engine JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 937 of 1784

red. Remove the exhaust tailpipe/muffler clamp and

twist the exhaust tailpipe out of the muffler.

INSTALLATION

(1) Install the muffler onto the catalytic converter.

Install the clamp and tighten the nuts finger tight.

(2) Install the exhaust tailpipe into the rear of the

muffler.

(3) Install the exhaust tailpipe/muffler assembly

on the rear exhaust tailpipe hanger. Make sure that

the exhaust tailpipe has sufficient clearance from the

floor pan.

(4) Install the remaining clamps and the front ex-

haust tailpipe hanger.

(5) Tighten the nuts on the muffler-to-catalytic

converter clamp to 61 Nzm (45 ft. lbs.) torque (Fig.

6). Tighten the nuts on the rear exhaust tailpipe

clamp to 14 Nzm (10 ft. lbs.) torque (Fig. 7).

(6) Lower the vehicle.

(7) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

MUFFLER AND EXHAUST TAILPIPEÐYJ VEHICLES

All original equipment exhaust systems are manu-

factured with the exhaust tailpipe welded to the muf-

fler. Service replacement mufflers and exhaust

tailpipes are clamped together.

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise the vehicle and support the rear of the

vehicle by the side rails and allow the axle to hang

free.

(2) Remove the front muffler clamp from the cata-

lytic converter and muffler connection (Fig. 6).

(3) Remove the exhaust tailpipe hanger/bracket

(Fig. 9).

(4) Remove the exhaust tailpipe from the front ex-

haust tailpipe hanger (Fig. 10).

(5) Heat the converter-to-muffler connection with

an oxyacetylene torch until the metal becomes cherry

red.

(6) While the metal is still cherry red, place a

block of wood against the front of the muffler and

drive the muffler rearward to disengage.

(7) Remove the exhaust tailpipe/muffler assembly.

(8) Remove the exhaust tailpipe from the muffler:

²To remove an original equipment exhaust tailpipe/

muffler combination, cut the exhaust tailpipe close to

the muffler. Collapse the part remaining in the muf-

fler and remove.

²To remove a service exhaust tailpipe/muffler com-

bination, remove the exhaust tailpipe/muffler clamp.

Heat the exhaust tailpipe-to-muffler connection with

an oxyacetylene torch until the metal becomes cherry

red. While the metal is still cherry red, twist the ex-

haust tailpipe out of the muffler.

INSTALLATION

(1) Install the muffler onto the catalytic converter

outlet. Ensure that the locator on the converter

aligns with the notch on the muffler, if so equipped.

Install the clamp and tighten the nuts finger tight.

