engine JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 926 of 1784

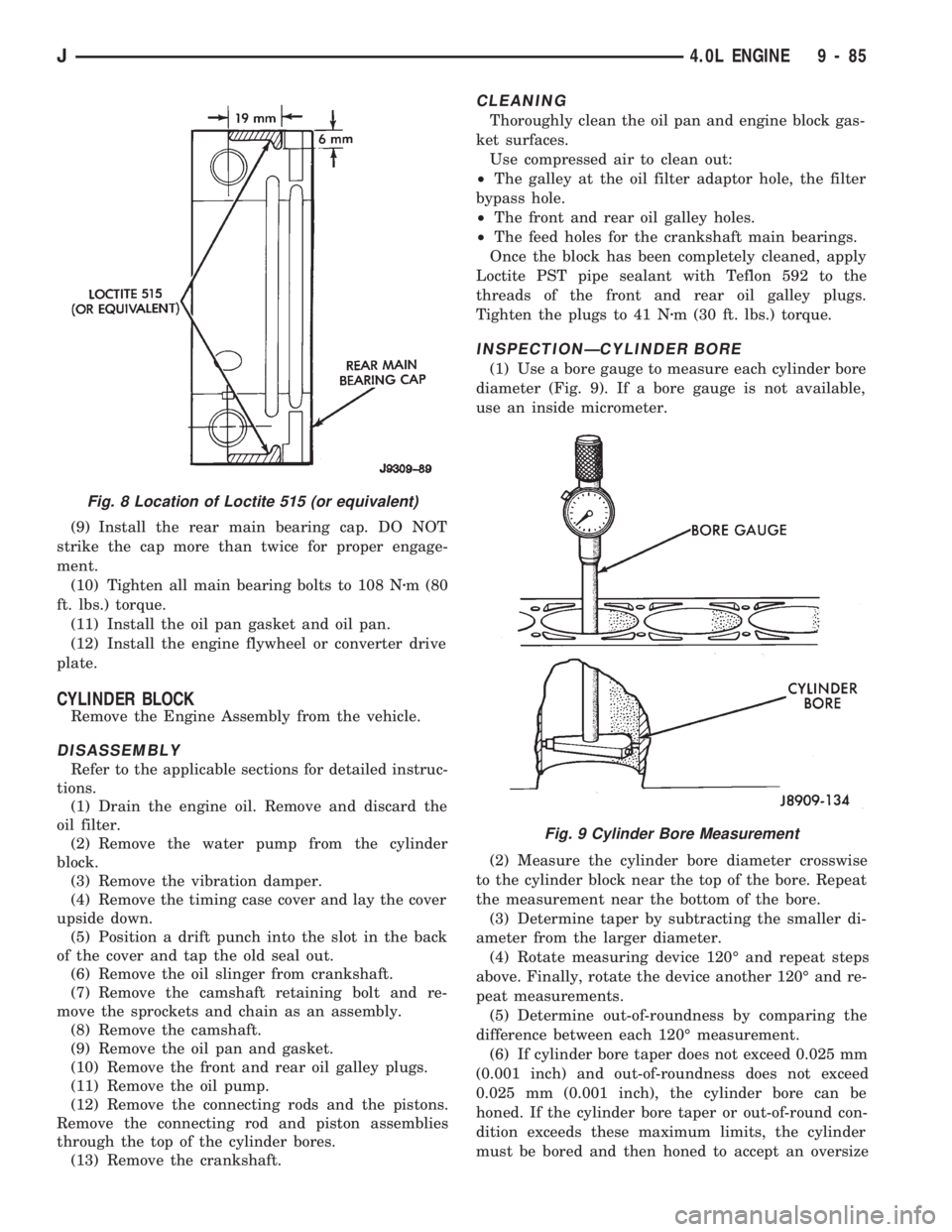

(9) Install the rear main bearing cap. DO NOT

strike the cap more than twice for proper engage-

ment.

(10) Tighten all main bearing bolts to 108 Nzm (80

ft. lbs.) torque.

(11) Install the oil pan gasket and oil pan.

(12) Install the engine flywheel or converter drive

plate.

CYLINDER BLOCK

Remove the Engine Assembly from the vehicle.

DISASSEMBLY

Refer to the applicable sections for detailed instruc-

tions.

(1) Drain the engine oil. Remove and discard the

oil filter.

(2) Remove the water pump from the cylinder

block.

(3) Remove the vibration damper.

(4) Remove the timing case cover and lay the cover

upside down.

(5) Position a drift punch into the slot in the back

of the cover and tap the old seal out.

(6) Remove the oil slinger from crankshaft.

(7) Remove the camshaft retaining bolt and re-

move the sprockets and chain as an assembly.

(8) Remove the camshaft.

(9) Remove the oil pan and gasket.

(10) Remove the front and rear oil galley plugs.

(11) Remove the oil pump.

(12) Remove the connecting rods and the pistons.

Remove the connecting rod and piston assemblies

through the top of the cylinder bores.

(13) Remove the crankshaft.

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole, the filter

bypass hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs.

Tighten the plugs to 41 Nzm (30 ft. lbs.) torque.

