display JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 150 of 1784

ABS BRAKE DIAGNOSIS

INDEX

page page

ABS Fault Diagnosis....................... 4

ABS System Wiring and Electrical Circuits...... 4

ABS Warning Light Display.................. 3

Brake Warning Light Display................. 4

Diagnosis Procedures...................... 3

ECU Diagnosis........................... 4

HCU Diagnosis........................... 4Loss of Sensor Input....................... 3

Operating Sound Levels.................... 3

Rear Speed Sensor Air Gap................. 3

Steering Response........................ 3

Vehicle Response in Antilock Mode............ 3

Wheel/Tire Size and Input Signals............. 3

DIAGNOSIS PROCEDURES

ABS diagnosis involves three basic steps. First is

observation of the warning light display. Second is a

visual examination for low fluid level, leaks, parking

brakes applied, or obvious damage to system compo-

nents or wires. The third step involves using the

DRB II scan tool to identify a faulty component.

The visual examination requires a check of reser-

voir fluid level and all system components. Things to

look for are leaks, loose connections, or obvious com-

ponent damage.

The final diagnosis step involves using the DRB II

scan tool to determine the specific circuit or compo-

nent at fault. The tester is connected to the ABS di-

agnostic connector in the passenger compartment.

The connector is at the driver side of the center con-

sole under the instrument panel. Refer to the DRB II

scan tool Manual for tester procedures. Also refer to

the ABS Fault Diagnosis charts at the end of this

section for additional diagnosis information.

Initial faults should be cleared and the vehicle road

tested to reset any faults that remain in the system.

Faults can be cleared with the DRB II scan tool.

REAR SPEED SENSOR AIR GAP

The front wheel sensors are fixed and cannot be ad-

justed. Only the rear sensor air gap is adjustable. Air

gap must be set with a brass feeler gauge.

Correct air gap is important to proper signal gen-

eration. An air gap that is too large may cause com-

plete loss of sensor input. Or, a gap that is too small

could produce a false input signal, or damaging con-

tact between the sensor and tone ring.

WHEEL/TIRE SIZE AND INPUT SIGNALS

Antilock system operation is dependant on accurate

signals from the wheel speed sensors. Ideally, the ve-

hicle wheels and tires should all be the same size

and type. However, the Jeep ABS system is designed

to function with a compact spare tire installed.

OPERATING SOUND LEVELS

The ABS pump and solenoid valves may produce

some sound as they cycle on and off. This is a normal

condition and should not be mistaken for faulty oper-

ation.

VEHICLE RESPONSE IN ANTILOCK MODE

During antilock braking, the HCU solenoid valves

cycle rapidly in response to ECU inputs.

The driver will experience a pulsing sensation

within the vehicle as the solenoids decrease, hold, or

increase pressure as needed. A pulsing brake pedal

will also be noted.

The pulsing sensation occurs as the solenoids cycle

during antilock mode braking. A slight pulse in the

brake pedal may also be noted during the dynamic

self check part of system initialization.

STEERING RESPONSE

A modest amount of steering input is required dur-

ing extremely high deceleration braking, or when

braking on differing traction surfaces. An example of

differing traction surfaces would be when the left

side wheels are on ice and the right side wheels are

on dry pavement.

LOSS OF SENSOR INPUT

Sensor malfunctions will most likely be due to

loose connections, damaged sensor wires, incorrect

rear sensor air gap, or a malfunctioning sensor. Ad-

ditional causes of sensor faults would be sensor and

tone ring misalignment or damage.

ABS WARNING LIGHT DISPLAY

ABS Light Illuminates At Startup

The amber ABS light illuminates at startup as

part of the system self check feature. The light illu-

minates for 2-3 seconds then goes off as part of the

normal self check routine.

ABS Light Remains On After Startup

An ABS system fault is indicated when the light

remains on after startup. Diagnosis with the DRB II

JBRAKES 5 - 3

Page 151 of 1784

scan tool will be necessary to determine which ABS

component has malfunctioned.

ABS Light Illuminates During Brake Stop

A system fault such as loss of speed sensor signal

or solenoid failure, will cause the amber warning

light to illuminate. The most effective procedure here

is to check for obvious damage first. Then check the

electronic components with the DRB II scan tool.

BRAKE WARNING LIGHT DISPLAY

The red brake warning light and the ABS light op-

erate independently. If the red light remains on after

startup or illuminates during a brake stop, refer to

the standard brake system diagnosis section. Either

the parking brakes are applied, or a wheel brake

malfunction has occurred.

ECU DIAGNOSIS

The ECU controls all phases of antilock system op-

eration. It also differentiates between normal and an-

tilock mode braking.

The ECU monitors and processes the signals gen-

erated from all of the system sensors at all times.

The ECU program includes a self check routine

that tests each of the system components. The self

check occurs during both phases of the initialization

program. A failure of the self check program will

cause the immediate illumination of the amber warn-

ing light. The light will also illuminate if a solenoid

or other system component fails during the dynamic

phase of initialization.

If a system malfunction should occur, do not imme-

diately replace the ECU. A blown system fuse, bad

chassis ground, or loss of feed voltage will each cause

a system malfunction similar to an ECU failure.

Never replace the ECU unless diagnosis with the

DRB II scan tool indicates this is necessary.

HCU DIAGNOSIS

The HCU pump and motor and solenoid valve body

are serviced only as an assembly. The HCU assembly

should not be replaced unless a fault has actually

been confirmed. Verify fault conditions with the DRB

II scan tool before proceeding with repair.