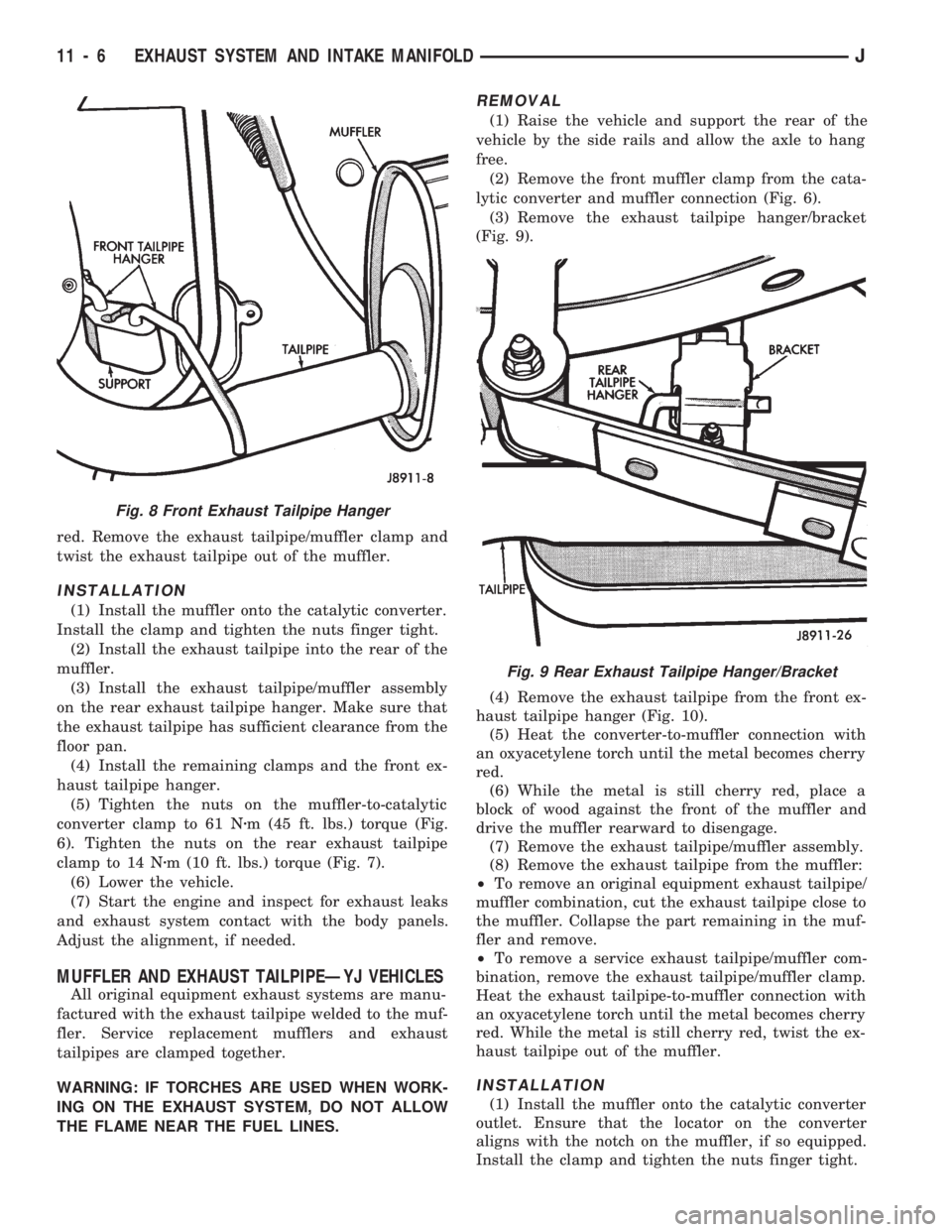

Fig. 8 Front Exhaust Tailpipe Hanger

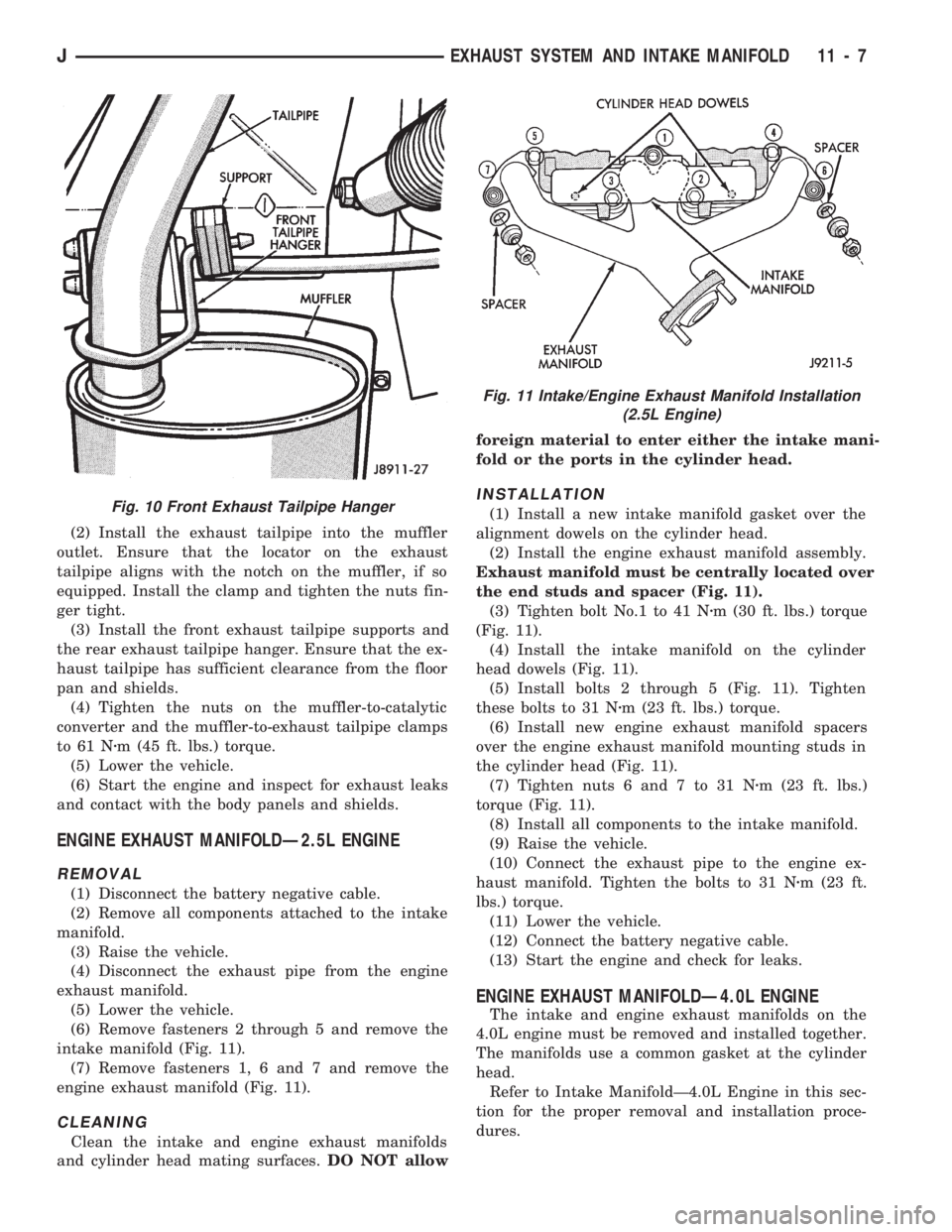

Fig. 9 Rear Exhaust Tailpipe Hanger/Bracket

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLDJ

Page 938 of 1784

(2) Install the exhaust tailpipe into the muffler

outlet. Ensure that the locator on the exhaust

tailpipe aligns with the notch on the muffler, if so

equipped. Install the clamp and tighten the nuts fin-

ger tight.

(3) Install the front exhaust tailpipe supports and

the rear exhaust tailpipe hanger. Ensure that the ex-

haust tailpipe has sufficient clearance from the floor

pan and shields.

(4) Tighten the nuts on the muffler-to-catalytic

converter and the muffler-to-exhaust tailpipe clamps

to 61 Nzm (45 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and contact with the body panels and shields.

ENGINE EXHAUST MANIFOLDÐ2.5L ENGINE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove all components attached to the intake

manifold.

(3) Raise the vehicle.

(4) Disconnect the exhaust pipe from the engine

exhaust manifold.

(5) Lower the vehicle.

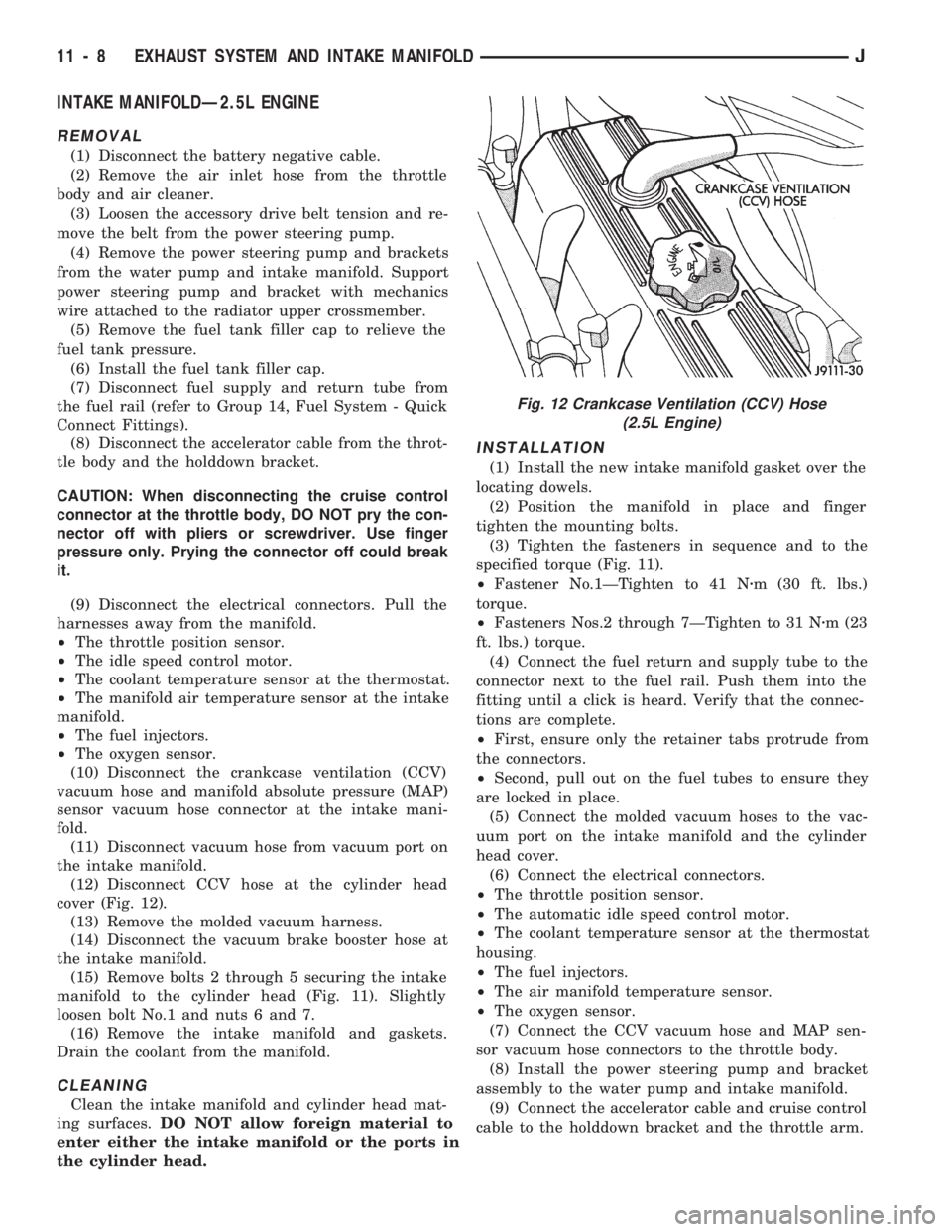

(6) Remove fasteners 2 through 5 and remove the

intake manifold (Fig. 11).

(7) Remove fasteners 1, 6 and 7 and remove the

engine exhaust manifold (Fig. 11).

