fuse JEEP CHEROKEE 1994 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 428 of 1784

LAMPS

CONTENTS

page page

EXTERIOR LAMPS....................... 1

INTERIOR LAMPS...................... 19SPECIFICATIONS....................... 23

EXTERIOR LAMPS

INDEX

page page

Back-up/Rear Turn Signal/Tail Lamp Bulb

Replacement........................... 9

Center High Mounted Stop Lamp (CHMSL)ÐXJ . 10

Center High Mounted Stop Lamp (CHMSL)ÐYJ . 11

Daytime Running Lights (Canada Only)........ 16

DRL Module Replacement.................. 16

Fog Lamp Beam Adjustment................ 12

Fog Lamp Bulb/Element Replacement......... 13

Fog Lamp Replacement................... 15

Fog Lamp Service Information............... 12

Fog Lamp Switch Replacement.............. 14

Fog Lamp Trouble Diagnosis................ 12

Front Park/Turn Signal Lamp Bulb Replacement . . 8

Headlamp Beam Adjustment................. 3

Headlamp Bulb Replacement................ 3

Headlamp Delay Function Trouble DiagnosisÐXJ

Vehicles.............................. 16Headlamp Delay Module ReplacementÐXJ

Vehicles.............................. 16

Headlamp Dimmer Switch Replacement........ 6

Headlamp Switch Replacement............... 4

Headlamp Trouble DiagnosisÐXJ Vehicles...... 1

Headlamp Trouble DiagnosisÐYJ Vehicles...... 2

License Plate Lamp....................... 10

Sentinel Headlamp Delay ModuleÐXJ Vehicles . . 15

Service Information........................ 1

Side Marker Lamp Bulb Replacement.......... 7

Switch Tests............................. 2

Underhood Lamp Bulb Replacement.......... 18

Underhood Lamp Replacement.............. 18

Underhood Lamp Service Information......... 17

SERVICE INFORMATION

Exterior lamp circuits are comprised of the head-

lamp circuit, fog lamp circuit, and tail/side marker/

park lamp circuit. Battery voltage is controlled by

both the headlamp ON/OFF switch and headlamp

dimmer switch.

The dimmer switch functions as a fog lamp switch.

Voltage is applied to the fog lamp switch only when

the dimmer switch is in the low beam position.

HEADLAMP TROUBLE DIAGNOSISÐXJ VEHICLES

LOW AND HIGH BEAM INOPERATIVE BOTH

HEADLAMPS

(1) Place the headlamp switch in the ON position.

(2) Test the 40 amp fuse for continuity. If bad, re-

place fuse.

(3) Insert the test probe into terminal 5 of the

front lamp wire harness connector. Measure the re-

sistance from terminal 5 to body ground. The ohm-

meter should indicate zero ohms. If not OK, repair

the open circuit in the harness to body ground.(4) Disconnect the front lamp wire connector. Mea-

sure resistance between connector terminals 5 and 2.

Next measure between terminal 5 and 7. The ohm-

meter should indicate zero ohms for both measure-

ments. If not OK, replace the headlamp bulbs.

(5) Measure the voltage between the dimmer

switch wire connector terminal 2 and body ground.

The voltmeter should indicate battery voltage. If not

OK, continue with the next step.

The dimmer switch is integral with the turn

signal and is located on the steering column.

The dimmer switch switches the headlamp beam

when the turn signal lever is pulled rearward.

(6) Disconnect the dimmer switch wire connector

and place the headlamp switch in the OFF position.

Measure the resistance from terminal 2 to vehicle

body ground. The ohmmeter should indicate infinite

resistance. If OK, replace the headlamp switch and

continue with the next step. If not OK, repair the

short circuit in the wire harness that leads to termi-

nal 2.

JLAMPS 8L - 1

Page 429 of 1784

(7) Measure the resistance from the dimmer switch

wire harness connector terminal 1 to vehicle body

ground. The ohmmeter should indicate zero ohms. If

OK, continue with the next step. If not OK, repair

the short circuit in the wire harness that leads to

terminal 1.

(8) Measure the resistance from the dimmer switch

wire harness connector terminal 3 to vehicle body

ground. The ohmmeter should indicate zero ohms. If

OK, test the dimmer switch. Replace, if defective.

Connect the wire harness connector to the dimmer

switch. If not defective, repair the short circuit in the

wire harness that leads to terminal 3.

LOW OR HIGH BEAM INOPERATIVE BOTH

HEADLAMPS

(1) Place the headlamp switch in the OFF position.

Disconnect the dimmer switch wire harness connec-

tor.

(2) Measure the resistance from the dimmer switch

connector terminal 1 to body ground. The ohmmeter

should indicate zero ohms. If not OK, repair the open

circuit in the wire harness that leads to the head-

lamp bulbs.

(3) Measure the resistance from the dimmer switch

connector terminal 3 to vehicle body ground. The

ohmmeter should indicate zero ohms. If OK, replace

the dimmer switch. If not OK, repair the open circuit

in the wire harness that leads to headlamp bulbs.

HEADLAMP TROUBLE DIAGNOSISÐYJ VEHICLES

(1) Place the headlamp switch in the ON position.

(2) Place the headlamp dimmer switch in the

HIGH or LOW position.

(3) Disconnect the wire harness connectors from

the headlamp bulbs.

(4) If applicable, measure voltage between each

headlamp bulb wire connector terminal B and vehi-

cle body ground. The voltmeter should indicate bat-

tery voltage. If not OK, repair the open circuit in

wire harness between connector and dimmer switch.

(5) If applicable, measure the voltage between each

headlamp bulb connector terminal C and body

ground. The voltmeter should indicate battery volt-

age. If not OK, repair the open circuit in the wire

harness between the connector and the dimmer

switch.

(6) Measure the resistance from each headlamp

bulb connector terminal A to body ground. The ohm-

meter should indicate zero ohms. If not OK, repair

the open circuit in the wire harness between the con-

nectors and vehicle body ground.

SWITCH TESTS

HEADLAMPÐALL VEHICLES

(1) Refer to the applicable wiring diagram for ter-

minal reference.(2) Place the headlamp switch in the ON position.

(3) Measure the voltage between the headlamp

switch connector voltage supply terminal and vehicle

body ground. The voltmeter should indicate battery

voltage. If not OK, repair the open circuit in the wire

harness between the fuse and the switch connector

terminal.

(4) Measure the voltage between the headlamp

switch connector battery voltage OUT terminal and

vehicle body ground. The voltmeter should indicate

battery voltage. If not OK, replace the headlamp

switch.