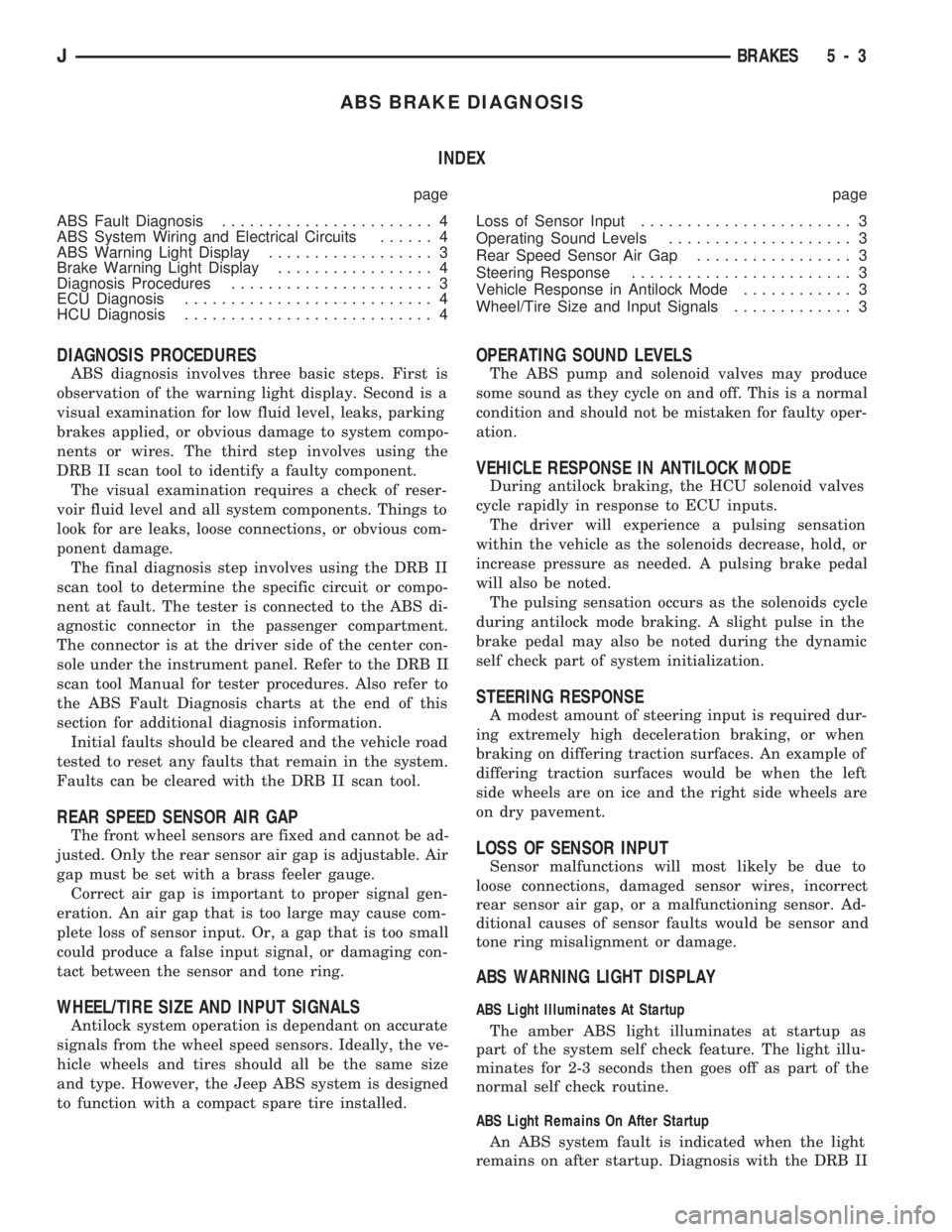

ABS SYSTEM WIRING AND ELECTRICAL CIRCUITS

Location of the ABS fuse (in the fuse panel) is

shown in Figure 1. The engine compartment harness

routing for the ABS components is shown in Figure 2.

ABS FAULT DIAGNOSIS

The fault diagnosis chart provides additional infor-

mation on potential ABS system faults. Use the

chart as a guide when diagnosing a system problem.

Fig. 1 ABS Fuse Location

5 - 4 BRAKESJ

Page 237 of 1784

DIAGNOSIS

INDEX

page page

DRB Scan Tool........................... 5

On-Board Diagnostics (OBD)................. 4Preliminary Checks........................ 5

ON-BOARD DIAGNOSTICS (OBD)

FOR COOLING SYSTEM COMPONENTS

The powertrain control module (PCM) has been

programmed to monitor the certain following cooling

system components:

²If the engine has remained cool for too long a pe-

riod, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) number 17 can be

observed at the Check Engine Lamp.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) number 35 can be

observed at the Check Engine Lamp.

If the problem is sensed in a monitored circuit of-

ten enough to indicate an actual problem, a DTC is

stored. The DTC will be stored in the PCM memory

for eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a DTC to be en-

tered into PCM memory. The criteria may be a spe-

cific range of engine rpm, engine temperature and/or

input voltage to the PCM.

A DTC indicates that the PCM has recognized an

abnormal signal in a circuit or the system. A DTC

may indicate the result of a failure, but never iden-

tify the failed component directly.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. Refer to On-Board Diagnostics

