bulb JEEP CHEROKEE 1994 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 447 of 1784

(3) Measure the voltage between the pink wire on

the switch connector and vehicle body ground. The

voltmeter should indicate battery voltage. If not OK,

repair the open circuit in the wire harness from the

splice.

(4) Connect a jumper wire from the ground side of

the switch to a good vehicle body ground. Measure

the resistance to vehicle body ground. The ohmmeter

should indicate zero ohms. If not, repair the open cir-

cuit in the wire harness to vehicle body ground.

DOME LAMP REPLACEMENT

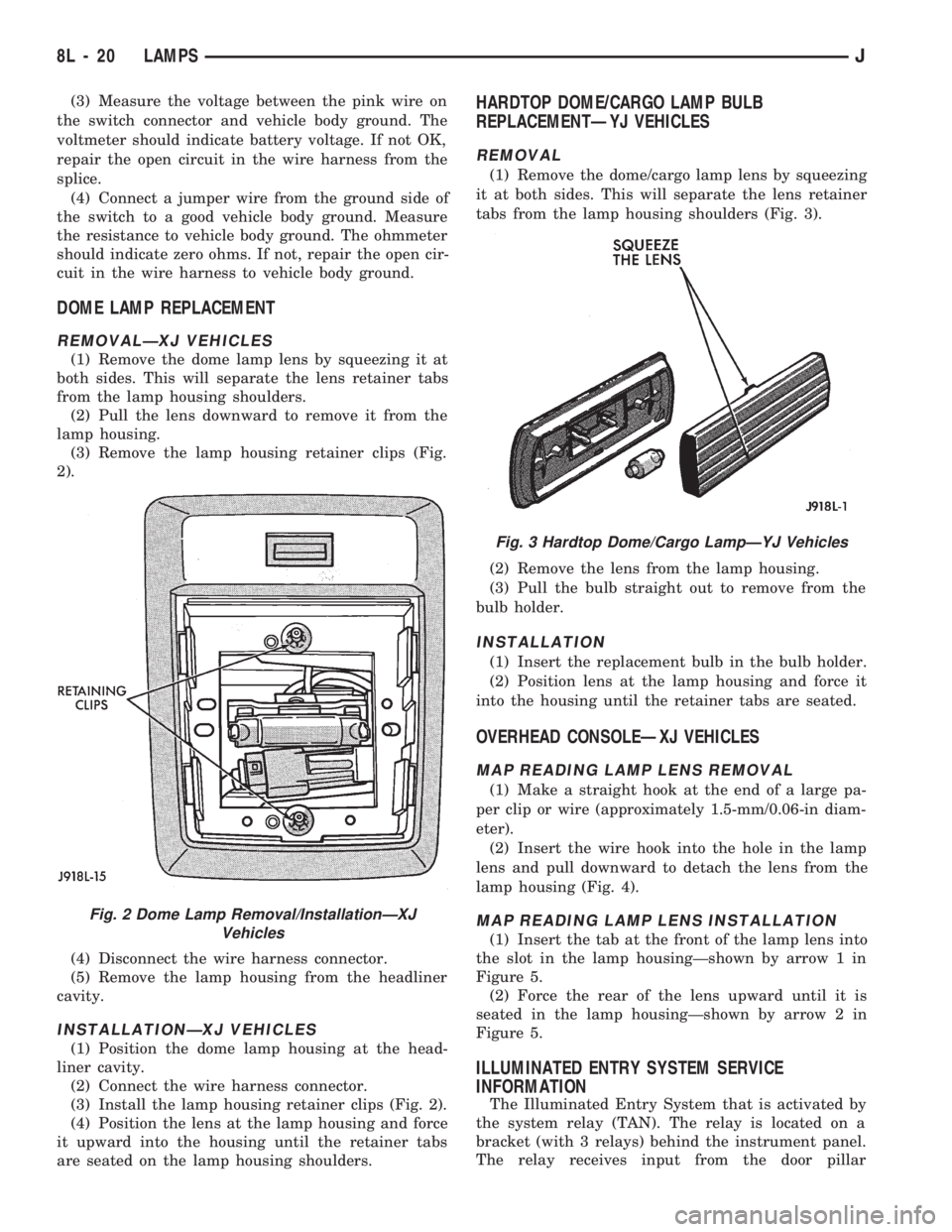

REMOVALÐXJ VEHICLES

(1) Remove the dome lamp lens by squeezing it at

both sides. This will separate the lens retainer tabs

from the lamp housing shoulders.

(2) Pull the lens downward to remove it from the

lamp housing.

(3) Remove the lamp housing retainer clips (Fig.

2).

(4) Disconnect the wire harness connector.

(5) Remove the lamp housing from the headliner

cavity.

INSTALLATIONÐXJ VEHICLES

(1) Position the dome lamp housing at the head-

liner cavity.

(2) Connect the wire harness connector.

(3) Install the lamp housing retainer clips (Fig. 2).

(4) Position the lens at the lamp housing and force

it upward into the housing until the retainer tabs

are seated on the lamp housing shoulders.

HARDTOP DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES

REMOVAL

(1) Remove the dome/cargo lamp lens by squeezing

it at both sides. This will separate the lens retainer

tabs from the lamp housing shoulders (Fig. 3).

(2) Remove the lens from the lamp housing.

(3) Pull the bulb straight out to remove from the

bulb holder.

INSTALLATION

(1) Insert the replacement bulb in the bulb holder.

(2) Position lens at the lamp housing and force it

into the housing until the retainer tabs are seated.

OVERHEAD CONSOLEÐXJ VEHICLES

MAP READING LAMP LENS REMOVAL

(1) Make a straight hook at the end of a large pa-

per clip or wire (approximately 1.5-mm/0.06-in diam-

eter).

(2) Insert the wire hook into the hole in the lamp

lens and pull downward to detach the lens from the

lamp housing (Fig. 4).

MAP READING LAMP LENS INSTALLATION

(1) Insert the tab at the front of the lamp lens into

the slot in the lamp housingÐshown by arrow 1 in

Figure 5.

(2) Force the rear of the lens upward until it is

seated in the lamp housingÐshown by arrow 2 in

Figure 5.

ILLUMINATED ENTRY SYSTEM SERVICE

INFORMATION

The Illuminated Entry System that is activated by

the system relay (TAN). The relay is located on a

bracket (with 3 relays) behind the instrument panel.

The relay receives input from the door pillar

Fig. 2 Dome Lamp Removal/InstallationÐXJ

Vehicles

Fig. 3 Hardtop Dome/Cargo LampÐYJ Vehicles

8L - 20 LAMPSJ

Page 448 of 1784

switches, the keyless entry system, and the ignition

switch (when in the RUN position). When correct in-

put is received, the entry module timer immediately

begins the timing-out process. The timing-out process

requires approximately 3066 seconds.

The illuminated entry system also operates

when a door is opened to exit the vehicle. When

the door is closed the interior illumination will

continue for the remaining portion of the 30 sec-

onds.

ILLUMINATED ENTRY SYSTEM TROUBLE

DIAGNOSIS

The Illuminated Entry System relay is located on a

bracket behind the instrument panel.

(1) Ensure that the ignition switch is in the Off po-

sition.

