spark plugs replace JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 845 of 1784

CONNECTING ROD BEARING CLEARANCE

Engine connecting rod bearing clearances can be

determined by use of Plastigage, or equivalent. The

following is the recommended procedures for the use

of Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing cap shell (Fig. 2). Position the

Plastigage approximately 6.35 mm (1/4 inch) off cen-

ter and away from the oil holes. In addition, suspect

areas can be checked by placing the Plastigage in the

suspect area.

(3) The crankshaft must be turned until the con-

necting rod to be checked starts moving toward the

top of the engine. Only then should the rod cap with

Plastigage in place be assembled. Tighten the rod

cap nut to 45 Nzm (33 ft. lbs.) torque.DO NOT ro-

tate the crankshaft or the Plastigage may be

smeared, giving inaccurate results.

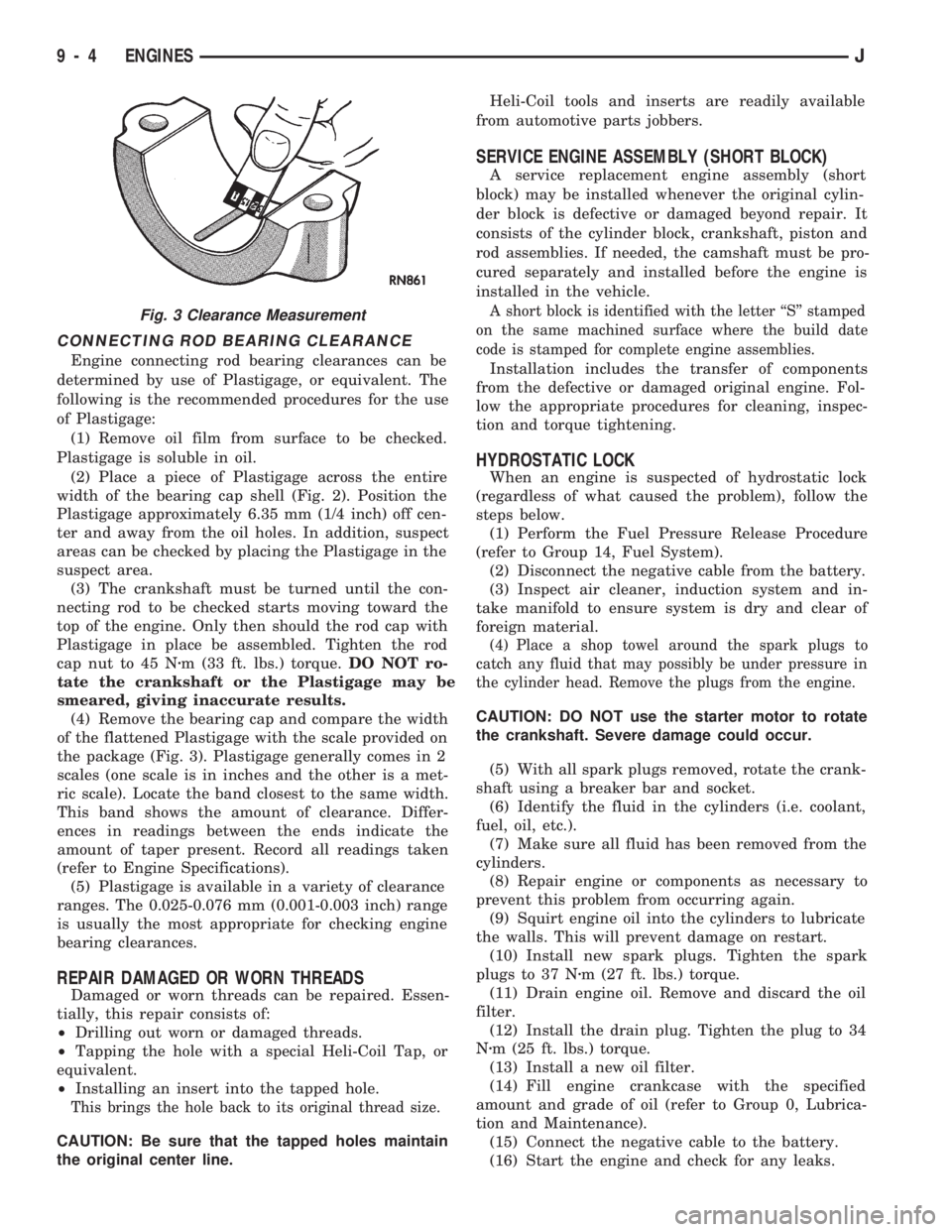

(4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2

scales (one scale is in inches and the other is a met-

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken

(refer to Engine Specifications).

(5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

REPAIR DAMAGED OR WORN THREADS

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole.

This brings the hole back to its original thread size.

CAUTION: Be sure that the tapped holes maintain

the original center line.Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

SERVICE ENGINE ASSEMBLY (SHORT BLOCK)

A service replacement engine assembly (short

block) may be installed whenever the original cylin-

der block is defective or damaged beyond repair. It

consists of the cylinder block, crankshaft, piston and

rod assemblies. If needed, the camshaft must be pro-

cured separately and installed before the engine is

installed in the vehicle.

A short block is identified with the letter ``S'' stamped

on the same machined surface where the build date

code is stamped for complete engine assemblies.

Installation includes the transfer of components

from the defective or damaged original engine. Fol-

low the appropriate procedures for cleaning, inspec-

tion and torque tightening.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the negative cable from the battery.

(3) Inspect air cleaner, induction system and in-

take manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure in

the cylinder head. Remove the plugs from the engine.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 37 Nzm (27 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil (refer to Group 0, Lubrica-

tion and Maintenance).

(15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

Fig. 3 Clearance Measurement

9 - 4 ENGINESJ

Page 861 of 1784

(a) Remove the bolts from the A/C compressor

mounting bracket and set the compressor aside.

(b) Remove the air conditioner compressor

bracket bolts from the engine cylinder head.

(c) Loosen the through bolt at the bottom of the

bracket.

(9) If equipped, disconnect the power steering

pump bracket. Set the pump and bracket aside. DO

NOT disconnect the hoses.

(10) Remove the fuel lines and vacuum advance

hose.

(11) Remove the intake and engine exhaust mani-

folds from the engine cylinder head (refer to Group

11, Exhaust System and Intake Manifold for the

proper procedures).

(12) Disconnect the ignition wires and remove the

spark plugs.

(13) Disconnect the temperature sending unit wire

connector.

(14) Remove the ignition coil and bracket assem-

bly.

(15) Remove the engine cylinder head bolts.

(16) Remove the engine cylinder head and gasket

(Fig. 3).

(17) If this was the first time the bolts were re-

moved, put a paint dab on the top of the bolt. If the

bolts have a paint dab on the top of the bolt or it

isn't known if they were used before, discard the

bolts.

(18) Stuff clean lint free shop towels into the cyl-

inder bores.

CLEANING

Thoroughly clean the engine cylinder head and cyl-

inder block mating surfaces. Clean the intake and

exhaust manifold and engine cylinder head mating

surfaces. Remove all gasket material and carbon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons.

INSPECTION

Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mat-

ing surfaces.

INSTALLATION

The engine cylinder head gasket is a composition

gasket. The gasket is to be installed DRY.DO NOT

use a gasket sealing compound on the gasket.

If the engine cylinder head is to be replaced and

the original valves used, measure the valve stem di-

ameter. Only standard size valves can be used with a

service replacement engine cylinder head unless the

replacement head valve stem guide bores are reamed

to accommodate oversize valve stems. Remove all

carbon buildup and reface the valves.

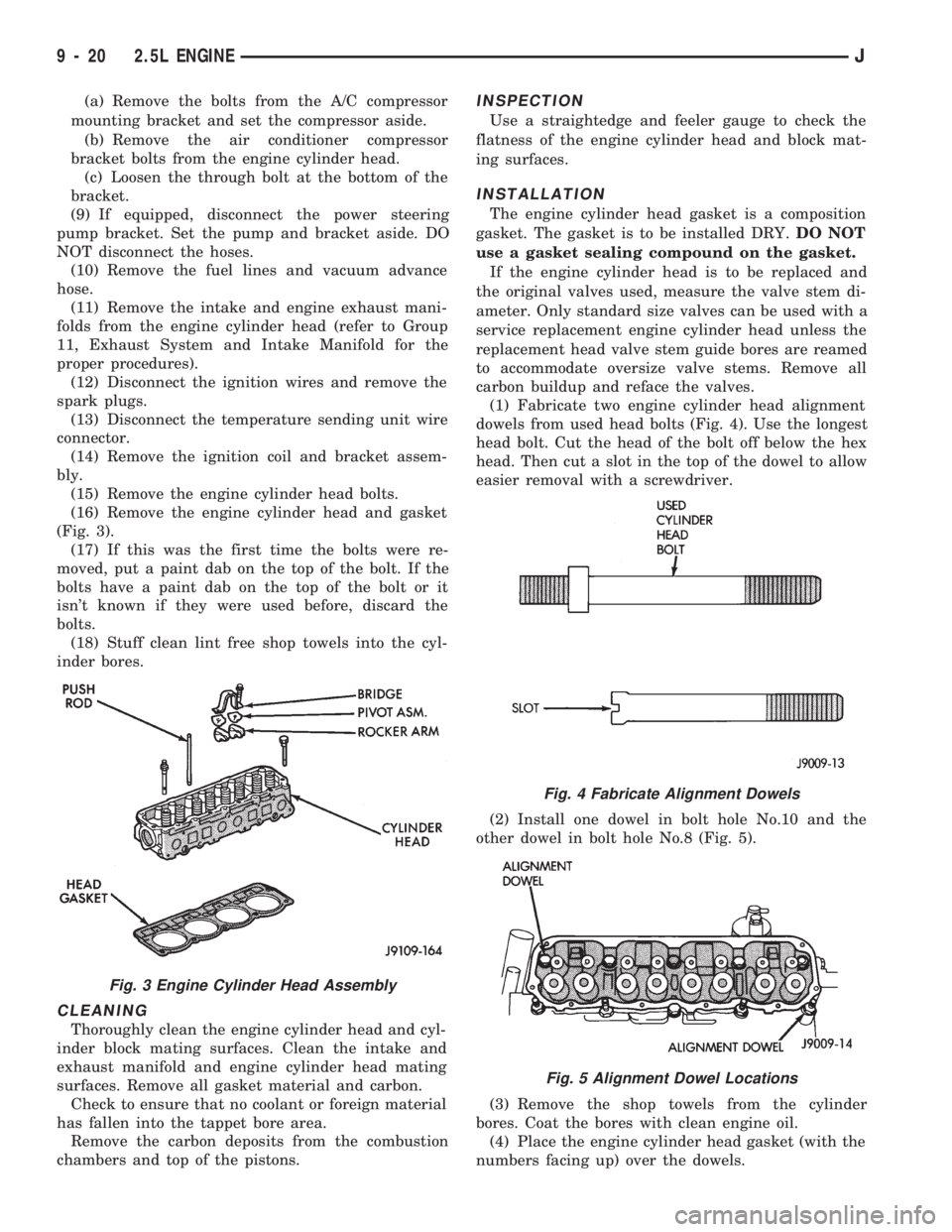

(1) Fabricate two engine cylinder head alignment

dowels from used head bolts (Fig. 4). Use the longest

head bolt. Cut the head of the bolt off below the hex

head. Then cut a slot in the top of the dowel to allow

easier removal with a screwdriver.