(OBD) in Group 14, Fuel Systems for additional in-

formation.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

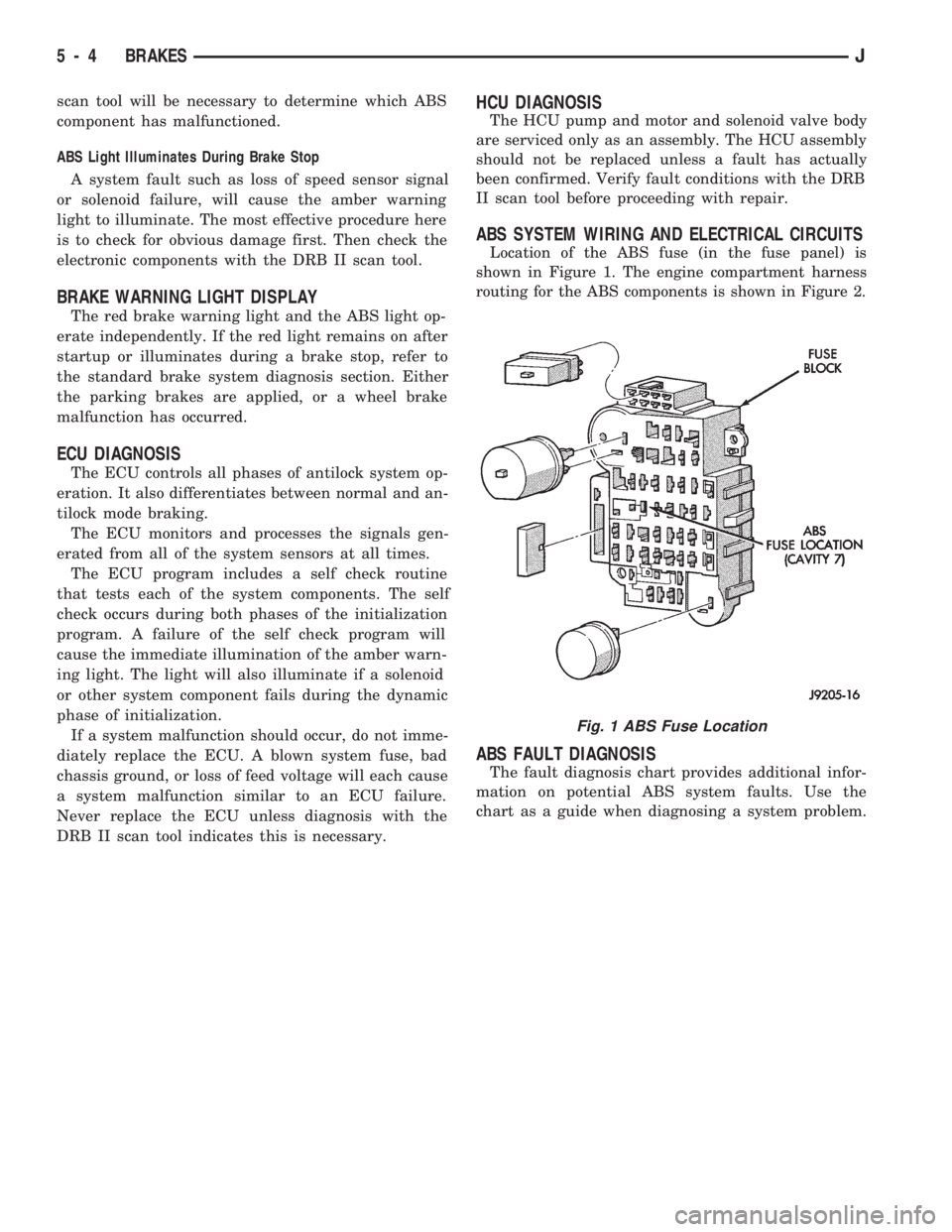

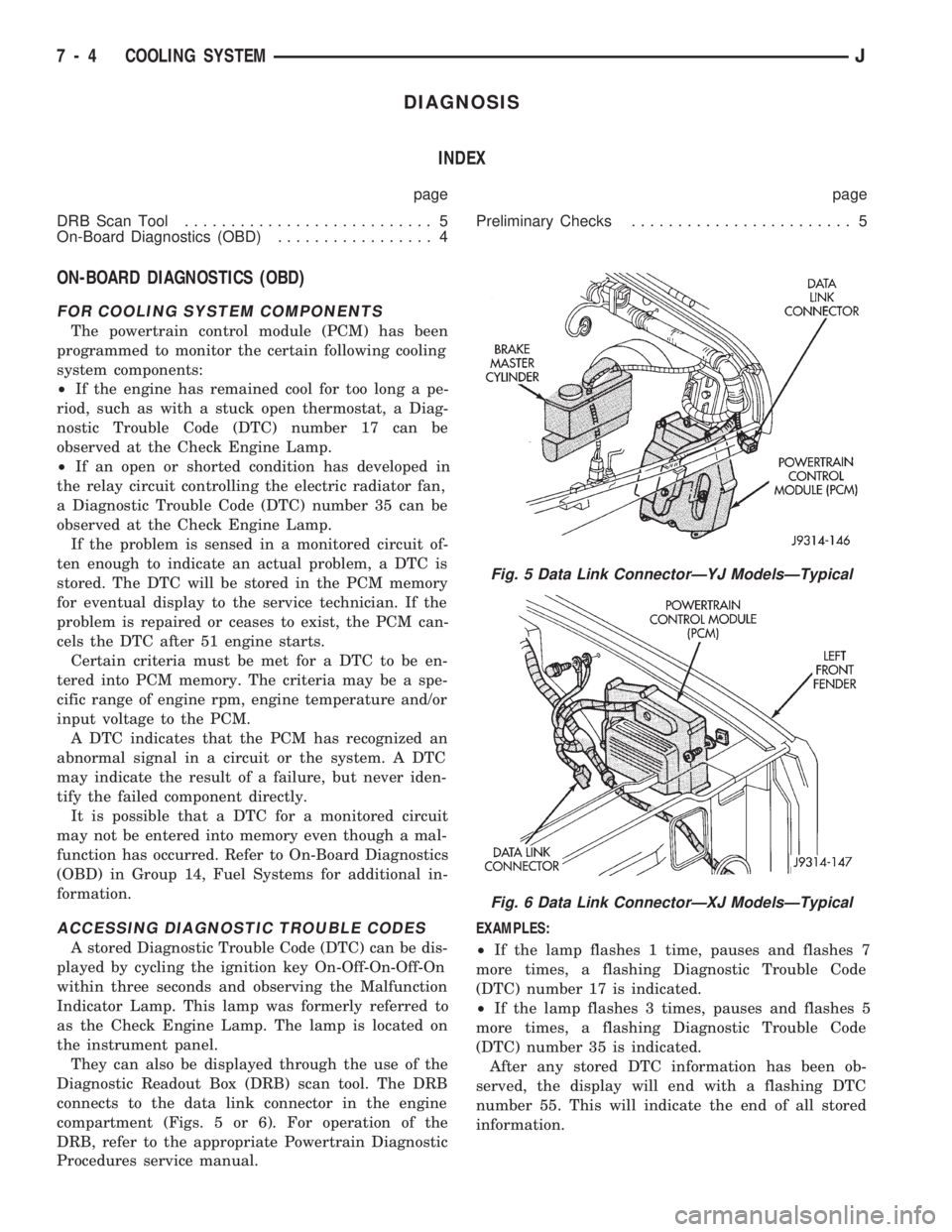

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

connects to the data link connector in the engine

compartment (Figs. 5 or 6). For operation of the

DRB, refer to the appropriate Powertrain Diagnostic

Procedures service manual.EXAMPLES:

²If the lamp flashes 1 time, pauses and flashes 7

more times, a flashing Diagnostic Trouble Code

(DTC) number 17 is indicated.

²If the lamp flashes 3 times, pauses and flashes 5

more times, a flashing Diagnostic Trouble Code

(DTC) number 35 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

Fig. 5 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 6 Data Link ConnectorÐXJ ModelsÐTypical

7 - 4 COOLING SYSTEMJ

Page 292 of 1784

USING ON-BOARD DIAGNOSTIC SYSTEM

OPERATION OF ON-BOARD DIAGNOSTIC

(OBD) SYSTEM

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem making sure they are OK. Some are checked

continuously and some are checked only under cer-

tain conditions.

If OBD system senses that one critical circuit is

bad during the monitoring cycle, it will put a diag-

nostic trouble code into memory. Each input and out-

put circuit monitored by the OBD system has its own

diagnostic trouble code. The diagnostic trouble code

(DTC) will stay in memory as long as the circuit con-

tinues to be bad. If the problem does not happen

again after the fault code is put into memory, the

PCM is programmed to clear the memory after 50 en-

gine starts.

DIAGNOSTIC TROUBLE CODES (DTC)

Diagnostic trouble codes are two-digit numbers

flashed on Malfunction Indicator (Check Engine)

Lamp that identify which circuit is bad. In most

cases they do not identify which component in a cir-

cuit is bad. A trouble code description can be read us-

ing the DRB scan tool. Refer to Group 14 - Fuel

Systems for more information. Therefore, a DTC is

only a symptom, not necessarily the cause for the

problem. In some cases, because of the design of the

driveability test procedure, a DTC can be the reason

for the problem. It is important that the test proce-

dure be followed to understand what caused the DTC

of the on-board diagnostic system to be set.

HOW TO USE MALFUNCTION INDICATOR (CHECK

ENGINE) LAMP FOR DIAGNOSTIC TROUBLE

CODES

To start this function, cycle the ignition switch ON-

OFF-ON-OFF-ON within 5 seconds and any trouble

code stored in the PCM will be displayed. The Mal-

function Indicator (Check Engine) Lamp will display

a DTC by flashing on and off. There is a short pause

between flashes and a longer pause between digits.

All codes displayed are two digit numbers with a 4

second pause between codes.

An example of a code is as follows:

(1) Lamp on for 2 seconds, then turns off.

(2) Lamp flashes 4 times pauses and then flashes 1

time.

(3) Lamp pauses for 4 seconds, flashes 4 times,

pauses and then flashes 7 times.

The 2 codes are 41 and 47. Any number of codes

can be displayed as long as they are in memory. The

lamp will flash until all are displayed (55 = End of

test).

