUnsuccessful attempt to update SPI miles in the PCM EEPROM.

63* .......... PCMFailure EEPROM

Write DeniedUnsuccessful attempt to write to an EEPROM location by the PCM.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key as

described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

JFUEL SYSTEM 14 - 53

Page 1017 of 1784

INSTALLATION

(1) Install the fuel injector(s) into the fuel rail as-

sembly and install retaining clip(s).

(2) Install fuel rail. Refer to Fuel Rail Installation

in this section.

(3) Start engine and check for fuel leaks.

FUEL PUMP MODULE

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

FUEL PUMP RELAY

The Fuel Pump relay is located in the Power Dis-

tribution Center (PDC) (Figs. 1 or 2). For location of

this relay within the PDC, refer to label on PDC

cover.

FUEL RAIL ASSEMBLY

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE (EVEN WITH THE ENGINE

OFF) OF APPROXIMATELY 131-269 KPA (19-39

PSI). THIS PRESSURE MUST BE RELEASED BE-

FORE SERVICING THE FUEL RAIL.

(1) Remove fuel tank filler tube cap.

(2) Disconnect the negative battery cable from bat-

tery.

(3) Perform the Fuel System Pressure Release Pro-

cedure as described in the Fuel Delivery System sec-

tion of this Group.

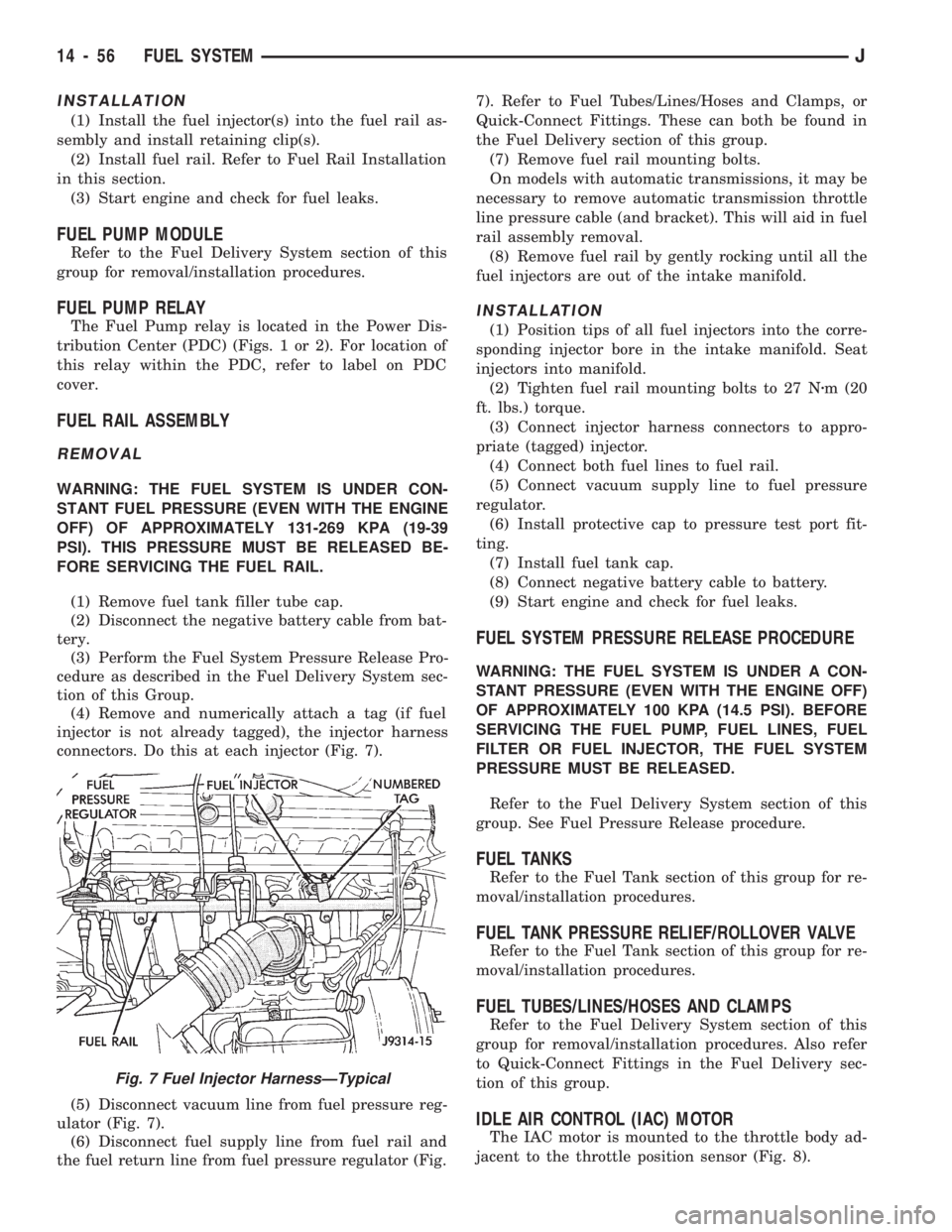

(4) Remove and numerically attach a tag (if fuel

injector is not already tagged), the injector harness

connectors. Do this at each injector (Fig. 7).

(5) Disconnect vacuum line from fuel pressure reg-

ulator (Fig. 7).

(6) Disconnect fuel supply line from fuel rail and

the fuel return line from fuel pressure regulator (Fig.7). Refer to Fuel Tubes/Lines/Hoses and Clamps, or

Quick-Connect Fittings. These can both be found in

the Fuel Delivery section of this group.

(7) Remove fuel rail mounting bolts.

On models with automatic transmissions, it may be

