display JEEP CHEROKEE 1994 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 332 of 1784

With the ignition key in the ON position and en-

gine not running, check the sensor output voltage at

the center terminal wire of the connector. Check this

at idle (throttle plate closed) and at wide open throt-

tle (WOT). At idle, sensor output voltage should be

greater than 200 millivolts. At wide open throttle,

sensor output voltage must be less than 4.8 volts.

The output voltage should increase gradually as the

throttle plate is slowly opened from idle to WOT.

OXYGEN SENSOR TESTS

For diagnosis, removal or installation, refer to

Group 14, Fuel Systems in this manual.

ON-BOARD DIAGNOSTICS (OBD)

FOR IGNITION SYSTEM COMPONENTS

The powertrain control module (PCM) has been

programmed to monitor certain ignition system cir-

cuits:

EXAMPLE:

If a reference signal is not being detected during

engine cranking from the crankshaft position sensor,

a Diagnostic Trouble Code (DTC) number 11 can be

observed at the Check Engine Lamp.

If the problem is sensed in a monitored circuit of-

ten enough to indicate an actual problem, a DTC is

stored. The DTC will be stored in the PCM memory

for eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a DTC to be en-

tered into PCM memory. The criteria may be a spe-

cific range of engine rpm, engine temperature and/or

input voltage to the PCM.

A DTC indicates that the PCM has recognized an

abnormal signal in a circuit or the system. A DTC

may indicate the result of a failure, but never iden-

tify the failed component directly.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. Refer to On-Board Diagnostics

