battery replacement JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 302 of 1784

CAUTION: Never force a belt over a pulley rim us-

ing a screwdriver as the synthetic fiber may be

damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

engine may overheat because the water pump will

be rotating in the wrong direction if the belt is in-

stalled incorrectly. Refer to the belt routing label in

engine compartment, or see Group 7 - Belt Sche-

matics.

(10) Place serpentine belt over pulley.

(11) Belt tension adjustment is made at power

steering pump (Fig. 6).

(12) Turn adjusting bolt until belt has correct ten-

sion. See Belt Tension in Specifications.

(13) Tighten rear mounting bolts, pivot bolt, and

lock nut to 27 Nzm (20 ft. lbs.) torque.

(14) Remove support and lower vehicle.

(15) Connect negative cable to battery.

GENERATOR REPLACEMENTÐRIGHT HAND DRIVE

The generator used on the right hand drive is the

same as used on left hand drive. However, the

mounting and accessory drive belt installation are

different.

WARNING: FAILURE TO DISCONNECT NEGATIVE

CABLE FROM BATTERY BEFORE DISCONNECTING

RED (OUTPUT) WIRE CONNECTOR FROM GENER-

ATOR CAN RESULT IN INJURY.

(1) Remove negative cable from battery.

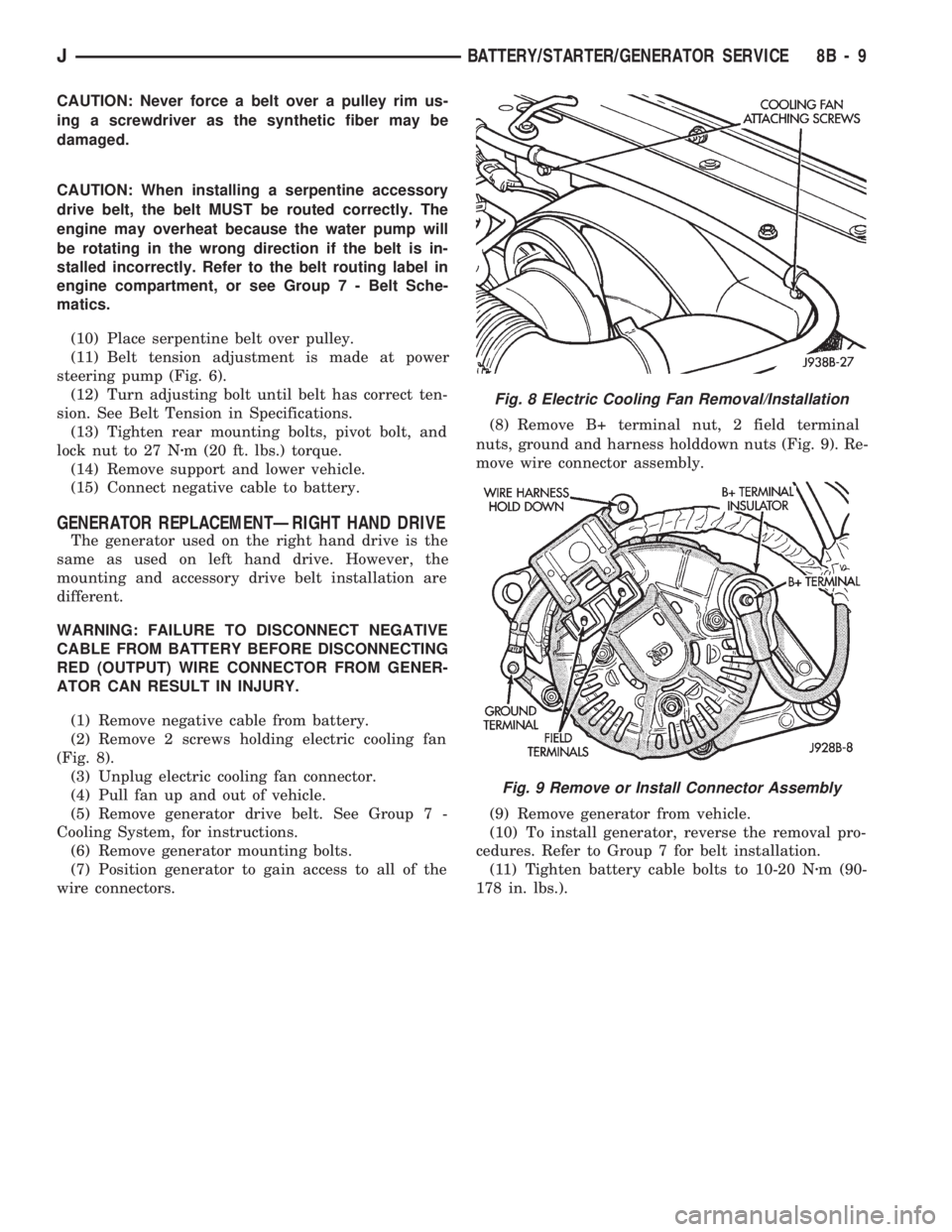

(2) Remove 2 screws holding electric cooling fan

(Fig. 8).

(3) Unplug electric cooling fan connector.

(4) Pull fan up and out of vehicle.

(5) Remove generator drive belt. See Group 7 -

Cooling System, for instructions.

(6) Remove generator mounting bolts.

(7) Position generator to gain access to all of the

wire connectors.(8) Remove B+ terminal nut, 2 field terminal

nuts, ground and harness holddown nuts (Fig. 9). Re-

move wire connector assembly.

(9) Remove generator from vehicle.

(10) To install generator, reverse the removal pro-

cedures. Refer to Group 7 for belt installation.

(11) Tighten battery cable bolts to 10-20 Nzm (90-

178 in. lbs.).

Fig. 8 Electric Cooling Fan Removal/Installation

Fig. 9 Remove or Install Connector Assembly

JBATTERY/STARTER/GENERATOR SERVICE 8B - 9

Page 338 of 1784

The camshaft position sensor is located in the dis-

tributor on all engines (Fig. 9).

Refer to figure 9 for an exploded view of the dis-

tributor.

(1) Disconnect the negative battery cable at bat-

tery.

(2) On XJ models equipped with A/C, remove the

electrical cooling fan and shroud assembly from the

radiator. This will provide room to turn the engine

with a socket and ratchet using the vibration damper

bolt.

