fuse JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 377 of 1784

REAR SPEAKERS

²Radio OFF, radio connector disconnected. Measure

resistance between radio left rear feed and return

connector pins. Measure between right rear feed and

return connector pins. The meter should read 5 to 8

ohms. If meter reading is correct remove radio for

service. If not, repair wiring or replace speakers as

required.

DISTORTED AUDIO OUTPUT ON ONE OR

MORE SPEAKERS

²With the radio ON, substitute known good speaker

or speakers. If the sound is still distorted, remove ra-

dio for service.

WEAK OR NO RECEPTION; NO AUDIO

OUTPUT; BACKGROUND NOISE PRESENT

Ignition switch in ON, radio ON.

²Inspect antenna cable and connector at radio and

tighten or repair as necessary.

²Unplug coax cable and connectors from radio. Mea-

sure resistance from center conductor to coaxial

shield. The meter should read infinite resistance

(open). If it does not, replace antenna assembly.

²Measure resistance of antenna mast to tip of cen-

ter conductor at radio end of cable. The meter should

read 0 to 0.5 ohms. If it does not, replace lead-in ca-

ble or antenna assembly.

²Measure resistance from coaxial shield to chassis

ground (vehicle body). The meter should read zero

ohms. If it does not, ground antenna base to vehicle

body, or replace antenna assembly as required

For all problems with no or low audio output

not resolved by these tests, remove radio for ser-

vice.

MEMORY DOES NOT OPERATE

²Inspect (F16 in Power Distribution Center-YJ),

(#9 in Fuse Panel-XJ) fuse and replace if necessary.

²Measure voltage at battery side of previously ref-

erenced fuse. There should be 12 volts at battery side

of fuse. If not, check the Maxi fuse.

Refer to Group 8W - Wiring Diagrams.

²Measure voltage at radio connector pin 4. There

should be 12 volts. If meter reading is correct, re-

move radio for service. If not, repair open from fuse.

RADIO DISPLAY ILLUMINATION (PARKLAMPS

AND HEADLAMPS OPERATING NORMALLY)

Headlamp switch OFF, radio ON.

²Measure voltage at radio connector pin 10. There

should be 12 volts. If not, go to next step. If OK, re-

move radio for repair by authorized outlet.

²Measure voltage at illumination relay pin 3. There

should be 12 volts. If 12 volts present, replace illumi-

nation relay. If not, repair open in circuit.RADIO DISPLAY ILLUMINATION DIMMING CIRCUIT

Turn headlamp switch to PARKLAMPS for

voltage tests; turn headlamp switch to OFF for

resistance tests.

²Separate relay connector from radio illumination

relay. Measure resistance from relay connector pin 2

to a clean chassis ground. The meter should read

zero ohms. If not, repair open between relay connec-

tor and ground.

²Measure voltage at radio illumination relay pin 5.

There should be battery voltage. If not repair open

from headlamp switch.

²Measure voltage at radio illumination relay pin 4.

Voltage should vary with dimmer switch. If OK, go

to next step. If not, repair open circuit between pin 4

and interior lamp rheostat.

²Measure voltage at radio illumination relay pin

10. Voltage should vary with dimmer switch. If OK,

remove radio for repair by authorized outlet. If not,

replace radio illumination relay.NOISE INTERFERENCE CHANGES WITH

ENGINE SPEED

²Inspect connections at: generator, ignition module,

antenna coaxial ground, radio ground, body to engine

block ground (braided ground strap). Repair as re-

quired.