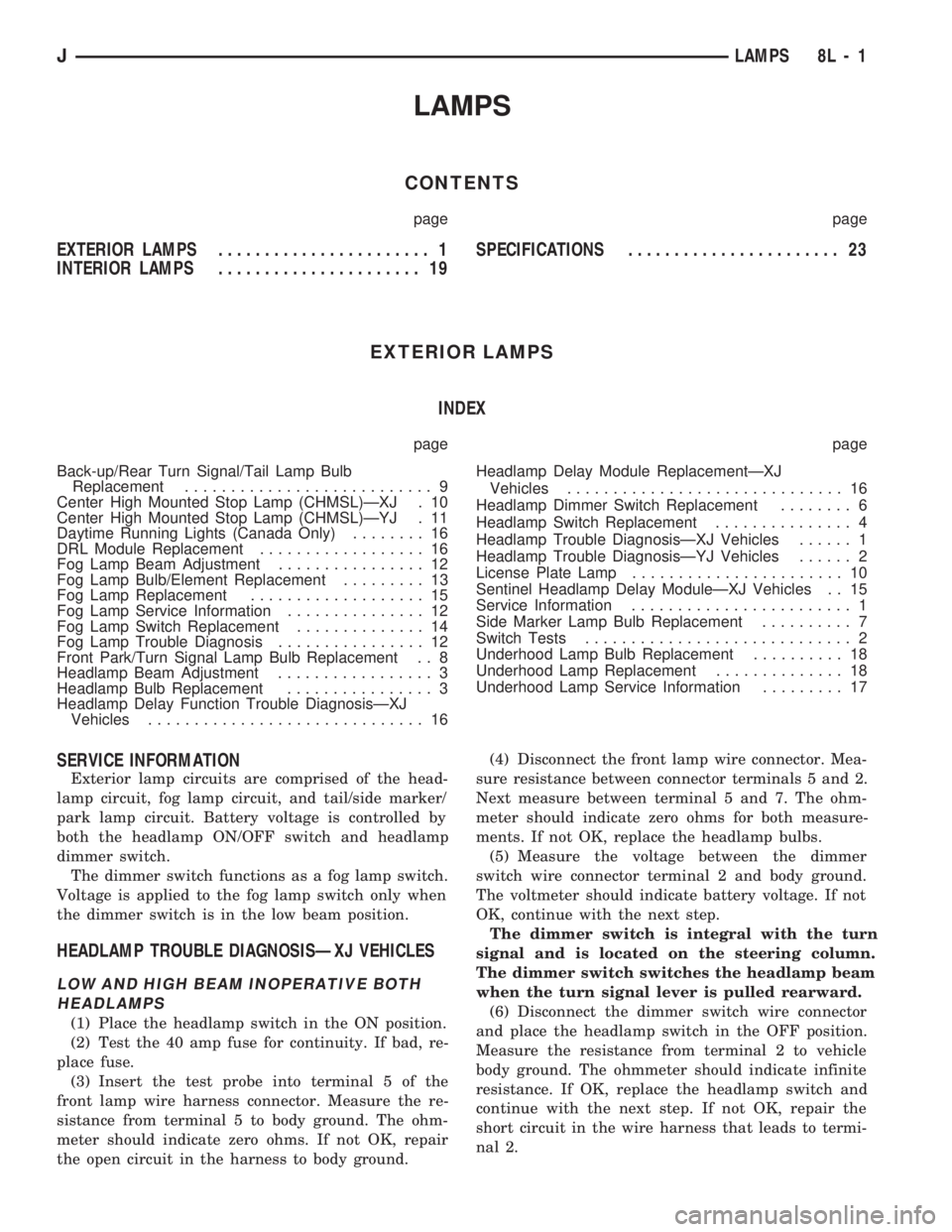

DIMMER SWITCHÐALL VEHICLES

(1) Place the headlamp switch in the ON position.

Place the dimmer switch in the HIGH or LOW beam

position, as applicable.

(2) Measure the voltage between the dimmer

switch connector voltage supply terminal and vehicle

body ground. The voltmeter should indicate battery

voltage. If not OK, repair the open circuit in the wire

harness between the headlamp switch and the dim-

mer switch.

(3) Place the dimmer switch in the LOW beam po-

sition. Measure the voltage between the dimmer

switch connector low beam voltage OUT terminal

and body ground. The voltmeter should indicate bat-

tery voltage. If not OK, replace the dimmer switch.

(4) Place the dimmer switch in the HIGH beam po-

sition. Measure the voltage between the dimmer

switch connector high beam voltage OUT terminal

and body ground. Voltmeter should indicate battery

voltage. If not OK, replace dimmer switch.

Fig. 1 Headlamp Dimmer Switch Terminals

8L - 2 LAMPSJ

Page 443 of 1784

switch is turned OFF. The driver engages the module

by turning the ignition switch OFF, then turning the

headlamps OFF.

The headlamp delay module is located behind the

I/P next to the headlamp switch.

HEADLAMP DELAY MODULE REPLACEMENTÐXJ

VEHICLES

The headlamp delay module is attached to the in-

side of the instrument panel to the right of the head-

lamp switch.

REMOVAL

(1) Remove the lower instrument panel.

(2) Remove the screw that attaches the module to

the inside of the instrument panel.

(3) Disconnect the wire harness connector and re-

move the module from the instrument panel.

INSTALLATION

(1) Position the module inside the I/P and connect

the wire harness connector to the module.

(2) Install the screw that attaches the module to

the inside of the instrument panel.(3) Remove the lower instrument panel.

HEADLAMP DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ VEHICLES

DELAY FUNCTION INOPERATIVE

(1) Remove, inspect and test the HD LP DLY fuse.

Replace if defective.

(2) Remove the delay module from the I/P. Do not

disconnect the wire harness connector. Turn the igni-

tion switch to the RUN position. Place the headlamp

switch in headlamps ON position. Turn the ignition

to the OFF position for a resistance test.

(3) Measure the resistance from the delay module

terminal 4 to vehicle body ground. The ohmmeter

should indicate zero ohms. If not, repair the open cir-

cuit in the wire harness to vehicle body ground.

(4) Measure the voltage between the delay module

terminal 8 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the instrument

cluster indicator connector terminal 14.

(5) Measure the voltage between the delay module

terminal 6 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the headlamp

switch.

(6) Measure the voltage between the delay module

terminal 2 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the fuse.

DAYTIME RUNNING LIGHTS (CANADA ONLY)

SERVICE INFORMATION

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. The headlamps are illuminated when the

ignition switch is turned to the ON position. The

DRL module receives a vehicle-moving signal from

the vehicle speed sensor. This provides a constant

headlamps-oncondition as long as the vehicle is

moving. The lamps are illuminated at less than 50

percent of normal intensity.

DRL MODULE REPLACEMENT

REMOVALÐXJ VEHICLES

The Daytime Running Lights (DRL) module is lo-

cated on the right fender inner panel adjacent to the

dash panel (Fig. 45).

(1) Disconnect the wire harness connector from the

module.

(2) Remove the screws that attach the module to

the fender inner panel.

(3) Remove the module from the fender inner

panel.

