charging JEEP CHEROKEE 1994 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 495 of 1784

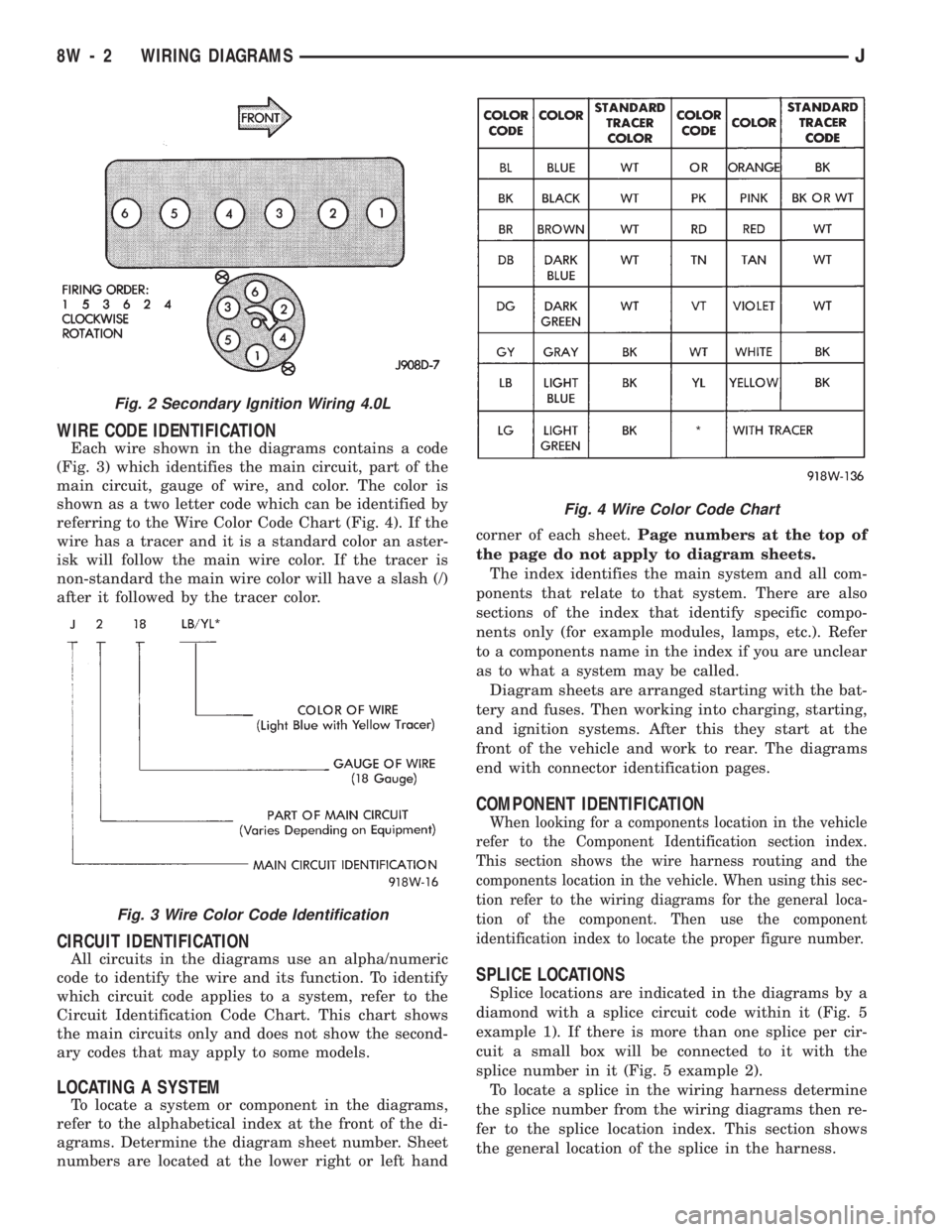

WIRE CODE IDENTIFICATION

Each wire shown in the diagrams contains a code

(Fig. 3) which identifies the main circuit, part of the

main circuit, gauge of wire, and color. The color is

shown as a two letter code which can be identified by

referring to the Wire Color Code Chart (Fig. 4). If the

wire has a tracer and it is a standard color an aster-

isk will follow the main wire color. If the tracer is

non-standard the main wire color will have a slash (/)

after it followed by the tracer color.

CIRCUIT IDENTIFICATION

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

LOCATING A SYSTEM

To locate a system or component in the diagrams,

refer to the alphabetical index at the front of the di-

agrams. Determine the diagram sheet number. Sheet

numbers are located at the lower right or left handcorner of each sheet.Page numbers at the top of

the page do not apply to diagram sheets.

The index identifies the main system and all com-

ponents that relate to that system. There are also

sections of the index that identify specific compo-

nents only (for example modules, lamps, etc.). Refer

to a components name in the index if you are unclear

as to what a system may be called.

Diagram sheets are arranged starting with the bat-

tery and fuses. Then working into charging, starting,

and ignition systems. After this they start at the

front of the vehicle and work to rear. The diagrams

end with connector identification pages.

COMPONENT IDENTIFICATION

When looking for a components location in the vehicle

refer to the Component Identification section index.

This section shows the wire harness routing and the

components location in the vehicle. When using this sec-

tion refer to the wiring diagrams for the general loca-

tion of the component. Then use the component

identification index to locate the proper figure number.

SPLICE LOCATIONS

Splice locations are indicated in the diagrams by a

diamond with a splice circuit code within it (Fig. 5

example 1). If there is more than one splice per cir-

cuit a small box will be connected to it with the

splice number in it (Fig. 5 example 2).

To locate a splice in the wiring harness determine

the splice number from the wiring diagrams then re-

fer to the splice location index. This section shows

the general location of the splice in the harness.

