battery replacement JEEP CHEROKEE 1994 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 398 of 1784

SERVICE PROCEDURES

INDEX

page page

Servo Cable Replacement................... 9

Speed Control Servo Replacement............ 9Speed Control Switch Replacement............ 9

SPEED CONTROL SERVO REPLACEMENT

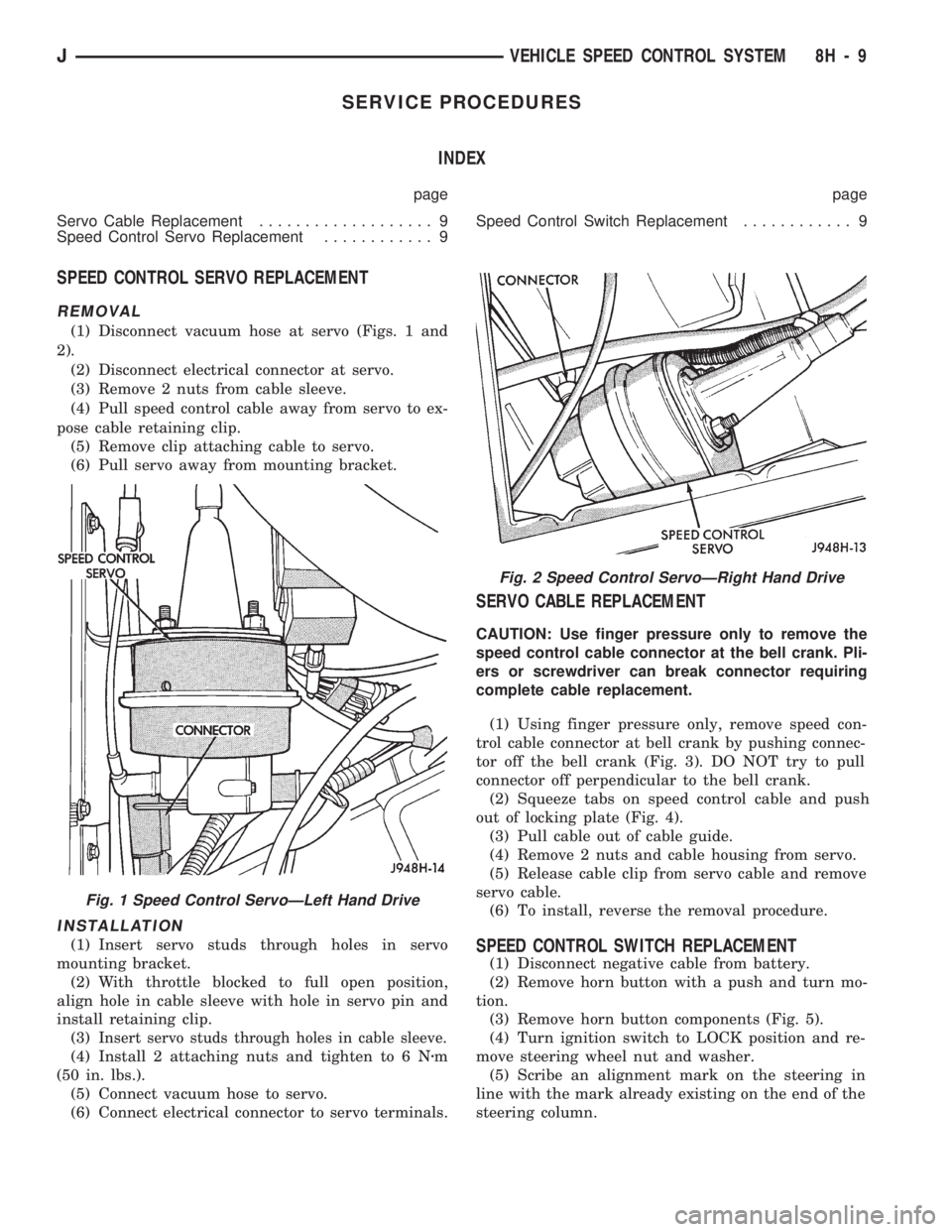

REMOVAL

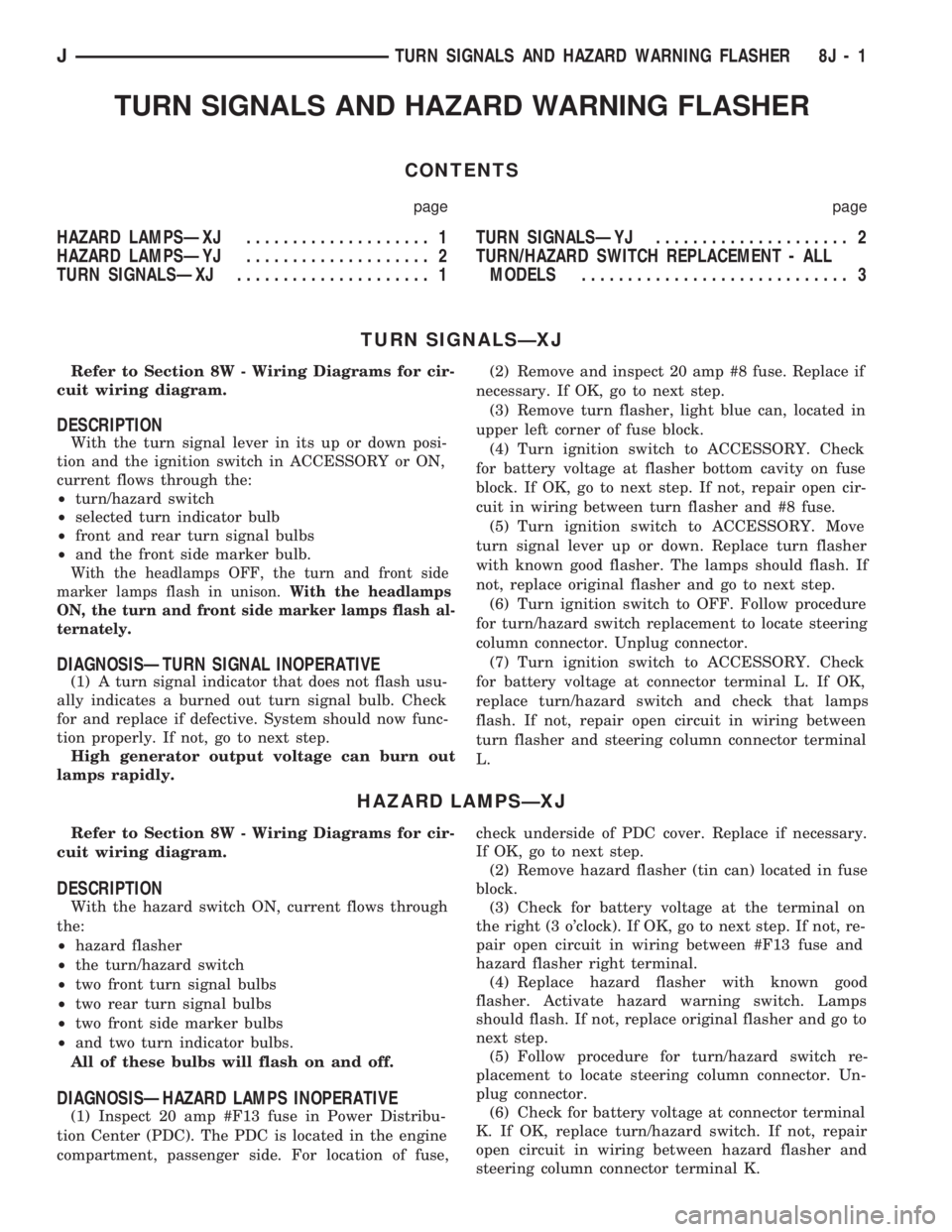

(1) Disconnect vacuum hose at servo (Figs. 1 and

2).

(2) Disconnect electrical connector at servo.

(3) Remove 2 nuts from cable sleeve.

(4) Pull speed control cable away from servo to ex-

pose cable retaining clip.

(5) Remove clip attaching cable to servo.

(6) Pull servo away from mounting bracket.

INSTALLATION

(1) Insert servo studs through holes in servo

mounting bracket.

(2) With throttle blocked to full open position,

align hole in cable sleeve with hole in servo pin and

install retaining clip.