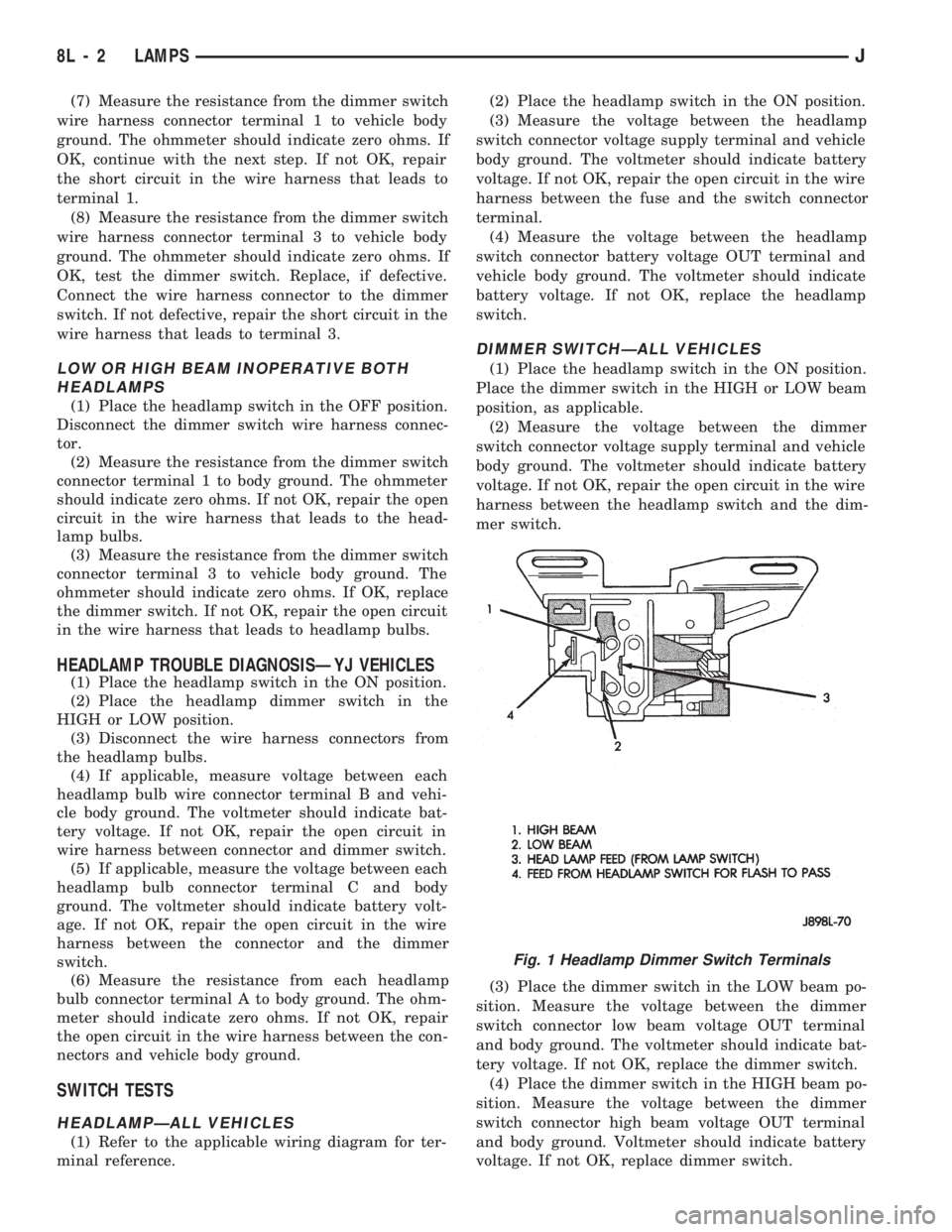

Fig. 43 Rectangular-Shaped Fog Lamp

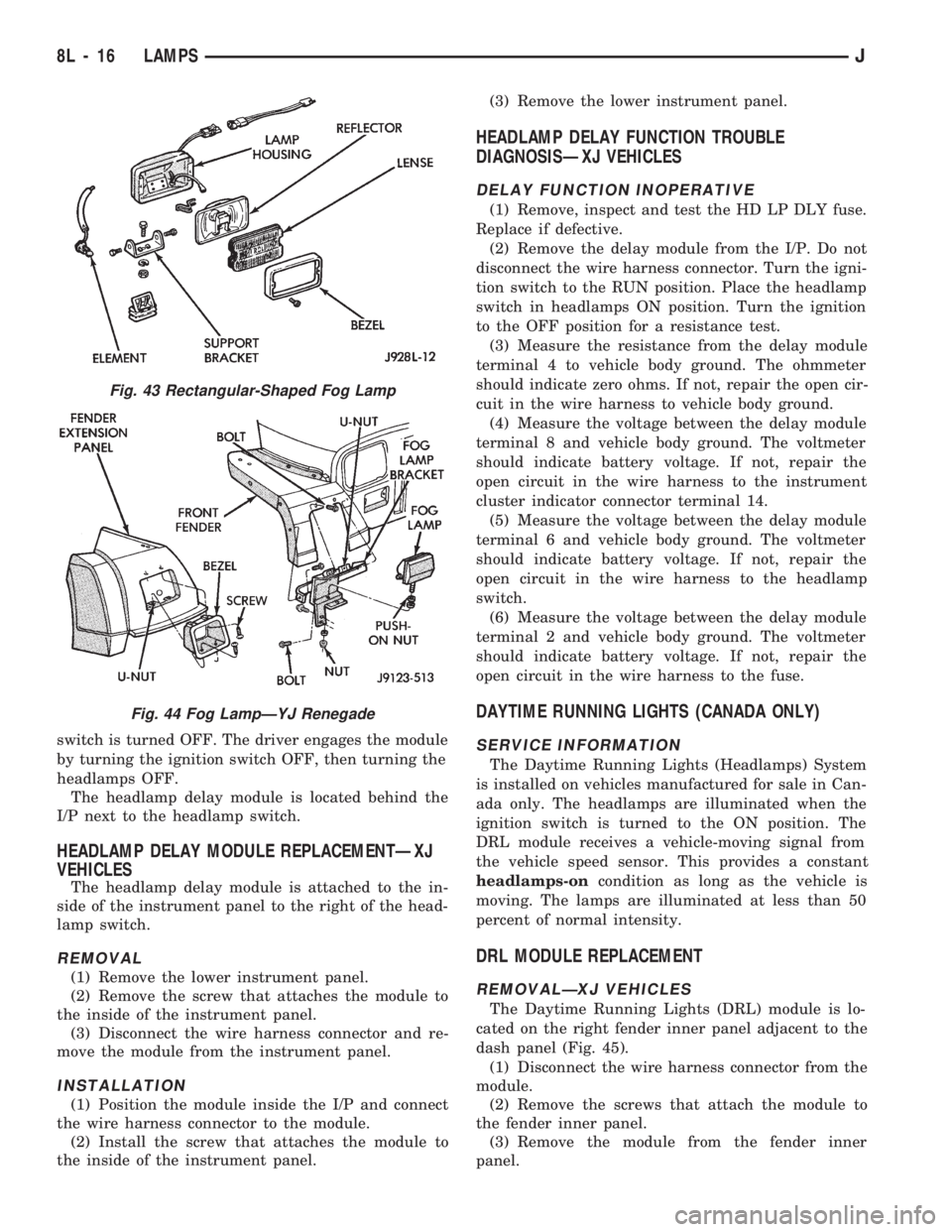

Fig. 44 Fog LampÐYJ Renegade

8L - 16 LAMPSJ

Page 446 of 1784

INTERIOR LAMPS

INDEX

page page

Dome Lamp Replacement.................. 20

Dome/Courtesy Lamp Service Information...... 19

Dome/Courtesy Lamp Trouble Diagnosis....... 19

Hardtop Dome/Cargo Lamp Bulb ReplacementÐYJ

Vehicles.............................. 20Illuminated Entry System Service Information . . . 20

Illuminated Entry System Trouble Diagnosis.... 21

Lighted Vanity Mirror...................... 19

Lighted Vanity Mirror Trouble Diagnosis....... 19

Overhead ConsoleÐXJ Vehicles............. 20

DOME/COURTESY LAMP SERVICE INFORMATION

XJ VEHICLES

Voltage is applied at all times via the dome lamp

fuse to each of the interior lamp bulbs. The interior

lamp bulbs illuminate when they are connected to

body ground via the switch:

²headlamp switch,

²glove box switch,

²door pillar switch, and

²liftgate switch (if the cargo lamp is ON.)

If equipped with Security Alarm Module, refer to

Group 8QÐVehicle Theft Security System.

YJ VEHICLES

The dome/cargo and courtesy lamps are controlled

via ON/OFF switches. The ON/OFF switches are in

the lamp ground circuits. Voltage via the dome/cour-

tesy lamp fuse is applied directly to the lamp bulbs.

When either door is opened, the door pillar switch

contacts close and provide a direct path to vehicle

body ground.

The cargo/cargo and courtesy lamps can also be

turned on via the interior lamp illumination rheo-

stat.