necessary to remove automatic transmission throttle

line pressure cable (and bracket). This will aid in fuel

rail assembly removal.

(8) Remove fuel rail by gently rocking until all the

fuel injectors are out of the intake manifold.

INSTALLATION

(1) Position tips of all fuel injectors into the corre-

sponding injector bore in the intake manifold. Seat

injectors into manifold.

(2) Tighten fuel rail mounting bolts to 27 Nzm (20

ft. lbs.) torque.

(3) Connect injector harness connectors to appro-

priate (tagged) injector.

(4) Connect both fuel lines to fuel rail.

(5) Connect vacuum supply line to fuel pressure

regulator.

(6) Install protective cap to pressure test port fit-

ting.

(7) Install fuel tank cap.

(8) Connect negative battery cable to battery.

(9) Start engine and check for fuel leaks.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF)

OF APPROXIMATELY 100 KPA (14.5 PSI). BEFORE

SERVICING THE FUEL PUMP, FUEL LINES, FUEL

FILTER OR FUEL INJECTOR, THE FUEL SYSTEM

PRESSURE MUST BE RELEASED.

Refer to the Fuel Delivery System section of this

group. See Fuel Pressure Release procedure.

FUEL TANKS

Refer to the Fuel Tank section of this group for re-

moval/installation procedures.

FUEL TANK PRESSURE RELIEF/ROLLOVER VALVE

Refer to the Fuel Tank section of this group for re-

moval/installation procedures.

FUEL TUBES/LINES/HOSES AND CLAMPS

Refer to the Fuel Delivery System section of this

group for removal/installation procedures. Also refer

to Quick-Connect Fittings in the Fuel Delivery sec-

tion of this group.

IDLE AIR CONTROL (IAC) MOTOR

The IAC motor is mounted to the throttle body ad-

jacent to the throttle position sensor (Fig. 8).

Fig. 7 Fuel Injector HarnessÐTypical

14 - 56 FUEL SYSTEMJ

Page 1019 of 1784

(3) Lower the vehicle.

PARK NEUTRAL SWITCH

Refer to Group 21, Transmissions for park neutral

switch service.