(3)

Insert servo studs through holes in cable sleeve.

(4) Install 2 attaching nuts and tighten to 6 Nzm

(50 in. lbs.).

(5) Connect vacuum hose to servo.

(6) Connect electrical connector to servo terminals.

SERVO CABLE REPLACEMENT

CAUTION: Use finger pressure only to remove the

speed control cable connector at the bell crank. Pli-

ers or screwdriver can break connector requiring

complete cable replacement.

(1) Using finger pressure only, remove speed con-

trol cable connector at bell crank by pushing connec-

tor off the bell crank (Fig. 3). DO NOT try to pull

connector off perpendicular to the bell crank.

(2) Squeeze tabs on speed control cable and push

out of locking plate (Fig. 4).

(3) Pull cable out of cable guide.

(4) Remove 2 nuts and cable housing from servo.

(5) Release cable clip from servo cable and remove

servo cable.

(6) To install, reverse the removal procedure.

SPEED CONTROL SWITCH REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove horn button with a push and turn mo-

tion.

(3) Remove horn button components (Fig. 5).

(4) Turn ignition switch to LOCK position and re-

move steering wheel nut and washer.

(5) Scribe an alignment mark on the steering in

line with the mark already existing on the end of the

steering column.

Fig. 2 Speed Control ServoÐRight Hand Drive

Fig. 1 Speed Control ServoÐLeft Hand Drive

JVEHICLE SPEED CONTROL SYSTEM 8H - 9

Page 402 of 1784

TURN SIGNALS AND HAZARD WARNING FLASHER

CONTENTS

page page

HAZARD LAMPSÐXJ.................... 1

HAZARD LAMPSÐYJ.................... 2

TURN SIGNALSÐXJ..................... 1TURN SIGNALSÐYJ..................... 2

TURN/HAZARD SWITCH REPLACEMENT - ALL

MODELS............................. 3

TURN SIGNALSÐXJ

Refer to Section 8W - Wiring Diagrams for cir-

cuit wiring diagram.

DESCRIPTION

With the turn signal lever in its up or down posi-

tion and the ignition switch in ACCESSORY or ON,

current flows through the:

²turn/hazard switch

²selected turn indicator bulb

²front and rear turn signal bulbs

²and the front side marker bulb.

With the headlamps OFF, the turn and front side

marker lamps flash in unison.With the headlamps

ON, the turn and front side marker lamps flash al-

ternately.

DIAGNOSISÐTURN SIGNAL INOPERATIVE

(1) A turn signal indicator that does not flash usu-

ally indicates a burned out turn signal bulb. Check

for and replace if defective. System should now func-

tion properly. If not, go to next step.

High generator output voltage can burn out

lamps rapidly.(2) Remove and inspect 20 amp #8 fuse. Replace if

necessary. If OK, go to next step.

(3) Remove turn flasher, light blue can, located in

upper left corner of fuse block.

(4) Turn ignition switch to ACCESSORY. Check

for battery voltage at flasher bottom cavity on fuse

block. If OK, go to next step. If not, repair open cir-

cuit in wiring between turn flasher and #8 fuse.

(5) Turn ignition switch to ACCESSORY. Move

turn signal lever up or down. Replace turn flasher

with known good flasher. The lamps should flash. If

not, replace original flasher and go to next step.

(6) Turn ignition switch to OFF. Follow procedure

for turn/hazard switch replacement to locate steering

column connector. Unplug connector.

(7) Turn ignition switch to ACCESSORY. Check

for battery voltage at connector terminal L. If OK,

replace turn/hazard switch and check that lamps

flash. If not, repair open circuit in wiring between

turn flasher and steering column connector terminal

L.

HAZARD LAMPSÐXJ

Refer to Section 8W - Wiring Diagrams for cir-

cuit wiring diagram.

DESCRIPTION

With the hazard switch ON, current flows through

the:

²hazard flasher

²the turn/hazard switch

²two front turn signal bulbs

²two rear turn signal bulbs

²two front side marker bulbs

²and two turn indicator bulbs.

All of these bulbs will flash on and off.

DIAGNOSISÐHAZARD LAMPS INOPERATIVE

(1) Inspect 20 amp #F13 fuse in Power Distribu-

tion Center (PDC). The PDC is located in the engine

compartment, passenger side. For location of fuse,check underside of PDC cover. Replace if necessary.

If OK, go to next step.

(2) Remove hazard flasher (tin can) located in fuse

block.

(3) Check for battery voltage at the terminal on

the right (3 o'clock). If OK, go to next step. If not, re-

pair open circuit in wiring between #F13 fuse and

hazard flasher right terminal.

(4) Replace hazard flasher with known good

flasher. Activate hazard warning switch. Lamps

should flash. If not, replace original flasher and go to

next step.

(5) Follow procedure for turn/hazard switch re-

placement to locate steering column connector. Un-

plug connector.

(6) Check for battery voltage at connector terminal

K. If OK, replace turn/hazard switch. If not, repair

open circuit in wiring between hazard flasher and

steering column connector terminal K.

JTURN SIGNALS AND HAZARD WARNING FLASHER 8J - 1

Page 403 of 1784

TURN SIGNALSÐYJ

Refer to Section 8W - Wiring Diagrams for cir-

cuit wiring diagram.

DESCRIPTION

With the turn signal lever in its up or down posi-

tion and the ignition switch in ACCESSORY or ON,

current flows through the:

²turn/hazard switch

²selected turn indicator bulb

²front and rear turn signal bulbs

²front side marker bulb

With the headlamps OFF, the turn and side

marker lamps flash in unison.With the headlamps

ON, the turn and side marker lamps flash alter-

nately.

DIAGNOSINGÐTURN SIGNAL INOPERATIVE

(1) A turn signal indicator that does not flash usu-

ally indicates a burned out turn signal bulb. Check

for and replace if defective. System should now func-

tion properly. If not, go to next step.

High generator output voltage can burn out

lamps rapidly.

(2) Locate fuse block under driver's side of instru-

ment panel.(3) Remove and inspect 15 amp #4 fuse. Replace if

necessary. If OK, go to next step.

(4) Remove turn flasher, light blue can, located in

fuse block.

(5) Turn ignition switch to ACCESSORY. Check

for battery voltage at cavity on left (closest to hazard

flasher can). If OK, go to next step. If not, repair

open circuit in wiring between turn flasher and #4

fuse.

(6) Turn ignition switch to ACCESSORY. Move

turn signal lever up or down. Replace turn flasher

with known good flasher. The lamps should flash. If

not, replace original flasher and go to next step.

(7) Turn ignition switch to OFF. Follow procedure

for turn/hazard switch replacement to locate steering

column connector. Unplug connector.

(8) Turn ignition switch to ACCESSORY. Check

for battery voltage at connector terminal L. If OK,

replace turn/hazard switch. If not, repair open circuit

in wiring between turn flasher and steering column

connector terminal L.

HAZARD LAMPSÐYJ

Refer to Section 8W - Wiring Diagrams for cir-

cuit wiring diagram.

DESCRIPTION

With the hazard switch ON, current flows through

the:

²hazard flasher

²turn/hazard switch

²two front turn signal bulbs

²two rear turn signal bulbs

²two front side marker bulbs

²two turn indicator bulbs.

All of these bulbs will flash on and off.

DIAGNOSISÐHAZARD LAMPS INOPERATIVE

(1) Inspect 20 amp #F5 fuse in Power Distribution

Center (PDC). The PDC is located in the engine com-

partment, passenger side. For location of fuse, check

underside of PDC cover. Replace if necessary. If OK,

go to next step.(2) Remove hazard flasher (tin can) located in fuse

block.

(3) Check for battery voltage at the terminal on

the left. If OK, go to next step. If not, repair open cir-

cuit in wiring between #F5 fuse and hazard flasher

left terminal.

(4) Replace hazard flasher with known good

flasher. Activate hazard warning switch. Lamps

should flash. If not, replace original flasher and go to

next step.

(5) Follow procedure for turn/hazard switch re-

placement to locate steering column connector. Un-

plug connector.

(6) Check for battery voltage at connector terminal

K. If OK, replace turn/hazard switch. If not, repair

open circuit in wiring between hazard flasher and

steering column connector terminal K.