(OBD) in Group 14, Fuel Systems for additional in-

formation.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

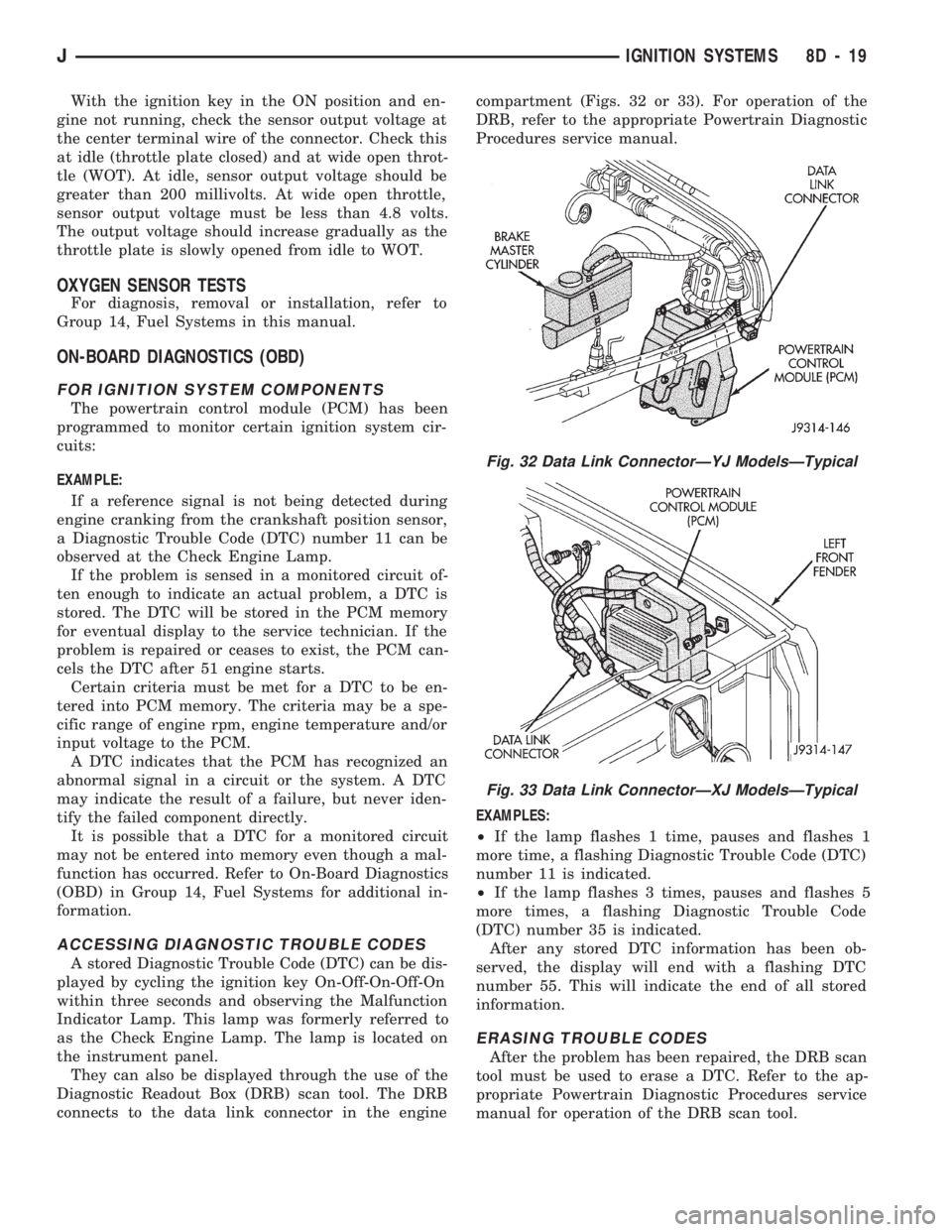

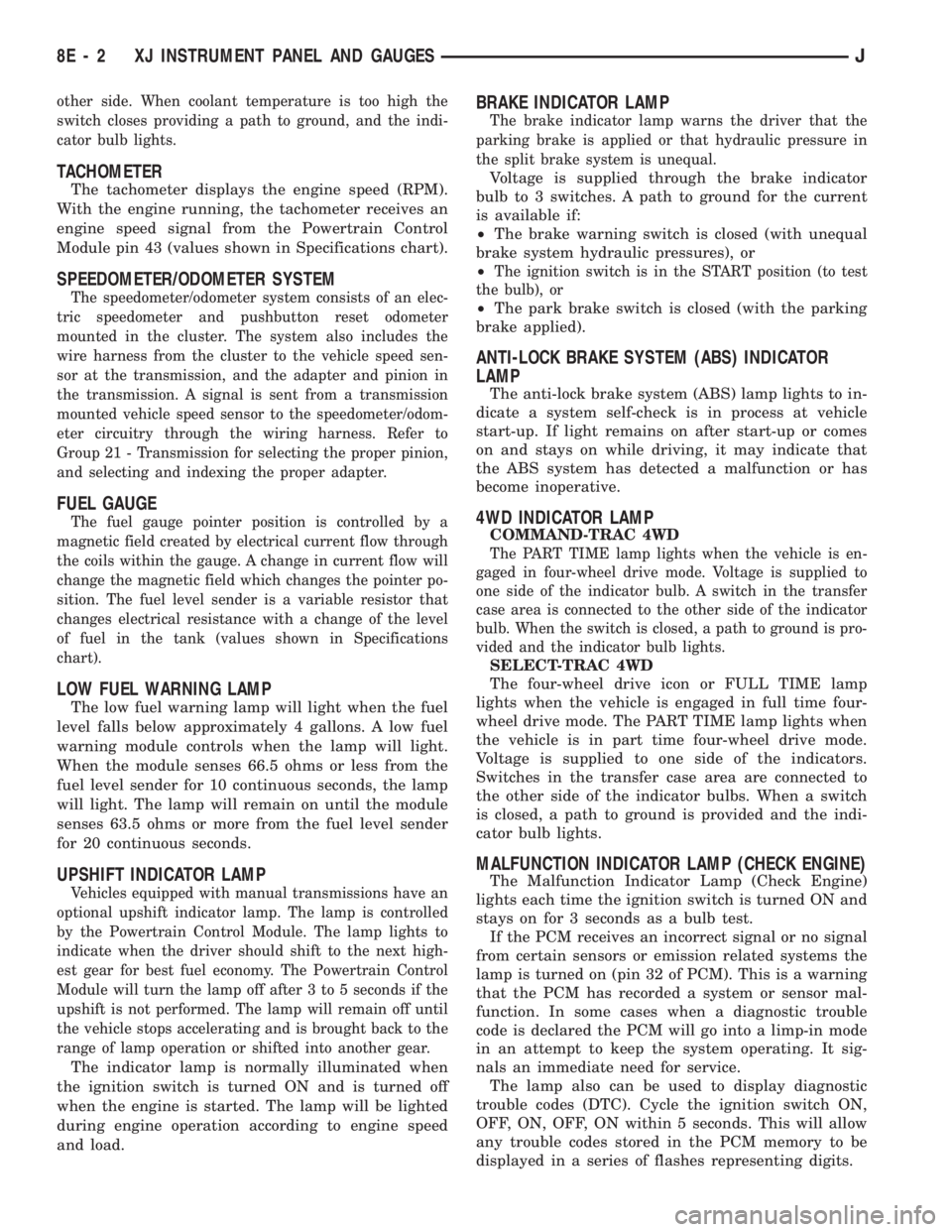

connects to the data link connector in the enginecompartment (Figs. 32 or 33). For operation of the

DRB, refer to the appropriate Powertrain Diagnostic

Procedures service manual.

EXAMPLES:

²If the lamp flashes 1 time, pauses and flashes 1

more time, a flashing Diagnostic Trouble Code (DTC)

number 11 is indicated.

²If the lamp flashes 3 times, pauses and flashes 5

more times, a flashing Diagnostic Trouble Code

(DTC) number 35 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

ERASING TROUBLE CODES

After the problem has been repaired, the DRB scan

tool must be used to erase a DTC. Refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual for operation of the DRB scan tool.

Fig. 32 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 33 Data Link ConnectorÐXJ ModelsÐTypical

JIGNITION SYSTEMS 8D - 19

Page 349 of 1784

other side. When coolant temperature is too high the

switch closes providing a path to ground, and the indi-

cator bulb lights.

TACHOMETER

The tachometer displays the engine speed (RPM).

With the engine running, the tachometer receives an

engine speed signal from the Powertrain Control

Module pin 43 (values shown in Specifications chart).

SPEEDOMETER/ODOMETER SYSTEM

The speedometer/odometer system consists of an elec-

tric speedometer and pushbutton reset odometer

mounted in the cluster. The system also includes the

wire harness from the cluster to the vehicle speed sen-

sor at the transmission, and the adapter and pinion in

the transmission. A signal is sent from a transmission

mounted vehicle speed sensor to the speedometer/odom-

eter circuitry through the wiring harness. Refer to

Group 21 - Transmission for selecting the proper pinion,

and selecting and indexing the proper adapter.

FUEL GAUGE

The fuel gauge pointer position is controlled by a

magnetic field created by electrical current flow through

the coils within the gauge. A change in current flow will

change the magnetic field which changes the pointer po-

sition. The fuel level sender is a variable resistor that

changes electrical resistance with a change of the level

of fuel in the tank (values shown in Specifications

chart).

LOW FUEL WARNING LAMP

The low fuel warning lamp will light when the fuel

level falls below approximately 4 gallons. A low fuel

warning module controls when the lamp will light.

When the module senses 66.5 ohms or less from the

fuel level sender for 10 continuous seconds, the lamp

will light. The lamp will remain on until the module

senses 63.5 ohms or more from the fuel level sender

for 20 continuous seconds.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have an

optional upshift indicator lamp. The lamp is controlled

by the Powertrain Control Module. The lamp lights to

indicate when the driver should shift to the next high-

est gear for best fuel economy. The Powertrain Control

Module will turn the lamp off after 3 to 5 seconds if the

upshift is not performed. The lamp will remain off until

the vehicle stops accelerating and is brought back to the

range of lamp operation or shifted into another gear.

The indicator lamp is normally illuminated when

the ignition switch is turned ON and is turned off

when the engine is started. The lamp will be lighted

during engine operation according to engine speed

and load.

BRAKE INDICATOR LAMP

The brake indicator lamp warns the driver that the

parking brake is applied or that hydraulic pressure in

the split brake system is unequal.

Voltage is supplied through the brake indicator

bulb to 3 switches. A path to ground for the current

is available if:

²The brake warning switch is closed (with unequal

brake system hydraulic pressures), or

²

The ignition switch is in the START position (to test

the bulb), or

²The park brake switch is closed (with the parking

brake applied).

ANTI-LOCK BRAKE SYSTEM (ABS) INDICATOR

LAMP

The anti-lock brake system (ABS) lamp lights to in-

dicate a system self-check is in process at vehicle

start-up. If light remains on after start-up or comes

on and stays on while driving, it may indicate that

the ABS system has detected a malfunction or has

become inoperative.

4WD INDICATOR LAMP

COMMAND-TRAC 4WD

The PART TIME lamp lights when the vehicle is en-

gaged in four-wheel drive mode. Voltage is supplied to

one side of the indicator bulb. A switch in the transfer

case area is connected to the other side of the indicator

bulb. When the switch is closed, a path to ground is pro-

vided and the indicator bulb lights.

SELECT-TRAC 4WD

The four-wheel drive icon or FULL TIME lamp

lights when the vehicle is engaged in full time four-

wheel drive mode. The PART TIME lamp lights when

the vehicle is in part time four-wheel drive mode.

Voltage is supplied to one side of the indicators.

Switches in the transfer case area are connected to

the other side of the indicator bulbs. When a switch

is closed, a path to ground is provided and the indi-

cator bulb lights.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

The Malfunction Indicator Lamp (Check Engine)

lights each time the ignition switch is turned ON and

stays on for 3 seconds as a bulb test.

If the PCM receives an incorrect signal or no signal

from certain sensors or emission related systems the

lamp is turned on (pin 32 of PCM). This is a warning

that the PCM has recorded a system or sensor mal-

function. In some cases when a diagnostic trouble

code is declared the PCM will go into a limp-in mode

in an attempt to keep the system operating. It sig-

nals an immediate need for service.

The lamp also can be used to display diagnostic

trouble codes (DTC). Cycle the ignition switch ON,

OFF, ON, OFF, ON within 5 seconds. This will allow

any trouble codes stored in the PCM memory to be

displayed in a series of flashes representing digits.

8E - 2 XJ INSTRUMENT PANEL AND GAUGESJ

Page 351 of 1784

(3) Connect a jumper between terminal A and B on

the body half of the fuel gauge sender connector. The

gauge should move to F. If gauge is OK, replace

sender. If not, go to step 4.