(2) Install one dowel in bolt hole No.10 and the

other dowel in bolt hole No.8 (Fig. 5).

(3) Remove the shop towels from the cylinder

bores. Coat the bores with clean engine oil.

(4) Place the engine cylinder head gasket (with the

numbers facing up) over the dowels.

Fig. 3 Engine Cylinder Head Assembly

Fig. 4 Fabricate Alignment Dowels

Fig. 5 Alignment Dowel Locations

9 - 20 2.5L ENGINEJ

Page 862 of 1784

(5) Place the engine cylinder head over the dowels.

CAUTION: Engine cylinder head bolts should be re-

used only once. Replace the head bolts if they were

used before or if they have a paint dab on the top

of the bolt.

(6) Coat the threads of bolt No.7, only, with Loctite

PST sealant or equivalent.

(7) Install all head bolts, except No.8 and No.10.

(8) Remove the dowels.

(9) Install No.8 and No.10 head bolts.

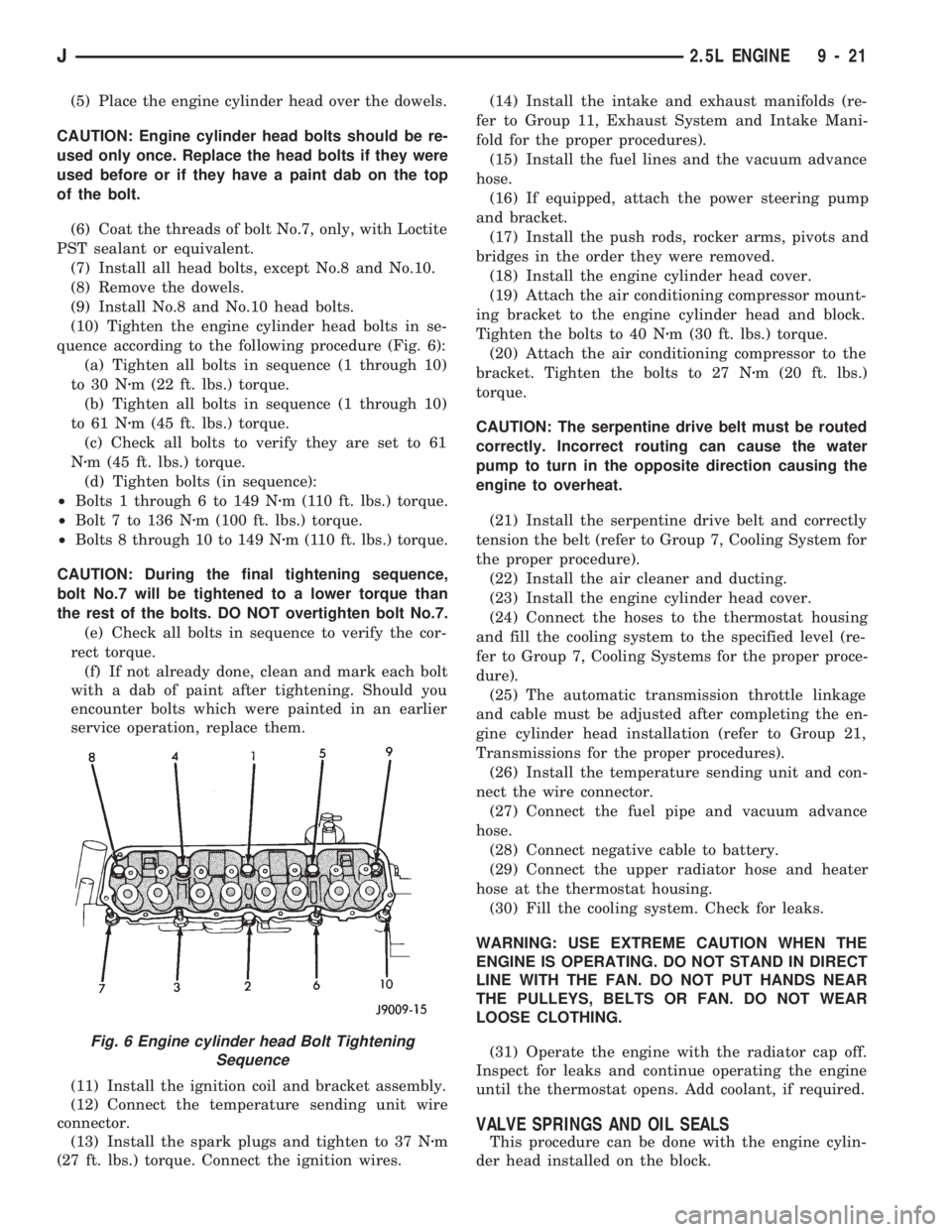

(10) Tighten the engine cylinder head bolts in se-

quence according to the following procedure (Fig. 6):

(a) Tighten all bolts in sequence (1 through 10)

to 30 Nzm (22 ft. lbs.) torque.

(b) Tighten all bolts in sequence (1 through 10)

to 61 Nzm (45 ft. lbs.) torque.

(c) Check all bolts to verify they are set to 61

Nzm (45 ft. lbs.) torque.

(d) Tighten bolts (in sequence):

²Bolts 1 through 6 to 149 Nzm (110 ft. lbs.) torque.

²Bolt 7 to 136 Nzm (100 ft. lbs.) torque.

²Bolts 8 through 10 to 149 Nzm (110 ft. lbs.) torque.

CAUTION: During the final tightening sequence,

bolt No.7 will be tightened to a lower torque than

the rest of the bolts. DO NOT overtighten bolt No.7.

(e) Check all bolts in sequence to verify the cor-

rect torque.

(f) If not already done, clean and mark each bolt

with a dab of paint after tightening. Should you

encounter bolts which were painted in an earlier

service operation, replace them.

(11) Install the ignition coil and bracket assembly.

(12) Connect the temperature sending unit wire

connector.

(13) Install the spark plugs and tighten to 37 Nzm

(27 ft. lbs.) torque. Connect the ignition wires.(14) Install the intake and exhaust manifolds (re-

fer to Group 11, Exhaust System and Intake Mani-

fold for the proper procedures).

(15) Install the fuel lines and the vacuum advance

hose.

(16) If equipped, attach the power steering pump

and bracket.

(17) Install the push rods, rocker arms, pivots and

bridges in the order they were removed.

(18) Install the engine cylinder head cover.

(19) Attach the air conditioning compressor mount-

ing bracket to the engine cylinder head and block.

Tighten the bolts to 40 Nzm (30 ft. lbs.) torque.

(20) Attach the air conditioning compressor to the

bracket. Tighten the bolts to 27 Nzm (20 ft. lbs.)

torque.

CAUTION: The serpentine drive belt must be routed

correctly. Incorrect routing can cause the water

pump to turn in the opposite direction causing the

engine to overheat.

(21) Install the serpentine drive belt and correctly

tension the belt (refer to Group 7, Cooling System for

the proper procedure).

(22) Install the air cleaner and ducting.

(23) Install the engine cylinder head cover.

(24) Connect the hoses to the thermostat housing

and fill the cooling system to the specified level (re-

fer to Group 7, Cooling Systems for the proper proce-

dure).

(25) The automatic transmission throttle linkage

and cable must be adjusted after completing the en-

gine cylinder head installation (refer to Group 21,

Transmissions for the proper procedures).

(26) Install the temperature sending unit and con-

nect the wire connector.

(27) Connect the fuel pipe and vacuum advance

hose.

(28) Connect negative cable to battery.

(29) Connect the upper radiator hose and heater

hose at the thermostat housing.

(30) Fill the cooling system. Check for leaks.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH THE FAN. DO NOT PUT HANDS NEAR

THE PULLEYS, BELTS OR FAN. DO NOT WEAR

LOOSE CLOTHING.

(31) Operate the engine with the radiator cap off.

Inspect for leaks and continue operating the engine

until the thermostat opens. Add coolant, if required.

VALVE SPRINGS AND OIL SEALS

This procedure can be done with the engine cylin-

der head installed on the block.

Fig. 6 Engine cylinder head Bolt Tightening

Sequence

J2.5L ENGINE 9 - 21

Page 867 of 1784

least 1 600 km (1,000 miles). The oil supplement

need not be drained until the next scheduled oil

change.

(7) Install the engine cylinder head cover.

VALVE TIMING

Disconnect the spark plug wires and remove the

spark plugs.

Remove the engine cylinder head cover.

Remove the capscrews, bridge and pivot assembly,

and rocker arms from above the No.1 cylinder.

Alternately loosen each capscrew, one turn at a

time, to avoid damaging the bridge.

Rotate the crankshaft until the No.4 piston is at

top dead center (TDC) on the compression stroke.

Rotate the crankshaft counterclockwise (viewed

from the front of the engine) 90É.

Install a dial indicator on the end of the No.1 cyl-

inder intake valve push rod. Use rubber tubing to se-

cure the indicator stem on the push rod.

Set the dial indicator pointer at zero.

Rotate the crankshaft clockwise (viewed from the

front of the engine) until the dial indicator pointer

indicates 0.305 mm (0.012 inch) travel distance (lift).

The timing notch index on the vibration damper

should be aligned with the TDC mark on the timing

degree scale.

If the timing notch is more than 13 mm (1/2 inch)

away from the TDC mark in either direction, the

valve timing is incorrect.

If the valve timing is incorrect, the cause may be a

broken camshaft pin. It is not necessary to replace

the camshaft because of pin failure. A spring pin is

available for service replacement.