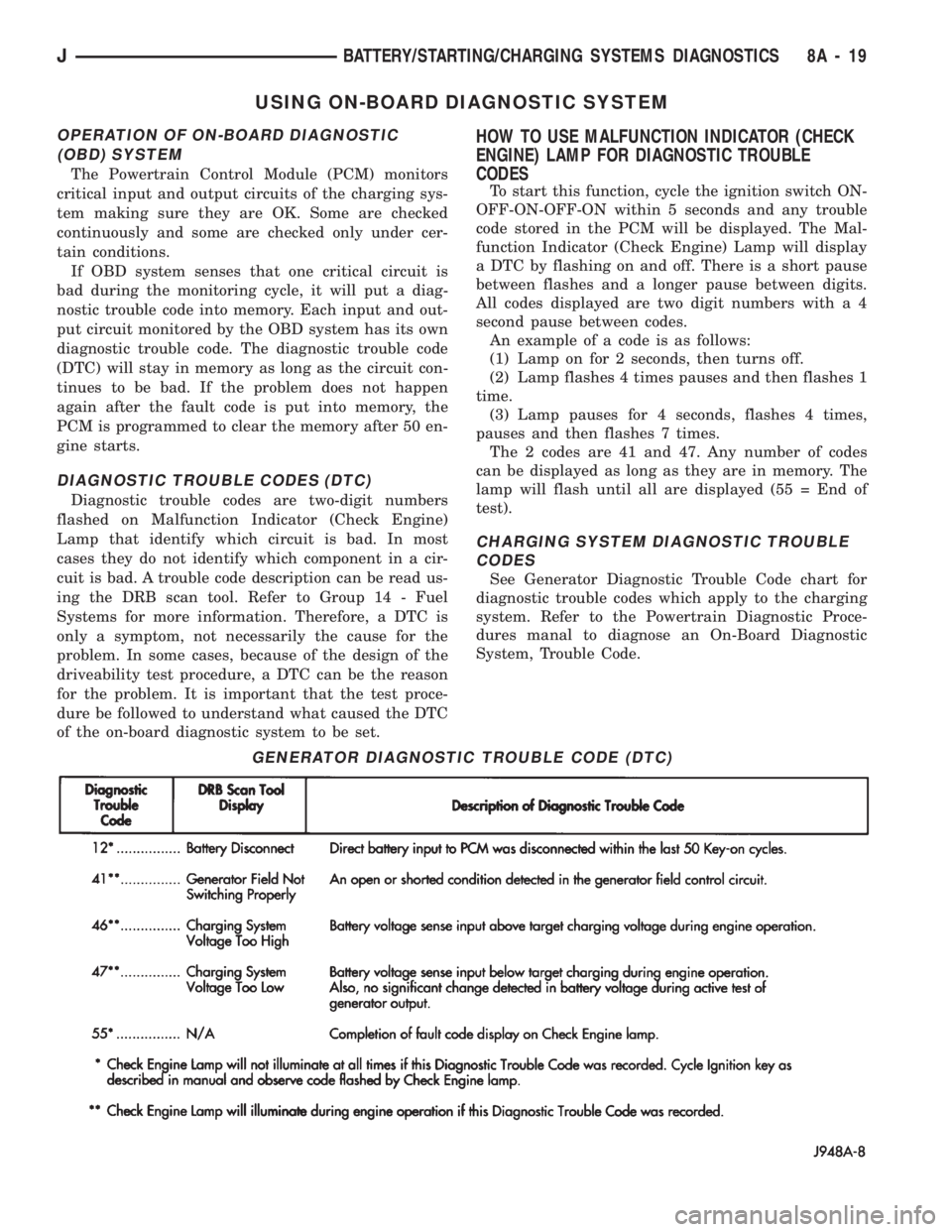

CHARGING SYSTEM DIAGNOSTIC TROUBLE

CODES

See Generator Diagnostic Trouble Code chart for

diagnostic trouble codes which apply to the charging

system. Refer to the Powertrain Diagnostic Proce-

dures manal to diagnose an On-Board Diagnostic

System, Trouble Code.

GENERATOR DIAGNOSTIC TROUBLE CODE (DTC)

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 19

Page 306 of 1784

OVERHEAD CONSOLE

CONTENTS

page page

COMPASS REPAIR PROCEDURES.......... 4

CONSOLE REPAIR PROCEDURES........... 6

DESCRIPTION........................... 1DIAGNOSTIC PROCEDURES............... 1

THERMOMETER AND SENSOR SYSTEM REPAIR

PROCEDURES......................... 6

DESCRIPTION

The overhead console includes:

²a compass/temperature display

²reading and courtesy lights for the front and rear

seats

²the receiver for the keyless entry system

²storage compartment for remote garage door

opener

²storage compartment for sunglasses.

COMPASS

The compass will display the direction the vehicle

is pointed, using the eight major compass headings

(Examples: North is ``N'', Northeast is ``NE''). It does

not display the headings in actual degrees. The dis-

play is turned on/off using the TEMP/COMP button

on the left of the display.

The compass is a self calibrating unit that should

not require recalibration. The only calibration that

may prove necessary is to drive the vehicle in 3 com-

plete circles, on level ground, in not less than 48 sec-

onds. This will ``reorient'' the unit to its vehicle. The

unit also will compensate for magnetism the vehicle

may acquire during its life. Care should be used to

avoid putting anything magnetic on the roof of the

vehicle.

The unit can compensate for some magnetic fields

in the body. The use of magnetic attachments like

antenna mounts or repair order ``hats'' placed di-

rectly on the roof can exceed the compensation abil-

ity of the unit. Magnetic bit drivers used on the

fasteners to hold the assembly to the roof header can

also affect operation. If the vehicle roof should be-

come magnetized, then the degaussing and calibra-

tion procedures may be required to restore proper

operation.

If the compass functions but accuracy is suspect, it

may be necessary to perform a variation adjustment.

This procedure allows the unit to accommodate vari-

ations in the earth's magnetic field strength based on

geographic location.

If the compass has blanked out and only CAL

appears, degaussing may be necessary to re-

move residual magnetic fields.

THERMOMETER

The ambient temperature display can be changed

from Fahrenheit to Celsius using the U.S./METRIC

button on the right of the display. The temperature

reported is not an instant reading of conditions but

an average temperature. It may take the unit several

minutes to react to a major change such as driving

out of a heated garage into winter temperatures.

When the ignition switch is turned OFF, the last

displayed temperature reading stays in memory.

When the ignition switch is turned ON again the

thermometer will display the memory temperature

for one minute; then update the display to the actual

temperature within five minutes.

READING AND COURTESY LAMPS

All reading and courtesy lamps in the overhead

console are activated by the door courtesy circuit.

When all four doors and the liftgate are closed the

lamps can be activated by depressing the correspond-

ing lens. When any door or the liftgate is open, the

switches are disabled. They will not turn the lamps

off.

MAP AND COURTESY LAMPS

These lamps offer several unique features. Both the

map and courtesy lamps can be turned on with the

integral ``Soft Touch'' switch. Pushing this switch en-

ergizes an electrical circuit, which in turn directs

power to the light. The map lamps are unaffected by

the door switches, while the courtesy lamps are

turned on with the opening of any door. When any

door is open, the ``Soft Touch'' switches are disabled,

you cannot turn the lights off with these switches.