(4) Measure resistance of sender. Meter should

read 105 to 5 ohms. If OK, go to step 5. If not, re-

place sender.

(5) Check for an open between sender connector

and gauge. If OK, replace gauge. If not, repair open

to gauge.

LOW FUEL WARNING INOPERATIVE

(1) Turn ignition switch to ON.

(2) Disconnect terminal B1 of the instrument clus-

ter connector. Wait at least 10 seconds. Lamp (LED)

should light. If OK, replace sender. If not, replace

low fuel warning module.

UPSHIFT INDICATOR INOPERATIVE

(1) Turn ignition switch to ON.

(2) Ground pin 7 of connector B. Lamp should

light. If not, replace bulb. If OK, continue with

step 3.

(3) Turn ignition switch to OFF. Check for conti-

nuity between connector B pin 2 and pin 54 of the

Powertrain Control Module. If OK, replace PCM. If

not, repair open.

BRAKE INDICATOR INOPERATIVE

(1) Turn ignition switch to ON. Apply parking

brake, brake warning switch connector unplugged.

(2) Jumper brake warning switch connector termi-

nal B to ground. Lamp should light. If bulb is OK,

repair open to indicator.

(3) Turn ignition switch to OFF. Measure resis-

tance between brake warning switch connector ter-

minal A and ground. Meter should read zero ohms. If

OK, check switch and/or brake system. If not, repair

open to park brake switch ground.

4WD INDICATOR INOPERATIVE

(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.

(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switch

operation, replace if bad. If bulb is OK, repair open

to indicator.

LOW WASHER INDICATOR INOPERATIVE

(1) Turn ignition switch to ON.

(2) Jumper 12 volts to fluid level switch connector

terminal B. Lamp should light. If not, go to step 3.

(3) Measure resistance between terminal B and

ground. Meter should read zero ohms. If not, repair

open to bulb. If OK, go to step 4.

(4) Measure voltage at fluid level switch connector

terminal A. Meter should read battery voltage. If

OK, replace switch. If not, repair open to fuse.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

(1) Turn ignition switch to ON.

(2) Jumper Powertrain Control Module terminal 2

to ground. Lamp should light. If bulb is OK, check

for open to instrument cluster connector terminal 2.

ANTI-LOCK INDICATOR

(1) Turn ignition switch to ON.

(2) Jumper instrument cluster connector terminal

6 to ground. Lamp should light. If bulb is OK, check

wiring for an open to module. Refer to Group 5 -

Brakes.

SEAT BELT INDICATOR

Jumper instrument cluster connector terminal 15

to 12 volts. Lamp should light. If not, replace bulb. If

OK, check wiring for an open to buzzer module. Re-

fer to Group 8U - Chime/Buzzer Warning Systems.

RADIO/CLOCK ILLUMINATION

With the ignition switch in ACCESSORY or ON,

power comes from the radio fuse. It then goes

through the normally closed contacts of the radio il-

lumination relay to the radio at connector terminal

11.

Pulling the headlamp switch to ON energizes the

radio illumination relay. This closes the normally

open contacts of the relay, and the brightness for the

radio display is controlled by the headlamp switch

rheostat. The back-lighting for the radio is also con-

trolled by the headlamp rheostat through radio con-

nector terminal 10.

Refer to Group 8F - Audio Systems, for radio illu-

mination relay diagnosis.

INSTRUMENT PANEL LAMPS

Voltage is supplied at all times from the 40 amp

Maxi fuse (located in the Power Distribution Center)

through the park lamps fuse to the headlamp switch.

The circuit continues through the instrument lamps

fuse to the individual instrument panel lamps to

ground. Lamp brightness is controlled by turning the

headlamp switch knob.

DIAGNOSIS

(1) Turn parking lamps ON.

(2) Check park lamps fuse. Replace as required.

(3) Check instrument lamps fuse. Replace as re-

quired.

(4) Measure voltage at battery side of instrument

lamps fuse with rheostat turned counterclockwise to

clockwise (LO to HI). Meter should read zero volts to

battery voltage. If not, replace headlamp switch.

(5) Measure resistance at ground side of instru-

ment lamps fuse with parking lamps OFF. Meter

should read almost zero ohms (except bulb filament).

If not, repair open to ground. If zero ohms, 12 volt

supply wire from fuse is shorted to ground, repair short.

8E - 4 XJ INSTRUMENT PANEL AND GAUGESJ

Page 361 of 1784

INSTRUMENT PANEL AND GAUGESÐYJE

CONTENTS

page page

GAUGE PACKAGE DIAGNOSIS............ 22

GAUGE PACKAGE GENERAL INFORMATION . 22

GAUGE PACKAGE SERVICE PROCEDURES . . 24

INSTRUMENT CLUSTER DIAGNOSIS....... 14INSTRUMENT CLUSTER GENERAL INFORMATION.14

INSTRUMENT CLUSTER SERVICE PROCEDURES.. 17

SPECIFICATIONS....................... 27

INSTRUMENT CLUSTER GENERAL INFORMATION

SPEEDOMETER/ODOMETER SYSTEM

The speedometer/odometer system consists of an

electric speedometer and pushbutton reset odometer

mounted in the cluster. The system also includes the

wire harness from the cluster to the vehicle speed

sensor at the transmission, and the adapter and pin-

ion in the transmission. A signal is sent from a

transmission mounted vehicle speed sensor to the

speedometer/odometer circuitry through the wiring

harness. Refer to Group 21 - Transmission for select-

ing the proper pinion, and selecting and indexing the

proper adapter.

TACHOMETER

The tachometer displays the engine speed (RPM).

With the engine running, the tachometer receives anengine speed signal from the Powertrain Control

Module pin 43 (values shown in Specifications chart).

INDICATOR LAMPS

The Brake, Upshift (2.5L with 5 speed transmis-

sion except California), and Malfunction Indicator

(Check Engine) lamps are located in the indicator

lamp panel above the steering column. The lamps

share a common battery feed connection through the

ignition switch and fuse #9.

The turn signals, high beam indicator, seat belt re-

minder, hazard lamp, master lighting and illumina-

tion bulbs are supplied battery voltage through

various switches and share a common ground.

INSTRUMENT CLUSTER DIAGNOSIS

INDEX

page page

Brake Indicator Lamp...................... 16

DiagnosingÐAll Lamps Out................. 16

Instrument Panel Illumination Lamps.......... 16

Malfunction Indicator Lamp (Check Engine)..... 16Seat Belt Reminder Lamp................... 16

Speedometer............................ 14

Tachometer............................. 14

Upshift Indicator Lamp..................... 16

SPEEDOMETER

(1) Raise vehicle.

(2) Disconnect the vehicle speed sensor connector.

(3) Connect a voltmeter between the black wire

pin of the connector and ground.

(4) Turn the ignition switch to the ON position.

(5) Check for approximately 5 volts. If OK, per-

form vehicle speed sensor test. Refer to the appropri-

ate Powertrain Diagnostic Procedures manual. If not

OK, continue with step 6.

(6) Turn ignition switch to OFF position.(7) Check continuity between vehicle speed sensor

connector and terminal 13 of instrument cluster con-

nector. If OK, replace speedometer. If not OK, repair

open circuit.