DOME/COURTESY LAMP TROUBLE DIAGNOSIS

ALL LAMPS INOPERATIVE

(1) Rotate the headlamp switch rheostat clockwise.

The lamps should light. If not OK, remove, inspect

and test the dome lamp fuse. Replace if bad.

(2) If the fuse is OK, repair the open circuit in the

wire harness to vehicle body ground.

ONE LAMP INOPERATIVE

(1) Measure the resistance across the bulb holder

terminals. The ohmmeter should indicate zero ohms.

If not, replace the bulb.

(2) Measure the voltage between the voltage side

of the bulb holder and vehicle body ground. The volt-

meter should indicate battery voltage. If not, repair

the open circuit in the wire harness to the splice.

LAMPS INOPERATIVE WITH ONE OR MORE

DOORS OPENED

(1) Remove the inoperative switch from the door

pillar and connect the switch wire directly to ground.

The lamp should light.

(2) If not, check for an open circuit in black

(ground) wire. Repair as necessary. If lamps still do

not light, replace the switch.

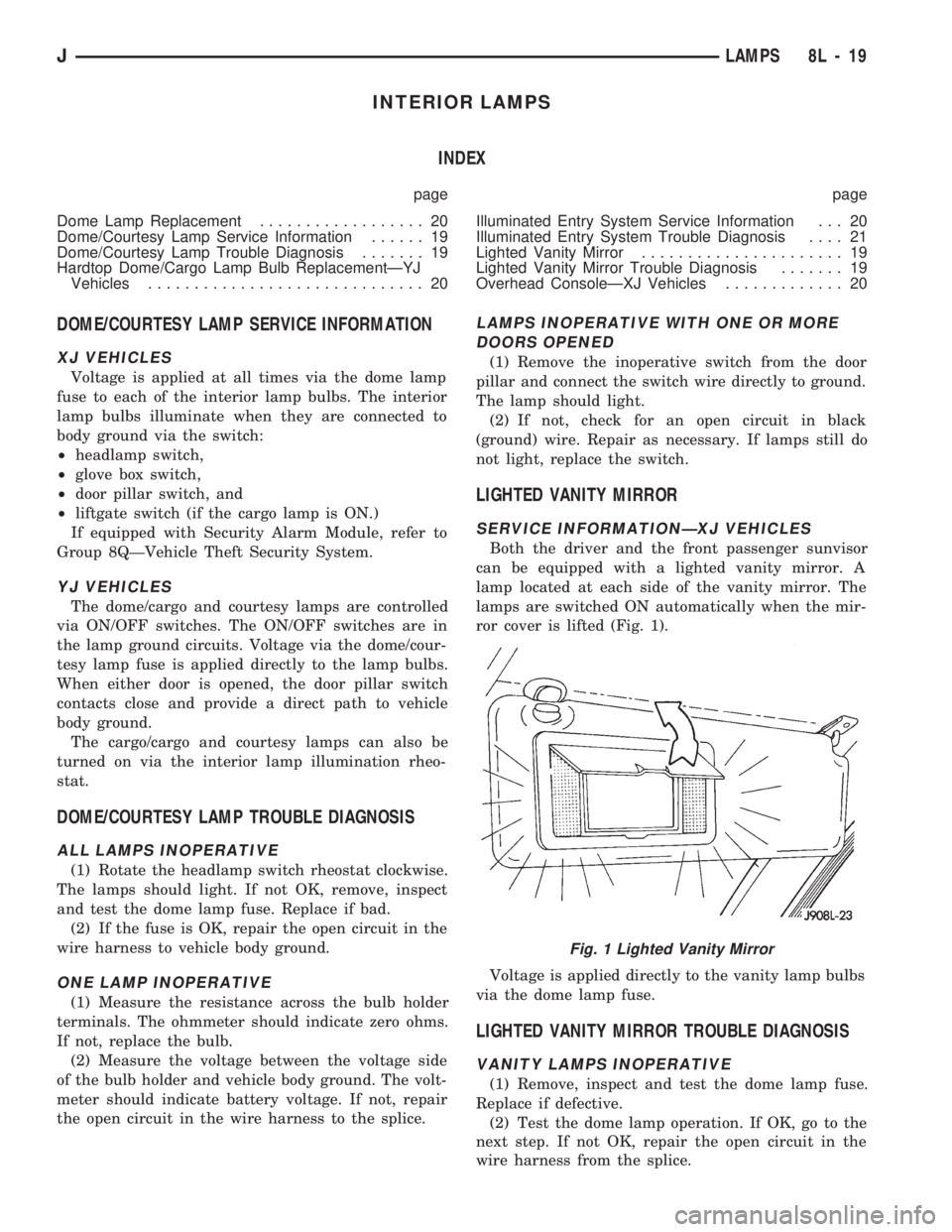

LIGHTED VANITY MIRROR

SERVICE INFORMATIONÐXJ VEHICLES

Both the driver and the front passenger sunvisor

can be equipped with a lighted vanity mirror. A

lamp located at each side of the vanity mirror. The

lamps are switched ON automatically when the mir-

ror cover is lifted (Fig. 1).

Voltage is applied directly to the vanity lamp bulbs

via the dome lamp fuse.

LIGHTED VANITY MIRROR TROUBLE DIAGNOSIS

VANITY LAMPS INOPERATIVE

(1) Remove, inspect and test the dome lamp fuse.

Replace if defective.

(2) Test the dome lamp operation. If OK, go to the

next step. If not OK, repair the open circuit in the

wire harness from the splice.

Fig. 1 Lighted Vanity Mirror

JLAMPS 8L - 19

Page 452 of 1784

REAR WINDOW DEFOGGER

CONTENTS

page page

GENERAL.............................. 1

XJ .................................... 4YJ .................................... 4

GENERAL

INDEX

page page

Diagnosis............................... 2

Rear Window Defogger Grid Repair........... 2Rear Window Defogger Grid Test............. 1

Switch Testing............................ 2

Using heating elements bonded to the rear window

glass, the rear defogger will clear condensation, frost

and light snow coverings from the rear window.

The horizontal grid lines and vertical bus bar lines,

printed and baked on inside surface of the rear win-

dow glass, comprise an electrical circuit. The electri-

cally conductive lines are composed of a silver-

ceramic material which when baked on glass

becomes bonded to the glass and is highly resistant

to abrasion.

The electrical current required to produce the heat

in the grid is supplied through a relay and driver op-

erated switch. When the switch is momentarily de-

pressed, the relay senses a voltage change. This

voltage change causes the relay to change state and

complete a circuit to energize the relay. Once the re-

lay energizes, the contacts close connecting the grid

to battery power.

On the XJ, the power circuit to the grid is pro-

tected by the 25 amp, #18 fuse in the fuse box.

Power for fuse #18 comes from the power distribu-

tion center, fuse #F10. Power for the relay is pro-

tected by the 20 amp, #8 fuse located in the fuse box.

On the YJ, the grid is protected by a 25 amp #6

fuse, located in the fuse box. Power for the relay is

protected by 15 amp #9 fuse, located in the fuse box.

To defog the rear window, momentarily depress the

rocker switch. A light on the rocker switch will illu-

minate indicating that the defogger is operating.

If the ignition switch is ON the first activation of

the defog/defrost feature will last for 10 minutes.

Succeeding activations will last for 5 minutes unless

the ignition switch is turned OFF; then it will recy-

cle back to 10 minutes for the first activation.To stop defogger operation, momentarily push the

switch a second time.

CAUTION: Use care when washing the inside of the

rear window to prevent damage to the defogger

heating elements. Use a soft cloth and a mild wash-

ing solution. Wiping motions should be parallel to

the heating elements. Also, keep all objects a safe

distance from the window to prevent damaging the

heating elements.