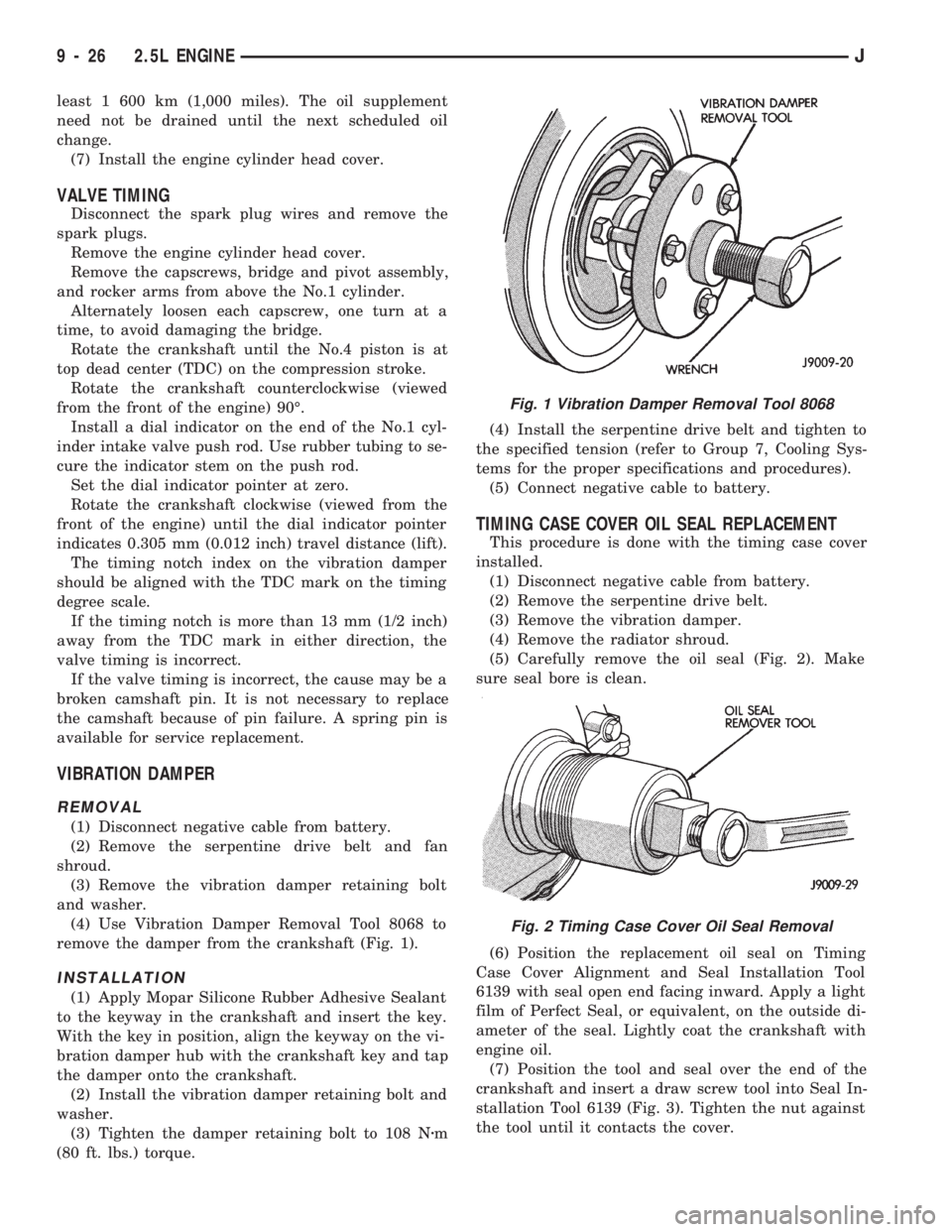

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt and fan

shroud.

(3) Remove the vibration damper retaining bolt

and washer.

(4) Use Vibration Damper Removal Tool 8068 to

remove the damper from the crankshaft (Fig. 1).

INSTALLATION

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in position, align the keyway on the vi-

bration damper hub with the crankshaft key and tap

the damper onto the crankshaft.

(2) Install the vibration damper retaining bolt and

washer.

(3) Tighten the damper retaining bolt to 108 Nzm

(80 ft. lbs.) torque.(4) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tems for the proper specifications and procedures).

(5) Connect negative cable to battery.

TIMING CASE COVER OIL SEAL REPLACEMENT

This procedure is done with the timing case cover

installed.

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt.

(3) Remove the vibration damper.

(4) Remove the radiator shroud.

(5) Carefully remove the oil seal (Fig. 2). Make

sure seal bore is clean.

(6) Position the replacement oil seal on Timing

Case Cover Alignment and Seal Installation Tool

6139 with seal open end facing inward. Apply a light

film of Perfect Seal, or equivalent, on the outside di-

ameter of the seal. Lightly coat the crankshaft with

engine oil.

(7) Position the tool and seal over the end of the

crankshaft and insert a draw screw tool into Seal In-

stallation Tool 6139 (Fig. 3). Tighten the nut against

the tool until it contacts the cover.

Fig. 1 Vibration Damper Removal Tool 8068

Fig. 2 Timing Case Cover Oil Seal Removal

9 - 26 2.5L ENGINEJ

Page 885 of 1784

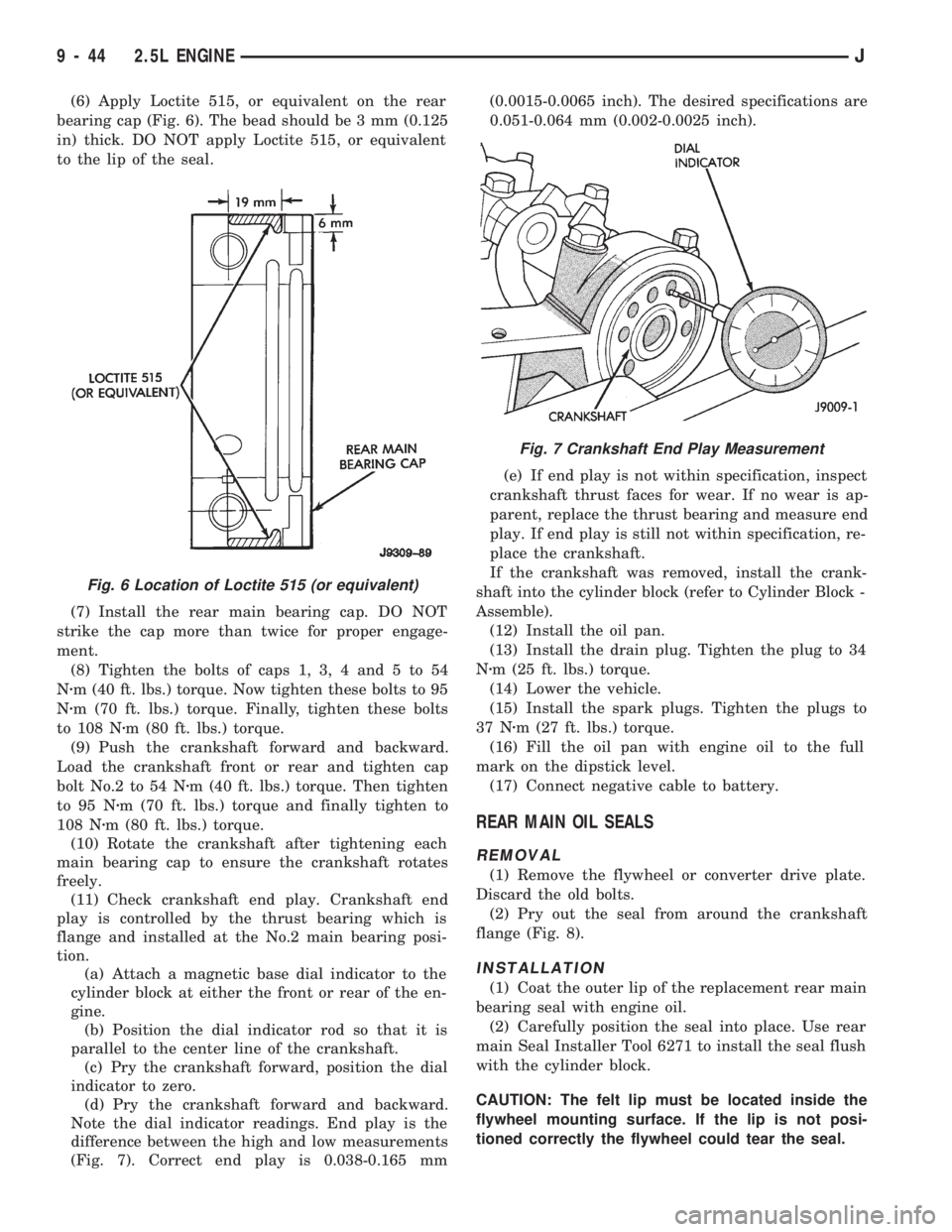

(6) Apply Loctite 515, or equivalent on the rear

bearing cap (Fig. 6). The bead should be 3 mm (0.125

in) thick. DO NOT apply Loctite 515, or equivalent

to the lip of the seal.

(7) Install the rear main bearing cap. DO NOT

strike the cap more than twice for proper engage-

ment.

(8) Tighten the bolts of caps 1, 3, 4 and 5 to 54

Nzm (40 ft. lbs.) torque. Now tighten these bolts to 95

Nzm (70 ft. lbs.) torque. Finally, tighten these bolts

to 108 Nzm (80 ft. lbs.) torque.

(9) Push the crankshaft forward and backward.

Load the crankshaft front or rear and tighten cap

bolt No.2 to 54 Nzm (40 ft. lbs.) torque. Then tighten

to 95 Nzm (70 ft. lbs.) torque and finally tighten to

108 Nzm (80 ft. lbs.) torque.

(10) Rotate the crankshaft after tightening each

main bearing cap to ensure the crankshaft rotates

freely.

(11) Check crankshaft end play. Crankshaft end

play is controlled by the thrust bearing which is

flange and installed at the No.2 main bearing posi-

tion.

(a) Attach a magnetic base dial indicator to the

cylinder block at either the front or rear of the en-

gine.

(b) Position the dial indicator rod so that it is

parallel to the center line of the crankshaft.

(c) Pry the crankshaft forward, position the dial

indicator to zero.

(d) Pry the crankshaft forward and backward.

Note the dial indicator readings. End play is the

difference between the high and low measurements

(Fig. 7). Correct end play is 0.038-0.165 mm(0.0015-0.0065 inch). The desired specifications are

0.051-0.064 mm (0.002-0.0025 inch).

(e) If end play is not within specification, inspect

crankshaft thrust faces for wear. If no wear is ap-

parent, replace the thrust bearing and measure end

play. If end play is still not within specification, re-

place the crankshaft.

If the crankshaft was removed, install the crank-

shaft into the cylinder block (refer to Cylinder Block -

Assemble).

(12) Install the oil pan.

(13) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(14) Lower the vehicle.

(15) Install the spark plugs. Tighten the plugs to

37 Nzm (27 ft. lbs.) torque.

(16) Fill the oil pan with engine oil to the full

mark on the dipstick level.

(17) Connect negative cable to battery.

REAR MAIN OIL SEALS

REMOVAL

(1) Remove the flywheel or converter drive plate.

Discard the old bolts.

(2) Pry out the seal from around the crankshaft

flange (Fig. 8).

INSTALLATION

(1) Coat the outer lip of the replacement rear main

bearing seal with engine oil.

(2) Carefully position the seal into place. Use rear

main Seal Installer Tool 6271 to install the seal flush

with the cylinder block.

CAUTION: The felt lip must be located inside the

flywheel mounting surface. If the lip is not posi-

tioned correctly the flywheel could tear the seal.