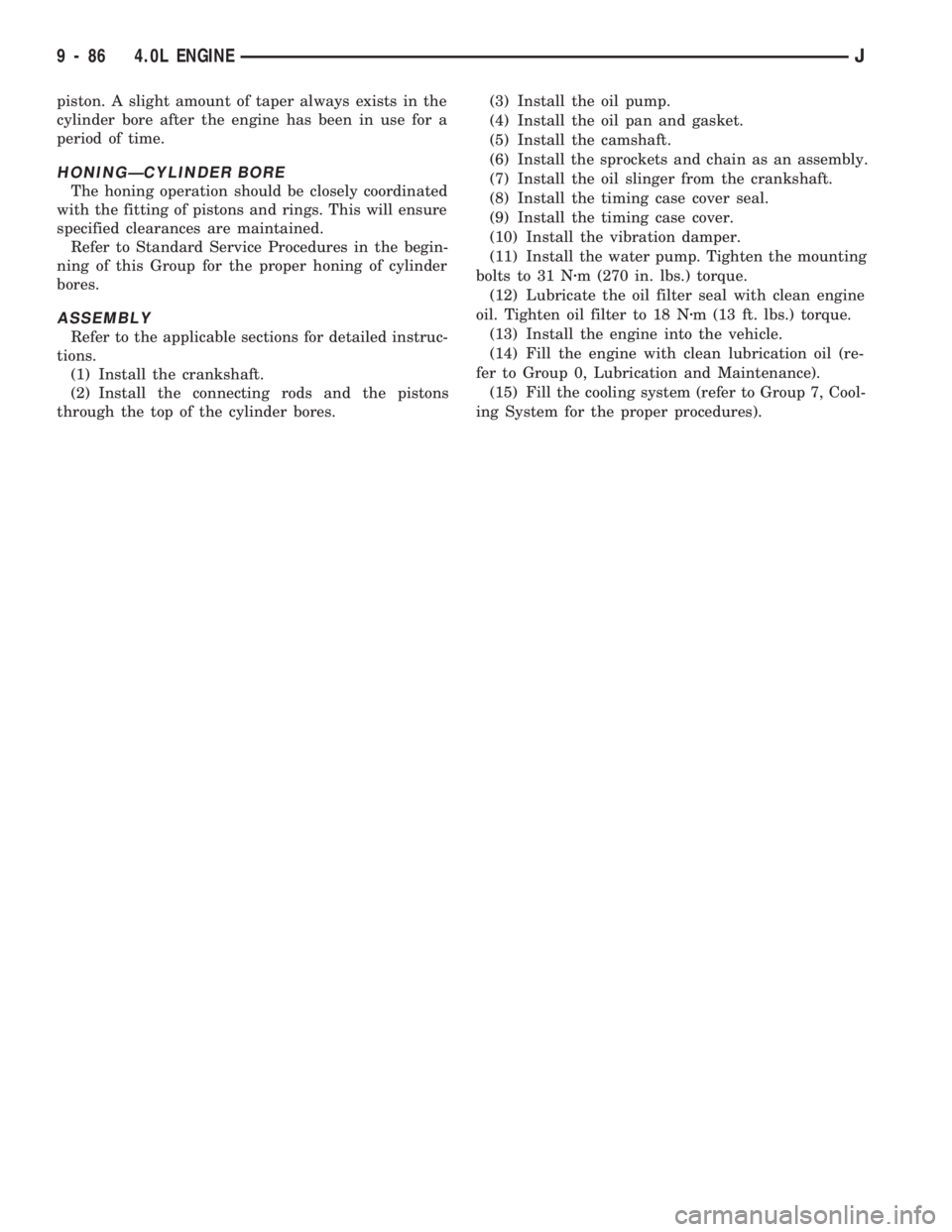

INSPECTIONÐCYLINDER BORE

(1) Use a bore gauge to measure each cylinder bore

diameter (Fig. 9). If a bore gauge is not available,

use an inside micrometer.

(2) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the bottom of the bore.

(3) Determine taper by subtracting the smaller di-

ameter from the larger diameter.

(4) Rotate measuring device 120É and repeat steps

above. Finally, rotate the device another 120É and re-

peat measurements.

(5) Determine out-of-roundness by comparing the

difference between each 120É measurement.

(6) If cylinder bore taper does not exceed 0.025 mm

(0.001 inch) and out-of-roundness does not exceed

0.025 mm (0.001 inch), the cylinder bore can be

honed. If the cylinder bore taper or out-of-round con-

dition exceeds these maximum limits, the cylinder

must be bored and then honed to accept an oversize

Fig. 8 Location of Loctite 515 (or equivalent)

Fig. 9 Cylinder Bore Measurement

J4.0L ENGINE 9 - 85

Page 927 of 1784

piston. A slight amount of taper always exists in the

cylinder bore after the engine has been in use for a

period of time.

HONINGÐCYLINDER BORE

The honing operation should be closely coordinated

with the fitting of pistons and rings. This will ensure

specified clearances are maintained.

Refer to Standard Service Procedures in the begin-

ning of this Group for the proper honing of cylinder

bores.

ASSEMBLY

Refer to the applicable sections for detailed instruc-

tions.

(1) Install the crankshaft.

(2) Install the connecting rods and the pistons

through the top of the cylinder bores.(3) Install the oil pump.

(4) Install the oil pan and gasket.

(5) Install the camshaft.

(6) Install the sprockets and chain as an assembly.

(7) Install the oil slinger from the crankshaft.

(8) Install the timing case cover seal.

(9) Install the timing case cover.

(10) Install the vibration damper.

(11) Install the water pump. Tighten the mounting

bolts to 31 Nzm (270 in. lbs.) torque.

(12) Lubricate the oil filter seal with clean engine

oil. Tighten oil filter to 18 Nzm (13 ft. lbs.) torque.

(13) Install the engine into the vehicle.

(14) Fill the engine with clean lubrication oil (re-

fer to Group 0, Lubrication and Maintenance).

(15) Fill the cooling system (refer to Group 7, Cool-

ing System for the proper procedures).