REAR WINDOW DEFOGGER GRID TEST

It is possible, that a break may exist or occur in an

individual grid line resulting in no current flow

through the line. When a grid has an open circuit,

the area of glass normally cleared by that grid re-

mains fogged or iced unless, and until it is cleared by

the adjacent grids.

With the engine running at idle, push the rear

window defogger switch to the ON position and re-

lease. The pilot lamp in the rocker switch should

light, indicating defogger operation.

Using a 12-volt DC voltmeter, contact the positive

lead to the feed side vertical bus element on the in-

side surface of the glass. Contact the negative lead to

the ground side bus element. Meter should read be-

tween 11 and 13 volts. Connect the negative lead of

the voltmeter to a good ground; the meter reading

should be constant.

Keep the negative lead connected to ground. Use

the positive lead and carefully contact each grid at

the approximate centerline of the window.

JREAR WINDOW DEFOGGER 8N - 1

Page 453 of 1784

A voltage drop of one-half the full amount, approx-

imately 6 volts, indicates a good grid or closed cir-

cuit.

A voltage drop of 12 volts at the centerline indi-

cates a break in the grid between the positive volt-

meter lead and the ground.

No voltage drop (0 volts) at the centerline indicates

a break in the grid between the centerline and the

voltage source or lead.

The exact location of the break can be pinpointed

by moving positive voltmeter lead to the left or right

along grid. An abrupt change in the voltage reading

will be noticed. The break is at that point in the

grid.

REAR WINDOW DEFOGGER GRID REPAIR

Locate the broken or open grid.

Use the grid repair kit (available as a service part)

by using the following procedure:

(1) Mark the location of the broken or open grid on

the exterior surface of the glass using a suitable

marking pencil.

(2) Lightly rub the area to be repaired (inside the

rear window) using fine steel wool. Clean the area

with alcohol.

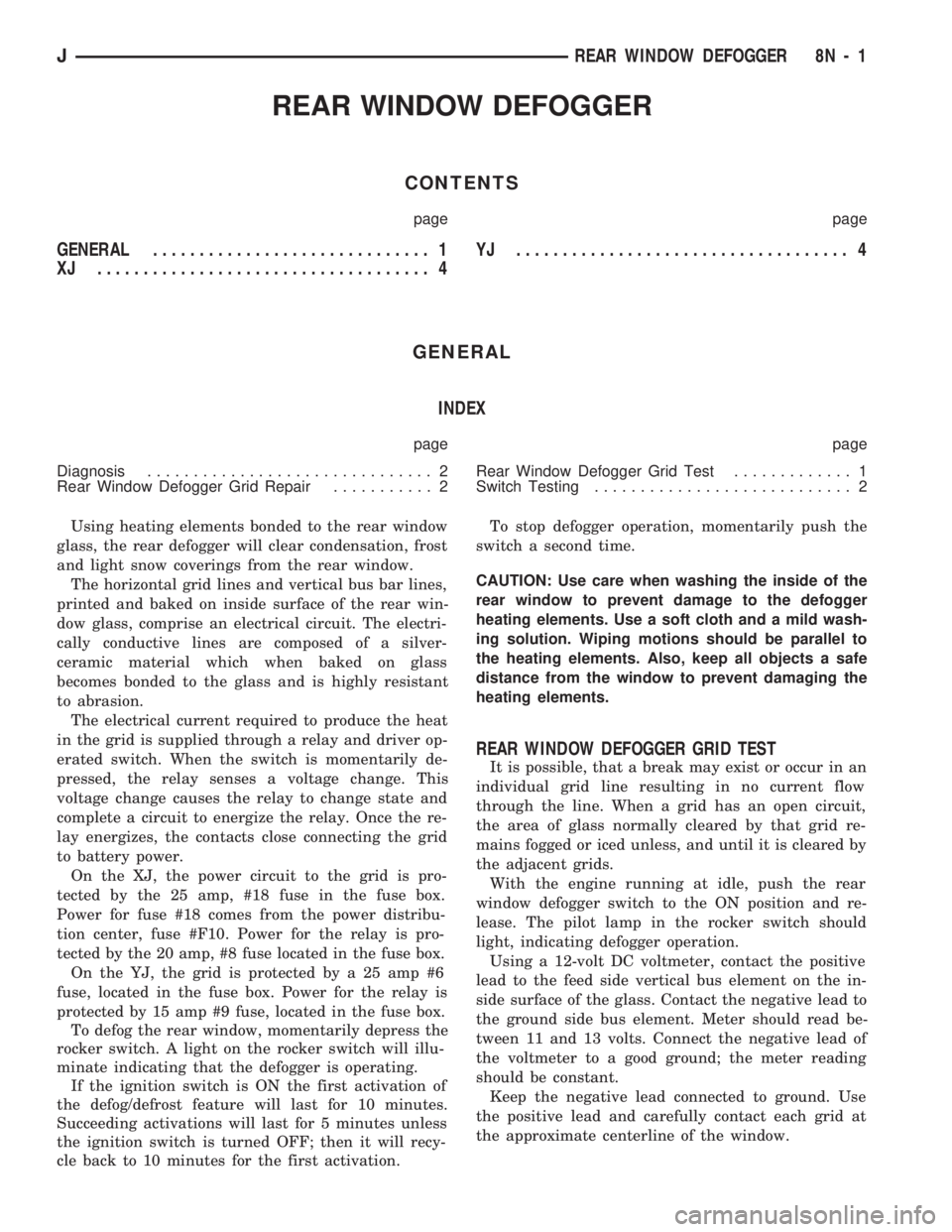

(3) Attach two strips of masking tape to the inside

surface of the rear window (above and below the

break in the grid) (Fig. 1).

(4) Remove package separator clamp and mix plas-

tic conductive epoxy thoroughly. Fold in half and cut

center corner to dispense epoxy.

(5) Apply conductive epoxy through slit in mask-

ing tape. Overlap both ends of the break.

(6) For a terminal or pigtail replacement, mask ad-

jacent areas so epoxy can be extended onto line and

buss bar. Apply a thin layer of epoxy to area where

terminal was fastened and to adjacent line.

(7) Apply a thin layer of conductive epoxy on ter-

minal and place terminal on desired location. To pre-

vent terminal from moving while the epoxy is curing,

it must be wedged or clamped.

(8) Carefully remove masking tape from grid line.

(9) Allow epoxy to cure 24 hours at room tempera-ture or use heat gun with a 260É-371ÉC (500É-700ÉF)

range for 15 minutes. Hold gun approximately

254mm (10 inches) from repaired area.

(10) After conductive epoxy is properly cured re-

move wedge from terminal and check out operation

of rear window defogger. Do not attach connectors

until curing is complete.

WARNING: REPAIR KIT MAY CAUSE SKIN OR EYE

IRRITATION.

CONTAINS EPOXY RESIN AND AMINE TYPE

HARDENER, HARMFUL IF SWALLOWED. AVOID

CONTACT WITH SKIN AND EYES. FOR SKIN,

WASH AFFECTED AREAS WITH SOAP AND WA-

TER. DO NOT TAKE INTERNALLY. IF TAKEN

INTERNALLY, INDUCE VOMITING; CALL A

PHYSICIAN IMMEDIATELY. IF IN CONTACT

WITH EYES, FLUSH WITH PLENTY OF WATER.

USE WITH ADEQUATE VENTILATION. DO NOT

USE NEAR FIRE OR FLAME. CONTENTS CON-

TAIN 3% FLAMMABLE SOLVENTS.