Fig. 2 Secondary Ignition Wiring 4.0L

Fig. 3 Wire Color Code Identification

Fig. 4 Wire Color Code Chart

8W - 2 WIRING DIAGRAMSJ

Page 566 of 1784

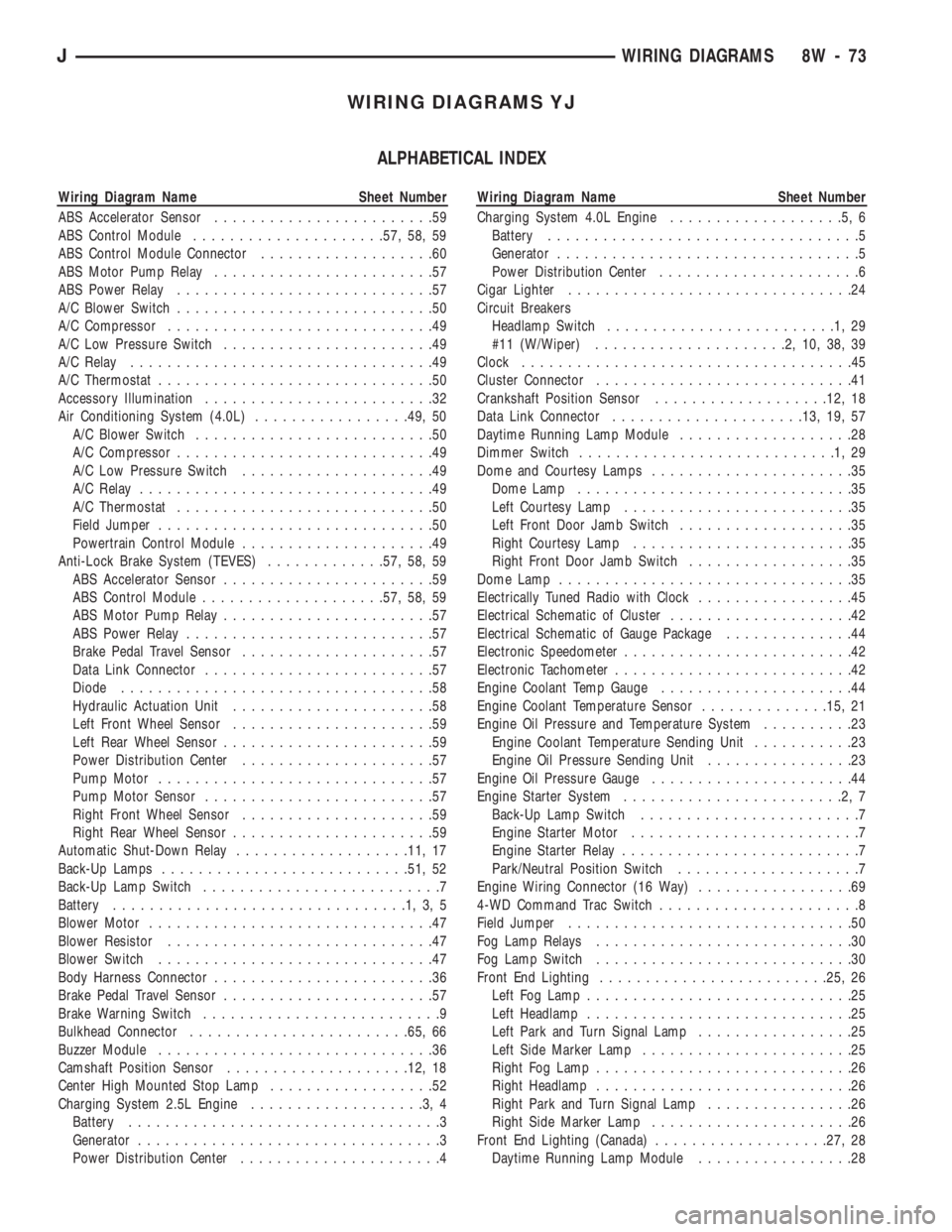

WIRING DIAGRAMS YJ

ALPHABETICAL INDEX

Wiring Diagram Name Sheet Number

ABS Accelerator Sensor........................59

ABS Control Module.....................57, 58, 59

ABS Control Module Connector...................60

ABS Motor Pump Relay........................57

ABS Power Relay............................57

A/C Blower Switch............................50

A/C Compressor.............................49

A/C Low Pressure Switch.......................49

A/C Relay.................................49

A/C Thermostat..............................50

Accessory Illumination.........................32

Air Conditioning System (4.0L).................49, 50

A/C Blower Switch..........................50

A/C Compressor............................49

A/C Low Pressure Switch.....................49

A/C Relay................................49

A/C Thermostat............................50

Field Jumper..............................50

Powertrain Control Module.....................49

Anti-Lock Brake System (TEVES).............57, 58, 59

ABS Accelerator Sensor.......................59

ABS Control Module....................57, 58, 59

ABS Motor Pump Relay.......................57

ABS Power Relay...........................57

Brake Pedal Travel Sensor.....................57

Data Link Connector.........................57

Diode..................................58

Hydraulic Actuation Unit......................58

Left Front Wheel Sensor......................59

Left Rear Wheel Sensor.......................59

Power Distribution Center.....................57

Pump Motor..............................57

Pump Motor Sensor.........................57

Right Front Wheel Sensor.....................59

Right Rear Wheel Sensor......................59

Automatic Shut-Down Relay...................11, 17

Back-Up Lamps...........................51, 52

Back-Up Lamp Switch..........................7

Battery................................1,3,5

Blower Motor...............................47

Blower Resistor.............................47

Blower Switch..............................47

Body Harness Connector........................36

Brake Pedal Travel Sensor.......................57

Brake Warning Switch..........................9

Bulkhead Connector........................65, 66

Buzzer Module..............................36

Camshaft Position Sensor....................12, 18

Center High Mounted Stop Lamp..................52

Charging System 2.5L Engine...................3,4

Battery..................................3

Generator.................................3

Power Distribution Center......................4Wiring Diagram Name Sheet Number

Charging System 4.0L Engine...................5,6

Battery..................................5

Generator.................................5

Power Distribution Center......................6

Cigar Lighter...............................24

Circuit Breakers

Headlamp Switch.........................1,29

#11 (W/Wiper).....................2,10,38,39

Clock....................................45

Cluster Connector............................41

Crankshaft Position Sensor...................12, 18

Data Link Connector.....................13, 19, 57

Daytime Running Lamp Module...................28

Dimmer Switch............................1,29

Dome and Courtesy Lamps......................35

Dome Lamp..............................35

Left Courtesy Lamp.........................35

Left Front Door Jamb Switch...................35

Right Courtesy Lamp........................35

Right Front Door Jamb Switch..................35

Dome Lamp................................35

Electrically Tuned Radio with Clock.................45

Electrical Schematic of Cluster....................42

Electrical Schematic of Gauge Package..............44

Electronic Speedometer.........................42

Electronic Tachometer..........................42

Engine Coolant Temp Gauge.....................44

Engine Coolant Temperature Sensor..............15, 21

Engine Oil Pressure and Temperature System..........23

Engine Coolant Temperature Sending Unit...........23

Engine Oil Pressure Sending Unit................23

Engine Oil Pressure Gauge......................44

Engine Starter System........................2,7

Back-Up Lamp Switch........................7

Engine Starter Motor.........................7

Engine Starter Relay..........................7

Park/Neutral Position Switch....................7

Engine Wiring Connector (16 Way).................69

4-WD Command Trac Switch......................8

Field Jumper...............................50

Fog Lamp Relays............................30

Fog Lamp Switch............................30

Front End Lighting.........................25, 26

Left Fog Lamp.............................25

Left Headlamp.............................25

Left Park and Turn Signal Lamp.................25

Left Side Marker Lamp.......................25

Right Fog Lamp............................26

Right Headlamp............................26

Right Park and Turn Signal Lamp................26

Right Side Marker Lamp......................26

Front End Lighting (Canada)...................27, 28

Daytime Running Lamp Module.................28

JWIRING DIAGRAMS 8W - 73

Page 642 of 1784

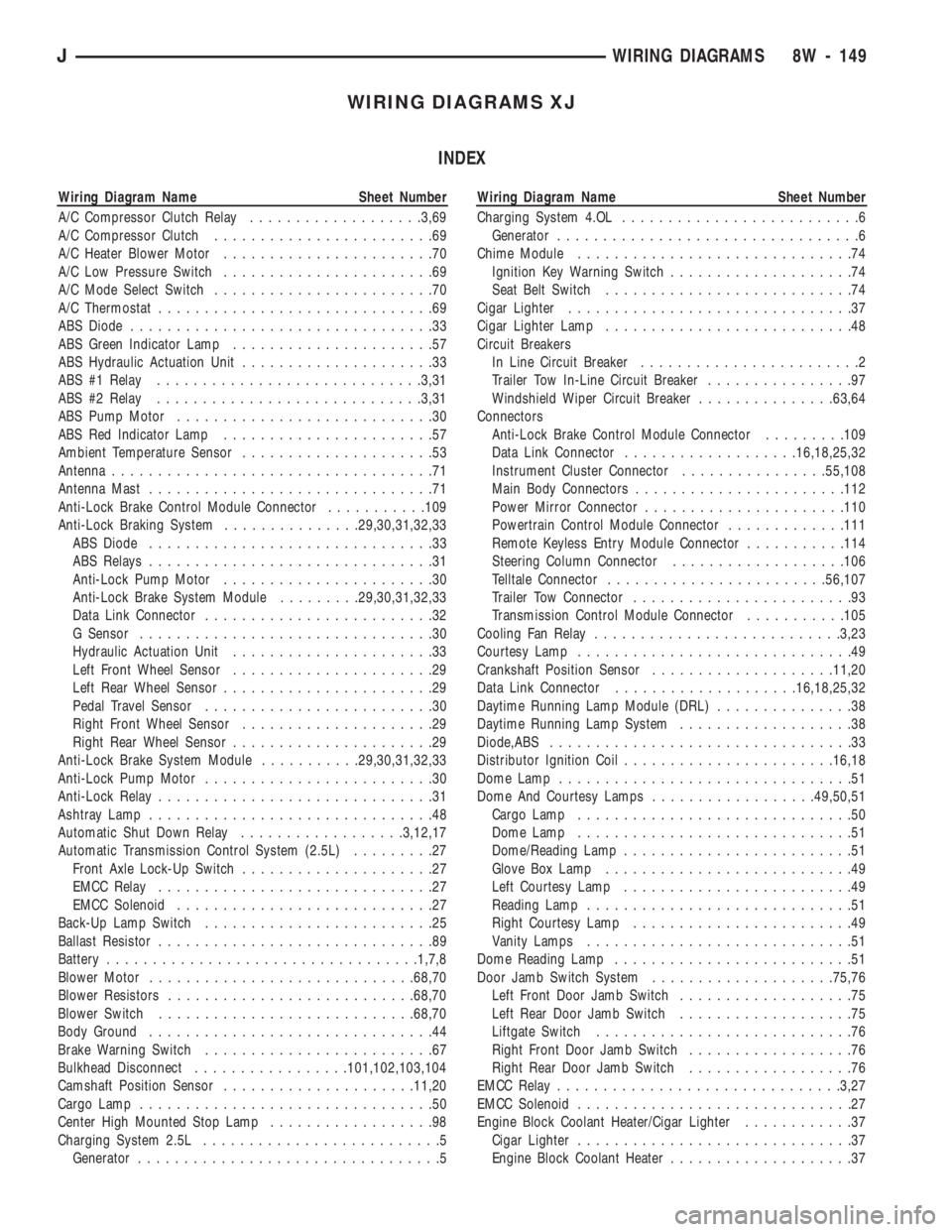

WIRING DIAGRAMS XJ

INDEX

Wiring Diagram Name Sheet Number

A/C Compressor Clutch Relay...................3,69

A/C Compressor Clutch........................69

A/C Heater Blower Motor.......................70

A/C Low Pressure Switch.......................69

A/C Mode Select Switch........................70

A/C Thermostat..............................69

ABS Diode.................................33

ABS Green Indicator Lamp......................57

ABS Hydraulic Actuation Unit.....................33

ABS #1 Relay.............................3,31

ABS #2 Relay.............................3,31

ABS Pump Motor............................30

ABS Red Indicator Lamp.......................57

Ambient Temperature Sensor.....................53

Antenna...................................71

Antenna Mast...............................71

Anti-Lock Brake Control Module Connector...........109

Anti-Lock Braking System...............29,30,31,32,33