9 - 86 4.0L ENGINEJ

Page 928 of 1784

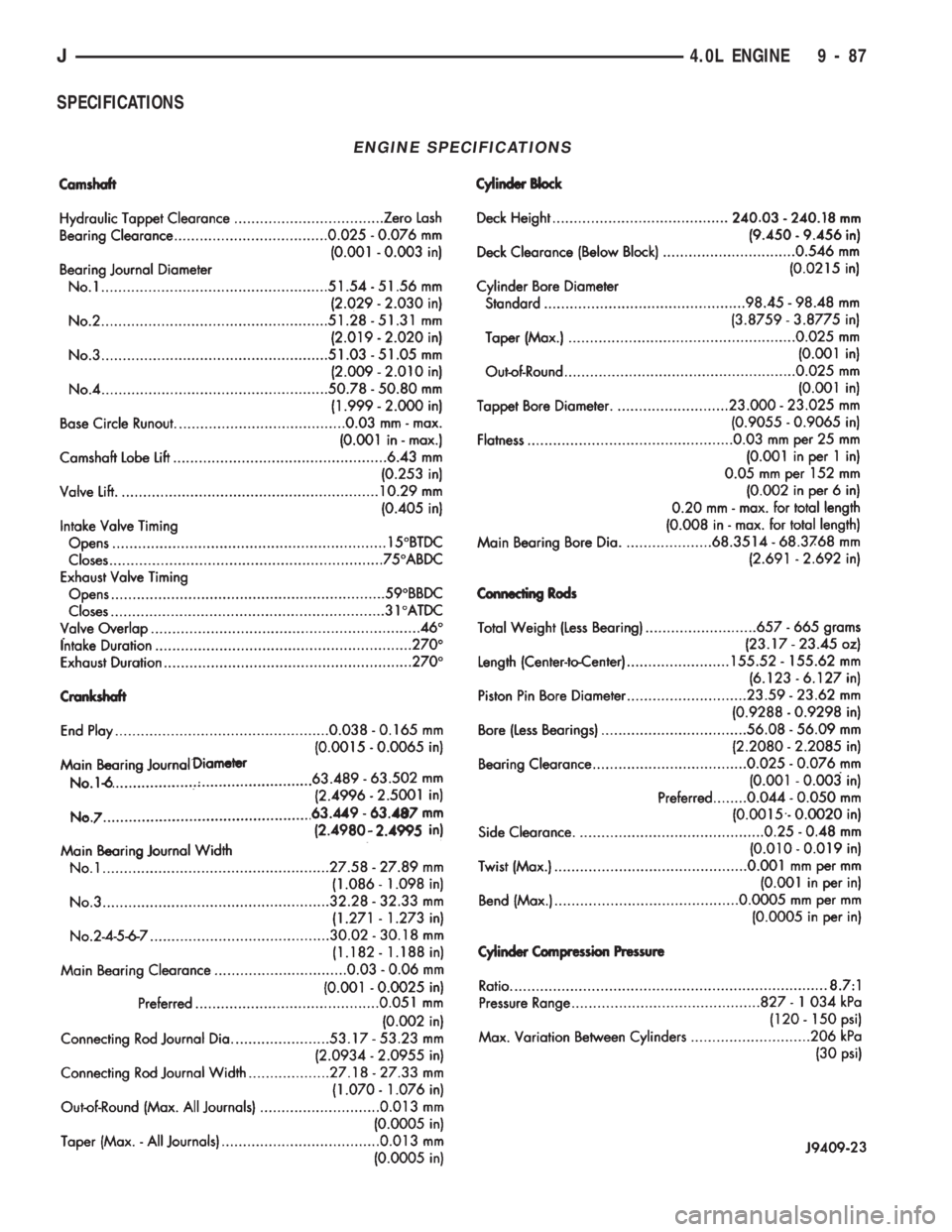

SPECIFICATIONS

ENGINE SPECIFICATIONS

J4.0L ENGINE 9 - 87

Page 929 of 1784

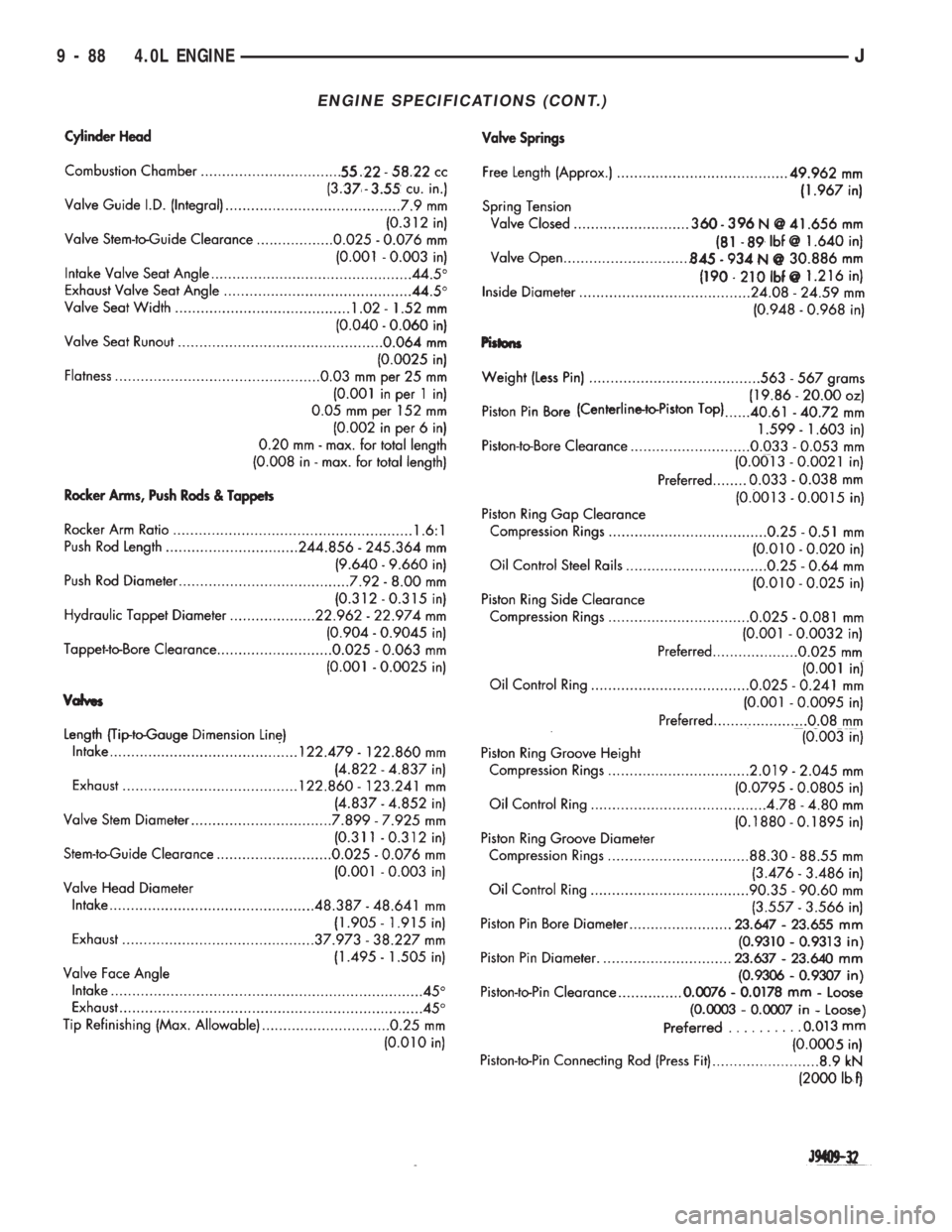

ENGINE SPECIFICATIONS (CONT.)