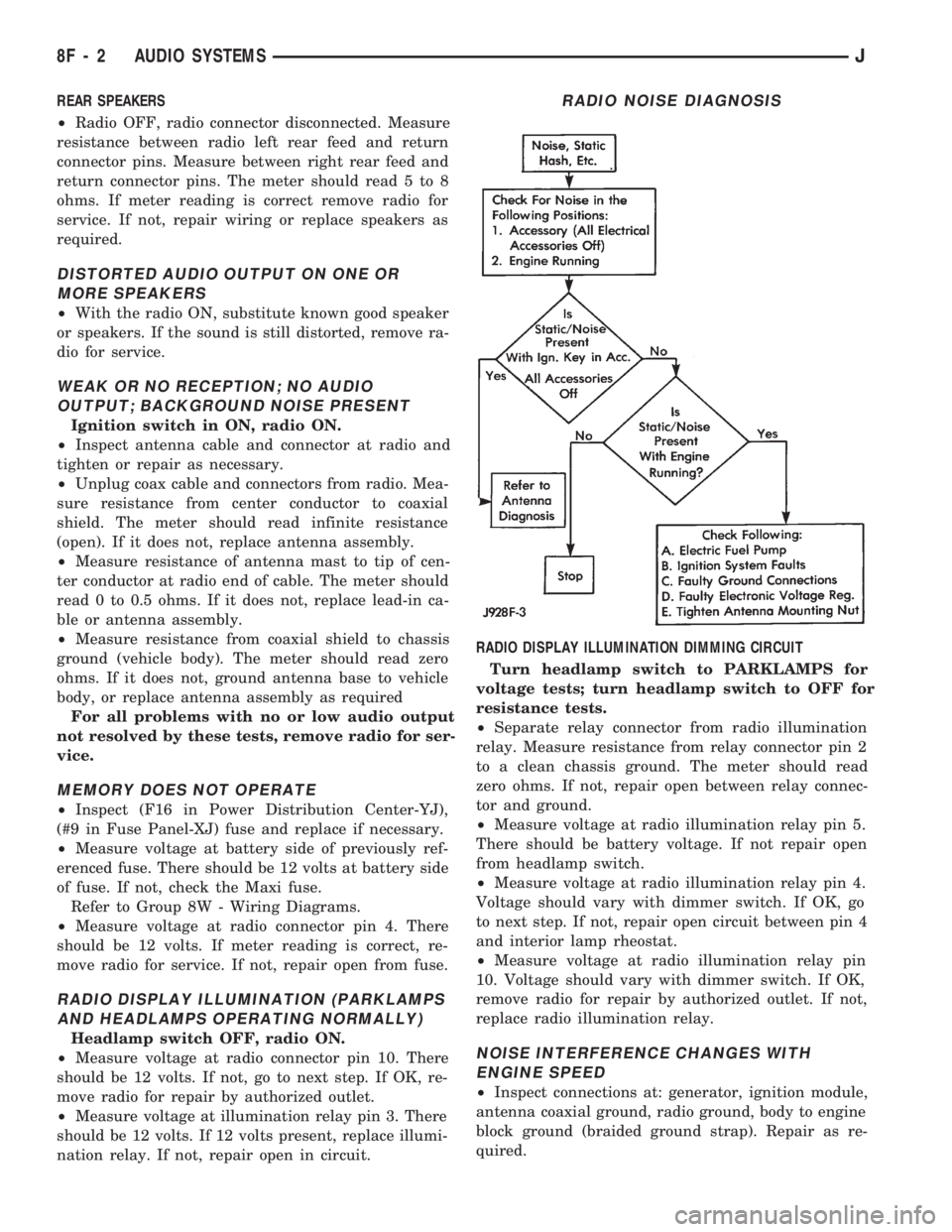

RADIO NOISE DIAGNOSIS

8F - 2 AUDIO SYSTEMSJ

Page 386 of 1784

HORNS

CONTENTS

page page

GENERAL INFORMATION.................. 1

HORN SWITCH (HORN PAD) REPLACEMENT . . 3

TORQUE SPECIFICATIONS................. 3XJ ..................................... 1

YJ ..................................... 2

GENERAL INFORMATION

For XJ/YJ vehicles battery voltage is applied to the

horn relay through a fuse.

When the horn switch is depressed, the horn relay

is grounded, pulling the contact closed and providing

battery voltage to the horns.

A slip ring and brush arrangement in the steering

wheel allows the switch circuit to maintain contact

while allowing rotation of the steering wheel.On XJ models, a cadmium-plated ground

screw is used to attach the horn(s) to the body.

Do not substitute other types of ground screws

as they may become corroded and cause a loss

of ground.

XJ

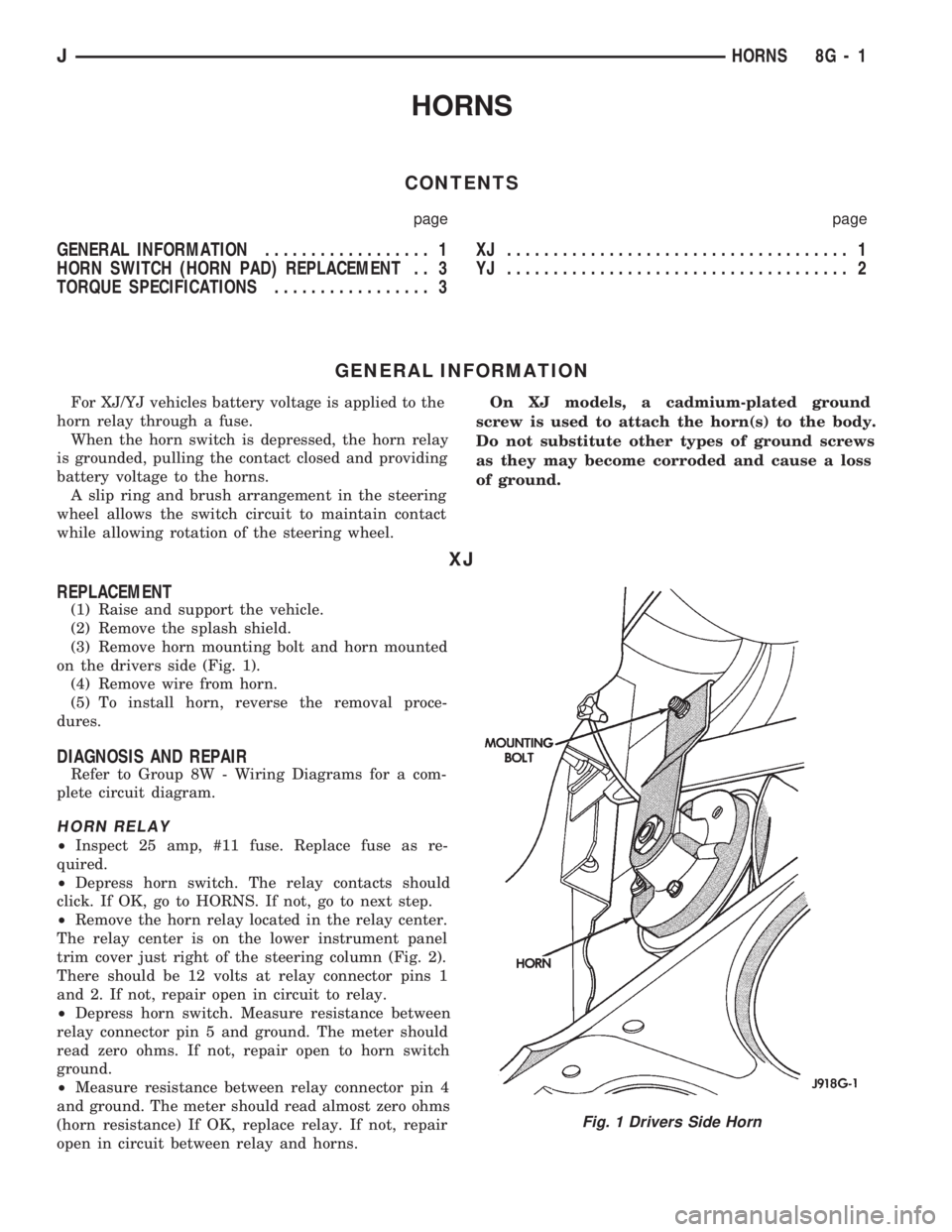

REPLACEMENT

(1) Raise and support the vehicle.

(2) Remove the splash shield.

(3) Remove horn mounting bolt and horn mounted

on the drivers side (Fig. 1).

(4) Remove wire from horn.

(5) To install horn, reverse the removal proce-

dures.

DIAGNOSIS AND REPAIR

Refer to Group 8W - Wiring Diagrams for a com-

plete circuit diagram.

HORN RELAY

²Inspect 25 amp, #11 fuse. Replace fuse as re-

quired.

²Depress horn switch. The relay contacts should

click. If OK, go to HORNS. If not, go to next step.