CLEANING

Clean the intake and engine exhaust manifolds

and cylinder head mating surfaces.DO NOT allowforeign material to enter either the intake mani-

fold or the ports in the cylinder head.

INSTALLATION

(1) Install a new intake manifold gasket over the

alignment dowels on the cylinder head.

(2) Install the engine exhaust manifold assembly.

Exhaust manifold must be centrally located over

the end studs and spacer (Fig. 11).

(3) Tighten bolt No.1 to 41 Nzm (30 ft. lbs.) torque

(Fig. 11).

(4) Install the intake manifold on the cylinder

head dowels (Fig. 11).

(5) Install bolts 2 through 5 (Fig. 11). Tighten

these bolts to 31 Nzm (23 ft. lbs.) torque.

(6) Install new engine exhaust manifold spacers

over the engine exhaust manifold mounting studs in

the cylinder head (Fig. 11).

(7) Tighten nuts 6 and 7 to 31 Nzm (23 ft. lbs.)

torque (Fig. 11).

(8) Install all components to the intake manifold.

(9) Raise the vehicle.

(10) Connect the exhaust pipe to the engine ex-

haust manifold. Tighten the bolts to 31 Nzm (23 ft.

lbs.) torque.

(11) Lower the vehicle.

(12) Connect the battery negative cable.

(13) Start the engine and check for leaks.

ENGINE EXHAUST MANIFOLDÐ4.0L ENGINE

The intake and engine exhaust manifolds on the

4.0L engine must be removed and installed together.

The manifolds use a common gasket at the cylinder

head.

Refer to Intake ManifoldÐ4.0L Engine in this sec-

tion for the proper removal and installation proce-

dures.

Fig. 10 Front Exhaust Tailpipe Hanger

Fig. 11 Intake/Engine Exhaust Manifold Installation

(2.5L Engine)

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 7

Page 939 of 1784

INTAKE MANIFOLDÐ2.5L ENGINE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the air inlet hose from the throttle

body and air cleaner.

(3) Loosen the accessory drive belt tension and re-

move the belt from the power steering pump.

(4) Remove the power steering pump and brackets

from the water pump and intake manifold. Support

power steering pump and bracket with mechanics

wire attached to the radiator upper crossmember.

(5) Remove the fuel tank filler cap to relieve the

fuel tank pressure.

(6) Install the fuel tank filler cap.

(7) Disconnect fuel supply and return tube from

the fuel rail (refer to Group 14, Fuel System - Quick

Connect Fittings).

(8) Disconnect the accelerator cable from the throt-

tle body and the holddown bracket.

CAUTION: When disconnecting the cruise control

connector at the throttle body, DO NOT pry the con-

nector off with pliers or screwdriver. Use finger

pressure only. Prying the connector off could break

it.

(9) Disconnect the electrical connectors. Pull the

harnesses away from the manifold.

²The throttle position sensor.

²The idle speed control motor.

²The coolant temperature sensor at the thermostat.

²The manifold air temperature sensor at the intake

manifold.

²The fuel injectors.

²The oxygen sensor.

(10) Disconnect the crankcase ventilation (CCV)

vacuum hose and manifold absolute pressure (MAP)

sensor vacuum hose connector at the intake mani-

fold.

(11) Disconnect vacuum hose from vacuum port on

the intake manifold.

(12) Disconnect CCV hose at the cylinder head

cover (Fig. 12).

(13) Remove the molded vacuum harness.

(14) Disconnect the vacuum brake booster hose at

the intake manifold.

(15) Remove bolts 2 through 5 securing the intake

manifold to the cylinder head (Fig. 11). Slightly

loosen bolt No.1 and nuts 6 and 7.

(16) Remove the intake manifold and gaskets.

Drain the coolant from the manifold.

CLEANING

Clean the intake manifold and cylinder head mat-

ing surfaces.DO NOT allow foreign material to

enter either the intake manifold or the ports in

the cylinder head.

INSTALLATION

(1) Install the new intake manifold gasket over the

locating dowels.

(2) Position the manifold in place and finger

tighten the mounting bolts.

(3) Tighten the fasteners in sequence and to the

specified torque (Fig. 11).

²Fastener No.1ÐTighten to 41 Nzm (30 ft. lbs.)

torque.

²Fasteners Nos.2 through 7ÐTighten to 31 Nzm (23

ft. lbs.) torque.

(4) Connect the fuel return and supply tube to the

connector next to the fuel rail. Push them into the

fitting until a click is heard. Verify that the connec-

tions are complete.

²First, ensure only the retainer tabs protrude from

the connectors.

²Second, pull out on the fuel tubes to ensure they

are locked in place.

(5) Connect the molded vacuum hoses to the vac-

uum port on the intake manifold and the cylinder

head cover.

(6) Connect the electrical connectors.

²The throttle position sensor.

²The automatic idle speed control motor.

²The coolant temperature sensor at the thermostat

housing.

²The fuel injectors.

²The air manifold temperature sensor.

²The oxygen sensor.

(7) Connect the CCV vacuum hose and MAP sen-

sor vacuum hose connectors to the throttle body.

(8) Install the power steering pump and bracket

assembly to the water pump and intake manifold.

(9) Connect the accelerator cable and cruise control

cable to the holddown bracket and the throttle arm.

Fig. 12 Crankcase Ventilation (CCV) Hose

(2.5L Engine)

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDJ

Page 940 of 1784

CAUTION: Ensure that the accessory drive belt is

routed correctly. Failure to do so can cause the wa-

ter pump to turn in the opposite direction resulting

in engine overheating. Refer to Group 7, Cooling

System for the proper procedure.

(10) Tension the accessory drive belt. Refer to

Group 7, Cooling System for the proper procedure.

(11) Connect the air inlet hose to the throttle body

and the air cleaner.

(12) Connect the battery negative cable.

(13) Start the engine and check for leaks.

INTAKE MANIFOLDÐ4.0L ENGINE

The intake and engine exhaust manifolds on the

4.0L engine must be removed and installed together.

The two manifolds use a common gasket at the cyl-

inder head.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove air cleaner inlet hose from throttle

plate assembly.

(3) Remove the air cleaner assembly.

(4) Remove the throttle cable, cruise control cable (if

equipped) and the transmission line pressure cable.

(5) Disconnect all electrical connectors on the in-

take manifold.

(6) Disconnect and remove the fuel supply and re-

turn lines from the fuel rail assembly (refer to Group

14, Fuel System).

(7) Loosen the accessory drive belt (refer to Group

7, Cooling System). Loosen the tensioner.

(8) Remove the power steering pump and bracket

from the intake manifold and set aside.

(9) Remove the fuel rail and injectors (refer to

Group 14, Fuel System).

(10) Raise the vehicle.

(11) Disconnect the exhaust pipe from the engine

exhaust manifold. Discard the seal.

(12) Lower the vehicle.

(13) Remove the intake manifold and engine ex-

haust manifold.

CLEANING

Clean the mating surfaces of the cylinder head and

the manifold if the original manifold is to be installed.

If the manifold is being replaced, ensure all the fit-

ting, etc. are transferred to the replacement manifold.