Fig. 6 Location of Loctite 515 (or equivalent)

Fig. 7 Crankshaft End Play Measurement

9 - 44 2.5L ENGINEJ

Page 902 of 1784

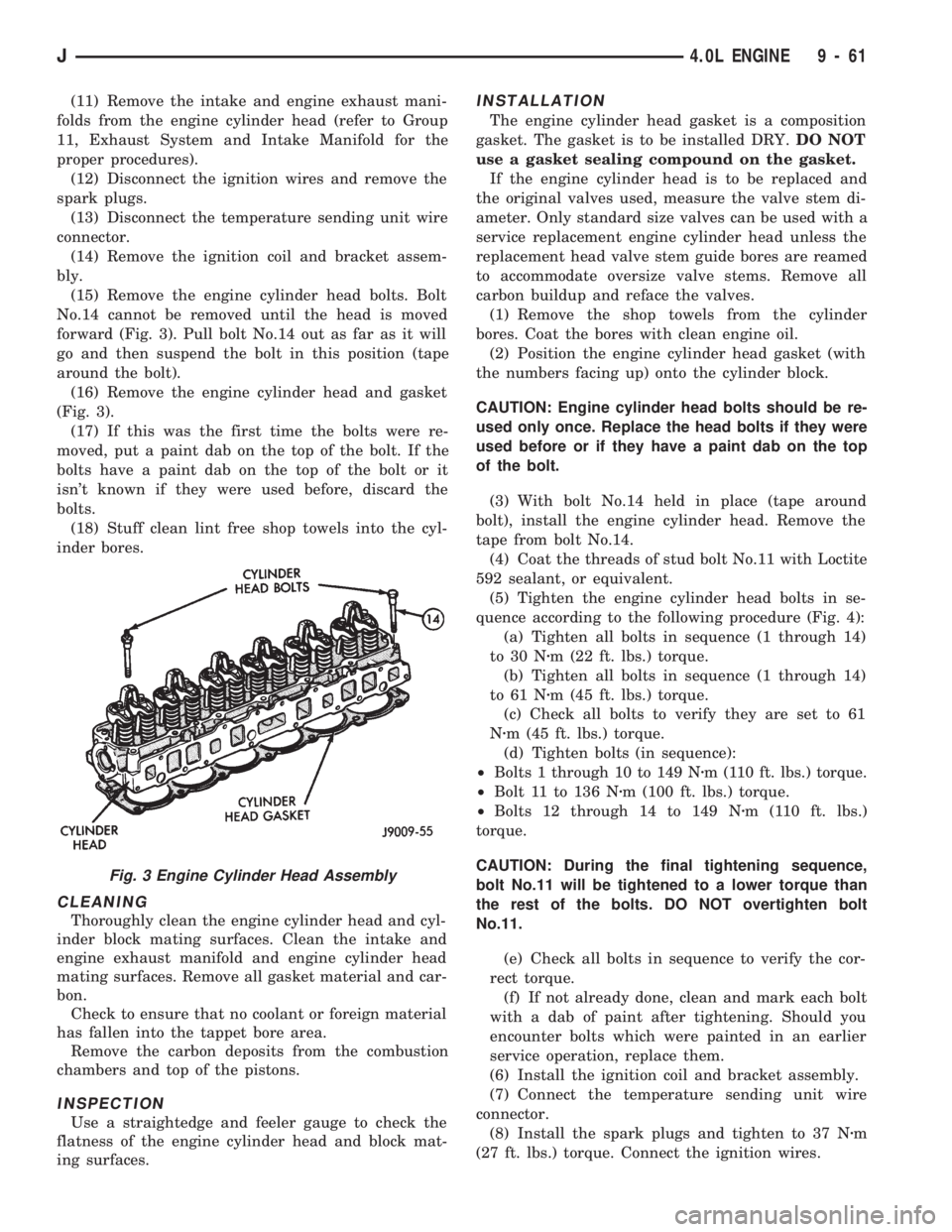

(11) Remove the intake and engine exhaust mani-

folds from the engine cylinder head (refer to Group

11, Exhaust System and Intake Manifold for the

proper procedures).

(12) Disconnect the ignition wires and remove the

spark plugs.

(13) Disconnect the temperature sending unit wire

connector.

(14) Remove the ignition coil and bracket assem-

bly.

(15) Remove the engine cylinder head bolts. Bolt

No.14 cannot be removed until the head is moved

forward (Fig. 3). Pull bolt No.14 out as far as it will

go and then suspend the bolt in this position (tape

around the bolt).

(16) Remove the engine cylinder head and gasket

(Fig. 3).

(17) If this was the first time the bolts were re-

moved, put a paint dab on the top of the bolt. If the

bolts have a paint dab on the top of the bolt or it

isn't known if they were used before, discard the

bolts.

(18) Stuff clean lint free shop towels into the cyl-

inder bores.

CLEANING

Thoroughly clean the engine cylinder head and cyl-

inder block mating surfaces. Clean the intake and

engine exhaust manifold and engine cylinder head

mating surfaces. Remove all gasket material and car-

bon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons.

INSPECTION

Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mat-

ing surfaces.

INSTALLATION

The engine cylinder head gasket is a composition

gasket. The gasket is to be installed DRY.DO NOT

use a gasket sealing compound on the gasket.

If the engine cylinder head is to be replaced and

the original valves used, measure the valve stem di-

ameter. Only standard size valves can be used with a

service replacement engine cylinder head unless the

replacement head valve stem guide bores are reamed

to accommodate oversize valve stems. Remove all

carbon buildup and reface the valves.

(1) Remove the shop towels from the cylinder

bores. Coat the bores with clean engine oil.

(2) Position the engine cylinder head gasket (with

the numbers facing up) onto the cylinder block.

CAUTION: Engine cylinder head bolts should be re-

used only once. Replace the head bolts if they were

used before or if they have a paint dab on the top

of the bolt.

(3) With bolt No.14 held in place (tape around

bolt), install the engine cylinder head. Remove the

tape from bolt No.14.

(4) Coat the threads of stud bolt No.11 with Loctite

592 sealant, or equivalent.

(5) Tighten the engine cylinder head bolts in se-

quence according to the following procedure (Fig. 4):

(a) Tighten all bolts in sequence (1 through 14)

to 30 Nzm (22 ft. lbs.) torque.

(b) Tighten all bolts in sequence (1 through 14)

to 61 Nzm (45 ft. lbs.) torque.

(c) Check all bolts to verify they are set to 61

Nzm (45 ft. lbs.) torque.

(d) Tighten bolts (in sequence):

²Bolts 1 through 10 to 149 Nzm (110 ft. lbs.) torque.

²Bolt 11 to 136 Nzm (100 ft. lbs.) torque.

²Bolts 12 through 14 to 149 Nzm (110 ft. lbs.)

torque.

CAUTION: During the final tightening sequence,

bolt No.11 will be tightened to a lower torque than

the rest of the bolts. DO NOT overtighten bolt

No.11.

(e) Check all bolts in sequence to verify the cor-

rect torque.

(f) If not already done, clean and mark each bolt

with a dab of paint after tightening. Should you

encounter bolts which were painted in an earlier

service operation, replace them.

(6) Install the ignition coil and bracket assembly.

(7) Connect the temperature sending unit wire

connector.

(8) Install the spark plugs and tighten to 37 Nzm

(27 ft. lbs.) torque. Connect the ignition wires.

Fig. 3 Engine Cylinder Head Assembly

J4.0L ENGINE 9 - 61

Page 907 of 1784

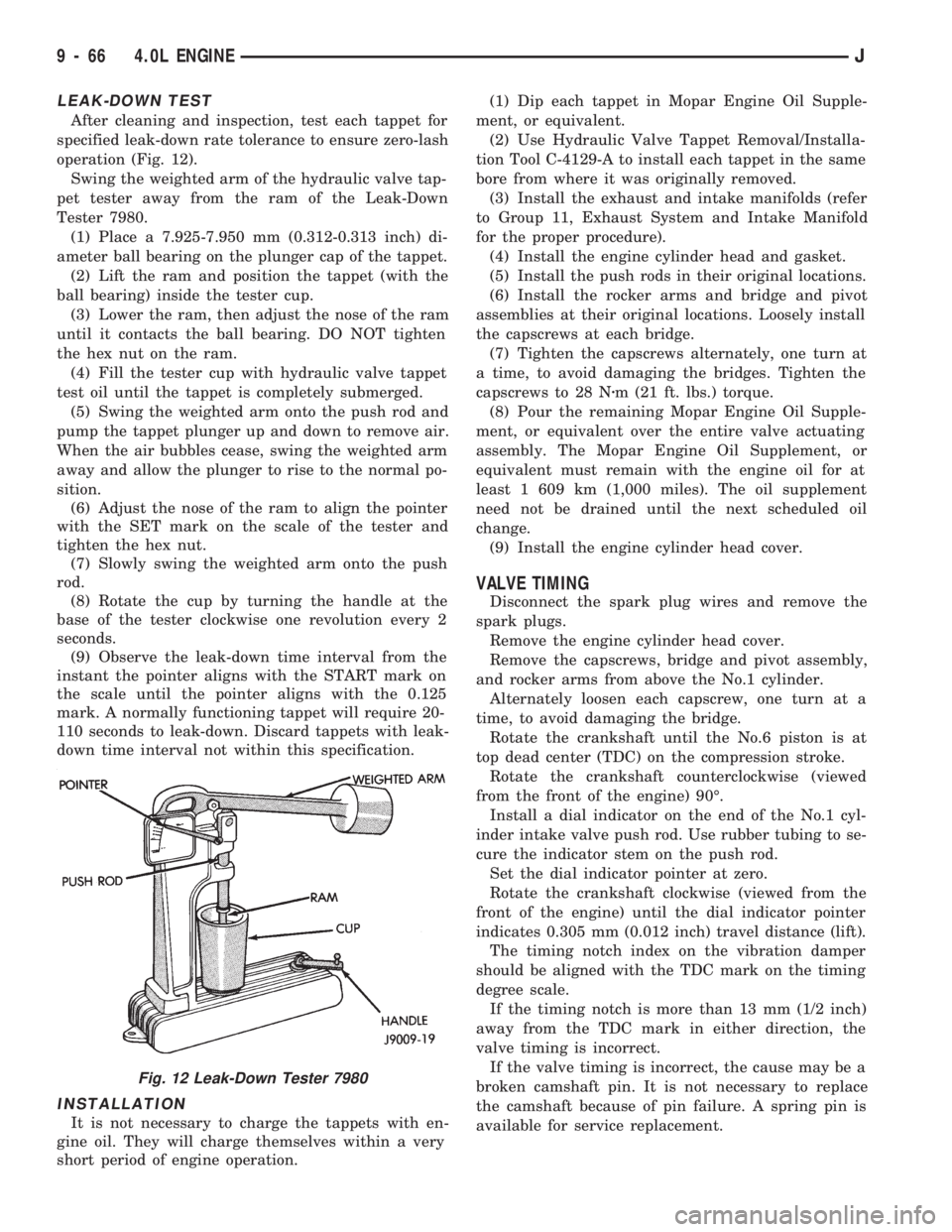

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 12).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Leak-Down

Tester 7980.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch) di-

ameter ball bearing on the plunger cap of the tappet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal po-

sition.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require 20-

110 seconds to leak-down. Discard tappets with leak-

down time interval not within this specification.

INSTALLATION

It is not necessary to charge the tappets with en-

gine oil. They will charge themselves within a very

short period of engine operation.(1) Dip each tappet in Mopar Engine Oil Supple-

ment, or equivalent.