(2) Open and immediately close the driver-side

door. The interior courtesy lamps should immediately

illuminate.

(3) Open driver-side door, enter the vehicle, close

the door and turn the ignition switch to the RUN po-sition. The courtesy lamps should go out. Turn the

ignition switch to the OFF position before exiting ve-

hicle.

(4) When exiting the vehicle, the courtesy lamps

should remain illuminated after the door is closed.

(5) From outside the vehicle, open and close the

passenger-side door. The courtesy lamps should illu-

minate.

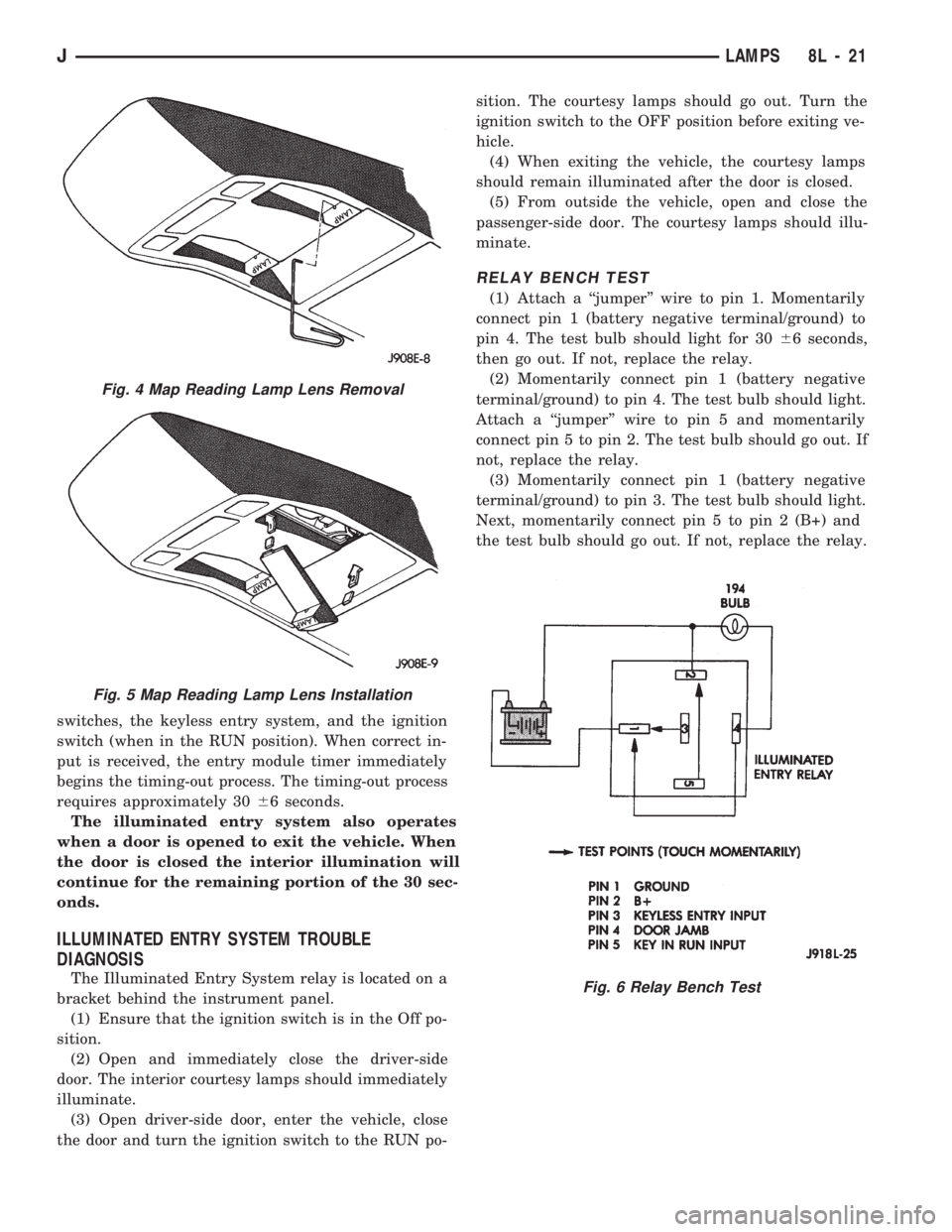

RELAY BENCH TEST

(1) Attach a ``jumper'' wire to pin 1. Momentarily

connect pin 1 (battery negative terminal/ground) to

pin 4. The test bulb should light for 3066 seconds,

then go out. If not, replace the relay.

(2) Momentarily connect pin 1 (battery negative

terminal/ground) to pin 4. The test bulb should light.

Attach a ``jumper'' wire to pin 5 and momentarily

connect pin 5 to pin 2. The test bulb should go out. If

not, replace the relay.

(3) Momentarily connect pin 1 (battery negative

terminal/ground) to pin 3. The test bulb should light.

Next, momentarily connect pin 5 to pin 2 (B+) and

the test bulb should go out. If not, replace the relay.