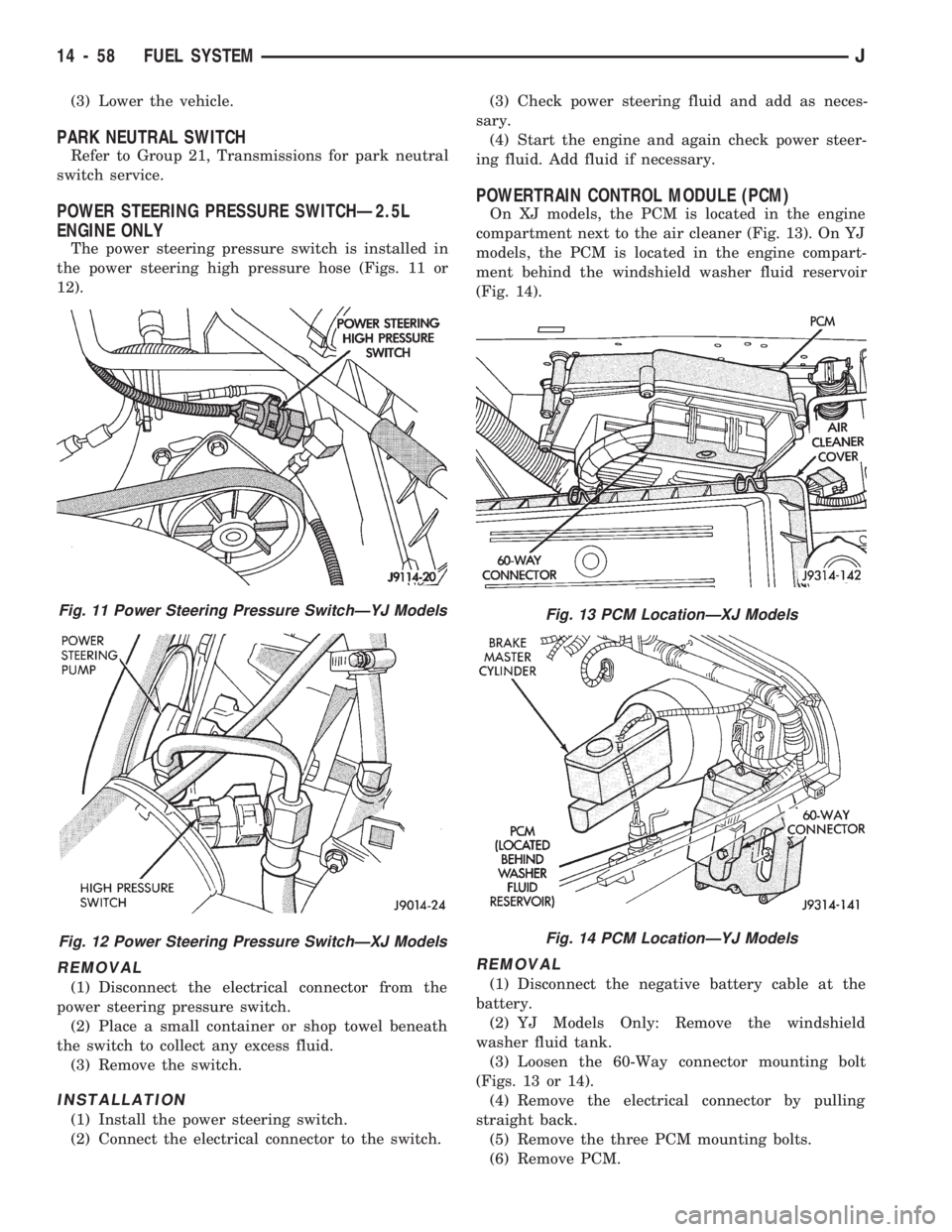

POWER STEERING PRESSURE SWITCHÐ2.5L

ENGINE ONLY

The power steering pressure switch is installed in

the power steering high pressure hose (Figs. 11 or

12).

REMOVAL

(1) Disconnect the electrical connector from the

power steering pressure switch.

(2) Place a small container or shop towel beneath

the switch to collect any excess fluid.

(3) Remove the switch.

INSTALLATION

(1) Install the power steering switch.

(2) Connect the electrical connector to the switch.(3) Check power steering fluid and add as neces-

sary.

(4) Start the engine and again check power steer-

ing fluid. Add fluid if necessary.

POWERTRAIN CONTROL MODULE (PCM)

On XJ models, the PCM is located in the engine

compartment next to the air cleaner (Fig. 13). On YJ

models, the PCM is located in the engine compart-

ment behind the windshield washer fluid reservoir

(Fig. 14).

REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) YJ Models Only: Remove the windshield

washer fluid tank.

(3) Loosen the 60-Way connector mounting bolt

(Figs. 13 or 14).

(4) Remove the electrical connector by pulling

straight back.

(5) Remove the three PCM mounting bolts.

(6) Remove PCM.