INSTALLATION

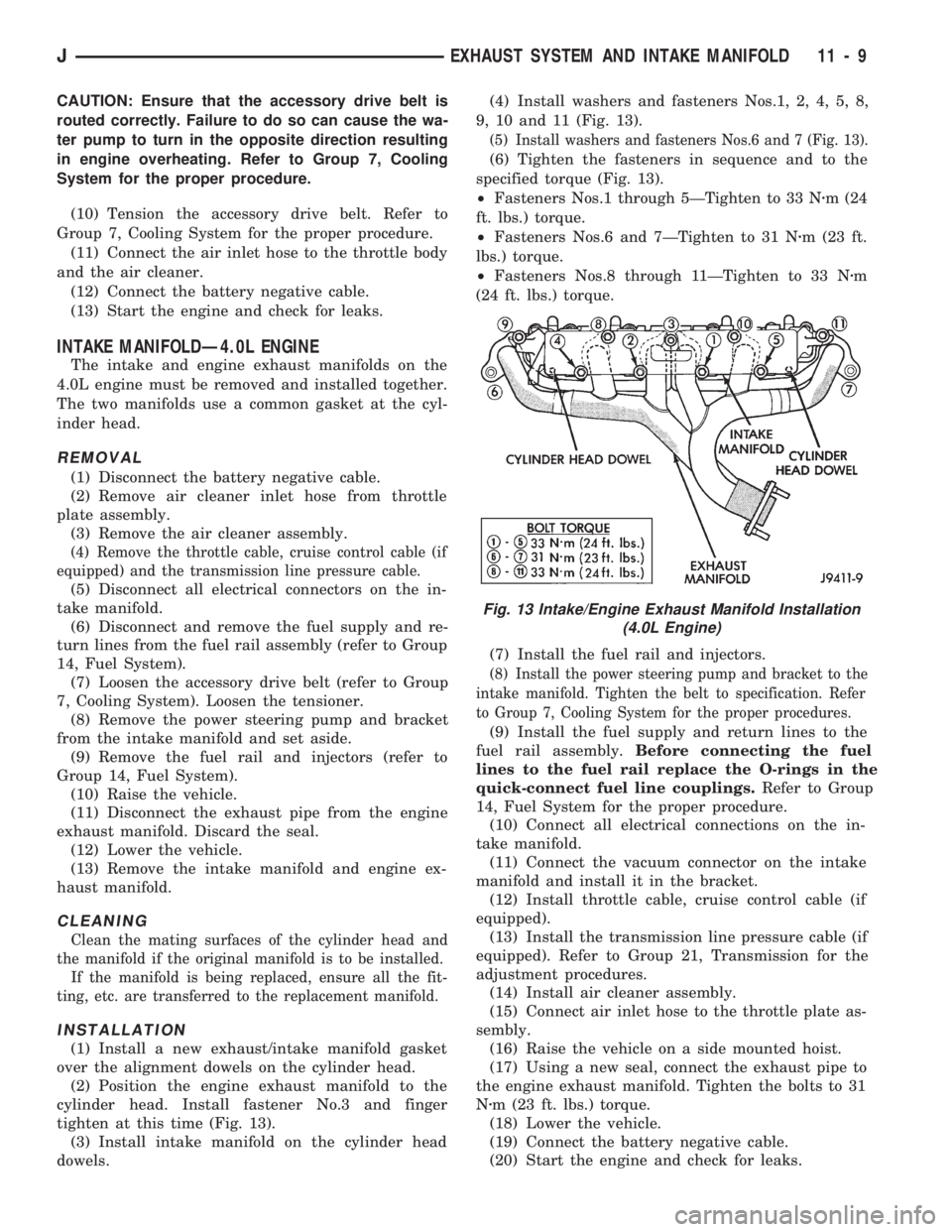

(1) Install a new exhaust/intake manifold gasket

over the alignment dowels on the cylinder head.

(2) Position the engine exhaust manifold to the

cylinder head. Install fastener No.3 and finger

tighten at this time (Fig. 13).

(3) Install intake manifold on the cylinder head

dowels.(4) Install washers and fasteners Nos.1, 2, 4, 5, 8,

9, 10 and 11 (Fig. 13).

(5) Install washers and fasteners Nos.6 and 7 (Fig. 13).

(6) Tighten the fasteners in sequence and to the

specified torque (Fig. 13).

²Fasteners Nos.1 through 5ÐTighten to 33 Nzm (24

ft. lbs.) torque.

²Fasteners Nos.6 and 7ÐTighten to 31 Nzm (23 ft.

lbs.) torque.

²Fasteners Nos.8 through 11ÐTighten to 33 Nzm

(24 ft. lbs.) torque.

(7) Install the fuel rail and injectors.

(8) Install the power steering pump and bracket to the

intake manifold. Tighten the belt to specification. Refer

to Group 7, Cooling System for the proper procedures.

(9) Install the fuel supply and return lines to the

fuel rail assembly.Before connecting the fuel

lines to the fuel rail replace the O-rings in the

quick-connect fuel line couplings.Refer to Group

14, Fuel System for the proper procedure.

(10) Connect all electrical connections on the in-

take manifold.

(11) Connect the vacuum connector on the intake

manifold and install it in the bracket.

(12) Install throttle cable, cruise control cable (if

equipped).

(13) Install the transmission line pressure cable (if

equipped). Refer to Group 21, Transmission for the

adjustment procedures.

(14) Install air cleaner assembly.

(15) Connect air inlet hose to the throttle plate as-

sembly.

(16) Raise the vehicle on a side mounted hoist.

(17) Using a new seal, connect the exhaust pipe to

the engine exhaust manifold. Tighten the bolts to 31

Nzm (23 ft. lbs.) torque.

(18) Lower the vehicle.

(19) Connect the battery negative cable.

(20) Start the engine and check for leaks.

Fig. 13 Intake/Engine Exhaust Manifold Installation

(4.0L Engine)

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 9

Page 955 of 1784

YJ BUMPERS AND FRAME ATTACHED COMPONENTS

INDEX

page page

Generator Splash Shield................... 14

Body.................................. 18

Engine Front Support Cushion............... 15

Frame Crossmember Cover................. 14

Front Bumper........................... 14

Fuel and Brake Fluid Tube Retainer Clip....... 16

Fuel Filter Shield and Bracket............... 17

Fuel Tank Skid Plate...................... 16Muffler and Tailpipe Heat Shields............ 17

Muffler/Tailpipe Hanger Bracket.............. 16

Rear Bumper............................ 18

Rear Jounce Bumper..................... 18

Service Information....................... 14

Tow Hooks............................. 14

Transfer Case Skid Plate.................. 15

SERVICE INFORMATION

In some cases, components in the following proce-

dures either support, or are hidden by other compo-

nents.