(2) Use Hydraulic Valve Tappet Removal/Installa-

tion Tool C-4129-A to install each tappet in the same

bore from where it was originally removed.

(3) Install the exhaust and intake manifolds (refer

to Group 11, Exhaust System and Intake Manifold

for the proper procedure).

(4) Install the engine cylinder head and gasket.

(5) Install the push rods in their original locations.

(6) Install the rocker arms and bridge and pivot

assemblies at their original locations. Loosely install

the capscrews at each bridge.

(7) Tighten the capscrews alternately, one turn at

a time, to avoid damaging the bridges. Tighten the

capscrews to 28 Nzm (21 ft. lbs.) torque.

(8) Pour the remaining Mopar Engine Oil Supple-

ment, or equivalent over the entire valve actuating

assembly. The Mopar Engine Oil Supplement, or

equivalent must remain with the engine oil for at

least 1 609 km (1,000 miles). The oil supplement

need not be drained until the next scheduled oil

change.

(9) Install the engine cylinder head cover.

VALVE TIMING

Disconnect the spark plug wires and remove the

spark plugs.

Remove the engine cylinder head cover.

Remove the capscrews, bridge and pivot assembly,

and rocker arms from above the No.1 cylinder.

Alternately loosen each capscrew, one turn at a

time, to avoid damaging the bridge.

Rotate the crankshaft until the No.6 piston is at

top dead center (TDC) on the compression stroke.

Rotate the crankshaft counterclockwise (viewed

from the front of the engine) 90É.

Install a dial indicator on the end of the No.1 cyl-

inder intake valve push rod. Use rubber tubing to se-

cure the indicator stem on the push rod.

Set the dial indicator pointer at zero.

Rotate the crankshaft clockwise (viewed from the

front of the engine) until the dial indicator pointer

indicates 0.305 mm (0.012 inch) travel distance (lift).

The timing notch index on the vibration damper

should be aligned with the TDC mark on the timing

degree scale.

If the timing notch is more than 13 mm (1/2 inch)

away from the TDC mark in either direction, the

valve timing is incorrect.

If the valve timing is incorrect, the cause may be a

broken camshaft pin. It is not necessary to replace

the camshaft because of pin failure. A spring pin is

available for service replacement.

Fig. 12 Leak-Down Tester 7980

9 - 66 4.0L ENGINEJ

Page 925 of 1784

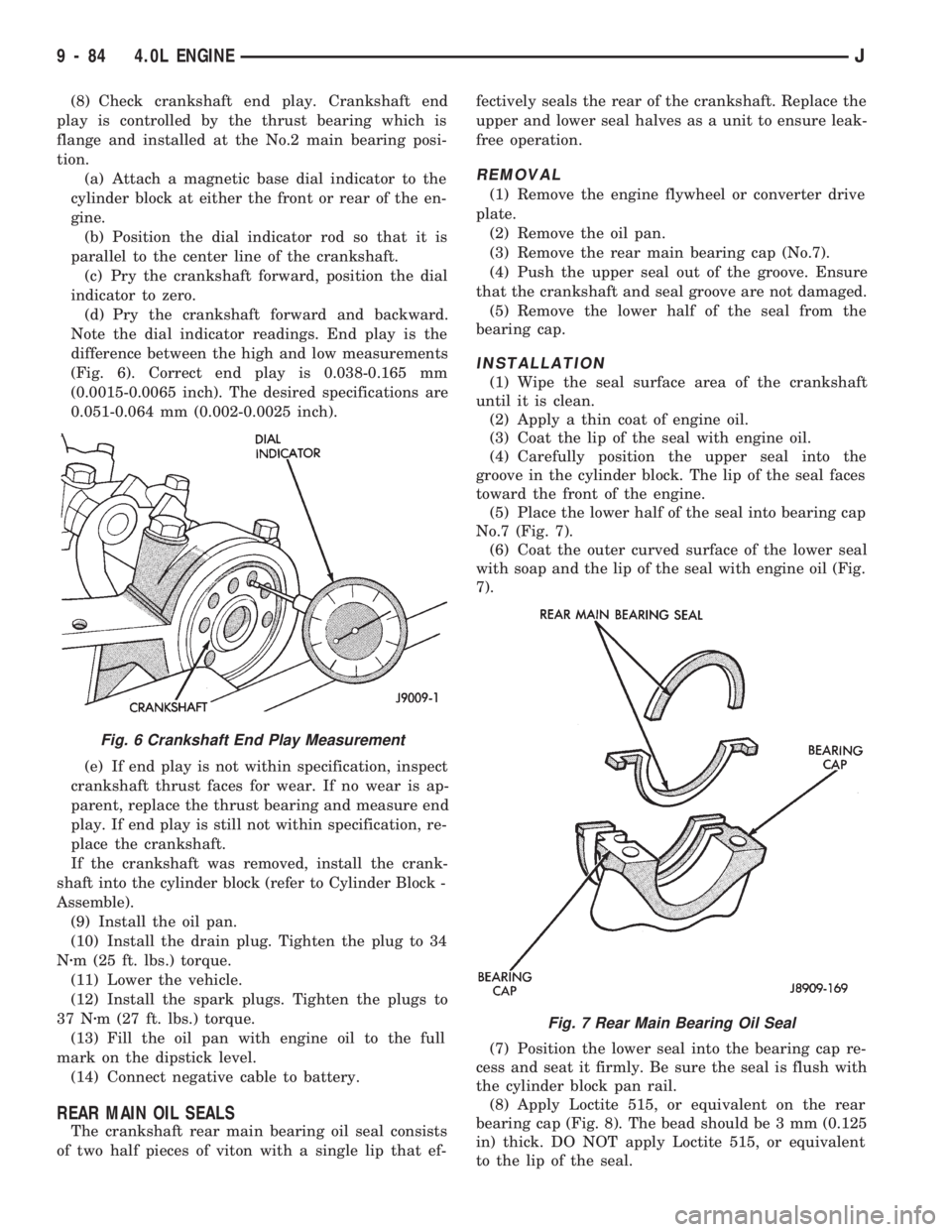

(8) Check crankshaft end play. Crankshaft end

play is controlled by the thrust bearing which is

flange and installed at the No.2 main bearing posi-

tion.

(a) Attach a magnetic base dial indicator to the

cylinder block at either the front or rear of the en-

gine.

(b) Position the dial indicator rod so that it is

parallel to the center line of the crankshaft.

(c) Pry the crankshaft forward, position the dial

indicator to zero.

(d) Pry the crankshaft forward and backward.

Note the dial indicator readings. End play is the

difference between the high and low measurements

(Fig. 6). Correct end play is 0.038-0.165 mm

(0.0015-0.0065 inch). The desired specifications are

0.051-0.064 mm (0.002-0.0025 inch).

(e) If end play is not within specification, inspect

crankshaft thrust faces for wear. If no wear is ap-

parent, replace the thrust bearing and measure end

play. If end play is still not within specification, re-

place the crankshaft.

If the crankshaft was removed, install the crank-

shaft into the cylinder block (refer to Cylinder Block -

Assemble).

(9) Install the oil pan.

(10) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(11) Lower the vehicle.

(12) Install the spark plugs. Tighten the plugs to

37 Nzm (27 ft. lbs.) torque.

(13) Fill the oil pan with engine oil to the full

mark on the dipstick level.

(14) Connect negative cable to battery.

REAR MAIN OIL SEALS

The crankshaft rear main bearing oil seal consists

of two half pieces of viton with a single lip that ef-fectively seals the rear of the crankshaft. Replace the

upper and lower seal halves as a unit to ensure leak-

free operation.

REMOVAL

(1) Remove the engine flywheel or converter drive

plate.

(2) Remove the oil pan.

(3) Remove the rear main bearing cap (No.7).

(4) Push the upper seal out of the groove. Ensure

that the crankshaft and seal groove are not damaged.

(5) Remove the lower half of the seal from the

bearing cap.

INSTALLATION

(1) Wipe the seal surface area of the crankshaft

until it is clean.

(2) Apply a thin coat of engine oil.

(3) Coat the lip of the seal with engine oil.

(4) Carefully position the upper seal into the

groove in the cylinder block. The lip of the seal faces

toward the front of the engine.

(5) Place the lower half of the seal into bearing cap

No.7 (Fig. 7).

(6) Coat the outer curved surface of the lower seal

with soap and the lip of the seal with engine oil (Fig.

7).

(7) Position the lower seal into the bearing cap re-

cess and seat it firmly. Be sure the seal is flush with

the cylinder block pan rail.

(8) Apply Loctite 515, or equivalent on the rear

bearing cap (Fig. 8). The bead should be 3 mm (0.125

in) thick. DO NOT apply Loctite 515, or equivalent

to the lip of the seal.