ABS Diode...............................33

ABS Relays...............................31

Anti-Lock Pump Motor.......................30

Anti-Lock Brake System Module.........29,30,31,32,33

Data Link Connector.........................32

G Sensor................................30

Hydraulic Actuation Unit......................33

Left Front Wheel Sensor......................29

Left Rear Wheel Sensor.......................29

Pedal Travel Sensor.........................30

Right Front Wheel Sensor.....................29

Right Rear Wheel Sensor......................29

Anti-Lock Brake System Module...........29,30,31,32,33

Anti-Lock Pump Motor.........................30

Anti-Lock Relay..............................31

Ashtray Lamp...............................48

Automatic Shut Down Relay..................3,12,17

Automatic Transmission Control System (2.5L).........27

Front Axle Lock-Up Switch.....................27

EMCC Relay..............................27

EMCC Solenoid............................27

Back-Up Lamp Switch.........................25

Ballast Resistor..............................89

Battery..................................1,7,8

Blower Motor.............................68,70

Blower Resistors...........................68,70

Blower Switch............................68,70

Body Ground...............................44

Brake Warning Switch.........................67

Bulkhead Disconnect.................101,102,103,104

Camshaft Position Sensor.....................11,20

Cargo Lamp................................50

Center High Mounted Stop Lamp..................98

Charging System 2.5L..........................5

Generator.................................5Wiring Diagram Name Sheet Number

Charging System 4.OL..........................6

Generator.................................6

Chime Module..............................74

Ignition Key Warning Switch....................74

Seat Belt Switch...........................74

Cigar Lighter...............................37

Cigar Lighter Lamp...........................48

Circuit Breakers

In Line Circuit Breaker........................2

Trailer Tow In-Line Circuit Breaker................97

Windshield Wiper Circuit Breaker...............63,64

Connectors

Anti-Lock Brake Control Module Connector.........109

Data Link Connector...................16,18,25,32

Instrument Cluster Connector................55,108

Main Body Connectors.......................112

Power Mirror Connector......................110

Powertrain Control Module Connector.............111

Remote Keyless Entry Module Connector...........114

Steering Column Connector...................106

Telltale Connector........................56,107

Trailer Tow Connector........................93

Transmission Control Module Connector...........105

Cooling Fan Relay...........................3,23

Courtesy Lamp..............................49

Crankshaft Position Sensor....................11,20

Data Link Connector....................16,18,25,32

Daytime Running Lamp Module (DRL)...............38

Daytime Running Lamp System...................38

Diode,ABS.................................33

Distributor Ignition Coil.......................16,18

Dome Lamp................................51

Dome And Courtesy Lamps..................49,50,51

Cargo Lamp..............................50

Dome Lamp..............................51

Dome/Reading Lamp.........................51

Glove Box Lamp...........................49

Left Courtesy Lamp.........................49

Reading Lamp.............................51

Right Courtesy Lamp........................49

Vanity Lamps.............................51

Dome Reading Lamp..........................51

Door Jamb Switch System....................75,76

Left Front Door Jamb Switch...................75

Left Rear Door Jamb Switch...................75

Liftgate Switch............................76

Right Front Door Jamb Switch..................76

Right Rear Door Jamb Switch..................76

EMCC Relay...............................3,27

EMCC Solenoid..............................27

Engine Block Coolant Heater/Cigar Lighter............37

Cigar Lighter..............................37

Engine Block Coolant Heater....................37

JWIRING DIAGRAMS 8W - 149

Page 764 of 1784

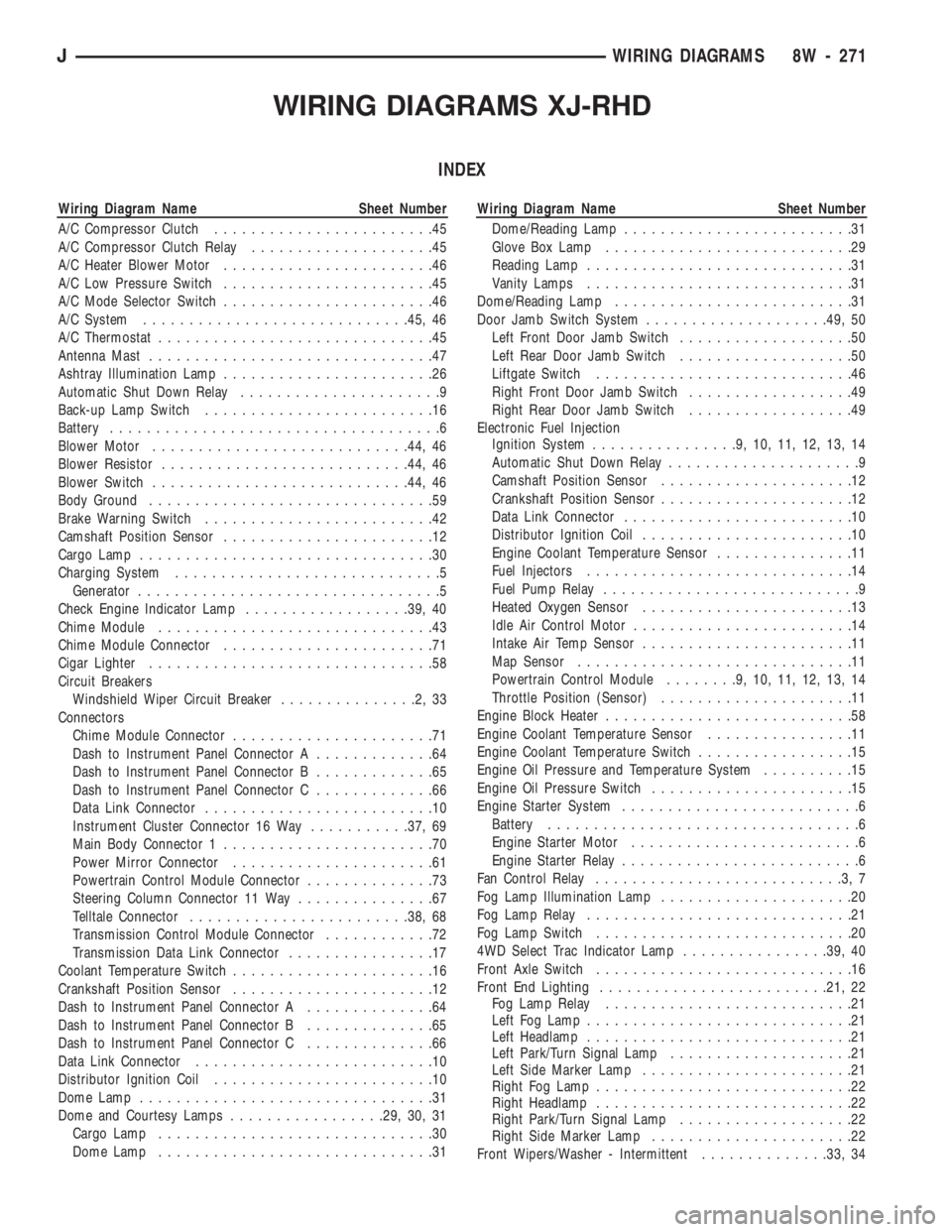

WIRING DIAGRAMS XJ-RHD

INDEX

Wiring Diagram Name Sheet Number

A/C Compressor Clutch........................45

A/C Compressor Clutch Relay....................45

A/C Heater Blower Motor.......................46

A/C Low Pressure Switch.......................45

A/C Mode Selector Switch.......................46

A/C System.............................45, 46

A/C Thermostat..............................45

Antenna Mast...............................47

Ashtray Illumination Lamp.......................26

Automatic Shut Down Relay......................9

Back-up Lamp Switch.........................16

Battery....................................6

Blower Motor............................44, 46

Blower Resistor...........................44, 46

Blower Switch............................44, 46

Body Ground...............................59

Brake Warning Switch.........................42

Camshaft Position Sensor.......................12

Cargo Lamp................................30

Charging System.............................5

Generator.................................5

Check Engine Indicator Lamp..................39, 40

Chime Module..............................43

Chime Module Connector.......................71

Cigar Lighter...............................58

Circuit Breakers

Windshield Wiper Circuit Breaker...............2,33

Connectors

Chime Module Connector......................71

Dash to Instrument Panel Connector A.............64

Dash to Instrument Panel Connector B.............65

Dash to Instrument Panel Connector C.............66

Data Link Connector.........................10

Instrument Cluster Connector 16 Way...........37, 69

Main Body Connector 1.......................70

Power Mirror Connector......................61

Powertrain Control Module Connector..............73

Steering Column Connector 11 Way...............67

Telltale Connector........................38, 68

Transmission Control Module Connector............72

Transmission Data Link Connector................17

Coolant Temperature Switch......................16