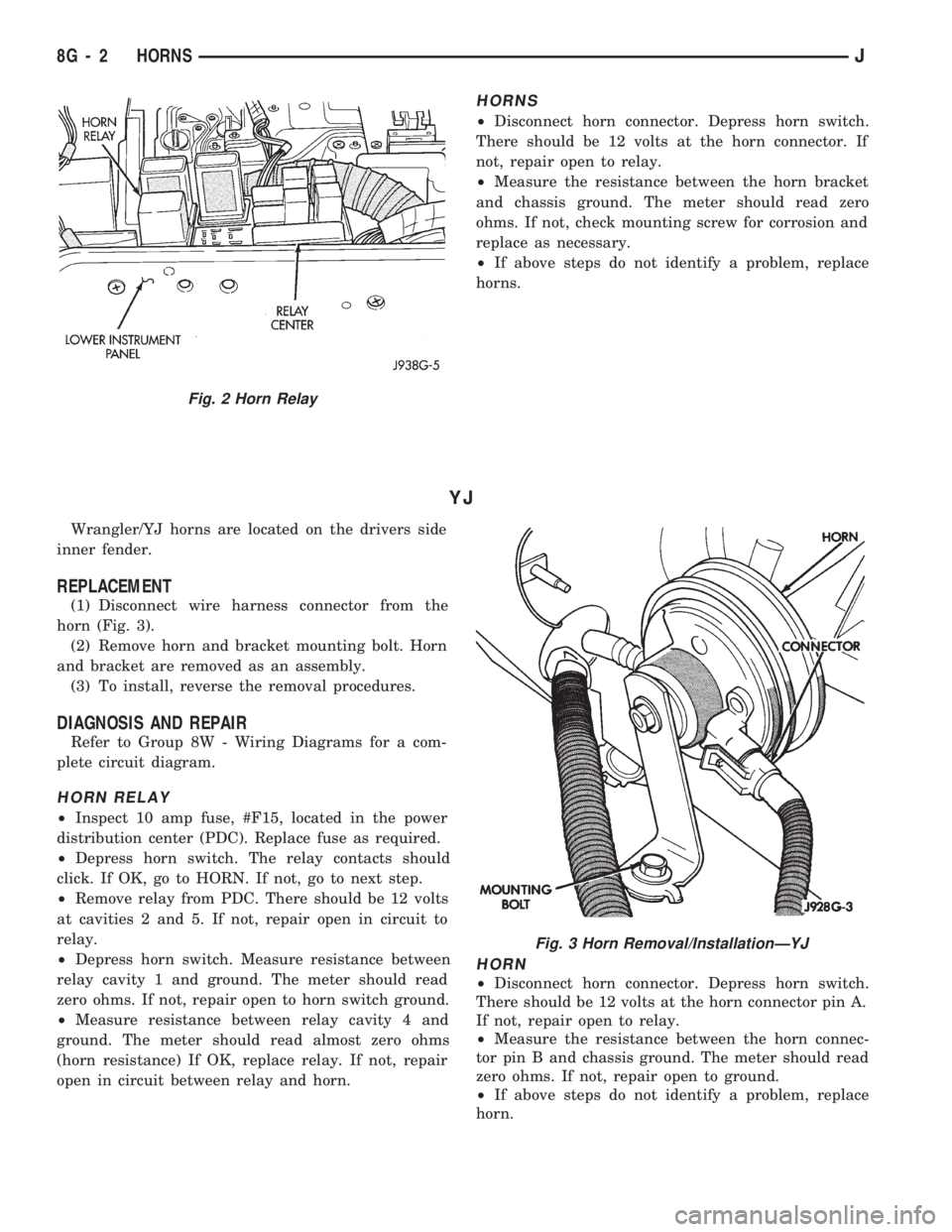

²Remove the horn relay located in the relay center.

The relay center is on the lower instrument panel

trim cover just right of the steering column (Fig. 2).

There should be 12 volts at relay connector pins 1

and 2. If not, repair open in circuit to relay.

²Depress horn switch. Measure resistance between

relay connector pin 5 and ground. The meter should

read zero ohms. If not, repair open to horn switch

ground.

²Measure resistance between relay connector pin 4

and ground. The meter should read almost zero ohms

(horn resistance) If OK, replace relay. If not, repair

open in circuit between relay and horns.

Fig. 1 Drivers Side Horn

JHORNS 8G - 1

Page 387 of 1784

HORNS

²Disconnect horn connector. Depress horn switch.

There should be 12 volts at the horn connector. If

not, repair open to relay.

²Measure the resistance between the horn bracket

and chassis ground. The meter should read zero

ohms. If not, check mounting screw for corrosion and

replace as necessary.

²If above steps do not identify a problem, replace

horns.

YJ

Wrangler/YJ horns are located on the drivers side

inner fender.

REPLACEMENT

(1) Disconnect wire harness connector from the

horn (Fig. 3).

(2) Remove horn and bracket mounting bolt. Horn

and bracket are removed as an assembly.

(3) To install, reverse the removal procedures.

DIAGNOSIS AND REPAIR

Refer to Group 8W - Wiring Diagrams for a com-

plete circuit diagram.

HORN RELAY

²Inspect 10 amp fuse, #F15, located in the power

distribution center (PDC). Replace fuse as required.

²Depress horn switch. The relay contacts should

click. If OK, go to HORN. If not, go to next step.

²Remove relay from PDC. There should be 12 volts

at cavities 2 and 5. If not, repair open in circuit to

relay.

²Depress horn switch. Measure resistance between

relay cavity 1 and ground. The meter should read

zero ohms. If not, repair open to horn switch ground.

²Measure resistance between relay cavity 4 and

ground. The meter should read almost zero ohms

(horn resistance) If OK, replace relay. If not, repair

open in circuit between relay and horn.

HORN

²Disconnect horn connector. Depress horn switch.

There should be 12 volts at the horn connector pin A.

If not, repair open to relay.

²Measure the resistance between the horn connec-

tor pin B and chassis ground. The meter should read

zero ohms. If not, repair open to ground.

²If above steps do not identify a problem, replace

horn.

Fig. 2 Horn Relay

Fig. 3 Horn Removal/InstallationÐYJ

8G - 2 HORNSJ

Page 402 of 1784

TURN SIGNALS AND HAZARD WARNING FLASHER

CONTENTS

page page

HAZARD LAMPSÐXJ.................... 1

HAZARD LAMPSÐYJ.................... 2

TURN SIGNALSÐXJ..................... 1TURN SIGNALSÐYJ..................... 2

TURN/HAZARD SWITCH REPLACEMENT - ALL

MODELS............................. 3

TURN SIGNALSÐXJ

Refer to Section 8W - Wiring Diagrams for cir-

cuit wiring diagram.

DESCRIPTION

With the turn signal lever in its up or down posi-

tion and the ignition switch in ACCESSORY or ON,

current flows through the:

²turn/hazard switch

²selected turn indicator bulb

²front and rear turn signal bulbs

²and the front side marker bulb.

With the headlamps OFF, the turn and front side

marker lamps flash in unison.With the headlamps

ON, the turn and front side marker lamps flash al-

ternately.

DIAGNOSISÐTURN SIGNAL INOPERATIVE

(1) A turn signal indicator that does not flash usu-

ally indicates a burned out turn signal bulb. Check

for and replace if defective. System should now func-

tion properly. If not, go to next step.

High generator output voltage can burn out

lamps rapidly.(2) Remove and inspect 20 amp #8 fuse. Replace if

necessary. If OK, go to next step.