Fig. 7 Rear Main Bearing Oil Seal

Fig. 6 Crankshaft End Play Measurement

9 - 84 4.0L ENGINEJ

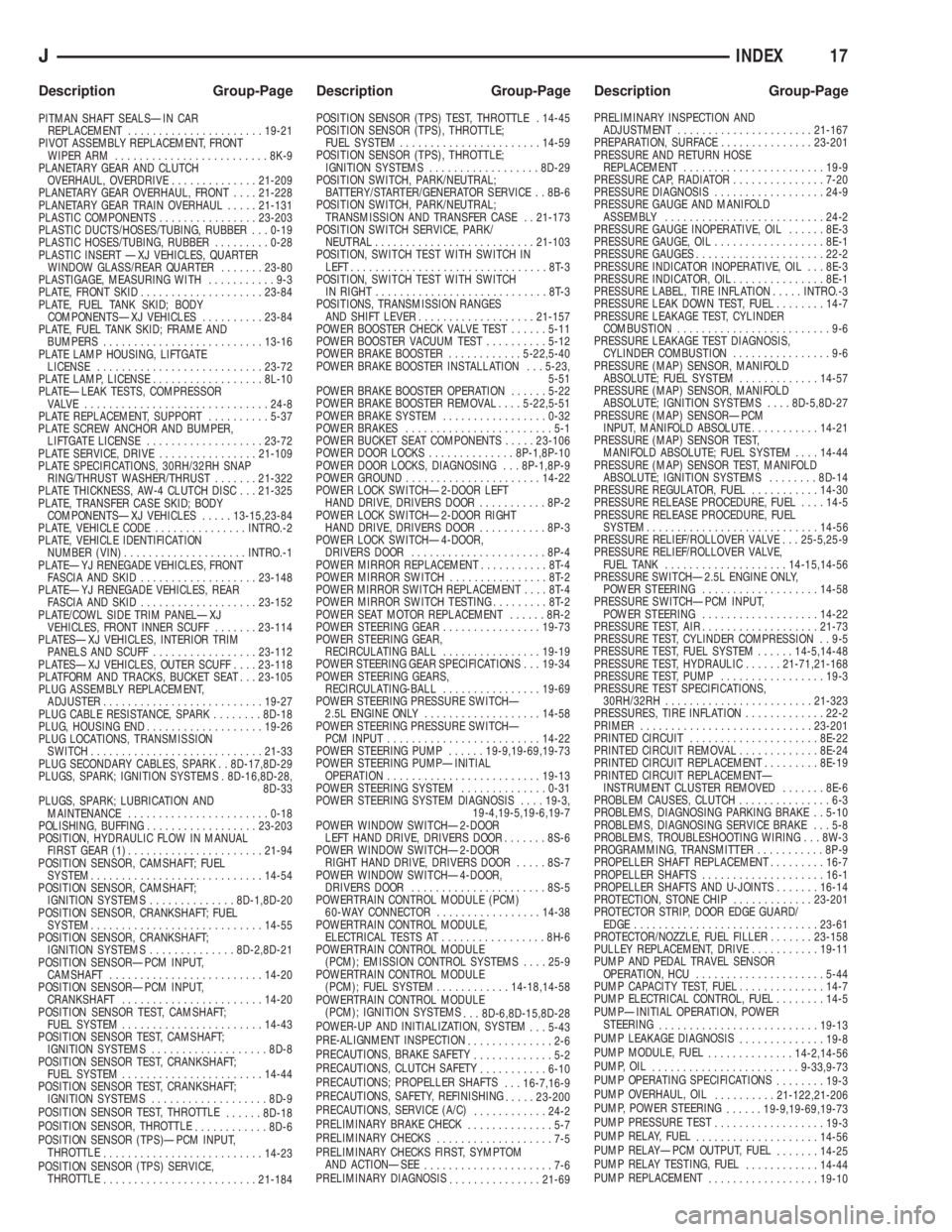

Page 1761 of 1784

PITMAN SHAFT SEALSÐIN CAR

REPLACEMENT......................19-21

PIVOT ASSEMBLY REPLACEMENT, FRONT

WIPER ARM.........................8K-9

PLANETARY GEAR AND CLUTCH

OVERHAUL, OVERDRIVE..............21-209

PLANETARY GEAR OVERHAUL, FRONT....21-228

PLANETARY GEAR TRAIN OVERHAUL.....21-131

PLASTIC COMPONENTS................23-203

PLASTIC DUCTS/HOSES/TUBING, RUBBER . . . 0-19

PLASTIC HOSES/TUBING, RUBBER.........0-28

PLASTIC INSERT ÐXJ VEHICLES, QUARTER

WINDOW GLASS/REAR QUARTER.......23-80

PLASTIGAGE, MEASURING WITH...........9-3

PLATE, FRONT SKID....................23-84

PLATE, FUEL TANK SKID; BODY

COMPONENTSÐXJ VEHICLES..........23-84

PLATE, FUEL TANK SKID; FRAME AND

BUMPERS..........................13-16

PLATE LAMP HOUSING, LIFTGATE

LICENSE...........................23-72

PLATE LAMP, LICENSE..................8L-10

PLATEÐLEAK TESTS, COMPRESSOR

VALVE ..............................24-8

PLATE REPLACEMENT, SUPPORT..........5-37

PLATE SCREW ANCHOR AND BUMPER,

LIFTGATE LICENSE...................23-72

PLATE SERVICE, DRIVE................21-109

PLATE SPECIFICATIONS, 30RH/32RH SNAP

RING/THRUST WASHER/THRUST.......21-322

PLATE THICKNESS, AW-4 CLUTCH DISC . . . 21-325

PLATE, TRANSFER CASE SKID; BODY

COMPONENTSÐXJ VEHICLES.....13-15,23-84

PLATE, VEHICLE CODE...............INTRO.-2

PLATE, VEHICLE IDENTIFICATION

NUMBER (VIN)....................INTRO.-1

PLATEÐYJ RENEGADE VEHICLES, FRONT

FASCIA AND SKID...................23-148

PLATEÐYJ RENEGADE VEHICLES, REAR

FASCIA AND SKID...................23-152

PLATE/COWL SIDE TRIM PANELÐXJ

VEHICLES, FRONT INNER SCUFF.......23-114

PLATESÐXJ VEHICLES, INTERIOR TRIM

PANELS AND SCUFF.................23-112

PLATESÐXJ VEHICLES, OUTER SCUFF....23-118

PLATFORM AND TRACKS, BUCKET SEAT . . . 23-105

PLUG ASSEMBLY REPLACEMENT,

ADJUSTER..........................19-27

PLUG CABLE RESISTANCE, SPARK........8D-18

PLUG, HOUSING END...................19-26

PLUG LOCATIONS, TRANSMISSION

SWITCH............................21-33

PLUG SECONDARY CABLES, SPARK . . 8D-17,8D-29

PLUGS, SPARK; IGNITION SYSTEMS . 8D-16,8D-28,

8D-33

PLUGS, SPARK; LUBRICATION AND

MAINTENANCE.......................0-18

POLISHING, BUFFING..................23-203

POSITION, HYDRAULIC FLOW IN MANUAL

FIRST GEAR (1)......................21-94

POSITION SENSOR, CAMSHAFT; FUEL

SYSTEM............................14-54

POSITION SENSOR, CAMSHAFT;

IGNITION SYSTEMS..............8D-1,8D-20

POSITION SENSOR, CRANKSHAFT; FUEL

SYSTEM............................14-55

POSITION SENSOR, CRANKSHAFT;

IGNITION SYSTEMS..............8D-2,8D-21

POSITION SENSORÐPCM INPUT,

CAMSHAFT.........................14-20

POSITION SENSORÐPCM INPUT,

CRANKSHAFT.......................14-20

POSITION SENSOR TEST, CAMSHAFT;

FUEL SYSTEM.......................14-43

POSITION SENSOR TEST, CAMSHAFT;

IGNITION SYSTEMS...................8D-8

POSITION SENSOR TEST, CRANKSHAFT;

FUEL SYSTEM.......................14-44

POSITION SENSOR TEST, CRANKSHAFT;

IGNITION SYSTEMS...................8D-9

POSITION SENSOR TEST, THROTTLE

......8D-18

POSITION SENSOR, THROTTLE

............8D-6

POSITION SENSOR (TPS)ÐPCM INPUT,

THROTTLE

..........................14-23

POSITION SENSOR (TPS) SERVICE,

THROTTLE

.........................21-184POSITION SENSOR (TPS) TEST, THROTTLE . 14-45

POSITION SENSOR (TPS), THROTTLE;

FUEL SYSTEM.......................14-59

POSITION SENSOR (TPS), THROTTLE;

IGNITION SYSTEMS..................8D-29

POSITION SWITCH, PARK/NEUTRAL;

BATTERY/STARTER/GENERATOR SERVICE . . 8B-6

POSITION SWITCH, PARK/NEUTRAL;

TRANSMISSION AND TRANSFER CASE . . 21-173

POSITION SWITCH SERVICE, PARK/

NEUTRAL..........................21-103

POSITION, SWITCH TEST WITH SWITCH IN

LEFT................................8T-3

POSITION, SWITCH TEST WITH SWITCH

IN RIGHT............................8T-3

POSITIONS, TRANSMISSION RANGES

AND SHIFT LEVER...................21-157

POWER BOOSTER CHECK VALVE TEST......5-11

POWER BOOSTER VACUUM TEST..........5-12

POWER BRAKE BOOSTER............5-22,5-40

POWER BRAKE BOOSTER INSTALLATION . . . 5-23,

5-51

POWER BRAKE BOOSTER OPERATION......5-22

POWER BRAKE BOOSTER REMOVAL....5-22,5-51

POWER BRAKE SYSTEM.................0-32

POWER BRAKES........................5-1

POWER BUCKET SEAT COMPONENTS.....23-106

POWER DOOR LOCKS..............8P-1,8P-10

POWER DOOR LOCKS, DIAGNOSING . . . 8P-1,8P-9

POWER GROUND......................14-22

POWER LOCK SWITCHÐ2-DOOR LEFT

HAND DRIVE, DRIVERS DOOR...........8P-2

POWER LOCK SWITCHÐ2-DOOR RIGHT

HAND DRIVE, DRIVERS DOOR...........8P-3

POWER LOCK SWITCHÐ4-DOOR,

DRIVERS DOOR......................8P-4

POWER MIRROR REPLACEMENT...........8T-4

POWER MIRROR SWITCH................8T-2

POWER MIRROR SWITCH REPLACEMENT....8T-4

POWER MIRROR SWITCH TESTING.........8T-2

POWER SEAT MOTOR REPLACEMENT......8R-2

POWER STEERING GEAR................19-73

POWER STEERING GEAR,

RECIRCULATING BALL................19-19

POWER STEERING GEAR SPECIFICATIONS . . . 19-34

POWER STEERING GEARS,

RECIRCULATING-BALL................19-69

POWER STEERING PRESSURE SWITCHÐ

2.5L ENGINE ONLY...................14-58

POWER STEERING PRESSURE SWITCHÐ

PCM INPUT.........................14-22

POWER STEERING PUMP......19-9,19-69,19-73

POWER STEERING PUMPÐINITIAL

OPERATION.........................19-13

POWER STEERING SYSTEM..............0-31

POWER STEERING SYSTEM DIAGNOSIS....19-3,

19-4,19-5,19-6,19-7

POWER WINDOW SWITCHÐ2-DOOR

LEFT HAND DRIVE, DRIVERS DOOR.......8S-6

POWER WINDOW SWITCHÐ2-DOOR

RIGHT HAND DRIVE, DRIVERS DOOR.....8S-7

POWER WINDOW SWITCHÐ4-DOOR,

DRIVERS DOOR......................8S-5

POWERTRAIN CONTROL MODULE (PCM)

60-WAY CONNECTOR.................14-38

POWERTRAIN CONTROL MODULE,

ELECTRICAL TESTS AT.................8H-6

POWERTRAIN CONTROL MODULE

(PCM); EMISSION CONTROL SYSTEMS....25-9

POWERTRAIN CONTROL MODULE

(PCM); FUEL SYSTEM............14-18,14-58

POWERTRAIN CONTROL MODULE

(PCM); IGNITION SYSTEMS

. . . 8D-6,8D-15,8D-28

POWER-UP AND INITIALIZATION, SYSTEM

. . . 5-43

PRE-ALIGNMENT INSPECTION

..............2-6

PRECAUTIONS, BRAKE SAFETY

.............5-2

PRECAUTIONS, CLUTCH SAFETY

...........6-10

PRECAUTIONS; PROPELLER SHAFTS

. . . 16-7,16-9

PRECAUTIONS, SAFETY, REFINISHING

.....23-200

PRECAUTIONS, SERVICE (A/C)