Crankshaft Position Sensor......................12

Dash to Instrument Panel Connector A..............64

Dash to Instrument Panel Connector B..............65

Dash to Instrument Panel Connector C..............66

Data Link Connector..........................10

Distributor Ignition Coil........................10

Dome Lamp................................31

Dome and Courtesy Lamps.................29, 30, 31

Cargo Lamp..............................30

Dome Lamp..............................31Wiring Diagram Name Sheet Number

Dome/Reading Lamp.........................31

Glove Box Lamp...........................29

Reading Lamp.............................31

Vanity Lamps.............................31

Dome/Reading Lamp..........................31

Door Jamb Switch System....................49, 50

Left Front Door Jamb Switch...................50

Left Rear Door Jamb Switch...................50

Liftgate Switch............................46

Right Front Door Jamb Switch..................49

Right Rear Door Jamb Switch..................49

Electronic Fuel Injection

Ignition System................9,10,11,12,13,14

Automatic Shut Down Relay.....................9

Camshaft Position Sensor.....................12

Crankshaft Position Sensor.....................12

Data Link Connector.........................10

Distributor Ignition Coil.......................10

Engine Coolant Temperature Sensor...............11

Fuel Injectors.............................14

Fuel Pump Relay............................9

Heated Oxygen Sensor.......................13

Idle Air Control Motor........................14

Intake Air Temp Sensor.......................11

Map Sensor..............................11

Powertrain Control Module........9,10,11,12,13,14

Throttle Position (Sensor).....................11

Engine Block Heater...........................58

Engine Coolant Temperature Sensor................11

Engine Coolant Temperature Switch.................15

Engine Oil Pressure and Temperature System..........15

Engine Oil Pressure Switch......................15

Engine Starter System..........................6

Battery..................................6

Engine Starter Motor.........................6

Engine Starter Relay..........................6

Fan Control Relay...........................3,7

Fog Lamp Illumination Lamp.....................20

Fog Lamp Relay.............................21

Fog Lamp Switch............................20

4WD Select Trac Indicator Lamp................39, 40

Front Axle Switch............................16

Front End Lighting.........................21, 22

Fog Lamp Relay...........................21

Left Fog Lamp.............................21

Left Headlamp.............................21

Left Park/Turn Signal Lamp....................21

Left Side Marker Lamp.......................21

Right Fog Lamp............................22

Right Headlamp............................22

Right Park/Turn Signal Lamp...................22

Right Side Marker Lamp......................22

Front Wipers/Washer - Intermittent..............33, 34

JWIRING DIAGRAMS 8W - 271

Page 978 of 1784

MULTI-PORT FUEL INJECTION (MFI)ÐCOMPONENT DESCRIPTION/SYSTEM

OPERATION

INDEX

page page

Air Conditioning (A/C) Clutch RelayÐPCM Output.24

Air Conditioning (A/C) ControlsÐPCM Input.... 19

Auto Shut Down (ASD) RelayÐPCM Output.... 24

Automatic Shut Down (ASD) SenseÐPCM Input . 19

Battery VoltageÐPCM Input................ 19

Brake SwitchÐPCM Input.................. 20

Camshaft Position SensorÐPCM Input........ 20

Crankshaft Position SensorÐPCM Input....... 20

Data Link ConnectorÐPCM Input............ 20

Data Link ConnectorÐPCM Output........... 24

EMR LampÐPCM Output.................. 24

Engine Coolant Temperature SensorÐPCM Input . 21

Extended Idle SwitchÐPCM Input............ 21

Fuel InjectorsÐPCM Output................ 25

Fuel Pressure Regulator................... 30

Fuel Pump RelayÐPCM Output............. 25

Fuel Rail............................... 30

General Information....................... 17

Generator FieldÐPCM Output............... 25

Generator LampÐPCM Output.............. 25

Idle Air Control (IAC) MotorÐPCM Output...... 25

Ignition Circuit SenseÐPCM Input............ 21

Ignition CoilÐPCM Output.................. 26Intake Air Temperature SensorÐPCM Input.... 20

Malfunction Indicator LampÐPCM Output...... 26

Manifold Absolute Pressure (MAP) SensorÐ

PCM Input............................ 21

Open Loop/Closed Loop Modes of Operation . . . 27

Overdrive/Override Switch.................. 22

Oxygen (O2S) SensorÐPCM Input........... 22

Park/Neutral SwitchÐPCM Input............. 22

Power Ground........................... 22

Power Steering Pressure SwitchÐPCM Input . . . 22

Powertrain Control Module (PCM)............ 18

Radiator Fan RelayÐPCM Output............ 26

SCI ReceiveÐPCM Input.................. 22

SCI TransmitÐPCM Output................. 26

Sensor ReturnÐPCM Input................. 23

Shift IndicatorÐPCM Output................ 26

Speed ControlÐPCM Input................. 23

Speed ControlÐPCM Output................ 27

TachometerÐPCM Output.................. 27

Throttle Body............................ 29

Throttle Position Sensor (TPS)ÐPCM Input..... 23

Torque Converter Clutch RelayÐPCM Output . . . 27

Vehicle Speed SensorÐPCM Input........... 23

GENERAL INFORMATION

All 2.5L 4 cylinder and 4.0L 6 cylinder engines are

equipped with sequential Multi-Port Fuel Injection

(MFI). The MFI system provides precise air/fuel ra-

tios for all driving conditions.

The Powertrain Control Module (PCM) operates

the fuel system. The PCM was formerly referred to

as the SBEC or engine controller. The PCM is a pre-

programmed, dual microprocessor digital computer.

It regulates ignition timing, air-fuel ratio, emission

control devices, charging system, speed control, air

conditioning compressor clutch engagement and idle

speed. The PCM can adapt its programming to meet

changing operating conditions.

Powertrain Control Module (PCM) Inputsrep-

resent the instantaneous engine operating conditions.

Air-fuel mixture and ignition timing calibrations for

various driving and atmospheric conditions are pre-

programmed into the PCM. The PCM monitors and

analyzes various inputs. It then computes engine fuel

and ignition timing requirements based on these in-

puts. Fuel delivery control and ignition timing will

then be adjusted accordingly.