8J - 2 TURN SIGNALS AND HAZARD WARNING FLASHERJ

Page 404 of 1784

TURN/HAZARD SWITCH REPLACEMENT - ALL MODELS

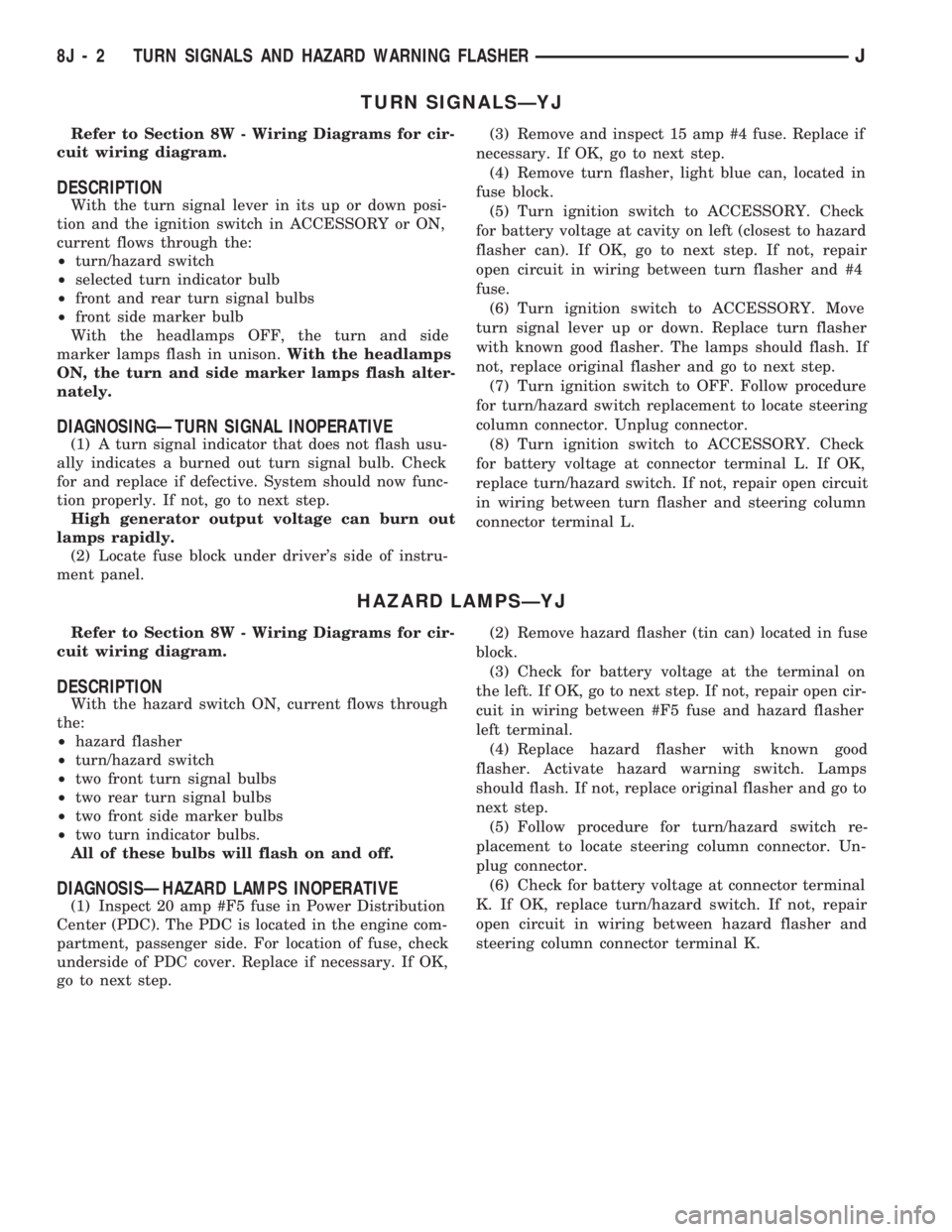

(1) Disconnect negative cable from battery.

(2) Remove the horn button with a push and turn

motion.

(3) Remove the horn button components (Fig. 1).

(4) Turn ignition switch to LOCK position and re-

move steering wheel nut and washer.

(5) Scribe an alignment mark on the steering in

line with the mark already existing on the end of the

steering column.

(6) Remove vibration damper from the steering col-

umn hub, if equipped.

(7) Remove the steering wheel using a steering

wheel puller. DO NOT hammer on puller or end of

steering shaft.

WARNING: TO REMOVE THE STEERING SHAFT

SNAP RING IN THE FOLLOWING STEP, THE LOCK-

PLATE MUST BE COMPRESSED. DO NOT AT-

TEMPT TO REMOVE THE LOCKPLATE WITHOUT

COMPRESSOR TOOL C4156 AS THE LOCKPLATE

IS UNDER HEAVY SPRING TENSION.

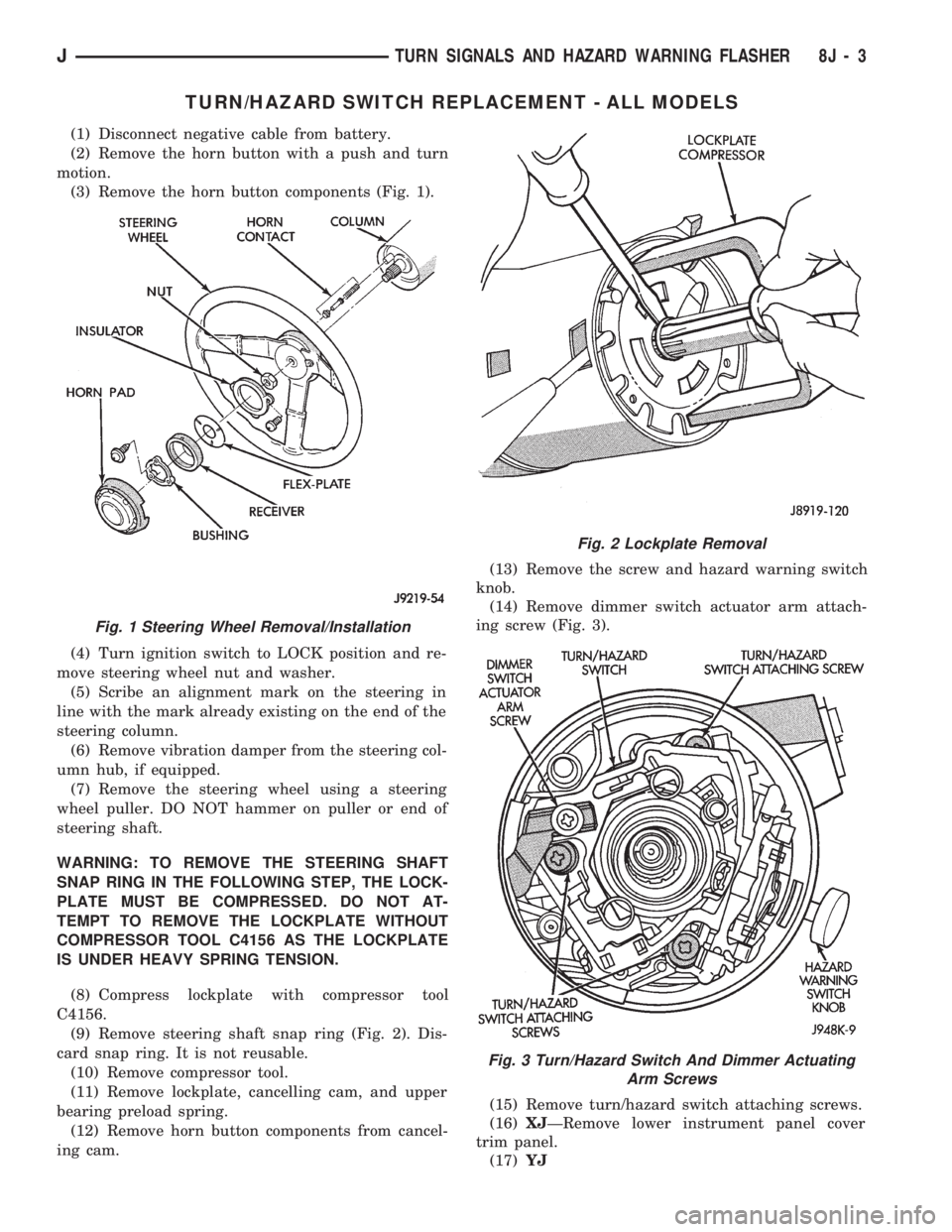

(8) Compress lockplate with compressor tool

C4156.