TACHOMETER

(1) Tachometer input is from the Powertrain Con-

trol Module (PCM) pin 43. Use the DRB scan tool to

perform actuator test. If OK, continue with step 2. If

not, replace PCM.

(2) Check for continuity between cluster connector

pin 12 and PCM pin 43. If OK, replace tachometer. If

not, repair open circuit.

8E - 14 YJ INSTRUMENT PANEL AND GAUGESJ

Page 363 of 1784

DIAGNOSINGÐALL LAMPS OUT

(1) Inspect fuse #9. Replace as required.

(2) Measure voltage at instrument cluster connec-

tor terminal 20. Meter should read zero ohms. If not,

repair open to ground.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have

an optional upshift indicator lamp. The lamp is con-

trolled by the PCM. The lamp lights to indicate when

the driver should shift to the next highest gear for best

fuel economy. The PCM will turn the lamp off after 3 to

5 seconds if the upshift is not performed. The lamp will

remain off until the vehicle stops accelerating and is

brought back to the range of lamp operation or shifted

into another gear.

The indicator lamp is normally illuminated when

the ignition switch is turned ON and it is turned off

when the engine is started. The lamp will be lighted

during engine operation according to engine speed

and load.

(1) Turn ignition switch to ON.

(2) Ground pin 2 of cluster connector. Lamp should

light. If not, replace bulb. If OK, continue with step 3.

(3) Turn ignition switch to OFF. Check for conti-

nuity between cluster connector pin 2 and pin 54 of

the PCM. If not, repair open. If OK, refer to DRB

scan tool actuator test of upshift indicator.

BRAKE INDICATOR LAMP

The brake indicator is a dual function lamp. It will in-

dicate an unequal pressure condition in the split brake

hydraulic system and it also will indicate when the park-

ing brake is engaged. Separate switches are used for each

indicator lamp function. A switch mounted on the brake

pedal assembly will close a ground circuit whenever the

parking brakes are applied. A second switch is installed

in the brake hydraulic lines near the master cylinder. If

the switch is balanced by equal pressure on both ends of

the switch valve, the valve remains centered and the

lamp remains off. If the valve is shifted by unequal pres-

sure between the front or rear brake hydraulic systems,

the lamp circuit is connected to ground. To make sure

the brake lamp is functional before the vehicle is driven,

it is illuminated through a ground circuit when the igni-

tion switch is turned to the START position.

(1) Turn ignition switch to ON.

(2) Ground pin 1 of the cluster connector. Lamp

should light. If not, replace bulb. If OK, continue

with step 3.

(3) Turn ignition switch to OFF. Check for continuity to

park brake switch and brake warning switch.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

The Malfunction Indicator Lamp (Check Engine) il-

luminates each time the ignition switch is turned

ON and stays on for 3 seconds as a bulb test.If the PCM receives an incorrect signal or no signal

from certain sensors or emission related systems the

lamp is turned on (pin 32 of PCM). This is a warning

that the PCM has recorded a system or sensor mal-

function. In some cases when a diagnostic fault is de-

clared the PCM will go into a limp-in mode in an

attempt to keep the system operating. It signals an

immediate need for service.

The lamp also can be used to display diagnostic

trouble codes (DTC). Cycle the ignition switch ON,

OFF, ON, OFF, ON within 5 seconds. This will allow

any DTC's stored in the PCM memory to be dis-

played in a series of flashes representing digits.

(1) Turn ignition switch to ON.

(2) Ground pin 4 of cluster connector. Lamp should

light. If not, replace bulb. If OK, continue with step 3.

(3) Turn ignition switch to OFF. Check for conti-

nuity between cluster connector pin 4 and PCM cav-

ity 32. If OK, replace PCM. If not, repair open.

SEAT BELT REMINDER LAMP

Apply 12 volts to terminal 16 of cluster connector.

Lamp should light. If not, replace bulb. If OK, check

wiring for an open to buzzer module. Refer to Group

8U - Chime/Buzzer Warning Systems.

INSTRUMENT PANEL ILLUMINATION LAMPS

The instrument panel illumination lamps share

two common connections. There is a splice after fuse

#10 that connects the lamps to battery feed. There is

also a splice that connects all lamps to ground. Be-

cause they share these common connection points in

a parallel circuit, the illumination lamps will all

come on at the same time. It also means one or more

lamps can be out without affecting the operation of

the other lamps.

On the battery side of the circuit, the headlamp

switch illumination rheostat/switch and panel lamps

fuse receive battery feed in series from the park/tail

fuse. In the park lamp position, the headlamp switch

completes the circuit from the park/tail fuse to the il-

lumination rheostat/switch and panel lamps fuse.

The illumination rheostat contains a variable resis-

tor that allows the driver to vary illumination inten-

sity from off to full brightness.

DIAGNOSIS

(1) Turn parking lamps ON.

(2) Check fuse #10. Replace as required.

(3) Measure voltage at battery side of fuse #10

with rheostat turned counterclockwise to clockwise

(LO to HI). Meter should read zero volts to battery

voltage. If not, replace headlamp switch.

(4) Measure resistance at ground side of fuse #10

with parking lamps OFF. Meter should read almost

zero ohms (except bulb filament). If not, repair open

to ground. If zero ohms, 12 volt supply wire from fuse

is shorted to ground, repair short.

8E - 16 YJ INSTRUMENT PANEL AND GAUGESJ

Page 376 of 1784

AUDIO SYSTEMS

CONTENTS

page page

GENERAL INFORMATION.................. 1

RADIO ANTENNA........................ 8XJ SERVICE PROCEDURES................ 4

YJ SERVICE PROCEDURES................ 6

GENERAL INFORMATION

DESCRIPTION

Each radio receives ignition feed from an ignition

switch controlled fuse. There is an additional in-line

fuse in the back of the radio chassis. The in-line fuse

will blow in the event an internal short occurs.