Fig. 11 Power Steering Pressure SwitchÐYJ Models

Fig. 12 Power Steering Pressure SwitchÐXJ Models

Fig. 13 PCM LocationÐXJ Models

Fig. 14 PCM LocationÐYJ Models

14 - 58 FUEL SYSTEMJ

Page 1021 of 1784

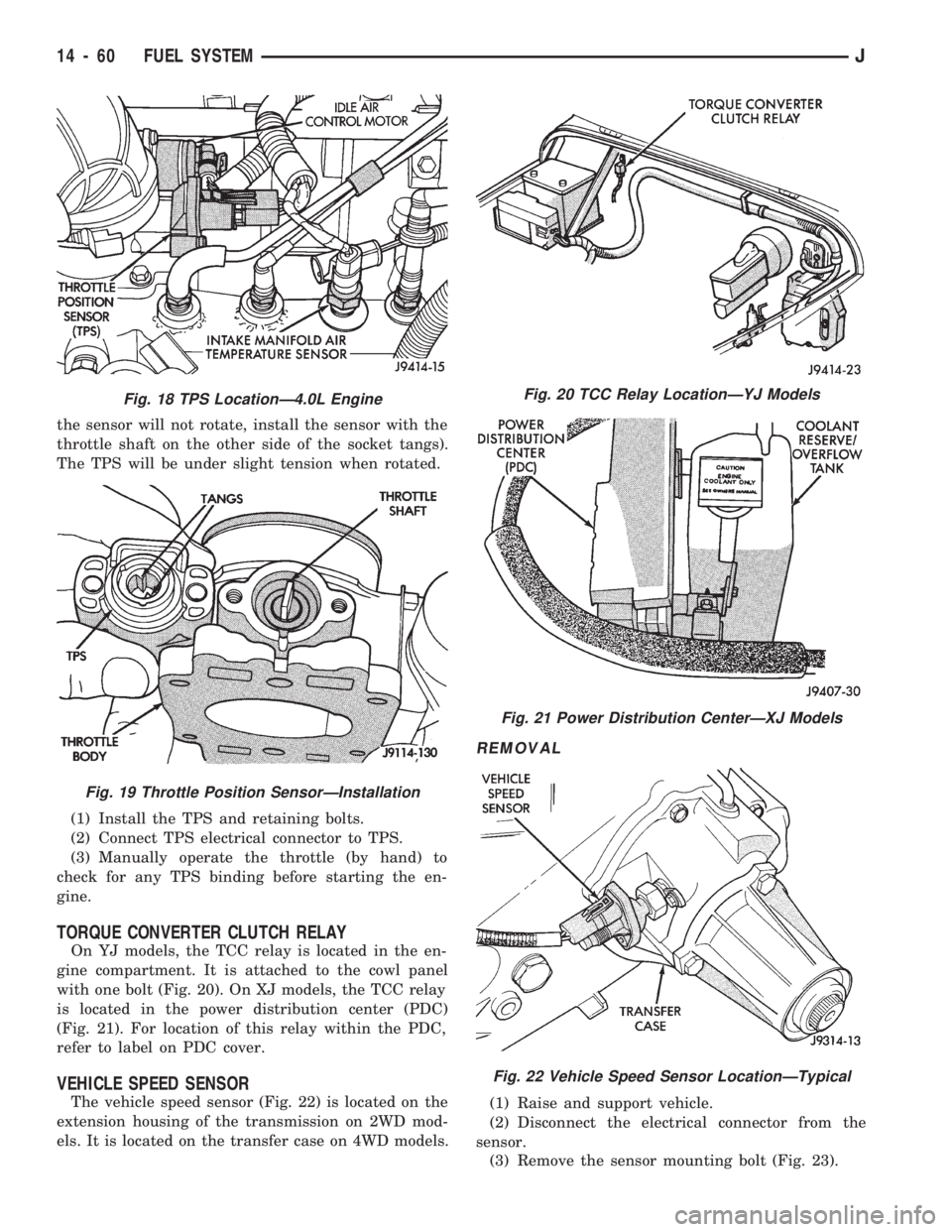

the sensor will not rotate, install the sensor with the

throttle shaft on the other side of the socket tangs).

The TPS will be under slight tension when rotated.

(1) Install the TPS and retaining bolts.

(2) Connect TPS electrical connector to TPS.

(3) Manually operate the throttle (by hand) to

check for any TPS binding before starting the en-

gine.

TORQUE CONVERTER CLUTCH RELAY

On YJ models, the TCC relay is located in the en-

gine compartment. It is attached to the cowl panel

with one bolt (Fig. 20). On XJ models, the TCC relay

is located in the power distribution center (PDC)

(Fig. 21). For location of this relay within the PDC,

refer to label on PDC cover.

VEHICLE SPEED SENSOR

The vehicle speed sensor (Fig. 22) is located on the

extension housing of the transmission on 2WD mod-

els. It is located on the transfer case on 4WD models.

REMOVAL

(1) Raise and support vehicle.