Other inputs to the PCM are provided by the brake

light switch, air conditioning select switch and the

speed control switches. All inputs to the PCM are

converted into signals.

Electrically operated fuel injectors spray fuel in

precise metered amounts into the intake port directlyabove the intake valve. The injectors are fired in a

specific sequence by the PCM. The PCM maintains

an air/fuel ratio of 14.7 to 1 by constantly adjusting

injector pulse width. Injector pulse width is the

length of time that the injector opens and sprays fuel

into the chamber. The PCM adjusts injector pulse

width by opening and closing the ground path to the

injector.

Manifold absolute pressure (air density) and engine

rpm (speed) are the primary inputs that determine

fuel injector pulse width. The PCM also monitors

other inputs when adjusting air-fuel ratio.

Inputs That Effect Fuel Injector Pulse Width

²Exhaust gas oxygen content

²Engine coolant temperature

²Manifold absolute pressure (MAP)

²Engine speed

²Throttle position

²Battery voltage

²Air conditioning selection

²Transmission gear selection (automatic transmis-

sions only)

²Speed control

The powertrain control module (PCM) adjusts igni-

tion timing by controlling ignition coil operation. The

ignition coil receives battery voltage when the igni-

tion key is in the run or starter position. The PCM

provides a ground for the ignition coil. The coil dis-

JFUEL SYSTEM 14 - 17

Page 979 of 1784

charges when the PCM supplies a ground. By switch-

ing the ground path on and off, the PCM regulates

ignition timing.

The sensors and switches that provide inputs to the

powertrain control module (PCM) comprise the En-

gine Control System. It is also comprised of the PCM

Outputs (engine control devices that the are operated

by the PCM).

SYSTEM DIAGNOSIS

The powertrain control module (PCM) tests many

of its own input and output circuits. If a Diagnostic

Trouble Code (DTC) is found in a major system, this

information is stored in the PCM memory. Refer to

On-Board Diagnostics in the MFI SystemÐGeneral

Diagnosis section of this group for DTC information.

POWERTRAIN CONTROL MODULE (PCM)

The PCM operates the fuel system. The PCM was

formerly referred to as the SBEC or engine control-

ler. The PCM is a pre-programmed, dual micropro-

cessor digital computer. It regulates ignition timing,

air-fuel ratio, emission control devices, charging sys-

tem, speed control, air conditioning compressor

clutch engagement and idle speed. The PCM can

adapt its programming to meet changing operating

conditions.