(3) Remove turn flasher, light blue can, located in

upper left corner of fuse block.

(4) Turn ignition switch to ACCESSORY. Check

for battery voltage at flasher bottom cavity on fuse

block. If OK, go to next step. If not, repair open cir-

cuit in wiring between turn flasher and #8 fuse.

(5) Turn ignition switch to ACCESSORY. Move

turn signal lever up or down. Replace turn flasher

with known good flasher. The lamps should flash. If

not, replace original flasher and go to next step.

(6) Turn ignition switch to OFF. Follow procedure

for turn/hazard switch replacement to locate steering

column connector. Unplug connector.

(7) Turn ignition switch to ACCESSORY. Check

for battery voltage at connector terminal L. If OK,

replace turn/hazard switch and check that lamps

flash. If not, repair open circuit in wiring between

turn flasher and steering column connector terminal

L.

HAZARD LAMPSÐXJ

Refer to Section 8W - Wiring Diagrams for cir-

cuit wiring diagram.

DESCRIPTION

With the hazard switch ON, current flows through

the:

²hazard flasher

²the turn/hazard switch

²two front turn signal bulbs

²two rear turn signal bulbs

²two front side marker bulbs

²and two turn indicator bulbs.

All of these bulbs will flash on and off.

DIAGNOSISÐHAZARD LAMPS INOPERATIVE

(1) Inspect 20 amp #F13 fuse in Power Distribu-

tion Center (PDC). The PDC is located in the engine

compartment, passenger side. For location of fuse,check underside of PDC cover. Replace if necessary.

If OK, go to next step.

(2) Remove hazard flasher (tin can) located in fuse

block.

(3) Check for battery voltage at the terminal on

the right (3 o'clock). If OK, go to next step. If not, re-

pair open circuit in wiring between #F13 fuse and

hazard flasher right terminal.

(4) Replace hazard flasher with known good

flasher. Activate hazard warning switch. Lamps

should flash. If not, replace original flasher and go to

next step.

(5) Follow procedure for turn/hazard switch re-

placement to locate steering column connector. Un-

plug connector.

(6) Check for battery voltage at connector terminal

K. If OK, replace turn/hazard switch. If not, repair

open circuit in wiring between hazard flasher and

steering column connector terminal K.

JTURN SIGNALS AND HAZARD WARNING FLASHER 8J - 1

Page 403 of 1784

TURN SIGNALSÐYJ

Refer to Section 8W - Wiring Diagrams for cir-

cuit wiring diagram.

DESCRIPTION

With the turn signal lever in its up or down posi-

tion and the ignition switch in ACCESSORY or ON,

current flows through the:

²turn/hazard switch

²selected turn indicator bulb

²front and rear turn signal bulbs

²front side marker bulb

With the headlamps OFF, the turn and side

marker lamps flash in unison.With the headlamps

ON, the turn and side marker lamps flash alter-

nately.

DIAGNOSINGÐTURN SIGNAL INOPERATIVE

(1) A turn signal indicator that does not flash usu-

ally indicates a burned out turn signal bulb. Check

for and replace if defective. System should now func-

tion properly. If not, go to next step.

High generator output voltage can burn out

lamps rapidly.

(2) Locate fuse block under driver's side of instru-

ment panel.(3) Remove and inspect 15 amp #4 fuse. Replace if

necessary. If OK, go to next step.

(4) Remove turn flasher, light blue can, located in

fuse block.

(5) Turn ignition switch to ACCESSORY. Check

for battery voltage at cavity on left (closest to hazard

flasher can). If OK, go to next step. If not, repair

open circuit in wiring between turn flasher and #4

fuse.

(6) Turn ignition switch to ACCESSORY. Move

turn signal lever up or down. Replace turn flasher

with known good flasher. The lamps should flash. If

not, replace original flasher and go to next step.

(7) Turn ignition switch to OFF. Follow procedure

for turn/hazard switch replacement to locate steering

column connector. Unplug connector.

(8) Turn ignition switch to ACCESSORY. Check

for battery voltage at connector terminal L. If OK,

replace turn/hazard switch. If not, repair open circuit

in wiring between turn flasher and steering column

connector terminal L.

HAZARD LAMPSÐYJ

Refer to Section 8W - Wiring Diagrams for cir-

cuit wiring diagram.

DESCRIPTION

With the hazard switch ON, current flows through

the:

²hazard flasher

²turn/hazard switch

²two front turn signal bulbs

²two rear turn signal bulbs

²two front side marker bulbs

²two turn indicator bulbs.

All of these bulbs will flash on and off.

DIAGNOSISÐHAZARD LAMPS INOPERATIVE

(1) Inspect 20 amp #F5 fuse in Power Distribution

Center (PDC). The PDC is located in the engine com-

partment, passenger side. For location of fuse, check

underside of PDC cover. Replace if necessary. If OK,

go to next step.(2) Remove hazard flasher (tin can) located in fuse

block.

(3) Check for battery voltage at the terminal on

the left. If OK, go to next step. If not, repair open cir-

cuit in wiring between #F5 fuse and hazard flasher

left terminal.

(4) Replace hazard flasher with known good

flasher. Activate hazard warning switch. Lamps

should flash. If not, replace original flasher and go to

next step.

(5) Follow procedure for turn/hazard switch re-

placement to locate steering column connector. Un-

plug connector.

(6) Check for battery voltage at connector terminal

K. If OK, replace turn/hazard switch. If not, repair

open circuit in wiring between hazard flasher and

steering column connector terminal K.

8J - 2 TURN SIGNALS AND HAZARD WARNING FLASHERJ

Page 408 of 1784

WINDSHIELD WIPERS

CONTENTS

page page

WIPER CONTROL SWITCH REPLACEMENT . . 15

WIPER SWITCH TESTING................ 19XJ .................................... 1

YJ .................................... 8

XJ

INDEX

page page

Diagnosing Rear Wiper..................... 6

Diagnosing Rear Wiper Washer.............. 6

Diagnosing Windshield Washer (Intermittent)..... 5

Diagnosing Windshield Washer (Non-Intermittent) . 4

Diagnosing Windshield Wipers............... 11

Front Wipers/Washers...................... 1

Intermittent Wiper Module................... 5

Liftgate Wiper............................ 5Liftgate Wiper Switch Replacement............ 6

Rear Wiper/Washer Switch Testing............ 7

Torque Specifications XJ.................... 7

Washer Pump Replacement................. 6

Washer Pump ReplacementÐLeft Hand Drive.... 2

Washer Pump ReplacementÐRight Hand Drive . . 3

Windshield Wiper Motor.................... 2

FRONT WIPERS/WASHERS

GENERAL

Two-speed electric windshield wipers and electric

washers are standard equipment. An optional inter-

mittent wiper system provides a pause between wipe

cycles for use during conditions of very light precipi-

tation.