Fig. 4 Map Reading Lamp Lens Removal

Fig. 5 Map Reading Lamp Lens Installation

Fig. 6 Relay Bench Test

JLAMPS 8L - 21

Page 489 of 1784

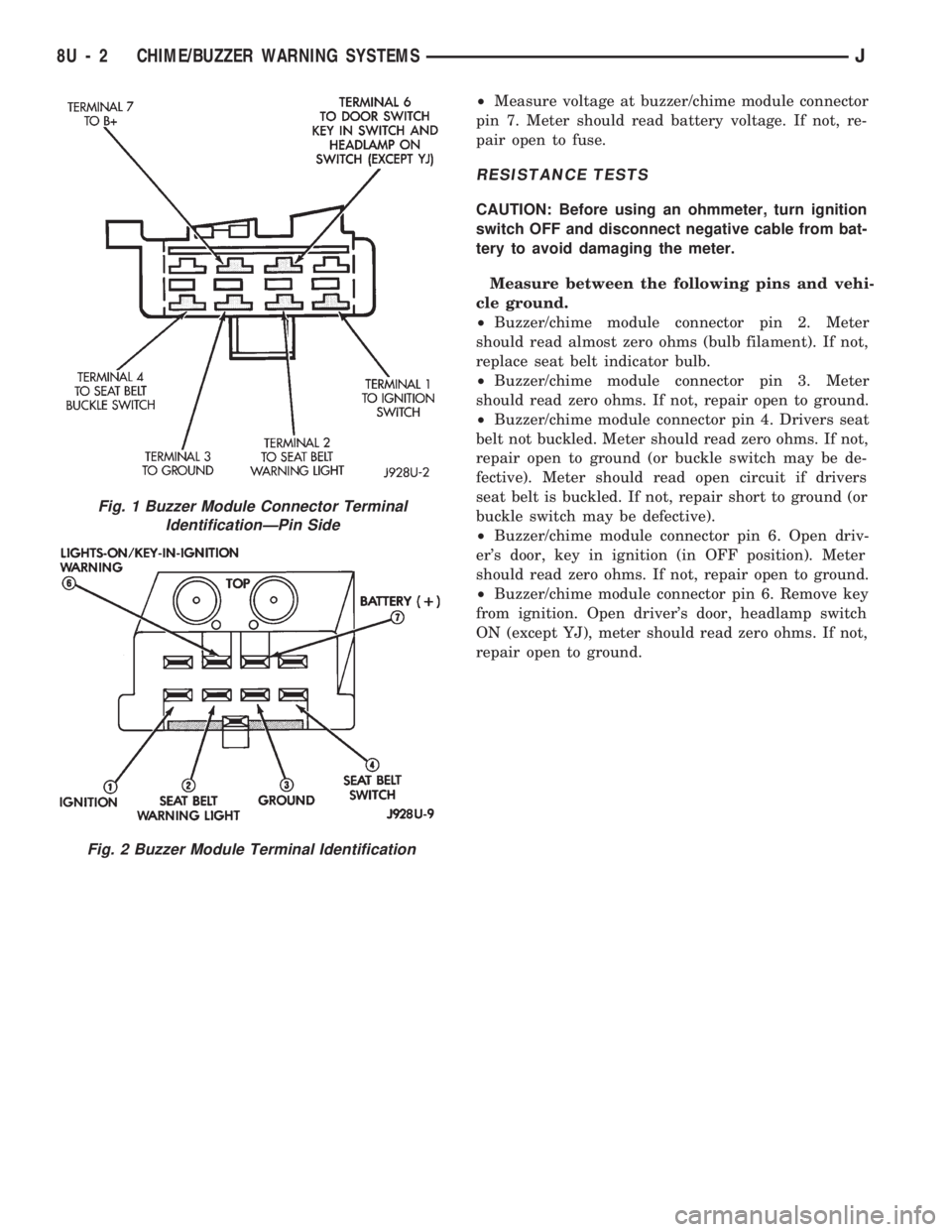

²Measure voltage at buzzer/chime module connector

pin 7. Meter should read battery voltage. If not, re-

pair open to fuse.

RESISTANCE TESTS

CAUTION: Before using an ohmmeter, turn ignition

switch OFF and disconnect negative cable from bat-

tery to avoid damaging the meter.

Measure between the following pins and vehi-

cle ground.

²Buzzer/chime module connector pin 2. Meter

should read almost zero ohms (bulb filament). If not,

replace seat belt indicator bulb.

²Buzzer/chime module connector pin 3. Meter

should read zero ohms. If not, repair open to ground.

²Buzzer/chime module connector pin 4. Drivers seat

belt not buckled. Meter should read zero ohms. If not,

repair open to ground (or buckle switch may be de-

fective). Meter should read open circuit if drivers

seat belt is buckled. If not, repair short to ground (or

buckle switch may be defective).

²Buzzer/chime module connector pin 6. Open driv-

er's door, key in ignition (in OFF position). Meter

should read zero ohms. If not, repair open to ground.

²Buzzer/chime module connector pin 6. Remove key

from ignition. Open driver's door, headlamp switch

ON (except YJ), meter should read zero ohms. If not,

repair open to ground.

Fig. 2 Buzzer Module Terminal Identification

Fig. 1 Buzzer Module Connector Terminal

IdentificationÐPin Side

8U - 2 CHIME/BUZZER WARNING SYSTEMSJ

Page 987 of 1784

ing the IAC motor pintle in and out of the air control

passage. The IAC motor is positioned when the igni-

tion key is turned to the On position.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

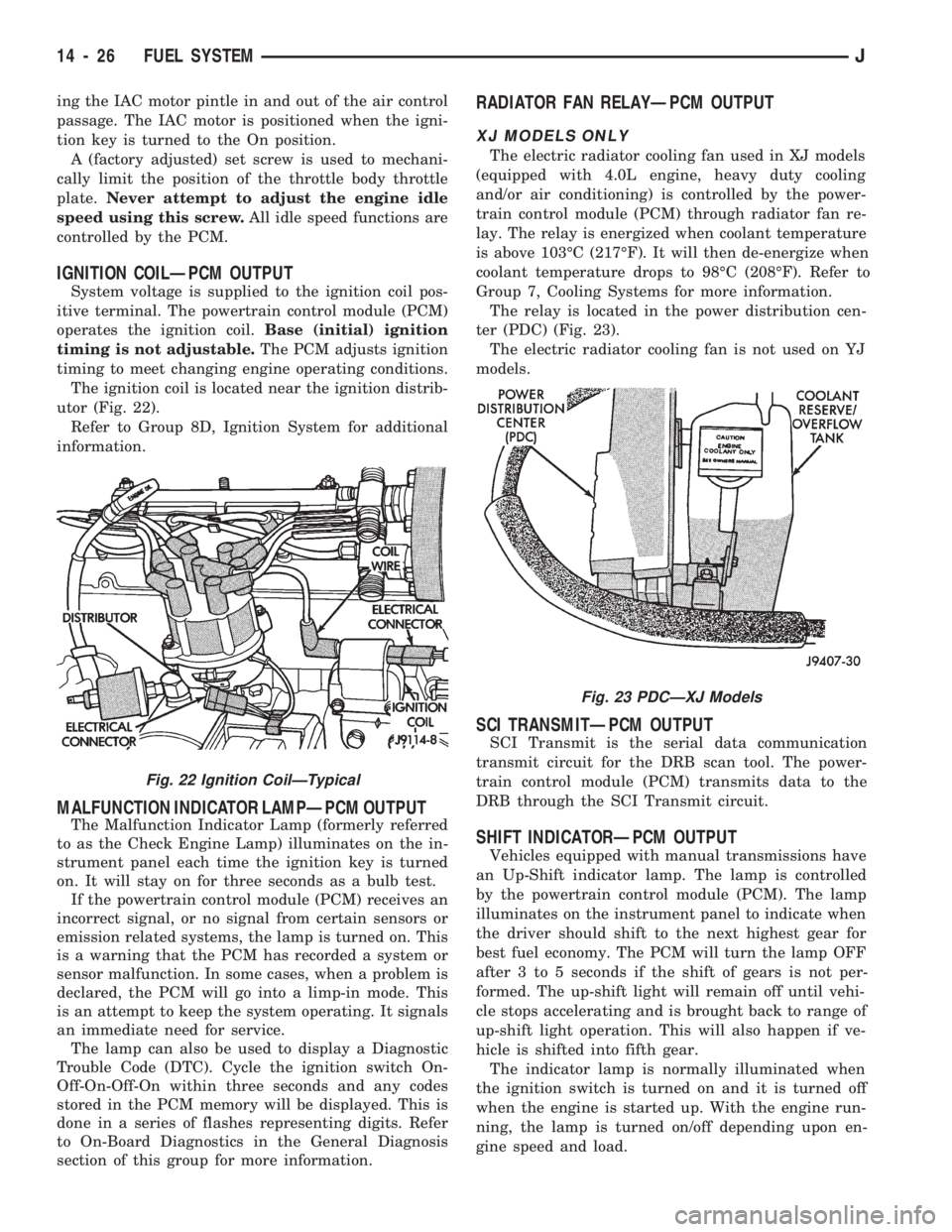

IGNITION COILÐPCM OUTPUT

System voltage is supplied to the ignition coil pos-

itive terminal. The powertrain control module (PCM)

operates the ignition coil.Base (initial) ignition

timing is not adjustable.The PCM adjusts ignition

timing to meet changing engine operating conditions.