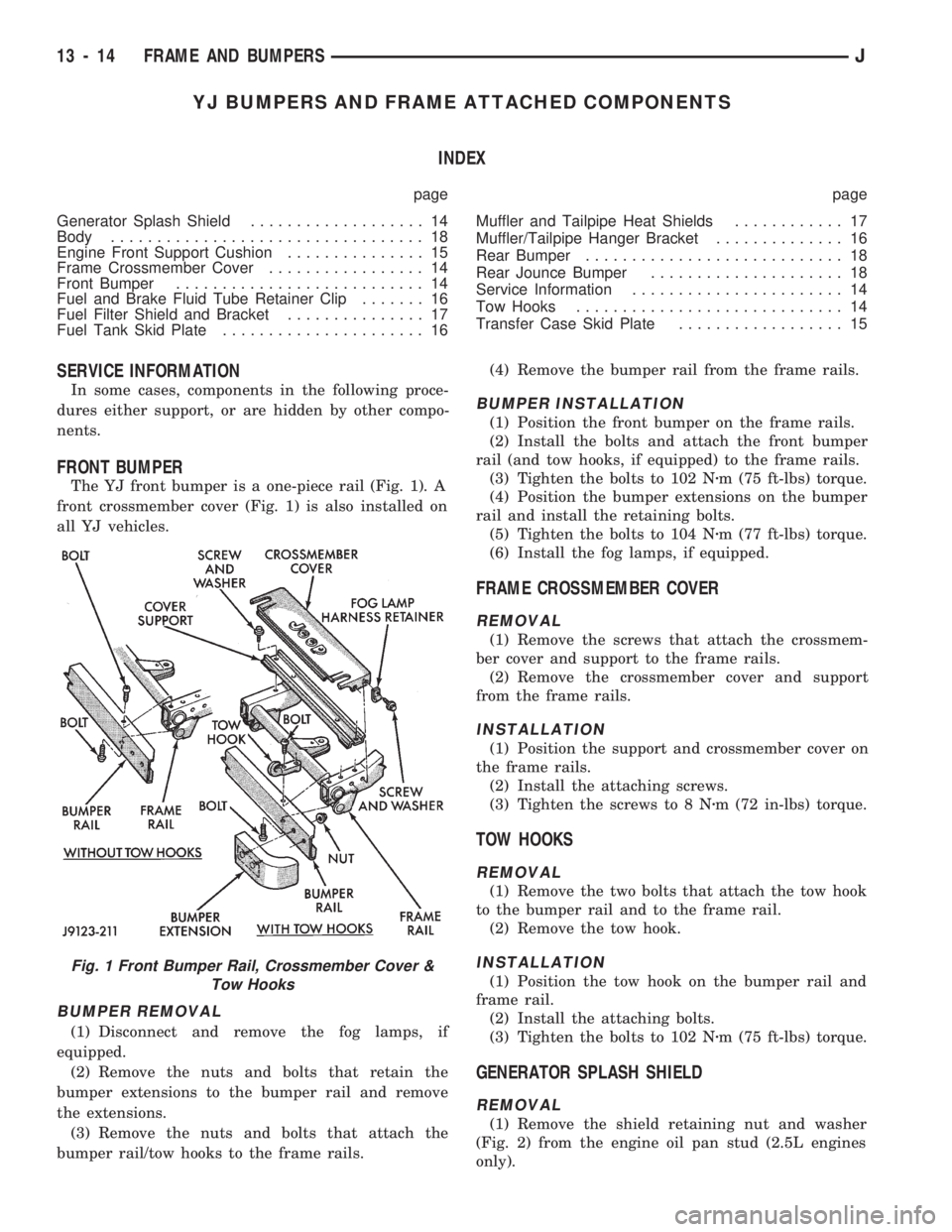

FRONT BUMPER

The YJ front bumper is a one-piece rail (Fig. 1). A

front crossmember cover (Fig. 1) is also installed on

all YJ vehicles.

BUMPER REMOVAL

(1) Disconnect and remove the fog lamps, if

equipped.

(2) Remove the nuts and bolts that retain the

bumper extensions to the bumper rail and remove

the extensions.

(3) Remove the nuts and bolts that attach the

bumper rail/tow hooks to the frame rails.(4) Remove the bumper rail from the frame rails.

BUMPER INSTALLATION

(1) Position the front bumper on the frame rails.

(2) Install the bolts and attach the front bumper

rail (and tow hooks, if equipped) to the frame rails.

(3) Tighten the bolts to 102 Nzm (75 ft-lbs) torque.

(4) Position the bumper extensions on the bumper

rail and install the retaining bolts.

(5) Tighten the bolts to 104 Nzm (77 ft-lbs) torque.

(6) Install the fog lamps, if equipped.

FRAME CROSSMEMBER COVER

REMOVAL

(1) Remove the screws that attach the crossmem-

ber cover and support to the frame rails.

(2) Remove the crossmember cover and support

from the frame rails.

INSTALLATION

(1) Position the support and crossmember cover on

the frame rails.

(2) Install the attaching screws.

(3) Tighten the screws to 8 Nzm (72 in-lbs) torque.

TOW HOOKS

REMOVAL

(1) Remove the two bolts that attach the tow hook

to the bumper rail and to the frame rail.

(2) Remove the tow hook.

INSTALLATION

(1) Position the tow hook on the bumper rail and

frame rail.

(2) Install the attaching bolts.

(3) Tighten the bolts to 102 Nzm (75 ft-lbs) torque.

GENERATOR SPLASH SHIELD

REMOVAL

(1) Remove the shield retaining nut and washer

(Fig. 2) from the engine oil pan stud (2.5L engines

only).

Fig. 1 Front Bumper Rail, Crossmember Cover &

Tow Hooks

13 - 14 FRAME AND BUMPERSJ

Page 956 of 1784

(2) Pry the serrated retainers from the frame rail

holes at each side of the vehicle.

(3) Pry the serrated retainers from the fan shroud

holes (Fig. 2).

(4) Remove the shield from the vehicle.

INSTALLATION

(1) Position the generator splash shield at the fan

shroud and frame rails.

(2) Force the serrated retainers into the fan shroud

holes.

(3) Force the serrated retainers into the frame rail

holes at each side of the vehicle.

ENGINE FRONT SUPPORT CUSHION

REMOVAL

(1) Raise and support the engine.

(2) Remove the nut and bolt that attach the engine

support cushion to the engine support bracket (Figs.

3 and 4).(3) Remove the nut and bolt that attach the sup-

port cushion to the frame adapter bracket.

(4) Remove the support cushion from the frame

adapter bracket.

INSTALLATION

(1) Position the support cushion on the frame

adapter bracket.

(2) Install the bolt and nut that attach the engine

support cushion to the frame adapter bracket.

Tighten the bolt and nut to 49 Nzm (36 ft-lbs) torque.

(3) Install the bolt and nut that attach the engine

support cushion to the engine support bracket.

Tighten the nut to 65 Nzm (48 ft-lbs) torque.

(4) Remove the support and lower the engine.

TRANSFER CASE SKID PLATE

REMOVAL

(1) Raise and support the transmission.

(2) Remove the nuts that attach the transmission

support cushion and torque bracket to the skid plate

(Fig. 5).

(3) Separate the transmission support cushion from

the skid plate.

(4) Remove the nuts and bolts that attach the skid

plate to the frame.

(5) Remove the skid plate from the vehicle.

INSTALLATION

(1) Position the skid plate at the frame and trans-

mission support cushion.

(2) Attach the skid plate to the frame.

(3) Install the nuts that attach the transmission

support cushion and torque bracket to the skid plate.

Tighten the nuts to 56 Nzm (41 ft-lbs) torque.

(4) Remove the support and lower the transmis-

sion.