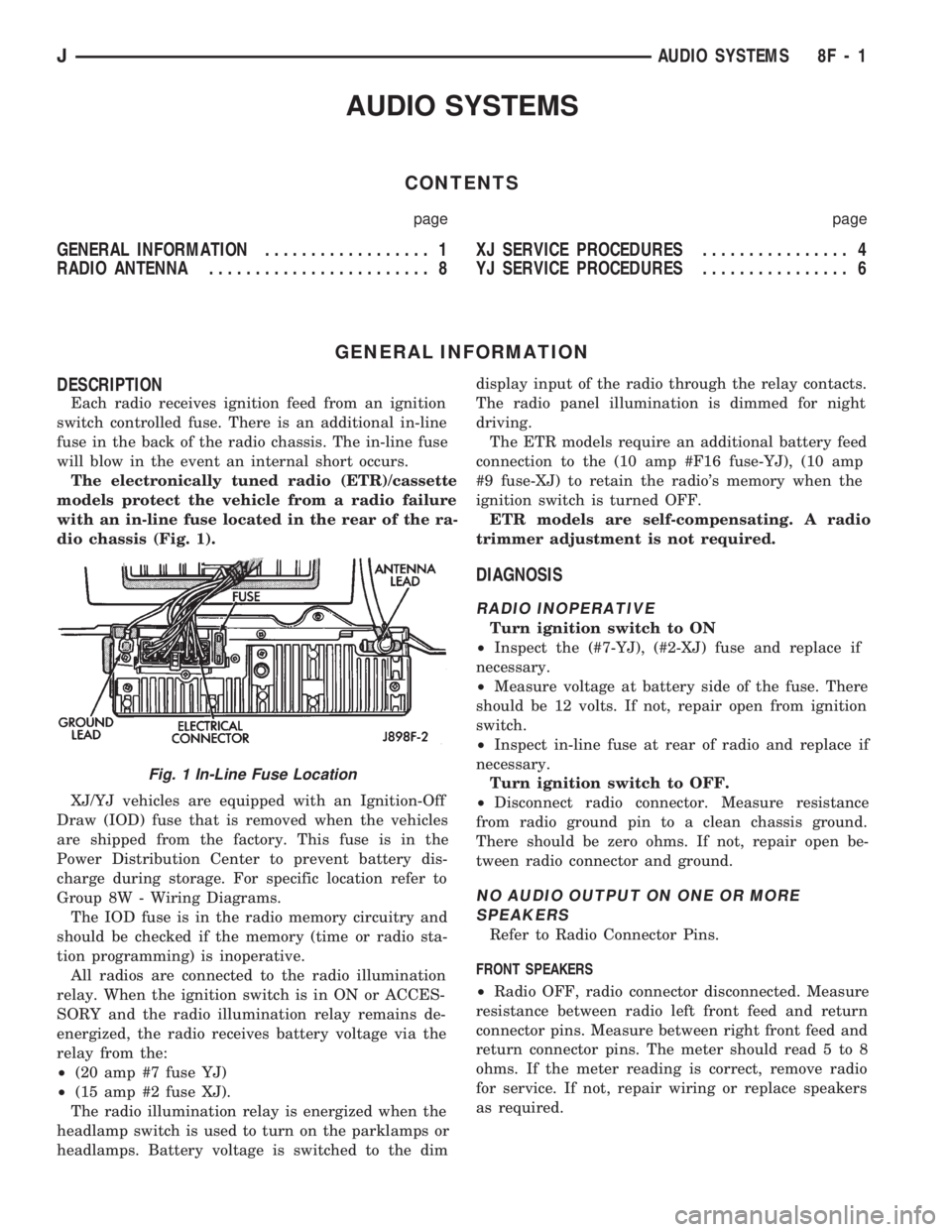

The electronically tuned radio (ETR)/cassette

models protect the vehicle from a radio failure

with an in-line fuse located in the rear of the ra-

dio chassis (Fig. 1).

XJ/YJ vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed when the vehicles

are shipped from the factory. This fuse is in the

Power Distribution Center to prevent battery dis-

charge during storage. For specific location refer to

Group 8W - Wiring Diagrams.

The IOD fuse is in the radio memory circuitry and

should be checked if the memory (time or radio sta-

tion programming) is inoperative.

All radios are connected to the radio illumination

relay. When the ignition switch is in ON or ACCES-

SORY and the radio illumination relay remains de-

energized, the radio receives battery voltage via the

relay from the:

²(20 amp #7 fuse YJ)

²(15 amp #2 fuse XJ).

The radio illumination relay is energized when the

headlamp switch is used to turn on the parklamps or

headlamps. Battery voltage is switched to the dimdisplay input of the radio through the relay contacts.

The radio panel illumination is dimmed for night

driving.

The ETR models require an additional battery feed

connection to the (10 amp #F16 fuse-YJ), (10 amp

#9 fuse-XJ) to retain the radio's memory when the

ignition switch is turned OFF.

ETR models are self-compensating. A radio

trimmer adjustment is not required.

DIAGNOSIS

RADIO INOPERATIVE

Turn ignition switch to ON

²Inspect the (#7-YJ), (#2-XJ) fuse and replace if

necessary.

²Measure voltage at battery side of the fuse. There

should be 12 volts. If not, repair open from ignition

switch.

²Inspect in-line fuse at rear of radio and replace if

necessary.

Turn ignition switch to OFF.

²Disconnect radio connector. Measure resistance

from radio ground pin to a clean chassis ground.

There should be zero ohms. If not, repair open be-

tween radio connector and ground.

NO AUDIO OUTPUT ON ONE OR MORE

SPEAKERS

Refer to Radio Connector Pins.

FRONT SPEAKERS

²Radio OFF, radio connector disconnected. Measure

resistance between radio left front feed and return

connector pins. Measure between right front feed and

return connector pins. The meter should read 5 to 8

ohms. If the meter reading is correct, remove radio

for service. If not, repair wiring or replace speakers

as required.

Fig. 1 In-Line Fuse Location

JAUDIO SYSTEMS 8F - 1

Page 377 of 1784

REAR SPEAKERS

²Radio OFF, radio connector disconnected. Measure

resistance between radio left rear feed and return

connector pins. Measure between right rear feed and

return connector pins. The meter should read 5 to 8

ohms. If meter reading is correct remove radio for

service. If not, repair wiring or replace speakers as

required.

DISTORTED AUDIO OUTPUT ON ONE OR

MORE SPEAKERS

²With the radio ON, substitute known good speaker

or speakers. If the sound is still distorted, remove ra-

dio for service.

WEAK OR NO RECEPTION; NO AUDIO

OUTPUT; BACKGROUND NOISE PRESENT

Ignition switch in ON, radio ON.

²Inspect antenna cable and connector at radio and

tighten or repair as necessary.

²Unplug coax cable and connectors from radio. Mea-

sure resistance from center conductor to coaxial

shield. The meter should read infinite resistance

(open). If it does not, replace antenna assembly.

²Measure resistance of antenna mast to tip of cen-

ter conductor at radio end of cable. The meter should

read 0 to 0.5 ohms. If it does not, replace lead-in ca-

ble or antenna assembly.

²Measure resistance from coaxial shield to chassis

ground (vehicle body). The meter should read zero

ohms. If it does not, ground antenna base to vehicle

body, or replace antenna assembly as required

For all problems with no or low audio output

not resolved by these tests, remove radio for ser-

vice.

MEMORY DOES NOT OPERATE

²Inspect (F16 in Power Distribution Center-YJ),

(#9 in Fuse Panel-XJ) fuse and replace if necessary.

²Measure voltage at battery side of previously ref-

erenced fuse. There should be 12 volts at battery side

of fuse. If not, check the Maxi fuse.

Refer to Group 8W - Wiring Diagrams.

²Measure voltage at radio connector pin 4. There

should be 12 volts. If meter reading is correct, re-

move radio for service. If not, repair open from fuse.

RADIO DISPLAY ILLUMINATION (PARKLAMPS

AND HEADLAMPS OPERATING NORMALLY)

Headlamp switch OFF, radio ON.

²Measure voltage at radio connector pin 10. There

should be 12 volts. If not, go to next step. If OK, re-

move radio for repair by authorized outlet.

²Measure voltage at illumination relay pin 3. There

should be 12 volts. If 12 volts present, replace illumi-

nation relay. If not, repair open in circuit.RADIO DISPLAY ILLUMINATION DIMMING CIRCUIT

Turn headlamp switch to PARKLAMPS for

voltage tests; turn headlamp switch to OFF for

resistance tests.