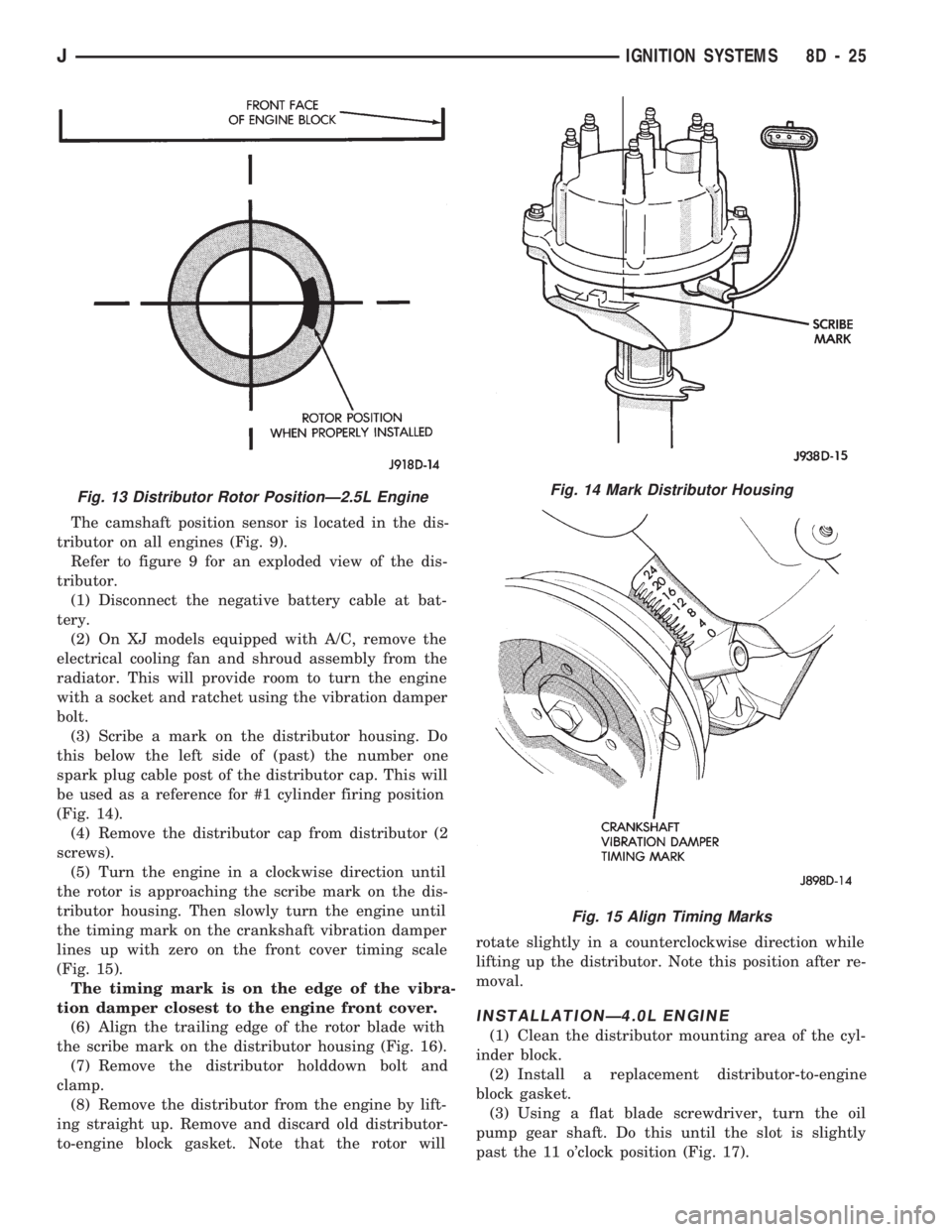

(3) Scribe a mark on the distributor housing. Do

this below the left side of (past) the number one

spark plug cable post of the distributor cap. This will

be used as a reference for #1 cylinder firing position

(Fig. 14).

(4) Remove the distributor cap from distributor (2

screws).

(5) Turn the engine in a clockwise direction until

the rotor is approaching the scribe mark on the dis-

tributor housing. Then slowly turn the engine until

the timing mark on the crankshaft vibration damper

lines up with zero on the front cover timing scale

(Fig. 15).

The timing mark is on the edge of the vibra-

tion damper closest to the engine front cover.

(6) Align the trailing edge of the rotor blade with

the scribe mark on the distributor housing (Fig. 16).

(7) Remove the distributor holddown bolt and

clamp.

(8) Remove the distributor from the engine by lift-

ing straight up. Remove and discard old distributor-

to-engine block gasket. Note that the rotor willrotate slightly in a counterclockwise direction while

lifting up the distributor. Note this position after re-

moval.

INSTALLATIONÐ4.0L ENGINE

(1) Clean the distributor mounting area of the cyl-

inder block.

(2) Install a replacement distributor-to-engine

block gasket.

(3) Using a flat blade screwdriver, turn the oil

pump gear shaft. Do this until the slot is slightly

past the 11 o'clock position (Fig. 17).