The windshield wipers can be operated with the

windshield wiper switch only when the ignition

switch is in the ON or ACCESSORY position. A cir-

cuit breaker located in the fuse block protects the cir-

cuitry of the wiper system.

WIPERS

The standard windshield wiper circuit contains

three components; wiper/washer switch, motor, and

front washer pump. Both standard and intermittent

circuits are the same, except that the intermittent

circuit requires a module and delay resistance in the

wiper switch. Both circuits receive battery feed from,

and are protected by a 5.5 amp circuit breaker.

In the standard wiper circuit, the switch connects

the motor directly to battery feed for low and high

speed operation. In the intermittent circuit, the

switch supplies battery feed to the intermittent wiper

module, which then supplies the motor. In the delay

position, the module is connected with the variable

resistor in the wiper switch. The value of the resis-tance is used by the module to charge a capacitor,

which triggers the amount of delay between wipes.

The wiper motor has an arrangement of brushes

providing the two wiper speeds. When the wipers are

turned off, the park switch maintains current to the

motor until the wipers reach the park position on the

windshield.

The park arm in the motor assembly is connected

to the park switch and is driven by the motor. When

the wiper switch is turned off, current flows through

the contact and the module to the motor until the

wipers reach the park position.

CAUTION: The wiper arms and blades must not be

moved manually from side to side or damage may

result.

WASHERS

With the washer switch ON, current flows through

the washer pump to ground. The front washer pump

runs as long as the driver holds the switch ON. On

standard wipers, the washer switch automatically

moves the wiper switch to LO when the washer is

turned on. On intermittent wipers, the wiper module

runs the wiper motor on LO. Turning the switch to

OFF stops the wipers.

If the washer knob is depressed while the wiper

switch is in the OFF position, the wiper control will

operate for approximately 3 wipes and automatically

turn OFF.

JWINDSHIELD WIPERS 8K - 1

Page 410 of 1784

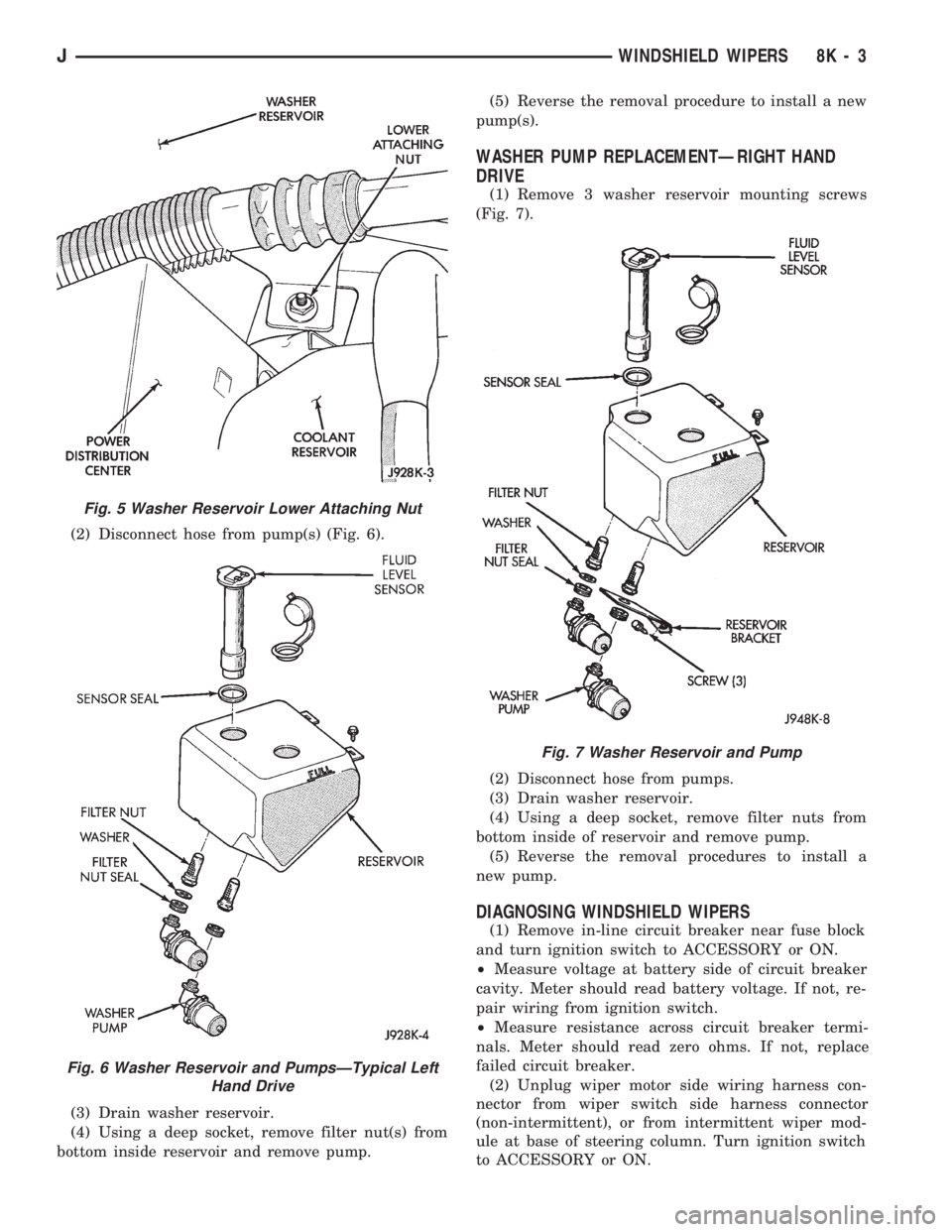

(2) Disconnect hose from pump(s) (Fig. 6).

(3) Drain washer reservoir.

(4) Using a deep socket, remove filter nut(s) from

bottom inside reservoir and remove pump.(5) Reverse the removal procedure to install a new

pump(s).

WASHER PUMP REPLACEMENTÐRIGHT HAND

DRIVE

(1) Remove 3 washer reservoir mounting screws

(Fig. 7).

(2) Disconnect hose from pumps.

(3) Drain washer reservoir.

(4) Using a deep socket, remove filter nuts from

bottom inside of reservoir and remove pump.

(5) Reverse the removal procedures to install a

new pump.

DIAGNOSING WINDSHIELD WIPERS

(1) Remove in-line circuit breaker near fuse block

and turn ignition switch to ACCESSORY or ON.

²Measure voltage at battery side of circuit breaker

cavity. Meter should read battery voltage. If not, re-

pair wiring from ignition switch.