²Separate relay connector from radio illumination

relay. Measure resistance from relay connector pin 2

to a clean chassis ground. The meter should read

zero ohms. If not, repair open between relay connec-

tor and ground.

²Measure voltage at radio illumination relay pin 5.

There should be battery voltage. If not repair open

from headlamp switch.

²Measure voltage at radio illumination relay pin 4.

Voltage should vary with dimmer switch. If OK, go

to next step. If not, repair open circuit between pin 4

and interior lamp rheostat.

²Measure voltage at radio illumination relay pin

10. Voltage should vary with dimmer switch. If OK,

remove radio for repair by authorized outlet. If not,

replace radio illumination relay.NOISE INTERFERENCE CHANGES WITH

ENGINE SPEED

²Inspect connections at: generator, ignition module,

antenna coaxial ground, radio ground, body to engine

block ground (braided ground strap). Repair as re-

quired.

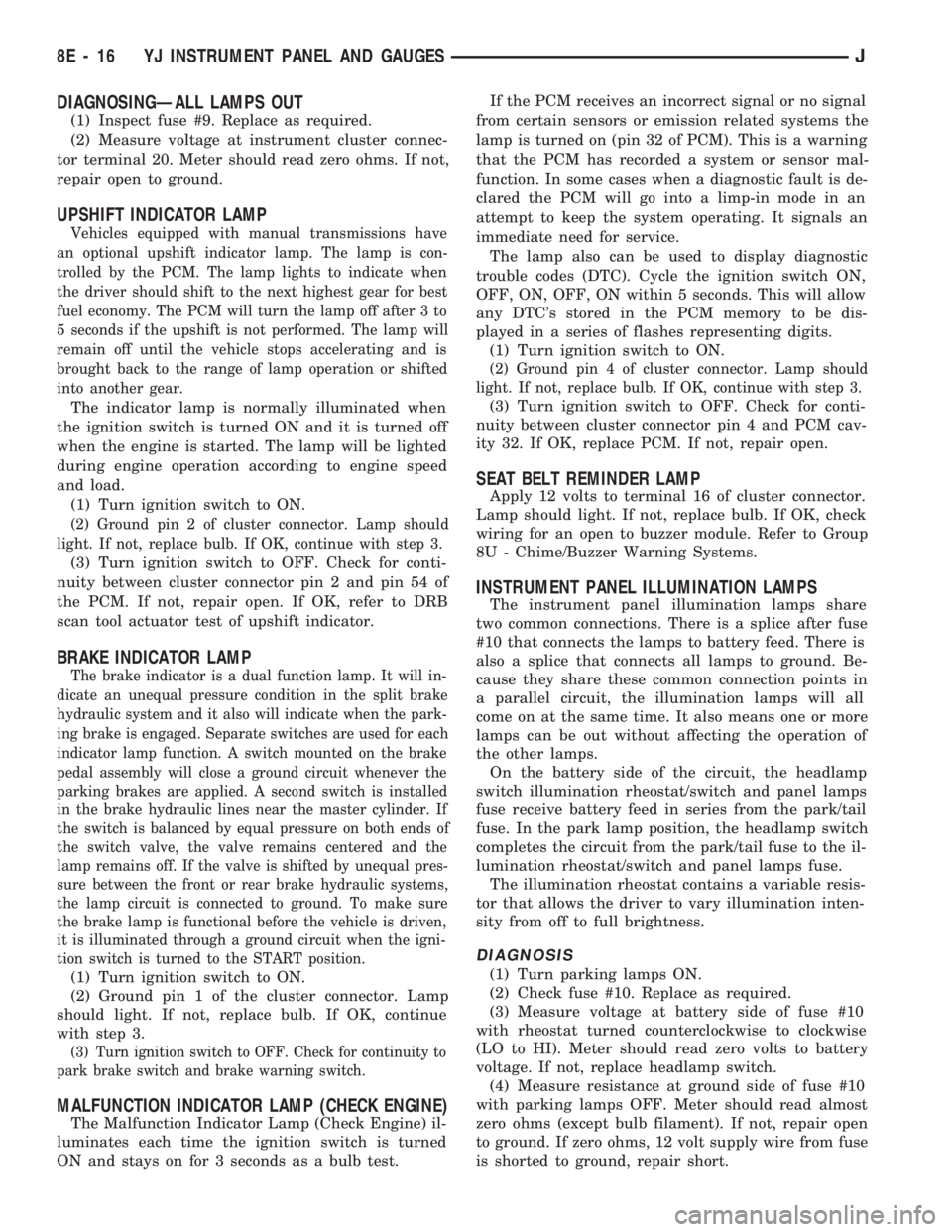

RADIO NOISE DIAGNOSIS

8F - 2 AUDIO SYSTEMSJ

Page 394 of 1784

TEST PROCEDURES

INDEX

page page

Checking for Diagnostic Trouble Code......... 5

Electrical Tests at Powertrain Control Module.... 6

Electrical Tests at Servo.................... 5

Inoperative System........................ 5

Operational Check (Road Test)............... 7

Road Test............................... 5Speed Control Switch (Turn Signal Lever) Test . . . 7

Stop Lamp Speed Control Switch Test......... 7

Vacuum Supply Test....................... 7

Vehicle Speed Control System Electrical Tests . . . 5

Vehicle Speed Sensor Test.................. 5

ROAD TEST

Refer to Operational Check (Road Test) section to

verify reports of speed control system malfunction.

INOPERATIVE SYSTEM

Road test vehicle to verify reports of speed control

system malfunction. An inspection should be made

for loose electrical and vacuum connections at the

servo.

Check for correct installation of the vacuum check

valve in the hose from servo to vacuum source. The

word VAC on the valve must point toward the vac-

uum source.

Corrosion should be removed from electrical termi-

nals and a light coating of Mopar MultiPurpose

Grease, or equivalent, applied.

Inspection also should be made to verify that both

ends of the speed control cable are securely attached.

CHECKING FOR DIAGNOSTIC TROUBLE CODE

(1) When trying to verify a speed control system

electronic malfunction use a DRB scan tool to find

the cause (refer to Powertrain Diagnostic Procedures

manual).

If DRB is not available, the Diagnostic Trouble

Code (DTC) may be determined with the following

method:

(a) With key inserted in ignition switch, cycle

switch to ON position 3 times. On third cycle, leave

switch in ON position.

(b) After switch has been cycled 3 times, observe

Malfunction Indicator Lamp (CHECK ENGINE)

on instrument cluster. If a DTC is present, the code

will be displayed in a series of flashes representing

digits. Three flashes in rapid succession, a slight

pause, then 4 flashes in rapid succession would in-

dicate DTC 34.

(2) If a DTC 34 is observed, perform tests in the

sections Electrical Tests at Servo and Electrical Tests

at Powertrain Control Module.

If a DTC 15 is observed, perform test for a faulty

vehicle speed sensor.

(3) Correct any problems found when performing

these tests and recheck for DTC if changes were

made.

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components, refer to Powertrain Diagnostic Proce-

dures manual.

VEHICLE SPEED CONTROL SYSTEM ELECTRICAL

TESTS

Vehicle speed control systems may be tested using

two different methods. One involves use of a DRB

scan tool. If this test method is desired, refer to Pow-

ertrain Diagnostic Procedures manual.