Fig. 13 Distributor Rotor PositionÐ2.5L EngineFig. 14 Mark Distributor Housing

Fig. 15 Align Timing Marks

JIGNITION SYSTEMS 8D - 25

Page 352 of 1784

INSTRUMENT CLUSTER SERVICE PROCEDURES

INDEX

page page

Gauge ReplacementÐInstrument Cluster Removed.. 5

Gear Selector Indicator ReplacementÐInstrument

Cluster Removed........................ 6

Instrument Cluster Replacement.............. 5

Instrument Panel Replacement (Fig. 9)......... 8

Printed Circuit ReplacementÐInstrumentCluster Removed........................ 6

Speedometer ReplacementÐInstrument

Cluster Removed........................ 5

Tachometer ReplacementÐInstrument

Cluster Removed........................ 5

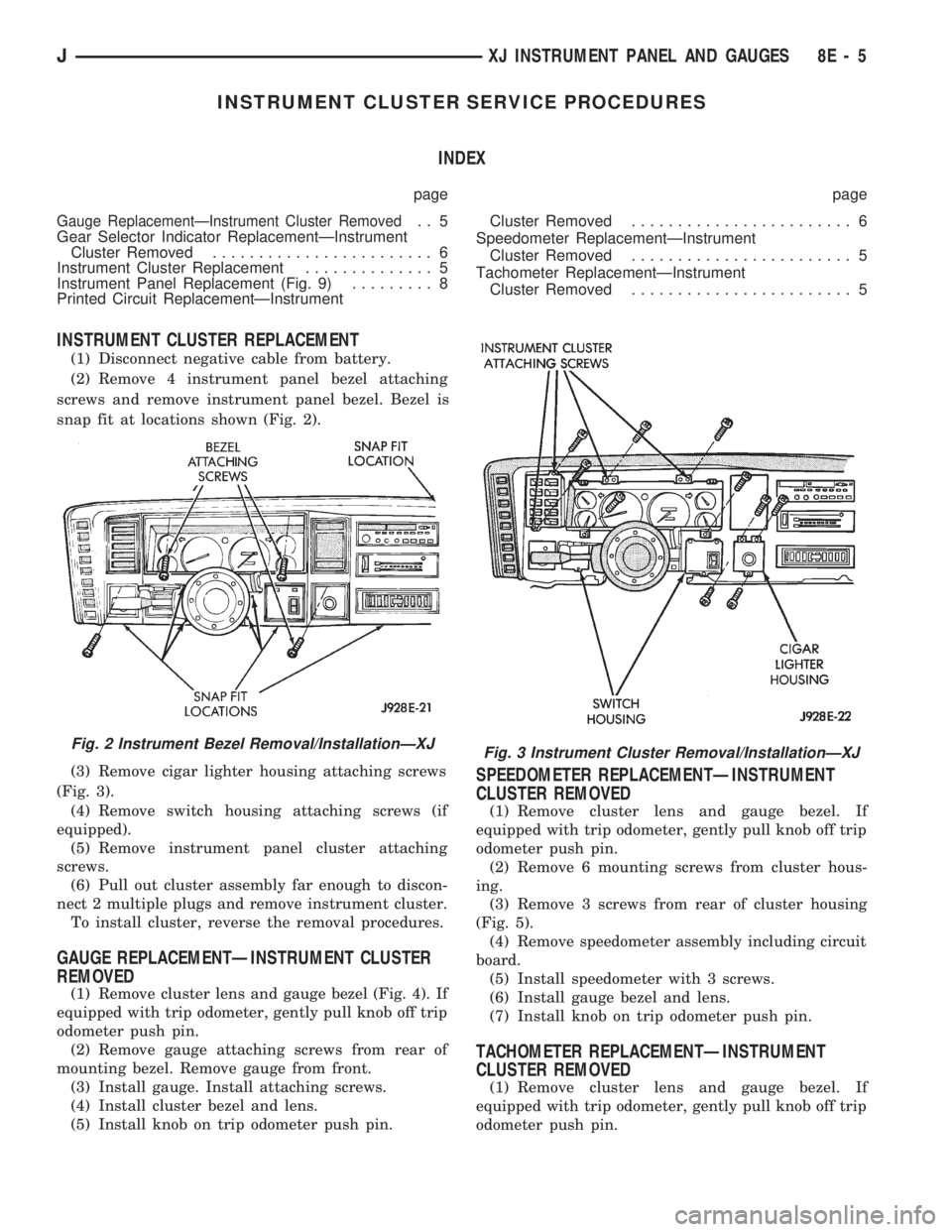

INSTRUMENT CLUSTER REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove 4 instrument panel bezel attaching

screws and remove instrument panel bezel. Bezel is

snap fit at locations shown (Fig. 2).

(3) Remove cigar lighter housing attaching screws

(Fig. 3).

(4) Remove switch housing attaching screws (if

equipped).

(5) Remove instrument panel cluster attaching

screws.

(6) Pull out cluster assembly far enough to discon-

nect 2 multiple plugs and remove instrument cluster.

To install cluster, reverse the removal procedures.

GAUGE REPLACEMENTÐINSTRUMENT CLUSTER

REMOVED

(1) Remove cluster lens and gauge bezel (Fig. 4). If

equipped with trip odometer, gently pull knob off trip

odometer push pin.

(2) Remove gauge attaching screws from rear of

mounting bezel. Remove gauge from front.

(3) Install gauge. Install attaching screws.

(4) Install cluster bezel and lens.

(5) Install knob on trip odometer push pin.

SPEEDOMETER REPLACEMENTÐINSTRUMENT

CLUSTER REMOVED

(1) Remove cluster lens and gauge bezel. If

equipped with trip odometer, gently pull knob off trip

odometer push pin.

(2) Remove 6 mounting screws from cluster hous-

ing.

(3) Remove 3 screws from rear of cluster housing

(Fig. 5).

(4) Remove speedometer assembly including circuit

board.

(5) Install speedometer with 3 screws.

(6) Install gauge bezel and lens.

(7) Install knob on trip odometer push pin.

TACHOMETER REPLACEMENTÐINSTRUMENT

CLUSTER REMOVED

(1) Remove cluster lens and gauge bezel. If

equipped with trip odometer, gently pull knob off trip

odometer push pin.

Fig. 2 Instrument Bezel Removal/InstallationÐXJFig. 3 Instrument Cluster Removal/InstallationÐXJ