²Measure resistance across circuit breaker termi-

nals. Meter should read zero ohms. If not, replace

failed circuit breaker.

(2) Unplug wiper motor side wiring harness con-

nector from wiper switch side harness connector

(non-intermittent), or from intermittent wiper mod-

ule at base of steering column. Turn ignition switch

to ACCESSORY or ON.

Fig. 5 Washer Reservoir Lower Attaching Nut

Fig. 6 Washer Reservoir and PumpsÐTypical Left

Hand Drive

Fig. 7 Washer Reservoir and Pump

JWINDSHIELD WIPERS 8K - 3

Page 413 of 1784

(2) Install the mounting screws.

(3) Connect the wiring harness.

(4) Install the pivot pin, seal, bezel and attaching

nut (Fig. 2). Torque nut to 4 Nzm (32 in. lbs.).

(5) Connect interior washer hose.

Lubricate the bezel nipples with a small amount

of water and then install the washer hoses.

(6) Install the liftgate trim panel.

(7) Install the wiper arm assembly and connect the

external washer hose to the bezel.

(8) Slide the clip along the hose until it is over

hose mount.

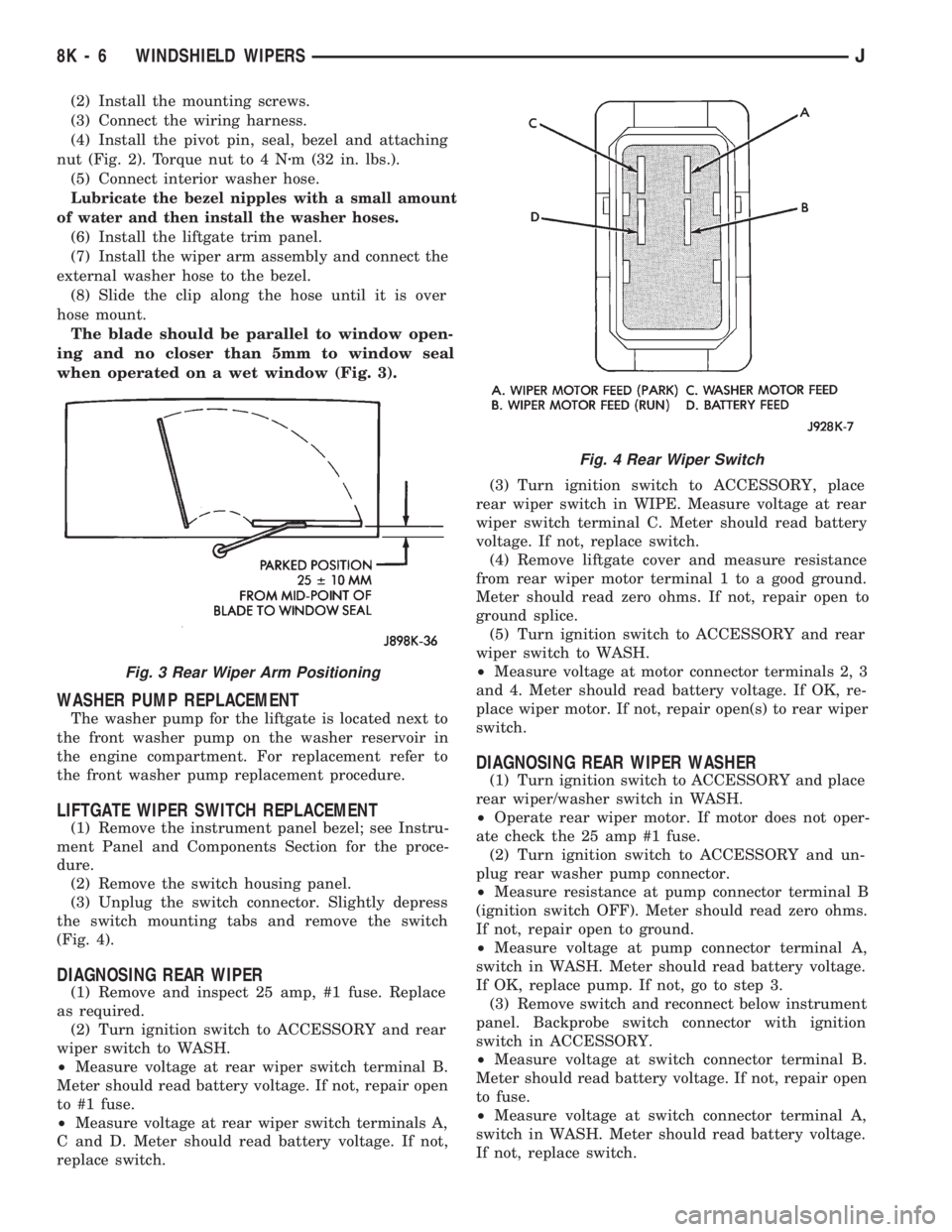

The blade should be parallel to window open-

ing and no closer than 5mm to window seal

when operated on a wet window (Fig. 3).

WASHER PUMP REPLACEMENT

The washer pump for the liftgate is located next to

the front washer pump on the washer reservoir in

the engine compartment. For replacement refer to

the front washer pump replacement procedure.

LIFTGATE WIPER SWITCH REPLACEMENT

(1) Remove the instrument panel bezel; see Instru-

ment Panel and Components Section for the proce-

dure.

(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch

(Fig. 4).

DIAGNOSING REAR WIPER

(1) Remove and inspect 25 amp, #1 fuse. Replace

as required.

(2) Turn ignition switch to ACCESSORY and rear

wiper switch to WASH.

²Measure voltage at rear wiper switch terminal B.

Meter should read battery voltage. If not, repair open

to #1 fuse.

²Measure voltage at rear wiper switch terminals A,

C and D. Meter should read battery voltage. If not,

replace switch.(3) Turn ignition switch to ACCESSORY, place

rear wiper switch in WIPE. Measure voltage at rear

wiper switch terminal C. Meter should read battery

voltage. If not, replace switch.

(4) Remove liftgate cover and measure resistance

from rear wiper motor terminal 1 to a good ground.

Meter should read zero ohms. If not, repair open to

ground splice.

(5) Turn ignition switch to ACCESSORY and rear

wiper switch to WASH.

²Measure voltage at motor connector terminals 2, 3

and 4. Meter should read battery voltage. If OK, re-

place wiper motor. If not, repair open(s) to rear wiper

switch.

DIAGNOSING REAR WIPER WASHER

(1) Turn ignition switch to ACCESSORY and place

rear wiper/washer switch in WASH.

²Operate rear wiper motor. If motor does not oper-

ate check the 25 amp #1 fuse.