The other test method uses a voltmeter. The volt-

meter method is described in the following tests.

If any information is needed concerning wiring, re-

fer to Section 8W - Wiring Diagrams.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

ELECTRICAL TESTS AT SERVO

(1) Turn ignition switch to the ON position. With

speed control switch in the ON position, setup a volt-

meter to read battery voltage and connect negative

lead to a good chassis ground.

(2) Disconnect 4-way connector going to servo

(Figs. 2 and 3). Blue wire with red tracer of main

harness 4-way connector should read approximately

battery voltage. If not, check for loose connections,

brake switch adjustment or, repair main harness as

necessary.

(3) Connect a jumper wire between male and fe-

male terminals of blue wire with red tracer. The

other 3 male terminals from servo should show bat-

tery voltage. If not, replace servo.

(4) Using an ohmmeter, connect one lead to a good

body ground. Touch other lead to black wire terminal

in 4-way connector of main harness. Meter should

show continuity. If not, repair ground circuit as nec-

essary.

JVEHICLE SPEED CONTROL SYSTEM 8H - 5

Page 439 of 1784

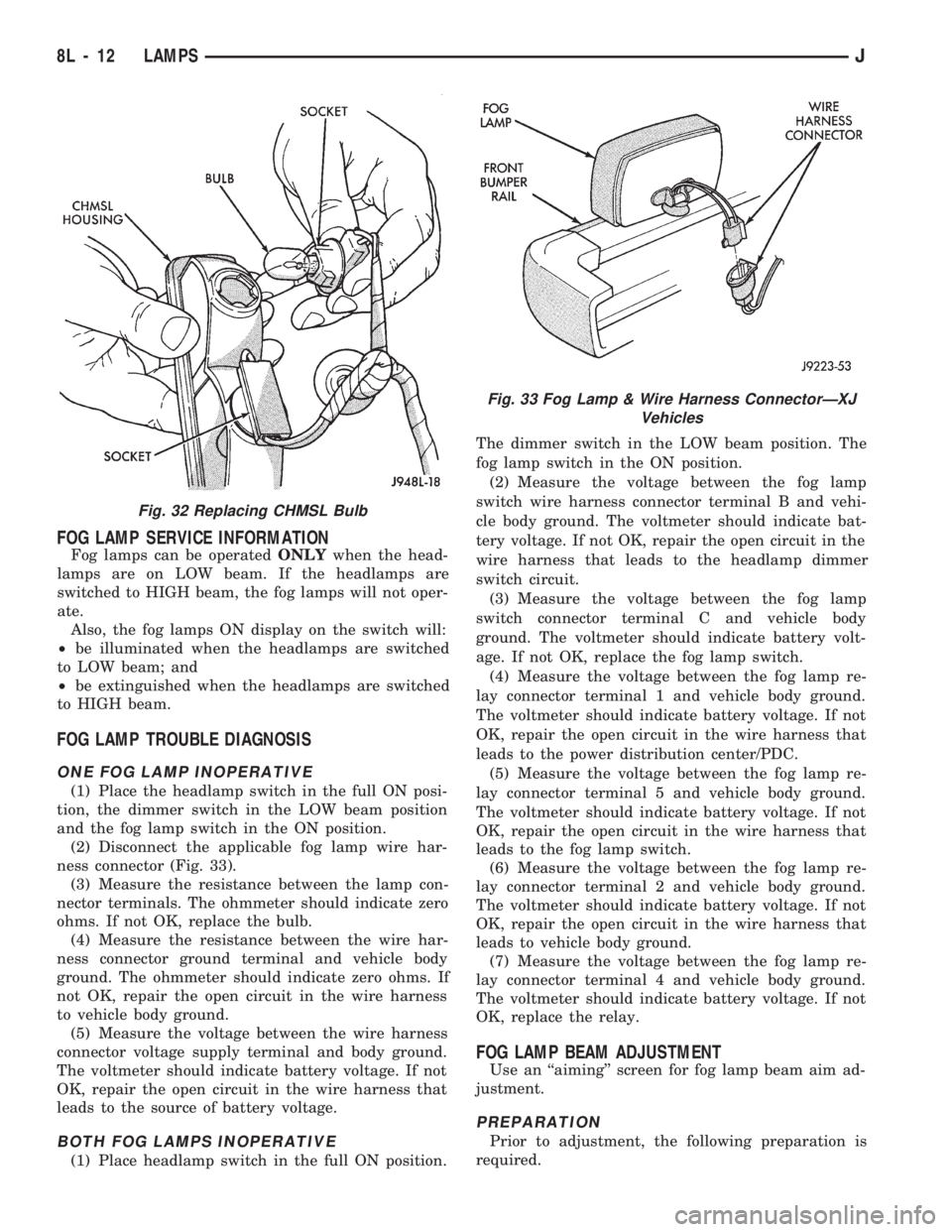

FOG LAMP SERVICE INFORMATION

Fog lamps can be operatedONLYwhen the head-

lamps are on LOW beam. If the headlamps are

switched to HIGH beam, the fog lamps will not oper-

ate.

Also, the fog lamps ON display on the switch will:

²be illuminated when the headlamps are switched

to LOW beam; and

²be extinguished when the headlamps are switched

to HIGH beam.

FOG LAMP TROUBLE DIAGNOSIS

ONE FOG LAMP INOPERATIVE

(1) Place the headlamp switch in the full ON posi-

tion, the dimmer switch in the LOW beam position

and the fog lamp switch in the ON position.

(2) Disconnect the applicable fog lamp wire har-

ness connector (Fig. 33).

(3) Measure the resistance between the lamp con-

nector terminals. The ohmmeter should indicate zero

ohms. If not OK, replace the bulb.

(4) Measure the resistance between the wire har-

ness connector ground terminal and vehicle body

ground. The ohmmeter should indicate zero ohms. If

not OK, repair the open circuit in the wire harness

to vehicle body ground.

(5) Measure the voltage between the wire harness

connector voltage supply terminal and body ground.

The voltmeter should indicate battery voltage. If not

OK, repair the open circuit in the wire harness that

leads to the source of battery voltage.

BOTH FOG LAMPS INOPERATIVE

(1) Place headlamp switch in the full ON position.The dimmer switch in the LOW beam position. The

fog lamp switch in the ON position.

(2) Measure the voltage between the fog lamp

switch wire harness connector terminal B and vehi-

cle body ground. The voltmeter should indicate bat-

tery voltage. If not OK, repair the open circuit in the

wire harness that leads to the headlamp dimmer

switch circuit.

(3) Measure the voltage between the fog lamp

switch connector terminal C and vehicle body

ground. The voltmeter should indicate battery volt-

age. If not OK, replace the fog lamp switch.

(4) Measure the voltage between the fog lamp re-

lay connector terminal 1 and vehicle body ground.

The voltmeter should indicate battery voltage. If not

OK, repair the open circuit in the wire harness that

leads to the power distribution center/PDC.

(5) Measure the voltage between the fog lamp re-

lay connector terminal 5 and vehicle body ground.

The voltmeter should indicate battery voltage. If not

OK, repair the open circuit in the wire harness that

leads to the fog lamp switch.

(6) Measure the voltage between the fog lamp re-

lay connector terminal 2 and vehicle body ground.