(9) Remove steering shaft snap ring (Fig. 2). Dis-

card snap ring. It is not reusable.

(10) Remove compressor tool.

(11) Remove lockplate, cancelling cam, and upper

bearing preload spring.

(12) Remove horn button components from cancel-

ing cam.(13) Remove the screw and hazard warning switch

knob.

(14) Remove dimmer switch actuator arm attach-

ing screw (Fig. 3).

(15) Remove turn/hazard switch attaching screws.

(16)XJÐRemove lower instrument panel cover

trim panel.

(17)YJ

Fig. 1 Steering Wheel Removal/Installation

Fig. 2 Lockplate Removal

Fig. 3 Turn/Hazard Switch And Dimmer Actuating

Arm Screws

JTURN SIGNALS AND HAZARD WARNING FLASHER 8J - 3

Page 408 of 1784

WINDSHIELD WIPERS

CONTENTS

page page

WIPER CONTROL SWITCH REPLACEMENT . . 15

WIPER SWITCH TESTING................ 19XJ .................................... 1

YJ .................................... 8

XJ

INDEX

page page

Diagnosing Rear Wiper..................... 6

Diagnosing Rear Wiper Washer.............. 6

Diagnosing Windshield Washer (Intermittent)..... 5

Diagnosing Windshield Washer (Non-Intermittent) . 4

Diagnosing Windshield Wipers............... 11

Front Wipers/Washers...................... 1

Intermittent Wiper Module................... 5

Liftgate Wiper............................ 5Liftgate Wiper Switch Replacement............ 6

Rear Wiper/Washer Switch Testing............ 7

Torque Specifications XJ.................... 7

Washer Pump Replacement................. 6

Washer Pump ReplacementÐLeft Hand Drive.... 2

Washer Pump ReplacementÐRight Hand Drive . . 3

Windshield Wiper Motor.................... 2

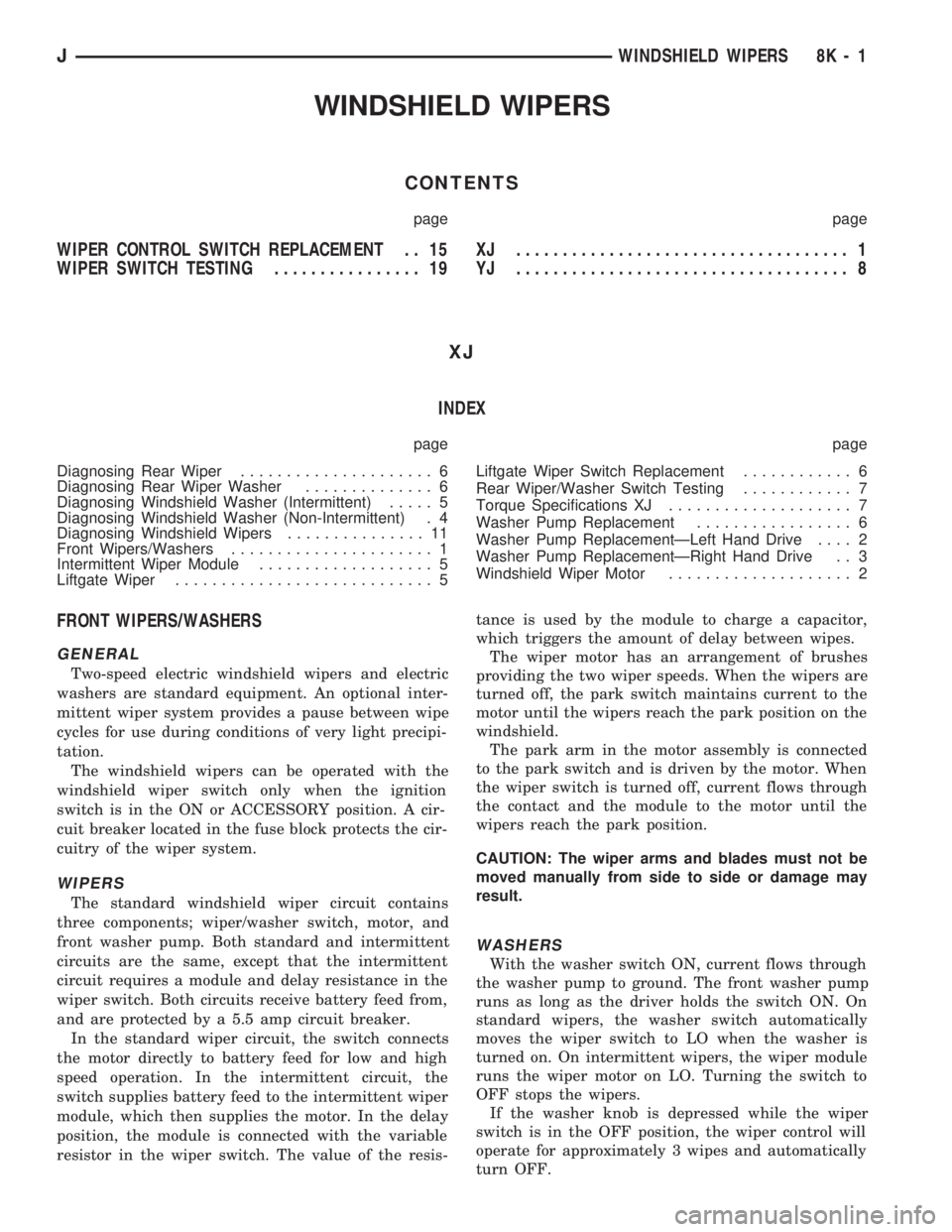

FRONT WIPERS/WASHERS

GENERAL

Two-speed electric windshield wipers and electric

washers are standard equipment. An optional inter-

mittent wiper system provides a pause between wipe

cycles for use during conditions of very light precipi-

tation.

The windshield wipers can be operated with the

windshield wiper switch only when the ignition

switch is in the ON or ACCESSORY position. A cir-

cuit breaker located in the fuse block protects the cir-

cuitry of the wiper system.

WIPERS

The standard windshield wiper circuit contains

three components; wiper/washer switch, motor, and

front washer pump. Both standard and intermittent

circuits are the same, except that the intermittent

circuit requires a module and delay resistance in the

wiper switch. Both circuits receive battery feed from,

and are protected by a 5.5 amp circuit breaker.

In the standard wiper circuit, the switch connects

the motor directly to battery feed for low and high

speed operation. In the intermittent circuit, the

switch supplies battery feed to the intermittent wiper

module, which then supplies the motor. In the delay

position, the module is connected with the variable

resistor in the wiper switch. The value of the resis-tance is used by the module to charge a capacitor,

which triggers the amount of delay between wipes.

The wiper motor has an arrangement of brushes

providing the two wiper speeds. When the wipers are

turned off, the park switch maintains current to the

motor until the wipers reach the park position on the

windshield.

The park arm in the motor assembly is connected

to the park switch and is driven by the motor. When

the wiper switch is turned off, current flows through

the contact and the module to the motor until the

wipers reach the park position.

CAUTION: The wiper arms and blades must not be

moved manually from side to side or damage may

result.

WASHERS

With the washer switch ON, current flows through

the washer pump to ground. The front washer pump

runs as long as the driver holds the switch ON. On

standard wipers, the washer switch automatically

moves the wiper switch to LO when the washer is

turned on. On intermittent wipers, the wiper module

runs the wiper motor on LO. Turning the switch to

OFF stops the wipers.

If the washer knob is depressed while the wiper

switch is in the OFF position, the wiper control will

operate for approximately 3 wipes and automatically

turn OFF.