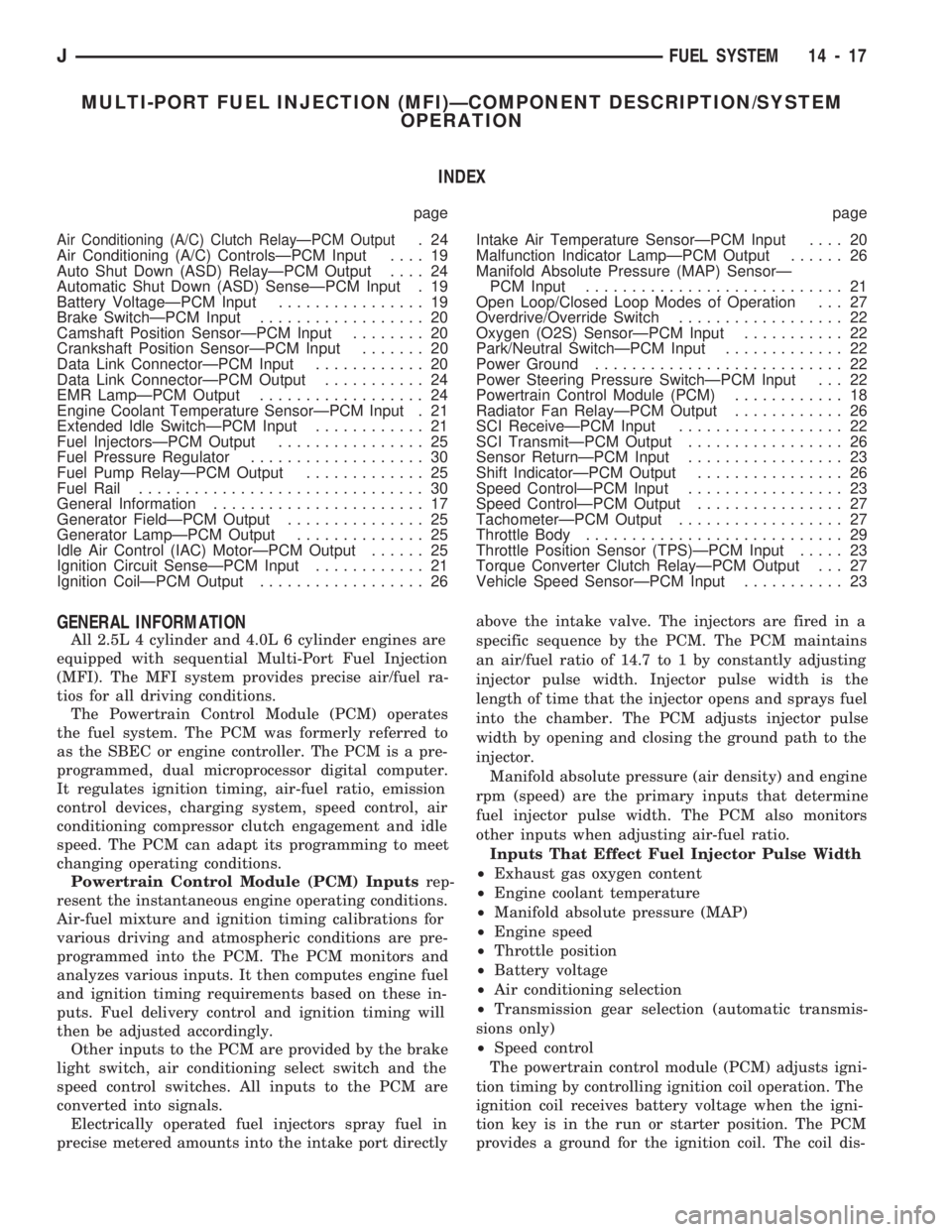

On XJ models, the PCM is located in the engine

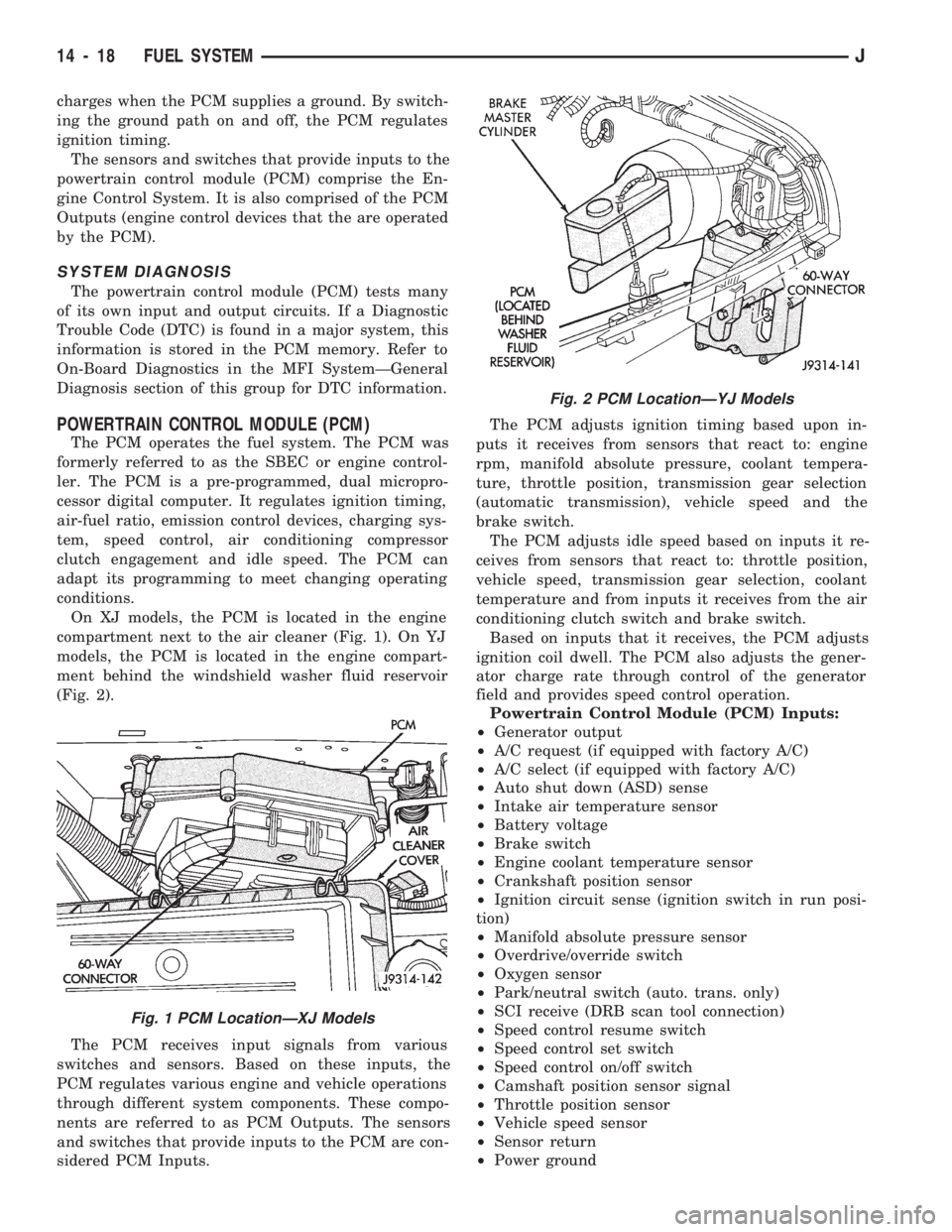

compartment next to the air cleaner (Fig. 1). On YJ

models, the PCM is located in the engine compart-

ment behind the windshield washer fluid reservoir

(Fig. 2).

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as PCM Outputs. The sensors

and switches that provide inputs to the PCM are con-

sidered PCM Inputs.The PCM adjusts ignition timing based upon in-

puts it receives from sensors that react to: engine

rpm, manifold absolute pressure, coolant tempera-

ture, throttle position, transmission gear selection

(automatic transmission), vehicle speed and the

brake switch.

The PCM adjusts idle speed based on inputs it re-

ceives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, coolant

temperature and from inputs it receives from the air

conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

Powertrain Control Module (PCM) Inputs:

²Generator output

²A/C request (if equipped with factory A/C)

²A/C select (if equipped with factory A/C)

²Auto shut down (ASD) sense

²Intake air temperature sensor

²Battery voltage

²Brake switch

²Engine coolant temperature sensor

²Crankshaft position sensor

²Ignition circuit sense (ignition switch in run posi-

tion)

²Manifold absolute pressure sensor

²Overdrive/override switch

²Oxygen sensor

²Park/neutral switch (auto. trans. only)

²SCI receive (DRB scan tool connection)

²Speed control resume switch

²Speed control set switch

²Speed control on/off switch

²Camshaft position sensor signal

²Throttle position sensor

²Vehicle speed sensor

²Sensor return

²Power ground

Fig. 1 PCM LocationÐXJ Models

Fig. 2 PCM LocationÐYJ Models

14 - 18 FUEL SYSTEMJ

Page 986 of 1784

FUEL PUMP RELAYÐPCM OUTPUT

The PCM energizes the fuel pump through the fuel

pump relay. Battery voltage is applied to the relay

from the ignition switch. The relay is energized when

a ground is provided by the PCM. Refer to Automatic

Shut Down Relay for additional information.

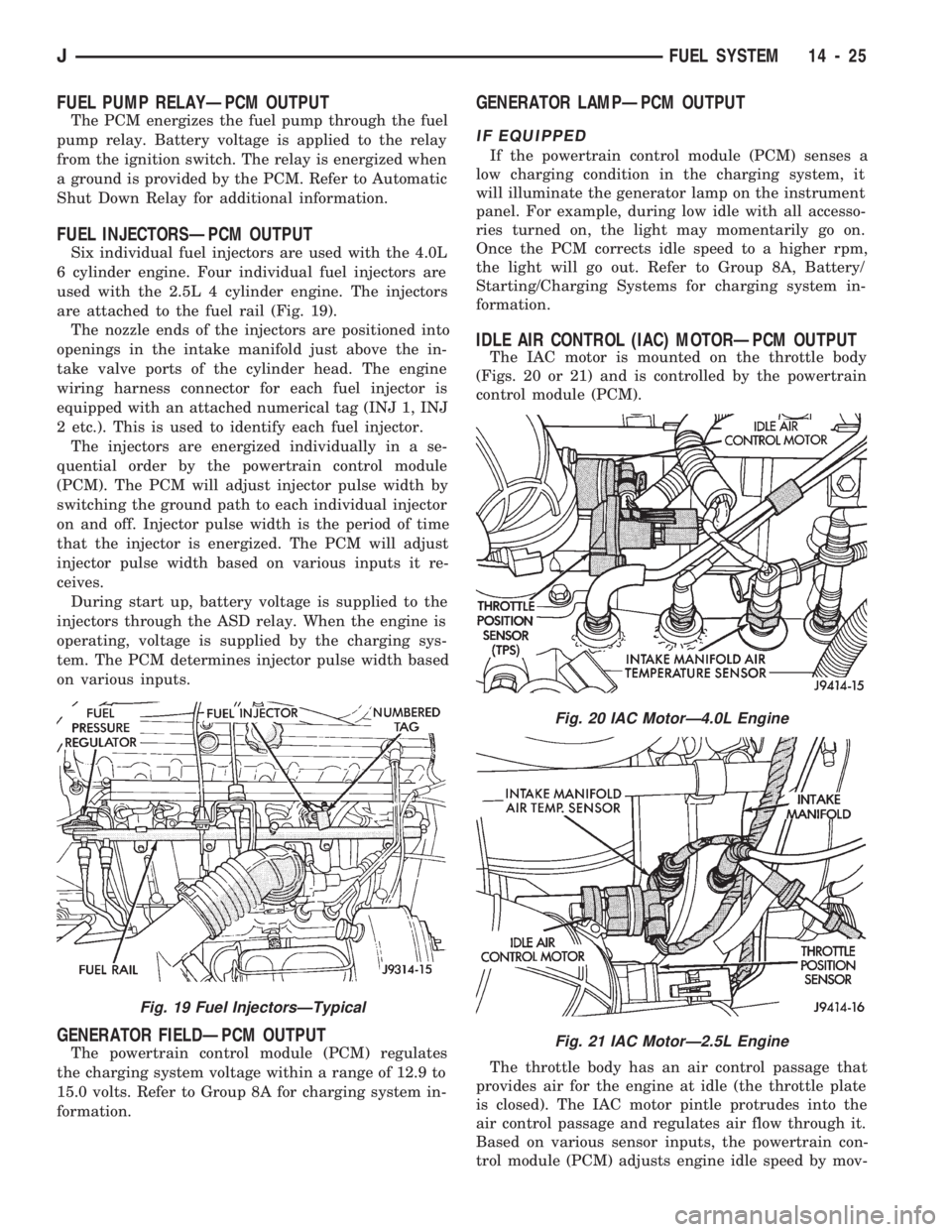

FUEL INJECTORSÐPCM OUTPUT

Six individual fuel injectors are used with the 4.0L

6 cylinder engine. Four individual fuel injectors are

used with the 2.5L 4 cylinder engine. The injectors

are attached to the fuel rail (Fig. 19).

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the in-

take valve ports of the cylinder head. The engine

wiring harness connector for each fuel injector is

equipped with an attached numerical tag (INJ 1, INJ

2 etc.). This is used to identify each fuel injector.

The injectors are energized individually in a se-

quential order by the powertrain control module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it re-

ceives.

During start up, battery voltage is supplied to the

injectors through the ASD relay. When the engine is

operating, voltage is supplied by the charging sys-

tem. The PCM determines injector pulse width based

on various inputs.

GENERATOR FIELDÐPCM OUTPUT

The powertrain control module (PCM) regulates

the charging system voltage within a range of 12.9 to

15.0 volts. Refer to Group 8A for charging system in-

formation.

GENERATOR LAMPÐPCM OUTPUT

IF EQUIPPED

If the powertrain control module (PCM) senses a

low charging condition in the charging system, it

will illuminate the generator lamp on the instrument

panel. For example, during low idle with all accesso-

ries turned on, the light may momentarily go on.