The voltmeter should indicate battery voltage. If not

OK, repair the open circuit in the wire harness that

leads to vehicle body ground.

(7) Measure the voltage between the fog lamp re-

lay connector terminal 4 and vehicle body ground.

The voltmeter should indicate battery voltage. If not

OK, replace the relay.

FOG LAMP BEAM ADJUSTMENT

Use an ``aiming'' screen for fog lamp beam aim ad-

justment.

PREPARATION

Prior to adjustment, the following preparation is

required.

Fig. 32 Replacing CHMSL Bulb

Fig. 33 Fog Lamp & Wire Harness ConnectorÐXJ

Vehicles

8L - 12 LAMPSJ

Page 864 of 1784

INSPECTION

Inspect for cracks in the combustion chambers and

valve ports.

Inspect for cracks on the exhaust seat.

Inspect for cracks in the gasket surface at each

coolant passage.

Inspect valves for burned, cracked or warped heads.

Inspect for scuffed or bent valve stems.

Replace valves displaying any damage.

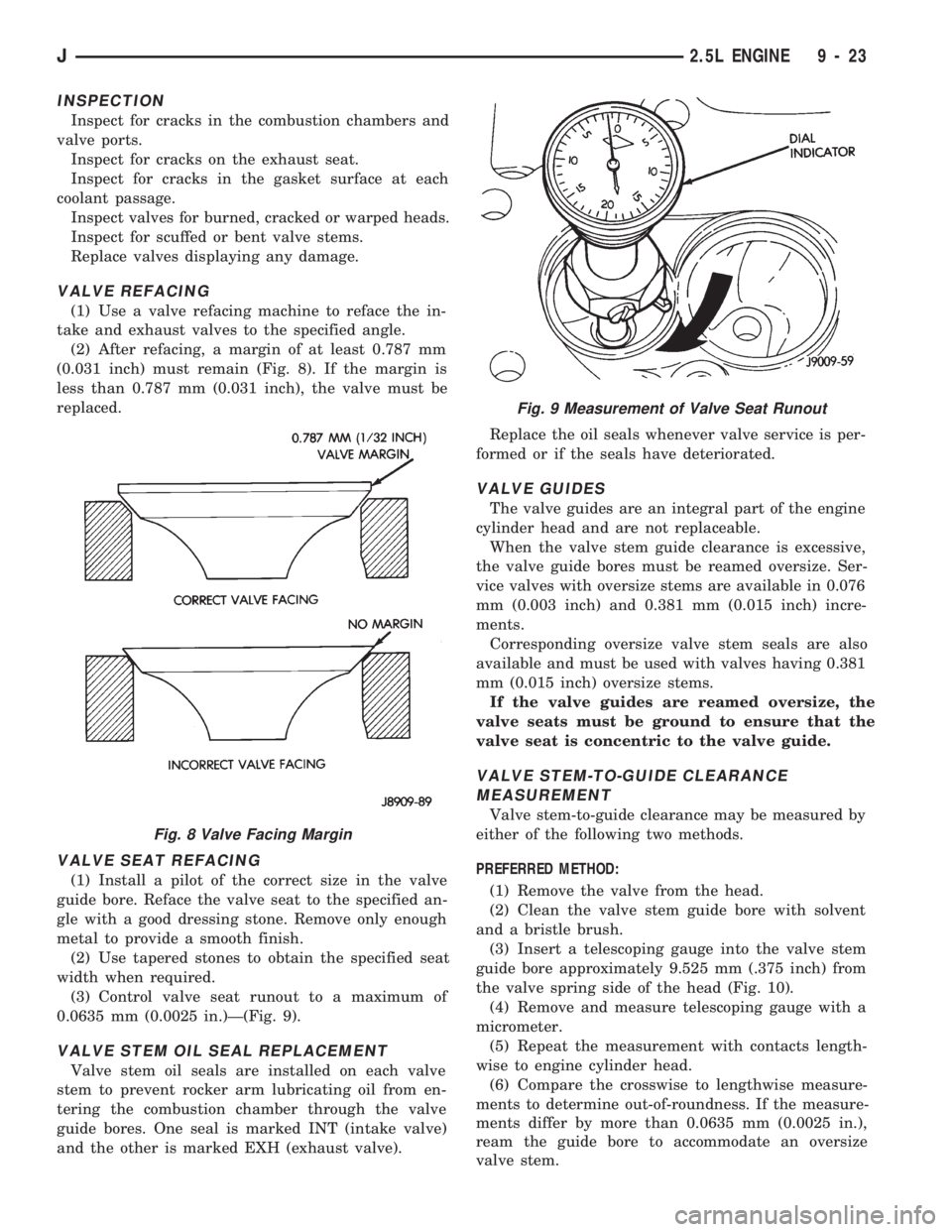

VALVE REFACING

(1) Use a valve refacing machine to reface the in-

take and exhaust valves to the specified angle.

(2) After refacing, a margin of at least 0.787 mm

(0.031 inch) must remain (Fig. 8). If the margin is

less than 0.787 mm (0.031 inch), the valve must be

replaced.

VALVE SEAT REFACING

(1) Install a pilot of the correct size in the valve

guide bore. Reface the valve seat to the specified an-

gle with a good dressing stone. Remove only enough

metal to provide a smooth finish.

(2) Use tapered stones to obtain the specified seat

width when required.

(3) Control valve seat runout to a maximum of

0.0635 mm (0.0025 in.)Ð(Fig. 9).

VALVE STEM OIL SEAL REPLACEMENT

Valve stem oil seals are installed on each valve

stem to prevent rocker arm lubricating oil from en-

tering the combustion chamber through the valve

guide bores. One seal is marked INT (intake valve)

and the other is marked EXH (exhaust valve).Replace the oil seals whenever valve service is per-

formed or if the seals have deteriorated.

VALVE GUIDES

The valve guides are an integral part of the engine

cylinder head and are not replaceable.

When the valve stem guide clearance is excessive,

the valve guide bores must be reamed oversize. Ser-

vice valves with oversize stems are available in 0.076

mm (0.003 inch) and 0.381 mm (0.015 inch) incre-

ments.

Corresponding oversize valve stem seals are also

available and must be used with valves having 0.381

mm (0.015 inch) oversize stems.

If the valve guides are reamed oversize, the

valve seats must be ground to ensure that the

valve seat is concentric to the valve guide.

VALVE STEM-TO-GUIDE CLEARANCE

MEASUREMENT

Valve stem-to-guide clearance may be measured by

either of the following two methods.

PREFERRED METHOD:

(1) Remove the valve from the head.

(2) Clean the valve stem guide bore with solvent

and a bristle brush.

(3) Insert a telescoping gauge into the valve stem

guide bore approximately 9.525 mm (.375 inch) from

the valve spring side of the head (Fig. 10).

(4) Remove and measure telescoping gauge with a

micrometer.

(5) Repeat the measurement with contacts length-

wise to engine cylinder head.

(6) Compare the crosswise to lengthwise measure-

ments to determine out-of-roundness. If the measure-

ments differ by more than 0.0635 mm (0.0025 in.),

ream the guide bore to accommodate an oversize

valve stem.

Fig. 8 Valve Facing Margin

Fig. 9 Measurement of Valve Seat Runout

J2.5L ENGINE 9 - 23