............24-2

PRELIMINARY BRAKE CHECK

..............5-7

PRELIMINARY CHECKS

...................7-5

PRELIMINARY CHECKS FIRST, SYMPTOM

AND ACTIONÐSEE

.....................7-6

PRELIMINARY DIAGNOSIS

...............21-69PRELIMINARY INSPECTION AND

ADJUSTMENT......................21-167

PREPARATION, SURFACE...............23-201

PRESSURE AND RETURN HOSE

REPLACEMENT.......................19-9

PRESSURE CAP, RADIATOR...............7-20

PRESSURE DIAGNOSIS..................24-9

PRESSURE GAUGE AND MANIFOLD

ASSEMBLY..........................24-2

PRESSURE GAUGE INOPERATIVE, OIL......8E-3

PRESSURE GAUGE, OIL..................8E-1

PRESSURE GAUGES.....................22-2

PRESSURE INDICATOR INOPERATIVE, OIL . . . 8E-3

PRESSURE INDICATOR, OIL...............8E-1

PRESSURE LABEL, TIRE INFLATION.....INTRO.-3

PRESSURE LEAK DOWN TEST, FUEL........14-7

PRESSURE LEAKAGE TEST, CYLINDER

COMBUSTION.........................9-6

PRESSURE LEAKAGE TEST DIAGNOSIS,

CYLINDER COMBUSTION................9-6

PRESSURE (MAP) SENSOR, MANIFOLD

ABSOLUTE; FUEL SYSTEM.............14-57

PRESSURE (MAP) SENSOR, MANIFOLD

ABSOLUTE; IGNITION SYSTEMS....8D-5,8D-27

PRESSURE (MAP) SENSORÐPCM

INPUT, MANIFOLD ABSOLUTE...........14-21

PRESSURE (MAP) SENSOR TEST,

MANIFOLD ABSOLUTE; FUEL SYSTEM....14-44

PRESSURE (MAP) SENSOR TEST, MANIFOLD

ABSOLUTE; IGNITION SYSTEMS........8D-14

PRESSURE REGULATOR, FUEL...........14-30

PRESSURE RELEASE PROCEDURE, FUEL....14-5

PRESSURE RELEASE PROCEDURE, FUEL

SYSTEM............................14-56

PRESSURE RELIEF/ROLLOVER VALVE . . . 25-5,25-9

PRESSURE RELIEF/ROLLOVER VALVE,

FUEL TANK....................14-15,14-56

PRESSURE SWITCHÐ2.5L ENGINE ONLY,

POWER STEERING...................14-58

PRESSURE SWITCHÐPCM INPUT,

POWER STEERING...................14-22

PRESSURE TEST, AIR...................21-73

PRESSURE TEST, CYLINDER COMPRESSION . . 9-5

PRESSURE TEST, FUEL SYSTEM......14-5,14-48

PRESSURE TEST, HYDRAULIC......21-71,21-168

PRESSURE TEST, PUMP.................19-3

PRESSURE TEST SPECIFICATIONS,

30RH/32RH........................21-323

PRESSURES, TIRE INFLATION.............22-2

PRIMER............................23-201

PRINTED CIRCUIT.....................8E-22

PRINTED CIRCUIT REMOVAL.............8E-24

PRINTED CIRCUIT REPLACEMENT.........8E-19

PRINTED CIRCUIT REPLACEMENTÐ

INSTRUMENT CLUSTER REMOVED.......8E-6

PROBLEM CAUSES, CLUTCH...............6-3

PROBLEMS, DIAGNOSING PARKING BRAKE . . 5-10

PROBLEMS, DIAGNOSING SERVICE BRAKE . . . 5-8

PROBLEMS, TROUBLESHOOTING WIRING . . . 8W-3

PROGRAMMING, TRANSMITTER...........8P-9

PROPELLER SHAFT REPLACEMENT.........16-7

PROPELLER SHAFTS....................16-1

PROPELLER SHAFTS AND U-JOINTS.......16-14

PROTECTION, STONE CHIP.............23-201

PROTECTOR STRIP, DOOR EDGE GUARD/

EDGE..............................23-61

PROTECTOR/NOZZLE, FUEL FILLER.......23-158

PULLEY REPLACEMENT, DRIVE...........19-11

PUMP AND PEDAL TRAVEL SENSOR

OPERATION, HCU.....................5-44

PUMP CAPACITY TEST, FUEL..............14-7

PUMP ELECTRICAL CONTROL, FUEL........14-5

PUMPÐINITIAL OPERATION, POWER

STEERING

..........................19-13

PUMP LEAKAGE DIAGNOSIS

..............19-8

PUMP MODULE, FUEL

..............14-2,14-56

PUMP, OIL

........................9-33,9-73

PUMP OPERATING SPECIFICATIONS

........19-3

PUMP OVERHAUL, OIL

..........21-122,21-206

PUMP, POWER STEERING

......19-9,19-69,19-73

PUMP PRESSURE TEST

..................19-3

PUMP RELAY, FUEL

....................14-56

PUMP RELAYÐPCM OUTPUT, FUEL

.......14-25

PUMP RELAY TESTING, FUEL

............14-44

PUMP REPLACEMENT

..................19-10

JINDEX17

Description Group-Page Description Group-Page Description Group-Page

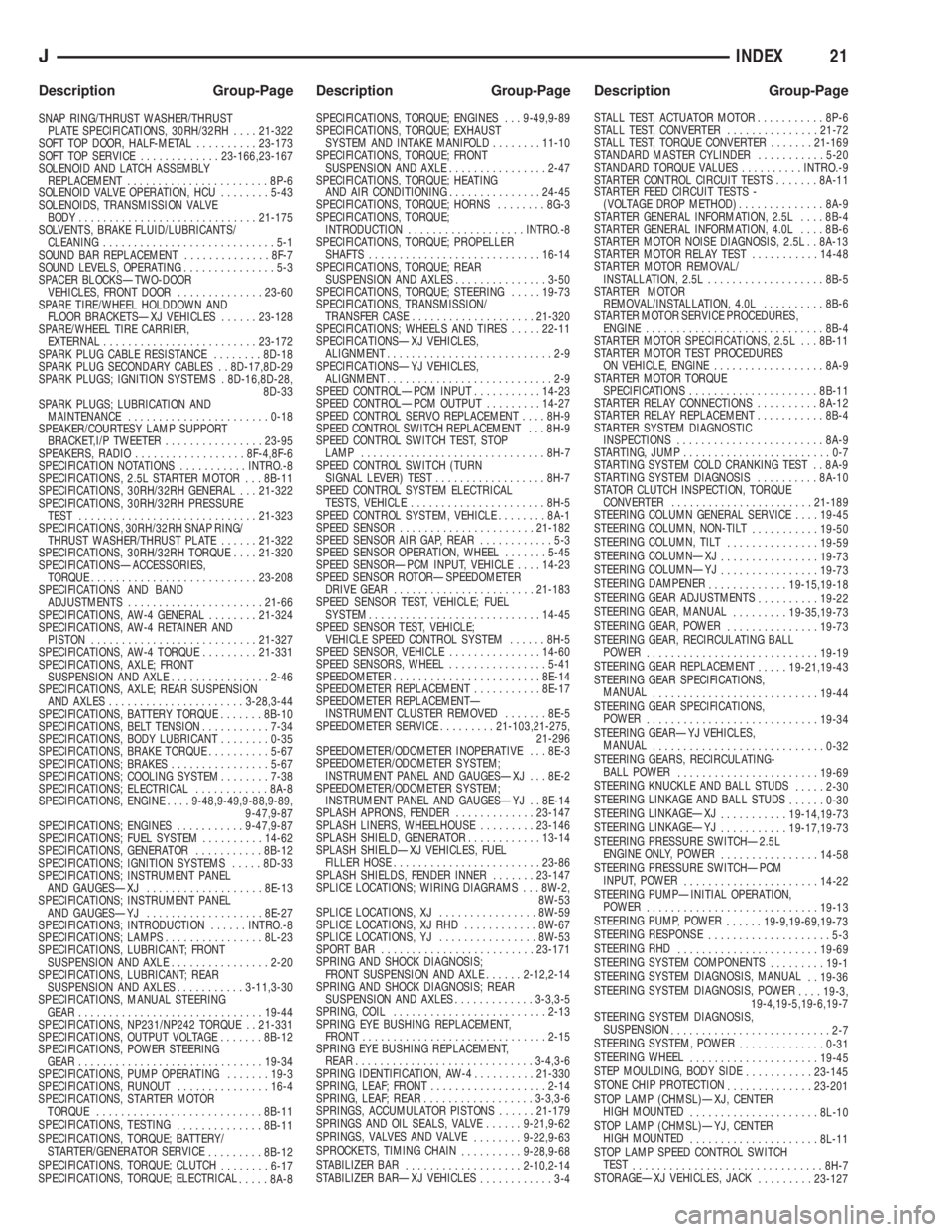

Page 1765 of 1784

SNAP RING/THRUST WASHER/THRUST

PLATE SPECIFICATIONS, 30RH/32RH....21-322

SOFT TOP DOOR, HALF-METAL..........23-173

SOFT TOP SERVICE.............23-166,23-167

SOLENOID AND LATCH ASSEMBLY

REPLACEMENT.......................8P-6

SOLENOID VALVE OPERATION, HCU........5-43

SOLENOIDS, TRANSMISSION VALVE

BODY.............................21-175

SOLVENTS, BRAKE FLUID/LUBRICANTS/

CLEANING............................5-1

SOUND BAR REPLACEMENT..............8F-7

SOUND LEVELS, OPERATING...............5-3

SPACER BLOCKSÐTWO-DOOR

VEHICLES, FRONT DOOR..............23-60

SPARE TIRE/WHEEL HOLDDOWN AND

FLOOR BRACKETSÐXJ VEHICLES......23-128

SPARE/WHEEL TIRE CARRIER,

EXTERNAL.........................23-172

SPARK PLUG CABLE RESISTANCE........8D-18

SPARK PLUG SECONDARY CABLES . . 8D-17,8D-29

SPARK PLUGS; IGNITION SYSTEMS . 8D-16,8D-28,

8D-33

SPARK PLUGS; LUBRICATION AND

MAINTENANCE.......................0-18

SPEAKER/COURTESY LAMP SUPPORT

BRACKET,I/P TWEETER................23-95

SPEAKERS, RADIO..................8F-4,8F-6

SPECIFICATION NOTATIONS...........INTRO.-8

SPECIFICATIONS, 2.5L STARTER MOTOR . . . 8B-11

SPECIFICATIONS, 30RH/32RH GENERAL . . . 21-322

SPECIFICATIONS, 30RH/32RH PRESSURE

TEST.............................21-323

SPECIFICATIONS, 30RH/32RH SNAP RING/

THRUST WASHER/THRUST PLATE......21-322

SPECIFICATIONS, 30RH/32RH TORQUE....21-320

SPECIFICATIONSÐACCESSORIES,

TORQUE...........................23-208

SPECIFICATIONS AND BAND

ADJUSTMENTS......................21-66

SPECIFICATIONS, AW-4 GENERAL........21-324

SPECIFICATIONS, AW-4 RETAINER AND

PISTON...........................21-327

SPECIFICATIONS, AW-4 TORQUE.........21-331

SPECIFICATIONS, AXLE; FRONT

SUSPENSION AND AXLE................2-46

SPECIFICATIONS, AXLE; REAR SUSPENSION

AND AXLES......................3-28,3-44

SPECIFICATIONS, BATTERY TORQUE.......8B-10

SPECIFICATIONS, BELT TENSION...........7-34

SPECIFICATIONS, BODY LUBRICANT........0-35

SPECIFICATIONS, BRAKE TORQUE..........5-67

SPECIFICATIONS; BRAKES................5-67

SPECIFICATIONS; COOLING SYSTEM........7-38

SPECIFICATIONS; ELECTRICAL............8A-8

SPECIFICATIONS, ENGINE....9-48,9-49,9-88,9-89,

9-47,9-87

SPECIFICATIONS; ENGINES...........9-47,9-87

SPECIFICATIONS; FUEL SYSTEM..........14-62

SPECIFICATIONS, GENERATOR...........8B-12

SPECIFICATIONS; IGNITION SYSTEMS.....8D-33

SPECIFICATIONS; INSTRUMENT PANEL

AND GAUGESÐXJ...................8E-13

SPECIFICATIONS; INSTRUMENT PANEL

AND GAUGESÐYJ...................8E-27

SPECIFICATIONS; INTRODUCTION......INTRO.-8

SPECIFICATIONS; LAMPS................8L-23

SPECIFICATIONS, LUBRICANT; FRONT

SUSPENSION AND AXLE................2-20

SPECIFICATIONS, LUBRICANT; REAR

SUSPENSION AND AXLES...........3-11,3-30

SPECIFICATIONS, MANUAL STEERING

GEAR..............................19-44

SPECIFICATIONS, NP231/NP242 TORQUE . . 21-331

SPECIFICATIONS, OUTPUT VOLTAGE.......8B-12

SPECIFICATIONS, POWER STEERING

GEAR..............................19-34

SPECIFICATIONS, PUMP OPERATING.......19-3

SPECIFICATIONS, RUNOUT...............16-4

SPECIFICATIONS, STARTER MOTOR