The ignition coil is located near the ignition distrib-

utor (Fig. 22).

Refer to Group 8D, Ignition System for additional

information.

MALFUNCTION INDICATOR LAMPÐPCM OUTPUT

The Malfunction Indicator Lamp (formerly referred

to as the Check Engine Lamp) illuminates on the in-

strument panel each time the ignition key is turned

on. It will stay on for three seconds as a bulb test.

If the powertrain control module (PCM) receives an

incorrect signal, or no signal from certain sensors or

emission related systems, the lamp is turned on. This

is a warning that the PCM has recorded a system or

sensor malfunction. In some cases, when a problem is

declared, the PCM will go into a limp-in mode. This

is an attempt to keep the system operating. It signals

an immediate need for service.

The lamp can also be used to display a Diagnostic

Trouble Code (DTC). Cycle the ignition switch On-

Off-On-Off-On within three seconds and any codes

stored in the PCM memory will be displayed. This is

done in a series of flashes representing digits. Refer

to On-Board Diagnostics in the General Diagnosis

section of this group for more information.

RADIATOR FAN RELAYÐPCM OUTPUT

XJ MODELS ONLY

The electric radiator cooling fan used in XJ models

(equipped with 4.0L engine, heavy duty cooling

and/or air conditioning) is controlled by the power-

train control module (PCM) through radiator fan re-

lay. The relay is energized when coolant temperature

is above 103ÉC (217ÉF). It will then de-energize when

coolant temperature drops to 98ÉC (208ÉF). Refer to

Group 7, Cooling Systems for more information.

The relay is located in the power distribution cen-

ter (PDC) (Fig. 23).

The electric radiator cooling fan is not used on YJ

models.

SCI TRANSMITÐPCM OUTPUT

SCI Transmit is the serial data communication

transmit circuit for the DRB scan tool. The power-

train control module (PCM) transmits data to the

DRB through the SCI Transmit circuit.

SHIFT INDICATORÐPCM OUTPUT

Vehicles equipped with manual transmissions have

an Up-Shift indicator lamp. The lamp is controlled

by the powertrain control module (PCM). The lamp

illuminates on the instrument panel to indicate when

the driver should shift to the next highest gear for

best fuel economy. The PCM will turn the lamp OFF

after 3 to 5 seconds if the shift of gears is not per-

formed. The up-shift light will remain off until vehi-

cle stops accelerating and is brought back to range of

up-shift light operation. This will also happen if ve-

hicle is shifted into fifth gear.

The indicator lamp is normally illuminated when

the ignition switch is turned on and it is turned off

when the engine is started up. With the engine run-

ning, the lamp is turned on/off depending upon en-

gine speed and load.

Fig. 23 PDCÐXJ Models

Fig. 22 Ignition CoilÐTypical

14 - 26 FUEL SYSTEMJ

Page 1477 of 1784

(2) Carefully pry the applique off the license plate

visor and tailgate (Fig. 62).

INSTALLATION

(1) Align the moulding with the visor and then

press the applique into place.

(2) Install the rivets to attach the outboard tabs on

applique to the tailgate.

WOODGRAIN OVERLAY

SERVICE INFORMATION

Exterior woodgrain overlay is a weather-resistant

vinyl. The adhesive backing is protected by a paper

liner until removed for installation.

OVERLAY REPAIR

Small nicks and scratches on an overlay can be

touched-up with paint.

To eliminate blisters and air bubbles, pierce them

with a needle or pin. Force the trapped air out of the

hole and press firmly on the overlay. Heat also can

be applied to remove small wrinkles.

Whenever an overlay must be stretched, do

not slit or cut it. Instead, apply heat and press

or squeegee the overlay into place.

INSTALLATION REQUIREMENTS

Overlay replacement requires metal repair and

paint refinish to be completed before the overlay is

installed.

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A woodgrain overlay

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for overlay installation:

²a commercial woodgrain overlay removal solution;

²a commercial adhesive removal solution;

²liquid dish detergent (for wetting solution);

²a mixture of wetting solution;

²a commercial wax and silicone removal solution;

²isopropyl alcohol (rubbing alcohol);

²a squeegee (4 to 5 inches wide, plastic or hard rub-

ber);

²a water bucket and sponge;

²sandpaper (no. 360 or no. 400, wet or dry type);

²a heat gun (or infra-red heat bulb);

²clean wiping rags or paper towels;

²a pair of scissors;

²a needle or pin; and

²a wax pencil.

Using a wetting solution helps the installation of

an overlay. Prepare a solution by mixing two or three

teaspoons of dish detergent with 1 gallon of water.

Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

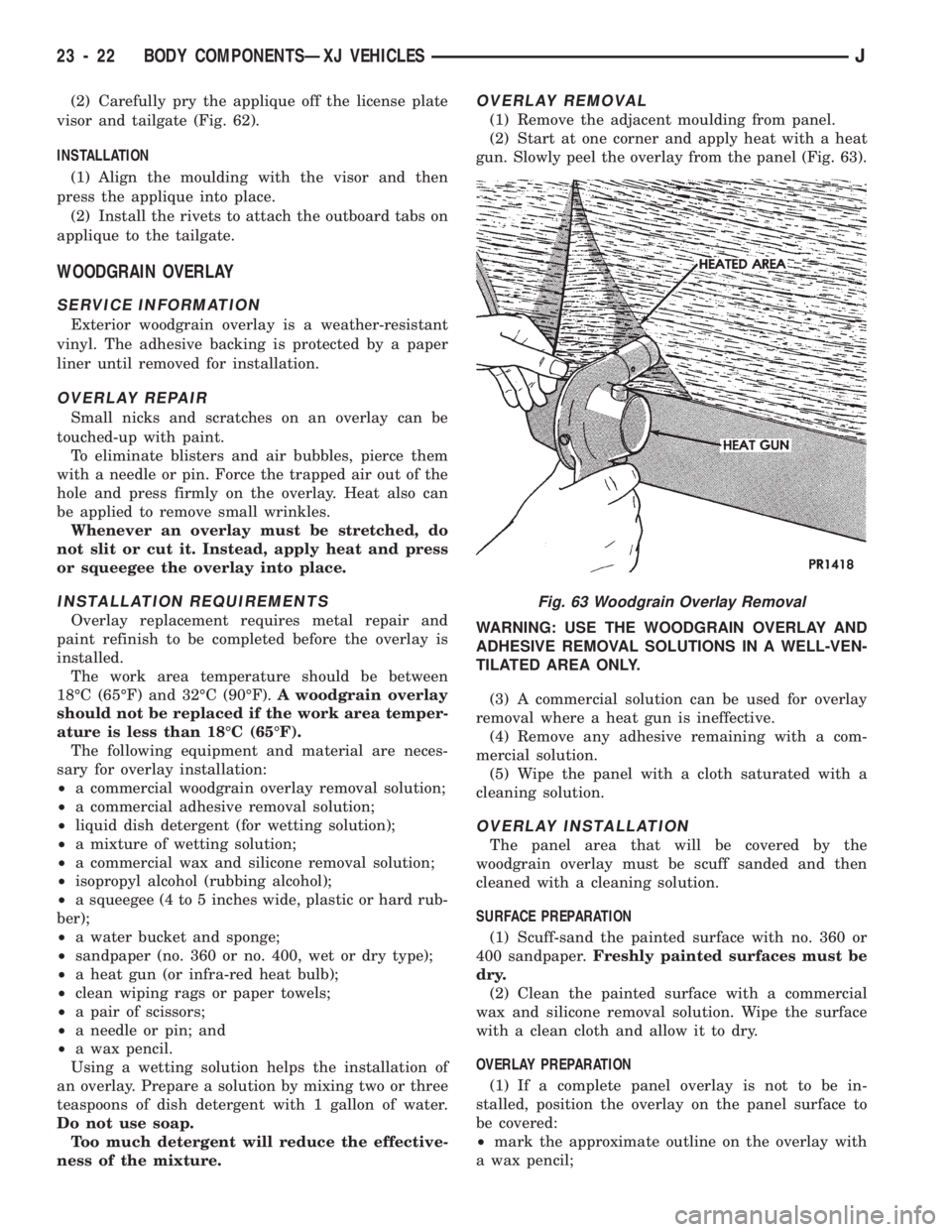

OVERLAY REMOVAL

(1) Remove the adjacent moulding from panel.

(2) Start at one corner and apply heat with a heat

gun. Slowly peel the overlay from the panel (Fig. 63).

WARNING: USE THE WOODGRAIN OVERLAY AND

ADHESIVE REMOVAL SOLUTIONS IN A WELL-VEN-

TILATED AREA ONLY.

(3) A commercial solution can be used for overlay

removal where a heat gun is ineffective.

(4) Remove any adhesive remaining with a com-

mercial solution.

(5) Wipe the panel with a cloth saturated with a

cleaning solution.

OVERLAY INSTALLATION

The panel area that will be covered by the

woodgrain overlay must be scuff sanded and then

cleaned with a cleaning solution.

SURFACE PREPARATION

(1) Scuff-sand the painted surface with no. 360 or

400 sandpaper.Freshly painted surfaces must be

dry.

(2) Clean the painted surface with a commercial

wax and silicone removal solution. Wipe the surface

with a clean cloth and allow it to dry.

OVERLAY PREPARATION

(1) If a complete panel overlay is not to be in-

stalled, position the overlay on the panel surface to

be covered:

²mark the approximate outline on the overlay with

a wax pencil;

Fig. 63 Woodgrain Overlay Removal

23 - 22 BODY COMPONENTSÐXJ VEHICLESJ

Page 1480 of 1784

FUEL FILLER DOOR OVERLAY APPLICATION

(1) Clean the door flange with an appropriate solu-

tion.

(2) Position the top edge of the overlay at the char-

acter line and notches at door edge.

(3) Wipe the adhesive side of fuel filler door over-

lay edges with isopropyl alcohol.

(4) Heat the door overlay edges with a heat gun to

soften and make them more pliable.

CAUTION: Avoid unnecessary pulling and stretch-

ing at the ends.

(5) Fold the overlay edges over onto the door panel

flange areas and press them into place.

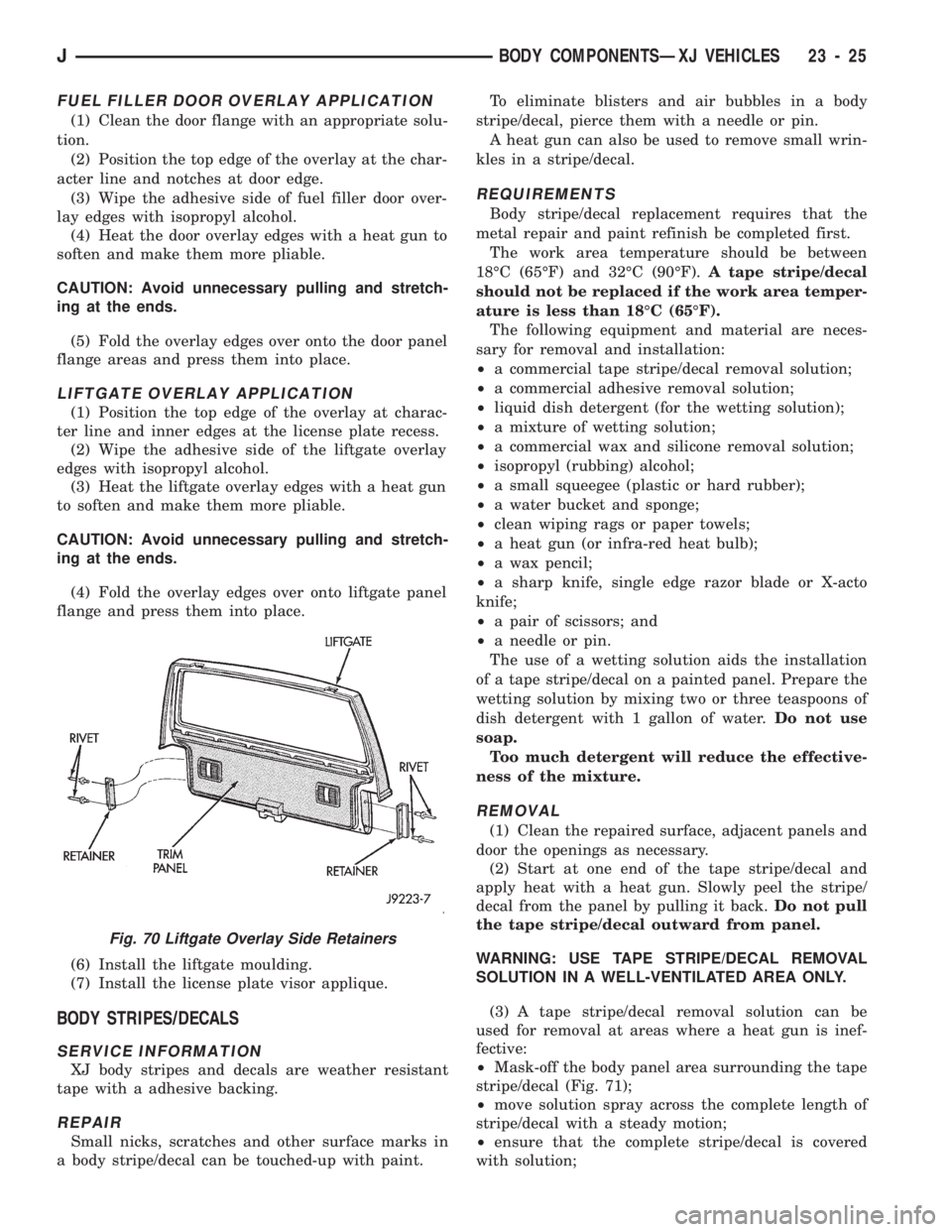

LIFTGATE OVERLAY APPLICATION

(1) Position the top edge of the overlay at charac-

ter line and inner edges at the license plate recess.

(2) Wipe the adhesive side of the liftgate overlay

edges with isopropyl alcohol.

(3) Heat the liftgate overlay edges with a heat gun

to soften and make them more pliable.

CAUTION: Avoid unnecessary pulling and stretch-

ing at the ends.