Once the PCM corrects idle speed to a higher rpm,

the light will go out. Refer to Group 8A, Battery/

Starting/Charging Systems for charging system in-

formation.

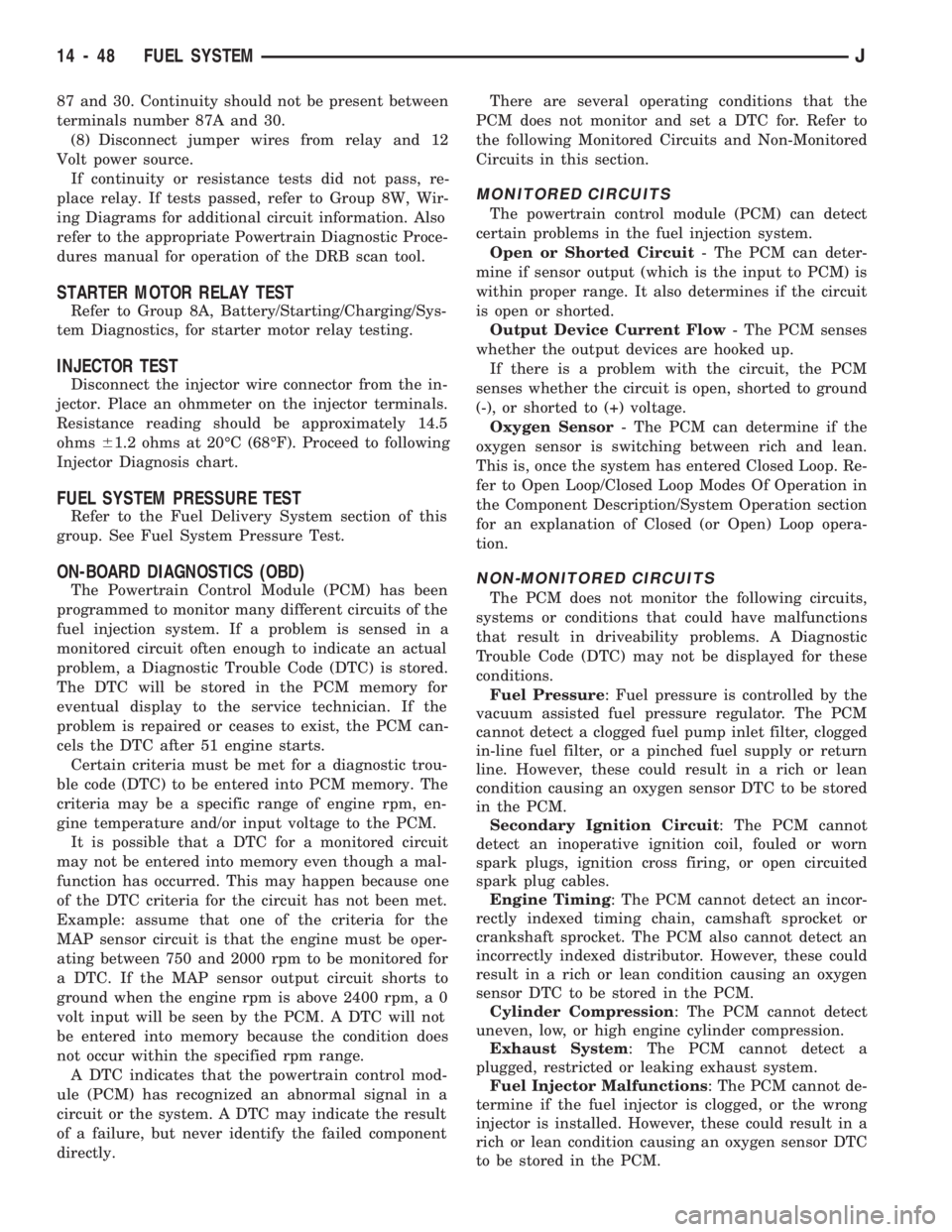

IDLE AIR CONTROL (IAC) MOTORÐPCM OUTPUT

The IAC motor is mounted on the throttle body

(Figs. 20 or 21) and is controlled by the powertrain

control module (PCM).

The throttle body has an air control passage that

provides air for the engine at idle (the throttle plate

is closed). The IAC motor pintle protrudes into the

air control passage and regulates air flow through it.

Based on various sensor inputs, the powertrain con-

trol module (PCM) adjusts engine idle speed by mov-

Fig. 19 Fuel InjectorsÐTypical

Fig. 20 IAC MotorÐ4.0L Engine

Fig. 21 IAC MotorÐ2.5L Engine

JFUEL SYSTEM 14 - 25

Page 1009 of 1784

87 and 30. Continuity should not be present between

terminals number 87A and 30.

(8) Disconnect jumper wires from relay and 12

Volt power source.

If continuity or resistance tests did not pass, re-

place relay. If tests passed, refer to Group 8W, Wir-

ing Diagrams for additional circuit information. Also

refer to the appropriate Powertrain Diagnostic Proce-

dures manual for operation of the DRB scan tool.

STARTER MOTOR RELAY TEST

Refer to Group 8A, Battery/Starting/Charging/Sys-

tem Diagnostics, for starter motor relay testing.

INJECTOR TEST

Disconnect the injector wire connector from the in-

jector. Place an ohmmeter on the injector terminals.

Resistance reading should be approximately 14.5

ohms61.2 ohms at 20ÉC (68ÉF). Proceed to following

Injector Diagnosis chart.

FUEL SYSTEM PRESSURE TEST

Refer to the Fuel Delivery System section of this

group. See Fuel System Pressure Test.

ON-BOARD DIAGNOSTICS (OBD)

The Powertrain Control Module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a

monitored circuit often enough to indicate an actual

problem, a Diagnostic Trouble Code (DTC) is stored.

The DTC will be stored in the PCM memory for

eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a diagnostic trou-

ble code (DTC) to be entered into PCM memory. The

criteria may be a specific range of engine rpm, en-

gine temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met.

Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper-

ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does

not occur within the specified rpm range.

A DTC indicates that the powertrain control mod-

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored

Circuits in this section.

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit- The PCM can deter-

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit

is open or shorted.

Output Device Current Flow- The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to (+) voltage.

Oxygen Sensor- The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re-

fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera-

tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A Diagnostic

Trouble Code (DTC) may not be displayed for these

conditions.

Fuel Pressure: Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

line. However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored

in the PCM.

Secondary Ignition Circuit: The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open circuited

spark plug cables.

Engine Timing: The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket or

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression: The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System: The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions: The PCM cannot de-