(2) Disconnect the electrical connector from the

sensor.

(3) Remove the sensor mounting bolt (Fig. 23).

Fig. 18 TPS LocationÐ4.0L Engine

Fig. 19 Throttle Position SensorÐInstallation

Fig. 20 TCC Relay LocationÐYJ Models

Fig. 21 Power Distribution CenterÐXJ Models

Fig. 22 Vehicle Speed Sensor LocationÐTypical

14 - 60 FUEL SYSTEMJ

Page 1026 of 1784

SERVICE DIAGNOSIS/PROCEDURES

INDEX

page page

Runout................................. 4

Unbalance............................... 3Universal Joint Angle Measurement............ 4

Vibration................................ 3

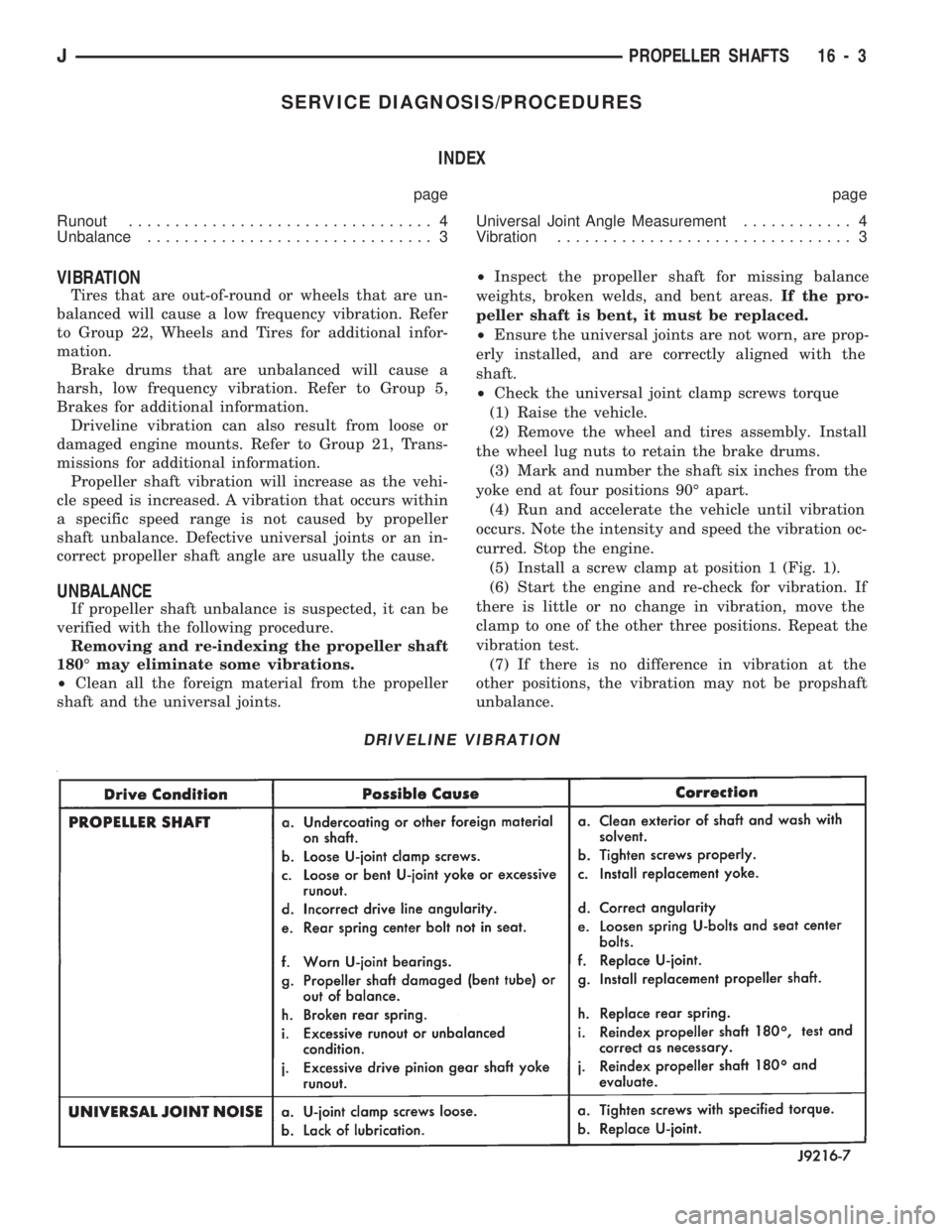

VIBRATION

Tires that are out-of-round or wheels that are un-

balanced will cause a low frequency vibration. Refer

to Group 22, Wheels and Tires for additional infor-

mation.