(4) Fold the overlay edges over onto liftgate panel

flange and press them into place.

(6) Install the liftgate moulding.

(7) Install the license plate visor applique.

BODY STRIPES/DECALS

SERVICE INFORMATION

XJ body stripes and decals are weather resistant

tape with a adhesive backing.

REPAIR

Small nicks, scratches and other surface marks in

a body stripe/decal can be touched-up with paint.To eliminate blisters and air bubbles in a body

stripe/decal, pierce them with a needle or pin.

A heat gun can also be used to remove small wrin-

kles in a stripe/decal.

REQUIREMENTS

Body stripe/decal replacement requires that the

metal repair and paint refinish be completed first.

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A tape stripe/decal

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for removal and installation:

²a commercial tape stripe/decal removal solution;

²a commercial adhesive removal solution;

²liquid dish detergent (for the wetting solution);

²a mixture of wetting solution;

²a commercial wax and silicone removal solution;

²isopropyl (rubbing) alcohol;

²a small squeegee (plastic or hard rubber);

²a water bucket and sponge;

²clean wiping rags or paper towels;

²a heat gun (or infra-red heat bulb);

²a wax pencil;

²a sharp knife, single edge razor blade or X-acto

knife;

²a pair of scissors; and

²a needle or pin.

The use of a wetting solution aids the installation

of a tape stripe/decal on a painted panel. Prepare the

wetting solution by mixing two or three teaspoons of

dish detergent with 1 gallon of water.Do not use

soap.

Too much detergent will reduce the effective-

ness of the mixture.

REMOVAL

(1) Clean the repaired surface, adjacent panels and

door the openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from panel.

WARNING: USE TAPE STRIPE/DECAL REMOVAL

SOLUTION IN A WELL-VENTILATED AREA ONLY.

(3) A tape stripe/decal removal solution can be

used for removal at areas where a heat gun is inef-

fective:

²Mask-off the body panel area surrounding the tape

stripe/decal (Fig. 71);

²move solution spray across the complete length of

stripe/decal with a steady motion;

²ensure that the complete stripe/decal is covered

with solution;

Fig. 70 Liftgate Overlay Side Retainers

JBODY COMPONENTSÐXJ VEHICLES 23 - 25

Page 1527 of 1784

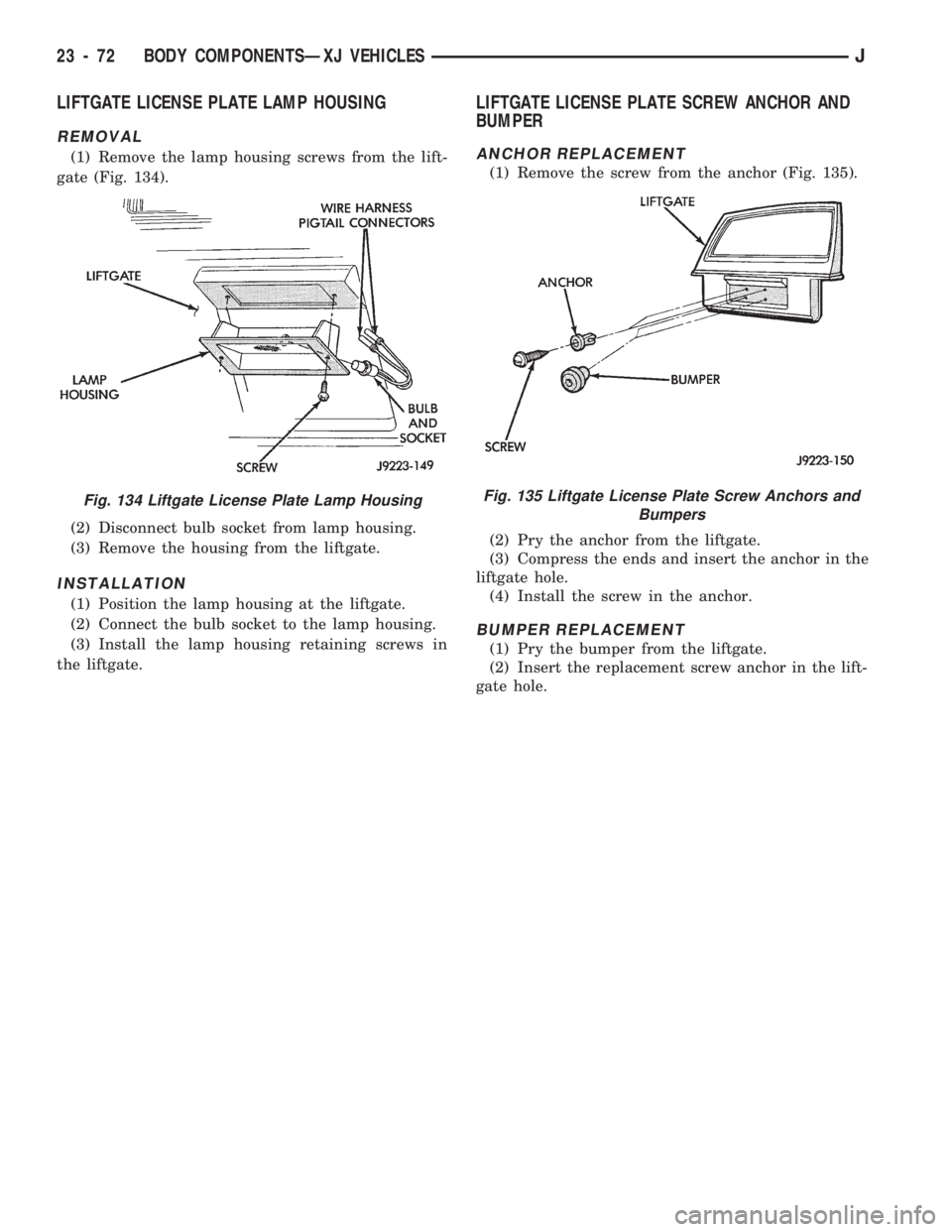

LIFTGATE LICENSE PLATE LAMP HOUSING

REMOVAL

(1) Remove the lamp housing screws from the lift-

gate (Fig. 134).

(2) Disconnect bulb socket from lamp housing.

(3) Remove the housing from the liftgate.

INSTALLATION

(1) Position the lamp housing at the liftgate.

(2) Connect the bulb socket to the lamp housing.

(3) Install the lamp housing retaining screws in

the liftgate.

LIFTGATE LICENSE PLATE SCREW ANCHOR AND

BUMPER

ANCHOR REPLACEMENT

(1) Remove the screw from the anchor (Fig. 135).

(2) Pry the anchor from the liftgate.

(3) Compress the ends and insert the anchor in the

liftgate hole.

(4) Install the screw in the anchor.

BUMPER REPLACEMENT

(1) Pry the bumper from the liftgate.

(2) Insert the replacement screw anchor in the lift-

gate hole.