JWINDSHIELD WIPERS 8K - 1

Page 410 of 1784

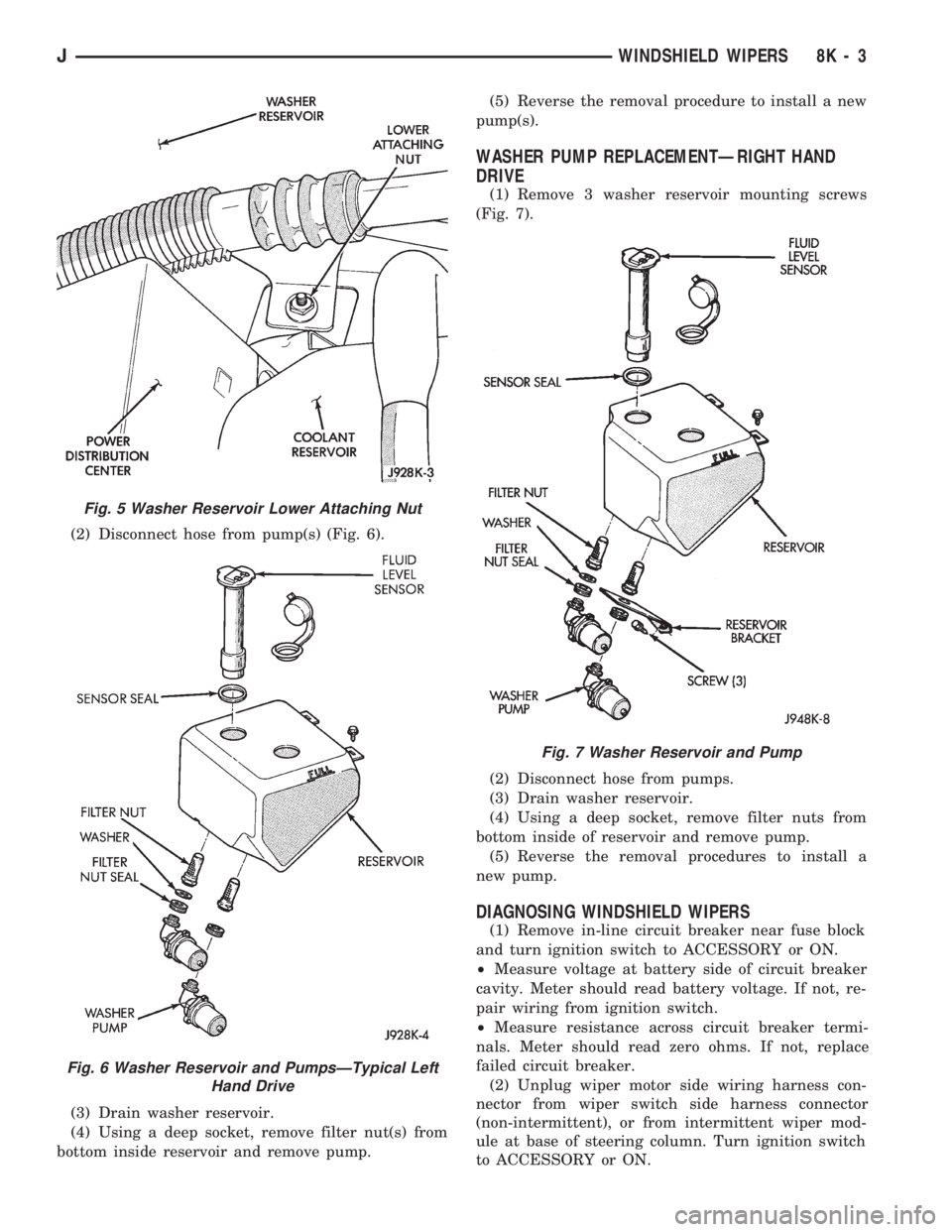

(2) Disconnect hose from pump(s) (Fig. 6).

(3) Drain washer reservoir.

(4) Using a deep socket, remove filter nut(s) from

bottom inside reservoir and remove pump.(5) Reverse the removal procedure to install a new

pump(s).

WASHER PUMP REPLACEMENTÐRIGHT HAND

DRIVE

(1) Remove 3 washer reservoir mounting screws

(Fig. 7).

(2) Disconnect hose from pumps.

(3) Drain washer reservoir.

(4) Using a deep socket, remove filter nuts from

bottom inside of reservoir and remove pump.

(5) Reverse the removal procedures to install a

new pump.

DIAGNOSING WINDSHIELD WIPERS

(1) Remove in-line circuit breaker near fuse block

and turn ignition switch to ACCESSORY or ON.

²Measure voltage at battery side of circuit breaker

cavity. Meter should read battery voltage. If not, re-

pair wiring from ignition switch.

²Measure resistance across circuit breaker termi-

nals. Meter should read zero ohms. If not, replace

failed circuit breaker.

(2) Unplug wiper motor side wiring harness con-

nector from wiper switch side harness connector

(non-intermittent), or from intermittent wiper mod-

ule at base of steering column. Turn ignition switch

to ACCESSORY or ON.

Fig. 5 Washer Reservoir Lower Attaching Nut

Fig. 6 Washer Reservoir and PumpsÐTypical Left

Hand Drive

Fig. 7 Washer Reservoir and Pump

JWINDSHIELD WIPERS 8K - 3

Page 413 of 1784

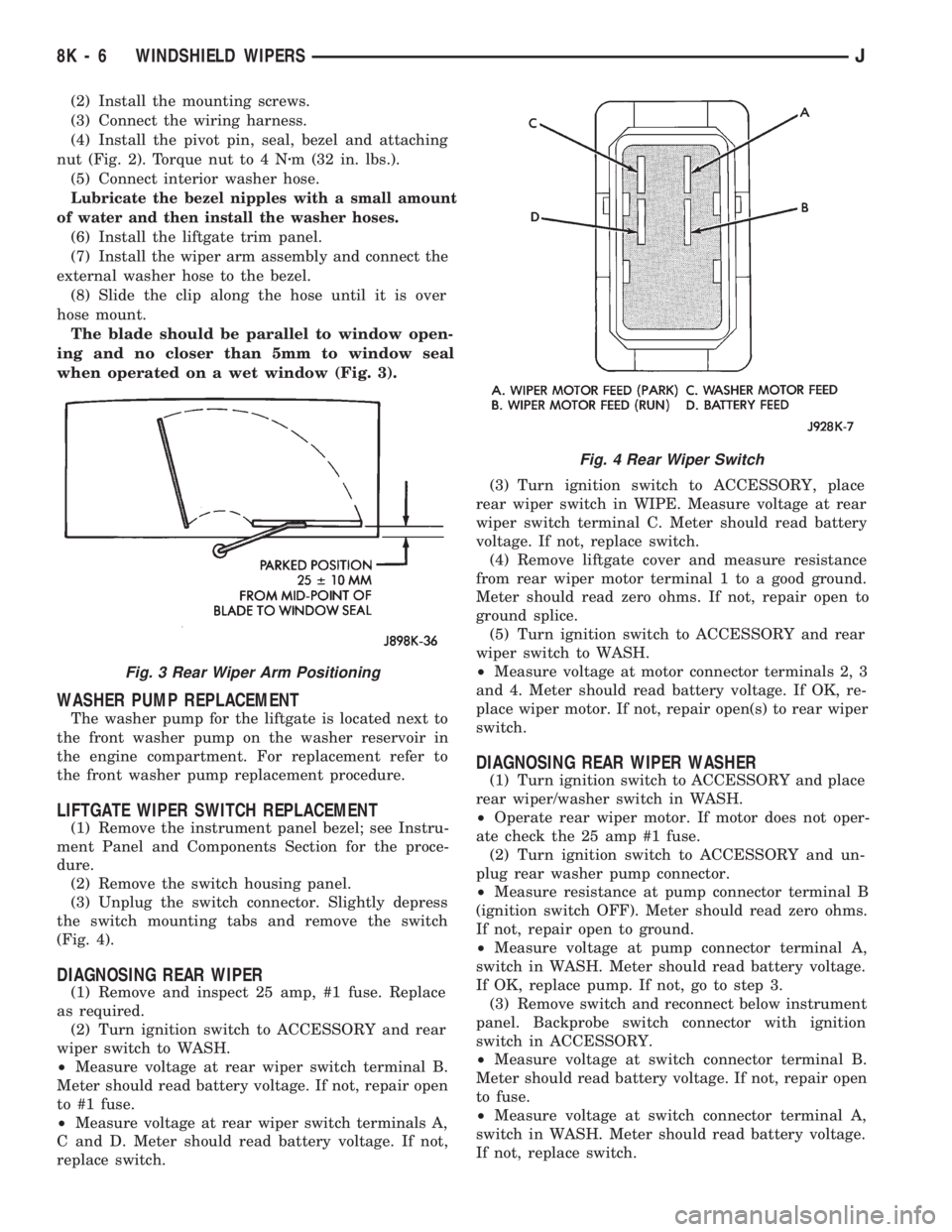

(2) Install the mounting screws.