(2) Turn ignition switch to ACCESSORY and un-

plug rear washer pump connector.

²Measure resistance at pump connector terminal B

(ignition switch OFF). Meter should read zero ohms.

If not, repair open to ground.

²Measure voltage at pump connector terminal A,

switch in WASH. Meter should read battery voltage.

If OK, replace pump. If not, go to step 3.

(3) Remove switch and reconnect below instrument

panel. Backprobe switch connector with ignition

switch in ACCESSORY.

²Measure voltage at switch connector terminal B.

Meter should read battery voltage. If not, repair open

to fuse.

²Measure voltage at switch connector terminal A,

switch in WASH. Meter should read battery voltage.

If not, replace switch.

Fig. 3 Rear Wiper Arm Positioning

Fig. 4 Rear Wiper Switch

8K - 6 WINDSHIELD WIPERSJ

Page 418 of 1784

(2) Remove the windshield holddown bolts in the

lower corners of the instrument panel.

(3) Remove wiper motor mounting screws (Fig. 4).

(4) Remove wiper motor harness retaining clip lo-

cated on bottom of windshield.

(5) Disconnect the wiper linkage drive arm (Fig. 5)

(6) Grasp the motor and pull the motor and drive

arm out of the access hole (Fig. 6).

(7) Pry the drive arm off the motor pivot. DO NOT

remove the pivot attaching nut (Fig. 7).

(8) Remove 2 screws holding intermittent wipe

module bracket to bottom of instrument panel.

(9) Reach up behind instrument panel and discon-

nect wiper motor harness.

(10) Remove wiper motor.

INSTALLATION

(1) Install wire harness through hole in top of in-

strument panel.

(2) Connect wiper motor connector behind instru-

ment panel.

(3) Install intermittent wipe module bracket to

bottom of instrument panel.

(4) Turn wipers on to allow motor to cycle to park

position.

(5) Install wiper linkage drive arm onto motor

(Fig. 8).

(6) Install motor and drive arm in the windshield

frame.

(7) Connect wiper linkage drive arm to pivot shaft

(Fig. 9).

(8) Install motor mounting screws. Tighten screws

to 10.5 Nzm (96 in. lbs.).

(9) Install wire harness retaining clip on bottom of

windshield.

Be sure wire harness is not pinched or cut when

windshield frame is rotated to upright position.

(10) Raise windshield to upright position and in-

stall left and right windshield holddown bolts.

(11) Install the necessary top components on wind-

shield frame.

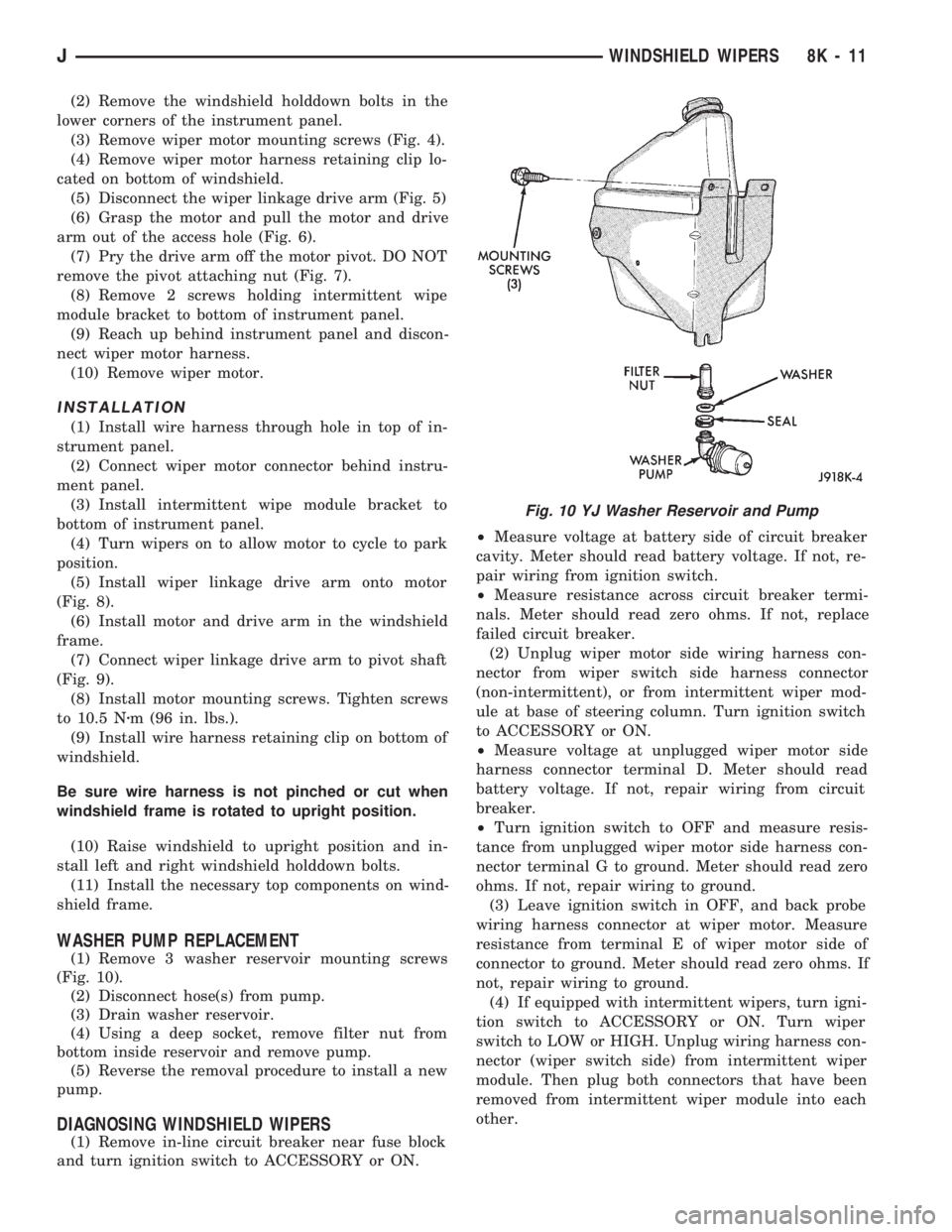

WASHER PUMP REPLACEMENT

(1) Remove 3 washer reservoir mounting screws

(Fig. 10).

(2) Disconnect hose(s) from pump.

(3) Drain washer reservoir.

(4) Using a deep socket, remove filter nut from

bottom inside reservoir and remove pump.

(5) Reverse the removal procedure to install a new

pump.