termine if the fuel injector is clogged, or the wrong

injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

14 - 48 FUEL SYSTEMJ

Page 1014 of 1784

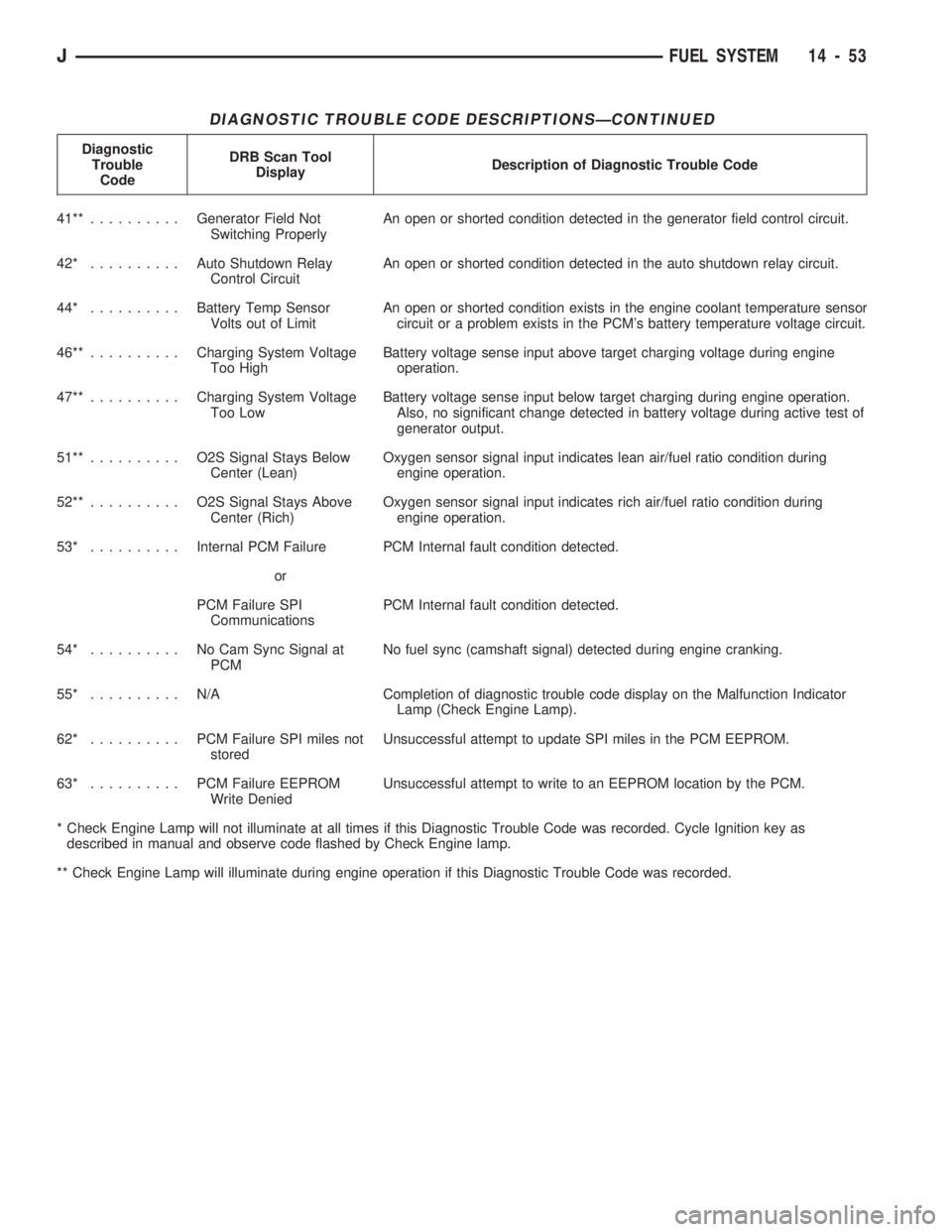

DIAGNOSTIC TROUBLE CODE DESCRIPTIONSÐCONTINUED

Diagnostic

Trouble

CodeDRB Scan Tool

DisplayDescription of Diagnostic Trouble Code

41**..........Generator Field Not

Switching ProperlyAn open or shorted condition detected in the generator field control circuit.

42* ..........Auto Shutdown Relay

Control CircuitAn open or shorted condition detected in the auto shutdown relay circuit.

44* ..........Battery Temp Sensor

Volts out of LimitAn open or shorted condition exists in the engine coolant temperature sensor

circuit or a problem exists in the PCM's battery temperature voltage circuit.

46**..........Charging System Voltage

Too HighBattery voltage sense input above target charging voltage during engine

operation.

47**..........Charging System Voltage

Too LowBattery voltage sense input below target charging during engine operation.

Also, no significant change detected in battery voltage during active test of

generator output.

51**.......... O2SSignal Stays Below

Center (Lean)Oxygen sensor signal input indicates lean air/fuel ratio condition during

engine operation.

52**.......... O2SSignal Stays Above

Center (Rich)Oxygen sensor signal input indicates rich air/fuel ratio condition during

engine operation.

53* ..........Internal PCM Failure PCM Internal fault condition detected.

or

PCM Failure SPI

CommunicationsPCM Internal fault condition detected.

54* .......... NoCamSync Signal at

PCMNo fuel sync (camshaft signal) detected during engine cranking.

55* .......... N/ACompletion of diagnostic trouble code display on the Malfunction Indicator

Lamp (Check Engine Lamp).

62* .......... PCMFailure SPI miles not

storedUnsuccessful attempt to update SPI miles in the PCM EEPROM.

63* .......... PCMFailure EEPROM

Write DeniedUnsuccessful attempt to write to an EEPROM location by the PCM.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key as

described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

JFUEL SYSTEM 14 - 53

Page 1665 of 1784

WARNING: LARGE AMOUNTS OF REFRIGERANT

RELEASED IN A CLOSED WORK AREA WILL DIS-

PLACE THE OXYGEN AND CAUSE SUFFOCATION.

ALWAYS MAINTAIN GOOD VENTILATION SUR-

ROUNDING THE WORK AREA.

R-12 gas, under normal conditions, is non-poison-

ous.

WARNING: THE DISCHARGE OF R-12 GAS NEAR

AN OPEN FLAME CAN PRODUCE A VERY POISON-

OUS GAS CALLED PHOSGENE. PHOSGENE IS

GENERATED WHEN A FLAME-TYPE LEAK DETEC-

TOR IS USED.

CAUTION: When charging an A/C system always

keep the tank in an upright position. If the tank is

on its side or upside down, liquid refrigerant will

enter the system and may damage the compressor.

In most instances when charging or adding refrig-

erant, moderate heat is required to bring the pres-

sure of the refrigerant above the pressure of the

system. A bucket or large pan of hot water, not over

52ÉC (125ÉF), is all the heat required for this pur-

pose. DO NOT heat the refrigerant container with a

blow torch or any other means that would raise the

temperature and pressure above this temperature.

CAUTION: DO NOT allow liquid refrigerant to touch

bright metal. Refrigerant will tarnish bright metal

and chrome surfaces. Refrigerant in combination

with moisture is very corrosive and can cause ex-

tensive damage to all metal surfaces.

Avoid splashing the refrigerant on any surface.

RECYCLING

(R-12) refrigerant is a chloroflorocarbon (CFC) that

can contribute to the depletion of the ozone layer in

the upper atmosphere. Ozone filters out harmful ra-

diation from the sun. To assist in protecting the

ozone layer, Chrysler Corporation requires that an

(R-12) refrigerant recovery device that meets SAE

standard J1991 be used. Contact an automotive ser-

vice equipment supplier for refrigerant recycling

equipment that is available in your area. Refer to

the operating instructions provided with the recy-

cling equipment for proper operation.

SERVICE PRECAUTIONS

Never open or loosen a connection before discharg-

ing the system refrigerant.

A system which has been opened to replace a com-

ponent or one which has discharged through leakage

must be evacuated before charging.

Immediately after disconnecting a component from

the system, seal the open fittings with a cap or plug.Before disconnecting a component from the system,

clean the outside of the fittings thoroughly.

DO NOT remove the sealing caps from a replace-

ment component until ready to install.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. DO NOT open an oil con-

tainer until ready to use and install the cap

immediately after using. Store the oil only in a clean

moisture-free container.

Before connecting an open fitting always install a

new seal ring. Coat the fitting and seal with clean

refrigerant oil before connecting.

When installing a refrigerant line avoid sharp

bends. Position the line away from the exhaust or

any sharp edges which may chafe the line.

Tighten fittings only to the specified torque. The

copper and aluminum fittings used in the A/C system

will not tolerate over tightening.

When disconnecting a fitting use a wrench on both

halves of the fitting to prevent twisting of the refrig-

erant lines or tubes.

DO NOT open a refrigerant system or uncap a re-

placement component unless it is as close as possible

to room temperature. This will prevent condensation

from forming inside of a component which is cooler

than the surrounding air.

Keep service tools and the work area clean. Con-

tamination of A/C system through careless work hab-

its must be avoided.

PRESSURE GAUGE AND MANIFOLD ASSEMBLY

Pressure Gauge and Manifold Assembly Tool

C-3740-B (Fig. 1) is the most important tool used to

service the air conditioning system. The gauge as-

sembly is used to determine:

²System high side gauge pressures

²System low side gauge pressures

²The correct refrigerant charge

²System diagnosis

It is designed to provide simultaneous high and low

side pressure indications, because these pressures

must be compared to determine the correct system

operation.

LOW SIDE GAUGE

The low side gauge is a compound gauge, which

means that it will register both pressure and vacuum

(Fig. 1). The compound gauge is calibrated 0-1034

kPa (0-150 psi) pressure and 0-760 mm (0-30 in.) of

mercury vacuum. It is connected to the suction ser-

vice valve to check the low side pressure or vacuum.

HIGH SIDE GAUGE

The high side gauge is used to check the pressure

in the discharge side of the air conditioning system

(Fig. 1).

24 - 2 HEATING AND AIR CONDITIONINGJ