TORQUE...........................8B-11

SPECIFICATIONS, TESTING

..............8B-11

SPECIFICATIONS, TORQUE; BATTERY/

STARTER/GENERATOR SERVICE

.........8B-12

SPECIFICATIONS, TORQUE; CLUTCH

........6-17

SPECIFICATIONS, TORQUE; ELECTRICAL

.....8A-8SPECIFICATIONS, TORQUE; ENGINES . . . 9-49,9-89

SPECIFICATIONS, TORQUE; EXHAUST

SYSTEM AND INTAKE MANIFOLD........11-10

SPECIFICATIONS, TORQUE; FRONT

SUSPENSION AND AXLE................2-47

SPECIFICATIONS, TORQUE; HEATING

AND AIR CONDITIONING...............24-45

SPECIFICATIONS, TORQUE; HORNS........8G-3

SPECIFICATIONS, TORQUE;

INTRODUCTION...................INTRO.-8

SPECIFICATIONS, TORQUE; PROPELLER

SHAFTS............................16-14

SPECIFICATIONS, TORQUE; REAR

SUSPENSION AND AXLES...............3-50

SPECIFICATIONS, TORQUE; STEERING.....19-73

SPECIFICATIONS, TRANSMISSION/

TRANSFER CASE....................21-320

SPECIFICATIONS; WHEELS AND TIRES.....22-11

SPECIFICATIONSÐXJ VEHICLES,

ALIGNMENT...........................2-9

SPECIFICATIONSÐYJ VEHICLES,

ALIGNMENT...........................2-9

SPEED CONTROLÐPCM INPUT...........14-23

SPEED CONTROLÐPCM OUTPUT.........14-27

SPEED CONTROL SERVO REPLACEMENT....8H-9

SPEED CONTROL SWITCH REPLACEMENT . . . 8H-9

SPEED CONTROL SWITCH TEST, STOP

LAMP..............................8H-7

SPEED CONTROL SWITCH (TURN

SIGNAL LEVER) TEST..................8H-7

SPEED CONTROL SYSTEM ELECTRICAL

TESTS, VEHICLE......................8H-5

SPEED CONTROL SYSTEM, VEHICLE........8A-1

SPEED SENSOR......................21-182

SPEED SENSOR AIR GAP, REAR............5-3

SPEED SENSOR OPERATION, WHEEL.......5-45

SPEED SENSORÐPCM INPUT, VEHICLE....14-23

SPEED SENSOR ROTORÐSPEEDOMETER

DRIVE GEAR.......................21-183

SPEED SENSOR TEST, VEHICLE; FUEL

SYSTEM............................14-45

SPEED SENSOR TEST, VEHICLE;

VEHICLE SPEED CONTROL SYSTEM......8H-5

SPEED SENSOR, VEHICLE...............14-60

SPEED SENSORS, WHEEL................5-41

SPEEDOMETER........................8E-14

SPEEDOMETER REPLACEMENT...........8E-17

SPEEDOMETER REPLACEMENTÐ

INSTRUMENT CLUSTER REMOVED.......8E-5

SPEEDOMETER SERVICE.........21-103,21-275,

21-296

SPEEDOMETER/ODOMETER INOPERATIVE . . . 8E-3

SPEEDOMETER/ODOMETER SYSTEM;

INSTRUMENT PANEL AND GAUGESÐXJ . . . 8E-2

SPEEDOMETER/ODOMETER SYSTEM;

INSTRUMENT PANEL AND GAUGESÐYJ . . 8E-14

SPLASH APRONS, FENDER.............23-147

SPLASH LINERS, WHEELHOUSE.........23-146

SPLASH SHIELD, GENERATOR............13-14

SPLASH SHIELDÐXJ VEHICLES, FUEL

FILLER HOSE........................23-86

SPLASH SHIELDS, FENDER INNER.......23-147

SPLICE LOCATIONS; WIRING DIAGRAMS . . . 8W-2,

8W-53

SPLICE LOCATIONS, XJ................8W-59

SPLICE LOCATIONS, XJ RHD............8W-67

SPLICE LOCATIONS, YJ................8W-53

SPORT BAR.........................23-171

SPRING AND SHOCK DIAGNOSIS;

FRONT SUSPENSION AND AXLE......2-12,2-14

SPRING AND SHOCK DIAGNOSIS; REAR

SUSPENSION AND AXLES.............3-3,3-5

SPRING, COIL.........................2-13

SPRING EYE BUSHING REPLACEMENT,

FRONT..............................2-15

SPRING EYE BUSHING REPLACEMENT,

REAR.............................3-4,3-6

SPRING IDENTIFICATION, AW-4..........21-330

SPRING, LEAF; FRONT...................2-14

SPRING, LEAF; REAR..................3-3,3-6

SPRINGS, ACCUMULATOR PISTONS......21-179

SPRINGS AND OIL SEALS, VALVE......9-21,9-62

SPRINGS, VALVES AND VALVE

........9-22,9-63

SPROCKETS, TIMING CHAIN

..........9-28,9-68

STABILIZER BAR

...................2-10,2-14

STABILIZER BARÐXJ VEHICLES

............3-4STALL TEST, ACTUATOR MOTOR...........8P-6

STALL TEST, CONVERTER...............21-72

STALL TEST, TORQUE CONVERTER.......21-169

STANDARD MASTER CYLINDER...........5-20

STANDARD TORQUE VALUES..........INTRO.-9

STARTER CONTROL CIRCUIT TESTS.......8A-11

STARTER FEED CIRCUIT TESTS -

(VOLTAGE DROP METHOD)..............8A-9

STARTER GENERAL INFORMATION, 2.5L....8B-4

STARTER GENERAL INFORMATION, 4.0L....8B-6

STARTER MOTOR NOISE DIAGNOSIS, 2.5L . . 8A-13

STARTER MOTOR RELAY TEST...........14-48

STARTER MOTOR REMOVAL/

INSTALLATION, 2.5L...................8B-5

STARTER MOTOR

REMOVAL/INSTALLATION, 4.0L..........8B-6

STARTER MOTOR SERVICE PROCEDURES,

ENGINE.............................8B-4

STARTER MOTOR SPECIFICATIONS, 2.5L . . . 8B-11

STARTER MOTOR TEST PROCEDURES

ON VEHICLE, ENGINE..................8A-9

STARTER MOTOR TORQUE

SPECIFICATIONS.....................8B-11

STARTER RELAY CONNECTIONS..........8A-12

STARTER RELAY REPLACEMENT...........8B-4

STARTER SYSTEM DIAGNOSTIC

INSPECTIONS........................8A-9

STARTING, JUMP........................0-7

STARTING SYSTEM COLD CRANKING TEST . . 8A-9

STARTING SYSTEM DIAGNOSIS..........8A-10

STATOR CLUTCH INSPECTION, TORQUE

CONVERTER.......................21-189

STEERING COLUMN GENERAL SERVICE....19-45

STEERING COLUMN, NON-TILT

...........19-50

STEERING COLUMN, TILT

...............19-59

STEERING COLUMNÐXJ

................19-73

STEERING COLUMNÐYJ

................19-73

STEERING DAMPENER

.............19-15,19-18

STEERING GEAR ADJUSTMENTS

..........19-22

STEERING GEAR, MANUAL

.........19-35,19-73

STEERING GEAR, POWER

...............19-73

STEERING GEAR, RECIRCULATING BALL

POWER

............................19-19

STEERING GEAR REPLACEMENT

.....19-21,19-43

STEERING GEAR SPECIFICATIONS,

MANUAL

...........................19-44

STEERING GEAR SPECIFICATIONS,

POWER

............................19-34

STEERING GEARÐYJ VEHICLES,

MANUAL

............................0-32

STEERING GEARS, RECIRCULATING-

BALL POWER

.......................19-69

STEERING KNUCKLE AND BALL STUDS

.....2-30

STEERING LINKAGE AND BALL STUDS

......0-30

STEERING LINKAGEÐXJ

...........19-14,19-73

STEERING LINKAGEÐYJ

...........19-17,19-73

STEERING PRESSURE SWITCHÐ2.5L

ENGINE ONLY, POWER

................14-58

STEERING PRESSURE SWITCHÐPCM

INPUT, POWER

......................14-22

STEERING PUMPÐINITIAL OPERATION,

POWER

............................19-13

STEERING PUMP, POWER

......19-9,19-69,19-73

STEERING RESPONSE

....................5-3

STEERING RHD

.......................19-69

STEERING SYSTEM COMPONENTS

.........19-1

STEERING SYSTEM DIAGNOSIS, MANUAL

. . 19-36

STEERING SYSTEM DIAGNOSIS, POWER

....19-3,

19-4,19-5,19-6,19-7

STEERING SYSTEM DIAGNOSIS,

SUSPENSION

..........................2-7

STEERING SYSTEM, POWER

..............0-31

STEERING WHEEL

.....................19-45

STEP MOULDING, BODY SIDE

...........23-145

STONE CHIP PROTECTION

..............23-201

STOP LAMP (CHMSL)ÐXJ, CENTER

HIGH MOUNTED

.....................8L-10

STOP LAMP (CHMSL)ÐYJ, CENTER

HIGH MOUNTED

.....................8L-11

STOP LAMP SPEED CONTROL SWITCH

TEST

...............................8H-7

STORAGEÐXJ VEHICLES, JACK

.........23-127

JINDEX21

Description Group-Page Description Group-Page Description Group-Page