WARNING: KEEP OUT OF REACH OF CHIL-

DREN.

SWITCH TESTING

DIAGNOSIS

Refer to Group 8W - Wiring Diagrams for a com-

plete circuit diagram.

BATTERY, IGNITION & FUSES

²Check fuses #6 and #9 (YJ), or #8 and #18 fuse

(XJ). Replace as required.

²If the fuses are not blown check the battery side of

#18 fuse (XJ) or fuse #6 (YJ) for battery voltage. If

battery voltage is not present replace the Maxi fuse

located in the power distribution center.

²Check the ignition side of fuse #9 (YJ), fuse #8

(XJ) for battery voltage. If battery voltage is not

present check for an open from the ignition switch.

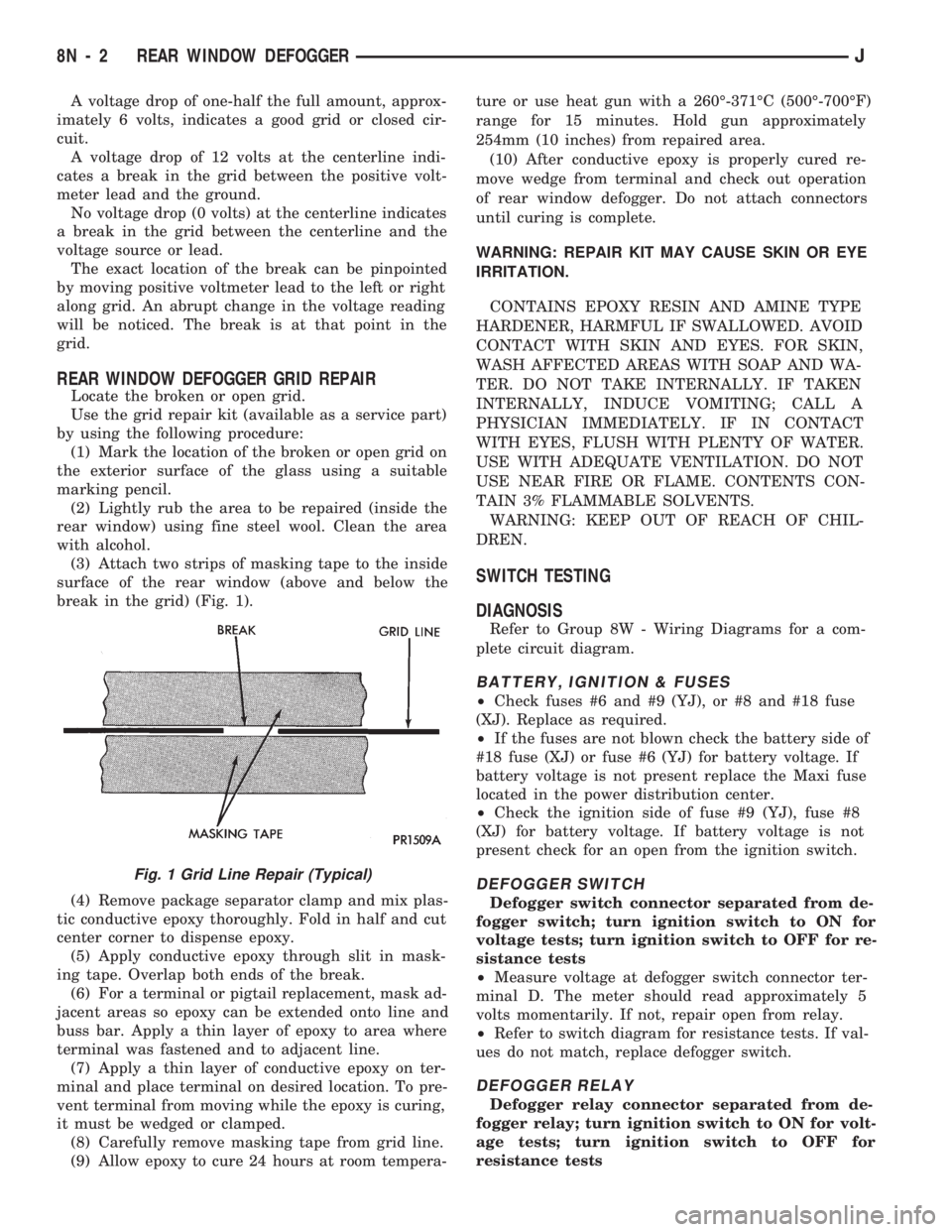

DEFOGGER SWITCH

Defogger switch connector separated from de-

fogger switch; turn ignition switch to ON for

voltage tests; turn ignition switch to OFF for re-

sistance tests

²Measure voltage at defogger switch connector ter-

minal D. The meter should read approximately 5

volts momentarily. If not, repair open from relay.

²Refer to switch diagram for resistance tests. If val-

ues do not match, replace defogger switch.

DEFOGGER RELAY

Defogger relay connector separated from de-

fogger relay; turn ignition switch to ON for volt-

age tests; turn ignition switch to OFF for

resistance tests

Fig. 1 Grid Line Repair (Typical)

8N - 2 REAR WINDOW DEFOGGERJ

Page 454 of 1784

²Measure voltage at relay connector terminal 4.

The meter should read battery voltage. If not, repair

open to fuse #18 (XJ), or fuse #9 (YJ).

²Measure voltage at relay connector terminal 5.

The meter should read battery voltage. If not, repair

open from #8 fuse XJ, or fuse #6 YJ.

²Measure resistance between relay connector termi-

nal 1 and left side (driver's side) of defogger grid.

The meter should read zero ohms. If not, repair open

between relay connector and left side of defogger

grid.

²Measure resistance between relay connector termi-

nal 2 and a clean chassis ground. The meter should

read zero ohms. If not, repair open between relay

connector and ground.

²Connect relay connector and measure voltage at

terminal 3. The meter should read approximately 5volts. If not, replace defogger relay.

INDICATOR LAMP

Refer to switch diagram for resistance tests. If val-

ues do not match, replace defogger switch.

DEFOGGER GRID

Turn defogger switch to ON; turn ignition

switch to ON for voltage tests; turn ignition

switch to OFF for resistance tests

²Measure voltage at left side (driver's side) of defog-

ger grid. The meter should read battery voltage. If

not, repair open from defogger relay.

²Measure resistance for right side of defogger grid

to a clean chassis ground. The meter should read

zero ohms. If not, repair open between right side of

defogger grid and ground.

JREAR WINDOW DEFOGGER 8N - 3

Page 456 of 1784

POWER DOOR LOCKS

CONTENTS

page page

KEYLESS ENTRY........................ 8POWER LOCKS......................... 1

POWER LOCKS

INDEX

page page

Actuator Motor Stall Test.................... 6

Description.............................. 1

Diagnosing Power Door Locks............... 1

General................................. 1Liftgate Lock Cylinder Replacement............ 7

Solenoid and Latch Assembly Replacement..... 6

Switch Replacement....................... 6

GENERAL

The door lock actuators, including liftgate, are con-

trolled by two-way switches. To lock the doors, push

down on either switch. To unlock doors from inside

the vehicle push upward on either switch.

The power door locks do not lock or unlock the

doors from outside the vehicle. Insert the key into

the lock cylinder to lock or unlock each individual

door.

DESCRIPTION

The door locks are operated by reversible motors

that receive voltage from fuse #13 in the fuse panel.

Voltage is applied to the driver's side door lock

switch and the passenger's side door lock switch

through the #9 fuse. With the driver's side door lock

switch in LOCK, voltage is applied through the

switch to the door lock relay coil. The relay coil is

energized which closes the circuit from the circuit

breaker to the lock motor. The motor is grounded by

the unlock relay.