JXJ INSTRUMENT PANEL AND GAUGES 8E - 5

Page 355 of 1784

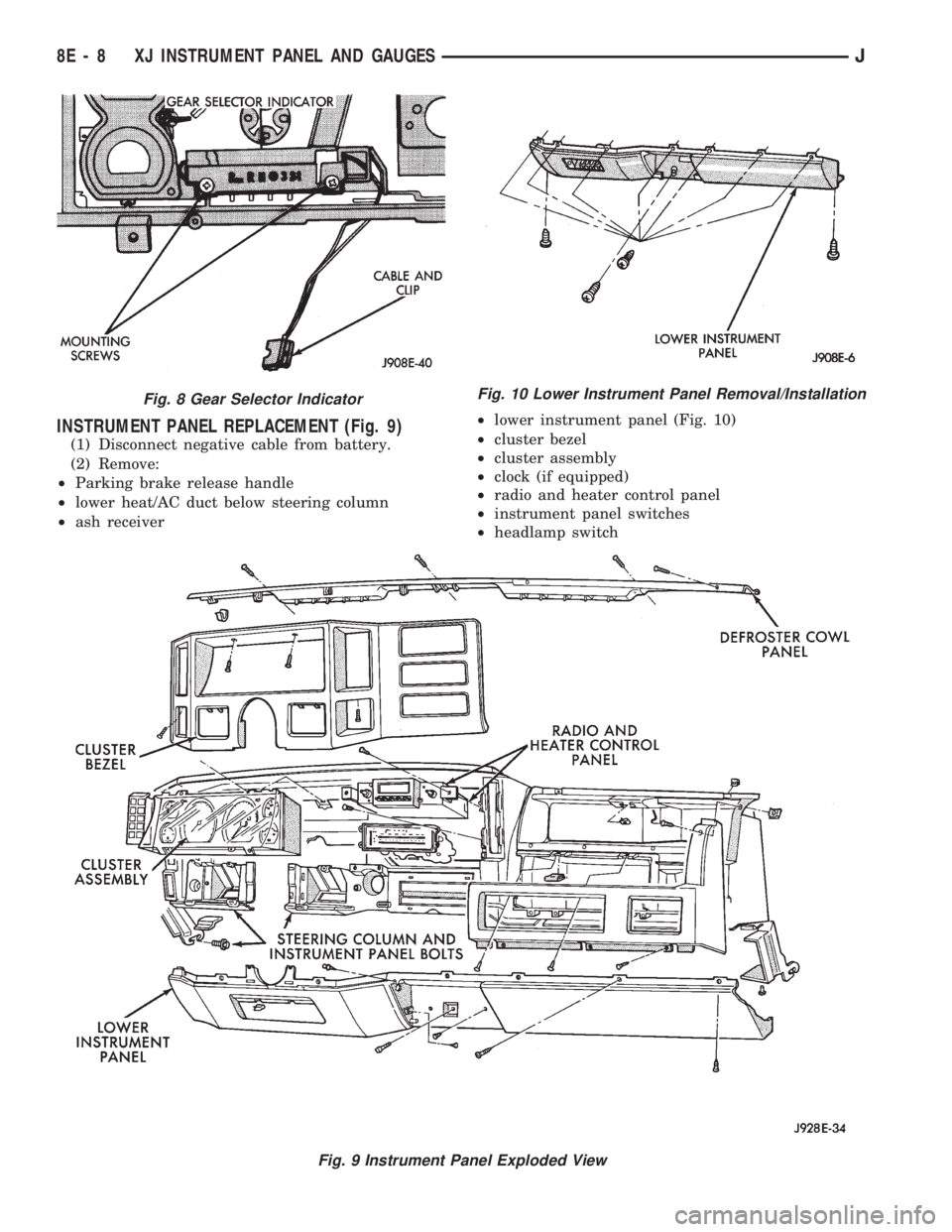

INSTRUMENT PANEL REPLACEMENT (Fig. 9)

(1) Disconnect negative cable from battery.

(2) Remove:

²Parking brake release handle

²lower heat/AC duct below steering column

²ash receiver²lower instrument panel (Fig. 10)

²cluster bezel

²cluster assembly

²clock (if equipped)

²radio and heater control panel

²instrument panel switches

²headlamp switch

Fig. 8 Gear Selector Indicator

Fig. 9 Instrument Panel Exploded View

Fig. 10 Lower Instrument Panel Removal/Installation

8E - 8 XJ INSTRUMENT PANEL AND GAUGESJ

Page 364 of 1784

INSTRUMENT CLUSTER SERVICE PROCEDURES

INDEX

page page

Headlamp Switch/Illumination Rheostat........ 21

Indicator Bezel Replacement................ 17

Instrument Cluster Bulb Replacement......... 19

Instrument Cluster Replacement............. 17Printed Circuit Replacement................ 19

Rear Defogger/Fog Lamp/Rear Wiper Switches . . 21

Speedometer Replacement................. 17

Tachometer Replacement.................. 17

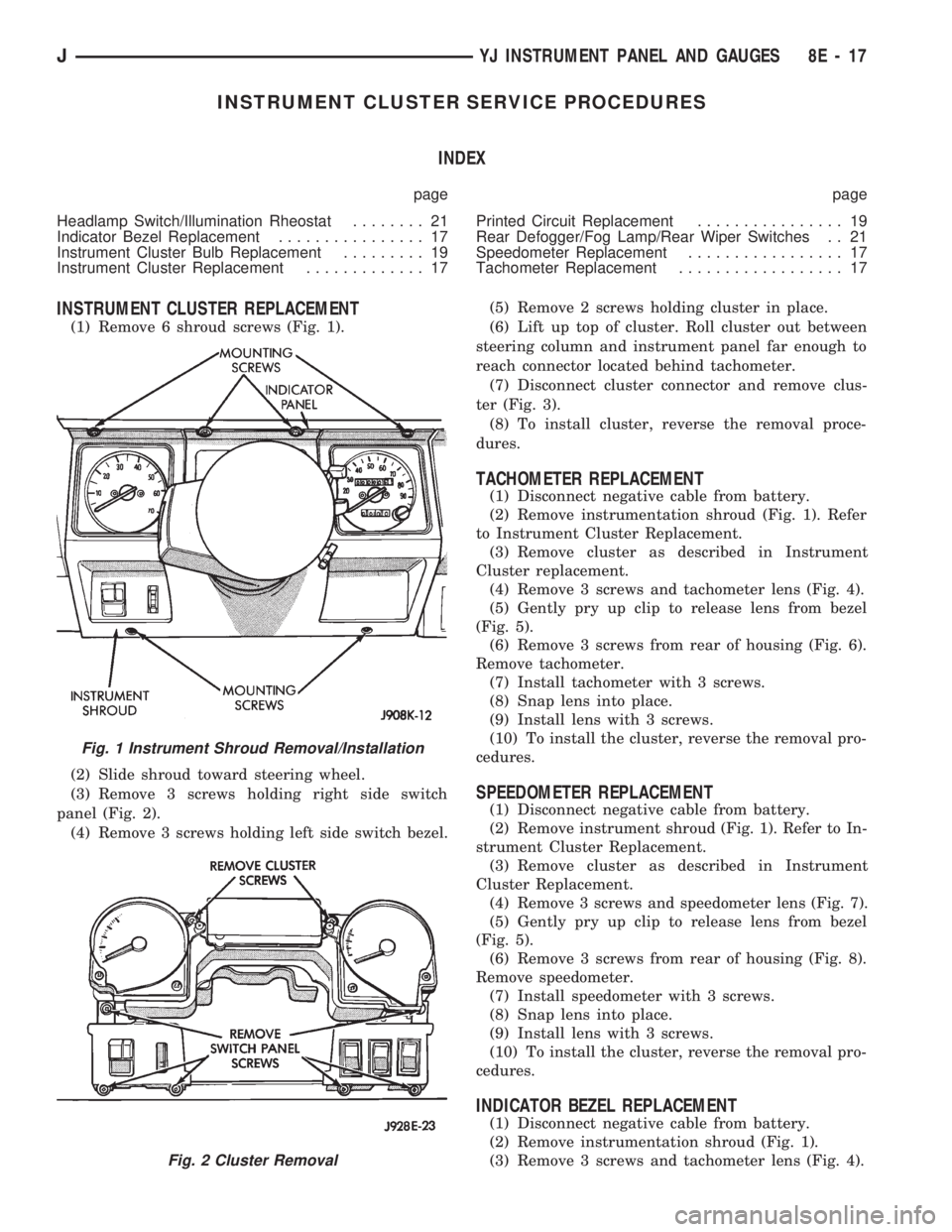

INSTRUMENT CLUSTER REPLACEMENT

(1) Remove 6 shroud screws (Fig. 1).

(2) Slide shroud toward steering wheel.

(3) Remove 3 screws holding right side switch

panel (Fig. 2).