Fig. 2 Generator Splash Shield

Fig. 3 Engine Support CushionÐ2.5L Engine

Fig. 4 Engine Support CushionÐ4.0L Engine

JFRAME AND BUMPERS 13 - 15

Page 961 of 1784

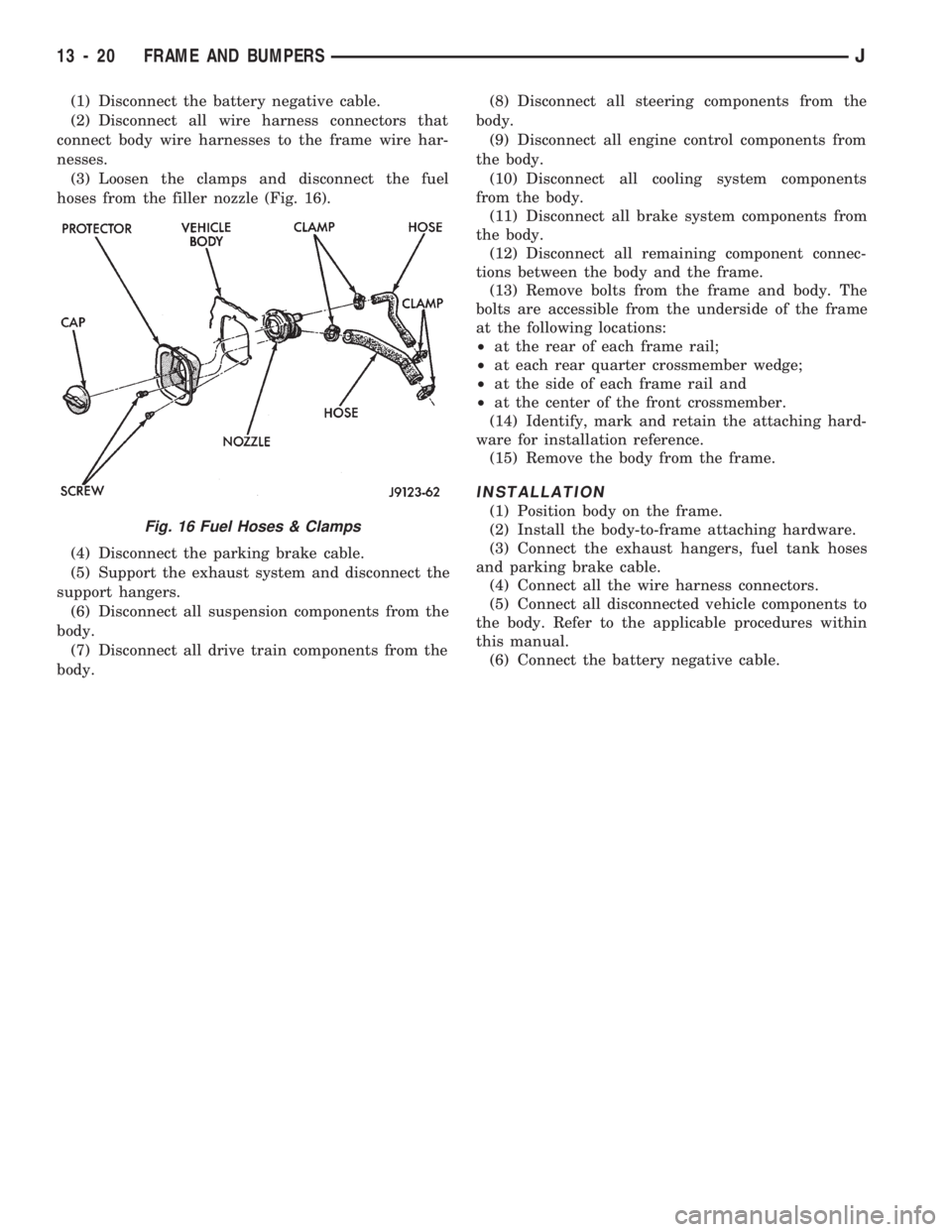

(1) Disconnect the battery negative cable.

(2) Disconnect all wire harness connectors that

connect body wire harnesses to the frame wire har-

nesses.

(3) Loosen the clamps and disconnect the fuel

hoses from the filler nozzle (Fig. 16).

(4) Disconnect the parking brake cable.

(5) Support the exhaust system and disconnect the

support hangers.

(6) Disconnect all suspension components from the

body.

(7) Disconnect all drive train components from the

body.(8) Disconnect all steering components from the

body.

(9) Disconnect all engine control components from

the body.

(10) Disconnect all cooling system components

from the body.

(11) Disconnect all brake system components from

the body.

(12) Disconnect all remaining component connec-

tions between the body and the frame.

(13) Remove bolts from the frame and body. The

bolts are accessible from the underside of the frame

at the following locations:

²at the rear of each frame rail;

²at each rear quarter crossmember wedge;

²at the side of each frame rail and

²at the center of the front crossmember.

(14) Identify, mark and retain the attaching hard-

ware for installation reference.

(15) Remove the body from the frame.

INSTALLATION

(1) Position body on the frame.

(2) Install the body-to-frame attaching hardware.

(3) Connect the exhaust hangers, fuel tank hoses

and parking brake cable.

(4) Connect all the wire harness connectors.

(5) Connect all disconnected vehicle components to

the body. Refer to the applicable procedures within

this manual.

(6) Connect the battery negative cable.

Fig. 16 Fuel Hoses & Clamps

13 - 20 FRAME AND BUMPERSJ

Page 962 of 1784

FUEL SYSTEM

CONTENTS

page page

ACCELERATOR PEDAL AND THROTTLE CABLE... 16

FUEL DELIVERY SYSTEM................. 2

FUEL TANKS........................... 12

GENERAL INFORMATION.................. 1

MULTI-PORT FUEL INJECTION (MFI)ÐCOMPO-

NENT DESCRIPTION/SYSTEM OPERATION . 17MULTI-PORT FUEL INJECTION (MFI)Ð

COMPONENT REMOVAL/INSTALLATION . . . 54

MULTI-PORT FUEL INJECTION (MFI)Ð

GENERAL DIAGNOSIS.................. 32

SPECIFICATIONS....................... 62

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicle models by alphabetical designation or

by the particular vehicle nameplate. A chart showing

a breakdown of the alphabetical designations is in-

cluded in the Introduction section at the beginning of

this manual.

TheFuel Systemconsists of: the fuel tank, an

electric (fuel tank mounted) fuel pump and a fuel fil-

ter. It also consists of fuel tubes/lines/hoses, vacuum

hoses, throttle body and fuel injectors.

TheFuel Delivery Systemconsists of: the electric

fuel pump, fuel filter, fuel tubes/lines/hoses, fuel rail,

fuel injectors and fuel pressure regulator.

AFuel Return Systemis used on all vehicles.

The system consists of: the fuel tubes/lines/hoses that

route fuel back to the fuel tank.

TheFuel Tank Assemblyconsists of: the fuel

tank, filler tube, fuel gauge sending unit/electric fuel

pump module, a pressure relief/rollover valve and a

pressure-vacuum filler cap.

Also to be considered part of the fuel system is the

Evaporation Control System.This is designed to

reduce the emission of fuel vapors into the atmo-

sphere. The description and function of the Evapora-

tive Control System is found in Group 25, Emission

Control Systems.

FUEL USAGE STATEMENT

Your vehicle was designed to meet all emission reg-

ulations and provide excellent fuel economy using

high quality unleaded gasoline. Only use unleaded

gasolines having a minimum posted octane of 87.

If your vehicle develops occasional light spark

knock (ping) at low engine speeds, this is not harm-

ful. However,continued heavy knock at high

speeds can cause damage and should be re-

ported to your dealer immediately.Engine dam-age as a result of heavy knock operation may not be

covered by the new vehicle warranty.

In addition to using unleaded gasoline with the

proper octane rating,those that contain deter-

gents, corrosion and stability additives are rec-

ommended.Using gasolines that have these

additives will help improve fuel economy, reduce

emissions and maintain vehicle performance. Gener-

ally, premium unleaded gasolines contain more addi-

tive than regular unleaded gasolines.