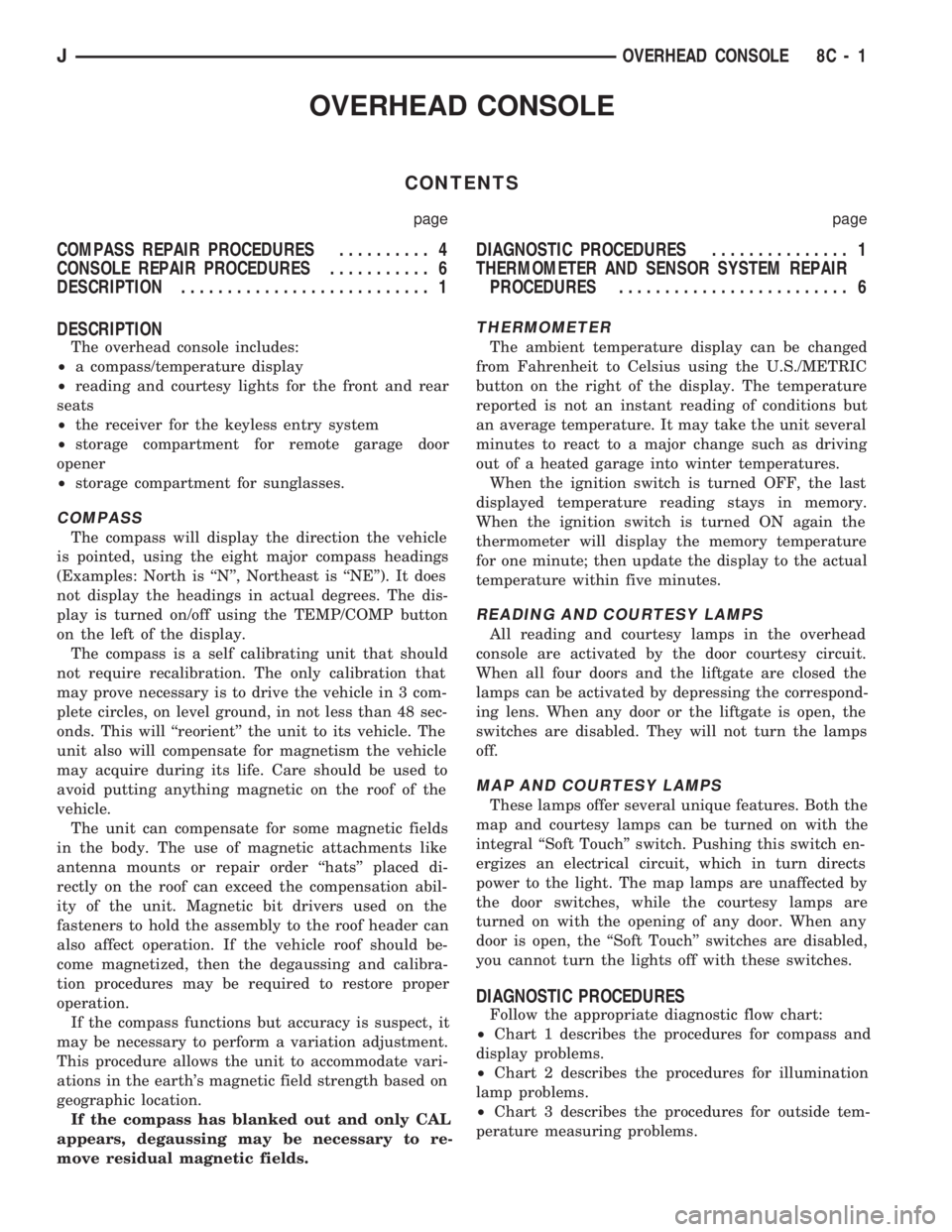

DIAGNOSTIC PROCEDURES

Follow the appropriate diagnostic flow chart:

²Chart 1 describes the procedures for compass and

display problems.

²Chart 2 describes the procedures for illumination

lamp problems.

²Chart 3 describes the procedures for outside tem-

perature measuring problems.

JOVERHEAD CONSOLE 8C - 1

Page 309 of 1784

COMPASS REPAIR PROCEDURES

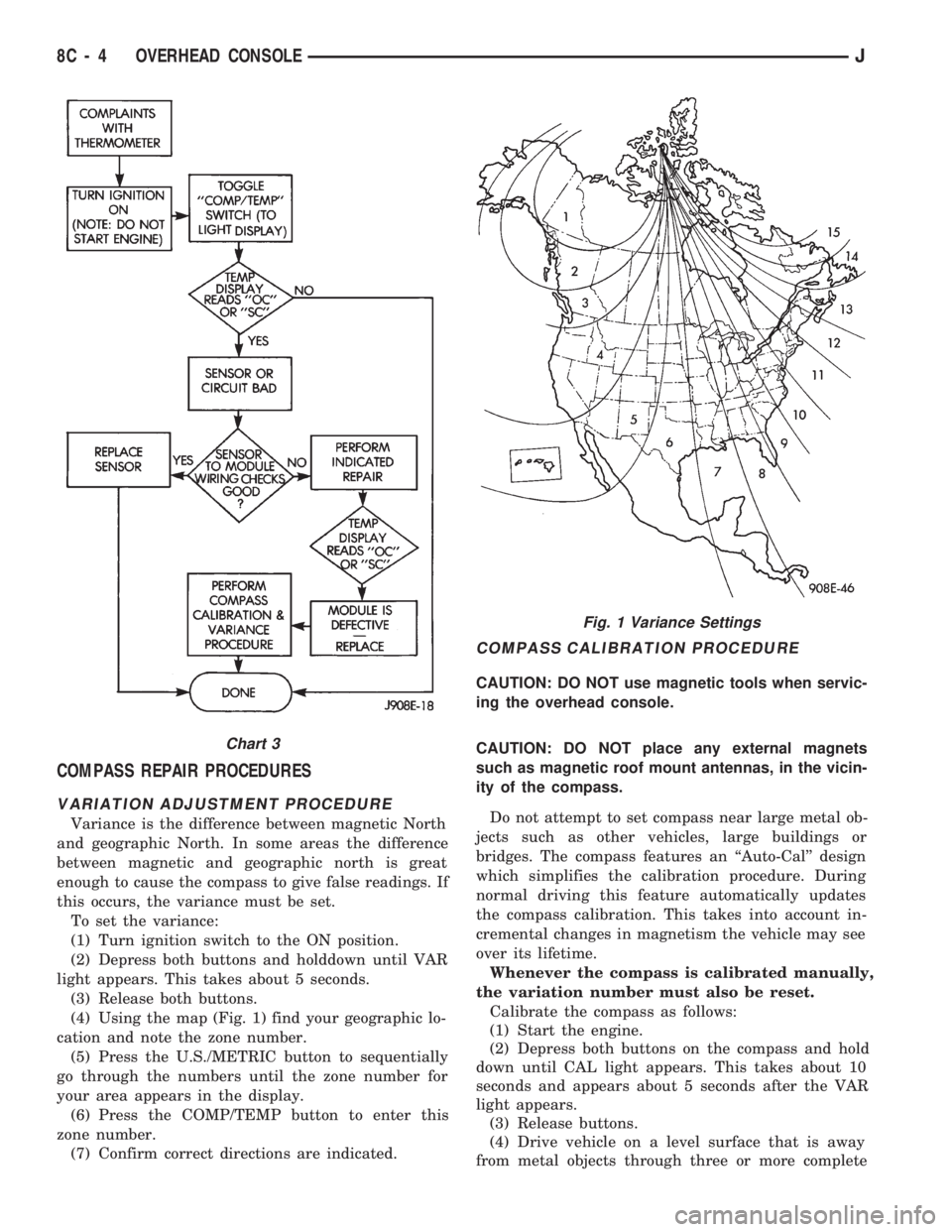

VARIATION ADJUSTMENT PROCEDURE

Variance is the difference between magnetic North

and geographic North. In some areas the difference

between magnetic and geographic north is great

enough to cause the compass to give false readings. If

this occurs, the variance must be set.

To set the variance:

(1) Turn ignition switch to the ON position.

(2) Depress both buttons and holddown until VAR

light appears. This takes about 5 seconds.

(3) Release both buttons.

(4) Using the map (Fig. 1) find your geographic lo-

cation and note the zone number.

(5) Press the U.S./METRIC button to sequentially

go through the numbers until the zone number for

your area appears in the display.

(6) Press the COMP/TEMP button to enter this

zone number.

(7) Confirm correct directions are indicated.

COMPASS CALIBRATION PROCEDURE

CAUTION: DO NOT use magnetic tools when servic-

ing the overhead console.

CAUTION: DO NOT place any external magnets

such as magnetic roof mount antennas, in the vicin-

ity of the compass.

Do not attempt to set compass near large metal ob-

jects such as other vehicles, large buildings or

bridges. The compass features an ``Auto-Cal'' design

which simplifies the calibration procedure. During

normal driving this feature automatically updates

the compass calibration. This takes into account in-

cremental changes in magnetism the vehicle may see

over its lifetime.

Whenever the compass is calibrated manually,

the variation number must also be reset.

Calibrate the compass as follows:

(1) Start the engine.

(2) Depress both buttons on the compass and hold

down until CAL light appears. This takes about 10

seconds and appears about 5 seconds after the VAR

light appears.

(3) Release buttons.

(4) Drive vehicle on a level surface that is away

from metal objects through three or more complete

Fig. 1 Variance Settings

Chart 3

8C - 4 OVERHEAD CONSOLEJ

Page 310 of 1784

circles, in not less than 48 seconds. The CAL light

will go off and the compass is now calibrated.

(5) Reset variation number. This step must be

done every time step 2 is performed.

If CAL light does not go off, either there is ex-

cessive magnetism near the compass or the unit

is defective. Repeat the degaussing and calibra-

tion procedures at least one more time.

If the wrong direction is still indicated, the

area selected may be too close to a magnetic

source. Repeat the calibration procedure in an-

other location.