(4) Remove 3 screws holding left side switch bezel.(5) Remove 2 screws holding cluster in place.

(6) Lift up top of cluster. Roll cluster out between

steering column and instrument panel far enough to

reach connector located behind tachometer.

(7) Disconnect cluster connector and remove clus-

ter (Fig. 3).

(8) To install cluster, reverse the removal proce-

dures.

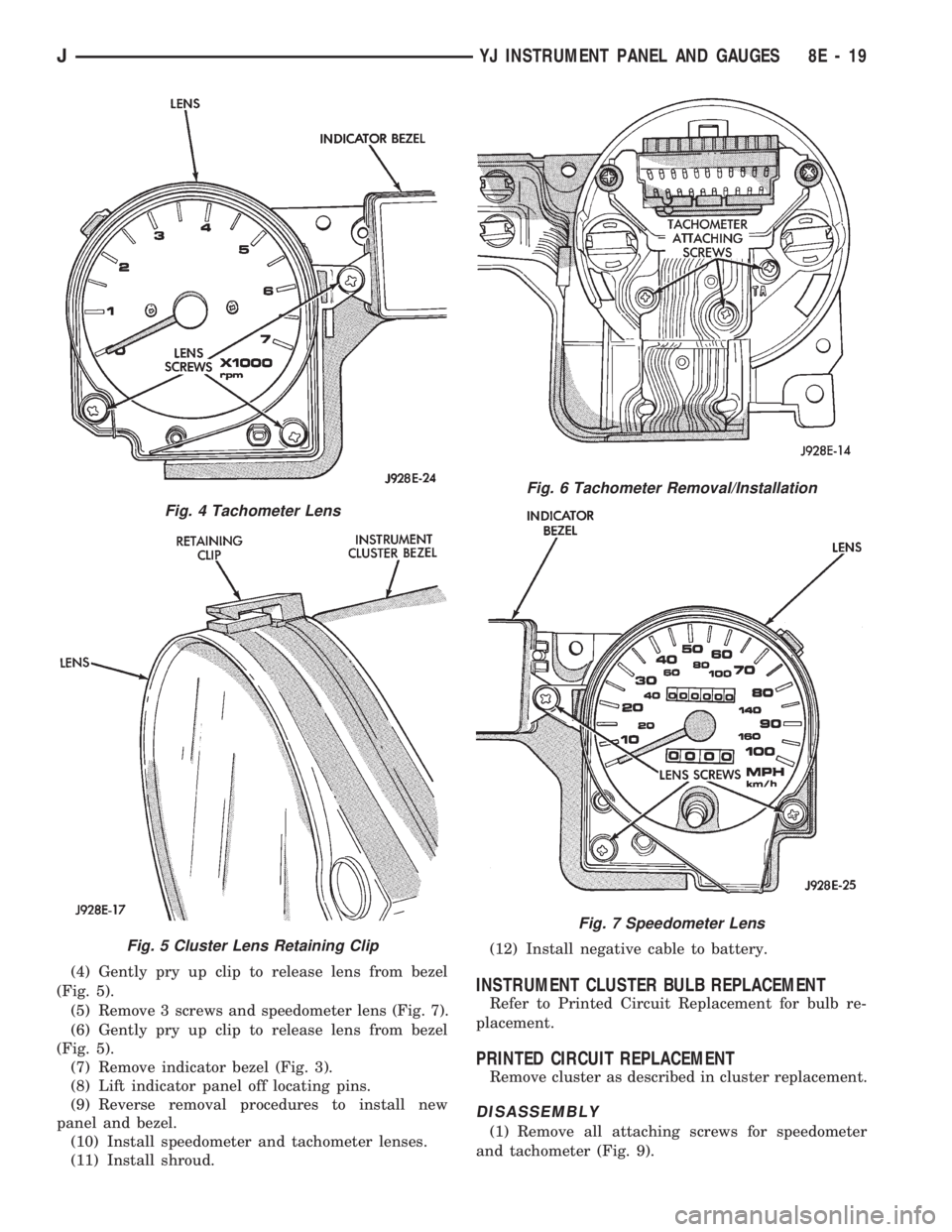

TACHOMETER REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove instrumentation shroud (Fig. 1). Refer

to Instrument Cluster Replacement.

(3) Remove cluster as described in Instrument

Cluster replacement.

(4) Remove 3 screws and tachometer lens (Fig. 4).

(5) Gently pry up clip to release lens from bezel

(Fig. 5).

(6) Remove 3 screws from rear of housing (Fig. 6).

Remove tachometer.

(7) Install tachometer with 3 screws.

(8) Snap lens into place.

(9) Install lens with 3 screws.

(10) To install the cluster, reverse the removal pro-

cedures.

SPEEDOMETER REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove instrument shroud (Fig. 1). Refer to In-

strument Cluster Replacement.

(3) Remove cluster as described in Instrument

Cluster Replacement.

(4) Remove 3 screws and speedometer lens (Fig. 7).

(5) Gently pry up clip to release lens from bezel

(Fig. 5).

(6) Remove 3 screws from rear of housing (Fig. 8).

Remove speedometer.

(7) Install speedometer with 3 screws.

(8) Snap lens into place.

(9) Install lens with 3 screws.

(10) To install the cluster, reverse the removal pro-

cedures.

INDICATOR BEZEL REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove instrumentation shroud (Fig. 1).

(3) Remove 3 screws and tachometer lens (Fig. 4).

Fig. 2 Cluster Removal

Fig. 1 Instrument Shroud Removal/Installation

JYJ INSTRUMENT PANEL AND GAUGES 8E - 17

Page 366 of 1784

(4) Gently pry up clip to release lens from bezel

(Fig. 5).

(5) Remove 3 screws and speedometer lens (Fig. 7).

(6) Gently pry up clip to release lens from bezel

(Fig. 5).

(7) Remove indicator bezel (Fig. 3).

(8) Lift indicator panel off locating pins.

(9) Reverse removal procedures to install new

panel and bezel.

(10) Install speedometer and tachometer lenses.

(11) Install shroud.(12) Install negative cable to battery.INSTRUMENT CLUSTER BULB REPLACEMENT

Refer to Printed Circuit Replacement for bulb re-

placement.

PRINTED CIRCUIT REPLACEMENT

Remove cluster as described in cluster replacement.

DISASSEMBLY

(1) Remove all attaching screws for speedometer

and tachometer (Fig. 9).