9 - 88 4.0L ENGINEJ

Page 930 of 1784

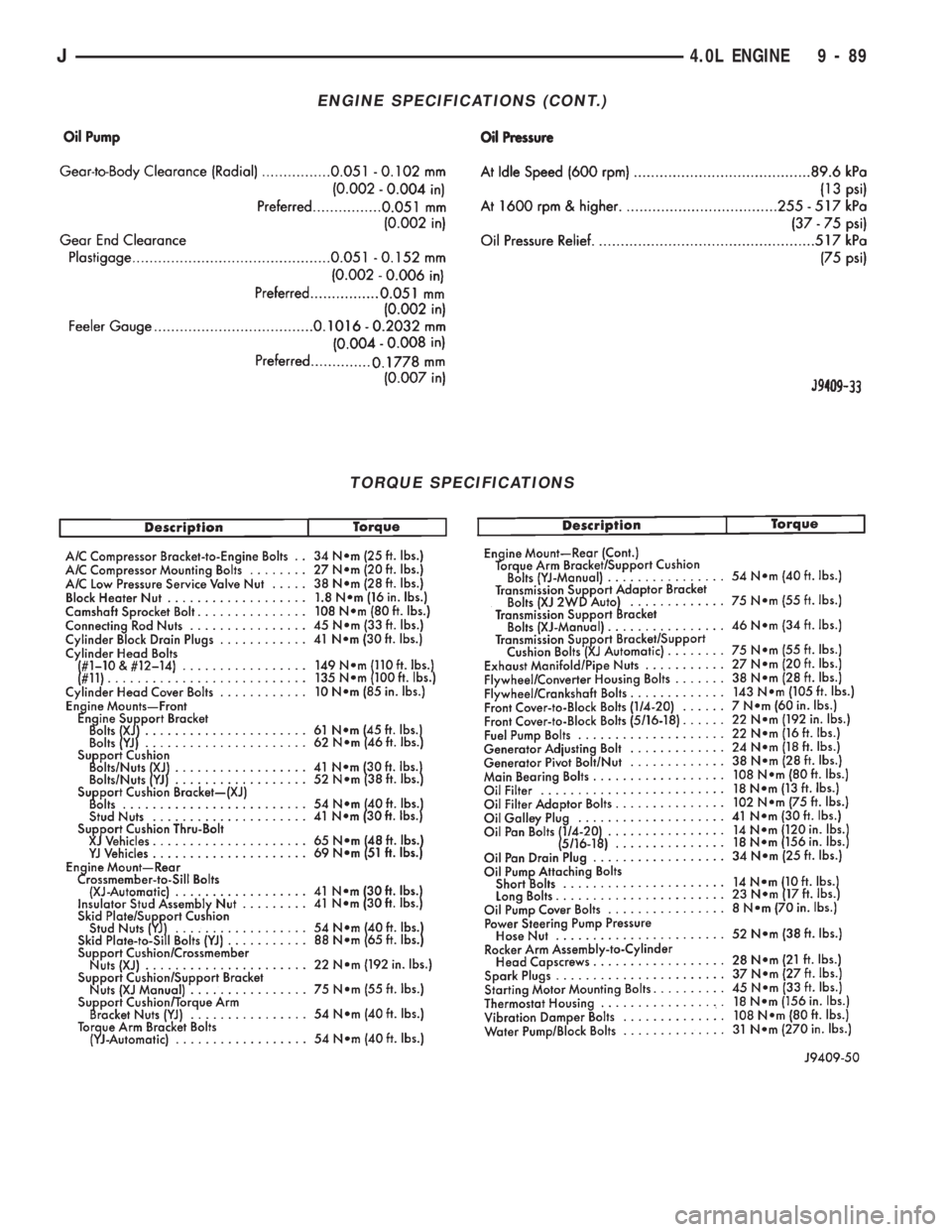

ENGINE SPECIFICATIONS (CONT.)