(3) Connect the wiring harness.

(4) Install the pivot pin, seal, bezel and attaching

nut (Fig. 2). Torque nut to 4 Nzm (32 in. lbs.).

(5) Connect interior washer hose.

Lubricate the bezel nipples with a small amount

of water and then install the washer hoses.

(6) Install the liftgate trim panel.

(7) Install the wiper arm assembly and connect the

external washer hose to the bezel.

(8) Slide the clip along the hose until it is over

hose mount.

The blade should be parallel to window open-

ing and no closer than 5mm to window seal

when operated on a wet window (Fig. 3).

WASHER PUMP REPLACEMENT

The washer pump for the liftgate is located next to

the front washer pump on the washer reservoir in

the engine compartment. For replacement refer to

the front washer pump replacement procedure.

LIFTGATE WIPER SWITCH REPLACEMENT

(1) Remove the instrument panel bezel; see Instru-

ment Panel and Components Section for the proce-

dure.

(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch

(Fig. 4).

DIAGNOSING REAR WIPER

(1) Remove and inspect 25 amp, #1 fuse. Replace

as required.

(2) Turn ignition switch to ACCESSORY and rear

wiper switch to WASH.

²Measure voltage at rear wiper switch terminal B.

Meter should read battery voltage. If not, repair open

to #1 fuse.

²Measure voltage at rear wiper switch terminals A,

C and D. Meter should read battery voltage. If not,

replace switch.(3) Turn ignition switch to ACCESSORY, place

rear wiper switch in WIPE. Measure voltage at rear

wiper switch terminal C. Meter should read battery

voltage. If not, replace switch.

(4) Remove liftgate cover and measure resistance

from rear wiper motor terminal 1 to a good ground.

Meter should read zero ohms. If not, repair open to

ground splice.

(5) Turn ignition switch to ACCESSORY and rear

wiper switch to WASH.

²Measure voltage at motor connector terminals 2, 3

and 4. Meter should read battery voltage. If OK, re-

place wiper motor. If not, repair open(s) to rear wiper

switch.

DIAGNOSING REAR WIPER WASHER

(1) Turn ignition switch to ACCESSORY and place

rear wiper/washer switch in WASH.

²Operate rear wiper motor. If motor does not oper-

ate check the 25 amp #1 fuse.

(2) Turn ignition switch to ACCESSORY and un-

plug rear washer pump connector.

²Measure resistance at pump connector terminal B

(ignition switch OFF). Meter should read zero ohms.

If not, repair open to ground.

²Measure voltage at pump connector terminal A,

switch in WASH. Meter should read battery voltage.

If OK, replace pump. If not, go to step 3.

(3) Remove switch and reconnect below instrument

panel. Backprobe switch connector with ignition

switch in ACCESSORY.

²Measure voltage at switch connector terminal B.

Meter should read battery voltage. If not, repair open

to fuse.

²Measure voltage at switch connector terminal A,

switch in WASH. Meter should read battery voltage.

If not, replace switch.

Fig. 3 Rear Wiper Arm Positioning

Fig. 4 Rear Wiper Switch

8K - 6 WINDSHIELD WIPERSJ

Page 415 of 1784

YJ

INDEX

page page

Diagnosing Windshield Wipers............... 11

Diagnosing Intermittent Windshield Washer..... 12

Diagnosing Non-Intermittent Windshield Washer . 12

Diagnosing Rear Wiper/Washer.............. 14

Front Wiper Arm and Pivot Assembly Replacement . 9

Front Wiper Arm Replacement............... 8

Front Wiper Blade Replacement.............. 8

Front Wiper Motor........................ 10Front Wipers/Washers General Information...... 8

Rear Washer Pump Replacement............ 13

Rear Wiper Arm Replacement............... 12

Rear Wiper Motor Replacement.............. 13

Rear Wiper Switch Replacement............. 13

Rear Wiper/Washer Switch Testing........... 14

Washer Nozzle Replacement................ 13

Washer Pump Replacement................ 11

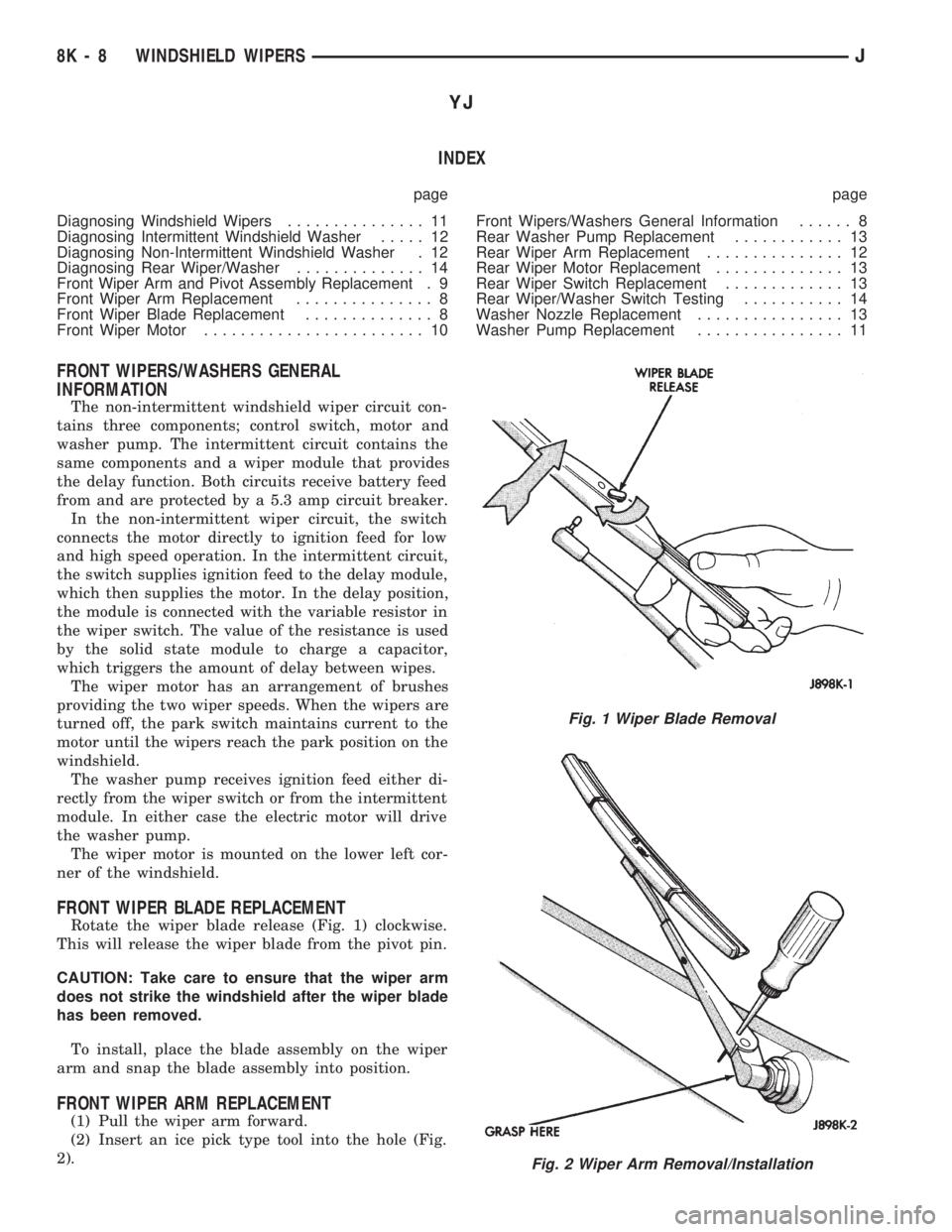

FRONT WIPERS/WASHERS GENERAL

INFORMATION

The non-intermittent windshield wiper circuit con-

tains three components; control switch, motor and

washer pump. The intermittent circuit contains the

same components and a wiper module that provides

the delay function. Both circuits receive battery feed

from and are protected by a 5.3 amp circuit breaker.