Fig. 4 Tachometer Lens

Fig. 5 Cluster Lens Retaining Clip

Fig. 6 Tachometer Removal/Installation

Fig. 7 Speedometer Lens

JYJ INSTRUMENT PANEL AND GAUGES 8E - 19

Page 379 of 1784

XJ SERVICE PROCEDURES

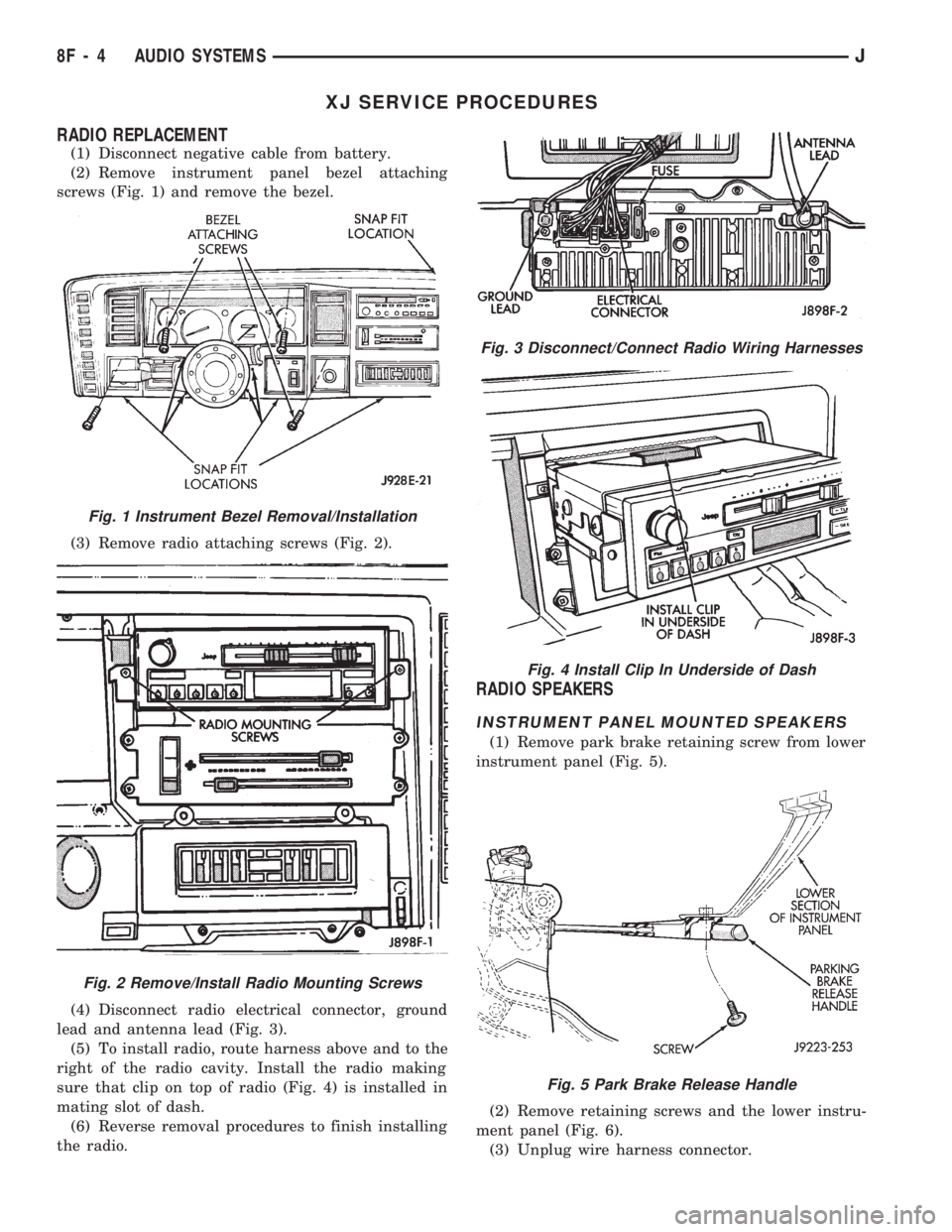

RADIO REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove instrument panel bezel attaching

screws (Fig. 1) and remove the bezel.

(3) Remove radio attaching screws (Fig. 2).

(4) Disconnect radio electrical connector, ground

lead and antenna lead (Fig. 3).

(5) To install radio, route harness above and to the

right of the radio cavity. Install the radio making

sure that clip on top of radio (Fig. 4) is installed in

mating slot of dash.

(6) Reverse removal procedures to finish installing

the radio.

RADIO SPEAKERS

INSTRUMENT PANEL MOUNTED SPEAKERS

(1) Remove park brake retaining screw from lower

instrument panel (Fig. 5).

(2) Remove retaining screws and the lower instru-

ment panel (Fig. 6).

(3) Unplug wire harness connector.