Poor quality gasolinecan cause problems such

as hard starting, stalling and stumble. If you experi-

ence these problems, use another brand of gasoline

before considering service for the vehicle.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

and ETBE. The type and amount of oxygenate used

in the blend is important. The following are generally

used in gasoline blends:

ETHANOL

Ethanol (Ethyl or Grain Alcohol) properly blended,

is used as a mixture of 10 percent ethanol and 90

percent gasoline.Gasoline with ethanol may be

used in your vehicle.

METHANOL

CAUTION: DO NOT USE GASOLINES CONTAINING

METHANOL.Use of methanol/gasoline blends may re-

sult in starting and driveability problems. In addition,

damage may be done to critical fuel system compo-

nents.

Methanol (Methyl or Wood Alcohol) is used in a va-

riety of concentrations blended with unleaded gaso-

JFUEL SYSTEM 14 - 1

Page 963 of 1784

line. You may encounter fuels containing 3 percent

or more methanol along with other alcohols called co-

solvents.

Problems that are the result of using methanol/gas-

oline blends are not the responsibility of Chrysler

Corporation. They may not be covered by the vehicle

warranty.

MTBE/ETBE

Gasoline and MTBE (Methyl Tertiary Butyl Ether)

blends are a mixture of unleaded gasoline and up to

15 percent MTBE. Gasoline and ETBE (Ethyl Ter-

tiary Butyl Ether) are blends of gasoline and up to

17 percent ETBE. Gasoline blended with MTBE or

ETBE may be used in your vehicle.CLEAN AIR GASOLINE

Many gasolines are now being blended that con-

tribute to cleaner air, especially in those areas of the

country where air pollution levels are high. These

new blends provide a cleaner burning fuel and some

are referred to asReformulated Gasoline.

In areas of the country where carbon monoxide lev-

els are high, gasolines are being treated with oxy-

genated materials such as MTBE, ETBE and

ethanol.

Chrysler Corporation supports these efforts toward

cleaner air and recommends that you use these gas-

olines as they become available.

FUEL DELIVERY SYSTEM

INDEX

page page

Fuel Filter............................... 8

Fuel Pressure Leak Down Test............... 7

Fuel Pressure Release Procedure............. 5

Fuel Pump Capacity Test................... 7

Fuel Pump Electrical Control................. 5Fuel Pump Module........................ 2

Fuel System Pressure Test.................. 5

Fuel Tubes/Lines/Hoses and Clamps........... 9

Quick-Connect Fittings..................... 9

FUEL PUMP MODULE

The fuel pump module is installed in the top of the

fuel tank. The fuel pump module contains the follow-

ing components:

²Electric fuel pump

²Fuel pump reservoir

²In-tank fuel filter

²Fuel gauge sending unit

²Fuel supply and return tube connections

The fuel pump used on all vehicles is a gear/rotor

type pump. It is driven by a permanent magnet 12

volt electric motor that is immersed in the fuel tank.

The electrical pump is integral with the fuel sender

unit. The pump/sender assembly is installed inside

the fuel tank.

The fuel pump has a check valve at the outlet end

that consists of a ball held against a seat by force ap-

plied from a spring. When the pump is operating,

fuel pressure overcomes spring pressure and forces

the ball off its seat, allowing fuel to flow. When the

pump is not operating, spring pressure forces the ball

back against the seat preventing fuel backflow

through the pump.

Fuel system pressure is maintained at approxi-

mately 214 kPa (31 psi). This is when the pump is

operating and vacuum is supplied to the fuel pres-

sure regulator. If vacuum is not supplied to the pres-

sure regulator, fuel pressure will be approximately

55-69 kPa (8-10 psi) higher. This may be due to a

broken or clogged vacuum line. When the fuel pumpis not operating, system fuel pressure of 131-269 kPa

(19-39 psi) is maintained. This is done by the fuel

pump outlet check valve and the vacuum assisted

fuel pressure regulator.

REMOVALÐXJ MODELS

The fuel pump/gauge sender unit assembly can be

removed from the fuel tank without removing the

tank from the vehicle.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE FUEL PUMP MODULE,

THE FUEL SYSTEM PRESSURE MUST BE RE-

LEASED. REFER TO THE FUEL PRESSURE RE-

LEASE PROCEDURE IN THIS GROUP.

WARNING: EXTINGUISH ALL TOBACCO SMOKING

PRODUCTS BEFORE SERVICING THE FUEL SYS-

TEM. KEEP OPEN FLAME AWAY FROM FUEL SYS-

TEM COMPONENTS.

(1) Remove fuel filler cap. Perform the Fuel Pres-

sure Release Procedure as outlined in this group.

(2) Disconnect negative battery cable.

(3) Using an approved portable gasoline siphon/

storage tank, drain fuel tank until fuel level is below

one quarter (1/4) full.

(4) Raise and support vehicle.

14 - 2 FUEL SYSTEMJ

Page 965 of 1784

(3) Using a brass punch and a hammer, install

lock ring. Carefully tap lock ring clockwise until it

seats against stop on fuel tank.

(4) Connect fuel supply and return hoses to fittings

on fuel pump module. Tighten hose clamps.

(5) Connect fuel pump module electrical harness

connector to main harness connector.

(6) Lower vehicle.

(7) Fill fuel tank. Install fuel tank cap.

(8) Connect negative battery cable.

(9) Start vehicle and inspect for leaks.

REMOVALÐYJ MODELS

The fuel tank must be removed to remove the fuel

pump module.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE FUEL PUMP MODULE,

THE FUEL SYSTEM PRESSURE MUST BE RE-

LEASED. REFER TO THE FUEL PRESSURE RE-

LEASE PROCEDURE IN THIS GROUP.

WARNING: EXTINGUISH ALL TOBACCO SMOKING

PRODUCTS BEFORE SERVICING THE FUEL SYS-

TEM. KEEP OPEN FLAME AWAY FROM FUEL SYS-

TEM COMPONENTS.

(1) Remove negative battery cable.

(2) Remove fuel filler cap. Perform the Fuel Pres-

sure Release Procedure as outlined in this group.

(3) Remove fuel tank. Refer to Fuel Tank Remov-

alÐYJ Models.

(4) Remove fuel pump module assembly.