In the non-intermittent wiper circuit, the switch

connects the motor directly to ignition feed for low

and high speed operation. In the intermittent circuit,

the switch supplies ignition feed to the delay module,

which then supplies the motor. In the delay position,

the module is connected with the variable resistor in

the wiper switch. The value of the resistance is used

by the solid state module to charge a capacitor,

which triggers the amount of delay between wipes.

The wiper motor has an arrangement of brushes

providing the two wiper speeds. When the wipers are

turned off, the park switch maintains current to the

motor until the wipers reach the park position on the

windshield.

The washer pump receives ignition feed either di-

rectly from the wiper switch or from the intermittent

module. In either case the electric motor will drive

the washer pump.

The wiper motor is mounted on the lower left cor-

ner of the windshield.

FRONT WIPER BLADE REPLACEMENT

Rotate the wiper blade release (Fig. 1) clockwise.

This will release the wiper blade from the pivot pin.

CAUTION: Take care to ensure that the wiper arm

does not strike the windshield after the wiper blade

has been removed.

To install, place the blade assembly on the wiper

arm and snap the blade assembly into position.

FRONT WIPER ARM REPLACEMENT

(1) Pull the wiper arm forward.

(2) Insert an ice pick type tool into the hole (Fig.

2).

Fig. 1 Wiper Blade Removal

Fig. 2 Wiper Arm Removal/Installation

8K - 8 WINDSHIELD WIPERSJ

Page 418 of 1784

(2) Remove the windshield holddown bolts in the

lower corners of the instrument panel.

(3) Remove wiper motor mounting screws (Fig. 4).

(4) Remove wiper motor harness retaining clip lo-

cated on bottom of windshield.

(5) Disconnect the wiper linkage drive arm (Fig. 5)

(6) Grasp the motor and pull the motor and drive

arm out of the access hole (Fig. 6).

(7) Pry the drive arm off the motor pivot. DO NOT

remove the pivot attaching nut (Fig. 7).

(8) Remove 2 screws holding intermittent wipe

module bracket to bottom of instrument panel.

(9) Reach up behind instrument panel and discon-

nect wiper motor harness.

(10) Remove wiper motor.

INSTALLATION

(1) Install wire harness through hole in top of in-

strument panel.

(2) Connect wiper motor connector behind instru-

ment panel.

(3) Install intermittent wipe module bracket to

bottom of instrument panel.

(4) Turn wipers on to allow motor to cycle to park

position.

(5) Install wiper linkage drive arm onto motor

(Fig. 8).

(6) Install motor and drive arm in the windshield

frame.

(7) Connect wiper linkage drive arm to pivot shaft

(Fig. 9).

(8) Install motor mounting screws. Tighten screws

to 10.5 Nzm (96 in. lbs.).

(9) Install wire harness retaining clip on bottom of

windshield.

Be sure wire harness is not pinched or cut when

windshield frame is rotated to upright position.

(10) Raise windshield to upright position and in-

stall left and right windshield holddown bolts.

(11) Install the necessary top components on wind-

shield frame.

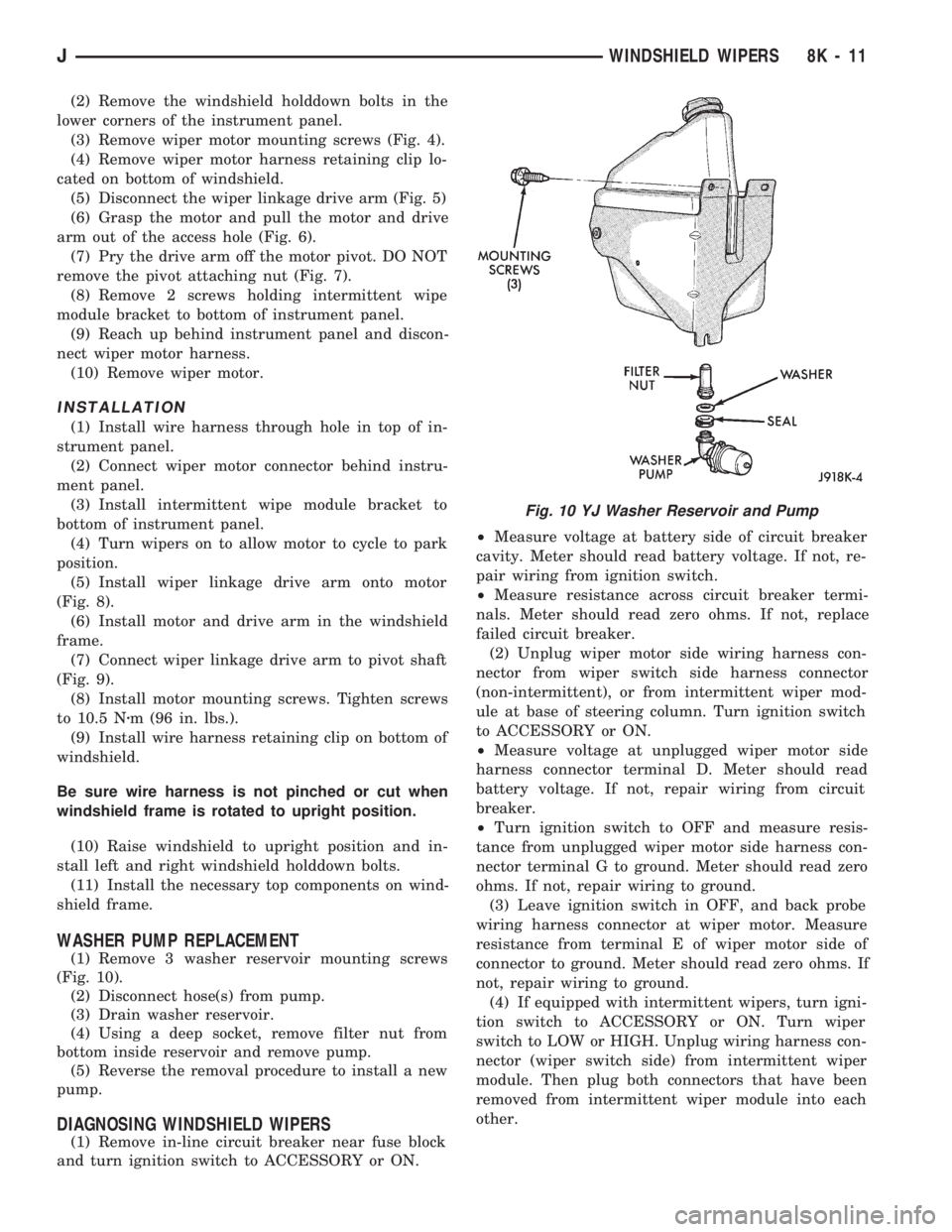

WASHER PUMP REPLACEMENT

(1) Remove 3 washer reservoir mounting screws

(Fig. 10).

(2) Disconnect hose(s) from pump.

(3) Drain washer reservoir.

(4) Using a deep socket, remove filter nut from

bottom inside reservoir and remove pump.

(5) Reverse the removal procedure to install a new

pump.

DIAGNOSING WINDSHIELD WIPERS

(1) Remove in-line circuit breaker near fuse block

and turn ignition switch to ACCESSORY or ON.²Measure voltage at battery side of circuit breaker

cavity. Meter should read battery voltage. If not, re-

pair wiring from ignition switch.

²Measure resistance across circuit breaker termi-

nals. Meter should read zero ohms. If not, replace

failed circuit breaker.

(2) Unplug wiper motor side wiring harness con-

nector from wiper switch side harness connector

(non-intermittent), or from intermittent wiper mod-

ule at base of steering column. Turn ignition switch

to ACCESSORY or ON.

²Measure voltage at unplugged wiper motor side

harness connector terminal D. Meter should read

battery voltage. If not, repair wiring from circuit

breaker.

²Turn ignition switch to OFF and measure resis-

tance from unplugged wiper motor side harness con-

nector terminal G to ground. Meter should read zero

ohms. If not, repair wiring to ground.

(3) Leave ignition switch in OFF, and back probe

wiring harness connector at wiper motor. Measure

resistance from terminal E of wiper motor side of

connector to ground. Meter should read zero ohms. If

not, repair wiring to ground.

(4) If equipped with intermittent wipers, turn igni-

tion switch to ACCESSORY or ON. Turn wiper

switch to LOW or HIGH. Unplug wiring harness con-

nector (wiper switch side) from intermittent wiper

module. Then plug both connectors that have been

removed from intermittent wiper module into each

other.