Brake drums that are unbalanced will cause a

harsh, low frequency vibration. Refer to Group 5,

Brakes for additional information.

Driveline vibration can also result from loose or

damaged engine mounts. Refer to Group 21, Trans-

missions for additional information.

Propeller shaft vibration will increase as the vehi-

cle speed is increased. A vibration that occurs within

a specific speed range is not caused by propeller

shaft unbalance. Defective universal joints or an in-

correct propeller shaft angle are usually the cause.

UNBALANCE

If propeller shaft unbalance is suspected, it can be

verified with the following procedure.

Removing and re-indexing the propeller shaft

180É may eliminate some vibrations.

²Clean all the foreign material from the propeller

shaft and the universal joints.²Inspect the propeller shaft for missing balance

weights, broken welds, and bent areas.If the pro-

peller shaft is bent, it must be replaced.

²Ensure the universal joints are not worn, are prop-

erly installed, and are correctly aligned with the

shaft.

²Check the universal joint clamp screws torque

(1) Raise the vehicle.

(2) Remove the wheel and tires assembly. Install

the wheel lug nuts to retain the brake drums.

(3) Mark and number the shaft six inches from the

yoke end at four positions 90É apart.

(4) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration oc-

curred. Stop the engine.

(5) Install a screw clamp at position 1 (Fig. 1).

(6) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(7) If there is no difference in vibration at the

other positions, the vibration may not be propshaft

unbalance.