The passenger's side door lock window switch oper-

ates the same as the driver's door switch. The volt-

age and ground paths are reversed to unlock the

doors.

The power door lock operates with battery power

and, therefore, is independent of the ignition switch.

DIAGNOSING POWER DOOR LOCKS

If vehicle has Keyless Entry and the door locks op-

erate properly using door switches but do not work

with transmitter, refer to Keyless Entry in this

group.

NO DOOR LOCKS OPERATE USING DOOR

LOCK SWITCHES

(1) Inspect fuse #13. Replace if necessary. If OK,

measure voltage at battery side of fuse. There should

be 12 volts. If not, repair open from Power Distribu-

tion Center.

(2) Remove door switch and measure voltage at

terminal 1. Meter should read battery voltage. If not,

repair open to #9 fuse.

(3) The power window relays are in the relay cen-

ter. The relay center is located on the lower instru-

ment panel trim cover just right of the steering

column (Fig. 1). Remove both relays.

(4) Measure resistance between lock and unlock re-

lay terminal 4 (87A) and ground. Meter should read

zero ohms. If not, repair open to ground.

(5) Measure voltage at terminal 5 (87) of both the

lock and unlock relays. Meter should read battery

voltage. If OK, next step. If not, repair open to cir-

cuit breaker.

(6) Measure resistance at terminal 2 (85) of both

the lock and unlock relays. Meter should read zero

ohms. If not, repair open to ground.

(7) Hold driver's side switch in LOCK position.

Measure voltage at lock relay terminal 1 (86). Meter

should read battery voltage. If OK, next step. If not,

repair open to driver's side switch.

(8) Hold driver's side switch in UNLOCK position.

Measure voltage at unlock relay terminal 1 (86).

Meter should read battery voltage. If OK, next step.

If not, repair open to driver's side switch.

JPOWER DOOR LOCKS 8P - 1

Page 464 of 1784

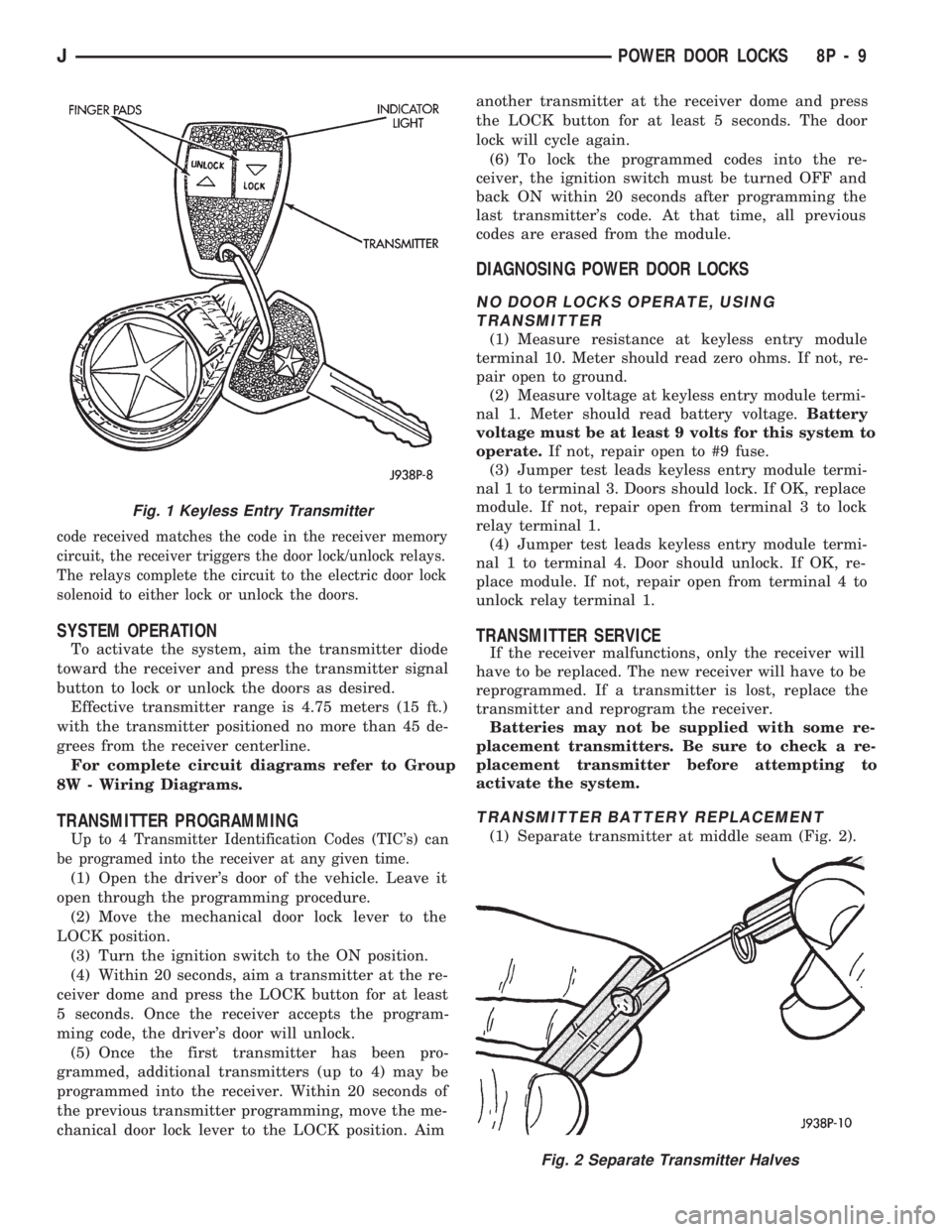

code received matches the code in the receiver memory

circuit, the receiver triggers the door lock/unlock relays.

The relays complete the circuit to the electric door lock

solenoid to either lock or unlock the doors.

SYSTEM OPERATION

To activate the system, aim the transmitter diode

toward the receiver and press the transmitter signal

button to lock or unlock the doors as desired.

Effective transmitter range is 4.75 meters (15 ft.)

with the transmitter positioned no more than 45 de-

grees from the receiver centerline.

For complete circuit diagrams refer to Group

8W - Wiring Diagrams.

TRANSMITTER PROGRAMMING

Up to 4 Transmitter Identification Codes (TIC's) can

be programed into the receiver at any given time.

(1) Open the driver's door of the vehicle. Leave it

open through the programming procedure.

(2) Move the mechanical door lock lever to the

LOCK position.

(3) Turn the ignition switch to the ON position.

(4) Within 20 seconds, aim a transmitter at the re-

ceiver dome and press the LOCK button for at least

5 seconds. Once the receiver accepts the program-

ming code, the driver's door will unlock.

(5) Once the first transmitter has been pro-

grammed, additional transmitters (up to 4) may be

programmed into the receiver. Within 20 seconds of

the previous transmitter programming, move the me-

chanical door lock lever to the LOCK position. Aimanother transmitter at the receiver dome and press

the LOCK button for at least 5 seconds. The door

lock will cycle again.

(6) To lock the programmed codes into the re-

ceiver, the ignition switch must be turned OFF and

back ON within 20 seconds after programming the

last transmitter's code. At that time, all previous

codes are erased from the module.

DIAGNOSING POWER DOOR LOCKS

NO DOOR LOCKS OPERATE, USING

TRANSMITTER

(1) Measure resistance at keyless entry module

terminal 10. Meter should read zero ohms. If not, re-

pair open to ground.