(5) Remove mounting screws. Lift assembly and

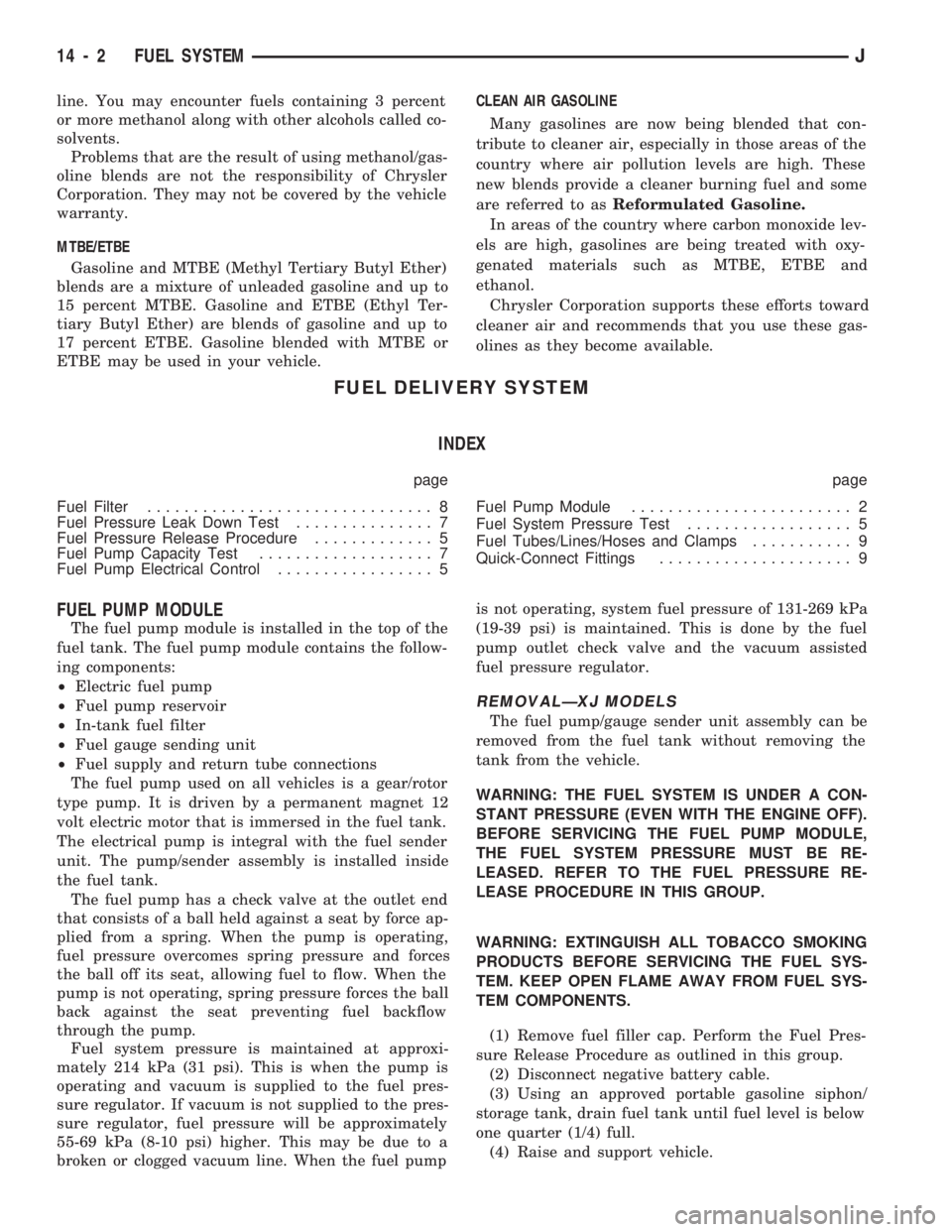

gasket out of fuel tank. Discard old gasket (Fig. 4).

(6) Remove and discard fuel pump inlet filter.DISASSEMBLYÐYJ MODELS

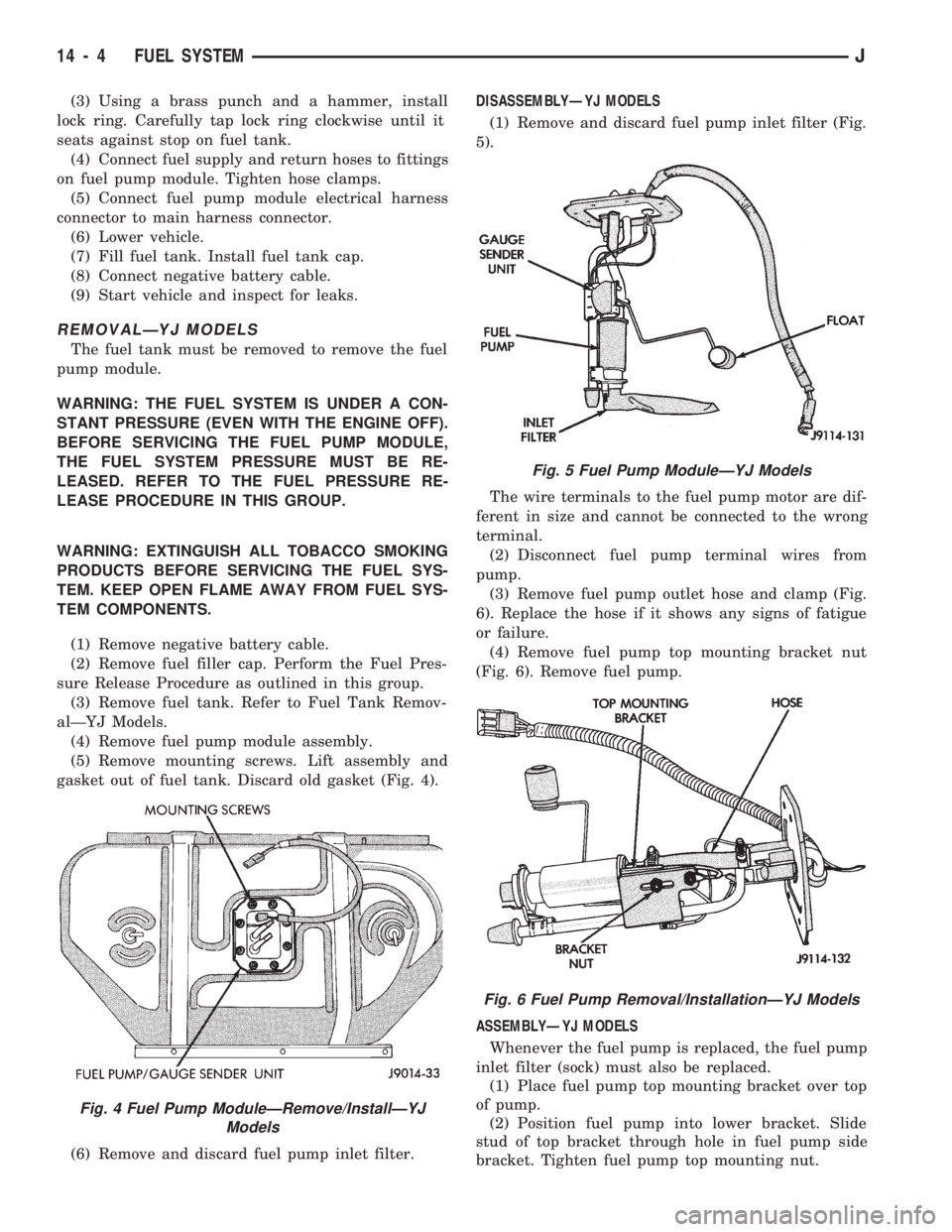

(1) Remove and discard fuel pump inlet filter (Fig.

5).

The wire terminals to the fuel pump motor are dif-

ferent in size and cannot be connected to the wrong

terminal.

(2) Disconnect fuel pump terminal wires from

pump.

(3) Remove fuel pump outlet hose and clamp (Fig.

6). Replace the hose if it shows any signs of fatigue

or failure.

(4) Remove fuel pump top mounting bracket nut

(Fig. 6). Remove fuel pump.

ASSEMBLYÐYJ MODELS

Whenever the fuel pump is replaced, the fuel pump

inlet filter (sock) must also be replaced.

(1) Place fuel pump top mounting bracket over top

of pump.

(2) Position fuel pump into lower bracket. Slide

stud of top bracket through hole in fuel pump side

bracket. Tighten fuel pump top mounting nut.

Fig. 4 Fuel Pump ModuleÐRemove/InstallÐYJ

Models

Fig. 5 Fuel Pump ModuleÐYJ Models

Fig. 6 Fuel Pump Removal/InstallationÐYJ Models

14 - 4 FUEL SYSTEMJ