Fig. 3 Disconnect/Connect Radio Wiring Harnesses

Fig. 4 Install Clip In Underside of Dash

Fig. 5 Park Brake Release Handle

Fig. 1 Instrument Bezel Removal/Installation

Fig. 2 Remove/Install Radio Mounting Screws

8F - 4 AUDIO SYSTEMSJ

Page 381 of 1784

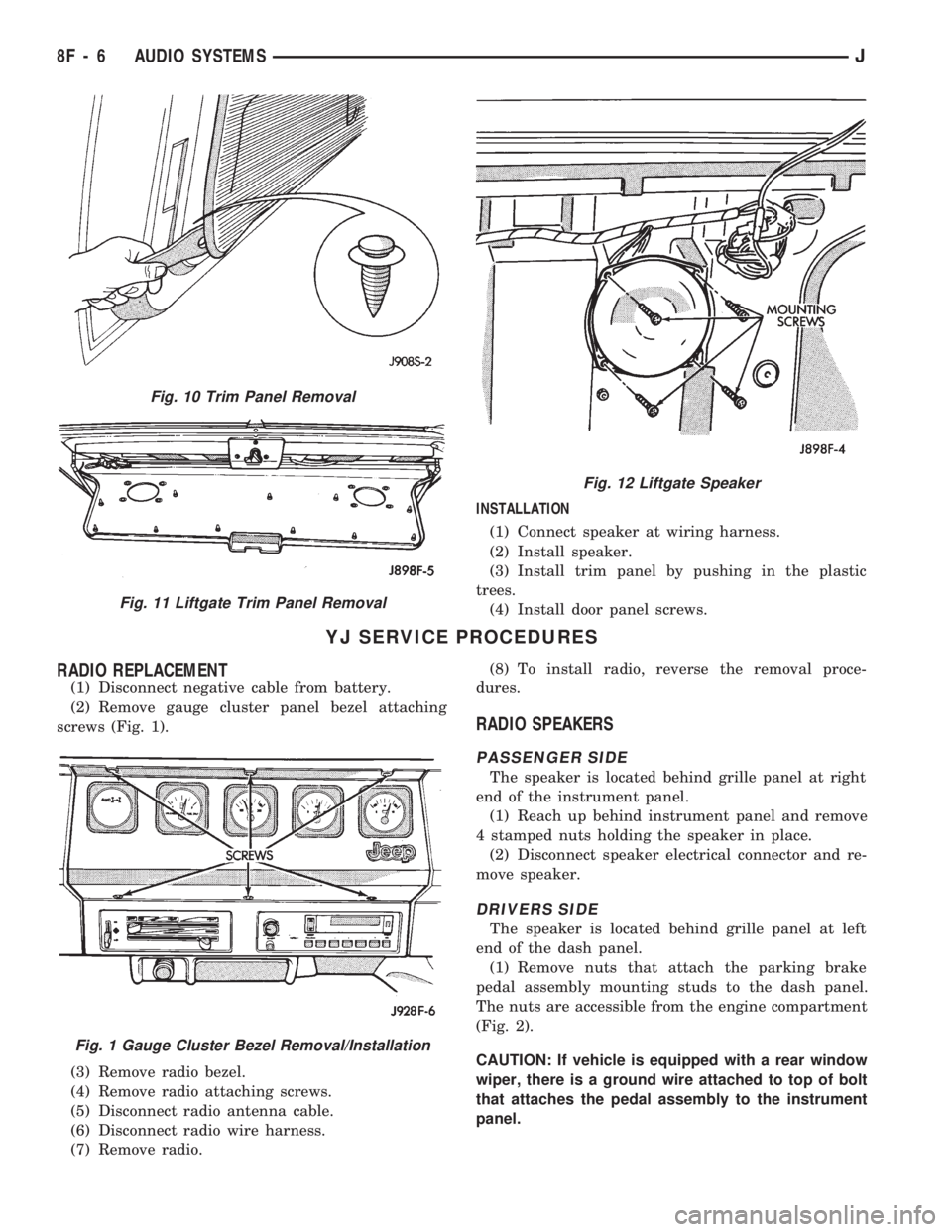

INSTALLATION

(1) Connect speaker at wiring harness.

(2) Install speaker.

(3) Install trim panel by pushing in the plastic

trees.

(4) Install door panel screws.

YJ SERVICE PROCEDURES

RADIO REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove gauge cluster panel bezel attaching

screws (Fig. 1).

(3) Remove radio bezel.

(4) Remove radio attaching screws.

(5) Disconnect radio antenna cable.

(6) Disconnect radio wire harness.

(7) Remove radio.(8) To install radio, reverse the removal proce-

dures.

RADIO SPEAKERS

PASSENGER SIDE

The speaker is located behind grille panel at right

end of the instrument panel.

(1) Reach up behind instrument panel and remove

4 stamped nuts holding the speaker in place.

(2) Disconnect speaker electrical connector and re-

move speaker.

DRIVERS SIDE

The speaker is located behind grille panel at left

end of the dash panel.

(1) Remove nuts that attach the parking brake

pedal assembly mounting studs to the dash panel.

The nuts are accessible from the engine compartment

(Fig. 2).

CAUTION: If vehicle is equipped with a rear window

wiper, there is a ground wire attached to top of bolt

that attaches the pedal assembly to the instrument

panel.

Fig. 10 Trim Panel Removal

Fig. 11 Liftgate Trim Panel Removal

Fig. 12 Liftgate Speaker

Fig. 1 Gauge Cluster Bezel Removal/Installation

8F - 6 AUDIO SYSTEMSJ

Page 386 of 1784

HORNS

CONTENTS

page page

GENERAL INFORMATION.................. 1

HORN SWITCH (HORN PAD) REPLACEMENT . . 3

TORQUE SPECIFICATIONS................. 3XJ ..................................... 1

YJ ..................................... 2

GENERAL INFORMATION

For XJ/YJ vehicles battery voltage is applied to the

horn relay through a fuse.

When the horn switch is depressed, the horn relay

is grounded, pulling the contact closed and providing

battery voltage to the horns.

A slip ring and brush arrangement in the steering

wheel allows the switch circuit to maintain contact

while allowing rotation of the steering wheel.On XJ models, a cadmium-plated ground

screw is used to attach the horn(s) to the body.

Do not substitute other types of ground screws

as they may become corroded and cause a loss

of ground.