(2) Measure voltage at keyless entry module termi-

nal 1. Meter should read battery voltage.Battery

voltage must be at least 9 volts for this system to

operate.If not, repair open to #9 fuse.

(3) Jumper test leads keyless entry module termi-

nal 1 to terminal 3. Doors should lock. If OK, replace

module. If not, repair open from terminal 3 to lock

relay terminal 1.

(4) Jumper test leads keyless entry module termi-

nal 1 to terminal 4. Door should unlock. If OK, re-

place module. If not, repair open from terminal 4 to

unlock relay terminal 1.

TRANSMITTER SERVICE

If the receiver malfunctions, only the receiver will

have to be replaced. The new receiver will have to be

reprogrammed. If a transmitter is lost, replace the

transmitter and reprogram the receiver.

Batteries may not be supplied with some re-

placement transmitters. Be sure to check a re-

placement transmitter before attempting to

activate the system.

TRANSMITTER BATTERY REPLACEMENT

(1) Separate transmitter at middle seam (Fig. 2).

Fig. 2 Separate Transmitter Halves

Fig. 1 Keyless Entry Transmitter

JPOWER DOOR LOCKS 8P - 9

Page 468 of 1784

POWER SEATS

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL.............................. 1POWER SEAT MOTOR REPLACEMENT....... 2

SWITCH TESTING....................... 2

GENERAL

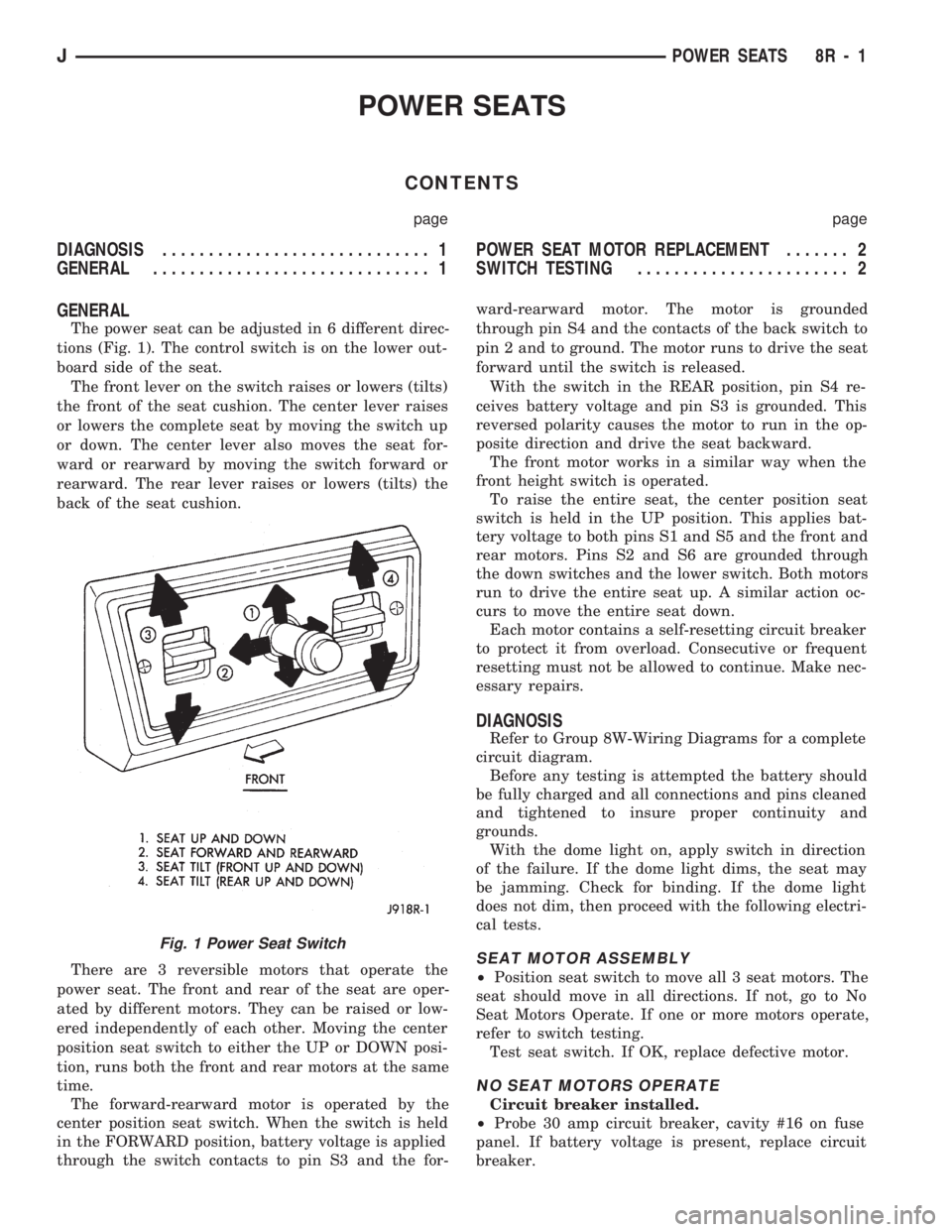

The power seat can be adjusted in 6 different direc-

tions (Fig. 1). The control switch is on the lower out-

board side of the seat.

The front lever on the switch raises or lowers (tilts)

the front of the seat cushion. The center lever raises

or lowers the complete seat by moving the switch up

or down. The center lever also moves the seat for-

ward or rearward by moving the switch forward or

rearward. The rear lever raises or lowers (tilts) the

back of the seat cushion.

There are 3 reversible motors that operate the

power seat. The front and rear of the seat are oper-

ated by different motors. They can be raised or low-

ered independently of each other. Moving the center

position seat switch to either the UP or DOWN posi-

tion, runs both the front and rear motors at the same

time.

The forward-rearward motor is operated by the

center position seat switch. When the switch is held

in the FORWARD position, battery voltage is applied

through the switch contacts to pin S3 and the for-ward-rearward motor. The motor is grounded

through pin S4 and the contacts of the back switch to

pin 2 and to ground. The motor runs to drive the seat

forward until the switch is released.

With the switch in the REAR position, pin S4 re-

ceives battery voltage and pin S3 is grounded. This

reversed polarity causes the motor to run in the op-

posite direction and drive the seat backward.

The front motor works in a similar way when the

front height switch is operated.

To raise the entire seat, the center position seat

switch is held in the UP position. This applies bat-

tery voltage to both pins S1 and S5 and the front and

rear motors. Pins S2 and S6 are grounded through

the down switches and the lower switch. Both motors

run to drive the entire seat up. A similar action oc-

curs to move the entire seat down.

Each motor contains a self-resetting circuit breaker

to protect it from overload. Consecutive or frequent

resetting must not be allowed to continue. Make nec-

essary repairs.

DIAGNOSIS

Refer to Group 8W-Wiring Diagrams for a complete

circuit diagram.

Before any testing is attempted the battery should

be fully charged and all connections and pins cleaned

and tightened to insure proper continuity and

grounds.

With the dome light on, apply switch in direction

of the failure. If the dome light dims, the seat may

be jamming. Check for binding. If the dome light

does not dim, then proceed with the following electri-

cal tests.

SEAT MOTOR ASSEMBLY

²Position seat switch to move all 3 seat motors. The

seat should move in all directions. If not, go to No

Seat Motors Operate. If one or more motors operate,

refer to switch testing.

Test seat switch. If OK, replace defective motor.

NO SEAT MOTORS OPERATE

Circuit breaker installed.

²Probe 30 amp circuit breaker, cavity #16 on fuse

panel. If battery voltage is present, replace circuit

breaker.

Fig. 1 Power Seat Switch

JPOWER SEATS 8R - 1