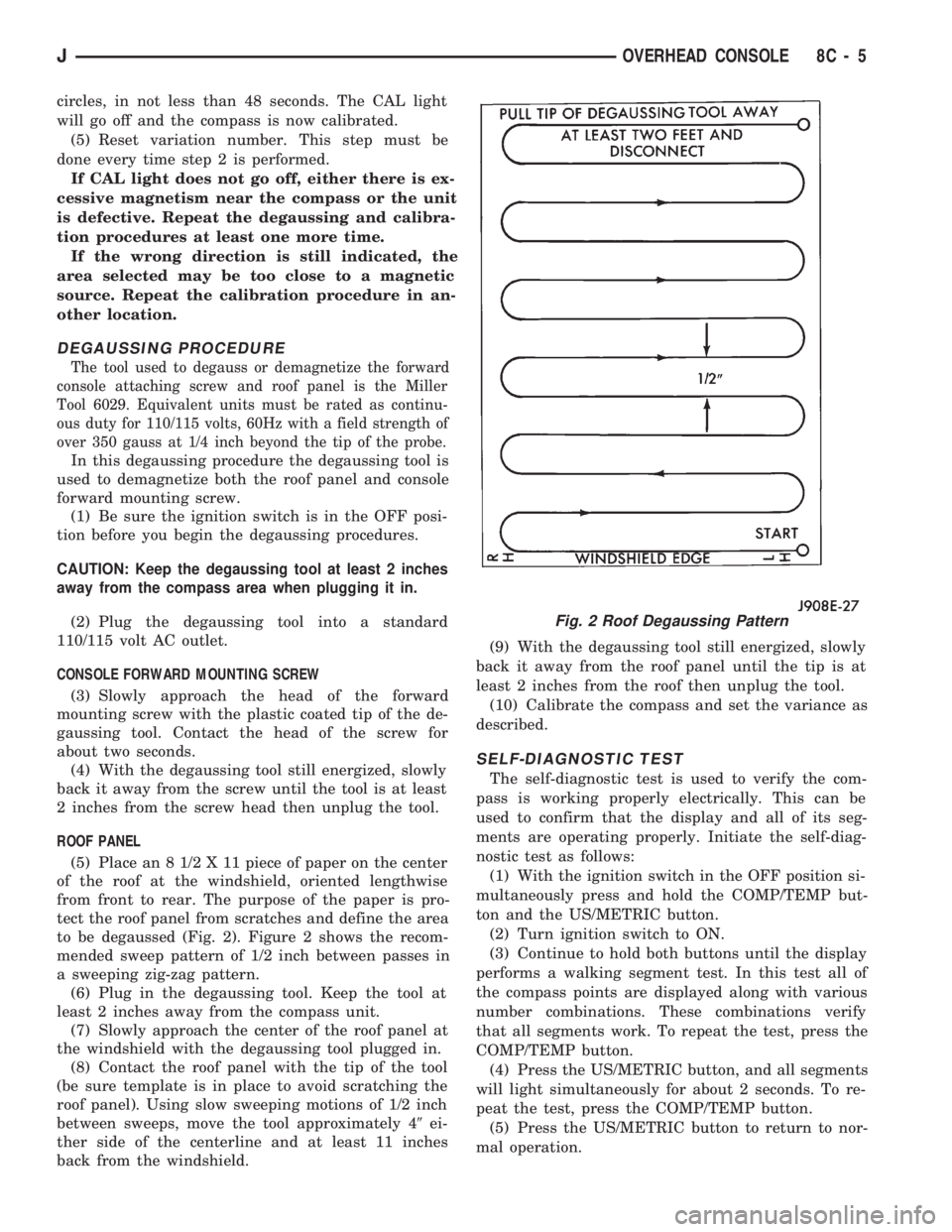

DEGAUSSING PROCEDURE

The tool used to degauss or demagnetize the forward

console attaching screw and roof panel is the Miller

Tool 6029. Equivalent units must be rated as continu-

ous duty for 110/115 volts, 60Hz with a field strength of

over 350 gauss at 1/4 inch beyond the tip of the probe.

In this degaussing procedure the degaussing tool is

used to demagnetize both the roof panel and console

forward mounting screw.

(1) Be sure the ignition switch is in the OFF posi-

tion before you begin the degaussing procedures.

CAUTION: Keep the degaussing tool at least 2 inches

away from the compass area when plugging it in.

(2) Plug the degaussing tool into a standard

110/115 volt AC outlet.

CONSOLE FORWARD MOUNTING SCREW

(3) Slowly approach the head of the forward

mounting screw with the plastic coated tip of the de-

gaussing tool. Contact the head of the screw for

about two seconds.

(4) With the degaussing tool still energized, slowly

back it away from the screw until the tool is at least

2 inches from the screw head then unplug the tool.

ROOF PANEL

(5) Place an 8 1/2 X 11 piece of paper on the center

of the roof at the windshield, oriented lengthwise

from front to rear. The purpose of the paper is pro-

tect the roof panel from scratches and define the area

to be degaussed (Fig. 2). Figure 2 shows the recom-

mended sweep pattern of 1/2 inch between passes in

a sweeping zig-zag pattern.

(6) Plug in the degaussing tool. Keep the tool at

least 2 inches away from the compass unit.

(7) Slowly approach the center of the roof panel at

the windshield with the degaussing tool plugged in.

(8) Contact the roof panel with the tip of the tool

(be sure template is in place to avoid scratching the

roof panel). Using slow sweeping motions of 1/2 inch

between sweeps, move the tool approximately 49ei-

ther side of the centerline and at least 11 inches

back from the windshield.(9) With the degaussing tool still energized, slowly

back it away from the roof panel until the tip is at

least 2 inches from the roof then unplug the tool.

(10) Calibrate the compass and set the variance as

described.

SELF-DIAGNOSTIC TEST

The self-diagnostic test is used to verify the com-

pass is working properly electrically. This can be

used to confirm that the display and all of its seg-

ments are operating properly. Initiate the self-diag-

nostic test as follows:

(1) With the ignition switch in the OFF position si-

multaneously press and hold the COMP/TEMP but-

ton and the US/METRIC button.

(2) Turn ignition switch to ON.

(3) Continue to hold both buttons until the display

performs a walking segment test. In this test all of

the compass points are displayed along with various

number combinations. These combinations verify

that all segments work. To repeat the test, press the

COMP/TEMP button.

(4) Press the US/METRIC button, and all segments

will light simultaneously for about 2 seconds. To re-

peat the test, press the COMP/TEMP button.

(5) Press the US/METRIC button to return to nor-

mal operation.

Fig. 2 Roof Degaussing Pattern

JOVERHEAD CONSOLE 8C - 5

Page 311 of 1784

(6) Should any segment in any of the digit positions

fail to light, the unit is defective and should be re-

placed.