TORQUE SPECIFICATIONS

J4.0L ENGINE 9 - 89

Page 932 of 1784

EXHAUST SYSTEM AND INTAKE MANIFOLD

CONTENTS

page page

EXHAUST SYSTEM....................... 1

EXHAUST SYSTEM DIAGNOSIS............ 2SERVICE PROCEDURES................... 3

TORQUE SPECIFICATIONS................ 10

EXHAUST SYSTEM

GENERAL INFORMATION

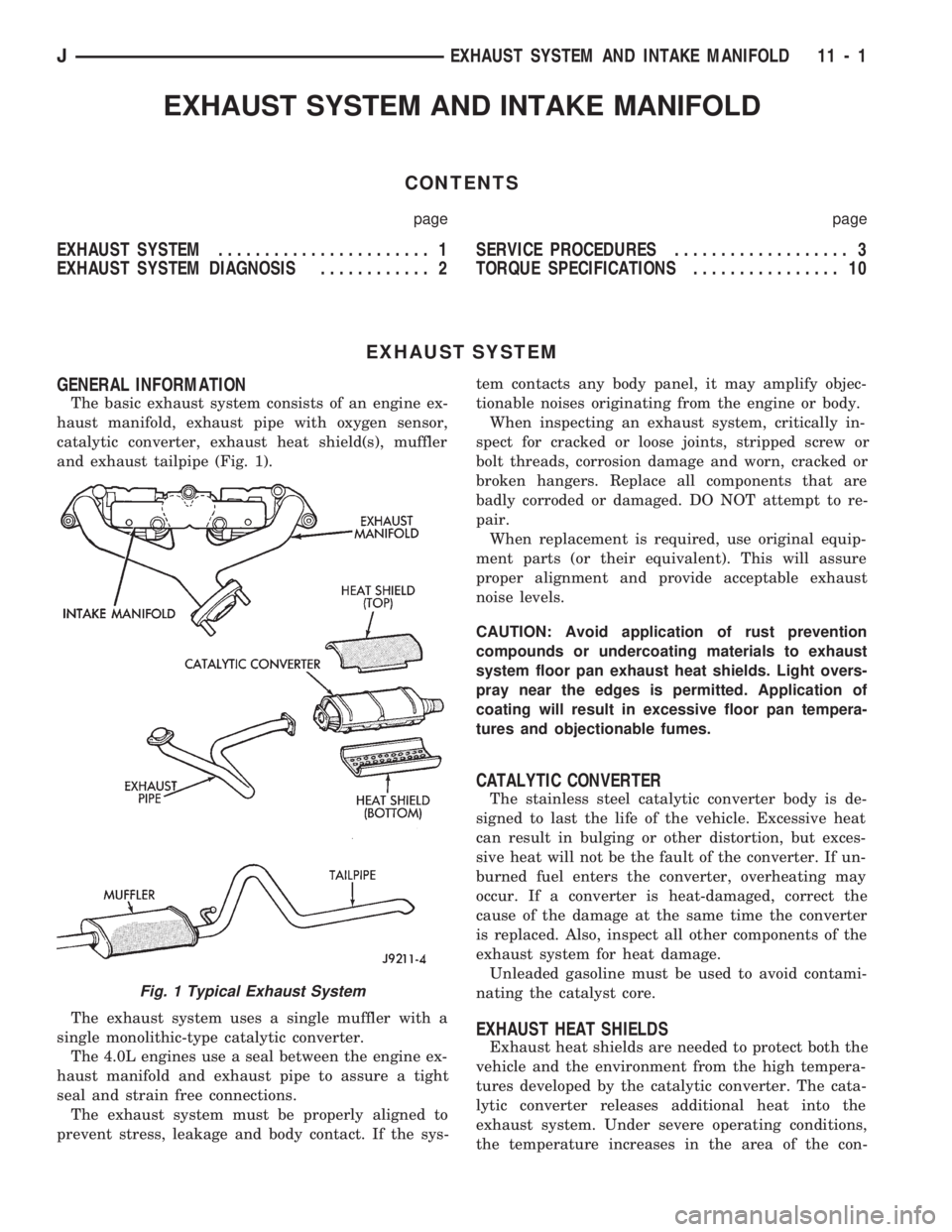

The basic exhaust system consists of an engine ex-

haust manifold, exhaust pipe with oxygen sensor,

catalytic converter, exhaust heat shield(s), muffler

and exhaust tailpipe (Fig. 1).

The exhaust system uses a single muffler with a

single monolithic-type catalytic converter.

The 4.0L engines use a seal between the engine ex-

haust manifold and exhaust pipe to assure a tight

seal and strain free connections.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. If the sys-tem contacts any body panel, it may amplify objec-

tionable noises originating from the engine or body.

When inspecting an exhaust system, critically in-

spect for cracked or loose joints, stripped screw or

bolt threads, corrosion damage and worn, cracked or

broken hangers. Replace all components that are

badly corroded or damaged. DO NOT attempt to re-

pair.

When replacement is required, use original equip-

ment parts (or their equivalent). This will assure

proper alignment and provide acceptable exhaust

noise levels.

CAUTION: Avoid application of rust prevention

compounds or undercoating materials to exhaust

system floor pan exhaust heat shields. Light overs-

pray near the edges is permitted. Application of

coating will result in excessive floor pan tempera-

tures and objectionable fumes.

CATALYTIC CONVERTER

The stainless steel catalytic converter body is de-

signed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but exces-

sive heat will not be the fault of the converter. If un-

burned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct the

cause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid contami-

nating the catalyst core.

EXHAUST HEAT SHIELDS

Exhaust heat shields are needed to protect both the

vehicle and the environment from the high tempera-

tures developed by the catalytic converter. The cata-

lytic converter releases additional heat into the

exhaust system. Under severe operating conditions,

the temperature increases in the area of the con-

Fig. 1 Typical Exhaust System

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 1

Page 933 of 1784

verter. Such conditions can exist when the engine

misfires or otherwise does not operate at peak effi-

ciency.

DO NOT remove spark plug wires from plugs or by

any other means short out cylinders. Failure of the

catalytic converter can occur due to a temperatureincrease caused by unburned fuel passing through

the converter.

DO NOT allow the engine to operate at fast idle for

extended periods (over 5 minutes). This condition

may result in excessive temperatures in the exhaust

system and on the floor pan.