DRIVELINE VIBRATION

JPROPELLER SHAFTS 16 - 3

Page 1028 of 1784

²Have a 3 degree maximum operating angle

²Have at least a 1/2 degree continuous operating

(propeller shaft) angle

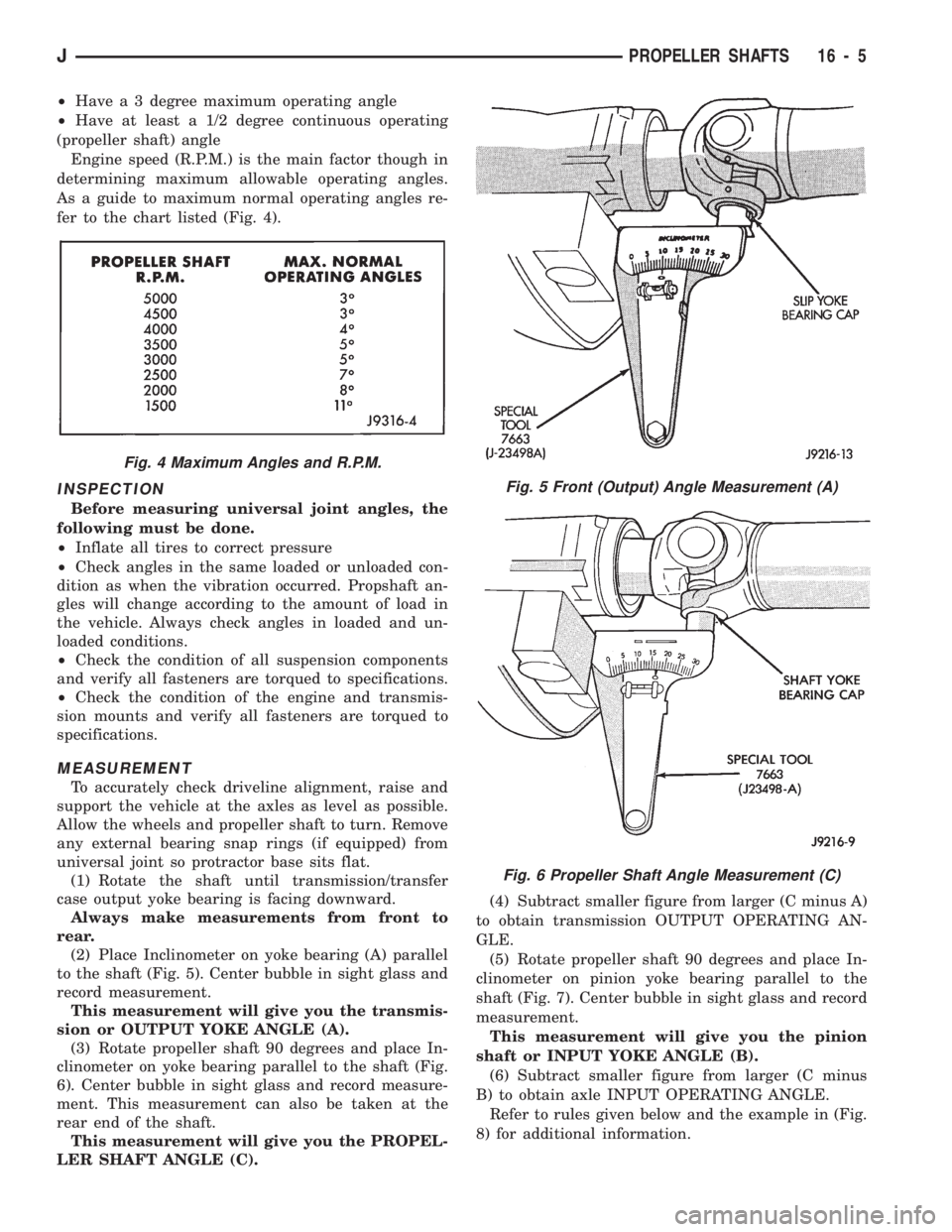

Engine speed (R.P.M.) is the main factor though in

determining maximum allowable operating angles.

As a guide to maximum normal operating angles re-

fer to the chart listed (Fig. 4).

INSPECTION

Before measuring universal joint angles, the

following must be done.

²Inflate all tires to correct pressure

²Check angles in the same loaded or unloaded con-

dition as when the vibration occurred. Propshaft an-

gles will change according to the amount of load in

the vehicle. Always check angles in loaded and un-

loaded conditions.

²Check the condition of all suspension components

and verify all fasteners are torqued to specifications.

²Check the condition of the engine and transmis-

sion mounts and verify all fasteners are torqued to

specifications.

MEASUREMENT

To accurately check driveline alignment, raise and

support the vehicle at the axles as level as possible.

Allow the wheels and propeller shaft to turn. Remove

any external bearing snap rings (if equipped) from

universal joint so protractor base sits flat.

(1) Rotate the shaft until transmission/transfer

case output yoke bearing is facing downward.

Always make measurements from front to

rear.

(2) Place Inclinometer on yoke bearing (A) parallel

to the shaft (Fig. 5). Center bubble in sight glass and

record measurement.

This measurement will give you the transmis-

sion or OUTPUT YOKE ANGLE (A).

(3) Rotate propeller shaft 90 degrees and place In-

clinometer on yoke bearing parallel to the shaft (Fig.

6). Center bubble in sight glass and record measure-

ment. This measurement can also be taken at the

rear end of the shaft.

This measurement will give you the PROPEL-

LER SHAFT ANGLE (C).(4) Subtract smaller figure from larger (C minus A)

to obtain transmission OUTPUT OPERATING AN-

GLE.

(5) Rotate propeller shaft 90 degrees and place In-

clinometer on pinion yoke bearing parallel to the

shaft (Fig. 7). Center bubble in sight glass and record

measurement.

This measurement will give you the pinion

shaft or INPUT YOKE ANGLE (B).

(6) Subtract smaller figure from larger (C minus

B) to obtain axle INPUT OPERATING ANGLE.

Refer to rules given below and the example in (Fig.

8) for additional information.

Fig. 4 Maximum Angles and R.P.M.

Fig. 5 Front (Output) Angle Measurement (A)

Fig. 6 Propeller Shaft Angle Measurement (C)