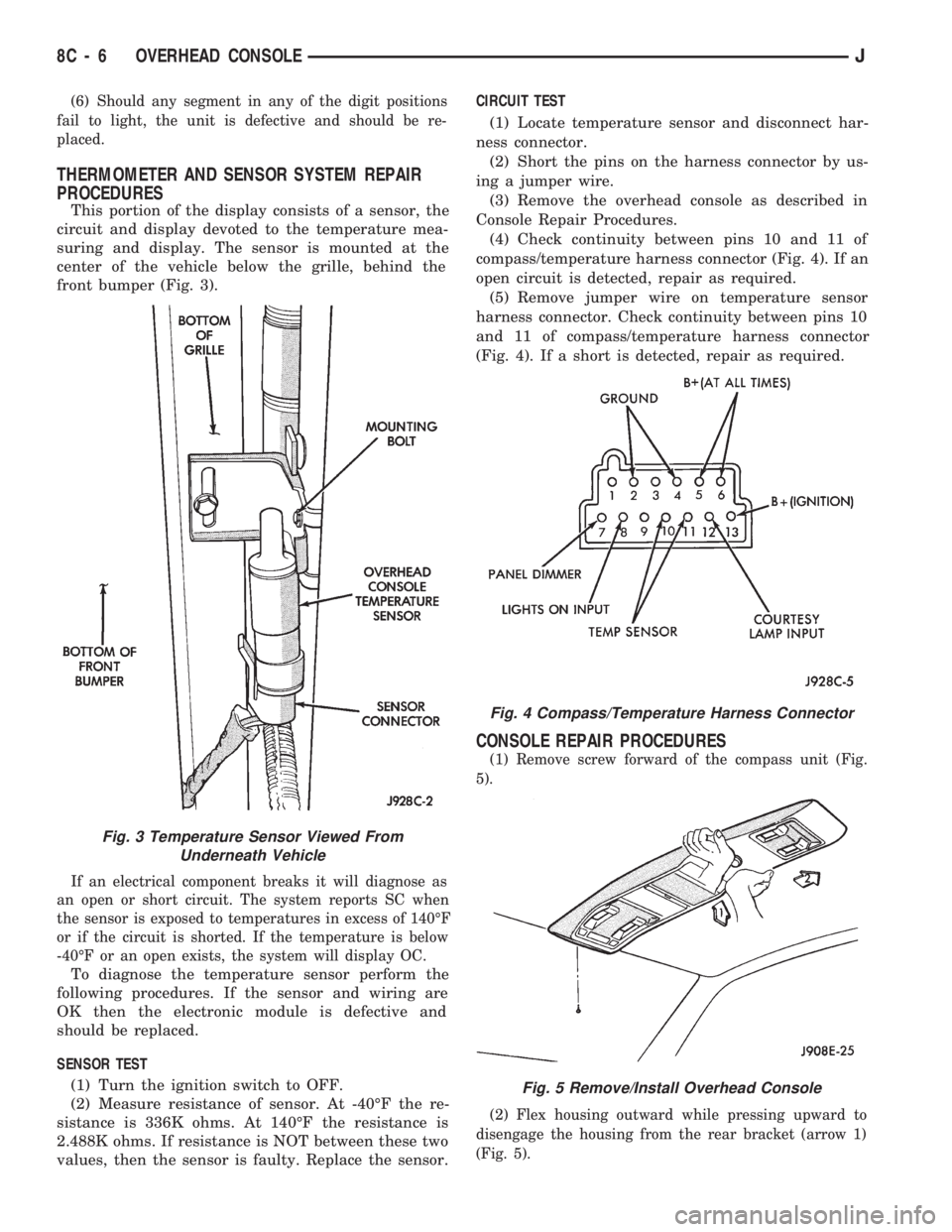

THERMOMETER AND SENSOR SYSTEM REPAIR

PROCEDURES

This portion of the display consists of a sensor, the

circuit and display devoted to the temperature mea-

suring and display. The sensor is mounted at the

center of the vehicle below the grille, behind the

front bumper (Fig. 3).

If an electrical component breaks it will diagnose as

an open or short circuit. The system reports SC when

the sensor is exposed to temperatures in excess of 140ÉF

or if the circuit is shorted. If the temperature is below

-40ÉF or an open exists, the system will display OC.

To diagnose the temperature sensor perform the

following procedures. If the sensor and wiring are

OK then the electronic module is defective and

should be replaced.

SENSOR TEST

(1) Turn the ignition switch to OFF.

(2) Measure resistance of sensor. At -40ÉF the re-

sistance is 336K ohms. At 140ÉF the resistance is

2.488K ohms. If resistance is NOT between these two

values, then the sensor is faulty. Replace the sensor.CIRCUIT TEST

(1) Locate temperature sensor and disconnect har-

ness connector.

(2) Short the pins on the harness connector by us-

ing a jumper wire.

(3) Remove the overhead console as described in

Console Repair Procedures.

(4) Check continuity between pins 10 and 11 of

compass/temperature harness connector (Fig. 4). If an

open circuit is detected, repair as required.

(5) Remove jumper wire on temperature sensor

harness connector. Check continuity between pins 10

and 11 of compass/temperature harness connector

(Fig. 4). If a short is detected, repair as required.

CONSOLE REPAIR PROCEDURES

(1) Remove screw forward of the compass unit (Fig.

5).

(2) Flex housing outward while pressing upward to

disengage the housing from the rear bracket (arrow 1)

(Fig. 5).

Fig. 4 Compass/Temperature Harness Connector

Fig. 5 Remove/Install Overhead Console

Fig. 3 Temperature Sensor Viewed From

Underneath Vehicle

8C - 6 OVERHEAD CONSOLEJ

Page 323 of 1784

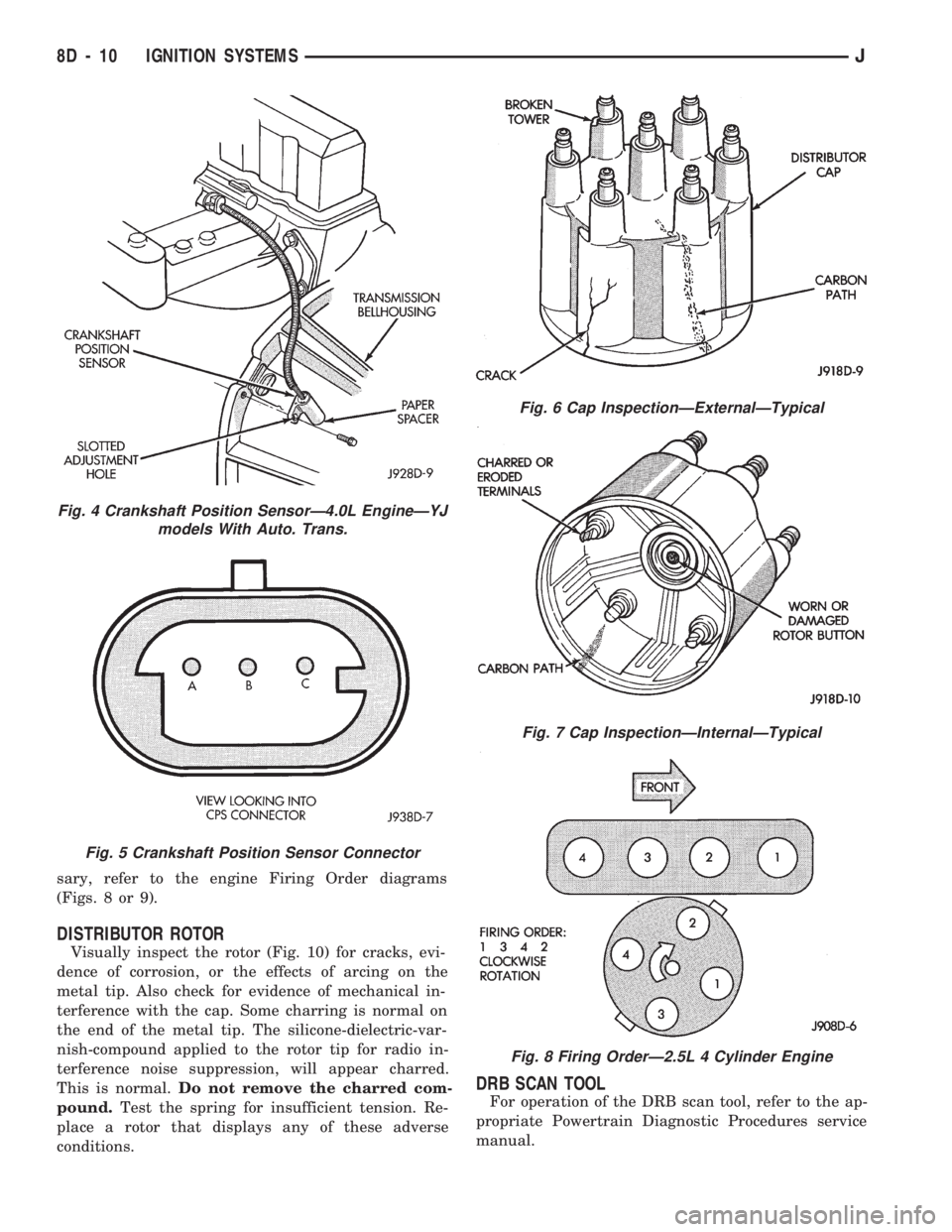

sary, refer to the engine Firing Order diagrams

(Figs. 8 or 9).