XJ

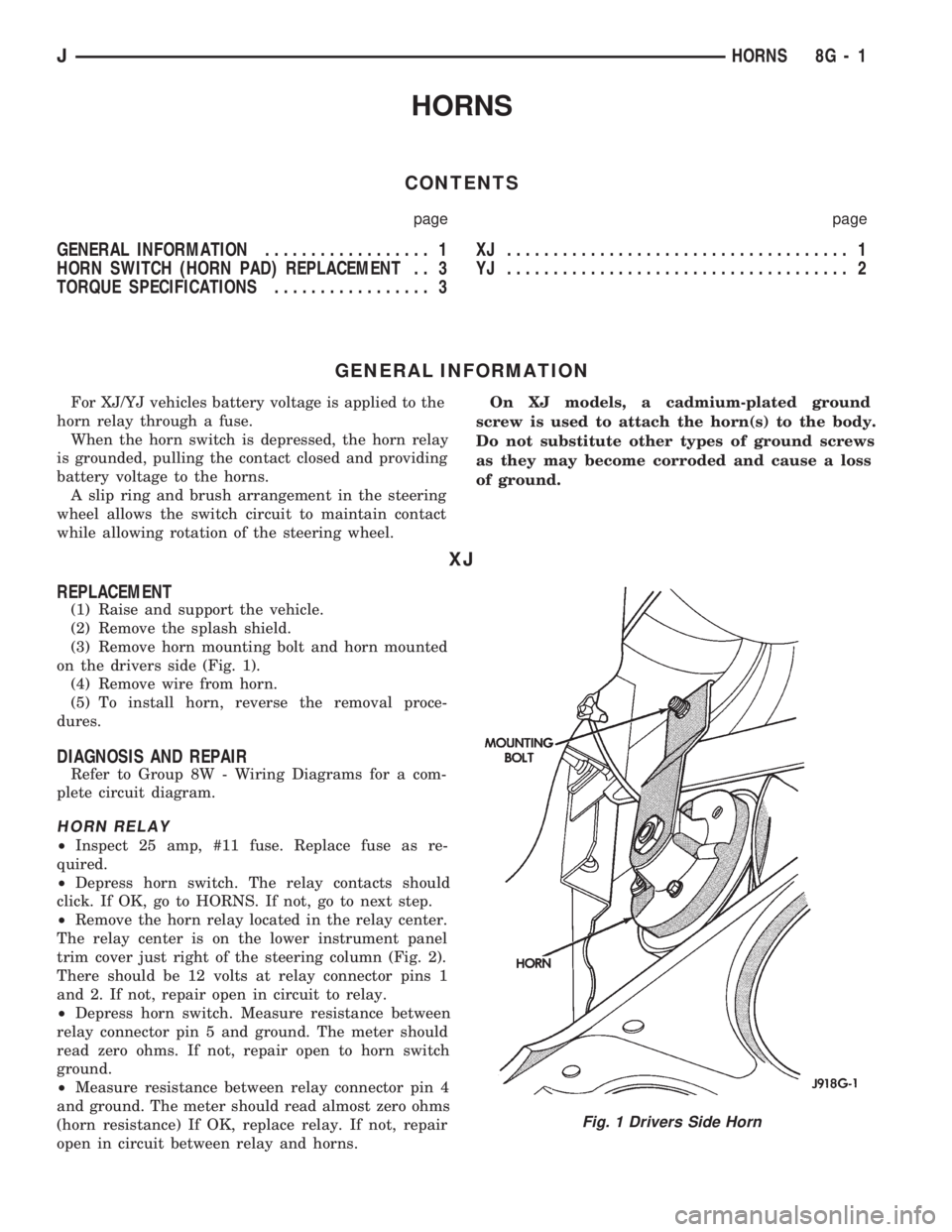

REPLACEMENT

(1) Raise and support the vehicle.

(2) Remove the splash shield.

(3) Remove horn mounting bolt and horn mounted

on the drivers side (Fig. 1).

(4) Remove wire from horn.

(5) To install horn, reverse the removal proce-

dures.

DIAGNOSIS AND REPAIR

Refer to Group 8W - Wiring Diagrams for a com-

plete circuit diagram.

HORN RELAY

²Inspect 25 amp, #11 fuse. Replace fuse as re-

quired.

²Depress horn switch. The relay contacts should

click. If OK, go to HORNS. If not, go to next step.

²Remove the horn relay located in the relay center.

The relay center is on the lower instrument panel

trim cover just right of the steering column (Fig. 2).

There should be 12 volts at relay connector pins 1

and 2. If not, repair open in circuit to relay.

²Depress horn switch. Measure resistance between

relay connector pin 5 and ground. The meter should

read zero ohms. If not, repair open to horn switch

ground.

²Measure resistance between relay connector pin 4

and ground. The meter should read almost zero ohms

(horn resistance) If OK, replace relay. If not, repair

open in circuit between relay and horns.

Fig. 1 Drivers Side Horn

JHORNS 8G - 1

Page 388 of 1784

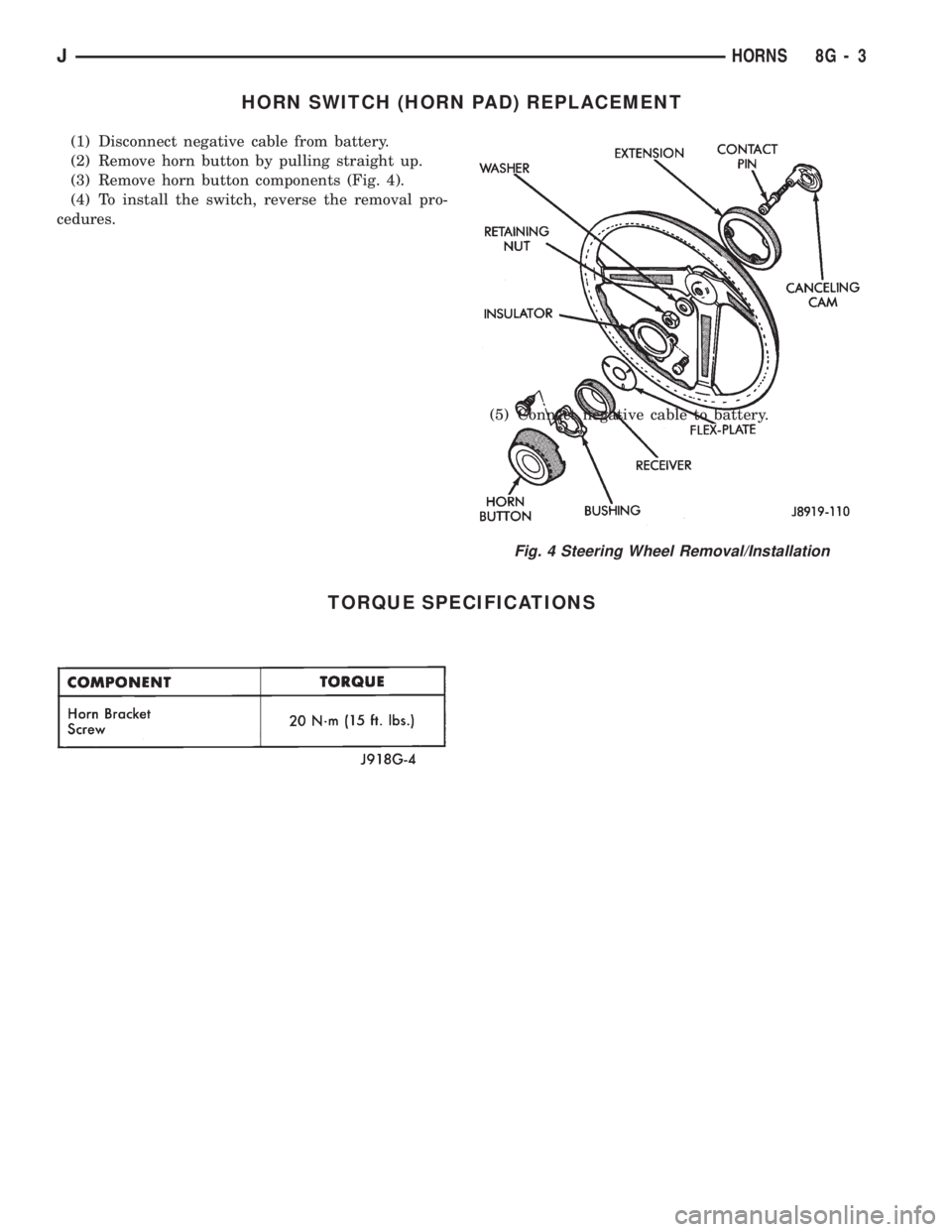

HORN SWITCH (HORN PAD) REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove horn button by pulling straight up.

(3) Remove horn button components (Fig. 4).

(4) To install the switch, reverse the removal pro-

cedures.

(5) Connect negative cable to battery.

TORQUE SPECIFICATIONS

Fig. 4 Steering Wheel Removal/Installation

JHORNS 8G - 3