JPROPELLER SHAFTS 16 - 5

Page 1040 of 1784

POWER STEERING SYSTEM DIAGNOSIS

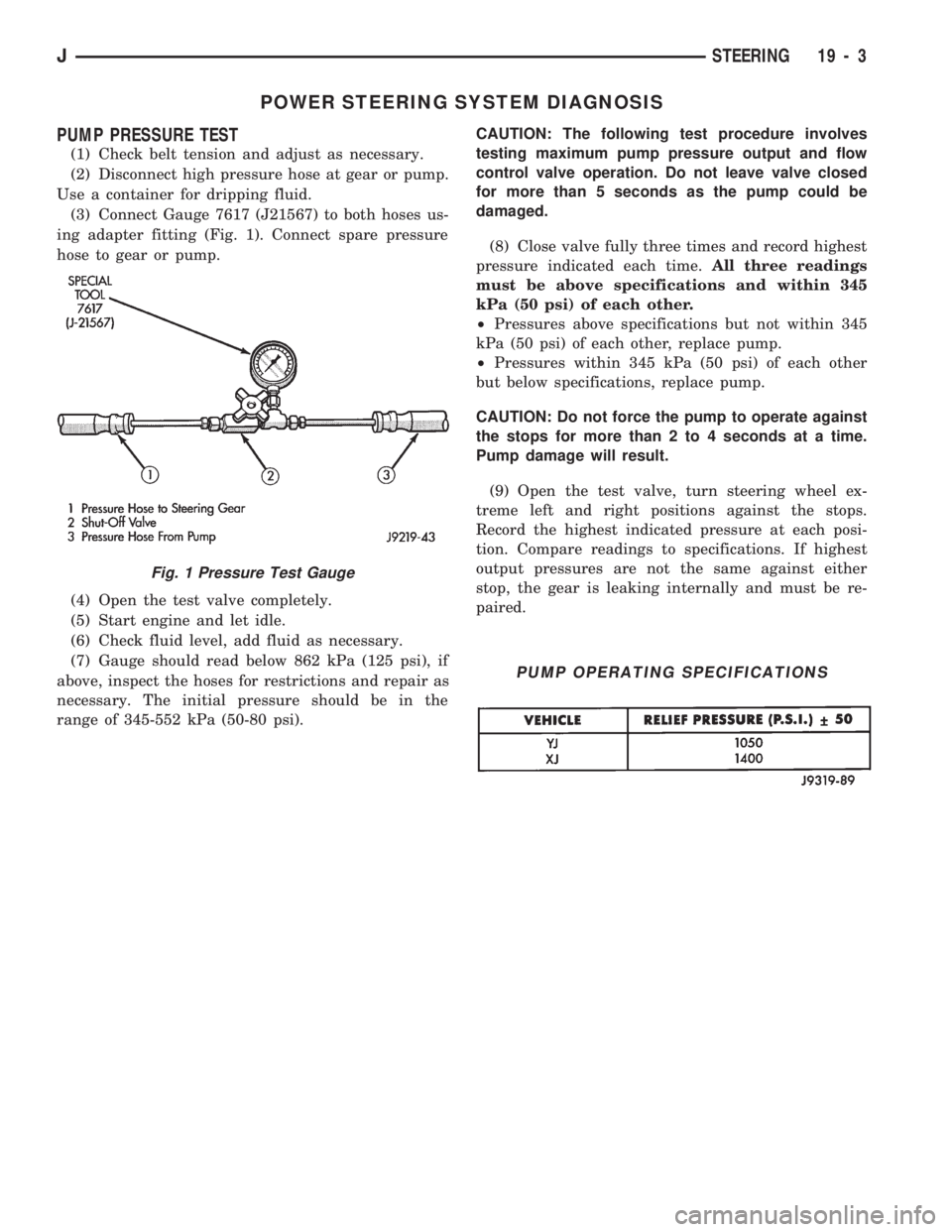

PUMP PRESSURE TEST

(1) Check belt tension and adjust as necessary.

(2) Disconnect high pressure hose at gear or pump.

Use a container for dripping fluid.

(3) Connect Gauge 7617 (J21567) to both hoses us-

ing adapter fitting (Fig. 1). Connect spare pressure

hose to gear or pump.

(4) Open the test valve completely.

(5) Start engine and let idle.

(6) Check fluid level, add fluid as necessary.

(7) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the

range of 345-552 kPa (50-80 psi).CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than 5 seconds as the pump could be

damaged.

(8) Close valve fully three times and record highest

pressure indicated each time.All three readings

must be above specifications and within 345

kPa (50 psi) of each other.

²Pressures above specifications but not within 345

kPa (50 psi) of each other, replace pump.

²Pressures within 345 kPa (50 psi) of each other

but below specifications, replace pump.

CAUTION: Do not force the pump to operate against

the stops for more than 2 to 4 seconds at a time.

Pump damage will result.

(9) Open the test valve, turn steering wheel ex-

treme left and right positions against the stops.

Record the highest indicated pressure at each posi-

tion. Compare readings to specifications. If highest

output pressures are not the same against either

stop, the gear is leaking internally and must be re-

paired.

Fig. 1 Pressure Test Gauge

PUMP OPERATING SPECIFICATIONS

JSTEERING 19 - 3