DIAGNOSING WINDSHIELD WIPERS

(1) Remove in-line circuit breaker near fuse block

and turn ignition switch to ACCESSORY or ON.²Measure voltage at battery side of circuit breaker

cavity. Meter should read battery voltage. If not, re-

pair wiring from ignition switch.

²Measure resistance across circuit breaker termi-

nals. Meter should read zero ohms. If not, replace

failed circuit breaker.

(2) Unplug wiper motor side wiring harness con-

nector from wiper switch side harness connector

(non-intermittent), or from intermittent wiper mod-

ule at base of steering column. Turn ignition switch

to ACCESSORY or ON.

²Measure voltage at unplugged wiper motor side

harness connector terminal D. Meter should read

battery voltage. If not, repair wiring from circuit

breaker.

²Turn ignition switch to OFF and measure resis-

tance from unplugged wiper motor side harness con-

nector terminal G to ground. Meter should read zero

ohms. If not, repair wiring to ground.

(3) Leave ignition switch in OFF, and back probe

wiring harness connector at wiper motor. Measure

resistance from terminal E of wiper motor side of

connector to ground. Meter should read zero ohms. If

not, repair wiring to ground.

(4) If equipped with intermittent wipers, turn igni-

tion switch to ACCESSORY or ON. Turn wiper

switch to LOW or HIGH. Unplug wiring harness con-

nector (wiper switch side) from intermittent wiper

module. Then plug both connectors that have been

removed from intermittent wiper module into each

other.

Fig. 10 YJ Washer Reservoir and Pump

JWINDSHIELD WIPERS 8K - 11

Page 421 of 1784

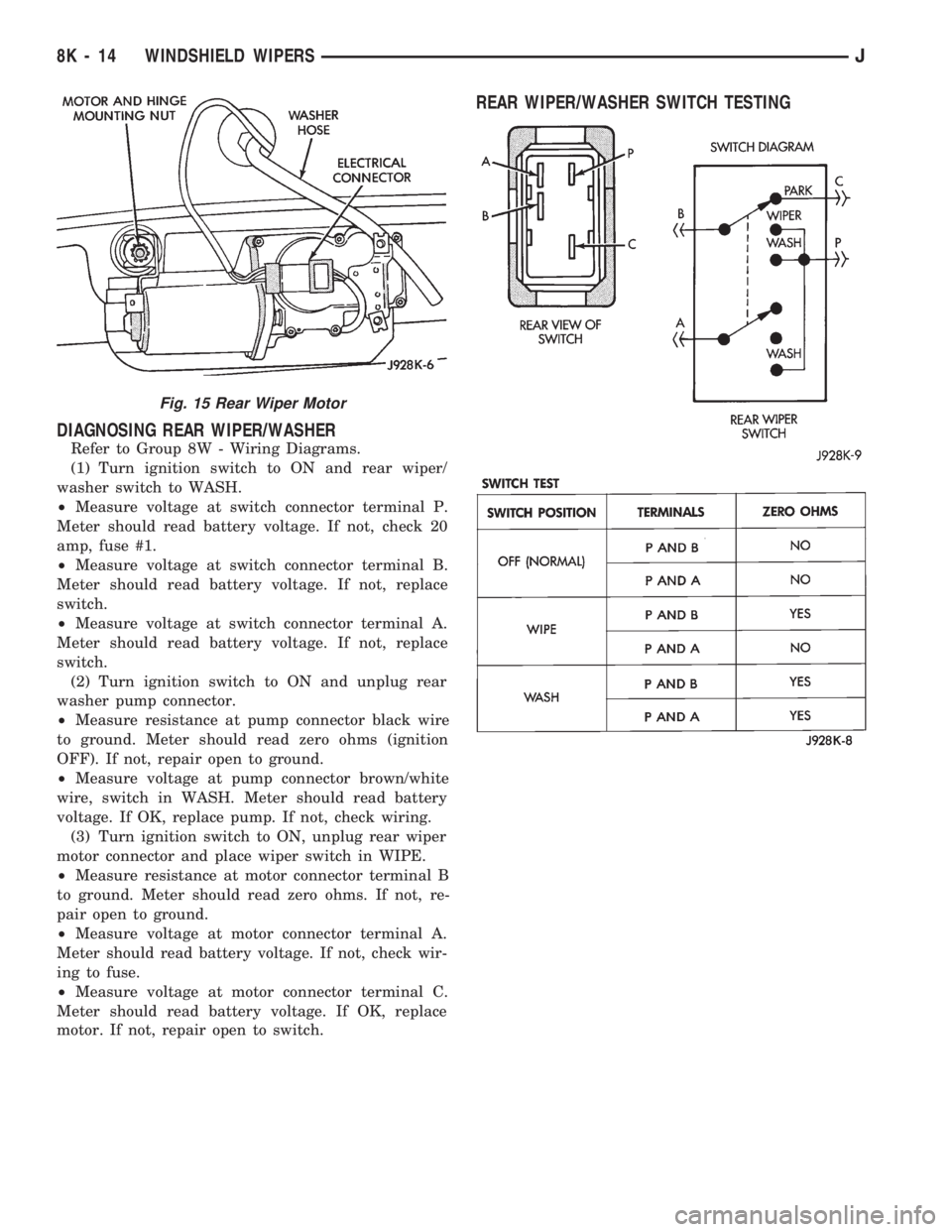

DIAGNOSING REAR WIPER/WASHER

Refer to Group 8W - Wiring Diagrams.

(1) Turn ignition switch to ON and rear wiper/

washer switch to WASH.

²Measure voltage at switch connector terminal P.

Meter should read battery voltage. If not, check 20

amp, fuse #1.

²Measure voltage at switch connector terminal B.

Meter should read battery voltage. If not, replace

switch.

²Measure voltage at switch connector terminal A.

Meter should read battery voltage. If not, replace

switch.

(2) Turn ignition switch to ON and unplug rear

washer pump connector.

²Measure resistance at pump connector black wire

to ground. Meter should read zero ohms (ignition

OFF). If not, repair open to ground.

²Measure voltage at pump connector brown/white

wire, switch in WASH. Meter should read battery

voltage. If OK, replace pump. If not, check wiring.

(3) Turn ignition switch to ON, unplug rear wiper

motor connector and place wiper switch in WIPE.

²Measure resistance at motor connector terminal B

to ground. Meter should read zero ohms. If not, re-

pair open to ground.

²Measure voltage at motor connector terminal A.

Meter should read battery voltage. If not, check wir-

ing to fuse.

²Measure voltage at motor connector terminal C.

Meter should read battery voltage. If OK, replace

motor. If not, repair open to switch.

REAR WIPER/WASHER SWITCH TESTING

Fig. 15 Rear Wiper Motor

8K - 14 WINDSHIELD WIPERSJ