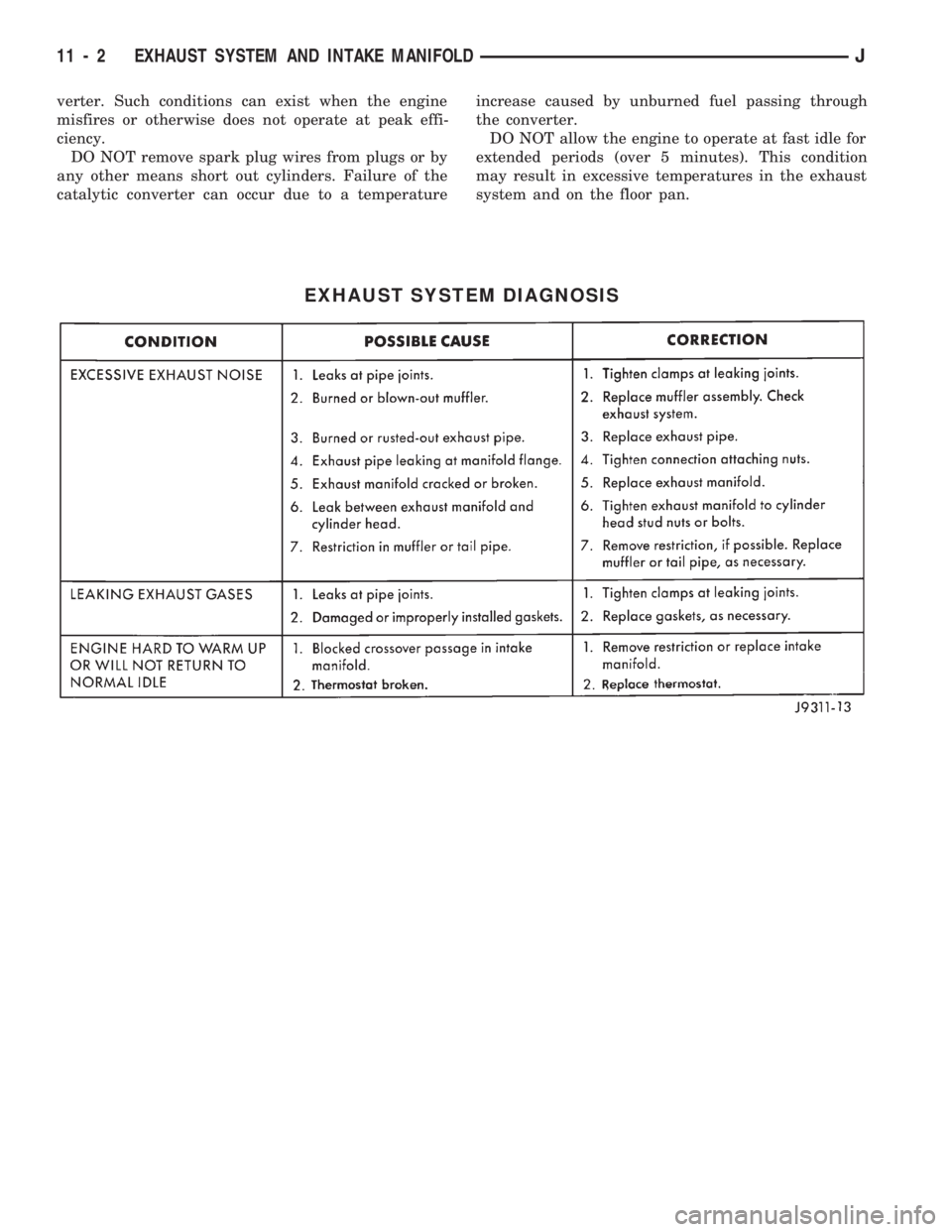

EXHAUST SYSTEM DIAGNOSIS

11 - 2 EXHAUST SYSTEM AND INTAKE MANIFOLDJ

Page 934 of 1784

SERVICE PROCEDURES

INDEX

page page

Catalytic Converter........................ 5

Engine Exhaust ManifoldÐ2.5L Engine......... 7

Engine Exhaust ManifoldÐ4.0L Engine......... 7

Exhaust PipeÐXJ Vehicles.................. 3

Exhaust PipeÐYJ Vehicles.................. 4Intake ManifoldÐ2.5L Engine................ 8

Intake ManifoldÐ4.0L Engine................ 9

Muffler and Exhaust TailpipeÐXJ Vehicles...... 5

Muffler and Exhaust TailpipeÐYJ Vehicles...... 6

EXHAUST PIPEÐXJ VEHICLES

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

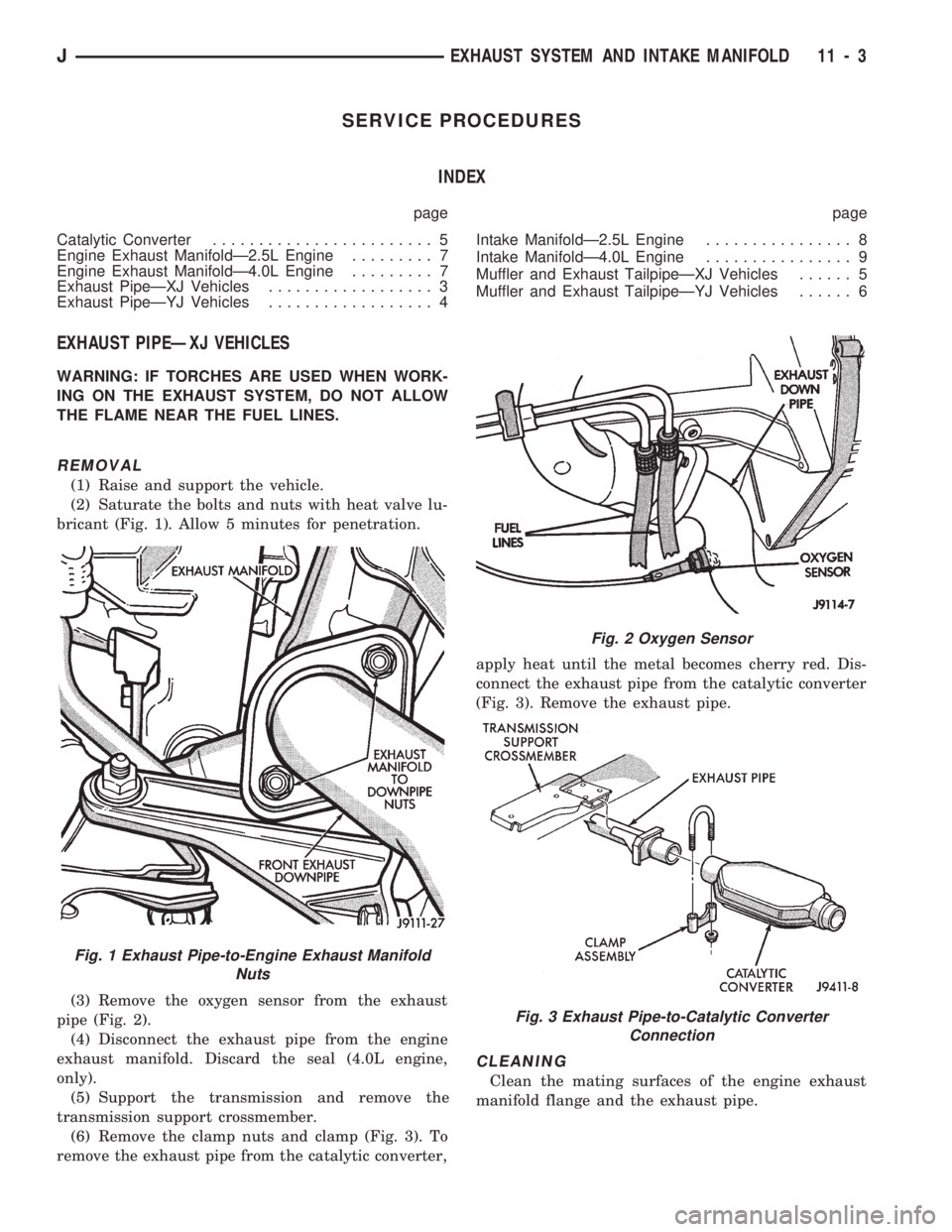

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve lu-

bricant (Fig. 1). Allow 5 minutes for penetration.

(3) Remove the oxygen sensor from the exhaust

pipe (Fig. 2).

(4) Disconnect the exhaust pipe from the engine

exhaust manifold. Discard the seal (4.0L engine,

only).

(5) Support the transmission and remove the

transmission support crossmember.

(6) Remove the clamp nuts and clamp (Fig. 3). To

remove the exhaust pipe from the catalytic converter,apply heat until the metal becomes cherry red. Dis-

connect the exhaust pipe from the catalytic converter

(Fig. 3). Remove the exhaust pipe.

CLEANING

Clean the mating surfaces of the engine exhaust

manifold flange and the exhaust pipe.

Fig. 1 Exhaust Pipe-to-Engine Exhaust Manifold

Nuts

Fig. 2 Oxygen Sensor

Fig. 3 Exhaust Pipe-to-Catalytic Converter

Connection

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3

Page 935 of 1784

INSTALLATION

(1) Assemble exhaust pipe to manifold and cata-

lytic converter loosely to permit proper alignment of

all parts.