Fig. 10 YJ Washer Reservoir and Pump

JWINDSHIELD WIPERS 8K - 11

Page 419 of 1784

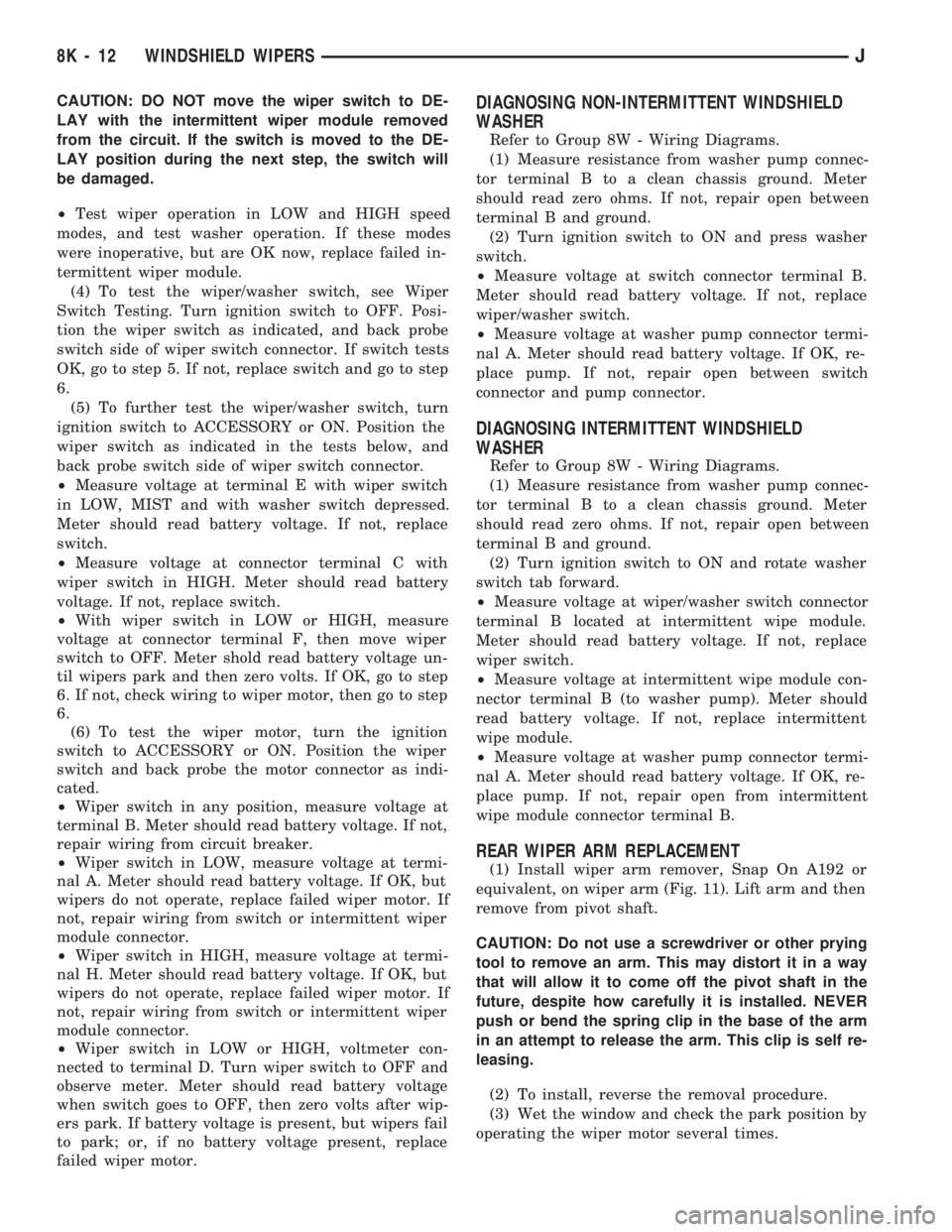

CAUTION: DO NOT move the wiper switch to DE-

LAY with the intermittent wiper module removed

from the circuit. If the switch is moved to the DE-

LAY position during the next step, the switch will

be damaged.

²Test wiper operation in LOW and HIGH speed

modes, and test washer operation. If these modes

were inoperative, but are OK now, replace failed in-

termittent wiper module.

(4) To test the wiper/washer switch, see Wiper

Switch Testing. Turn ignition switch to OFF. Posi-

tion the wiper switch as indicated, and back probe

switch side of wiper switch connector. If switch tests

OK, go to step 5. If not, replace switch and go to step

6.

(5) To further test the wiper/washer switch, turn

ignition switch to ACCESSORY or ON. Position the

wiper switch as indicated in the tests below, and

back probe switch side of wiper switch connector.

²Measure voltage at terminal E with wiper switch

in LOW, MIST and with washer switch depressed.

Meter should read battery voltage. If not, replace

switch.

²Measure voltage at connector terminal C with

wiper switch in HIGH. Meter should read battery

voltage. If not, replace switch.

²With wiper switch in LOW or HIGH, measure

voltage at connector terminal F, then move wiper

switch to OFF. Meter shold read battery voltage un-

til wipers park and then zero volts. If OK, go to step

6. If not, check wiring to wiper motor, then go to step

6.

(6) To test the wiper motor, turn the ignition

switch to ACCESSORY or ON. Position the wiper

switch and back probe the motor connector as indi-

cated.

²Wiper switch in any position, measure voltage at

terminal B. Meter should read battery voltage. If not,

repair wiring from circuit breaker.

²Wiper switch in LOW, measure voltage at termi-

nal A. Meter should read battery voltage. If OK, but

wipers do not operate, replace failed wiper motor. If

not, repair wiring from switch or intermittent wiper

module connector.

²Wiper switch in HIGH, measure voltage at termi-

nal H. Meter should read battery voltage. If OK, but

wipers do not operate, replace failed wiper motor. If

not, repair wiring from switch or intermittent wiper

module connector.

²Wiper switch in LOW or HIGH, voltmeter con-

nected to terminal D. Turn wiper switch to OFF and

observe meter. Meter should read battery voltage

when switch goes to OFF, then zero volts after wip-

ers park. If battery voltage is present, but wipers fail

to park; or, if no battery voltage present, replace

failed wiper motor.DIAGNOSING NON-INTERMITTENT WINDSHIELD

WASHER

Refer to Group 8W - Wiring Diagrams.

(1) Measure resistance from washer pump connec-

tor terminal B to a clean chassis ground. Meter

should read zero ohms. If not, repair open between

terminal B and ground.

(2) Turn ignition switch to ON and press washer

switch.

²Measure voltage at switch connector terminal B.

Meter should read battery voltage. If not, replace

wiper/washer switch.

²Measure voltage at washer pump connector termi-

nal A. Meter should read battery voltage. If OK, re-

place pump. If not, repair open between switch

connector and pump connector.

DIAGNOSING INTERMITTENT WINDSHIELD

WASHER

Refer to Group 8W - Wiring Diagrams.

(1) Measure resistance from washer pump connec-

tor terminal B to a clean chassis ground. Meter

should read zero ohms. If not, repair open between

terminal B and ground.

(2) Turn ignition switch to ON and rotate washer

switch tab forward.

²Measure voltage at wiper/washer switch connector

terminal B located at intermittent wipe module.

Meter should read battery voltage. If not, replace

wiper switch.

²Measure voltage at intermittent wipe module con-

nector terminal B (to washer pump). Meter should

read battery voltage. If not, replace intermittent

wipe module.

²Measure voltage at washer pump connector termi-

nal A. Meter should read battery voltage. If OK, re-

place pump. If not, repair open from intermittent

wipe module connector terminal B.

REAR WIPER ARM REPLACEMENT

(1) Install wiper arm remover, Snap On A192 or

equivalent, on wiper arm (Fig. 11). Lift arm and then

remove from pivot shaft.

CAUTION: Do not use a screwdriver or other prying

tool to remove an arm. This may distort it in a way

that will allow it to come off the pivot shaft in the

future, despite how carefully it is installed. NEVER

push or bend the spring clip in the base of the arm

in an attempt to release the arm. This clip is self re-

leasing.

(2) To install, reverse the removal procedure.

(3) Wet the window and check the park position by

operating the wiper motor several times.

8K - 12 WINDSHIELD WIPERSJ