Fig. 134 Liftgate License Plate Lamp HousingFig. 135 Liftgate License Plate Screw Anchors and

Bumpers

23 - 72 BODY COMPONENTSÐXJ VEHICLESJ

Page 1589 of 1784

EXTERIOR COMPONENTS

INDEX

page page

Battery Tray........................... 140

Body Extension Panels and FasciasÐYJ

Renegade Vehicles..................... 147

Body Side Step Moulding................. 145

Body Stripes/Decals..................... 153

Cowl Grille and Screen................... 139

Cowl Weatherstrip Seal................... 139

Exterior Nameplates (Adhesive-Backed)....... 158

External Spare/Wheel Tire Carrier........... 172

Fender Flare........................... 144

Fender Inner Splash Shields............... 147

Fender Splash Aprons.................... 147

Fenders............................... 141

Fog LampÐYJ Renegade Vehicles.......... 150

Front Fascia and Skid PlateÐYJ Renegade

Vehicles............................. 148

Front Fender Extension PanelÐYJ Renegade

Vehicles............................. 149

Fuel Filler Protector/Nozzle................ 158

Half Metal Door Mirror (External)............ 158

Hard Top Liftgate Glass.................. 162

Hard Top Repair........................ 165

Hard Top Roof Vent..................... 165

Hard Top Service....................... 164

Hard Top Service Information.............. 164Hood................................. 137

Hood Alignment......................... 138

Hood Insulator Panel..................... 138

Hood Safety Latch....................... 139

Liftgate Glass Weatherstrip Seal Replacement . . 163

Radiator Grille Applique................... 134

Rear Fascia and Skid PlateÐYJ Renegade

Vehicles............................. 152

Rear Quarter Extension PanelÐYJ Renegade

Vehicles............................. 151

Rocker Extension PanelÐYJ Renegade

Vehicles............................. 150

Soft Top Service........................ 167

Soft Top Service Information............... 166

Sport Bar............................. 171

Tailgate Adjustment...................... 160

Tailgate Hinge.......................... 159

Tailgate Latch and Release Handle.......... 160

Tailgate Latch Striker..................... 161

Tailgate Lock Cylinder.................... 160

Tailgate Service......................... 159

Tailgate Service Information................ 159

Tailgate Weatherstrip Seal................. 161

Wheelhouse Splash Liners................ 146

RADIATOR GRILLE APPLIQUE

REMOVAL

(1) Raise the hood.

(2) Remove the headlamp bezels (Fig. 1).

(3) Remove the headlamp bulb retainer screws

(Fig. 2).

(4) Disconnect and remove the headlamps and

buckets as a unit (Fig. 2).

(5) Remove the parking lamp retaining screws

(Fig. 2).

(6) Disconnect the wire harness connectors and re-

move the parking lamps (Fig. 2).

(7) Remove the front crossmember cover.

(8) Remove the retaining screws and the bumper

inserts at the top of the grille panel (Fig. 1).

(9) Detach the grille applique from the grille panel

(Fig. 1).

(10) Remove the double faced foam adhesive tape

at the bottom of the grille applique (Fig. 1).

INSTALLATION

(1) Install double faced foam tape at the bottom,

interior side of the grille applique (Fig. 1).

(2) Position the grille applique over the grille

panel and press inward along the bottom where the

tape is located (Fig. 1).

(3) Install the grille applique retaining screws and

the bumper inserts (Fig. 1).(4) Connect the wire harness connectors and posi-

tion the headlamp buckets and headlamps in the

grille panel (Fig. 2).

(5) Install the headlamp bulb retainer and the

screws (Fig. 1). Tighten the screws to 2 Nzm (18 in-

lbs) torque.

(6) Install the headlamp bezels and the retaining

screws (Fig. 1). Tighten the screws securely.

(7) Connect the wire harness connectors and in-

stall the parking lamps (Fig. 2).

(8) Install the parking lamp retaining screws.

Tighten the screws to 2 Nzm (18 in-lbs) torque.

(9) Close the hood.

(10) Install the front crossmember cover.

23 - 134 BODY COMPONENTSÐXJ VEHICLESJ

Page 1598 of 1784

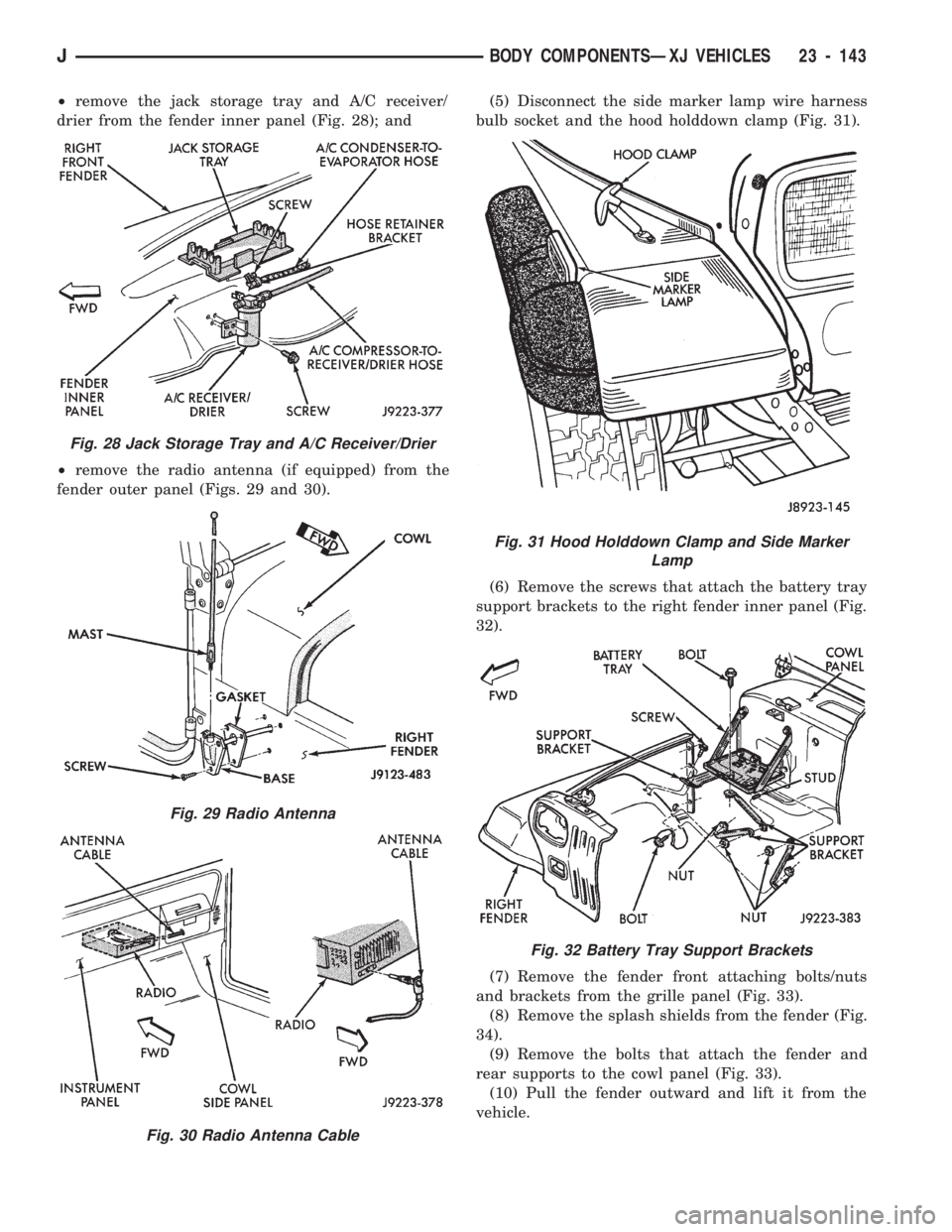

²remove the jack storage tray and A/C receiver/

drier from the fender inner panel (Fig. 28); and

²remove the radio antenna (if equipped) from the

fender outer panel (Figs. 29 and 30).(5) Disconnect the side marker lamp wire harness

bulb socket and the hood holddown clamp (Fig. 31).