(2) Use a new clamp at the exhaust pipe to cata-

lytic converter connection and tighten the nuts to 61

NzIm (45 ft. lbs.) torque.

(3) Connect the exhaust pipe to the engine exhaust

manifold using new nuts. Install a new seal between

the exhaust manifold and the exhaust pipe (4.0L en-

gine, only). Tighten the nuts to 31 Nzm (23 ft. lbs.)

torque (Fig. 1).

(4) Align the transmission support crossmember to

the exhaust pipe (Fig. 3) and position on the sill.

Tighten the crossmember-to-sill bolts to 41 Nzm (30

ft. lbs.) torque. Remove the support from the trans-

mission.

(5) Coat the oxygen sensor with anti-seize com-

pound. Install the sensor and tighten the nut to 48

Nzm (35 ft. lbs.) torque.

(6) Lower the vehicle.

(7) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

EXHAUST PIPEÐYJ VEHICLES

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise and support the vehicle.

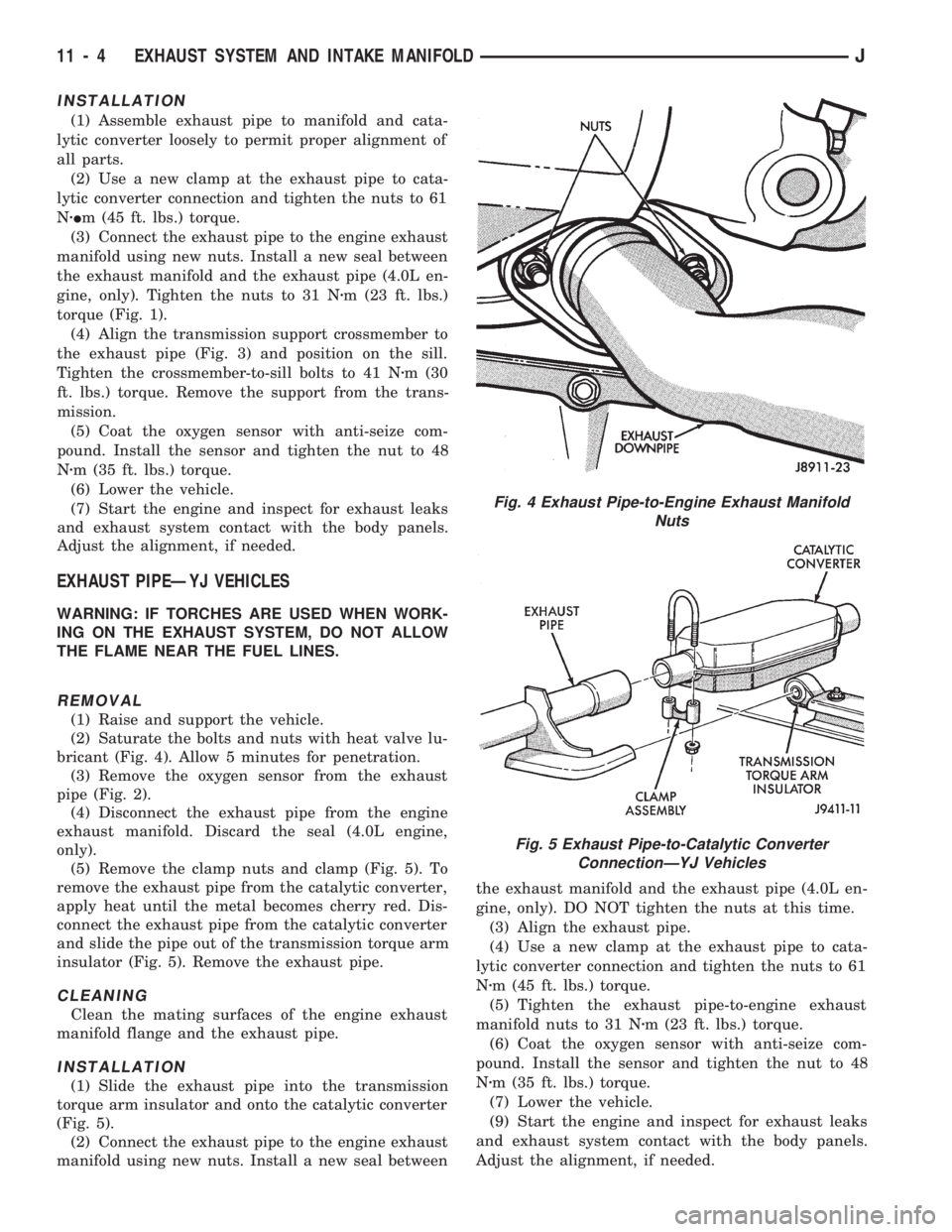

(2) Saturate the bolts and nuts with heat valve lu-

bricant (Fig. 4). Allow 5 minutes for penetration.

(3) Remove the oxygen sensor from the exhaust

pipe (Fig. 2).

(4) Disconnect the exhaust pipe from the engine

exhaust manifold. Discard the seal (4.0L engine,

only).