DISTRIBUTOR ROTOR

Visually inspect the rotor (Fig. 10) for cracks, evi-

dence of corrosion, or the effects of arcing on the

metal tip. Also check for evidence of mechanical in-

terference with the cap. Some charring is normal on

the end of the metal tip. The silicone-dielectric-var-

nish-compound applied to the rotor tip for radio in-

terference noise suppression, will appear charred.

This is normal.Do not remove the charred com-

pound.Test the spring for insufficient tension. Re-

place a rotor that displays any of these adverse

conditions.

DRB SCAN TOOL

For operation of the DRB scan tool, refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual.

Fig. 4 Crankshaft Position SensorÐ4.0L EngineÐYJ

models With Auto. Trans.

Fig. 5 Crankshaft Position Sensor Connector

Fig. 6 Cap InspectionÐExternalÐTypical

Fig. 7 Cap InspectionÐInternalÐTypical

Fig. 8 Firing OrderÐ2.5L 4 Cylinder Engine

8D - 10 IGNITION SYSTEMSJ

Page 329 of 1784

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB scan tool.

SPARK PLUGS

For spark plug removal, cleaning, gap adjustment

and installation, refer to the Component Removal/In-

stallation section of this group.

Faulty carbon and/or gas fouled plugs generally

cause hard starting, but they will clean up at higher

engine speeds. Faulty plugs can be identified in a

number of ways: poor fuel economy, power loss, de-

crease in engine speed, hard starting and, in general,

poor engine performance.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in the maintenance chart in Group 0, Lubri-

cation and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

following Spark Plug Condition section of this group.

CONDITION

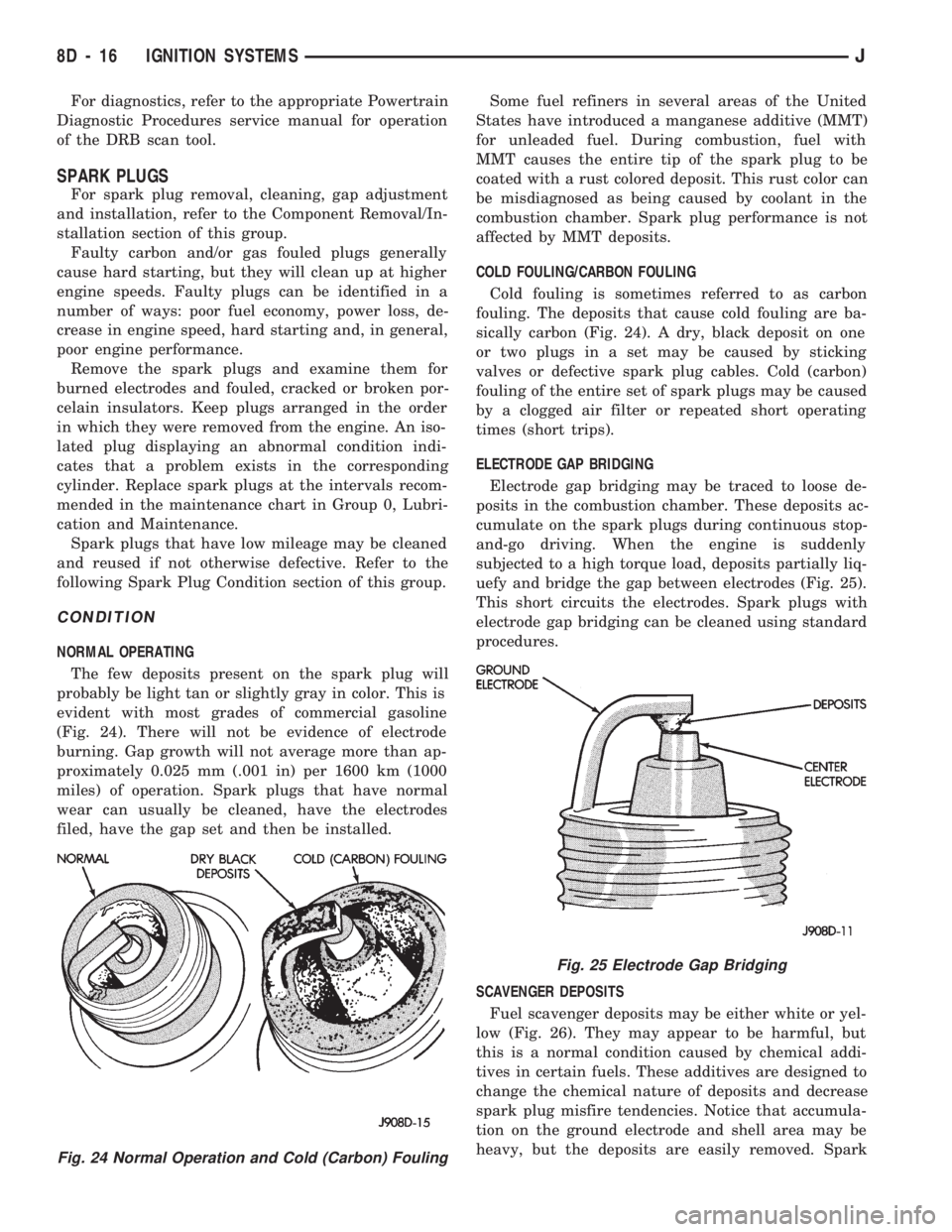

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

(Fig. 24). There will not be evidence of electrode

burning. Gap growth will not average more than ap-

proximately 0.025 mm (.001 in) per 1600 km (1000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes

filed, have the gap set and then be installed.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with

MMT causes the entire tip of the spark plug to be

coated with a rust colored deposit. This rust color can

be misdiagnosed as being caused by coolant in the

combustion chamber. Spark plug performance is not

affected by MMT deposits.

COLD FOULING/CARBON FOULING

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

sically carbon (Fig. 24). A dry, black deposit on one

or two plugs in a set may be caused by sticking

valves or defective spark plug cables. Cold (carbon)

fouling of the entire set of spark plugs may be caused

by a clogged air filter or repeated short operating

times (short trips).

ELECTRODE GAP BRIDGING

Electrode gap bridging may be traced to loose de-

posits in the combustion chamber. These deposits ac-

cumulate on the spark plugs during continuous stop-

and-go driving. When the engine is suddenly

subjected to a high torque load, deposits partially liq-

uefy and bridge the gap between electrodes (Fig. 25).

This short circuits the electrodes. Spark plugs with

electrode gap bridging can be cleaned using standard

procedures.

SCAVENGER DEPOSITS

Fuel scavenger deposits may be either white or yel-

low (Fig. 26). They may appear to be harmful, but

this is a normal condition caused by chemical addi-

tives in certain fuels. These additives are designed to

change the chemical nature of deposits and decrease

spark plug misfire tendencies. Notice that accumula-

tion on the ground electrode and shell area may be

heavy, but the deposits are easily removed. Spark

Fig. 24 Normal Operation and Cold (Carbon) Fouling

Fig. 25 Electrode Gap Bridging

8D - 16 IGNITION SYSTEMSJ