(6) Remove the screws that attach the battery tray

support brackets to the right fender inner panel (Fig.

32).

(7) Remove the fender front attaching bolts/nuts

and brackets from the grille panel (Fig. 33).

(8) Remove the splash shields from the fender (Fig.

34).

(9) Remove the bolts that attach the fender and

rear supports to the cowl panel (Fig. 33).

(10) Pull the fender outward and lift it from the

vehicle.

Fig. 28 Jack Storage Tray and A/C Receiver/Drier

Fig. 29 Radio Antenna

Fig. 30 Radio Antenna Cable

Fig. 31 Hood Holddown Clamp and Side Marker

Lamp

Fig. 32 Battery Tray Support Brackets

JBODY COMPONENTSÐXJ VEHICLES 23 - 143

Page 1599 of 1784

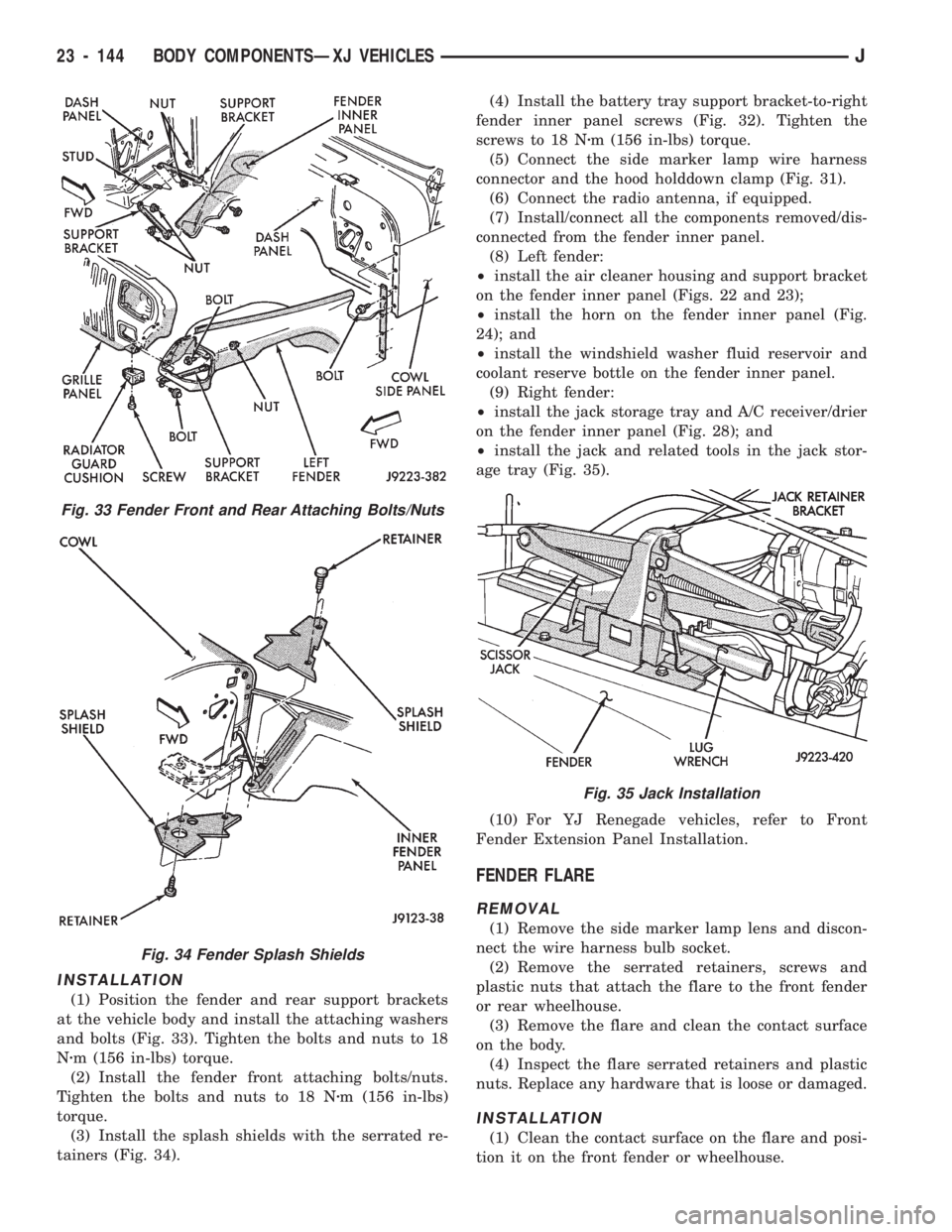

INSTALLATION

(1) Position the fender and rear support brackets

at the vehicle body and install the attaching washers

and bolts (Fig. 33). Tighten the bolts and nuts to 18

Nzm (156 in-lbs) torque.

(2) Install the fender front attaching bolts/nuts.

Tighten the bolts and nuts to 18 Nzm (156 in-lbs)

torque.

(3) Install the splash shields with the serrated re-

tainers (Fig. 34).(4) Install the battery tray support bracket-to-right

fender inner panel screws (Fig. 32). Tighten the

screws to 18 Nzm (156 in-lbs) torque.

(5) Connect the side marker lamp wire harness

connector and the hood holddown clamp (Fig. 31).

(6) Connect the radio antenna, if equipped.

(7) Install/connect all the components removed/dis-

connected from the fender inner panel.

(8) Left fender:

²install the air cleaner housing and support bracket

on the fender inner panel (Figs. 22 and 23);

²install the horn on the fender inner panel (Fig.

24); and

²install the windshield washer fluid reservoir and

coolant reserve bottle on the fender inner panel.

(9) Right fender:

²install the jack storage tray and A/C receiver/drier

on the fender inner panel (Fig. 28); and

²install the jack and related tools in the jack stor-

age tray (Fig. 35).

(10) For YJ Renegade vehicles, refer to Front

Fender Extension Panel Installation.

FENDER FLARE

REMOVAL

(1) Remove the side marker lamp lens and discon-

nect the wire harness bulb socket.

(2) Remove the serrated retainers, screws and

plastic nuts that attach the flare to the front fender

or rear wheelhouse.

(3) Remove the flare and clean the contact surface

on the body.

(4) Inspect the flare serrated retainers and plastic

nuts. Replace any hardware that is loose or damaged.

INSTALLATION

(1) Clean the contact surface on the flare and posi-

tion it on the front fender or wheelhouse.

Fig. 33 Fender Front and Rear Attaching Bolts/Nuts

Fig. 34 Fender Splash Shields

Fig. 35 Jack Installation

23 - 144 BODY COMPONENTSÐXJ VEHICLESJ