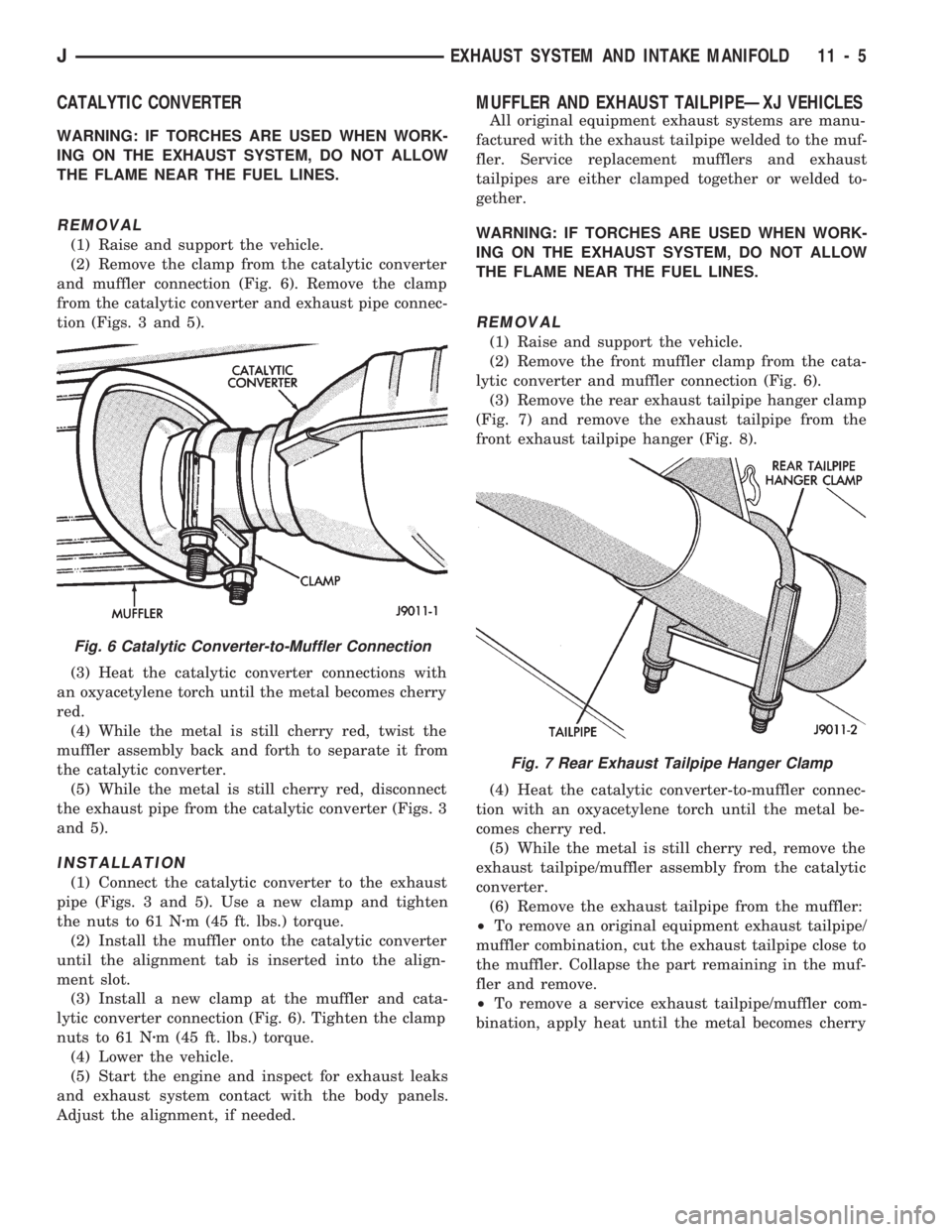

(5) Remove the clamp nuts and clamp (Fig. 5). To

remove the exhaust pipe from the catalytic converter,

apply heat until the metal becomes cherry red. Dis-

connect the exhaust pipe from the catalytic converter

and slide the pipe out of the transmission torque arm

insulator (Fig. 5). Remove the exhaust pipe.

CLEANING

Clean the mating surfaces of the engine exhaust

manifold flange and the exhaust pipe.

INSTALLATION

(1) Slide the exhaust pipe into the transmission

torque arm insulator and onto the catalytic converter

(Fig. 5).

(2) Connect the exhaust pipe to the engine exhaust

manifold using new nuts. Install a new seal betweenthe exhaust manifold and the exhaust pipe (4.0L en-

gine, only). DO NOT tighten the nuts at this time.

(3) Align the exhaust pipe.

(4) Use a new clamp at the exhaust pipe to cata-

lytic converter connection and tighten the nuts to 61

Nzm (45 ft. lbs.) torque.

(5) Tighten the exhaust pipe-to-engine exhaust

manifold nuts to 31 Nzm (23 ft. lbs.) torque.

(6) Coat the oxygen sensor with anti-seize com-

pound. Install the sensor and tighten the nut to 48

Nzm (35 ft. lbs.) torque.

(7) Lower the vehicle.

(9) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

Fig. 4 Exhaust Pipe-to-Engine Exhaust Manifold

Nuts

Fig. 5 Exhaust Pipe-to-Catalytic Converter

ConnectionÐYJ Vehicles

11 - 4 EXHAUST SYSTEM AND INTAKE MANIFOLDJ

Page 936 of 1784

CATALYTIC CONVERTER

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the clamp from the catalytic converter

and muffler connection (Fig. 6). Remove the clamp

from the catalytic converter and exhaust pipe connec-

tion (Figs. 3 and 5).

(3) Heat the catalytic converter connections with

an oxyacetylene torch until the metal becomes cherry

red.

(4) While the metal is still cherry red, twist the

muffler assembly back and forth to separate it from

the catalytic converter.

(5) While the metal is still cherry red, disconnect

the exhaust pipe from the catalytic converter (Figs. 3

and 5).

INSTALLATION

(1) Connect the catalytic converter to the exhaust

pipe (Figs. 3 and 5). Use a new clamp and tighten

the nuts to 61 Nzm (45 ft. lbs.) torque.

(2) Install the muffler onto the catalytic converter

until the alignment tab is inserted into the align-

ment slot.

(3) Install a new clamp at the muffler and cata-

lytic converter connection (Fig. 6). Tighten the clamp

nuts to 61 Nzm (45 ft. lbs.) torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

MUFFLER AND EXHAUST TAILPIPEÐXJ VEHICLES

All original equipment exhaust systems are manu-

factured with the exhaust tailpipe welded to the muf-

fler. Service replacement mufflers and exhaust

tailpipes are either clamped together or welded to-

gether.

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the front muffler clamp from the cata-

lytic converter and muffler connection (Fig. 6).

(3) Remove the rear exhaust tailpipe hanger clamp

(Fig. 7) and remove the exhaust tailpipe from the

front exhaust tailpipe hanger (Fig. 8).

(4) Heat the catalytic converter-to-muffler connec-

tion with an oxyacetylene torch until the metal be-

comes cherry red.

(5) While the metal is still cherry red, remove the

exhaust tailpipe/muffler assembly from the catalytic

converter.

(6) Remove the exhaust tailpipe from the muffler:

²To remove an original equipment exhaust tailpipe/

muffler combination, cut the exhaust tailpipe close to

the muffler. Collapse the part remaining in the muf-

fler and remove.

²To remove a service exhaust tailpipe/muffler com-

bination, apply heat until the metal becomes cherry

Fig. 6 Catalytic Converter-to-Muffler Connection

Fig. 7 Rear Exhaust Tailpipe Hanger Clamp

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 5